Self-leveling dry hanging assembly and mounting method thereof

A self-leveling and dry-hanging technology, used in covering/lining, architecture, building structure, etc., can solve problems such as deviation of parallelism between veneer panel and wall, cumbersome construction of leveling components, and unsatisfactory seismic performance. , to avoid unsatisfactory work efficiency, improve heat transfer efficiency, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

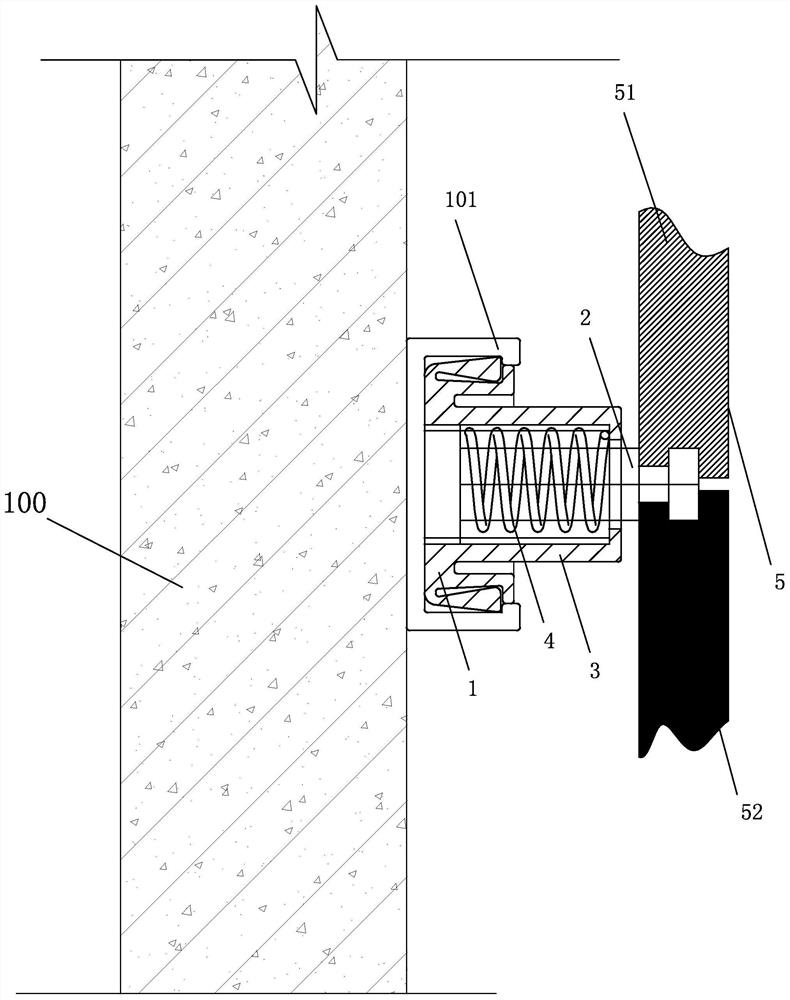

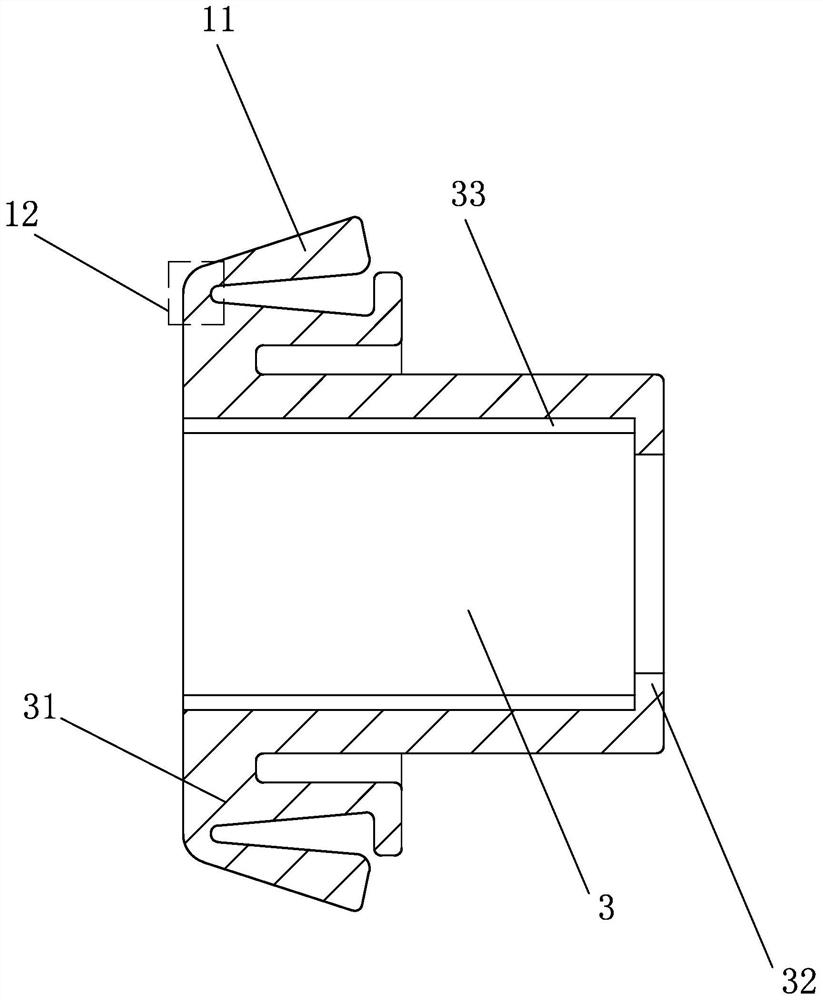

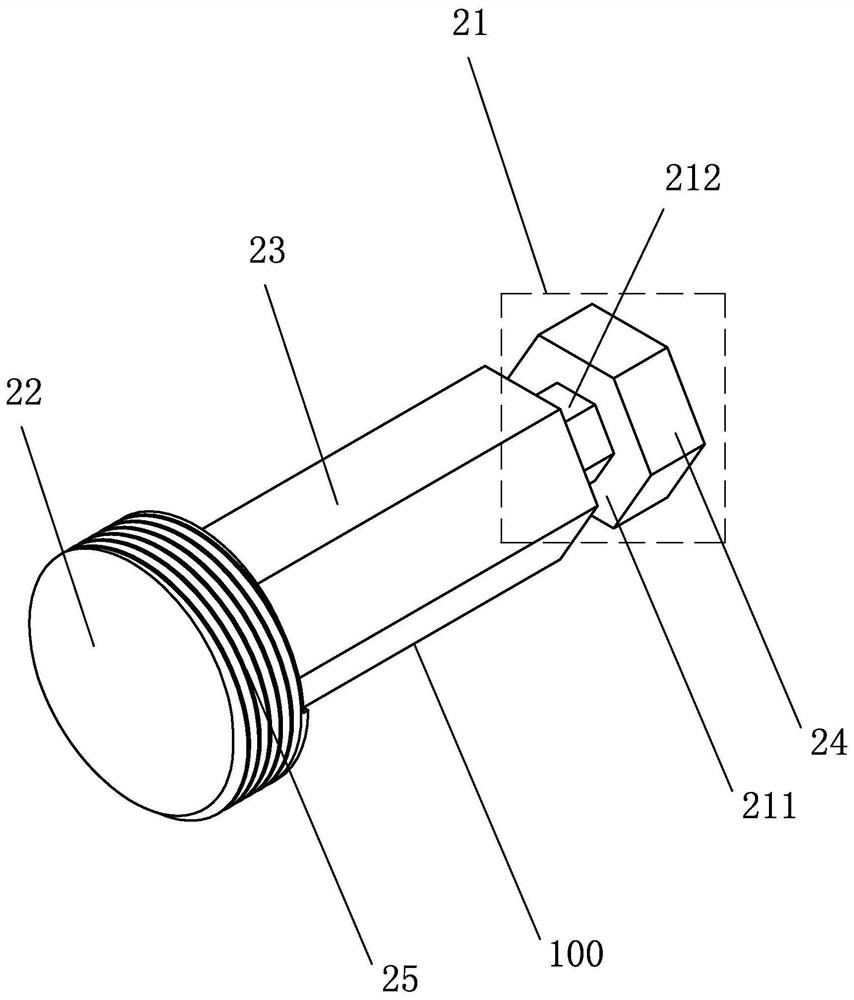

[0037] Such as figure 1 , as shown in 5, a self-leveling dry hanging assembly, including a leveling base 1 and a leveling clip 2, the leveling base is a cylindrical structure, and the outer edge of the leveling base is provided with a locking wing 11; The clamping piece is arranged through the leveling base, the leveling clamping piece and the leveling base can move relatively, and the end of the leveling clamping piece away from the leveling clamping piece is provided with a clamping portion 21 . The leveling base is connected to the wall and the components through the clamping wings, the leveling clamps are set in the leveling base, and the leveling base is connected to the decorative wall panel 5 through the clamping part; the leveling base with the clamping wings is set by adjusting The relative distance between the leveling clip and the leveling clip provided in the snap ring groove 211 can complete the adjustment of the distance between the decorative wallboard and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com