Production method of millimetric wave voltage-controlled phase shifter for microelectronic machine

A technology of microelectronic machinery and manufacturing methods, which is applied in the direction of optomechanical equipment, manufacturing microstructure devices, and photolithography on patterned surfaces, etc., can solve problems such as high turn-on voltage, poor electrical performance, and small phase shift, and achieve The effect of low turn-on voltage, superior electrical performance, and large phase shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

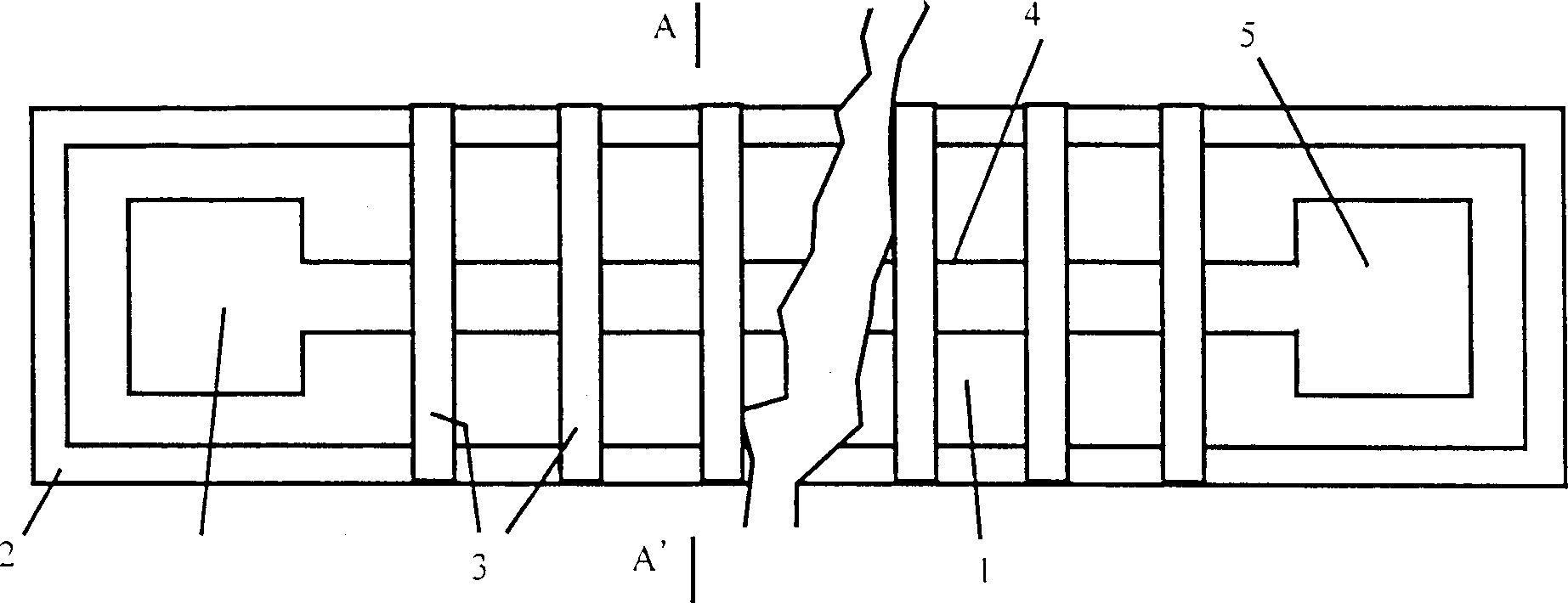

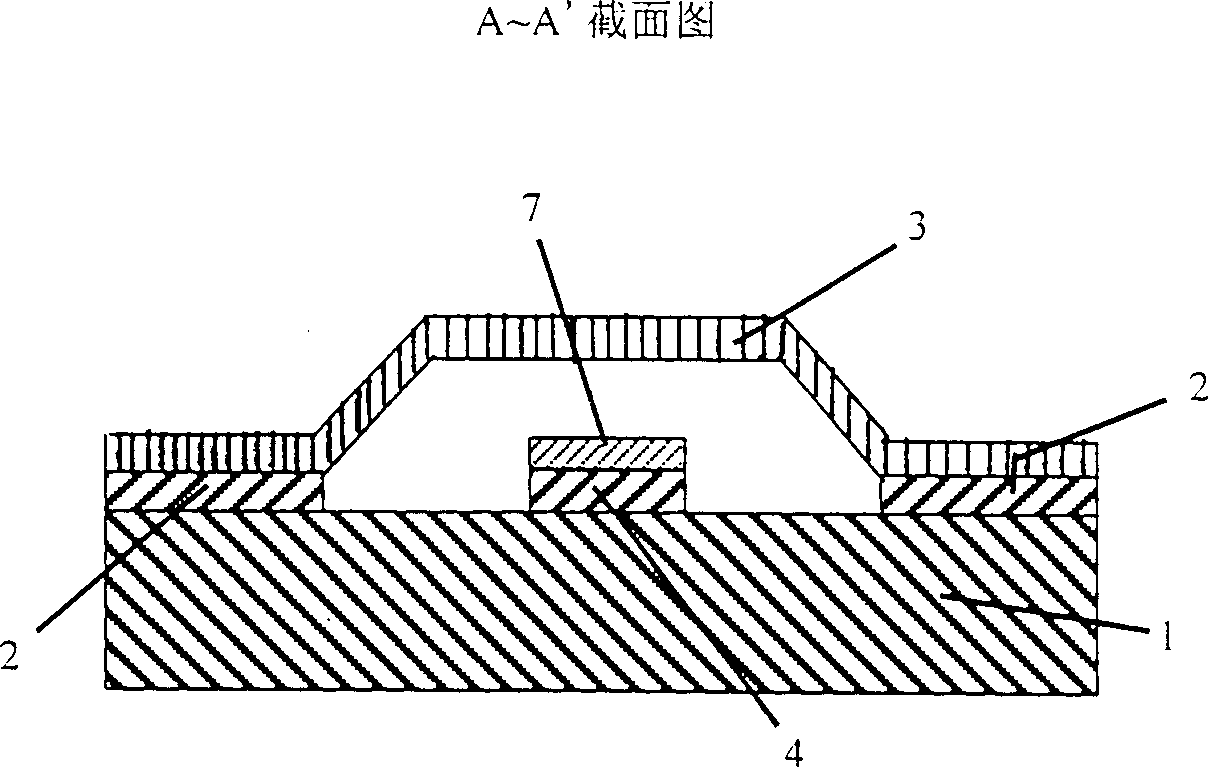

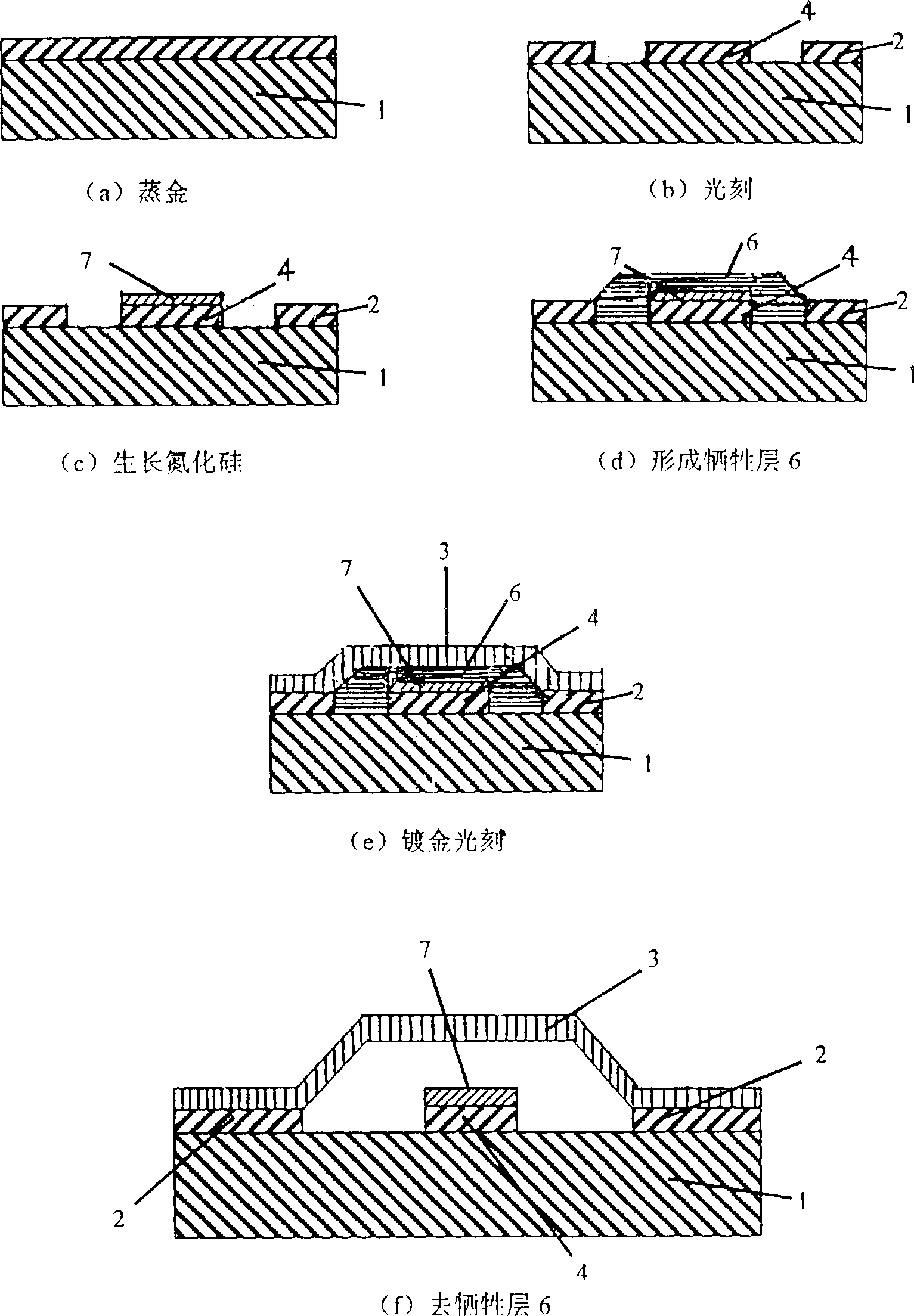

[0025] Example. A batch of microelectromechanical millimeter wave voltage-controlled phase shifters with 21 bridges and 35 GHz are made by adopting the method of the present invention, and the yield rate is high, reaching more than 80%; the electrical performance is superior, and when the product works at 15 GHz, when the DC bias voltage changes from 5 At ~25V, the phase shift can reach 170°; when the product works at 35GHz, when the DC bias voltage is continuously adjustable within the range of 5 ~ 20V, the phase shift can be continuously adjusted within the range of 0 ~ 370° .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com