Patents

Literature

615results about How to "Highly consistent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

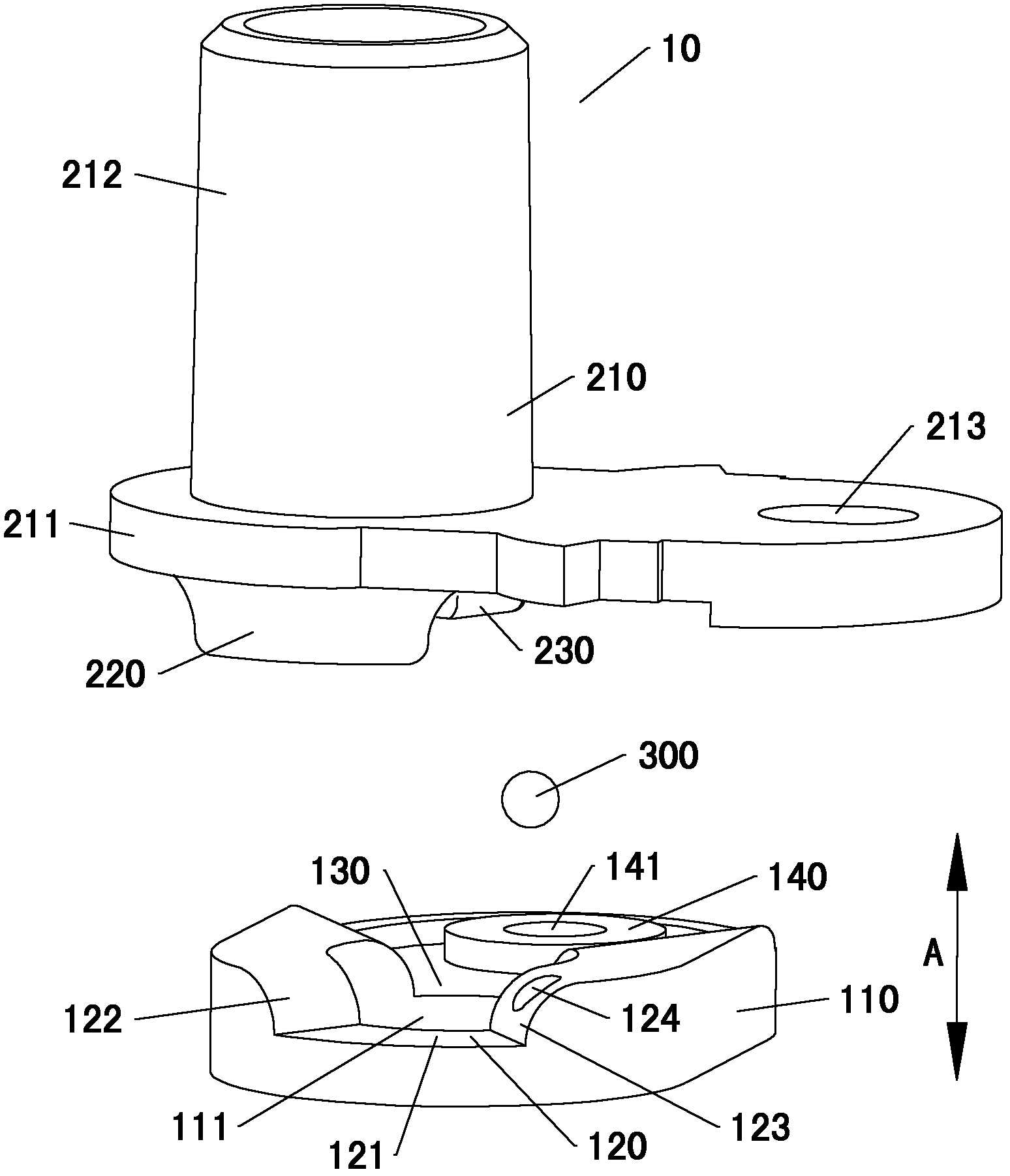

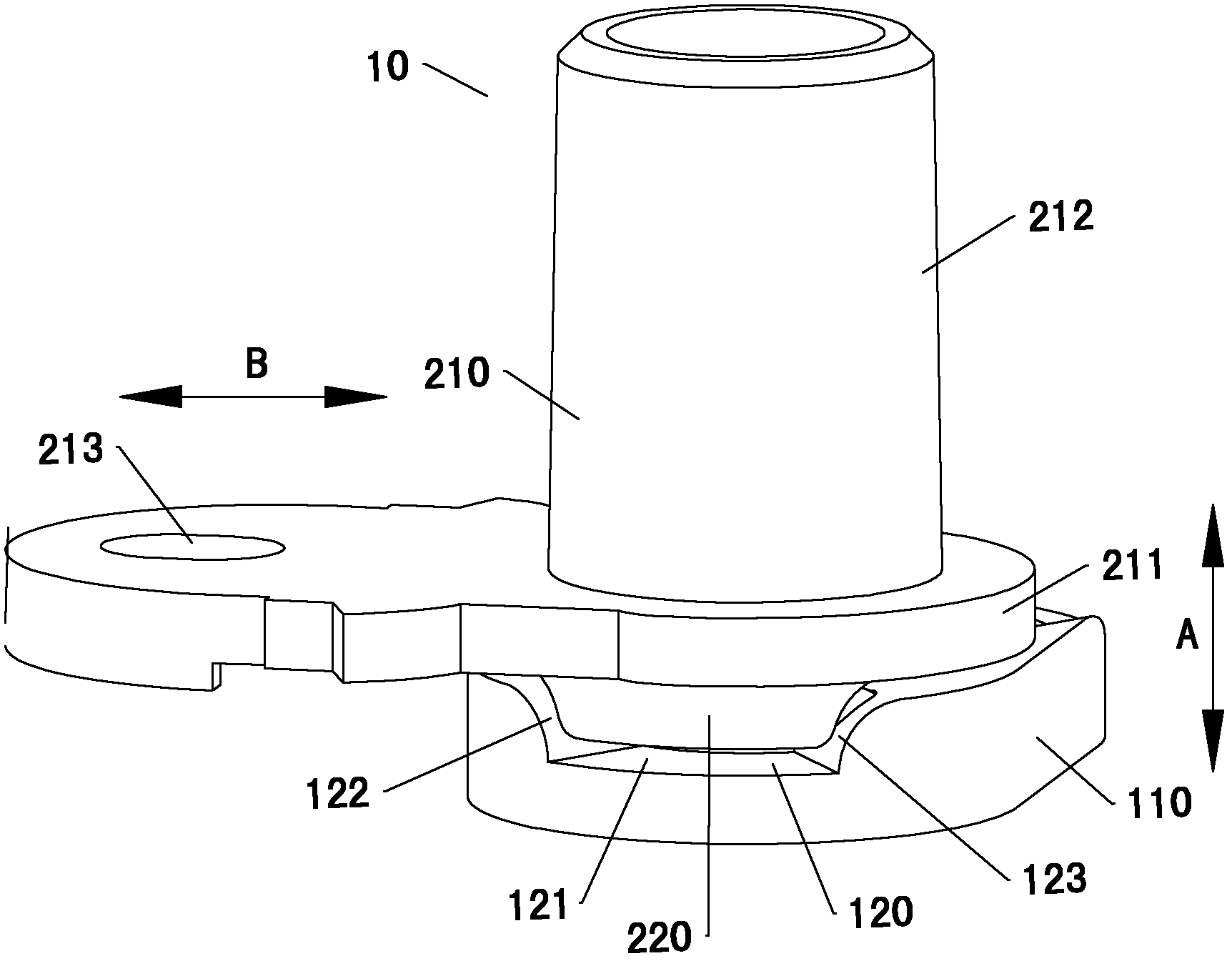

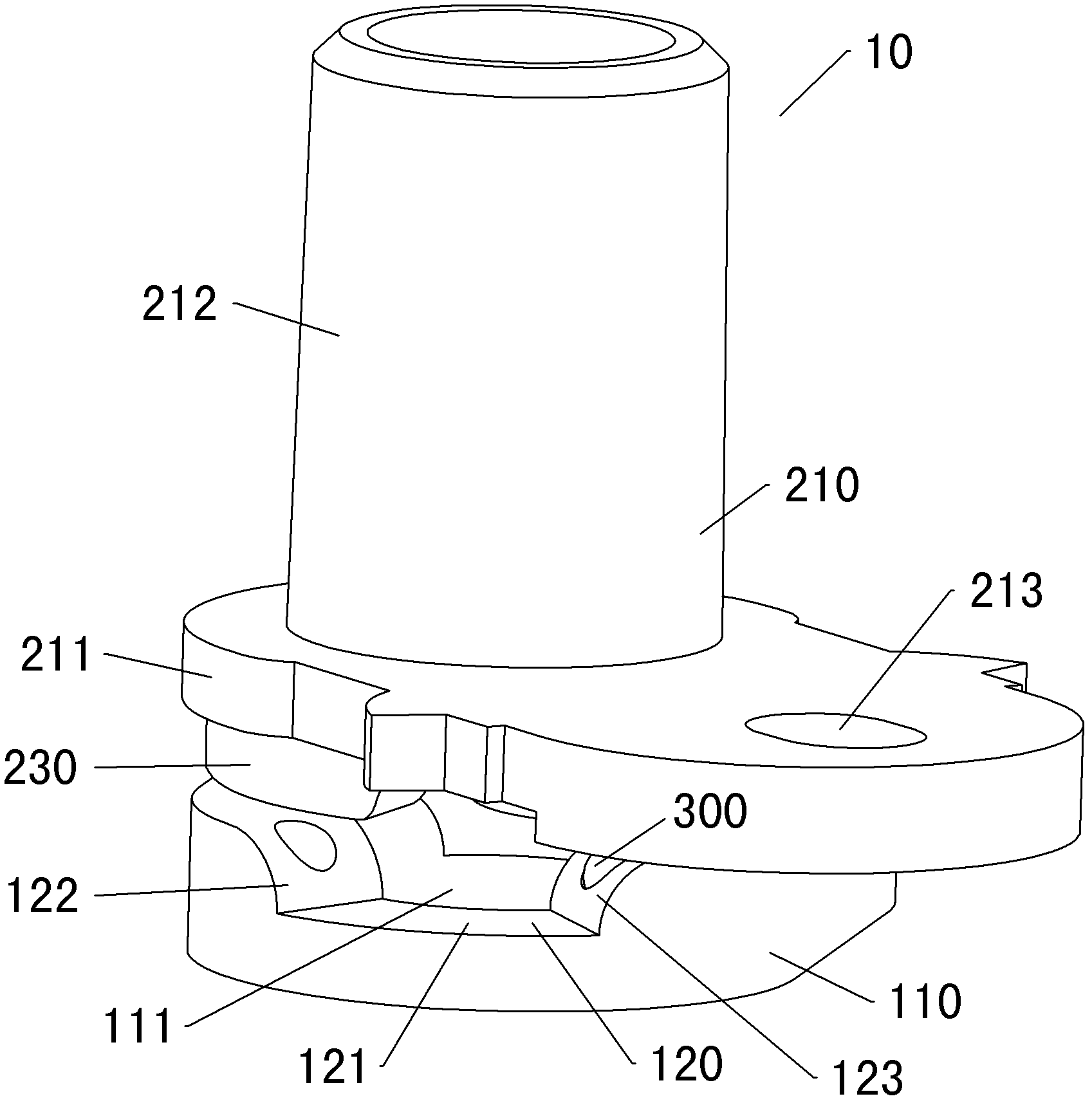

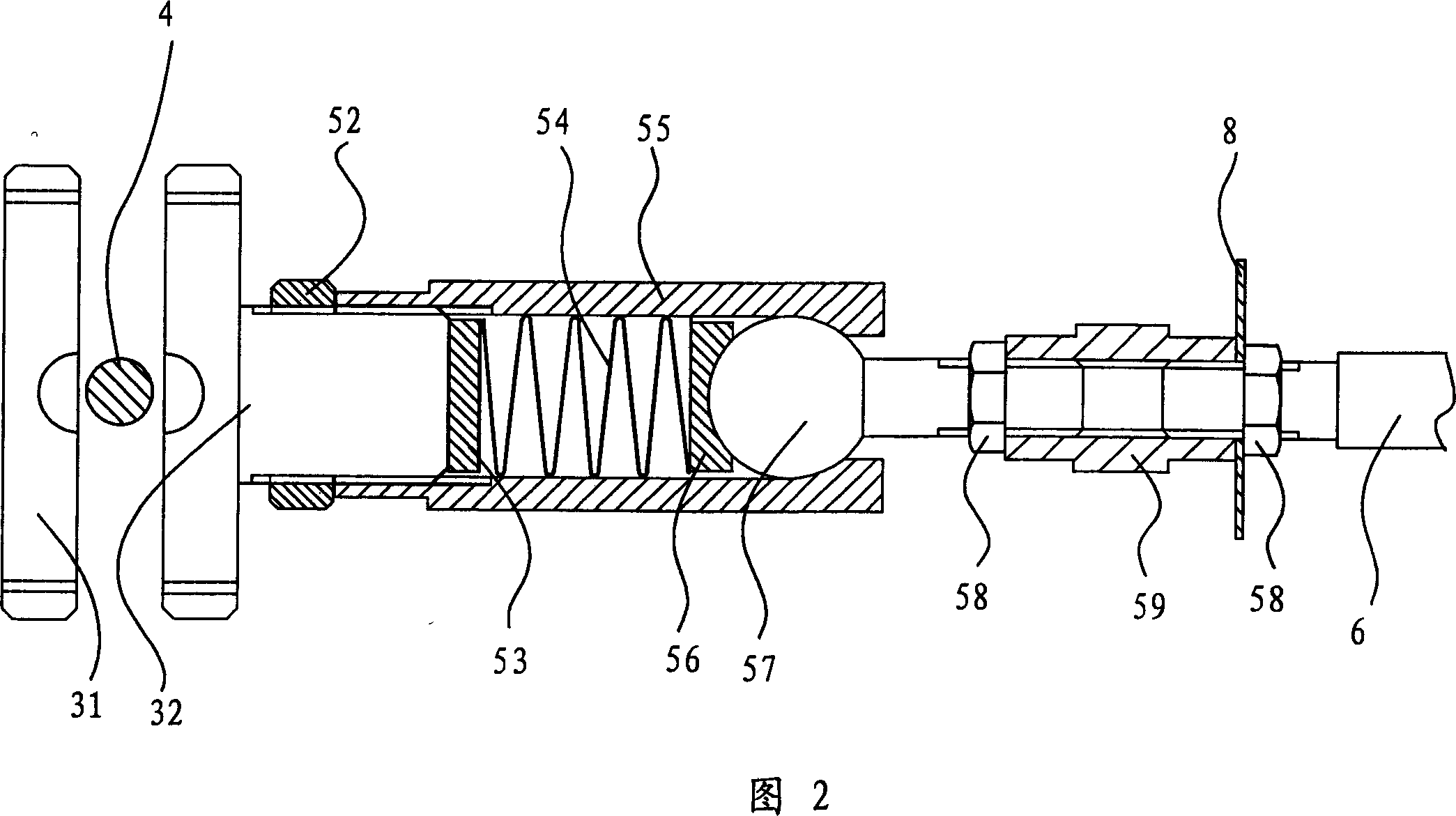

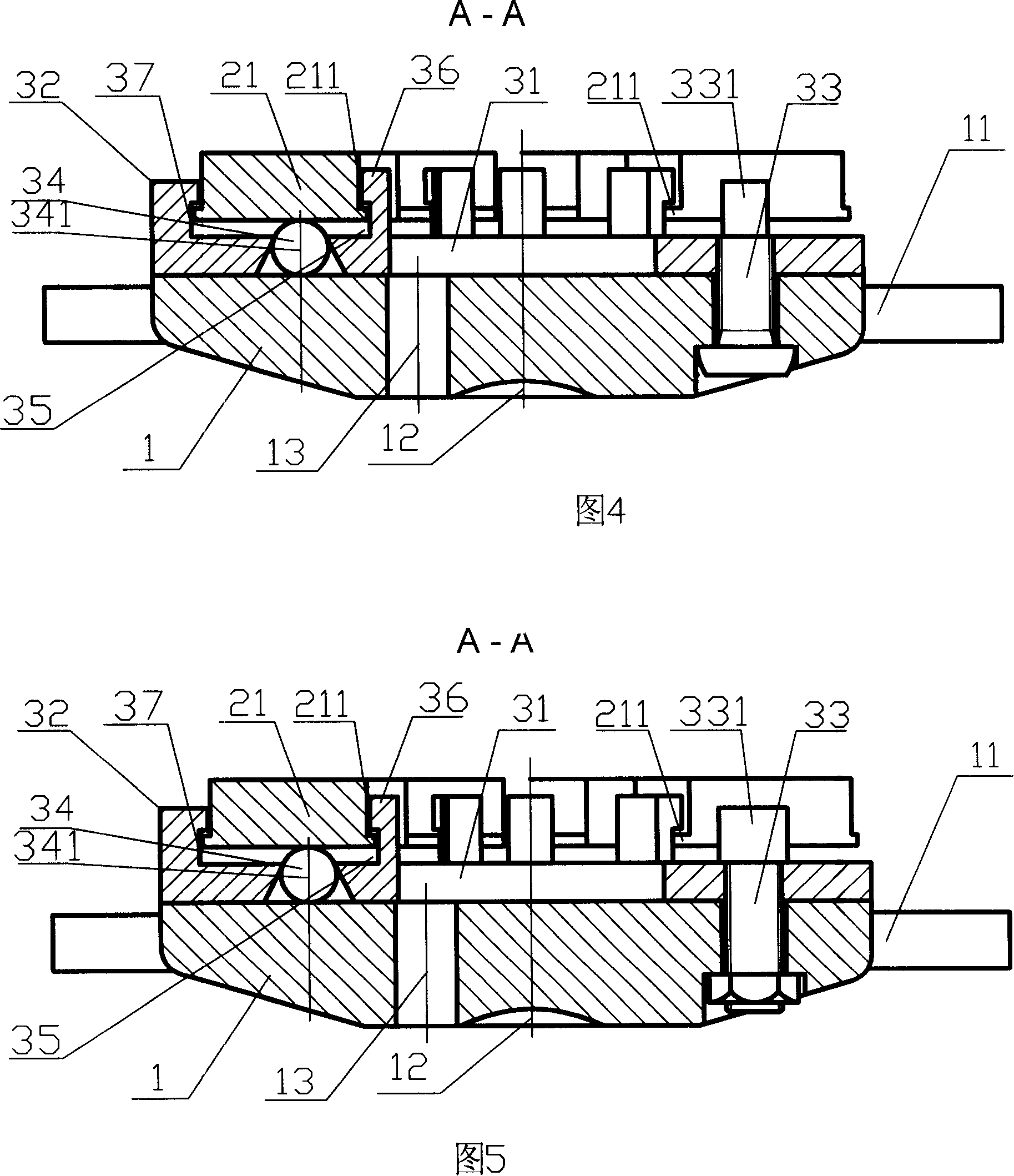

Door closer for refrigerator and refrigerator with door closer

ActiveCN102425351ANice appearanceExtended service lifeDomestic cooling apparatusLighting and heating apparatusEngineeringMechanical engineering

The invention discloses a door closer for a refrigerator and the refrigerator with the door closer. The door closer for the refrigerator comprises a lower door closing piece, an upper door closing piece and a ball, wherein the lower door closing piece comprises a first body, the first body is provided with a lower hinge shaft hole penetrating the first body in the vertical direction, the upper surface of the first body is provided with a front groove, the bottom wall of the front groove is a fan-shaped surface, two side walls of the front groove are relatively protruding arc surfaces, and at least one of the two side walls of the front groove is provided with a ball holding hole; the upper door closing piece comprises a second body, the second ball is provided with an upper hinge shaft, the lower surface of the second body is provided with a front protrusion, and the front protrusion adapts to the front groove; and one part of the ball is held in the ball holding hole, and the other part of the ball extends out of the ball holding hole to support the lower door closing piece. According to the embodiment, the door closer for the refrigerator has the advantages of low friction force, long service life and the like.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

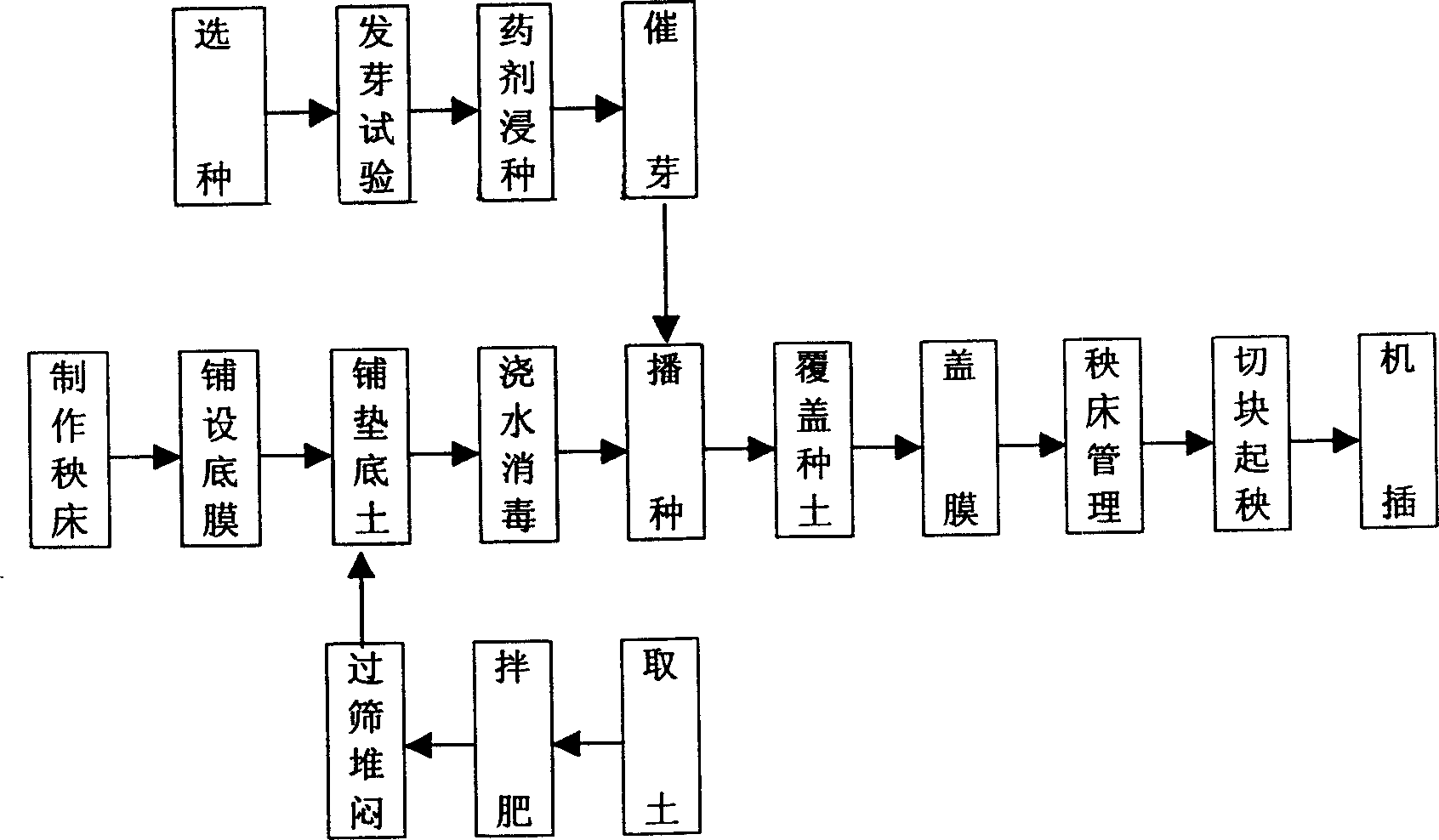

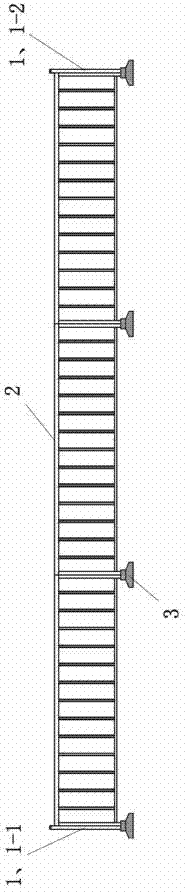

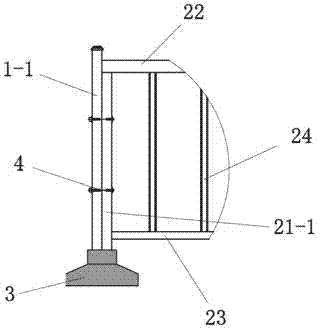

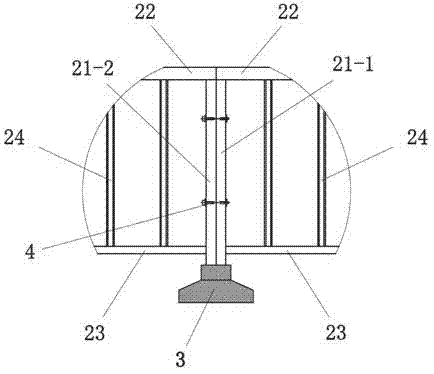

Sprout cultivation method and equipment for rice seedling plugged in by machine

InactiveCN1907005ASolve the technical problem that mechanical rice transplanting cannot be appliedExtend seedling ageCultivating equipmentsRice cultivationMoistureSeedling

The invention discloses a sprout cultivation method and device of machine-plugging rice seed, which comprises the following parts: sprout cultivation bed with frame structure, substrate, covering film and micro-hole permeating film. the sprout cultivation method comprises the following steps: 1. paving substrate; 2. paving soil on the sprout cultivation bed; strickling the surface; 3. irrigating to make bottom soil reach saturated condition; 4. weighing seed; sowing evenly; 5. covering sowing soil evenly; 6. covering film to conserve soil moisture; 7. managing seed bed; 8. cutting block to obtain the plant for plugging.

Owner:CROP INST SICHUAN PROVINCE ACAD OF AGRI SCI

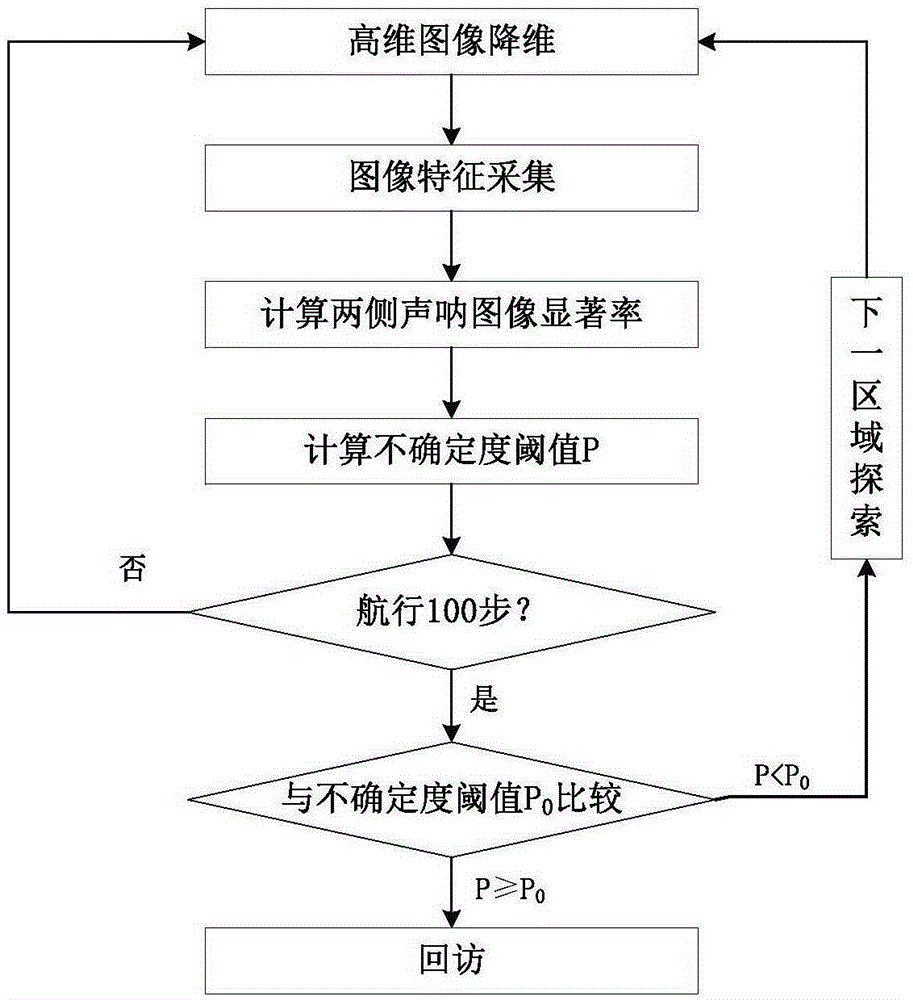

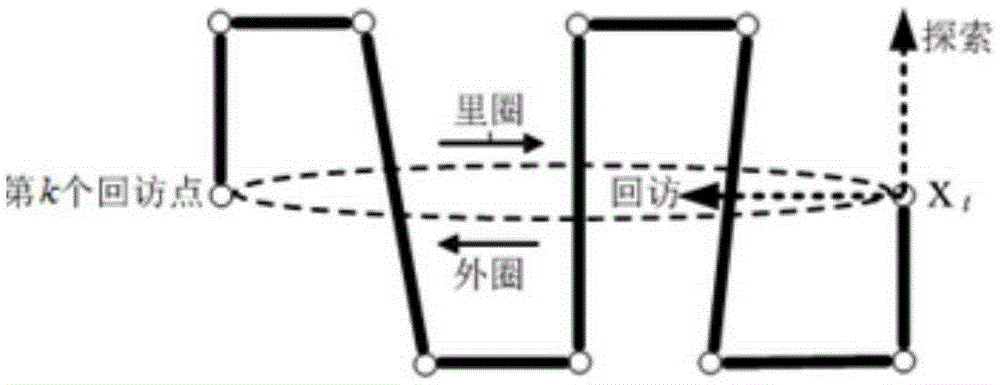

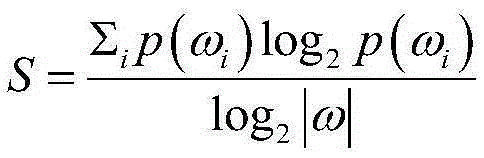

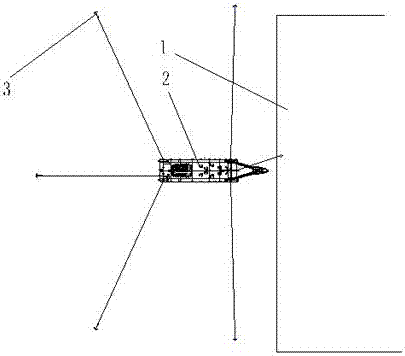

AUV navigation method based on sonar-assisted autonomous navigation

InactiveCN105352496AAvoid defectsImprove navigation performanceNavigation instrumentsAcoustic wave reradiationOcean bottomSonar

The invention relates to an AUV navigation method based on sonar-assisted autonomous navigation, belongs to the technical field of seabed detection, and mainly solves the problem that the ideal detection track of a conventional mapping system is different from an actual value. According to the method, by utilizing an strategy that iSAM (incremental Smoothing and Mapping) algorithm runs at a constant term step number, an object region is partitioned, so that AUV at a local mapping region makes an intelligentized decision on choices of going on exploring unknown regions or performing return visit on the previous seabed environment, two competition appeals about seabed navigation performance and object-region covering rate are both considered, and a feasible plan is provided for solving the key technology problem about position error accumulation when seabed kinetic observation is performed.

Owner:OCEAN UNIV OF CHINA

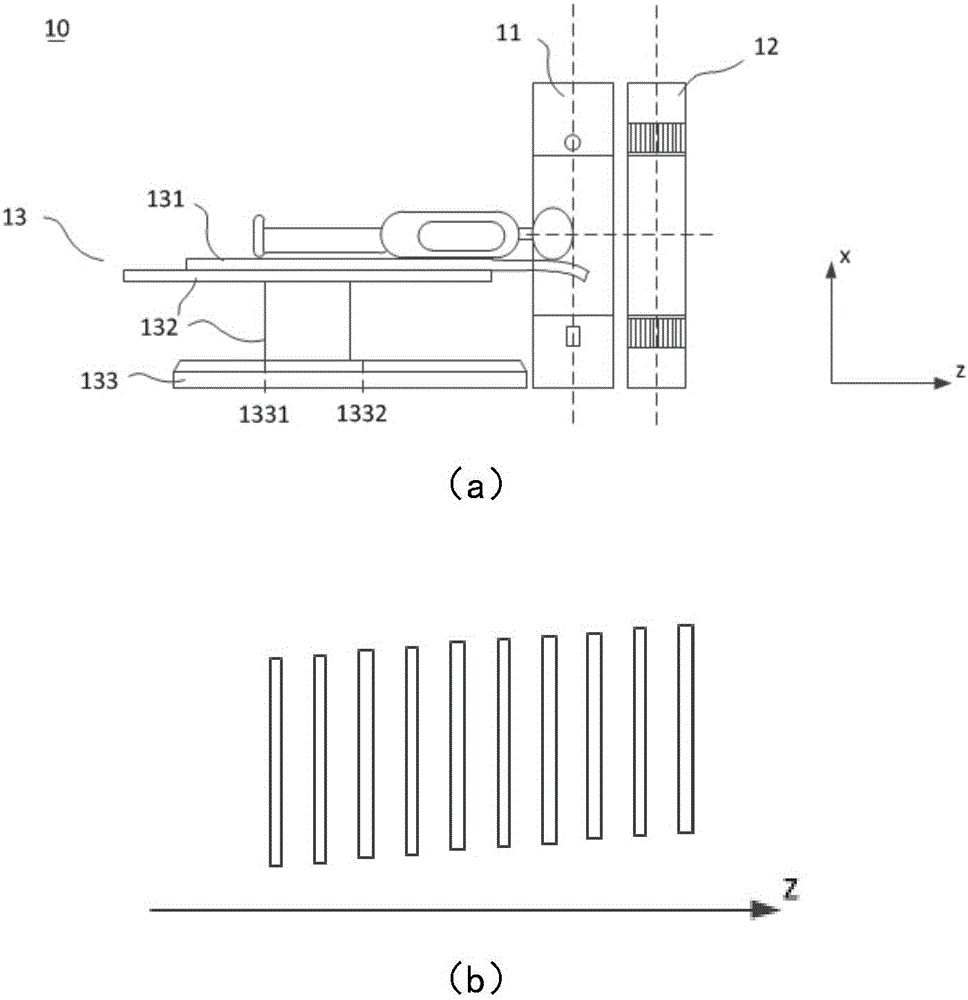

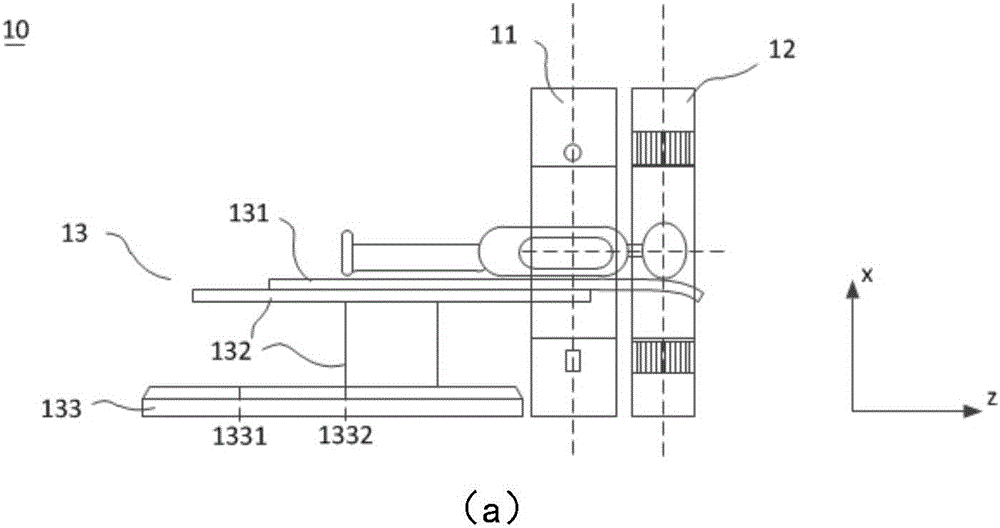

Imaging device and method as well as PET/CT (positron emission tomography/computed tomography) imaging device

InactiveCN106175810ARegistration is simpleEasy to operatePatient positioning for diagnosticsComputerised tomographsMedical imagingComputed tomography

The invention relates to the field of medical imaging and discloses an imaging method and device. The imaging device comprises an acquiring unit for acquiring images, a determining unit, a height adjusting unit and an imaging unit for executing imaging scanning, wherein the determining unit is used for determining the linear relation between the bed board height in the images and the moving distance of a bed board in the length direction of the bed board; the height adjusting unit is used for adjusting the bed board according to the linear relation, so that the surface of the adjusted bed board meets the linear relation. The imaging method and device can compensate the difference between the bed board sinkage in different imaging modes and facilitate image fusion.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

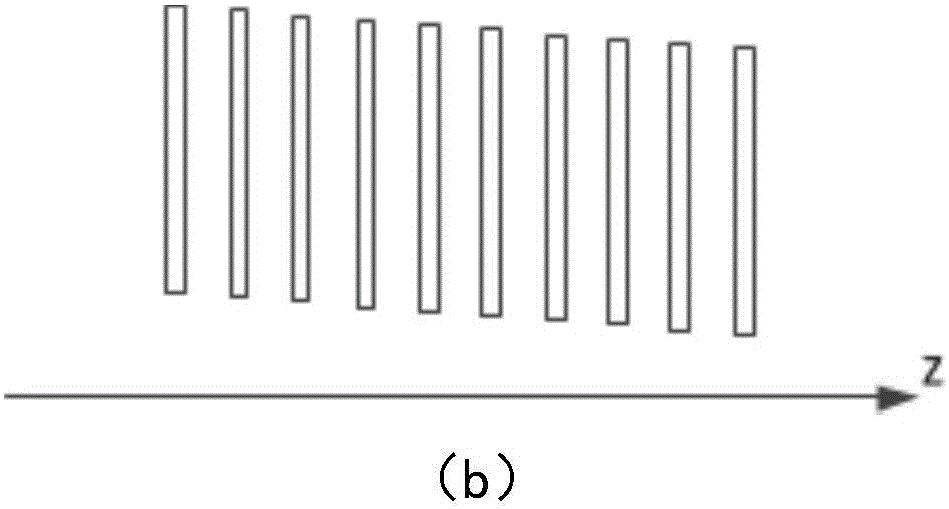

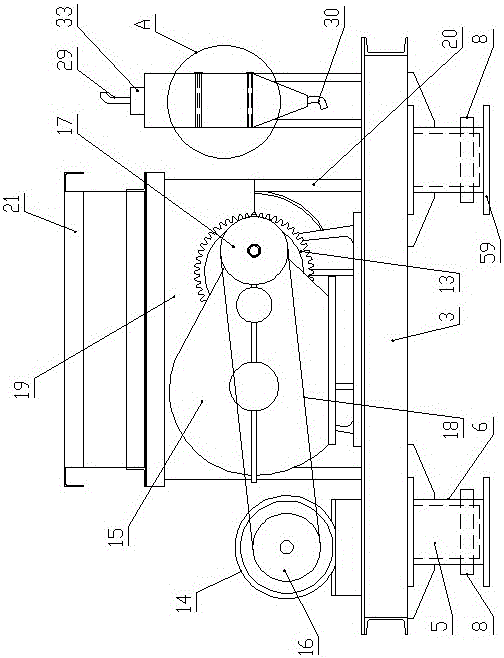

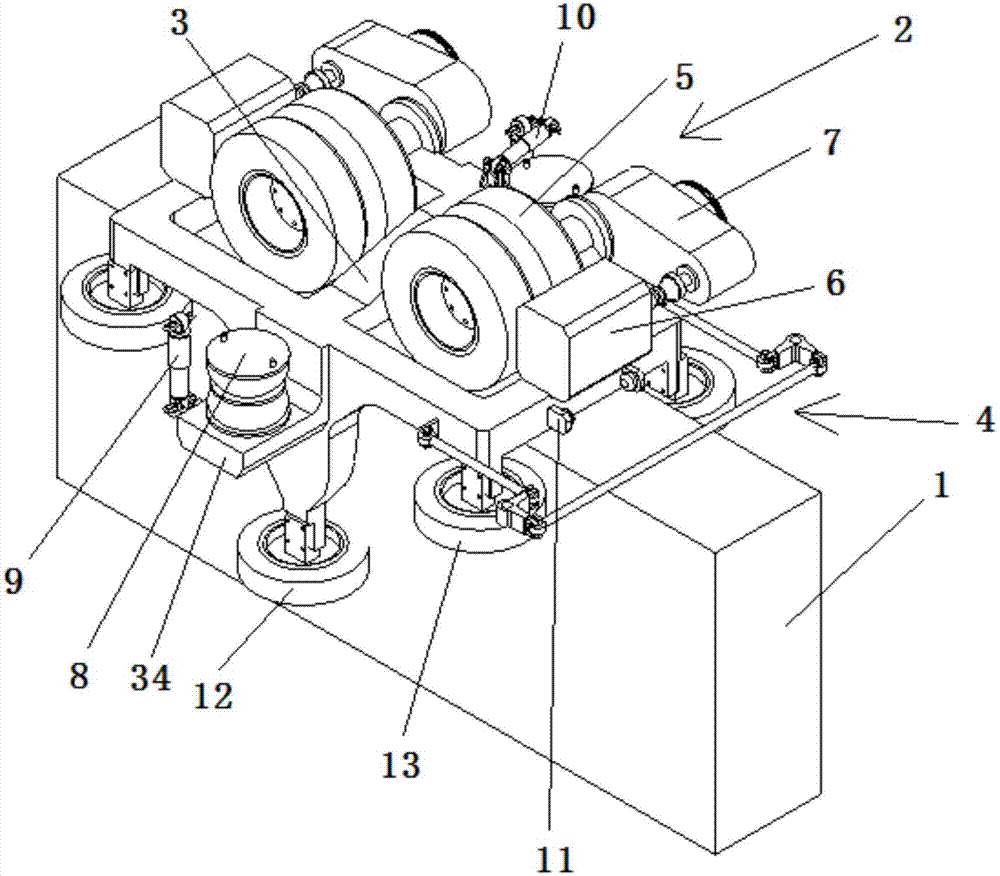

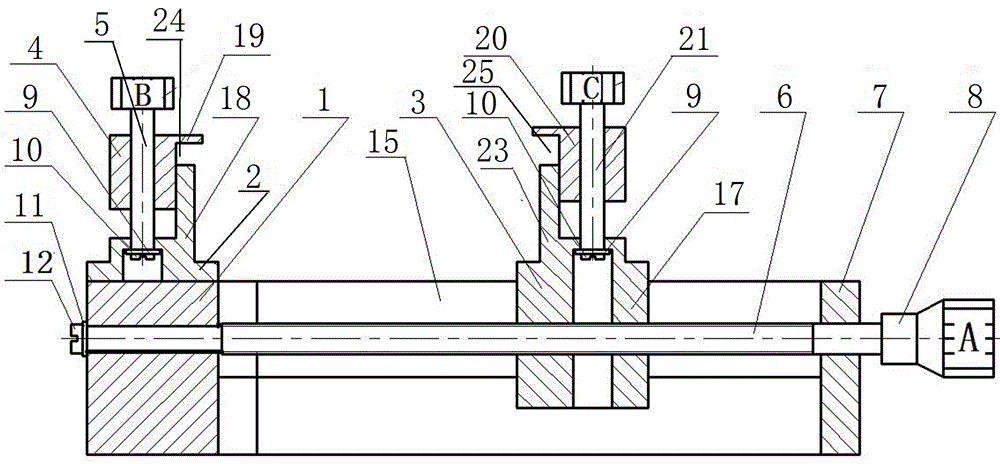

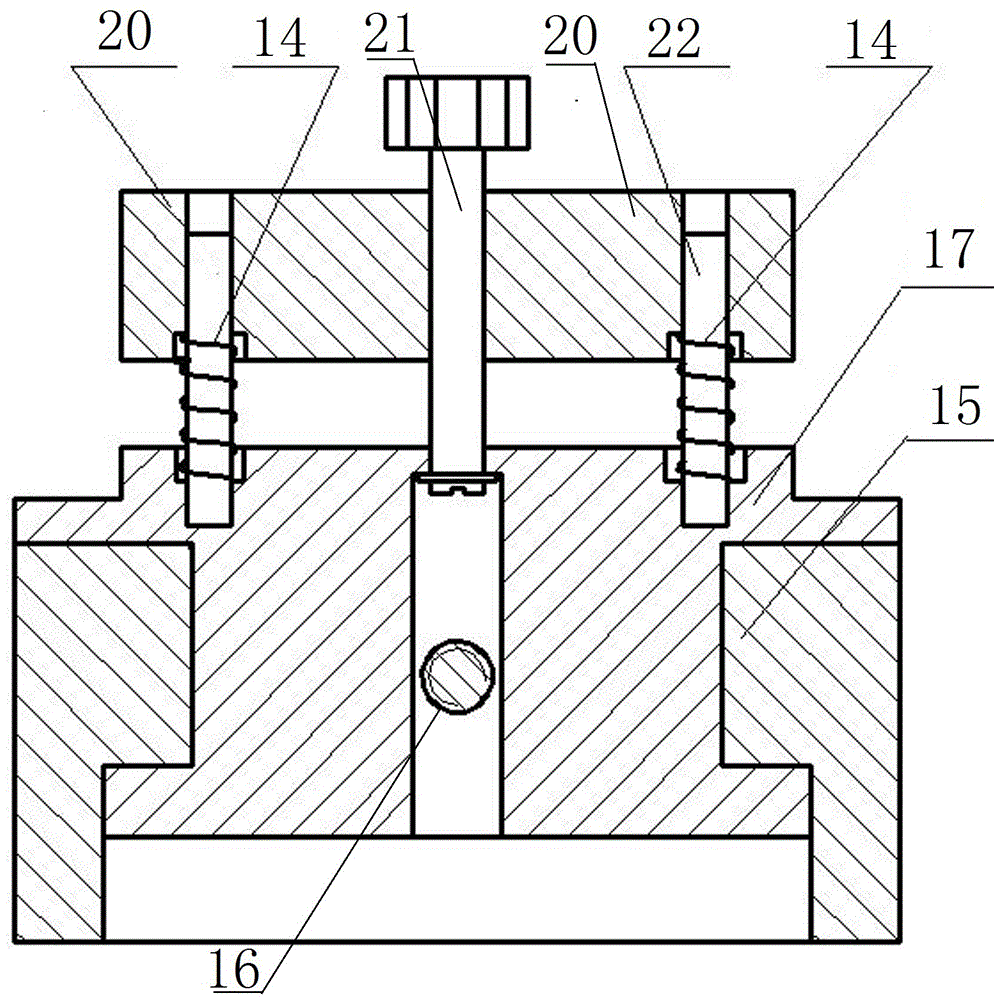

Disinfection cabinet drawer life test machine

InactiveCN1995953ASave human effortImprove test efficiencyStructural/machines measurementTest efficiencyPush and pull

The invention relates to a disinfection cabinet drawer endurance tester. It comprises fixture, automatic push-pull unit, calculator, with the said fixture detachably connected with the handle of the disinfection cabinet drawer, the fixture connected with the automatic push-pull device, and the calculator connected with the automatic push-pull device. It is simple, with automatic push and pull of the drawer, precise calculation, saving man power, and improved in testing efficiency and accuracy.

Owner:陈柯杰

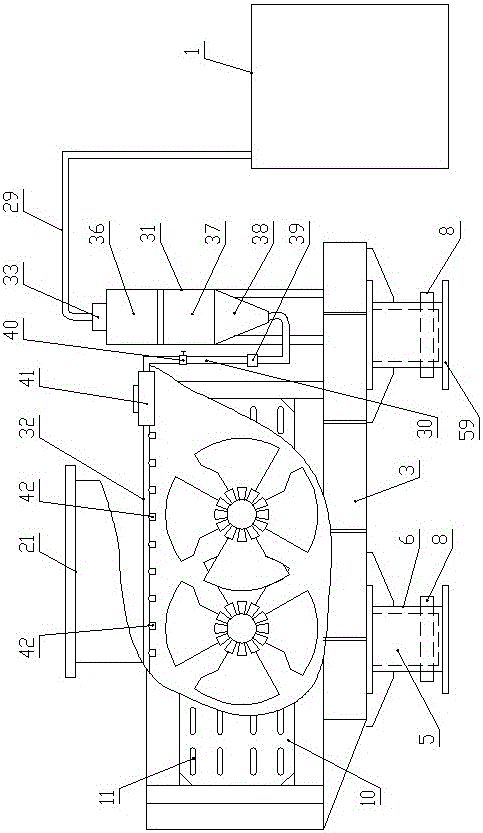

Building garbage crusher

InactiveCN106040362AAchieve recyclingIncrease profitUsing liquid separation agentGrain treatmentsDrive shaftLitter

The invention discloses a building garbage crusher which comprises a rack, wherein the left end part of the rack is provided with a power drive system; the power output end of the power drive system is in transmission connection to a material crushing system positioned at the right side of the power drive system; the material crushing system is fixed to the rack; an automatic spraying and dust-reducing system in front of a charging part of the material crushing system is arranged on the rack; a spraying part of the automatic spraying and dust-reducing system is positioned in the material crushing system; and one side of the rack is provided with a settling tank. According to the building garbage crusher disclosed by the invention, synchronous drive of a primary transmission shaft and a secondary transmission shaft is realized through the power drive system, dust generated in a crushing process is effectively reduced through the automatic spraying and dust-reducing system, cyclic utilization of water flow is realized, and material crushing is realized through the material crushing system, so that building garbage is recycled; and the building garbage crusher is simple to operate, is stable in work, is good in crushing effect, increases a waste utilization rate, reduces production cost, and is energy-saving and environmentally friendly.

Owner:HUANGHE S & T COLLEGE

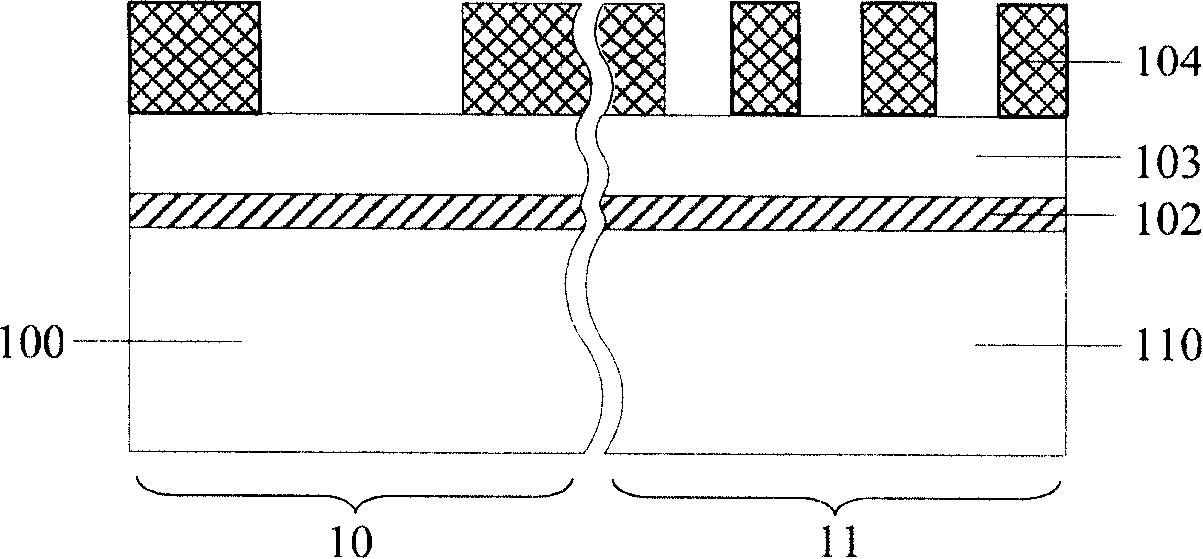

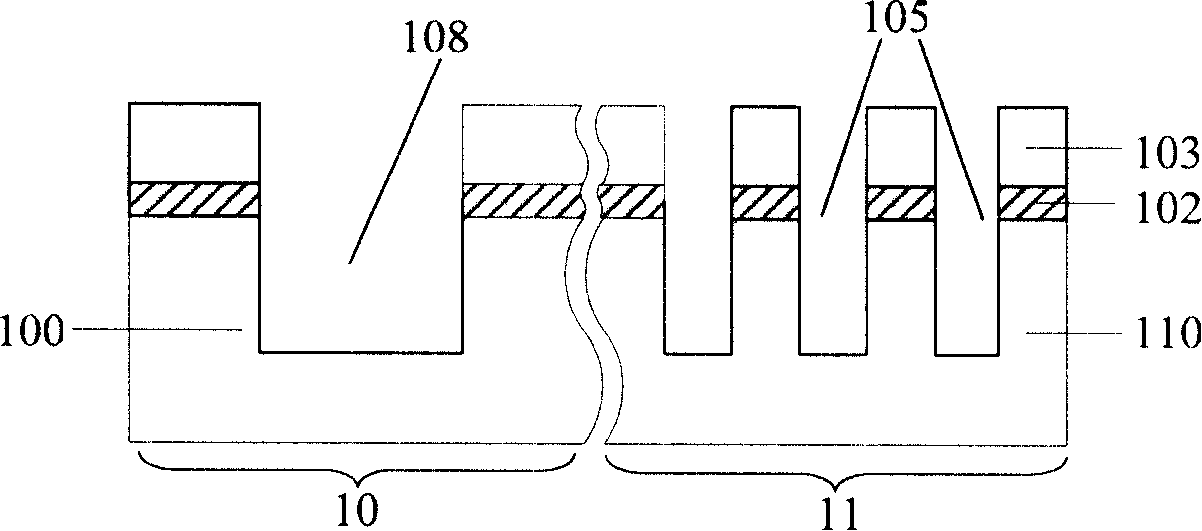

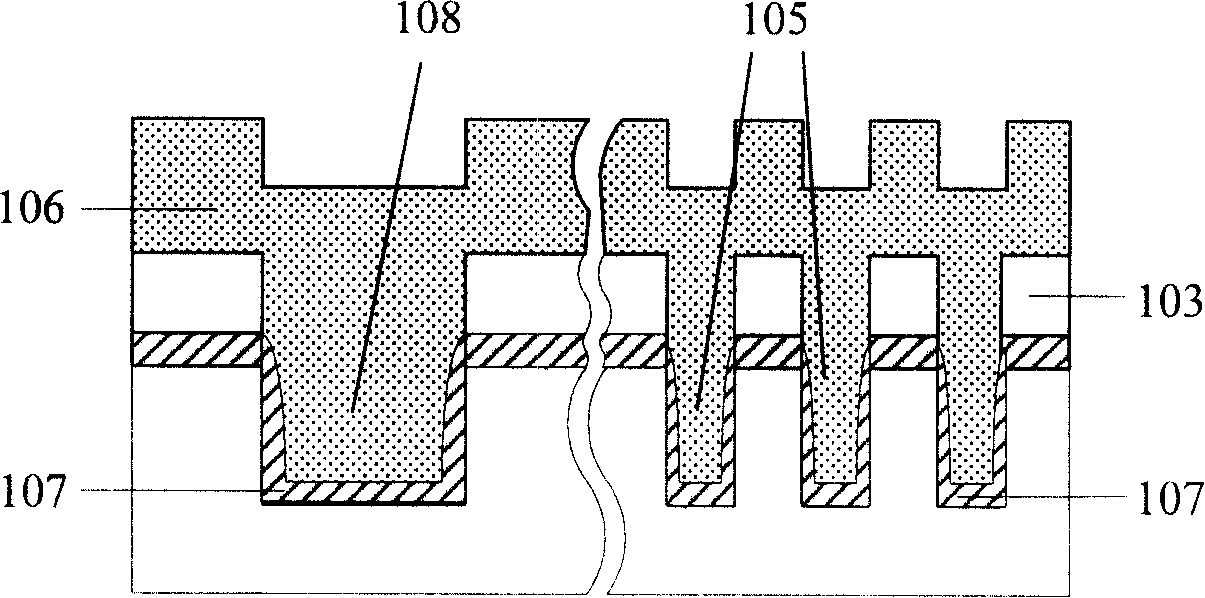

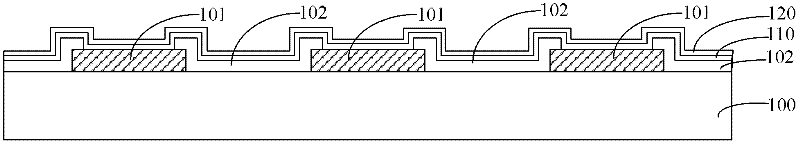

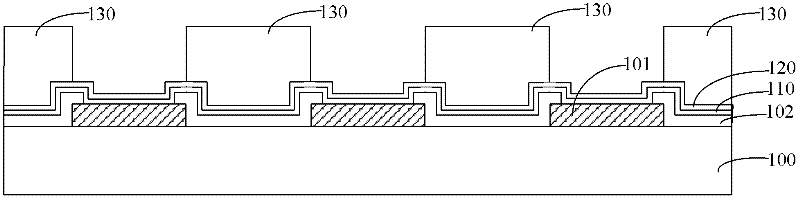

Method for forming device isolation region

InactiveCN101207064AKeep highReduced quiescent leakage currentSemiconductor/solid-state device manufacturingPhotoresistSilicon nitride

The invention relates to a formation method of a device isolation area. The method comprises the following steps: a silicon substrate comprising a peripheral circuit area and a storage unit area is provided; a pad oxide layer and a silicon nitride layer are formed on the silicon substrate in sequence; the pad oxide layer, the silicon nitride layer and the silicon substrate are etched to form a groove; an insulating oxide layer is formed on the silicon nitride layer, and the insulating oxide layer is filled into the groove; the insulating oxide layer is grounded until the silicon nitride layer is exposed; photoresist is formed on the peripheral circuit area; the photoresist is taken as a mask, the insulating oxide layer in the storage unit area is etched until the height is coincident with the height of the insulating oxide layer in the peripheral circuit area; the photoresist, the silicon nitride layer and the pad silicon oxide layer are removed, so as to form a shallow groove isolation structure. The height of shallow groove isolation structure of the storage unit is reduced through the said steps, the phenomenon that the shallow groove isolation structure of the storage unit area generates excessive grinding is avoided during the subsequent planarization process of the polysilicon layer, and the phenomenon that the residues of the polysilicon layer is generated during the etching process of the subsequent word line of the storage unit to result in the word line short circuit is also avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

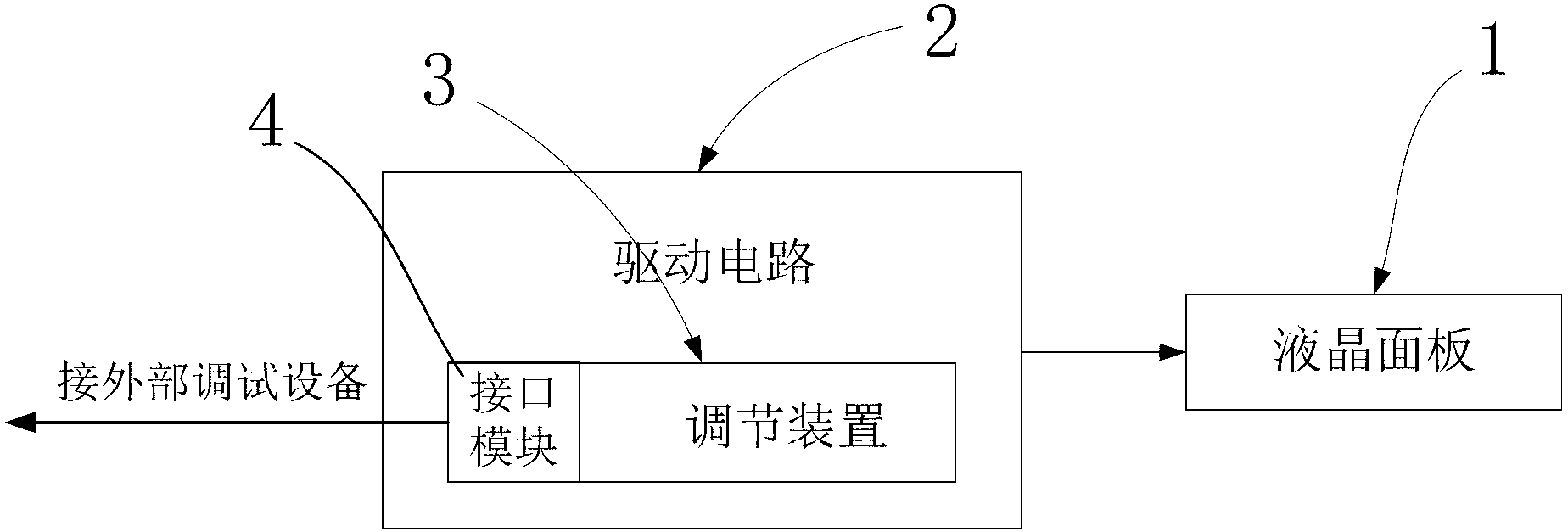

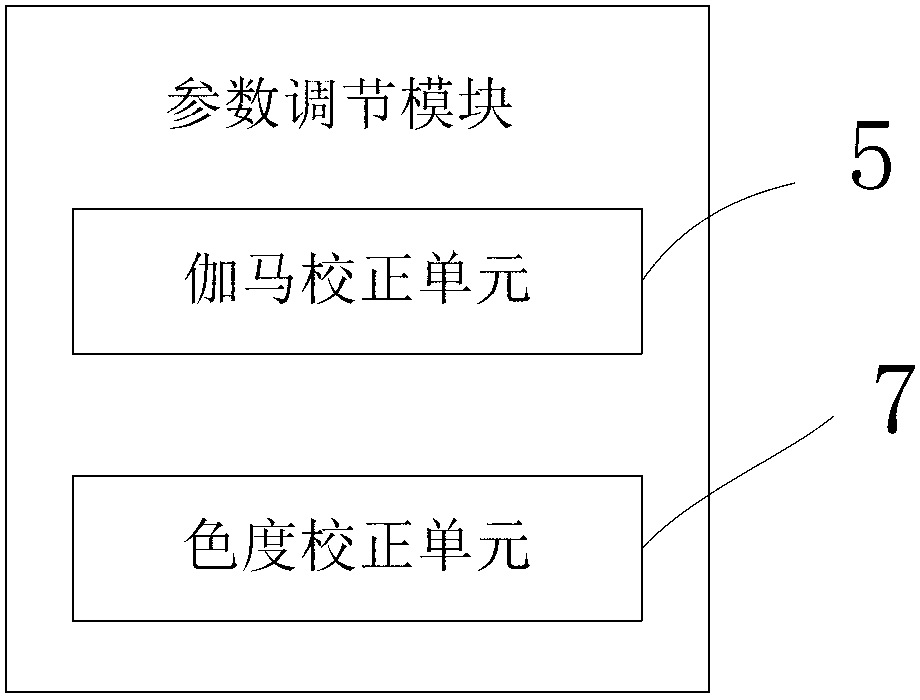

Liquid crystal spliced screen, correcting method thereof and liquid crystal display device

ActiveCN103077691ALower requirementThe display effect is consistentStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a liquid crystal spliced screen, a correcting method thereof and a liquid crystal display device. The liquid crystal spliced screen comprises a plurality of liquid crystal display devices, wherein each liquid crystal display device comprises a liquid crystal display panel and a driving circuit for controlling the display of the liquid crystal display panel, and each driving circuit comprises an adjusting device in which display parameters are stored; and the display parameters of the adjusting devices of at least two liquid crystal display devices in the plurality of liquid crystal display devices are different. According to the invention, the design difficulty and the cost can be reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

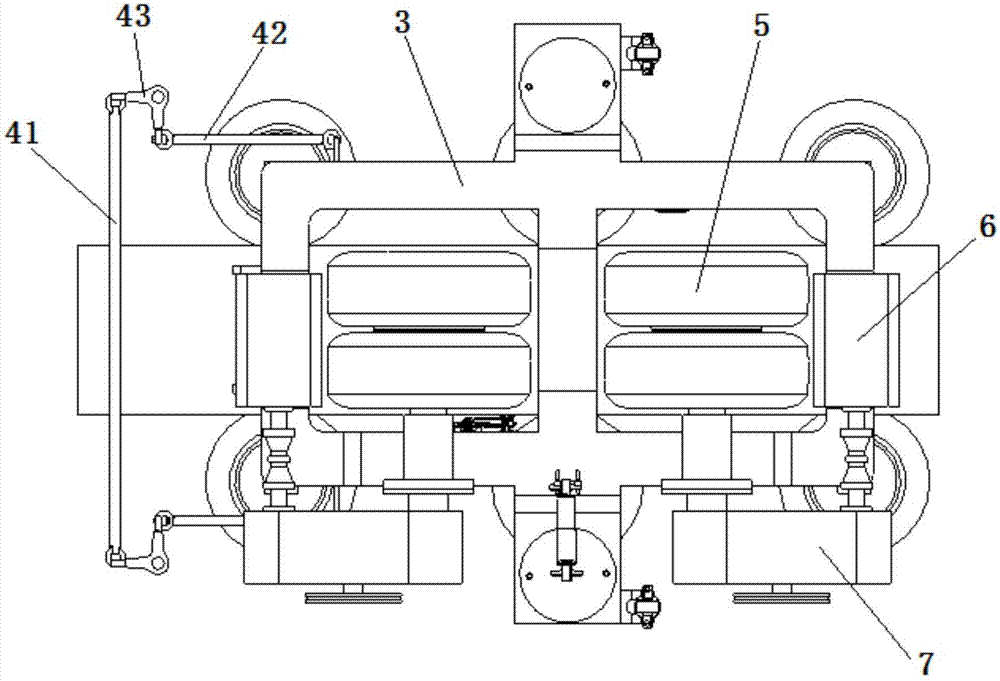

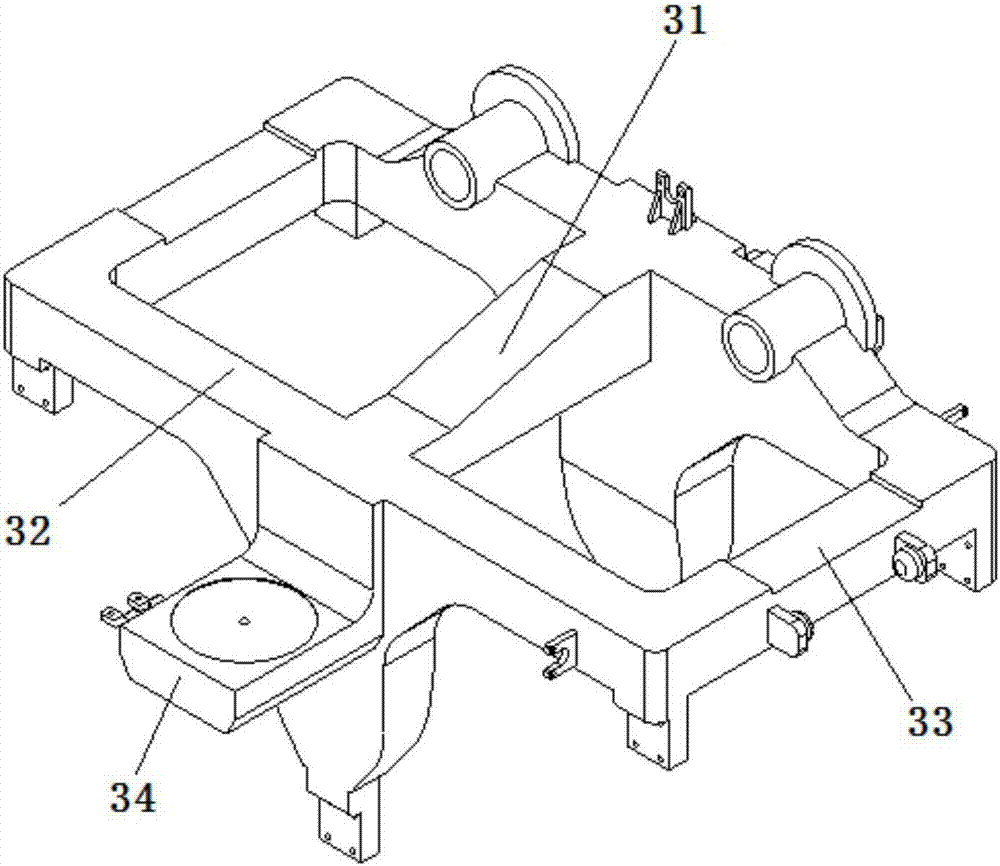

Low-floor-surface straddle type two-shaft one-rail bogie

InactiveCN107472281ABig spaceImprove stabilityElectric motor propulsion transmissionBogiesBogieEngineering

The invention relates to a low-floor-surface straddle type two-shaft one-rail bogie comprising a framework, two traction motors and two sets of travelling wheels. The framework is provided with a middle beam, two side beams and end beams located at the two ends. From the train operation direction, the framework is in an inverted-U shape to be arranged on rail beams in a straddle mode, the two sides of the middle of the formwork are provided with L-shaped cantilevers extending downwards, and secondary damping springs are mounted on the cantilevers. The two traction motors are arranged at the front end and the rear end of the formwork correspondingly, the two sets of travelling wheels are arranged on the front side and the rear side of the middle of the formwork correspondingly, the traction motors drive the travelling wheels on the corresponding sides to rotate through gear boxes correspondingly, and the two gear boxes are located on the same side of the formwork. According to the low-floor-surface straddle type two-shaft one-rail bogie comprising a framework, the two gear boxes are arranged on the same side of the formwork, and the other side of the bogie reserves a large space so that the floor surface of the position of a vehicle can be lower.

Owner:CRRC NANJING PUZHEN CO LTD

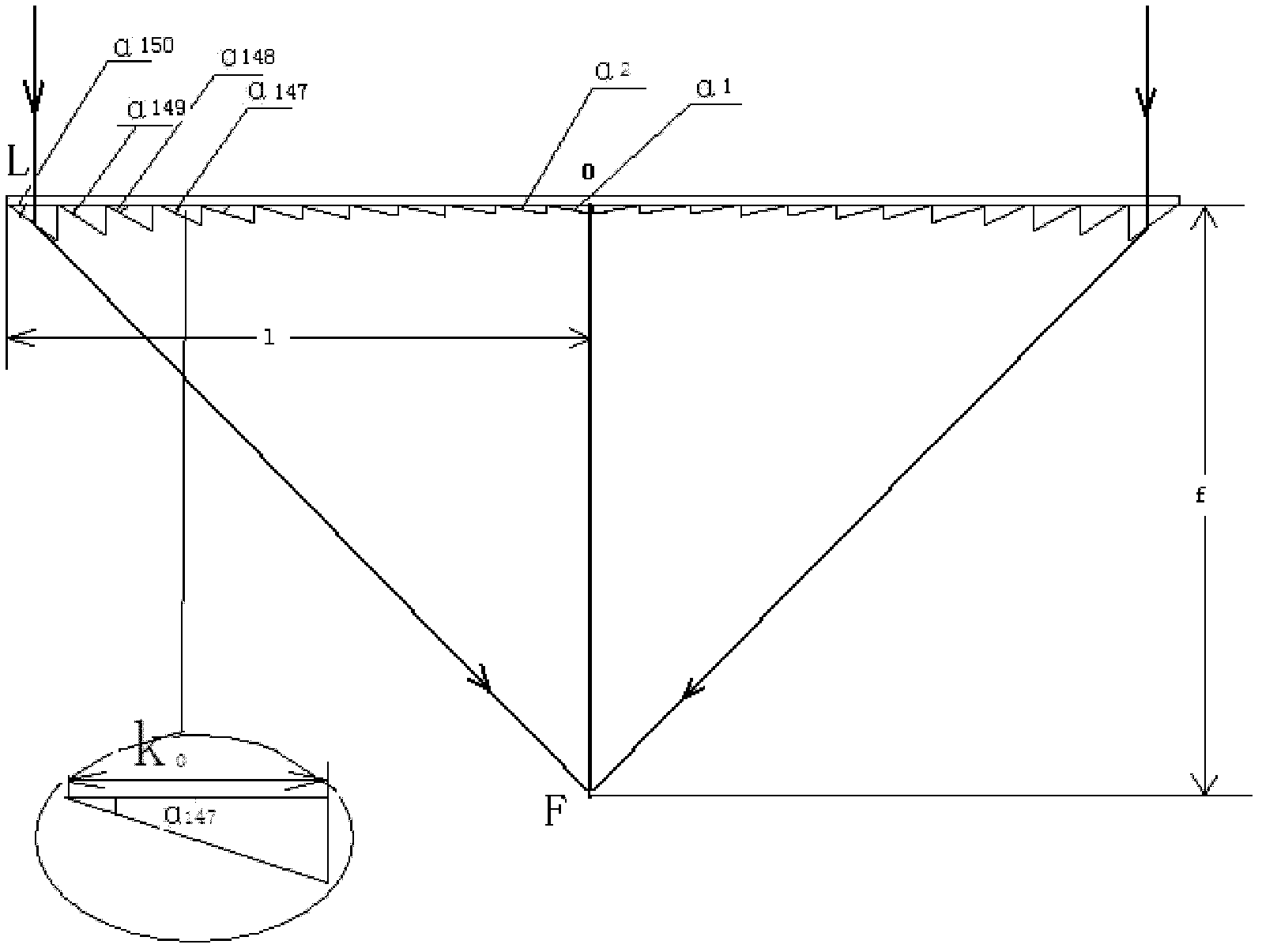

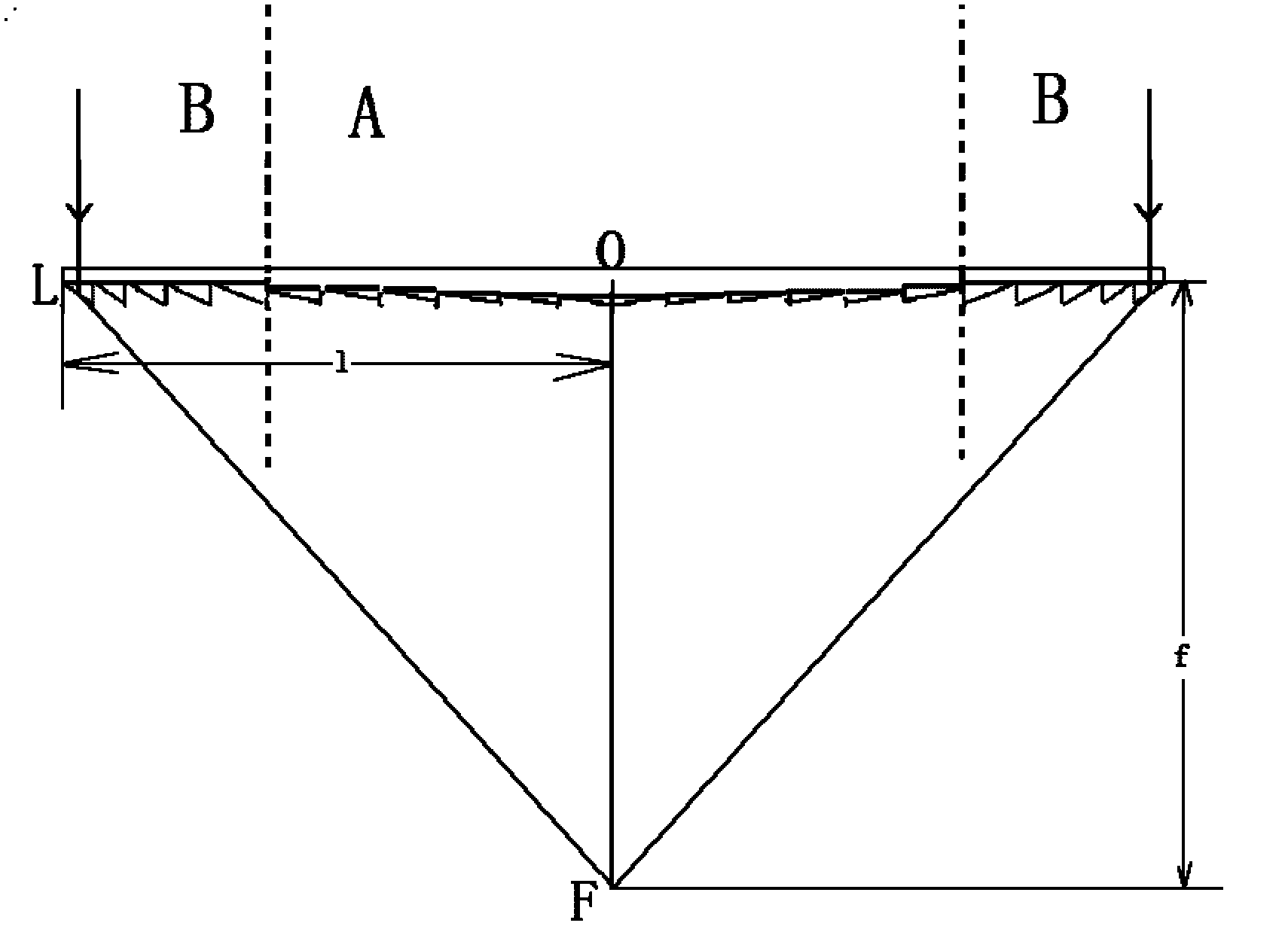

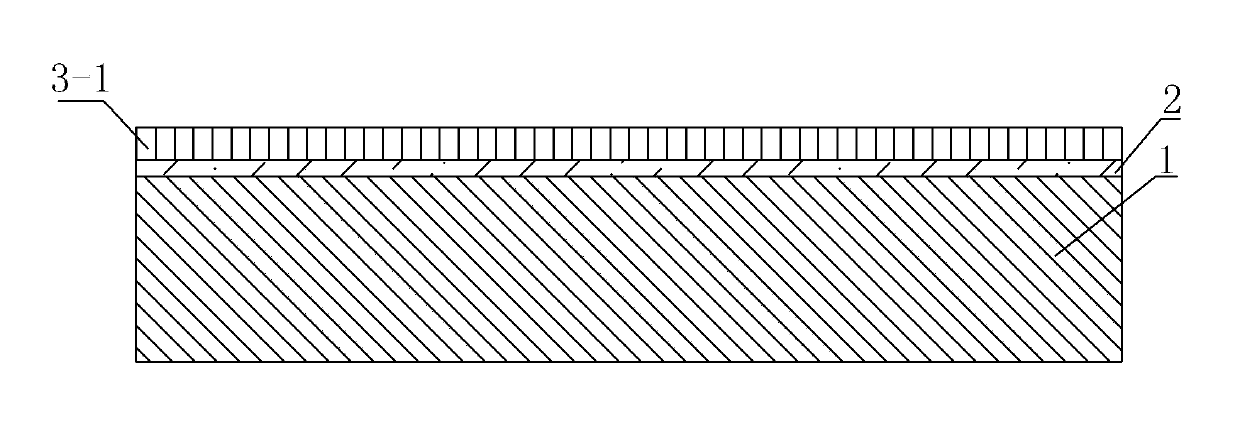

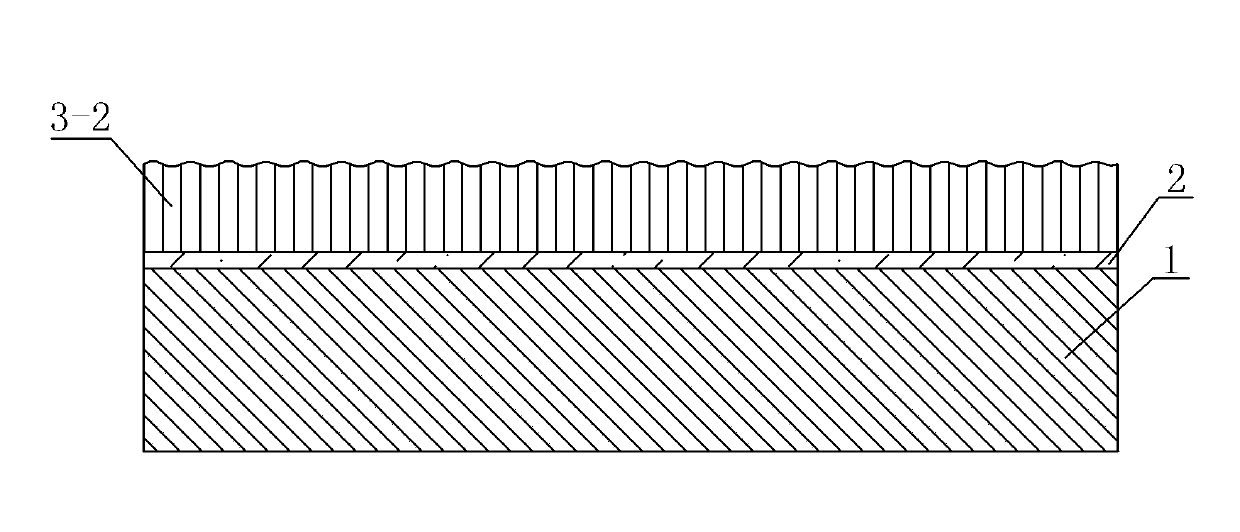

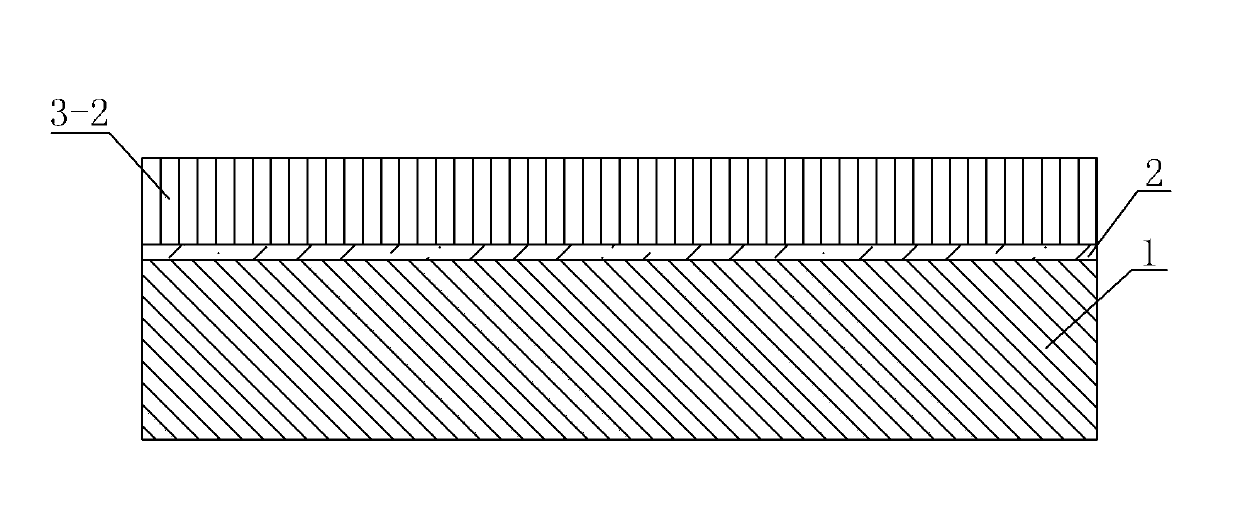

Design method for glass Fresnel lens mould

A design method for a glass Fresnel lens mould is characterized in that the conformity of contour line heights of edge teeth are ensured through changing widths or heights of the edge teeth having different distances to a center of the glass Fresnel lens mould, that is, the heights of the edge teeth closed to the center and close to edges of the glass Fresnel lens mould are basically same, so that the thicknesses of outer wall contour lines of the glass Fresnel lens mould represent the basically uniform state, that is, the uniformity of outer wall contour line thicknesses of the glass Fresnel lens mould are basically ensured. Therefore, necessary conditions are provided for the smooth realization of running water cooling of the mould and the technological requirement for uniform glass stress distribution.

Owner:SHAANXI UNIV OF SCI & TECH

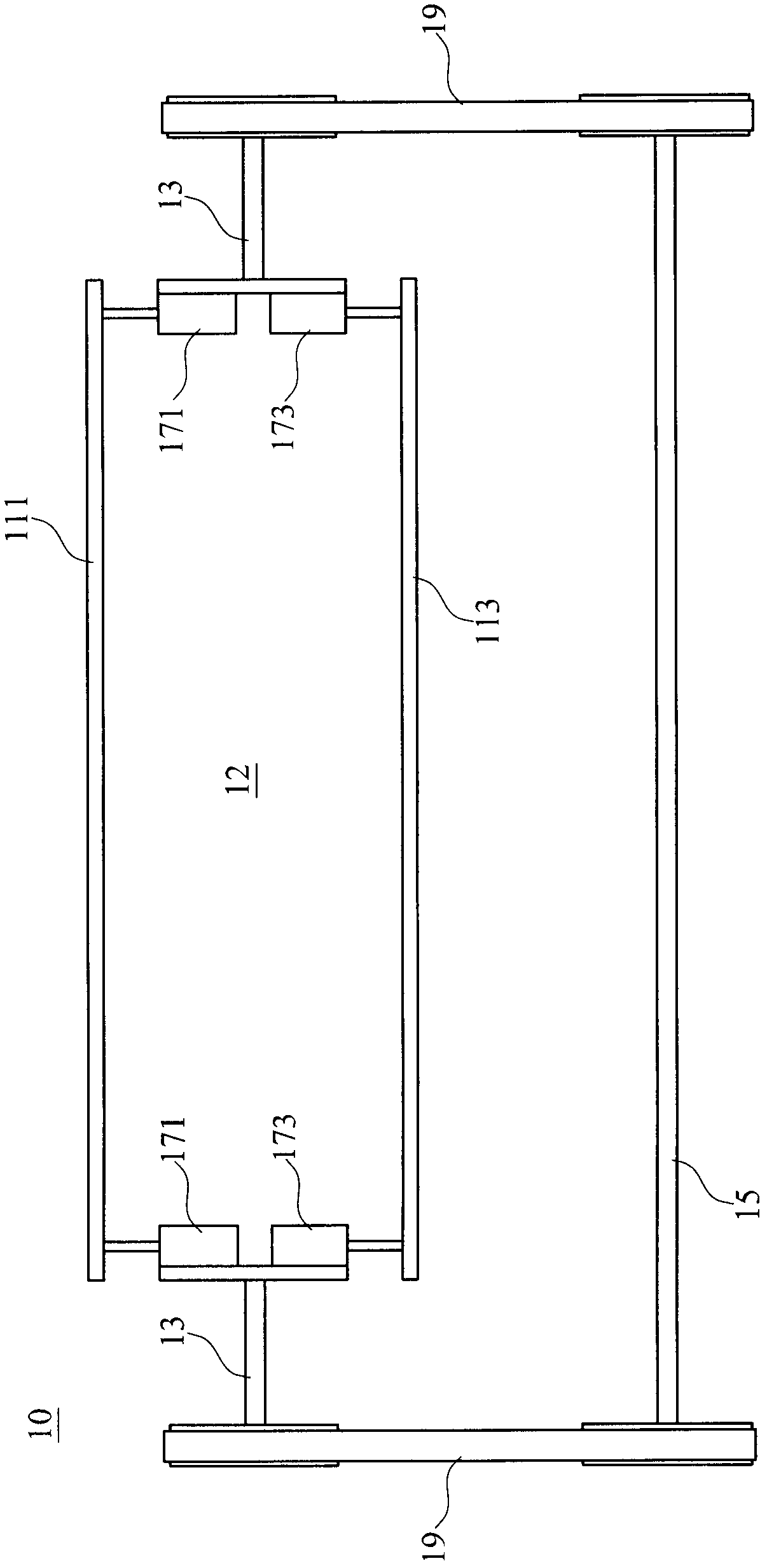

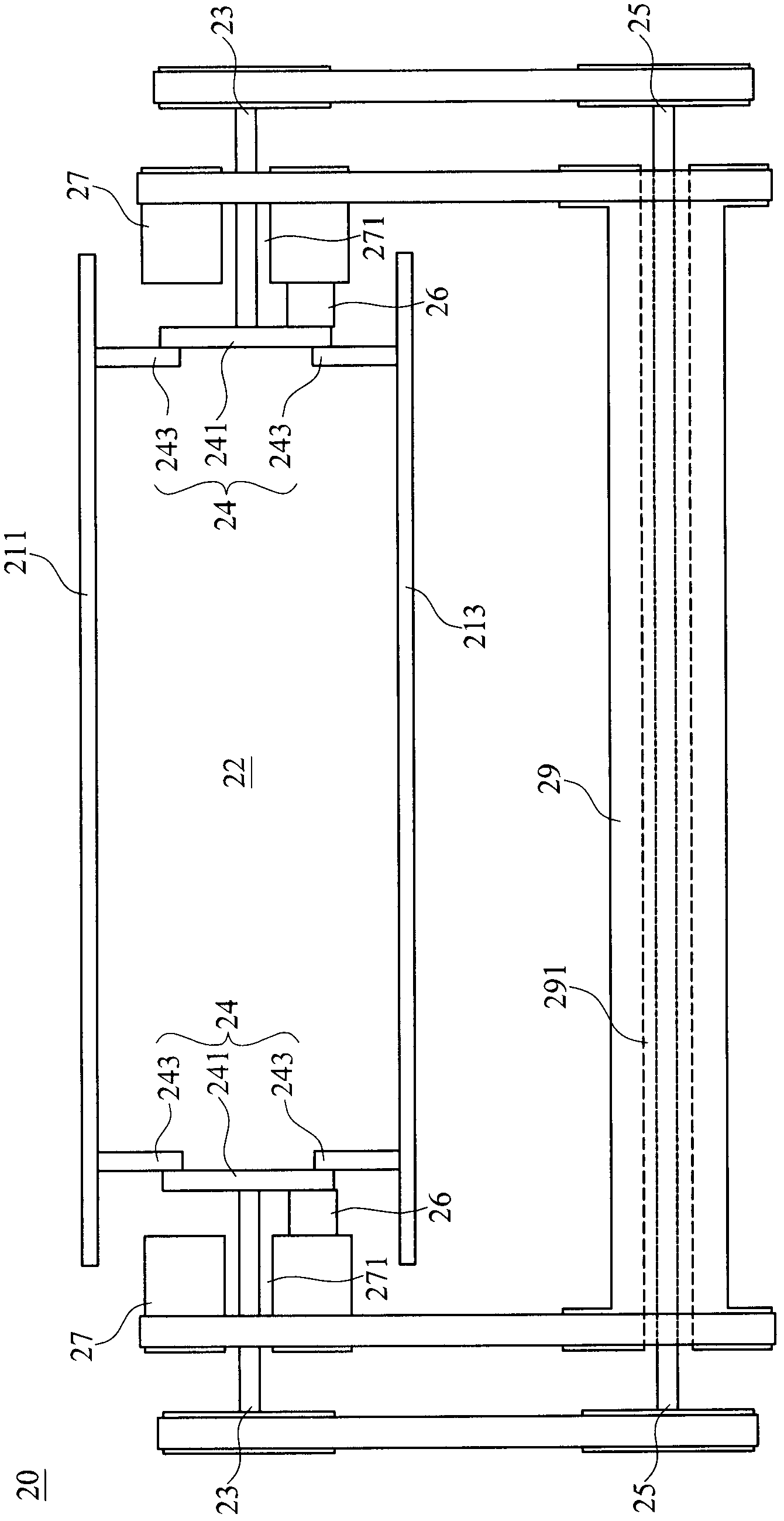

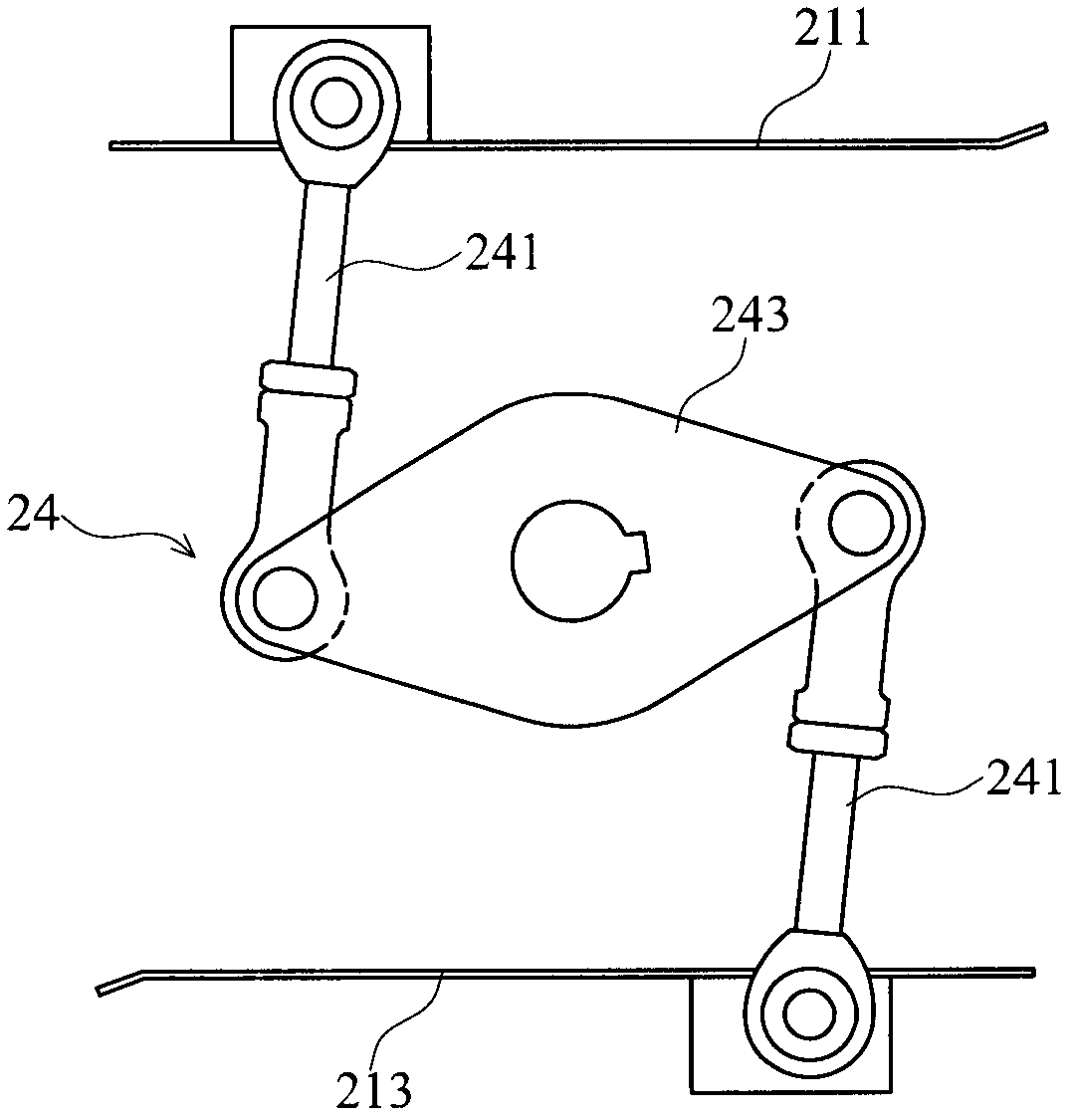

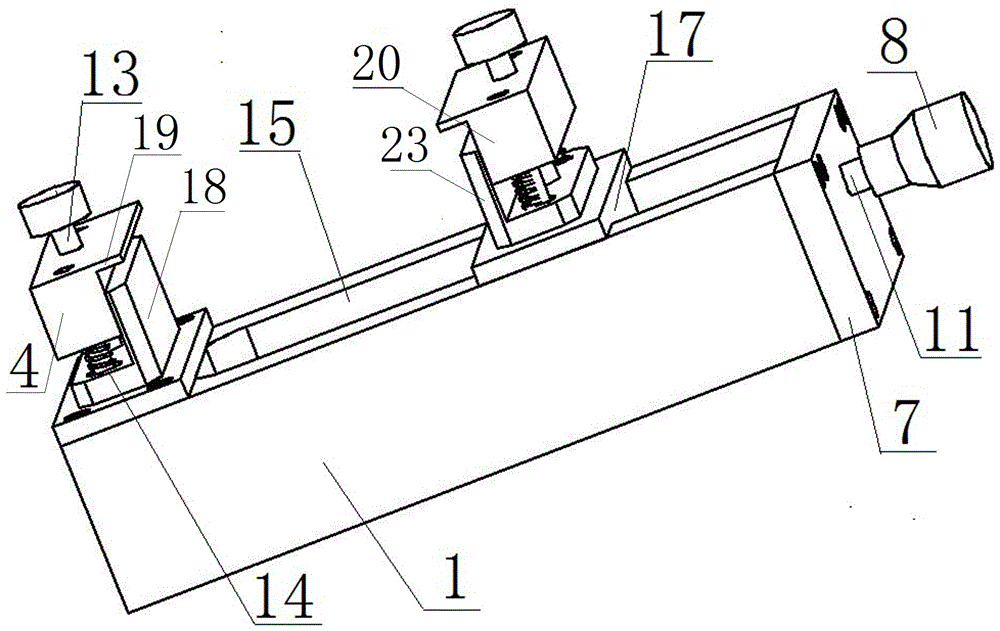

Clamping and turning device

InactiveCN102070112AImprove convenienceConsistent displacement speedGearingLifting devicesEngineeringMechanical engineering

Owner:CHAN LI MACHINERY

Streamer guardrail

InactiveCN102767146AHighly consistentSmooth visual experienceTraffic signalsRoad signsEngineeringMotor Vehicle Operators

Owner:李琳

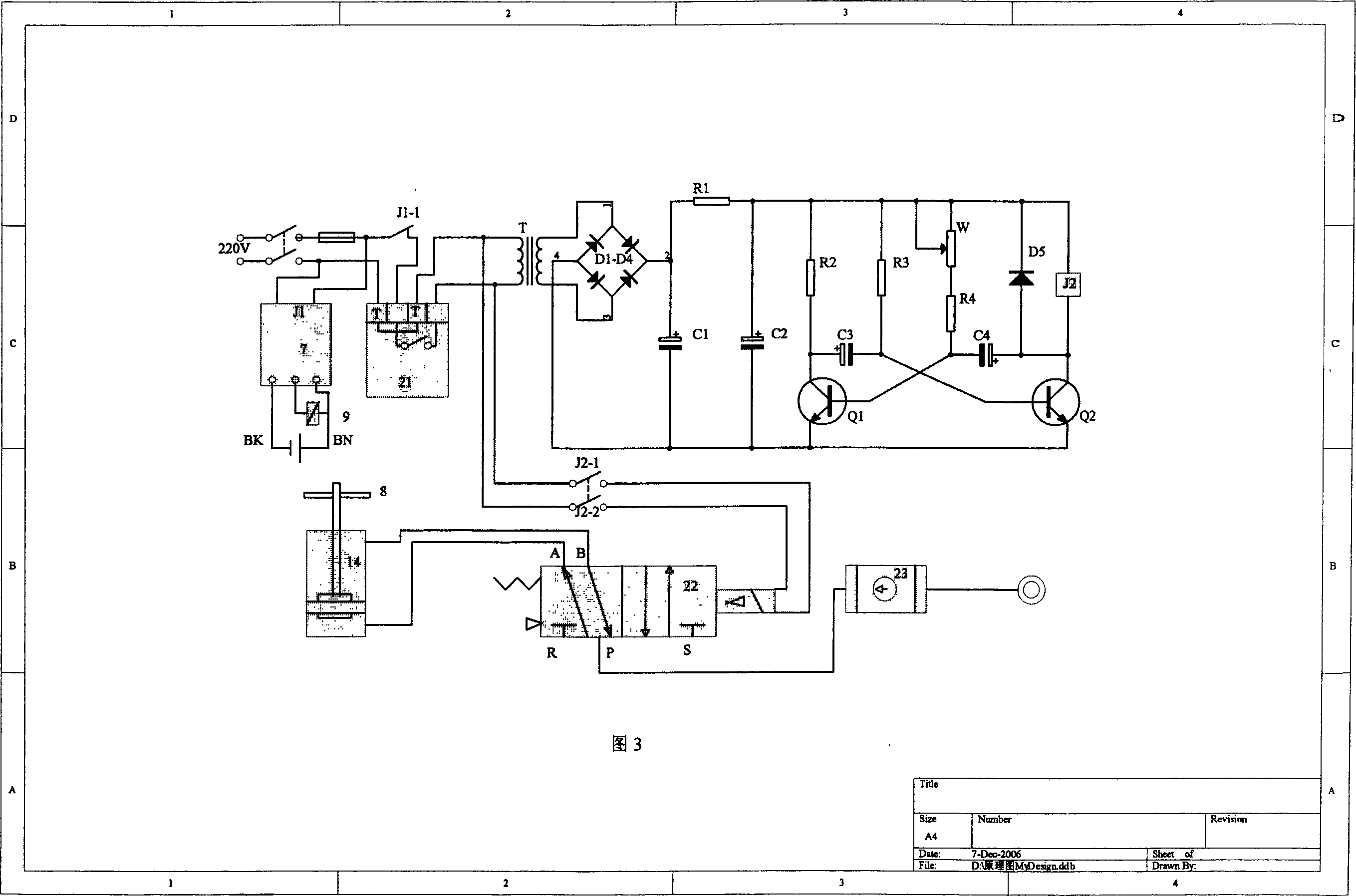

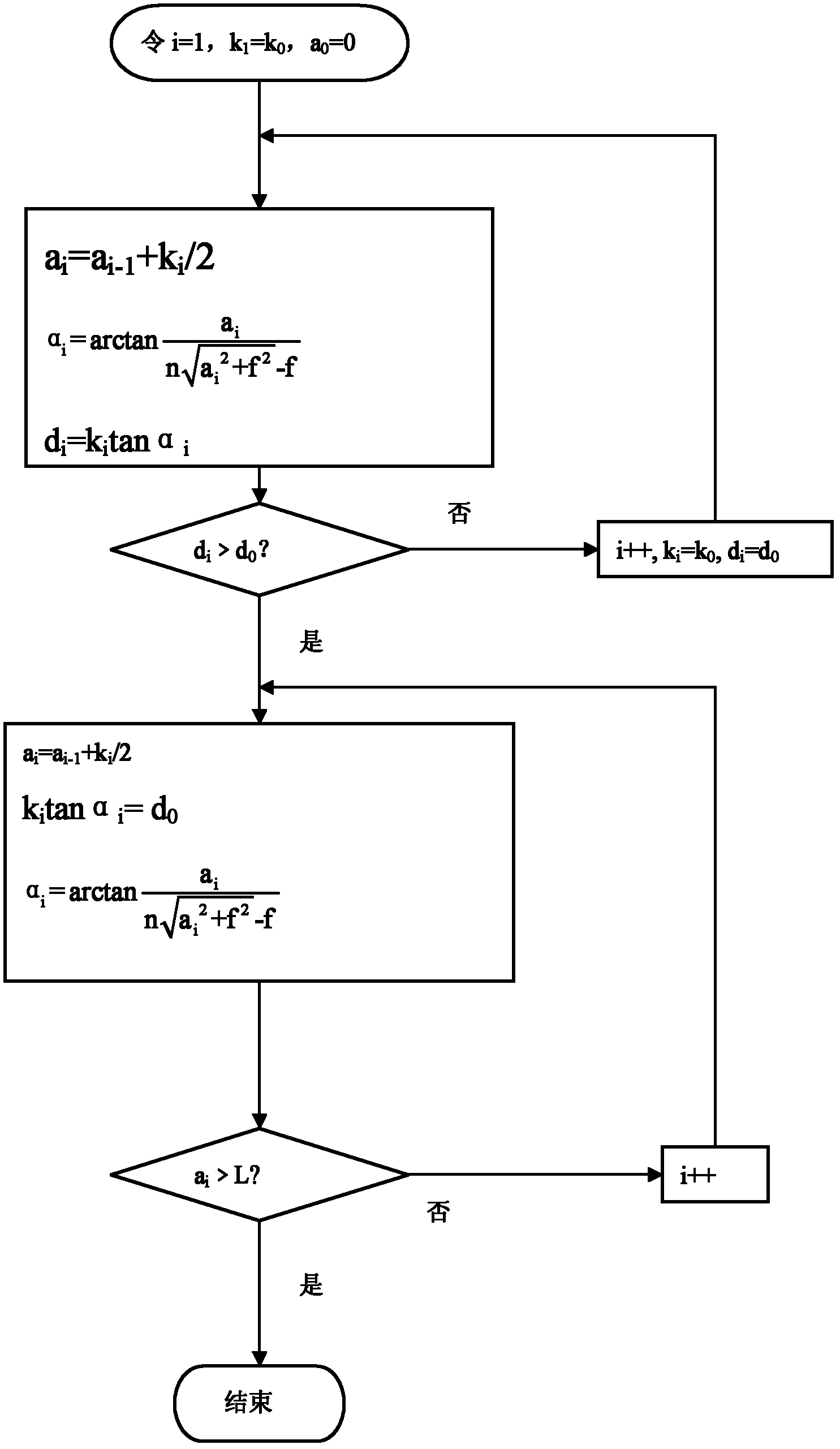

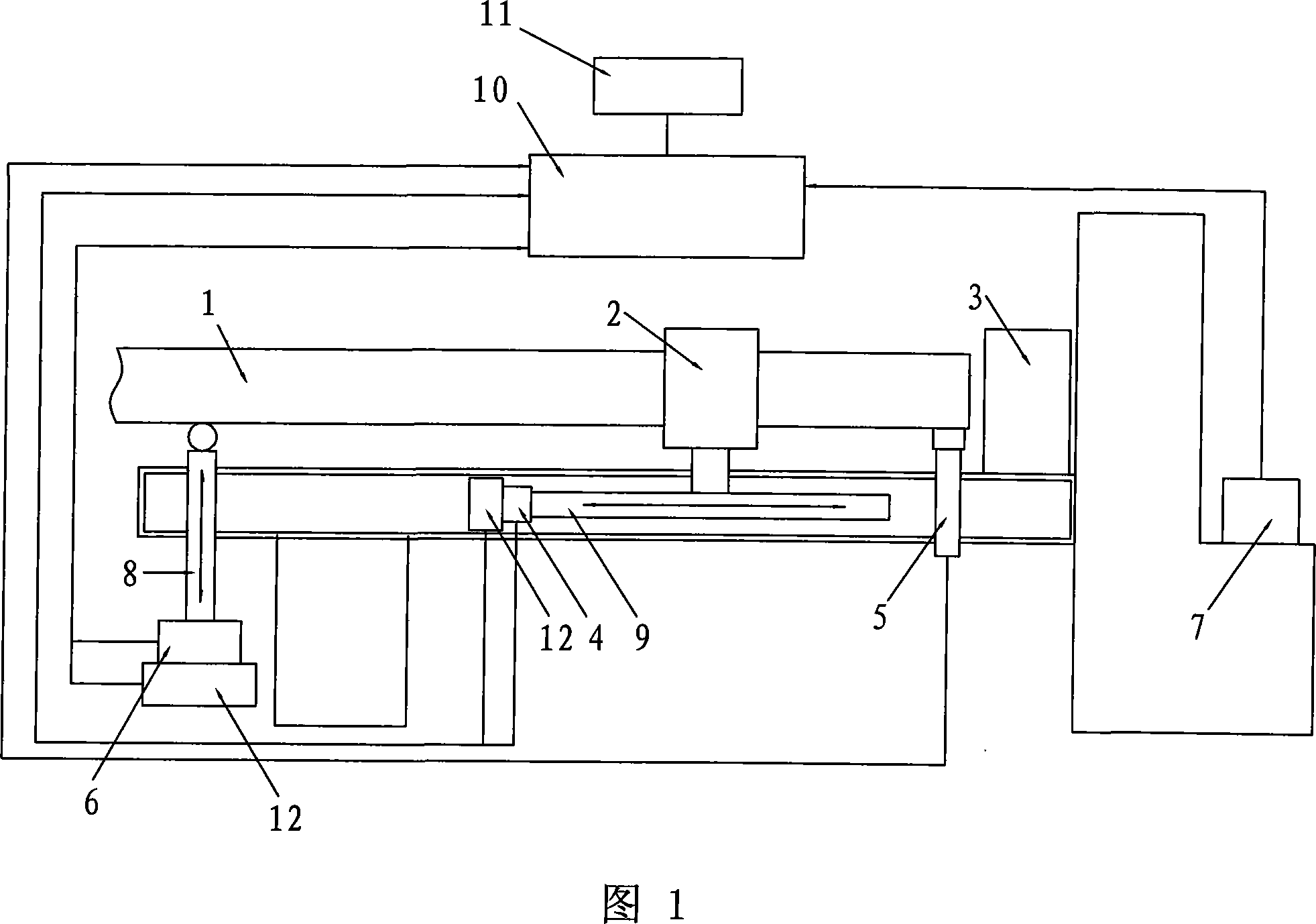

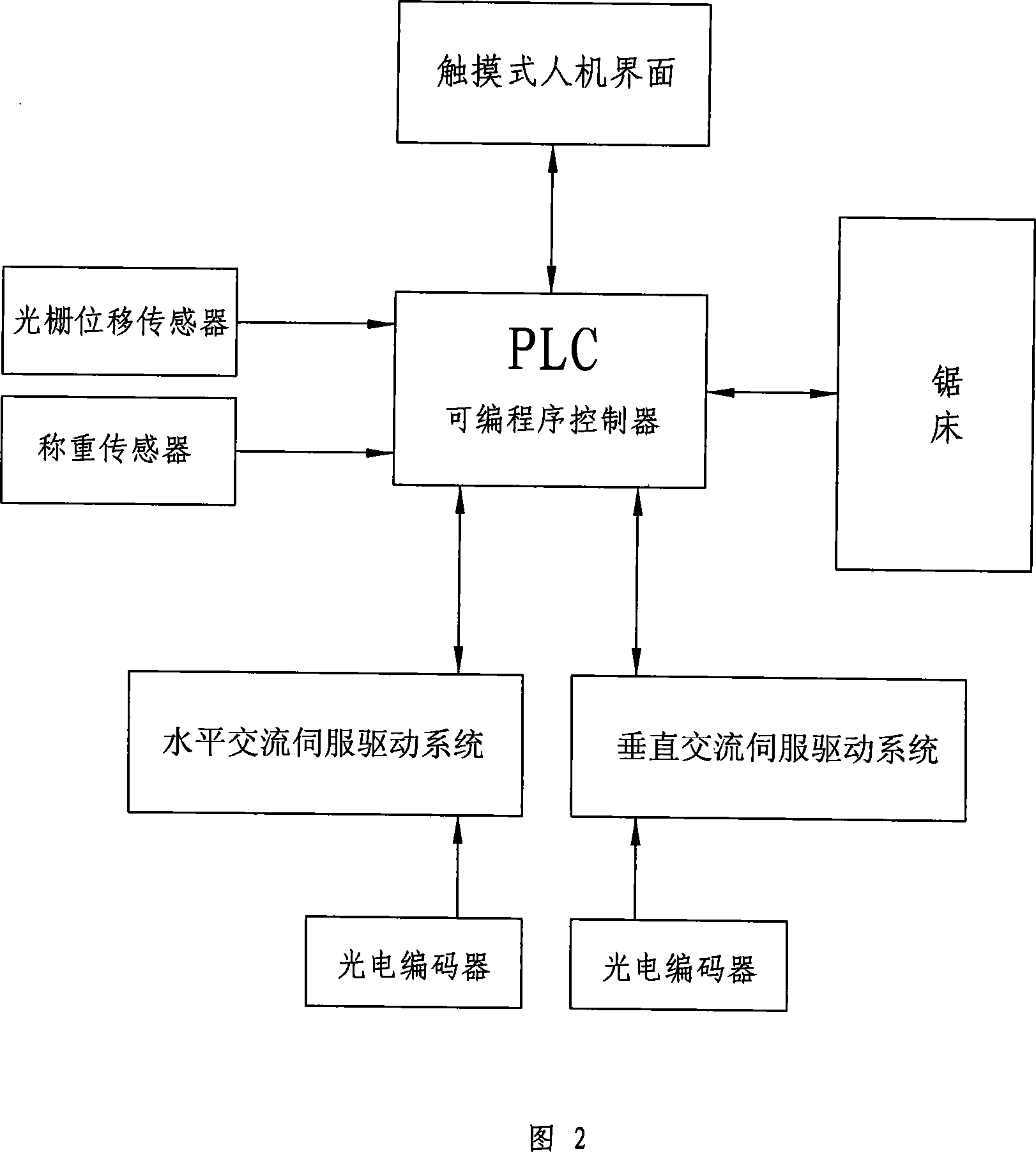

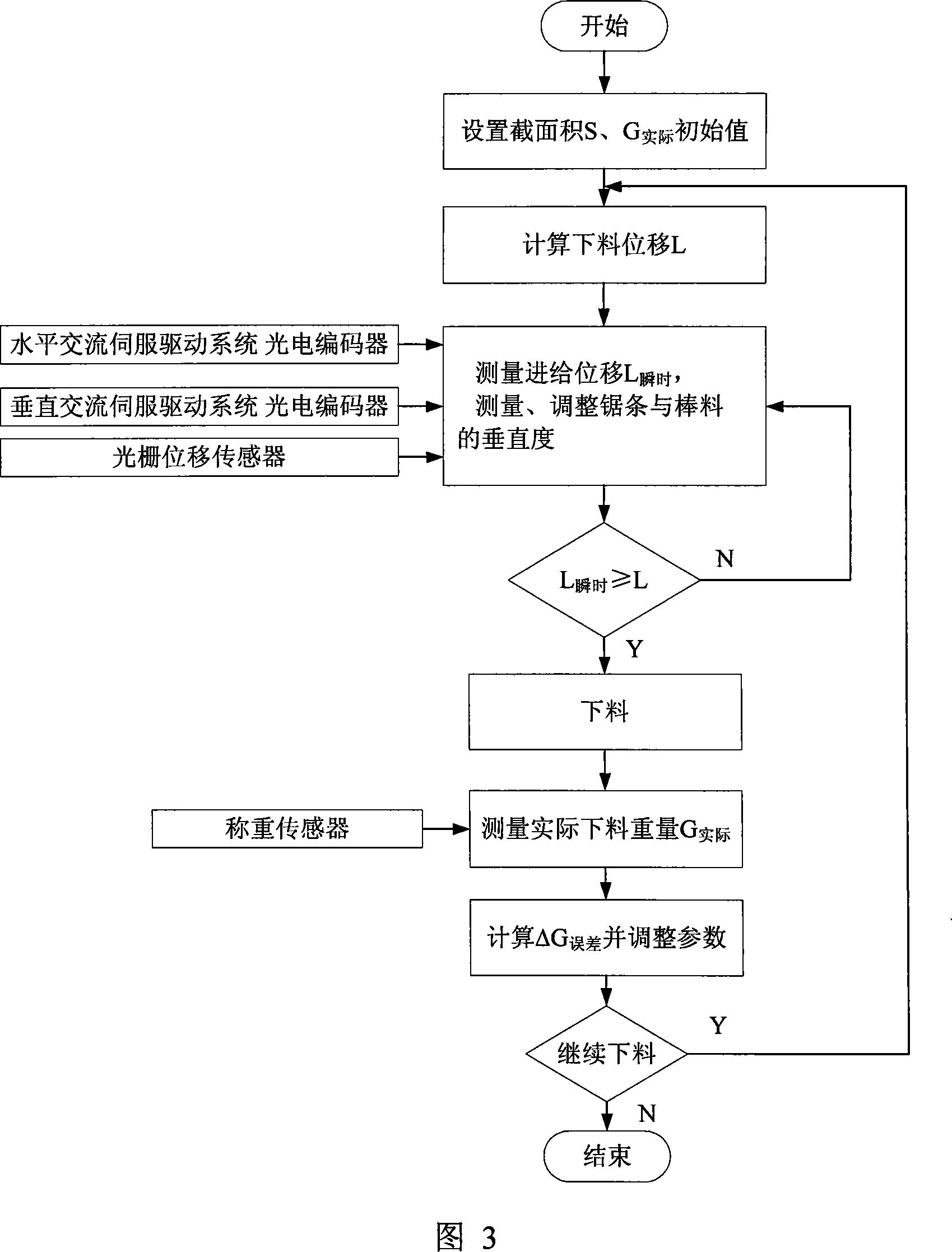

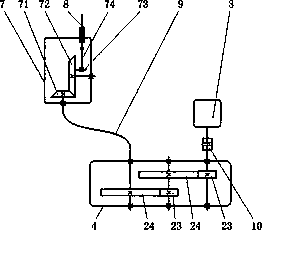

Control method for bar stock saw cutting self-adapting precision baiting

InactiveCN101135895AAccurately control the actual length accuracyRealize adaptive control of precision sawingProgramme control in sequence/logic controllersEngineeringSelf adaptive

The method comprises: using a bar stock saw automatically-adaptive lay- off system. The method comprises: a horizontal AC servo drive system is used for realizing the rod feed; a highly-accurate photoelectric encoder is used to detect the amount of fed rod; a grating shifting sensor is used to detect the height value of front end of the rod; a vertical AC servo drive system is used to adjust the height of the rear end of the rod to keep the consistency between the front end and the rear end of the rod; a highly-accurate weight sensor is used to weigh the actual weight G of the rod and to compare the actual weight of rod with the reset value, and according to the difference Delta G to adjust the cutting length.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

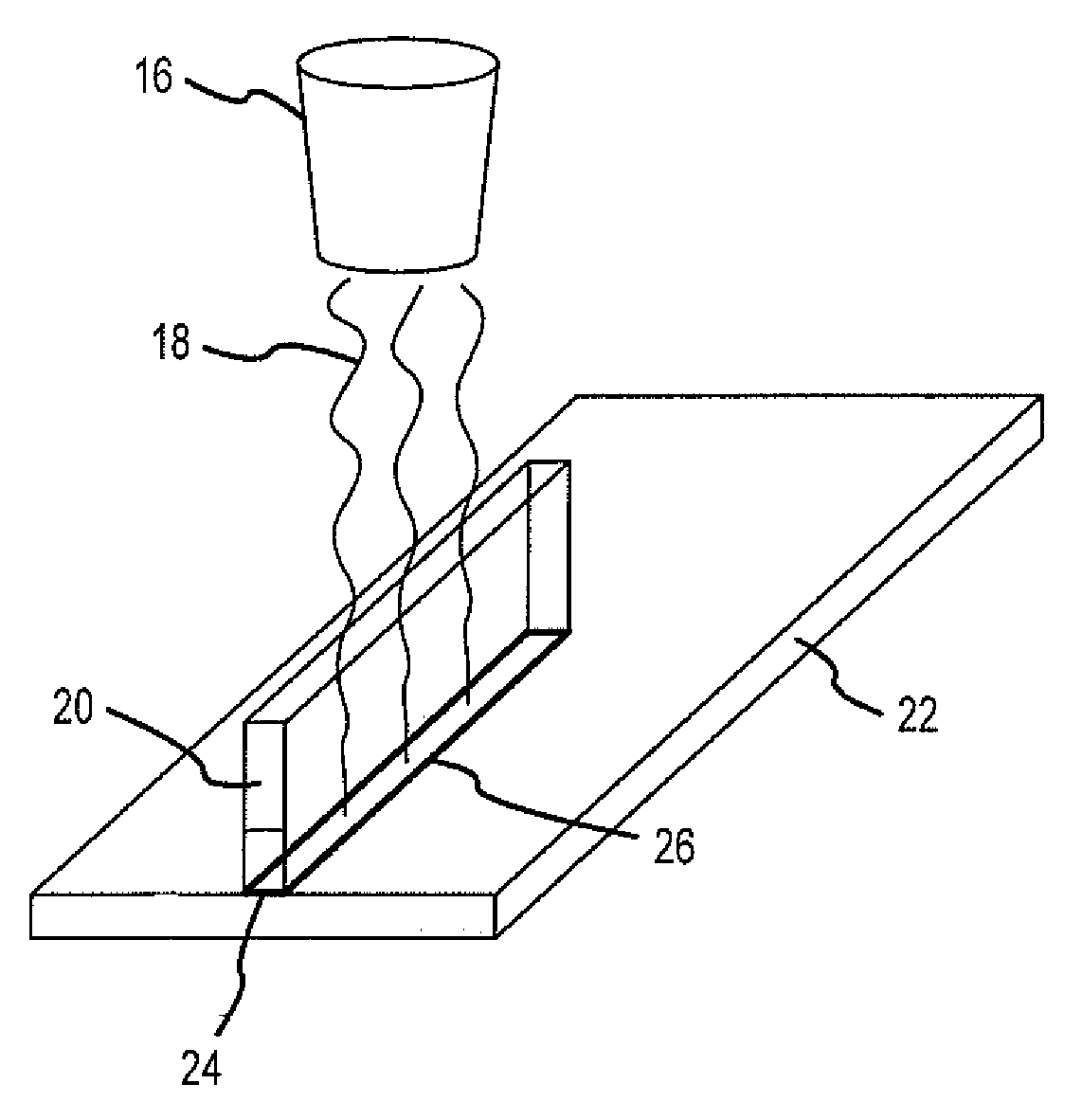

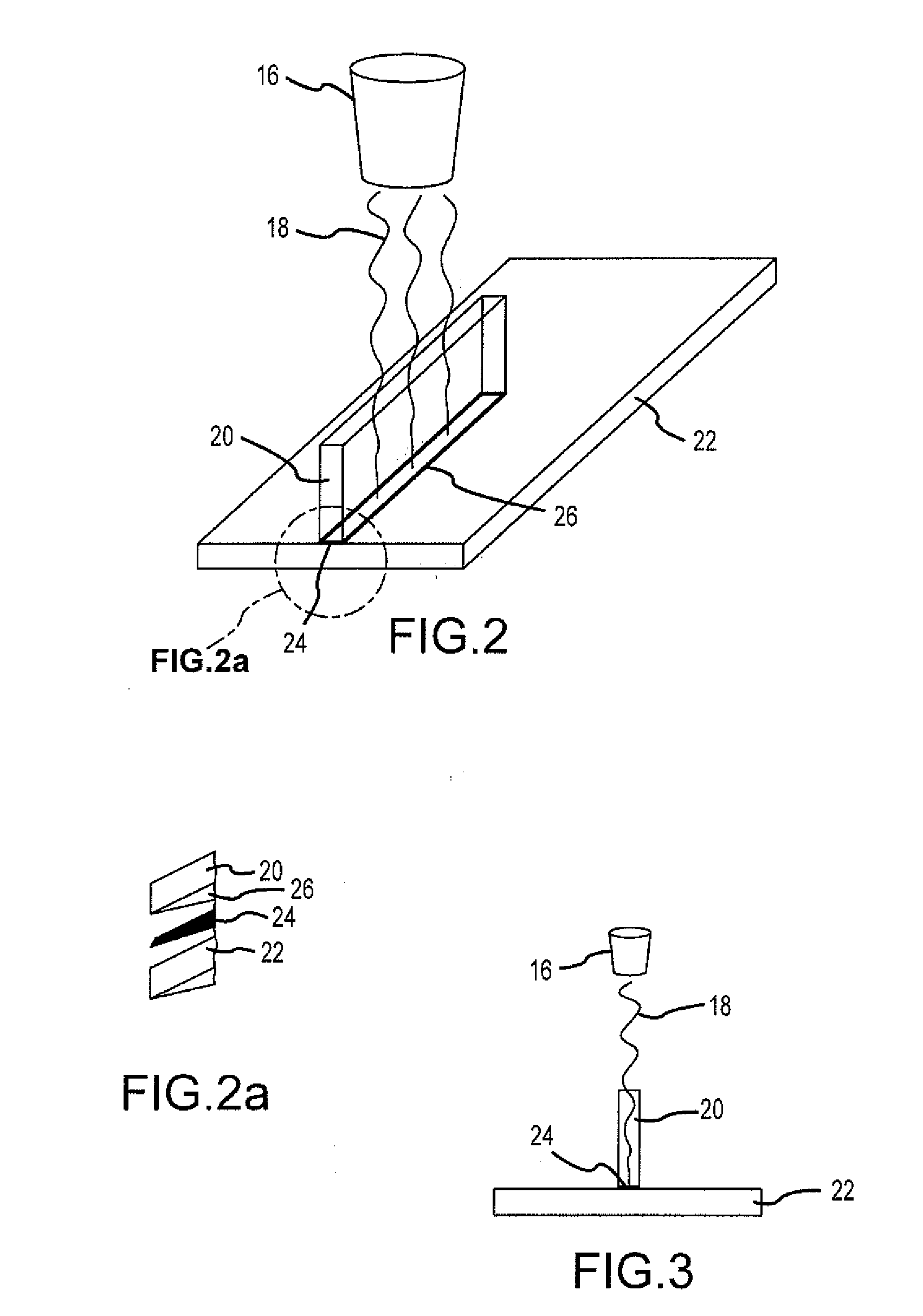

Method of making a transparency

InactiveUS20090258233A1Strong jointHighly repeatable and consistentLamination ancillary operationsLayered product treatmentThermoplasticNear infrared absorption

A method of making a transparency is provided, the method comprising the steps of: layering at least two pieces of transparent thermoplastic, wherein a portion of at least one of the pieces of transparent thermoplastic is treated with a near infrared absorbing material; and, fusing the layered pieces of transparent thermoplastic together using a heat source to form an optically transparent and undistorted transparency. There is also provided a transparency comprising at least two layers of transparent thermoplastic, wherein the layers of transparent thermoplastic have been fused together using a heat source, such that the transparency is optically transparent and undistorted.

Owner:THE BOEING CO

PCB plate mount-connect positioning device and method

ActiveCN106817844ASave development and production costsHigh speedPrinted circuit assemblingCircuit board tools positioningProduct typeEngineering

The invention provides a PCB plate mount-connect positioning device and method; the device comprises two leading screw mechanisms, wherein the first set refers to a transmission mechanism using a horizontal leading screw shaft as the main body, and the second set refers to two transmission mechanisms using a vertical leading screw shaft as the main body; the PCB plate mount-connect positioning device can horizontally and vertically fix a PCB plate, thus satisfying product laminate high consistency and reliable welding technical requests, and solving the problems that a conventional machine fitting is various in product types, thus causing large clamp tool processing load; aiming at a dual-layer PCB plate product of different sizes, only one machine fitting set is needed and developed; the device and method has no limits on product pin structures, are strong in versatility, convenient in adjustment, thus greatly saving clamp tool developing and making costs.

Owner:TIANSHUI 749 ELECTRONICS

Manufacturing method of copper-copper bonding salient points

ActiveCN103730382AHigh surface flatnessHighly consistentSolid-state devicesSemiconductor/solid-state device manufacturingElectricitySurface roughness

The invention provides a manufacturing method of copper-copper bonding salient points. The surface roughness of a copper cylinder is effectively reduced, the surface evenness of the micro salient points is improved, meanwhile, the consistency of the heights of the micro salient points in different areas of a wafer is guaranteed, and the requirements of a copper-copper bonding technology for the surface smoothness are met. The manufacturing method is characterized by including the following steps: (1) manufacturing an adhesion layer and a seed layer on the surface of the wafer, (2) depositing a copper layer on the surface of the wafer, (3) processing the copper layer on the surface of the wafer, and improving the surface roughness and the surface evenness of copper; (4) imaging the copper layer with a photolithography technique, (5) removing copper outside the positions of the micro salient points, and forming micro salient point structures on the wafer, (6) removing adhesion layer materials outside micro salient point areas of the surface of the wafer, and forming electrical isolation micro salient point structures, and (7) removing photoresist on the surface of the wafer, and obtaining the micro salient point structures with the even heights and the flat and smooth surfaces.

Owner:NAT CENT FOR ADVANCED PACKAGING

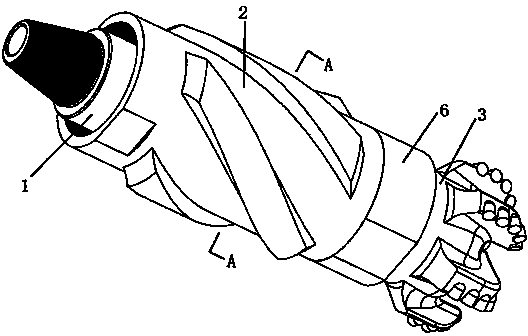

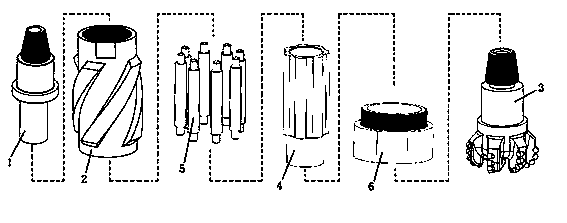

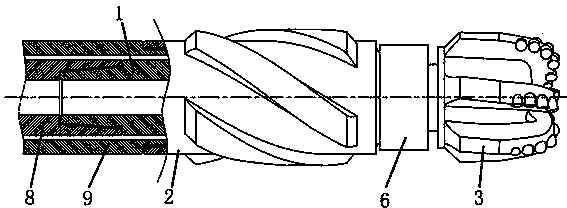

PDC drill tool with alternating cutting trajectory

ActiveCN104196456AHighly consistentEccentric rotation is normalDrill bitsConstructionsEngineeringHardness

The invention discloses a PDC drill tool with an alternating cutting trajectory, and belongs to the field of rock breaking tools for drilling equipment. The PDC drill tool with the alternating cutting trajectory comprises an eccentric shaft, an outer shell, a PDC drill and a cycloid shaft. The PDC drill is fixedly connected to the cycloid shaft, the cycloid shaft is matched inside the outer shell and can eccentrically rotate relative to the alternating trajectory, and an eccentric shaft section arranged on the eccentric shaft is matched in an inner cavity of the cycloid shaft to form a revolute pair. An inner flow channel of the eccentric shaft, an inner flow channel of the cycloid shaft and an inner flow channel of the PDC drill are communicated. By the adoption of the PDC drill tool, the alternating cutting trajectory movement can be made, the stratum eating-in capacity of the PDC drill can be improved remarkably, rock breaking efficiency is improved, the abrasion speed of cutting teeth can be better lowered, and in particular, the PDC drill tool has obvious technical advantages in a deep stratum which cannot be drilled easily and in a high hardness and high abrasiveness stratum.

Owner:四川宝石机械石油钻头有限责任公司

Tin-bismuth jet printing soldering paste modified by silver powder particles and preparation method thereof

ActiveCN107825001AImprove printing effectRigorous processWelding/cutting media/materialsSoldering mediaAdhesiveDiluent

The invention discloses tin-bismuth jet printing soldering paste modified by silver powder particles. The tin-bismuth jet printing soldering paste modified by the silver powder particles comprises, byweight, 50 wt%-80 wt% of SnBi soldering paste and 20 wt%-50 wt% of conductive silver adhesive. The conductive silver adhesive comprises, by mass, 65 %-67% of Ag and 33%-35% of assistant. The assistant comprises bisphenol-A epoxy resin, a curing agent, a coupling agent, a diluent, an accelerant and a defoaming agent. The invention further provides a preparation method of the tin-bismuth jet printing soldering paste modified by the silver powder particles. According to the preparation method, the SnBi soldering paste and the conductive silver adhesive are respectively prepared; the prepared soldering paste and the conductive silver adhesive are evenly mixed at a corresponding ratio, and the tin-bismuth jet printing soldering paste modified by the silver powder particles are obtained. By theadoption of the technical scheme, the modified soldering paste mixed with the silver particles has good jet printing performance, the prepared jet printing soldering paste modified by the silver powder particles is free of lead and halogen, when used, the prepared jet printing soldering paste modified by the silver powder particles is environmentally friendly, harmless and good in wetting performance; and during jet printing, the spot diameters are uniform, the heights are identical, welding spots are smooth and full, and the mechanical performance is excellent.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST +1

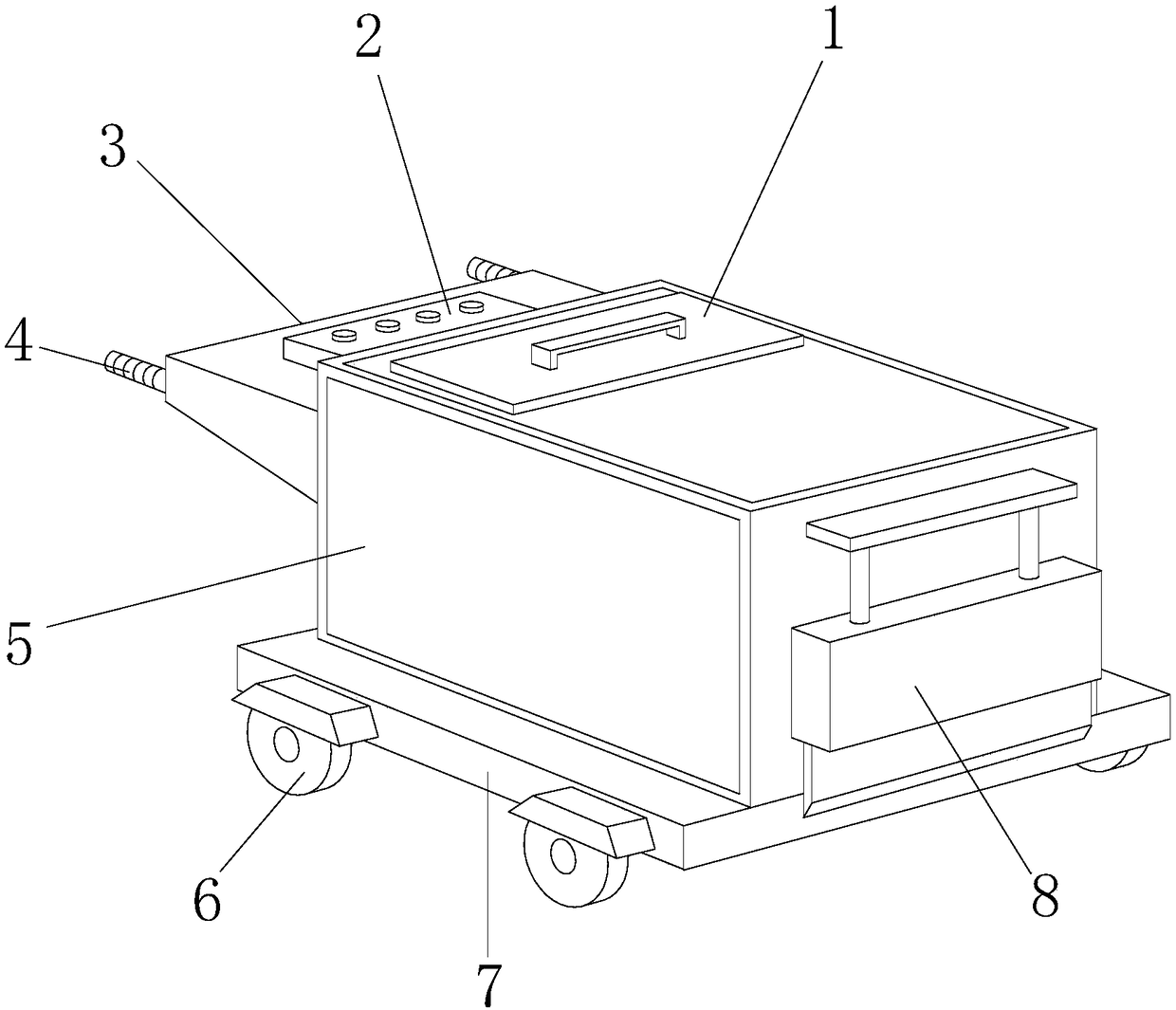

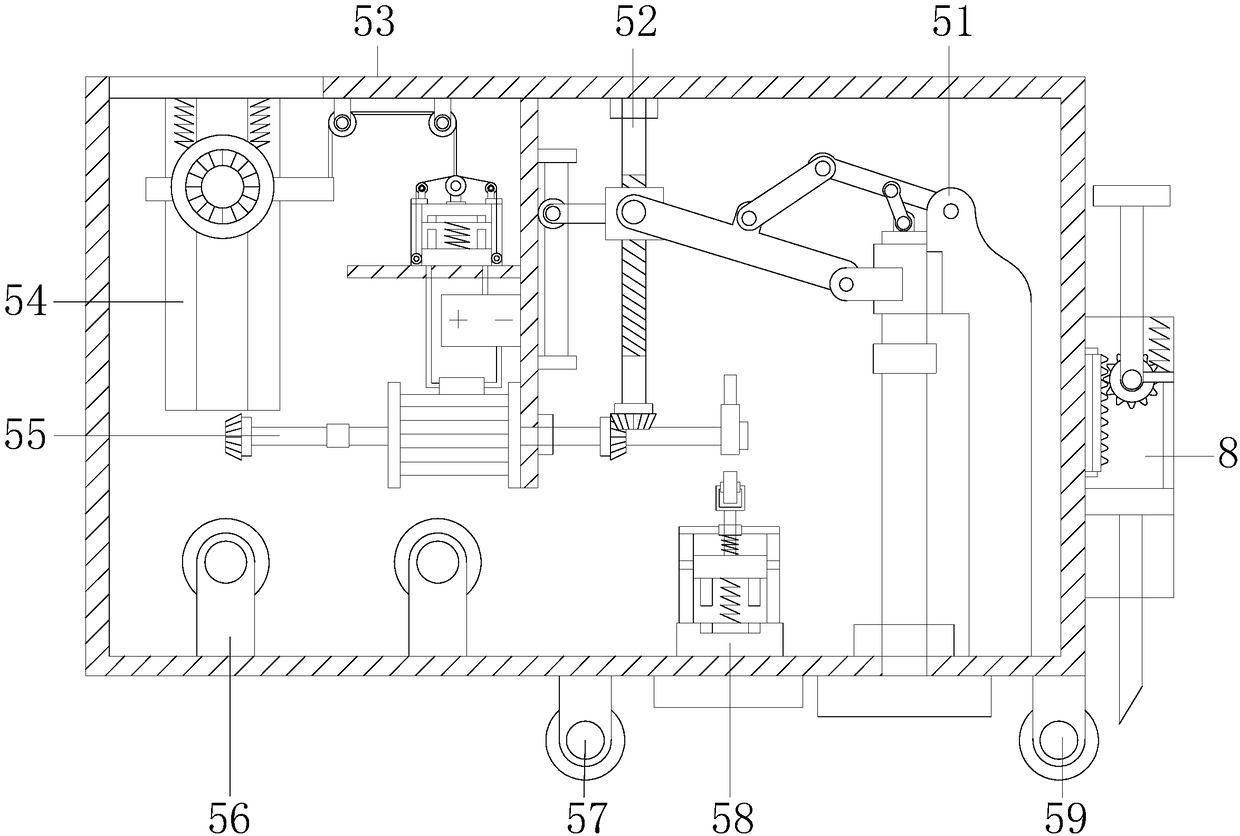

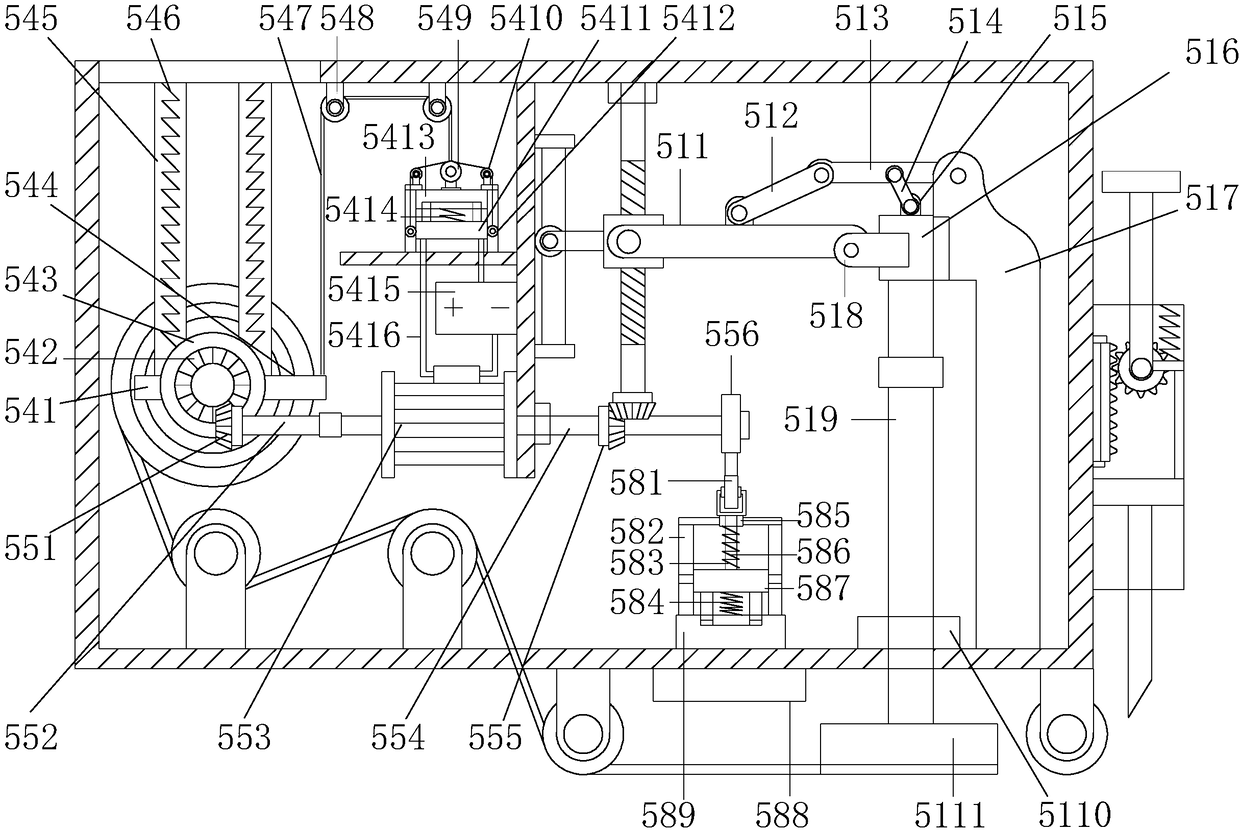

Petroleum asphalt coiled material laying equipment

The invention discloses petroleum asphalt coiled material laying equipment. The structure of the petroleum asphalt coiled material laying equipment comprises a material placing box cover, a controller, a workbench, hand pushing rods, a coiled material petroleum asphalt laying device, directional casters, a dustproof cover and a cutting device; a petroleum asphalt coiled material is placed on a coiled material assembling mechanism; when the coiled material slides off to the bottom of a supporting carriage, a static contact and a movable contact are closed to form a loop so that a motor is electrified to work; and a second bevel gear arranged at the left end of the motor is engaged with a No. 2 gear; therefore, the coiled material can be gradually unwound and the coiled material is laid on the ground by using a first flattening roller; the petroleum asphalt laid on the ground is softened by using a petroleum asphalt coiled material softening mechanism; the softened petroleum asphalt is pressed on the ground by using a flattening mechanism so that the bonding degree of the petroleum asphalt and the ground is enhanced; and then the petroleum asphalt laid on the ground is rolled by using a second flattening roller so that the laying height of the petroleum asphalt is consistent and a flat effect is achieved.

Owner:平邑经济开发区投资发展有限公司

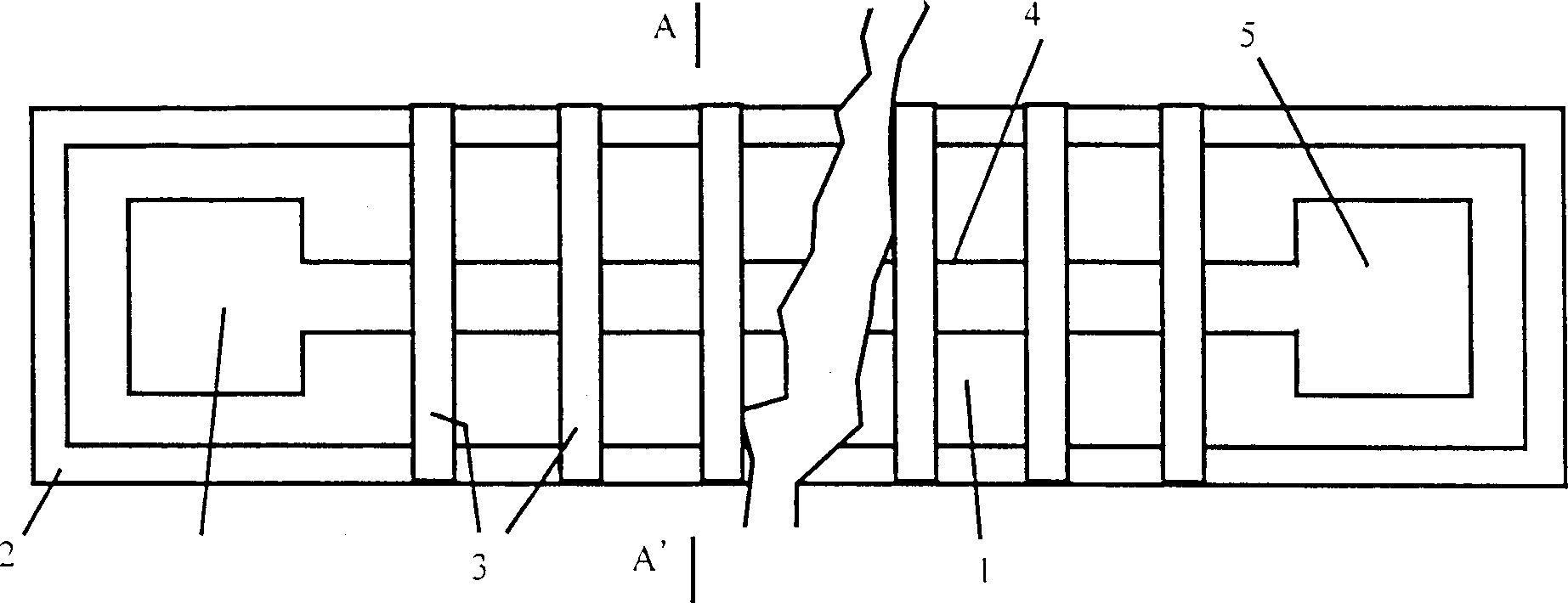

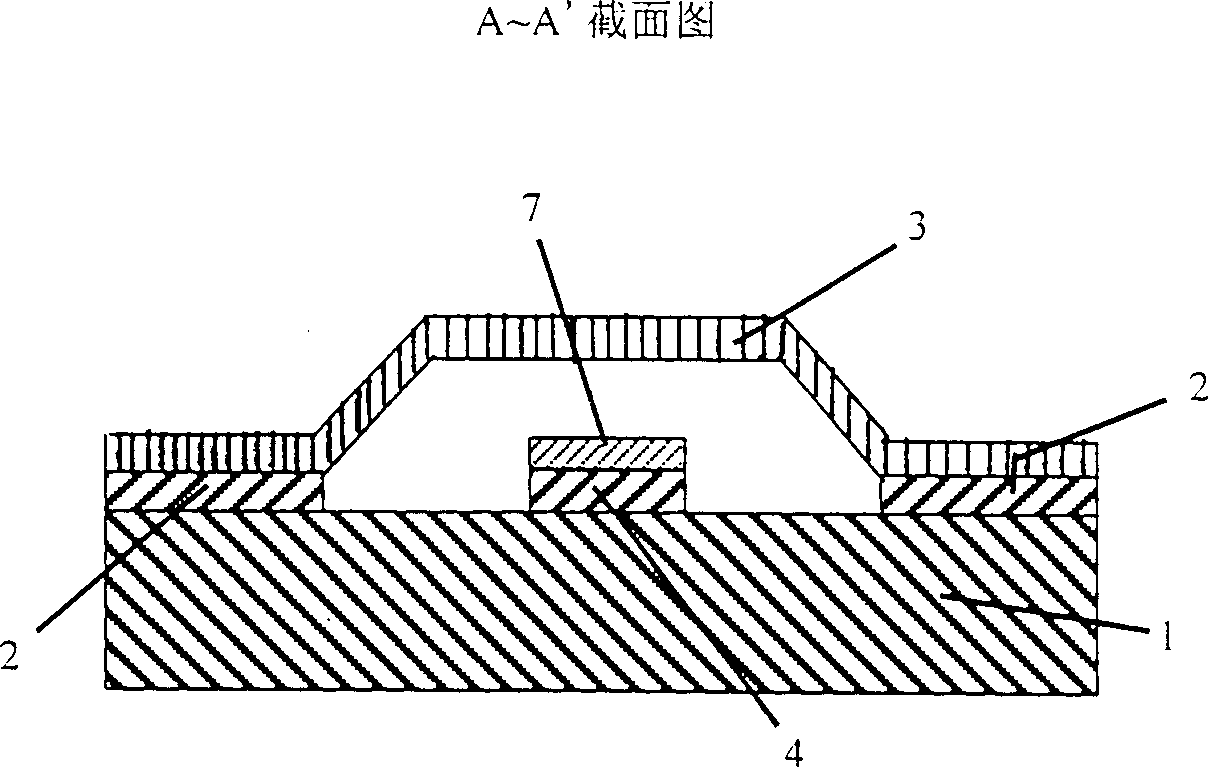

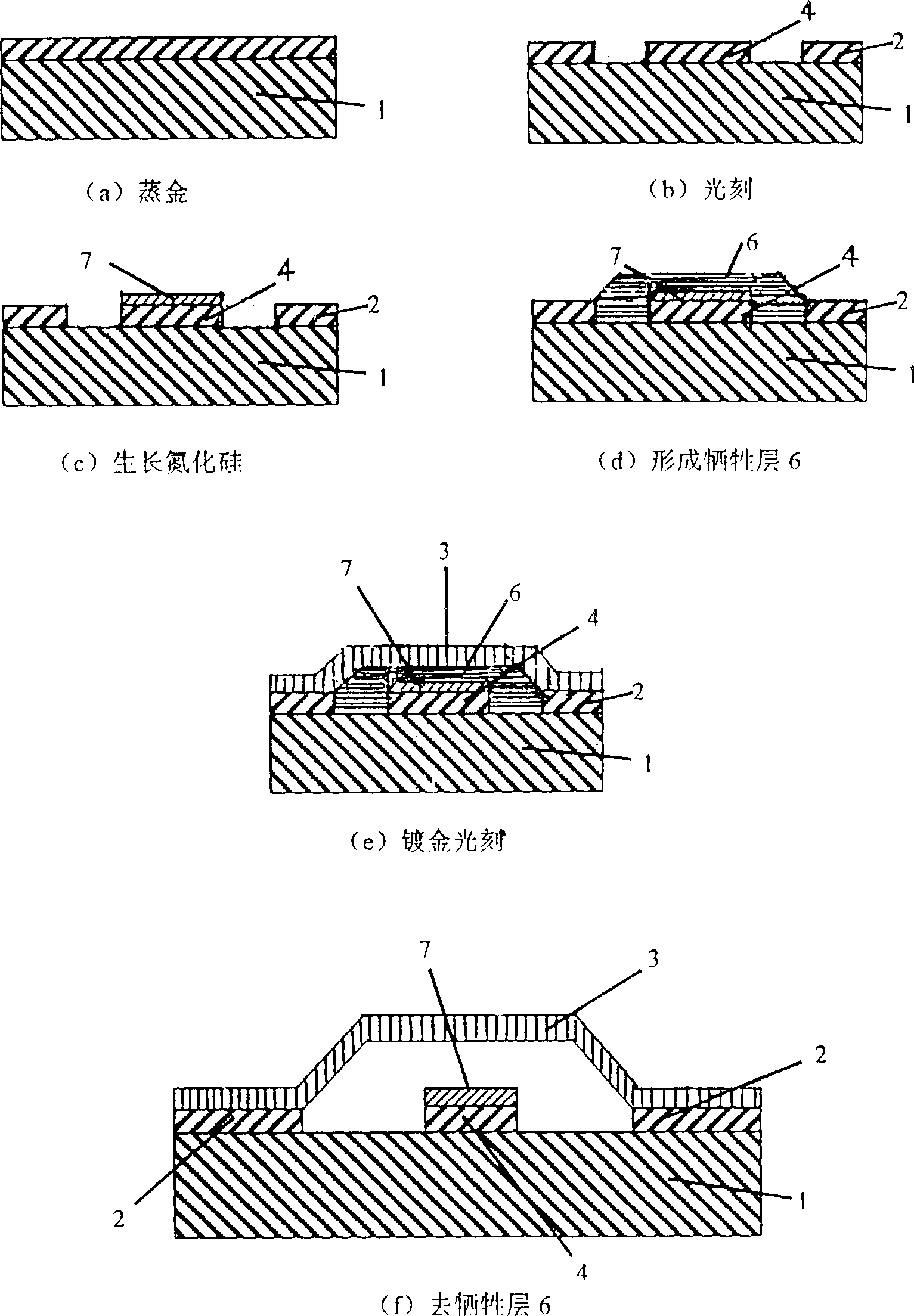

Production method of millimetric wave voltage-controlled phase shifter for microelectronic machine

InactiveCN1380245AHighly consistentSame widthDecorative surface effectsPhotomechanical apparatusPhotoresistWork in process

The production method of millimetric wave voltage-controlled phase shifter belongs to the field of microelectronic solid device production technology, and is characterized by that it uses the semifinished product of said invented product, i.e. processed substrate whose surface has etched strip pattern containing grounding conductor strip, signal wire and connecting terminal and on the signal wirethe silicon nitride layer is grown as raw material, adopts prepared thermoprene negative photoresist as sacrificial layer and photoresist coating technology to make 20-30-odd metal microbridges whichare arranged regularly and whose height is uniform and width is identical on the semi-finished product. It possesses excellent electric performance, can be used as millimetric wave voltage-controlledphase shifter.

Owner:EAST CHINA NORMAL UNIVERSITY

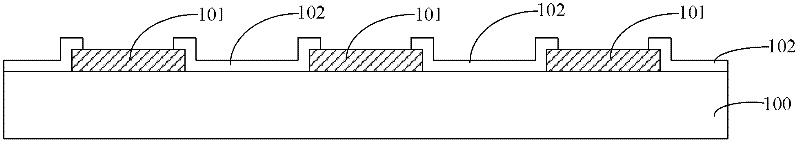

Wafer level packaging structure and packaging method

InactiveCN102270590AHighly consistentImprove thickness uniformitySemiconductor/solid-state device detailsSolid-state devicesWafer-level packagingEngineering

A wafer-level packaging structure and packaging method, wherein the wafer-level packaging method includes: providing a wafer to be packaged, a plurality of discrete pads are formed on the surface of the wafer; forming conductive contour columns on the surface of the pads ; Form bumps on the surface of the contour column. The wafer-level packaging method provided by the invention has a simple process, and the wafer-level packaging structure provided by the invention has high packaging quality.

Owner:CHINA WAFER LEVEL CSP

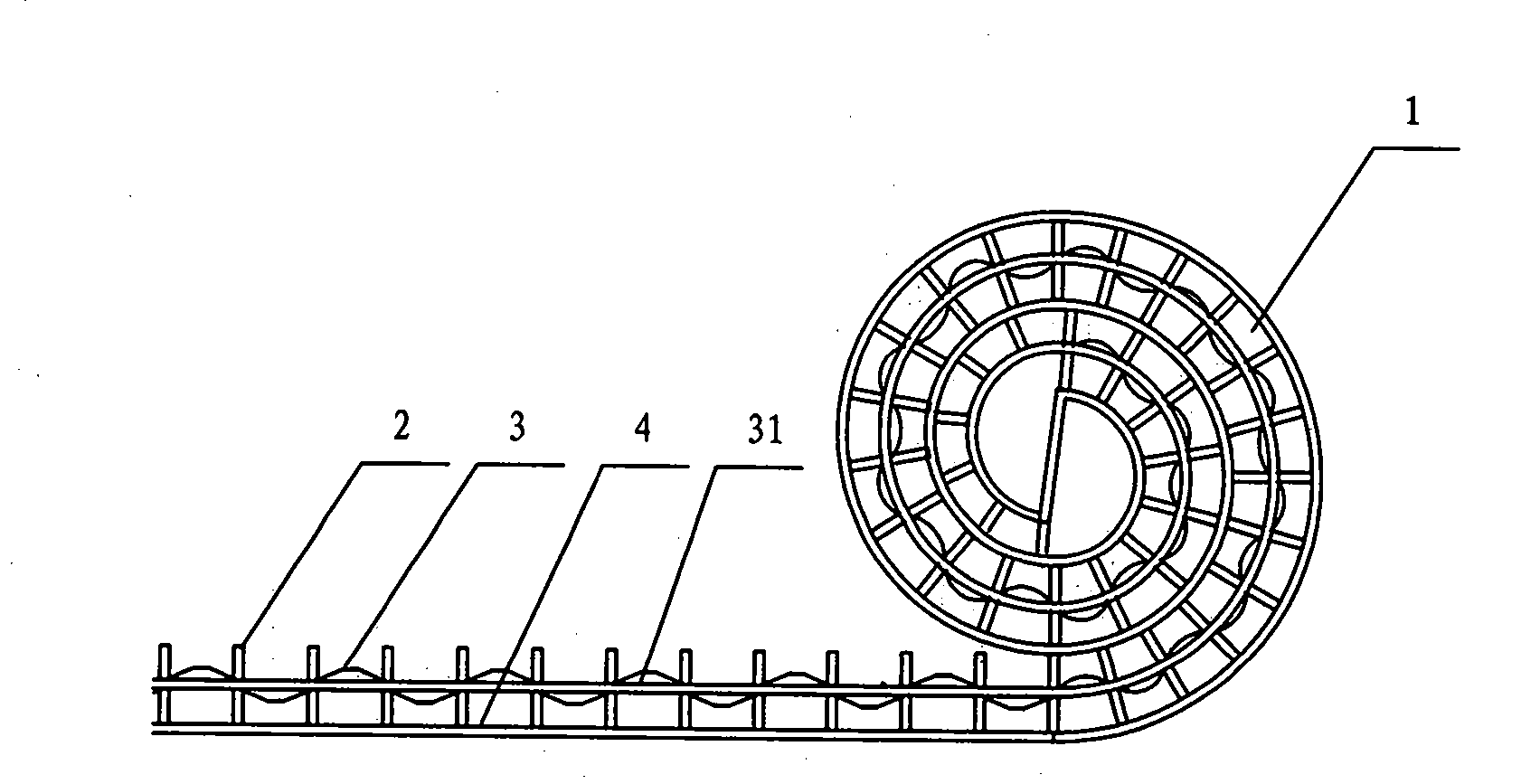

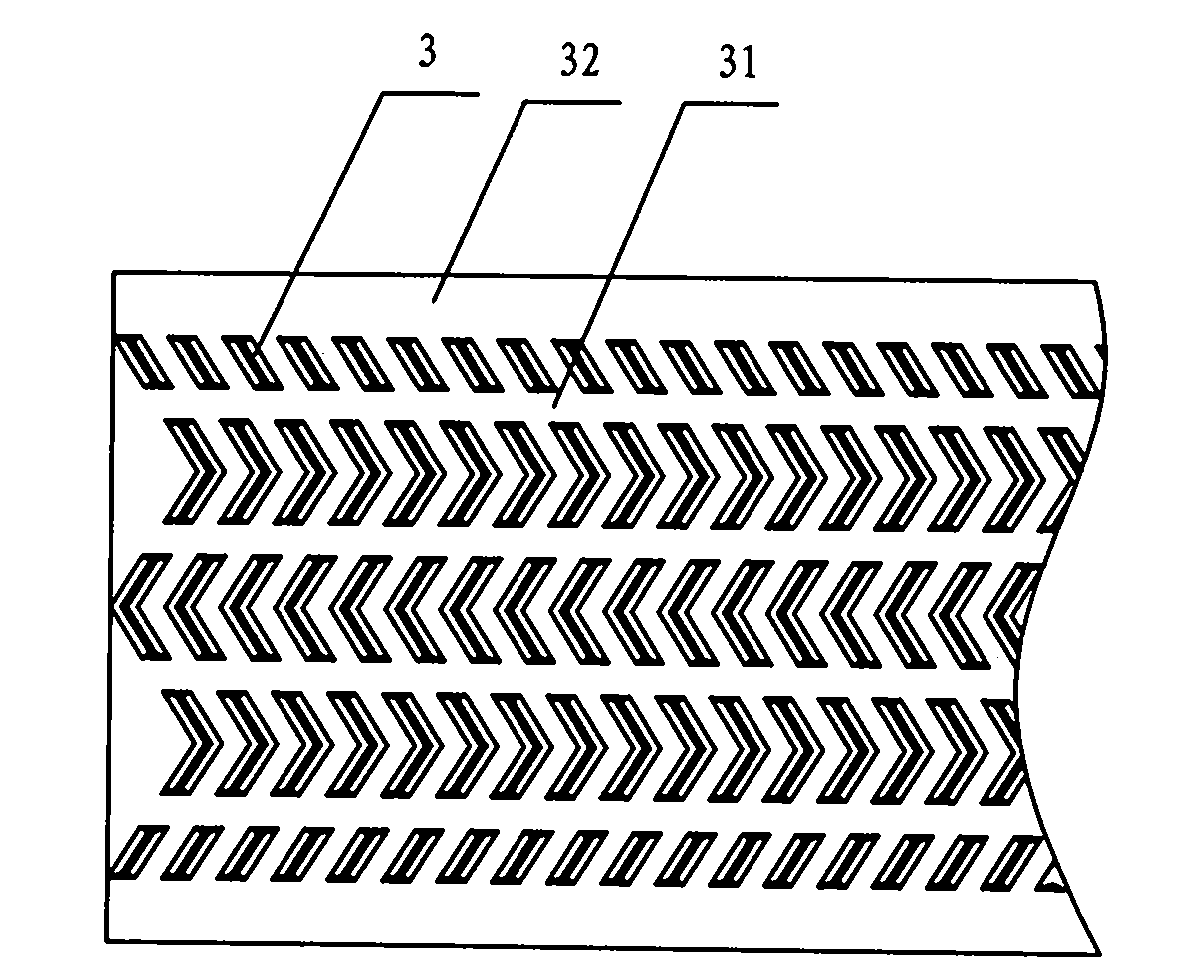

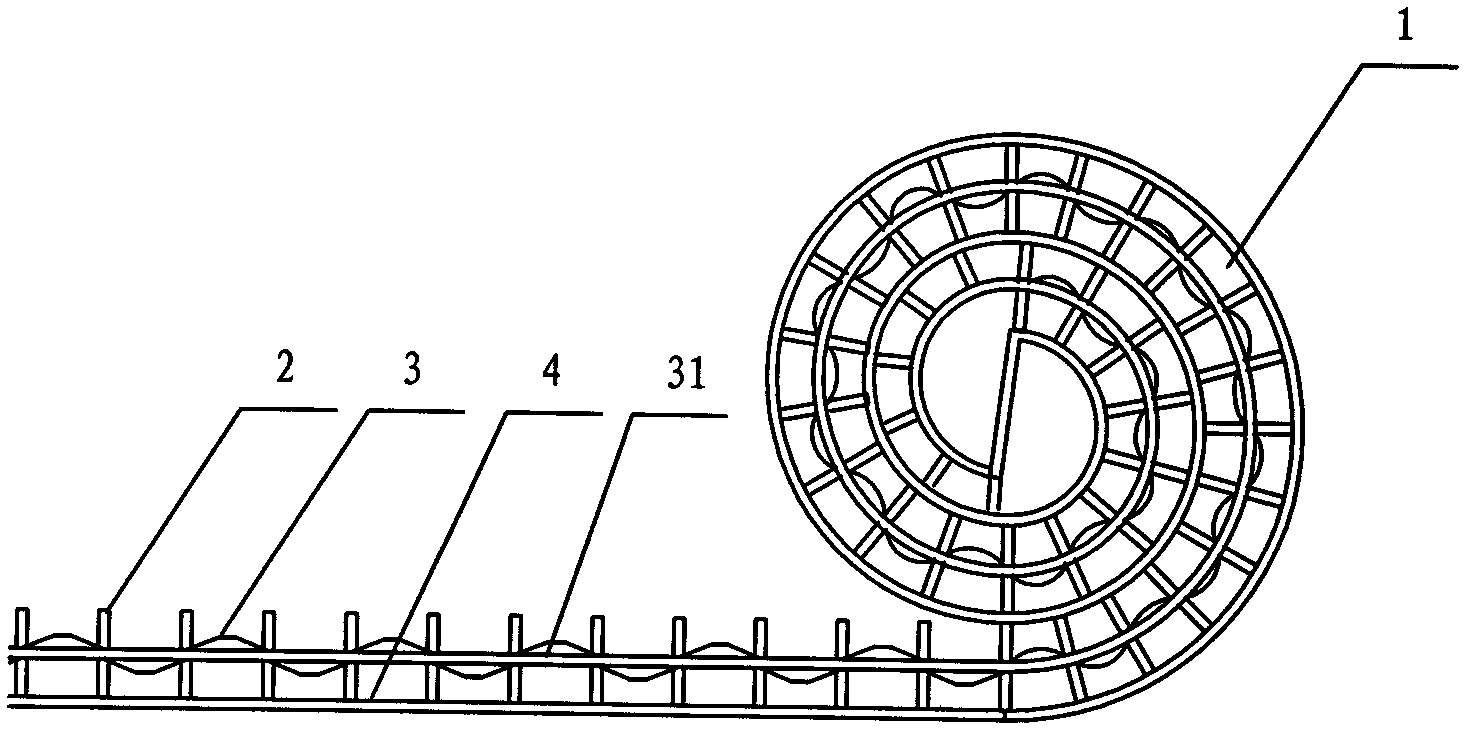

Corrugated spiral plate heat exchanger

InactiveCN102213560AIncrease heat transfer areaImprove heat transfer efficiencyLaminated elementsStationary plate conduit assembliesSteel platesSheet steel

The invention discloses a corrugated spiral plate heat exchanger which comprises a dual-spiral heat exchanger in a shell, wherein the dual-spiral heat exchanger is formed by rolling a flat steel plate and a corrugated steel plate; the corrugated steel plate is provided with a non-corrugated spacing column welding zone; spacing columns are welded on the positive surface and negative surface of the spacing column welding zone; and the spacing column welding zone is a non-corrugated ribbon along the length direction of the corrugated steel plate. The heat exchanger has the advantages of simple structure, large heat exchange area and high heat exchange efficiency.

Owner:LIAONING DENIXI ENERGY SAVING EQUIP

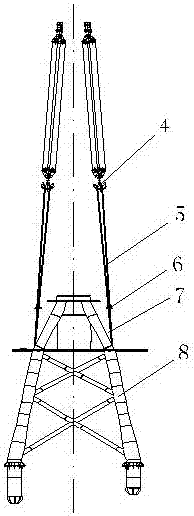

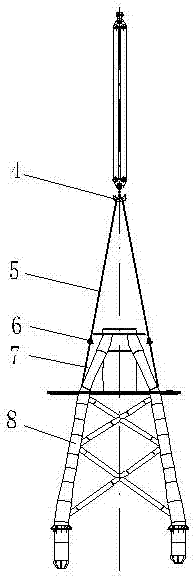

Jacket lifting and binding process

ActiveCN107089584AGuaranteed stabilitySimple materialLoad-engaging elementsMarine engineeringMechanical equipment

The invention relates to a jacket lifting and binding process. The jacket lifting and binding process comprises the following steps in sequence: a crane ship is positioned in the field; a barge leans against a wharf on the left side of the crane ship; mechanical equipment of each part is checked to determine good conditions; two main hooks are loosened, and steel wire ropes are respectively hung to corresponding lifting hooks; O-shaped lifting belts are manually mounted; constructors connect the steel wire ropes on the main lifting hooks with shackles for the lifting belts in sequence; hook hanging persons use iron rods for knocking on conduction parts of the lifting belts, so that the lifting belts are firmly bound with steel pipes at lifting point parts; after the hanging persons check each lifting point normally, the main hooks are continuously lifted up to reach a preset height; an anchor system of the crane ship is twisted to shift the ship; and a jacket is shifted above the barge, and is loosened to fall on the barge. The jacket lifting and binding process has the following advantages: lifting equipment adopts a floating crane; connecting devices adopt the O-shaped lifting belts, the steel wire ropes and the shackles; the materials are simple; the lifting is stable; and the jacket is vertically lifted, and is vertically mounted on the barge without needing such operations as turning, so that the operation is simple and easy.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

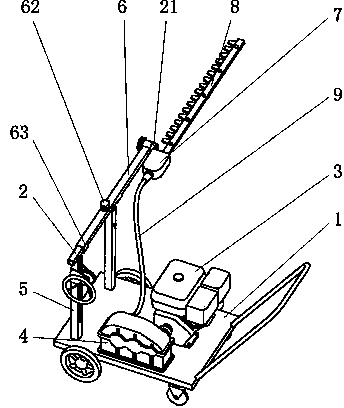

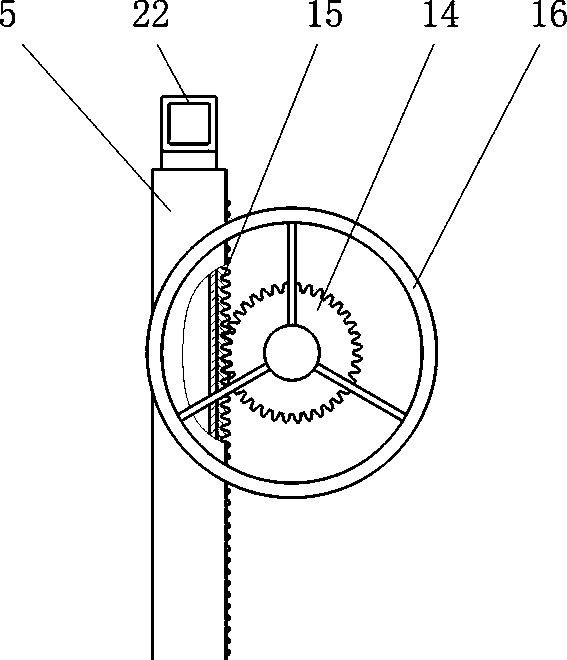

Hand-push type hedge shearing machine

The invention discloses a hand-push type hedge shearing machine which comprises a cart, a liftable bearing frame, a gasoline engine, a reduction gearbox and fixed bearing frames. The liftable bearing frame comprises two vertical steel pipes and a cross beam connected to the tops of the vertical steel pipes, the vertical steel pipes are respectively inserted in two steel pipes of the fixed bearing frames, one end of the cross beam is connected with an angle adjusting device through an overhanging beam and connected with a power switching box through the angle adjusting device, a hedge cutter is assembled on one side of the power switching box, the other side of the power switching box is communicated with the reduction gearbox through a flexible wire shaft, and the reduction gearbox is connected to a gasoline engine; in addition, a height adjusting mechanism is mounted on one fixed bearing frame spaced away from the overhanging beam. The hand-push type hedge shearing machine is simple and compact in structure, flexible and convenient to adjust and labor saving and quick in operation; hedges are good in smoothness after shearing and clearly contoured.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

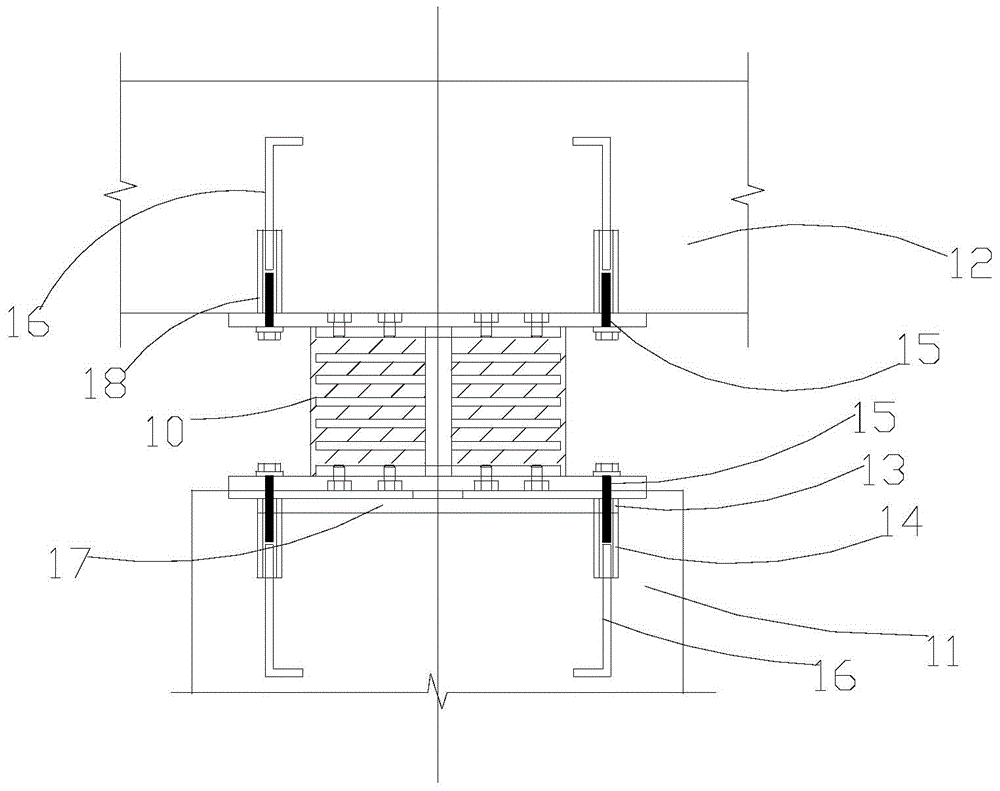

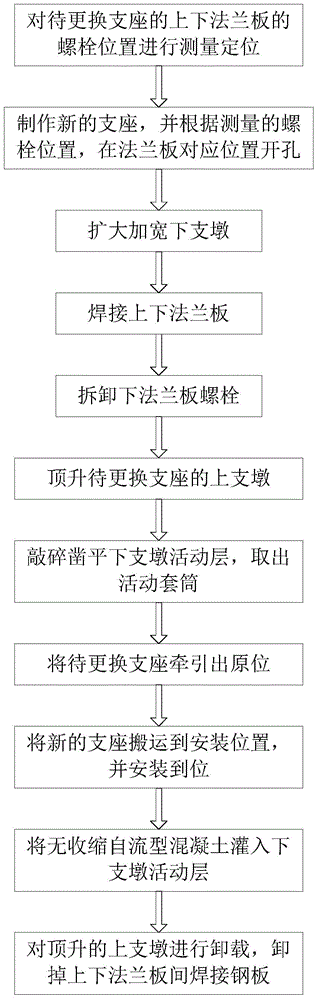

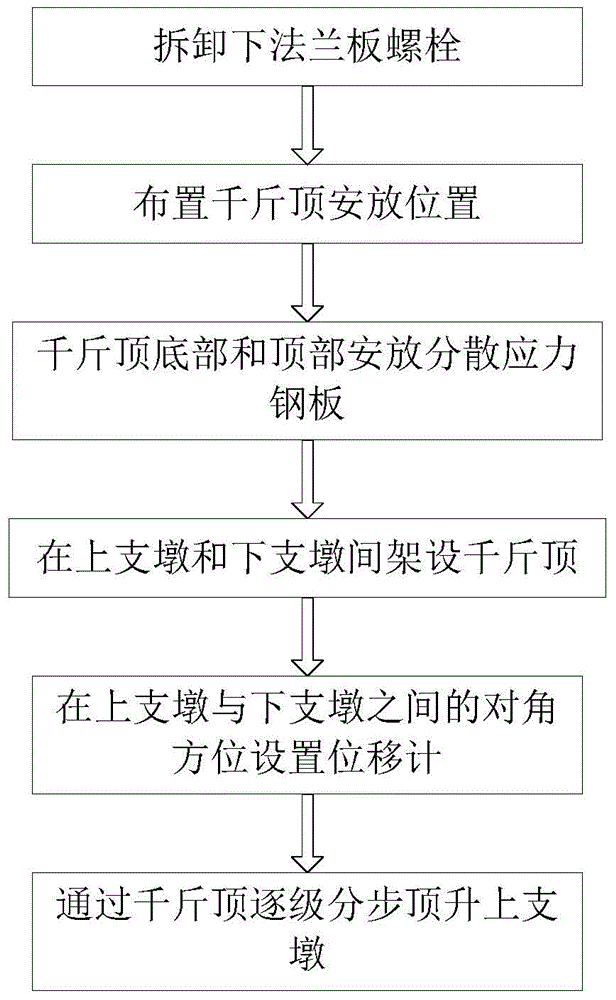

Method for replacing rubber isolation bearing

The invention relates to a method for replacing a rubber isolation bearing. The method comprises the following steps of (1) enlarging a lower buttress; (2) measuring and positioning bolts of upper and lower flange plates of a rubber isolation bearing to be replaced; (3) manufacturing a new isolation bearing, and forming holes in corresponding positions of flange plates of the new isolation bearing according to the measured bolt positions; (4) welding the upper and lower flange plates of the bearing to be replaced; (5) taking out lower flange plate bolts of the isolation bearing to be replaced; (6) jacking an upper buttress of the isolation bearing to be replaced; (7) taking an embedded plate, knocking off a lower buttress movable layer and taking out a movable sleeve out; (8) dragging the isolation bearing to be replace out of the normal position; (9) prestressing the new isolation bearing, and welding the upper and lower flange plates; (10) carrying the new bearing to the installation position, and fixedly installing the new bearing; (11) pouring non-shrinkage automatic flow concrete into the lower buttress movable layer; (12) unloading the jacked upper buttress. According to the method, aims of safety, high efficiency, no damage to an upper structural layer and reduction of replacement cost can be fulfilled.

Owner:YUNNAN QUAKESAFE SEISMIC ISOLATION TECH

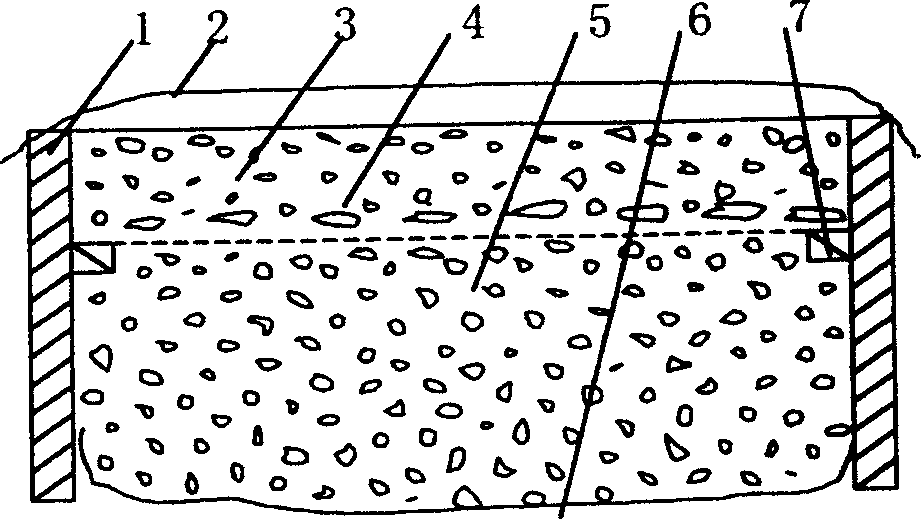

Thermal insulation filler and thermal insulation building block as well as manufacturing method of thermal insulation building block

InactiveCN101805202AShort maintenance timeIncrease productivityConstruction materialCeramicwareSodium bicarbonateThermal insulation

The invention discloses a thermal insulation filler, a thermal insulation building block as well as a manufacturing method of the thermal insulation building block. The thermal insulation filler is prepared by mixing the following components in percentage by weight: 30-38 percent of fly ash, 52-58 percent of early-strength double-fast cement, 1.8-2.1 percent of foaming agent, 1.7-2.2 percent of foam stabilizer and 6.2-8 percent of water repellent; wherein the foaming agent is one or more of lauryl sodium sulfate, sodium bicarbonate or dichlorotetrafluoroethane; the foam stabilizer is one or more of rigid polyurethane foams, polyacrylamide or sodium dodecyl benzene sulfonate; and the water repellent is one or more of methyl polyhydrosiloxane, paraffin or magnesium stearate. The thermal insulation filler has filling density lower than 200kg / m<3>, heat conductivity coefficient lower than 0.06w / m.k and combustion performance reaching grade A in a filling carrier. The thermal insulation fillers can be fully bonded with the inner wall of a filler carrier after being subjected to foaming and has difficult shedding.

Owner:CHONGQING KAIKANG TECH

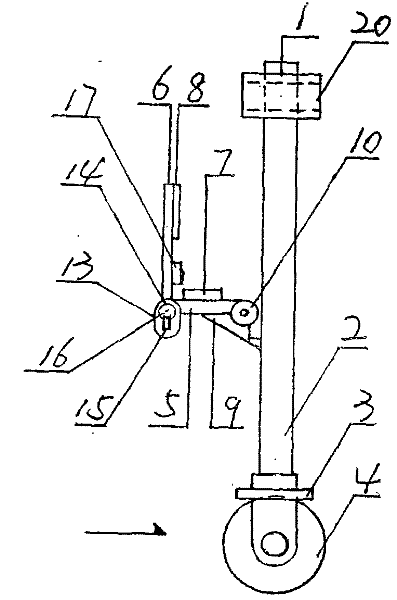

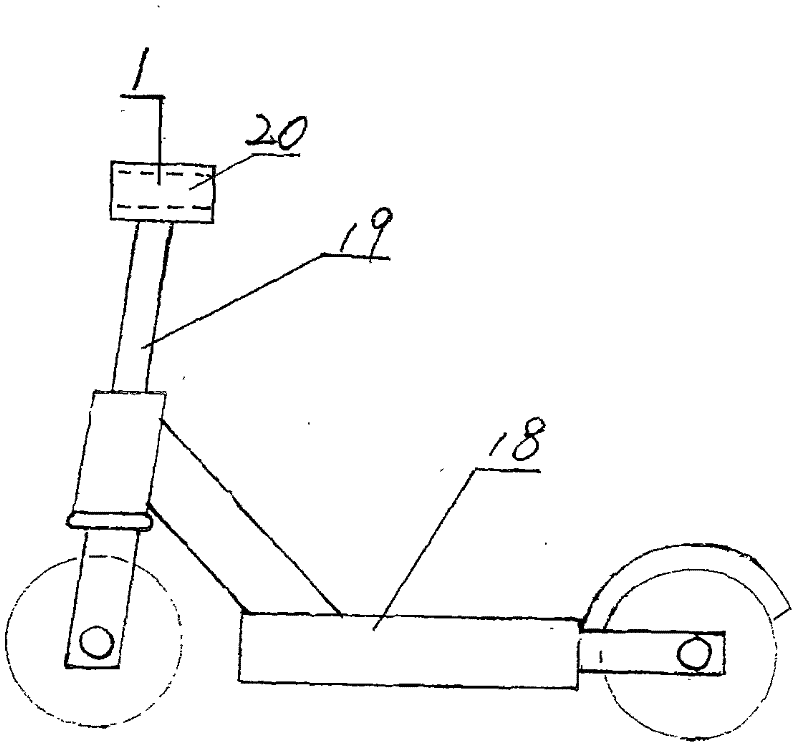

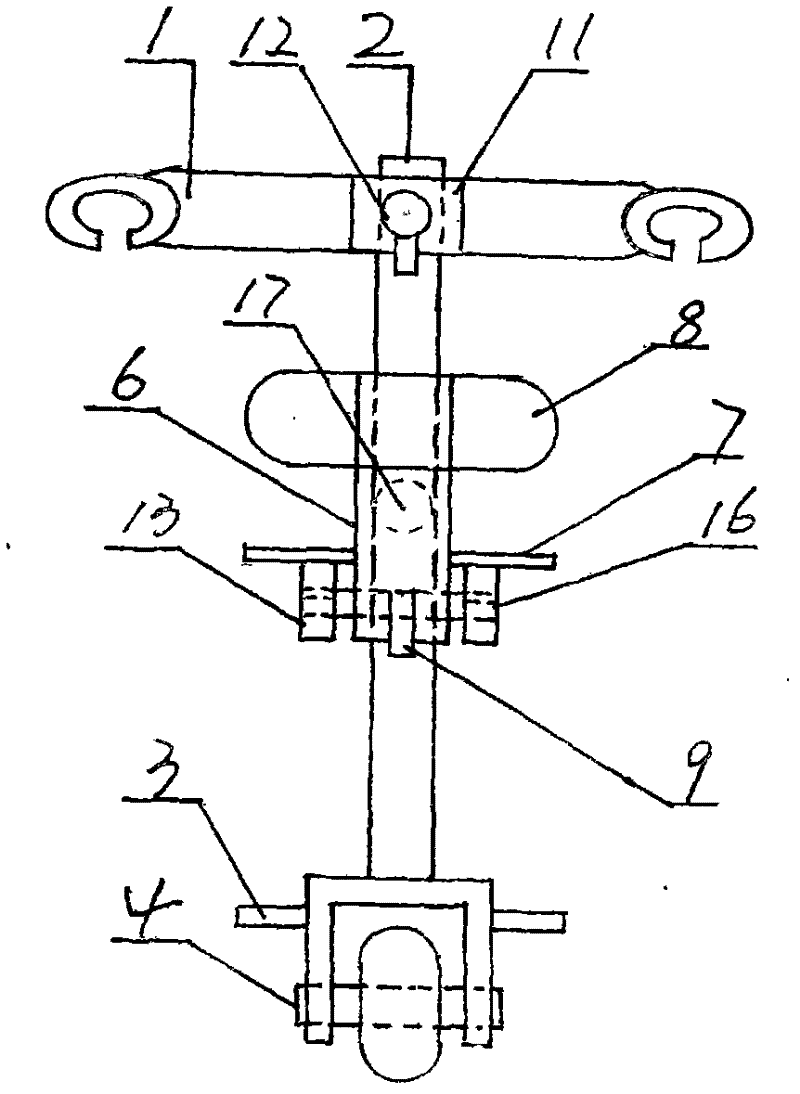

Mine walking aid

The invention discloses a mine walking aid, which has two types of structures: a single-wheel type structure and a sliding plate type structure, wherein the single-wheel type structure consists of a rope clamping rod, a vertical beam, a pedal, a truckle assembly and a folding chair; the rope clamping rod, the vertical beam, the truckle assembly and the pedal are connected into a whole in sequence; the vertical beam is provided with a hinge; and the folding chair and the vertical beam are connected into a whole by the hinge. The sliding plate type mine walking aid is modified by using a handle type two-wheel scooter; a handle of the scooter is fixed with the body in a perpendicular way; clamping hooks are connected to the two ends of the handle of the scooter, so that the scooter can be clamped on a wire rope of a walking aid device; and the height of the handle is adjusted to be the same as that of the wire rope of the walking aid device to put the mine walking aid into use.

Owner:NANTONG YISHENG AGRI COOP

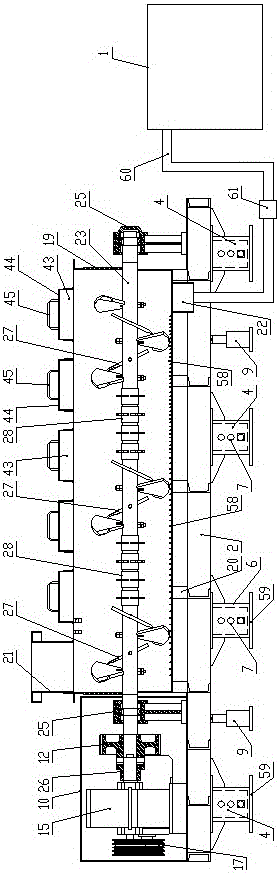

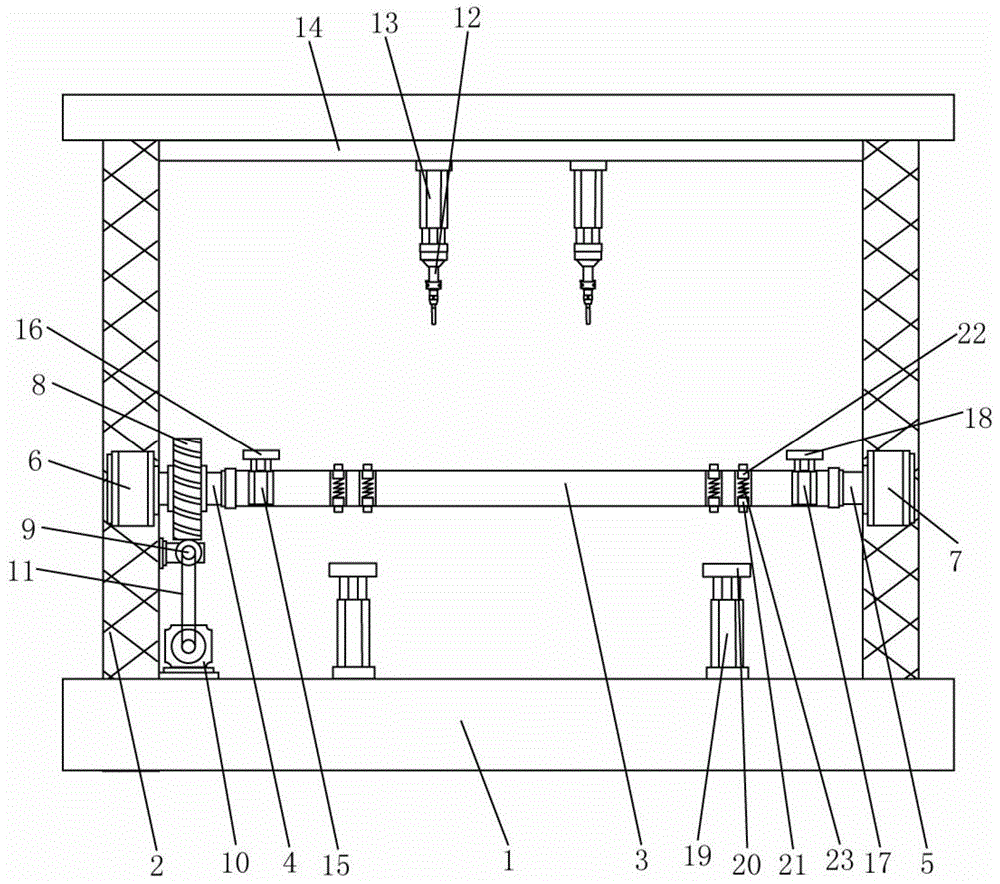

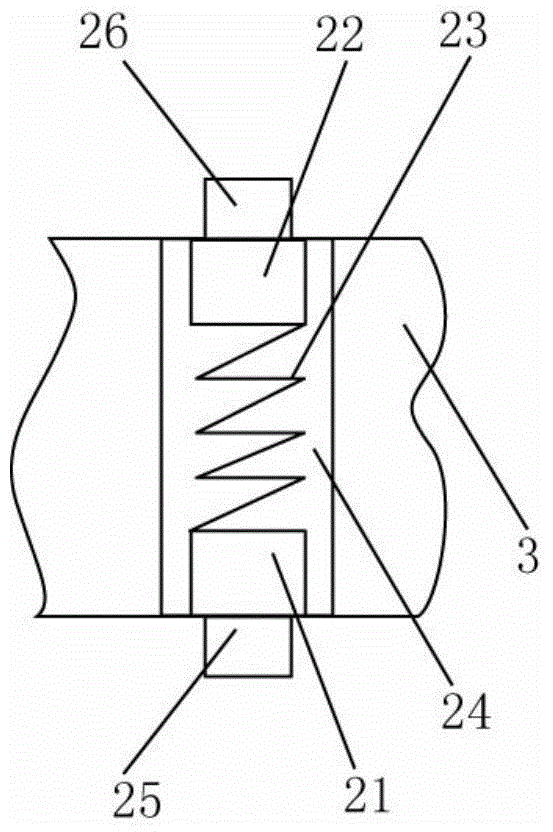

Bed board surface processing machine

ActiveCN104384052AHighly consistentEvenly paintedLiquid surface applicatorsSpraying apparatusSurface finishingBed boards

The invention belongs to the field of bed board processing machines, and particularly relates to a bed board surface processing machine. The bed board surface processing machine is characterized in that a worm gear is mounted on a first rotary shaft, one end of a worm is engaged with the worm gear, spray gun cylinders are mounted on a slide rail and connected with spray guns, push plate cylinders are mounted on a base, the piston rods of the push plate cylinders are connected with push plates, first retractable parts, second retractable parts and springs are located in holder through holes, the springs are clamped between the first retractable parts and the second retractable parts, a first retractable head is mounted on one end of each first retractable part, the first retractable heads are located outside the holder through holes, a second retractable head is mounted on one end of each second retractable part, the second retractable heads are located outside the holder through holes, and the first retractable heads and the second retractable heads are located over the push plates.

Owner:JINYUE TIANJIN METAL PROD

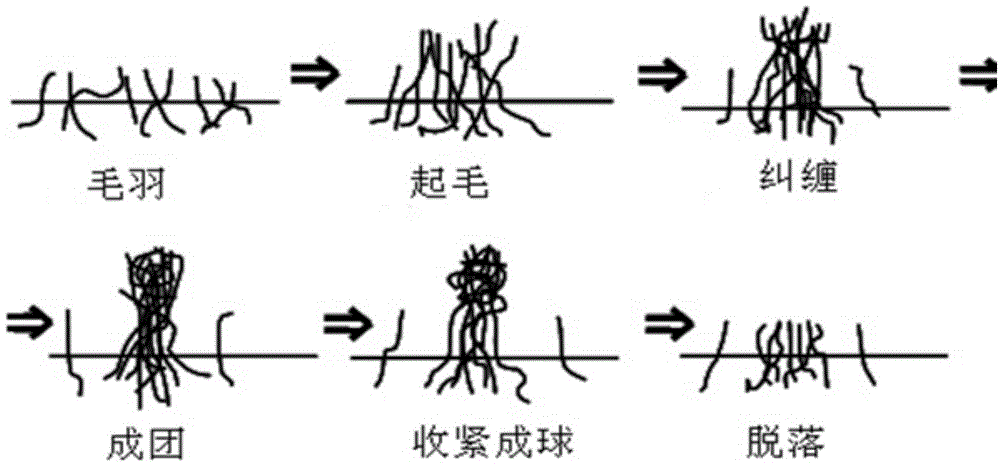

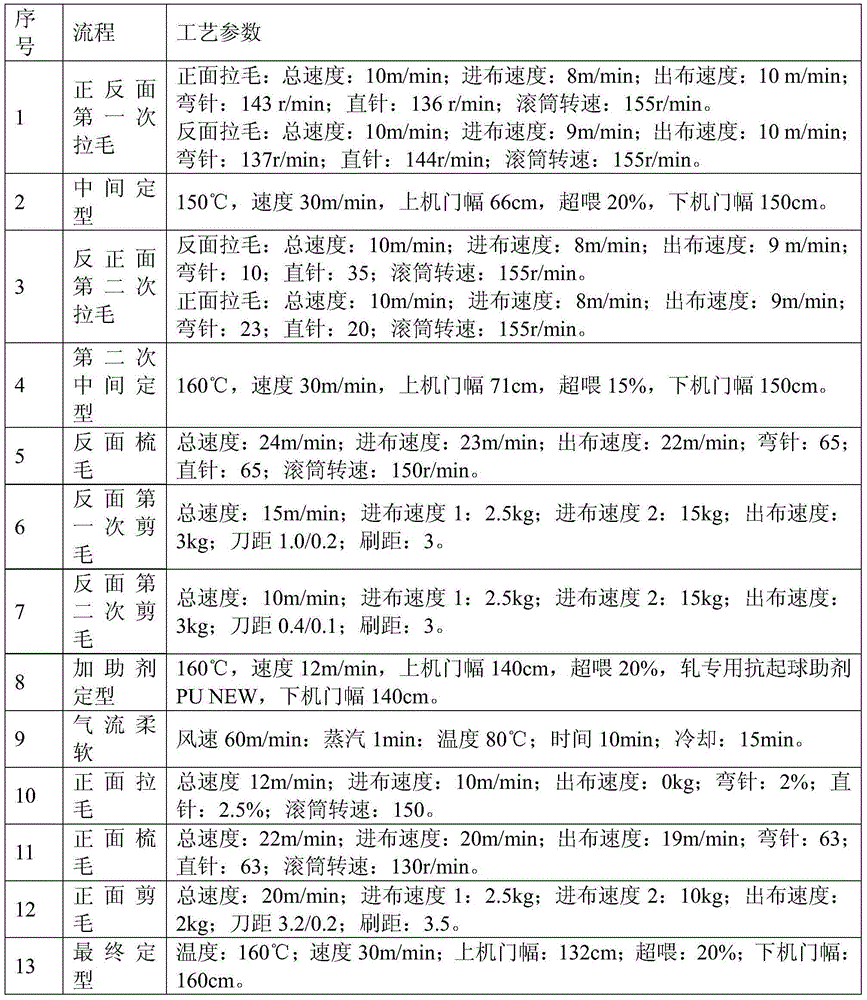

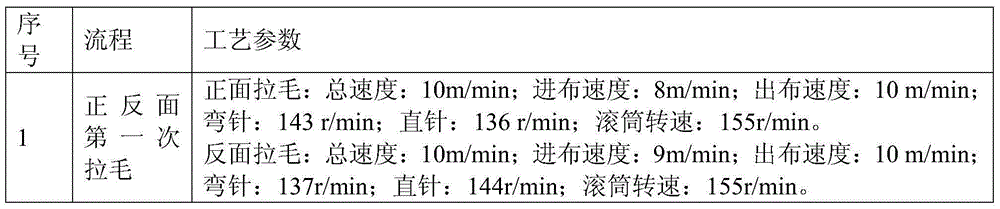

Anti-pilling finishing method of large needle gage loop-raised fabric

ActiveCN104480665AImprove anti-pilling performanceImproved pilling resistanceFabric breaking/softeningHeating/cooling textile fabricsFiberYarn

The invention relates to an anti-pilling finishing method of large needle gage loop-raised fabric. The anti-pilling finishing method comprises following steps: (1) galling processing, used for pulling fluff out of fiber yarn; (2) carding processing, used for carding the fluff to be vertical; and (3) shearing processing, used for removing the float fluff obtained via carding. The anti-pilling finishing method is capable of improving anti-pilling performance of large needle gage loop-raised fabric to half to one grade. The anti-pilling finishing method is simple; original style of the processed fabric is not changed; and no extra processing process is increased.

Owner:上海嘉麟杰纺织科技有限公司

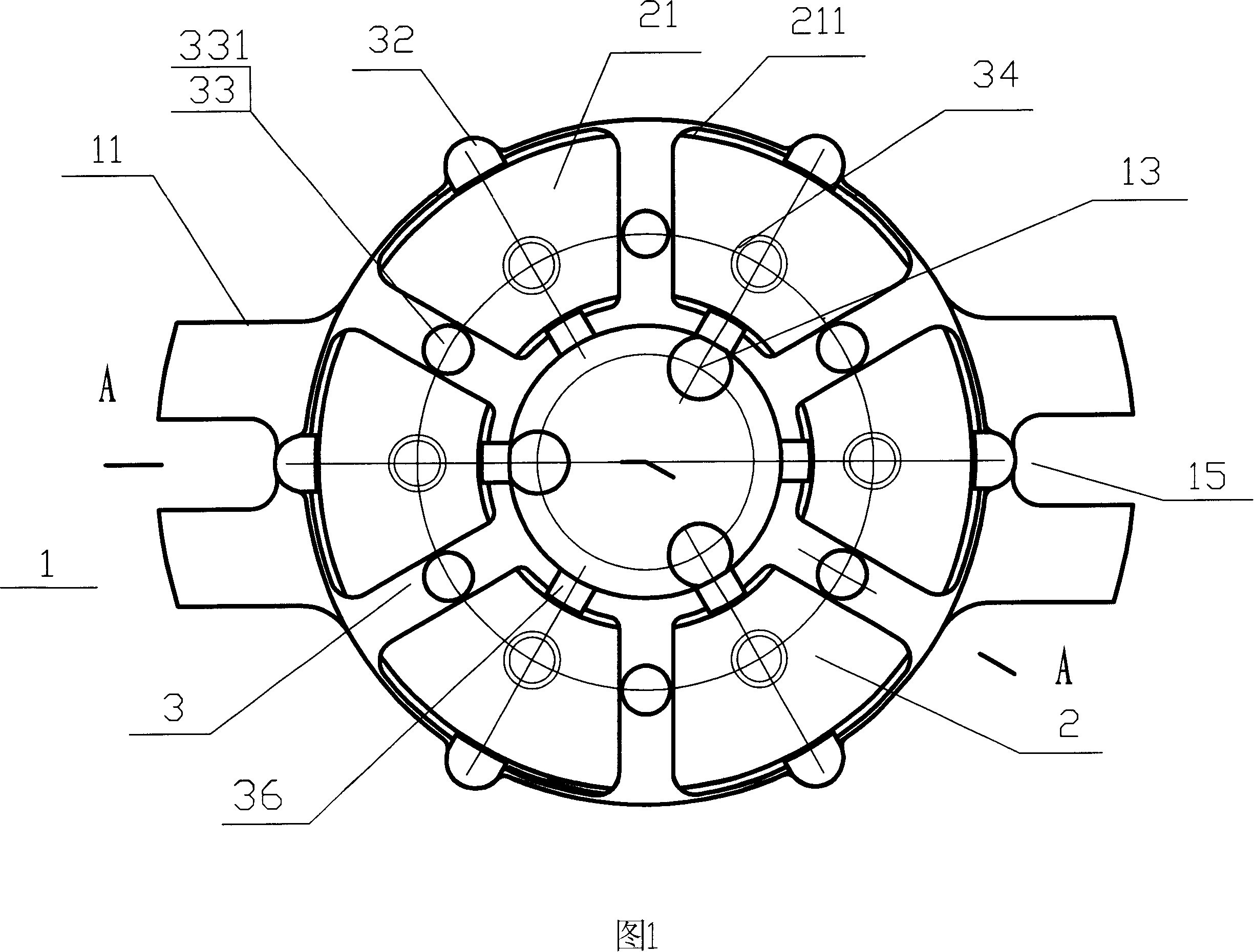

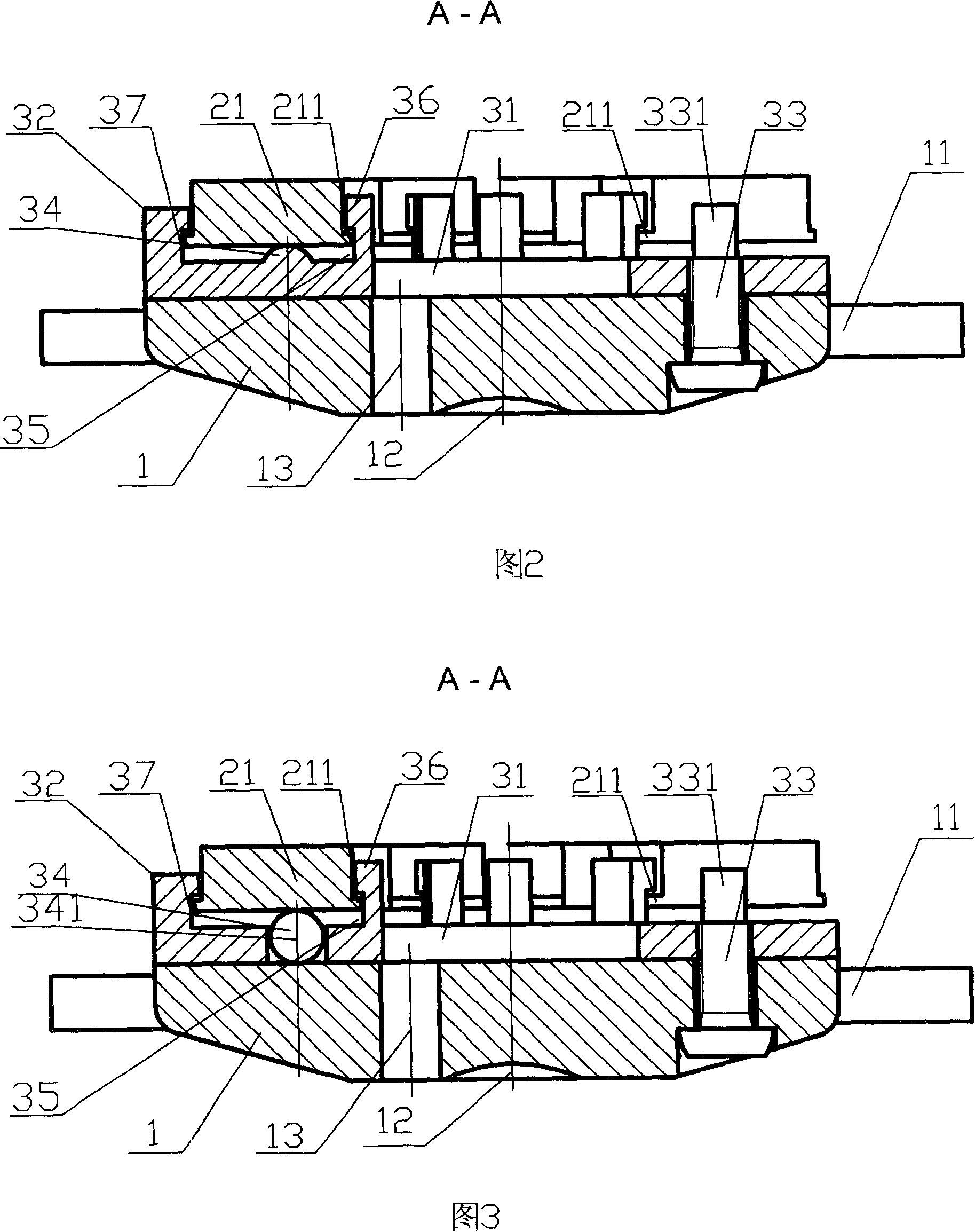

Thrust bearing

ActiveCN101153628AIncreasing the thicknessFlexible activitiesBearing componentsSliding contact bearingsSurface finishCircular disc

The invention discloses an end thrust bearing for submersible motor in well, comprising a disk bearing support with a chucking lug and a concave spherical surface in the center of the bottom, a gap block consisting of a plurality of independent multipart bearing slide blocks, and a bearing disk fixed on the disk bearing support, wherein, the bearing disk is provided with a center hole, a limited post I with a groove I arranged on the inner circle edge, a limited post II with a groove II arranged on the outer circle edge, a positioning stud limiting the position of the multipart bearing slide block, and a spherical crown convex hall; the two surfaces of the multipart bearing slide block are smooth, and the big and small circular arc edges are provided with a flange. When the invention is installed, the big and the small circular arc edges are respectively embedded into the groove II and the groove I and then locked after being limited by the positioning stud, and each slide block is in a flexible and nondeciduous state. Therefore, the shape and the structure as well as the way of installation of the multipart bearing slide block are improved, the thickness of the multipart bearing slide block is greatly increased, the intensity and the surface finish quality are greatly improved, and the full contact of the multipart bearing with a trust disk is guaranteed. With good carrying capacity, abrasive resistance and simple structure, the friction plane is easy to be processed and the manufacturing accuracy is easy to be guaranteed.

Owner:GUANGDONG RUIRONG PUMP IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com