Self-resetting composite structure beam-column joint and construction method thereof

A combined structure and beam-column node technology, which is applied in the direction of building construction, construction, and building material processing, can solve the problems of weak energy consumption capacity of self-resetting nodes, difficult installation, and single structural form, so as to improve energy consumption Scatter ability, ensure effective transmission, and simple node form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

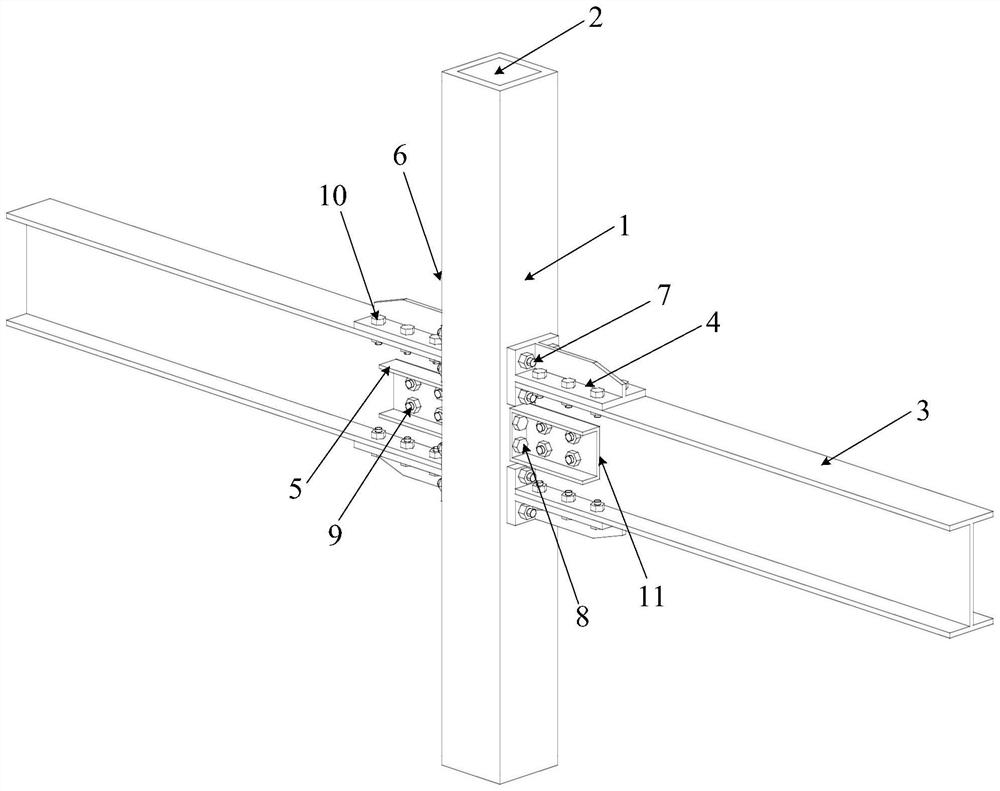

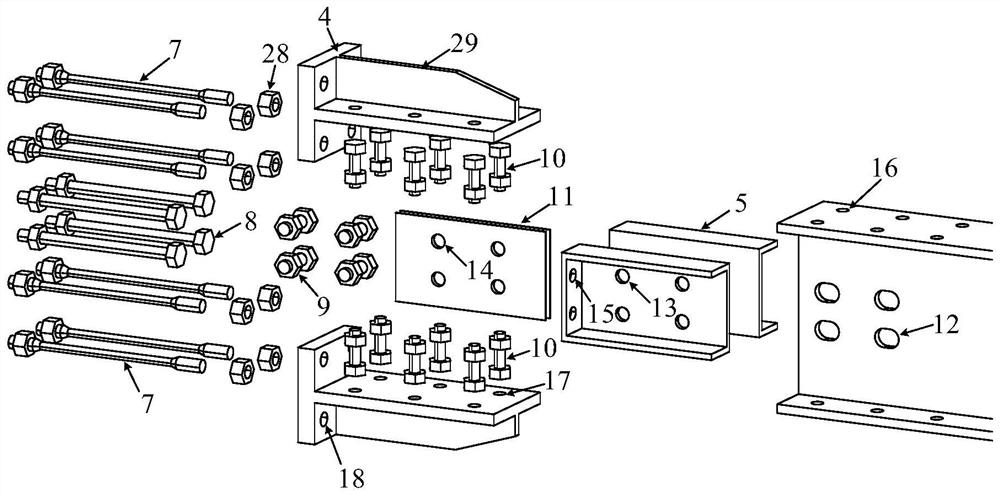

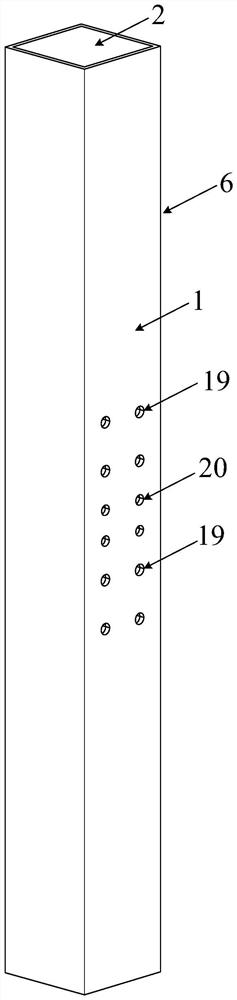

[0055] Take the form of beam-column joints in which I-shaped steel beams 3 are arranged symmetrically on both sides of the square steel tube concrete column 6 as an example.

[0056] as attached Figure 1-8 As shown, this embodiment provides a beam-column joint of a self-resetting composite structure, including two I-shaped steel beams 3, four T-shaped connectors 4, four friction members 5, square steel tube concrete columns 6, and SMA screws 7. The first connecting bolt 8, the second connecting bolt 9, the third connecting bolt 10 and the high-strength nut 28; wherein, the T-shaped connecting piece 4 is used as a beam-column connecting element for connecting the I-shaped steel beam 3 and the square steel pipe The concrete columns 6 are connected together; the SMA screw 7 serves as a reset element, and the friction member 5 serves as a frictional energy dissipation element.

[0057] Two I-shaped steel beams 3 are horizontally and symmetrically arranged on both sides of the sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com