Thrust bearing

A thrust bearing, bearing technology, applied in the direction of bearings, bearing components, shafts and bearings, can solve the problems of poor self-aligning ability, poor pressure bearing capacity, easy to wear, etc., to achieve surface finish and strength increase, pressure bearing capacity Strong, high-pressure-resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

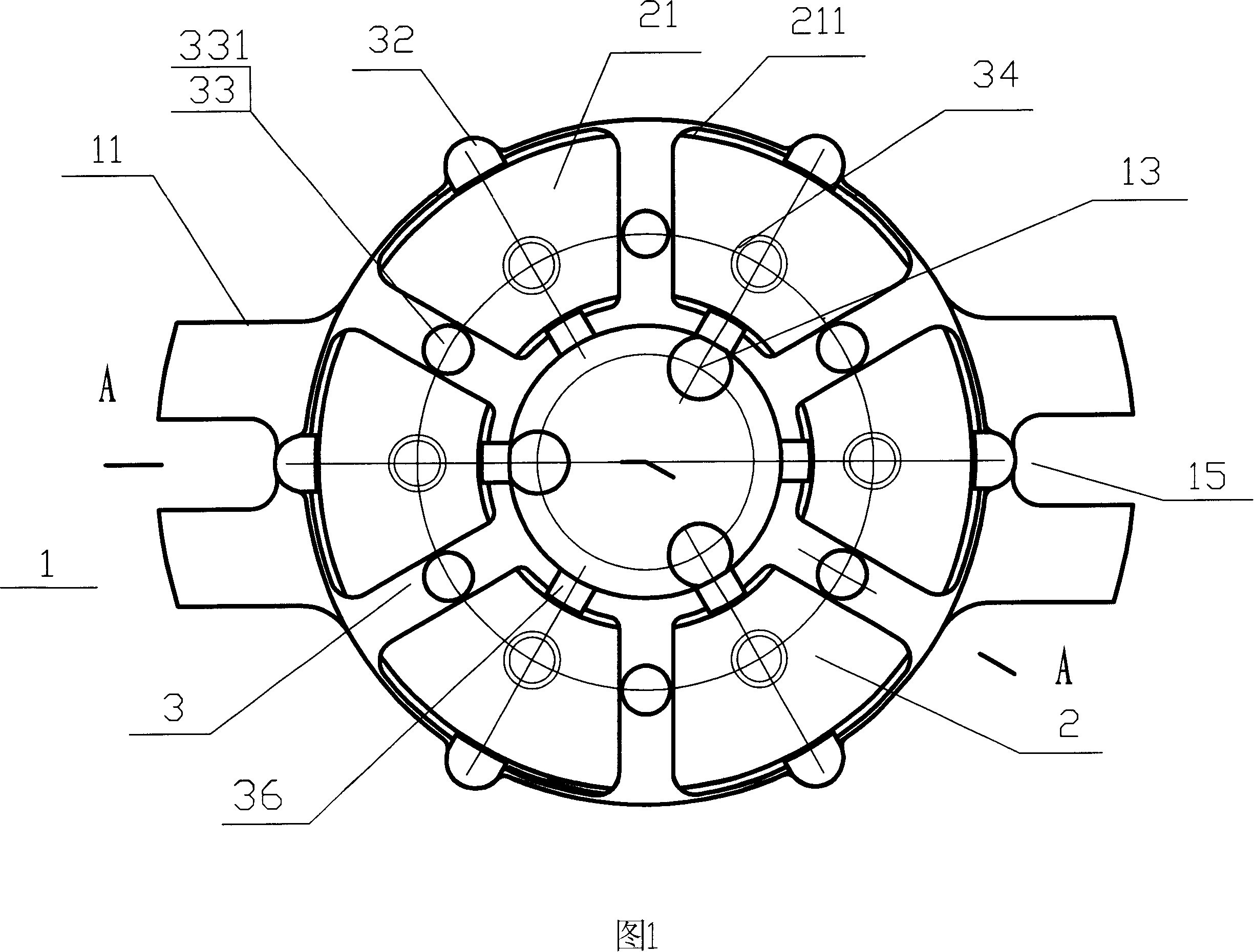

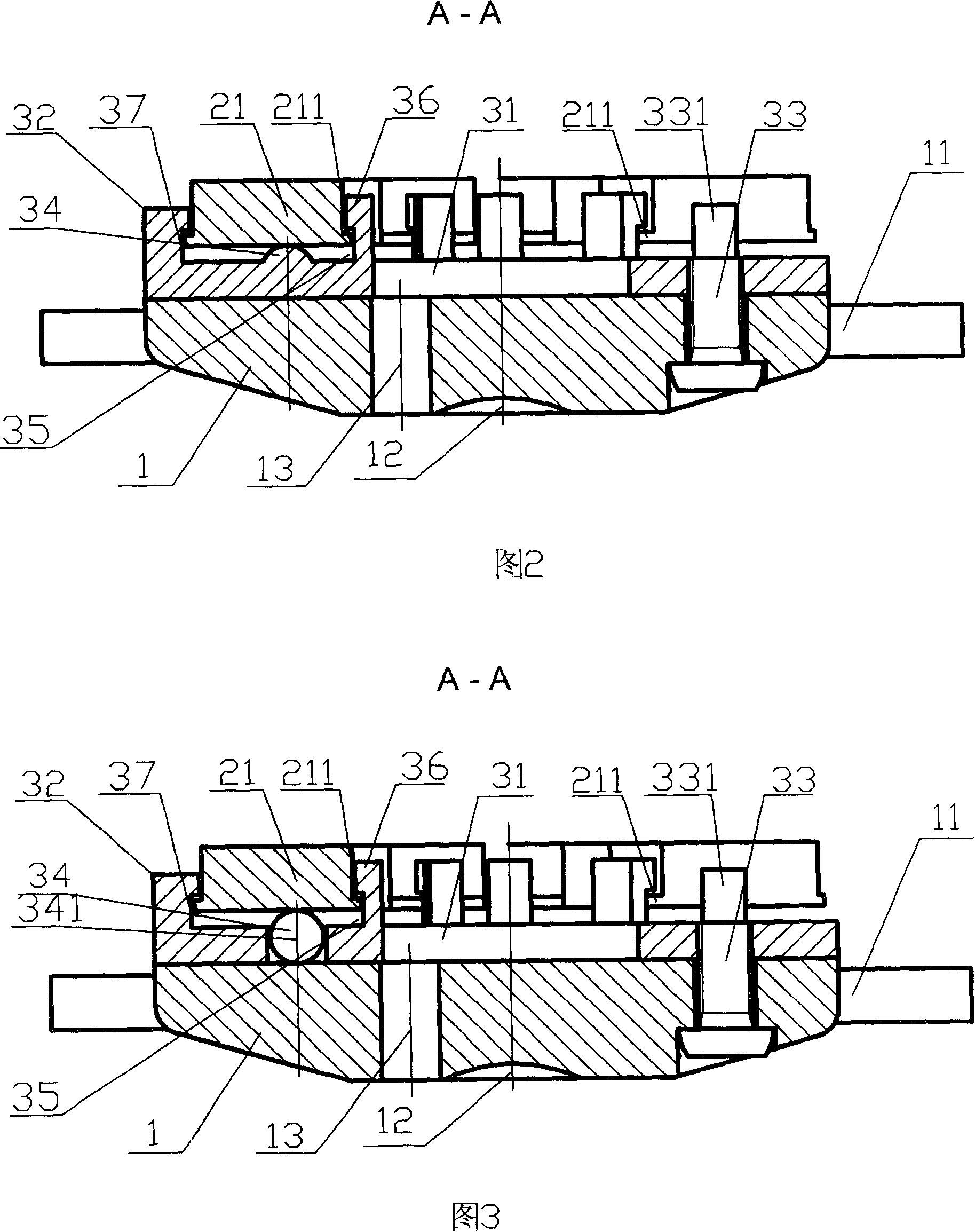

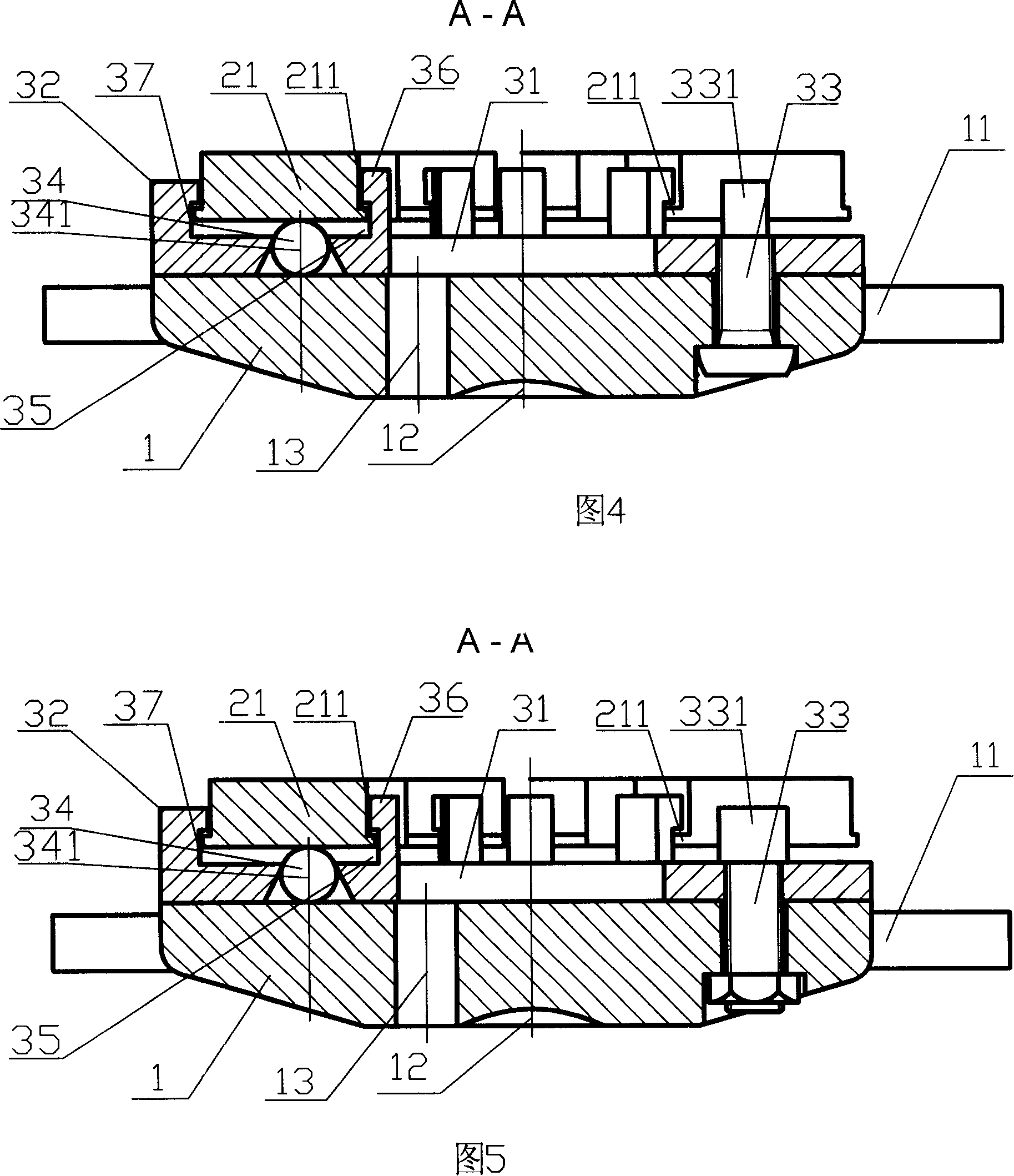

[0026] The thrust bearing of the present invention will be described in more detail below with reference to the accompanying drawings.

[0027] As shown in Figures 1 to 15, the thrust bearing of the present invention includes a disc bearing seat 1 and a bearing bush 2 with positioning lugs 11, and a bearing disc 3 between the disc bearing seat 1 and the bearing bush 2, and the bearing bush 2 It is composed of 6 independent fan-shaped bearing sliders 21, which are evenly distributed on the bearing disc 3 according to the circumference. The slider positioning stud 33 has a protruding end 331 on the bearing disc 3, and the position is on both sides of the fan-shaped bearing slider 21 to limit the position. The positioning lug 11 is arranged on both sides of the disc bearing seat 1 and has a U-shaped notch 15, this U-shaped notch 15 is to make disc bearing seat 1 unable to rotate but can allow to swing, there is also a concave spherical surface 12 in the center of the bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com