Construction method and structure of assembly anchor rod frame beam

A construction method and sash beam technology, applied in basic structure engineering, excavation, sheet pile wall and other directions, can solve the problems of casualties of construction personnel, easy occurrence of landslides and falling objects from high places, difficult to control the quality of graded construction projects, etc. The effect of speeding up ergonomics and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

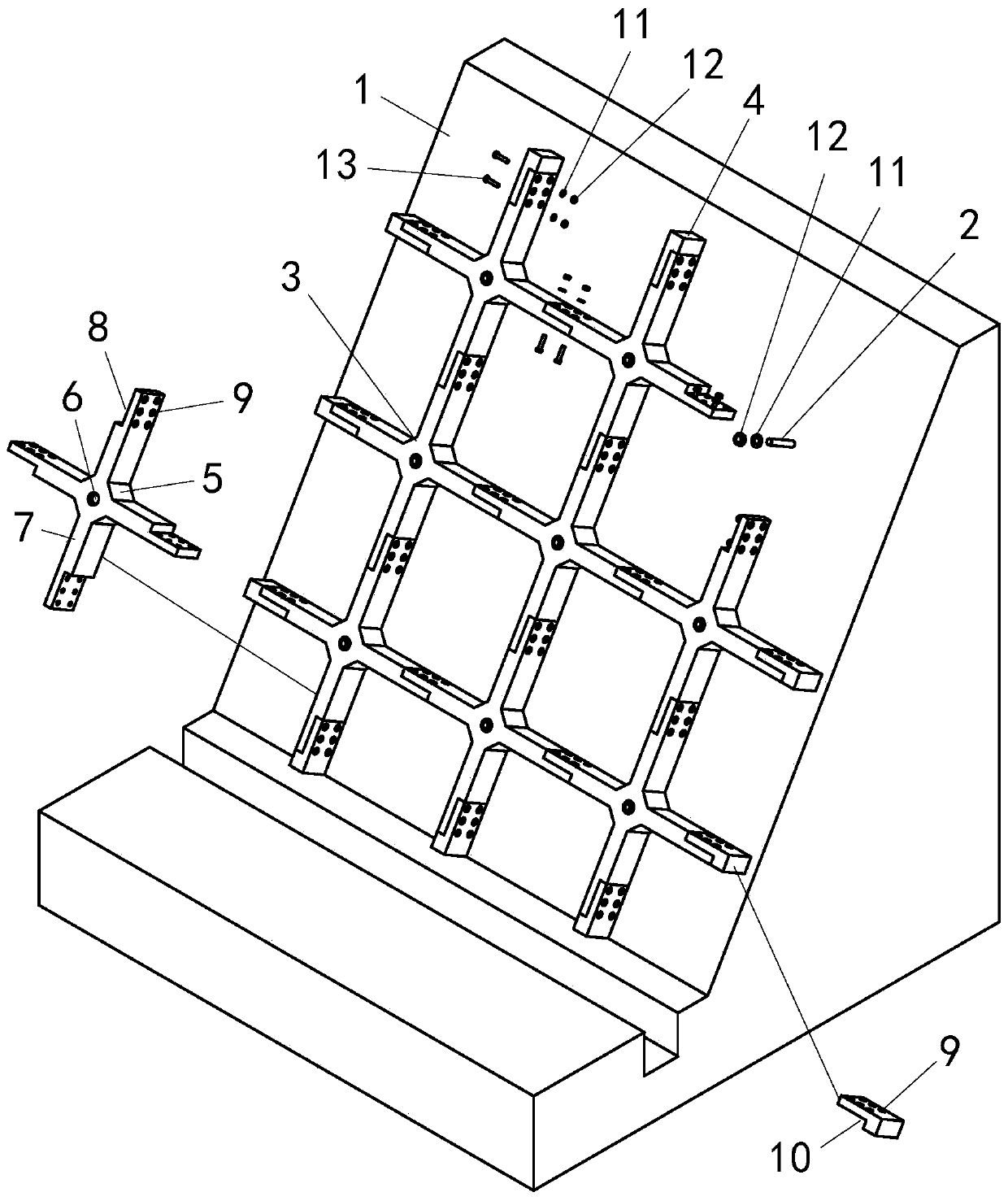

[0019] A construction method of an assembled anchor frame lattice beam of the present invention, the method is to decompose the existing integrally poured anchor bolt frame lattice beam into two different prefabricated parts: a cross prefabricated part and a head prefabricated part; the specific construction At the same time, the method of on-site assembly is adopted to improve the slope protection work efficiency, so that the slope protection work effect is close to the slope excavation work efficiency, so as to realize the first-level protection standard requirements of the slope excavation from top to top. Cross prefabrication and head prefabrication can be customized from qualified prefabrication specialized factories. An anchor hole is provided in the middle of the cross prefabricated part, through which the exposed part of the anchor rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com