Patents

Literature

638results about How to "Short maintenance time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

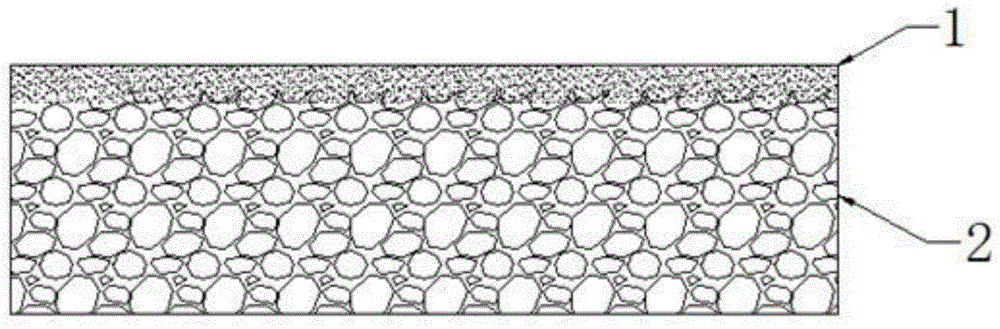

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

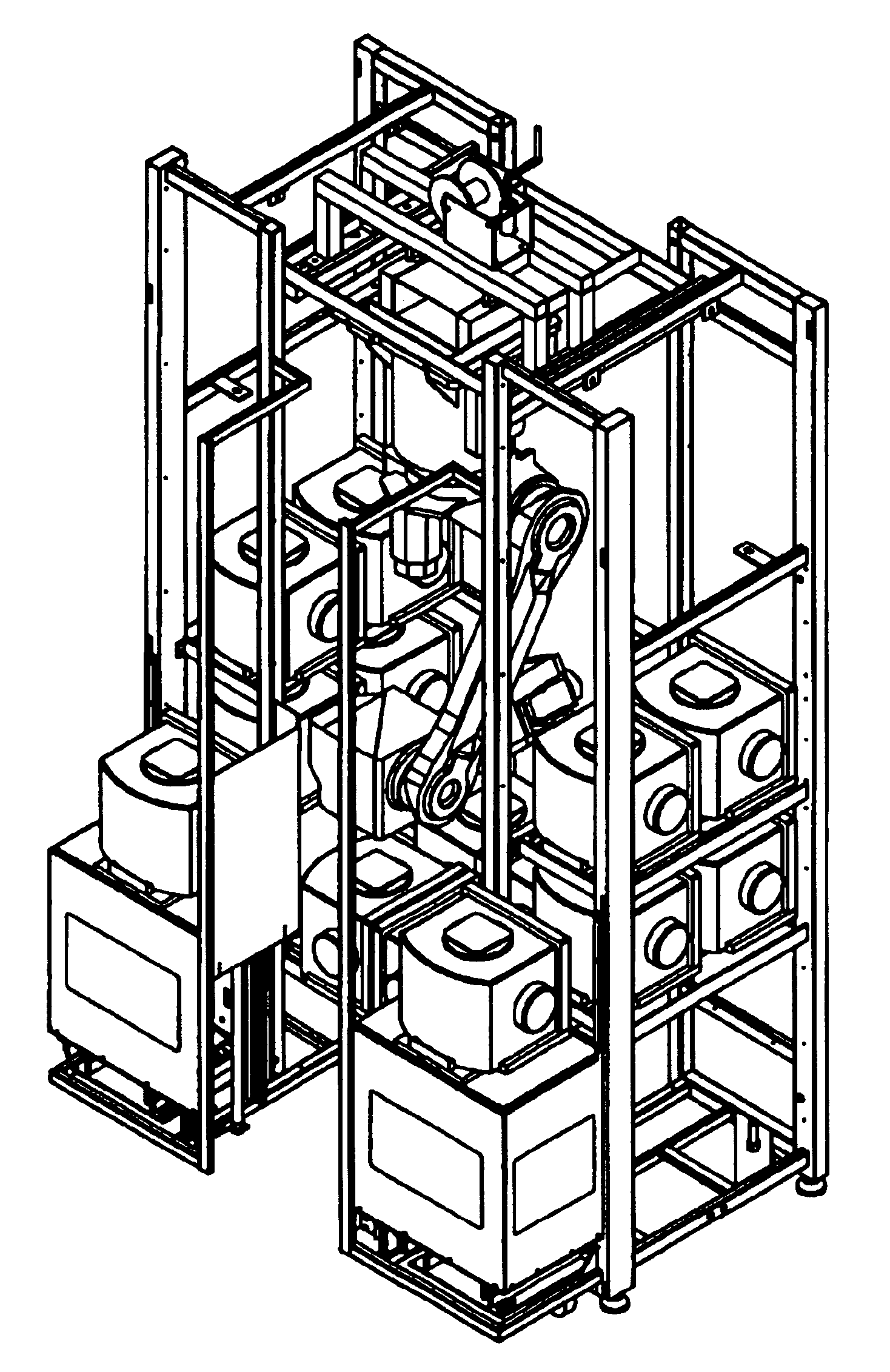

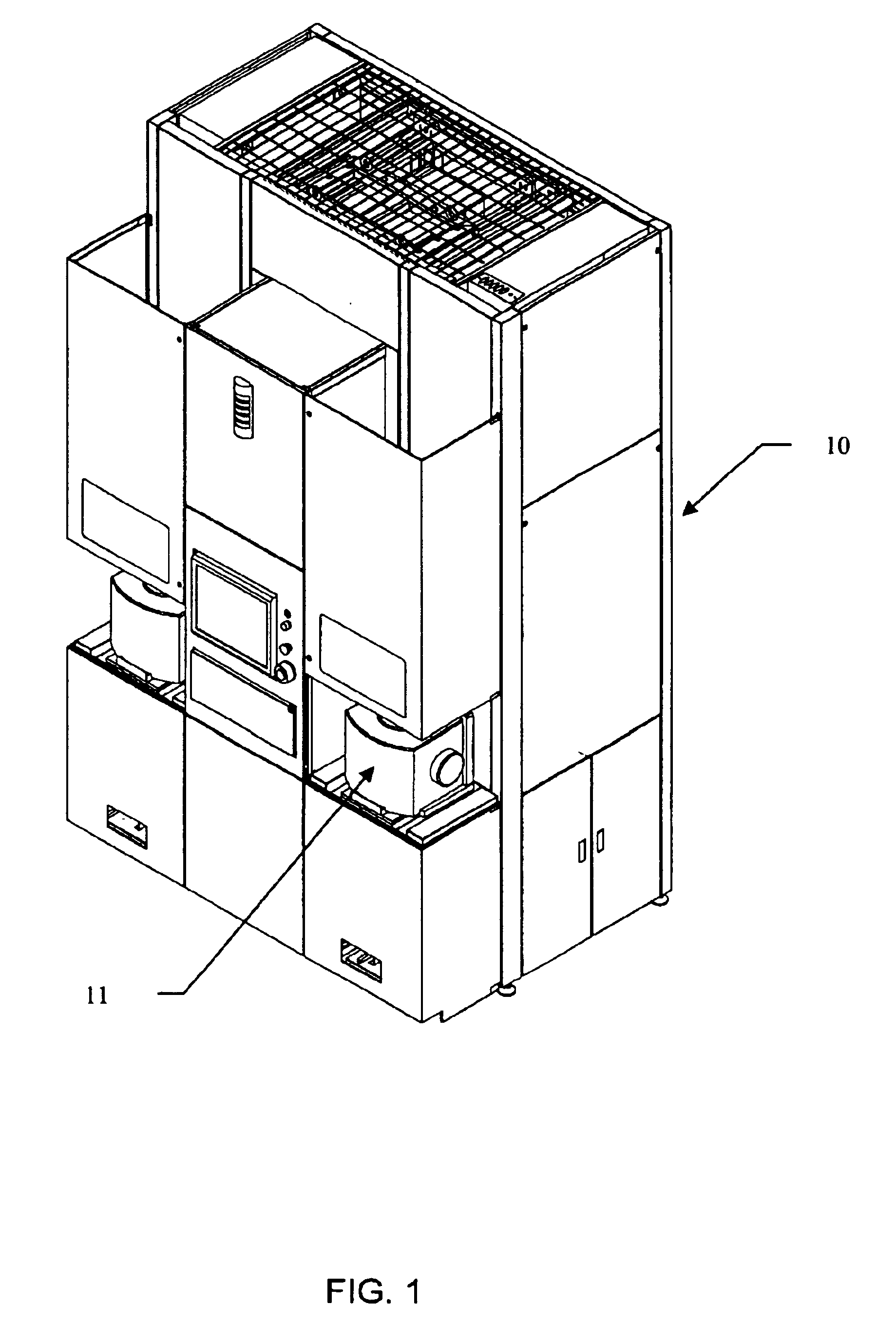

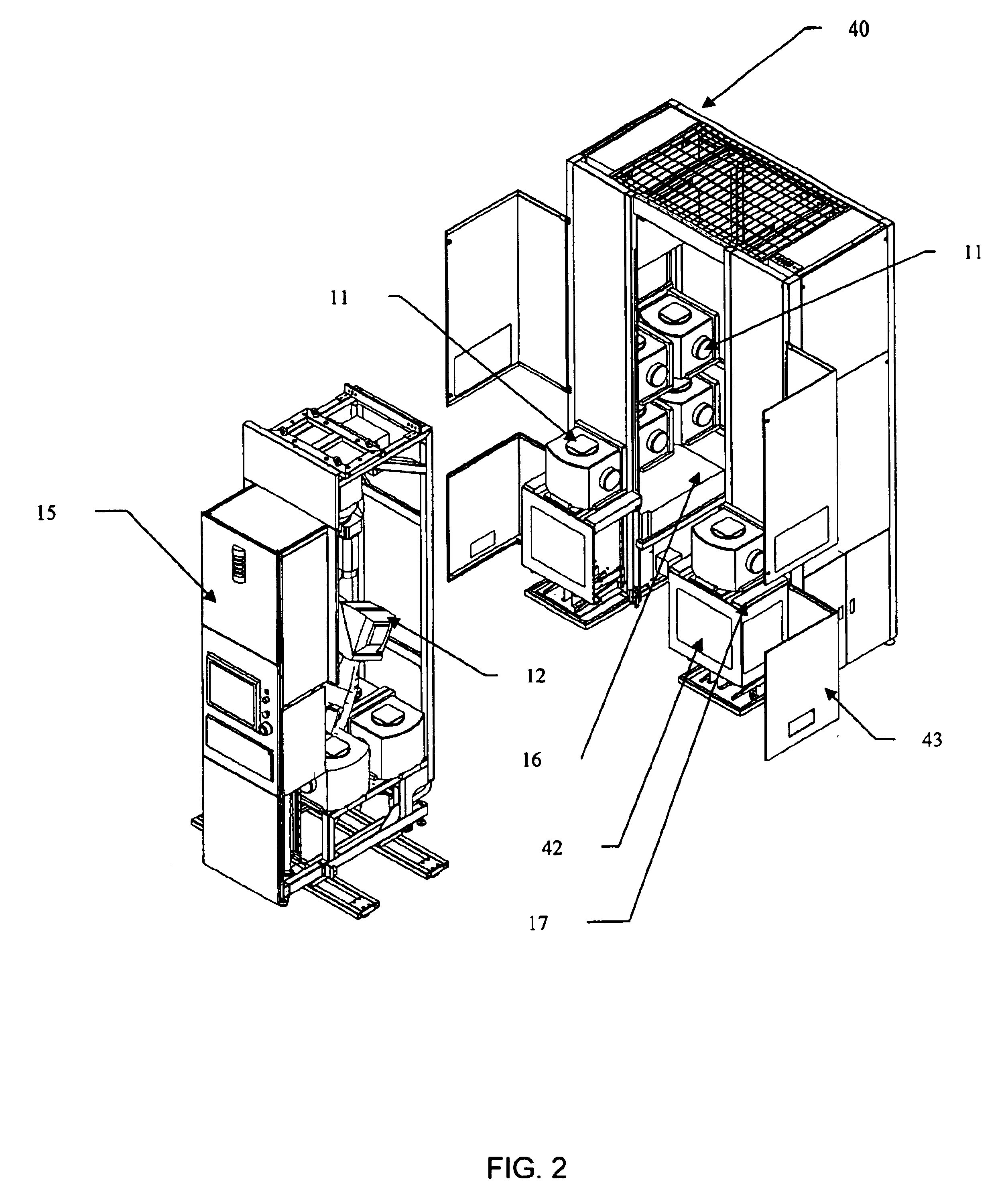

Robotic storage buffer system for substrate carrier pods

InactiveUS7039499B1Expand capacityMinimal footprintProgramme-controlled manipulatorDigital data processing detailsCartActuator

A storage / buffering system for the stocking and / or buffering of substrate and / or substrate carriers in a process environment includes a 6-axis robot. An end-effector is connected with the robot providing an additional one degree of freedom and a mechanism for grabbing and moving of substrate and / or substrate carriers. The robot is mounted in an inverted orientation to a removable service cart for easy removal of the robot to a service area in the event of breakdown. The robot receives commands from a programmable controller connected to control the robot and configured to direct the arm of the robot through a set of movements. Product is loaded in and out of the system through I / O load ports. Product is stored inside the storage / buffering system on a plurality of storage locations, each with product presence / absence detect sensor. The robot can alternatively be mounted directly to the storage system enclosure structure.

Owner:SEMINET

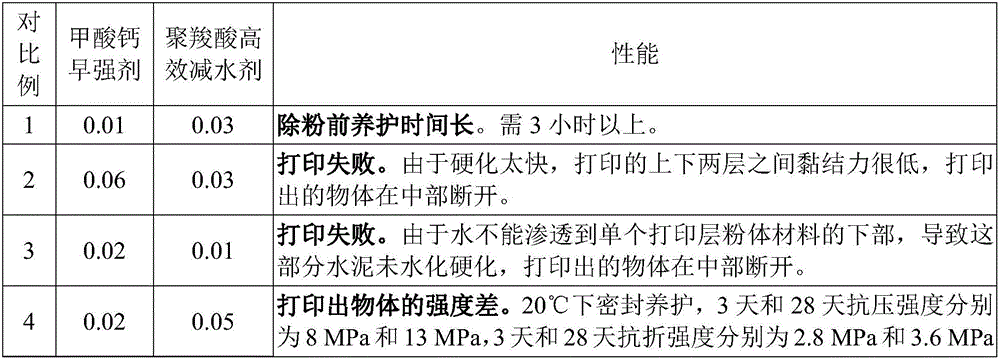

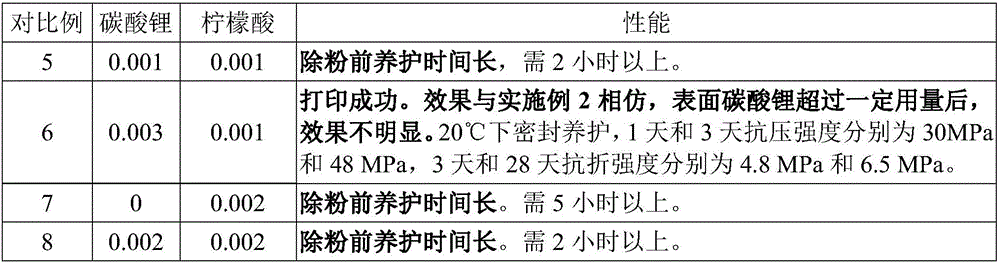

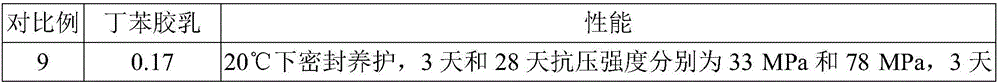

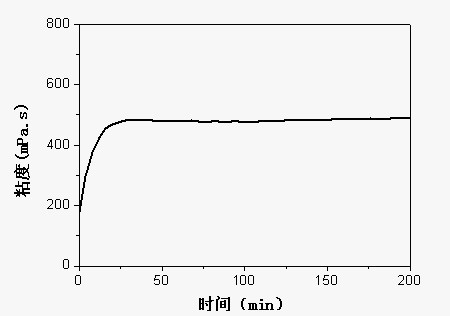

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

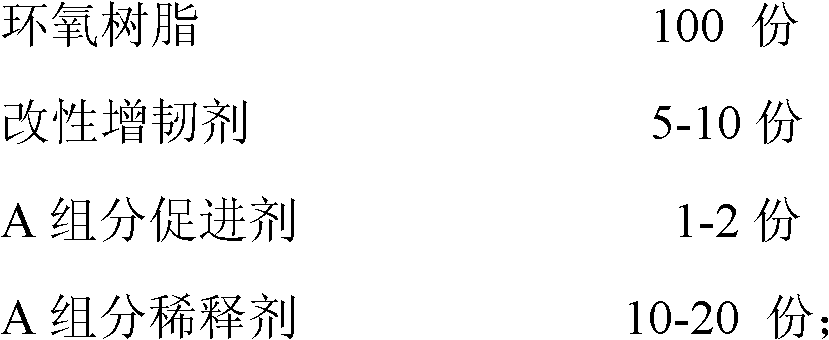

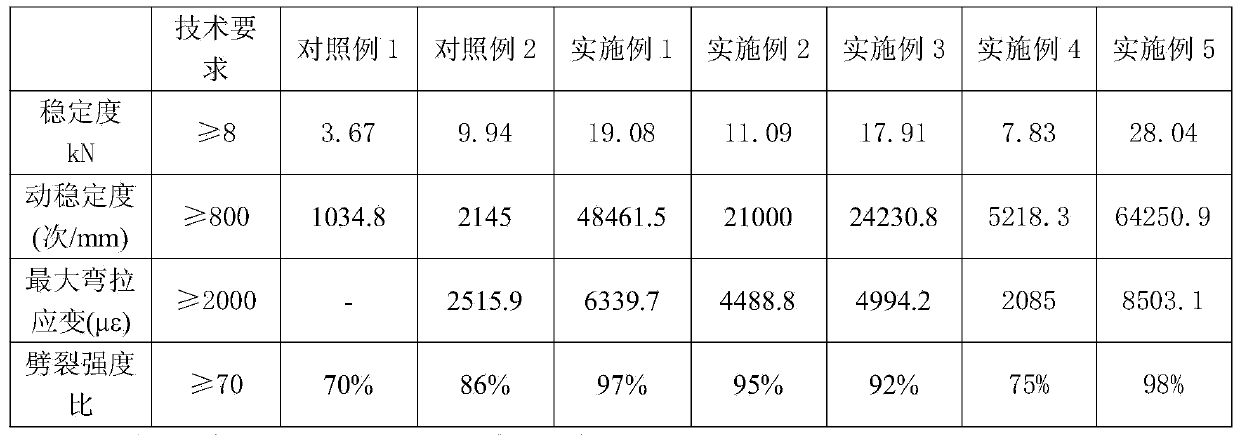

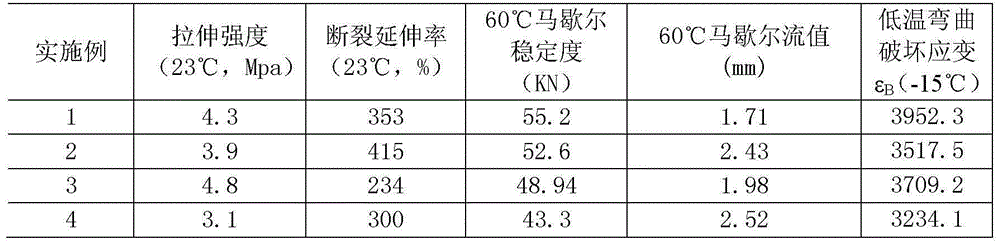

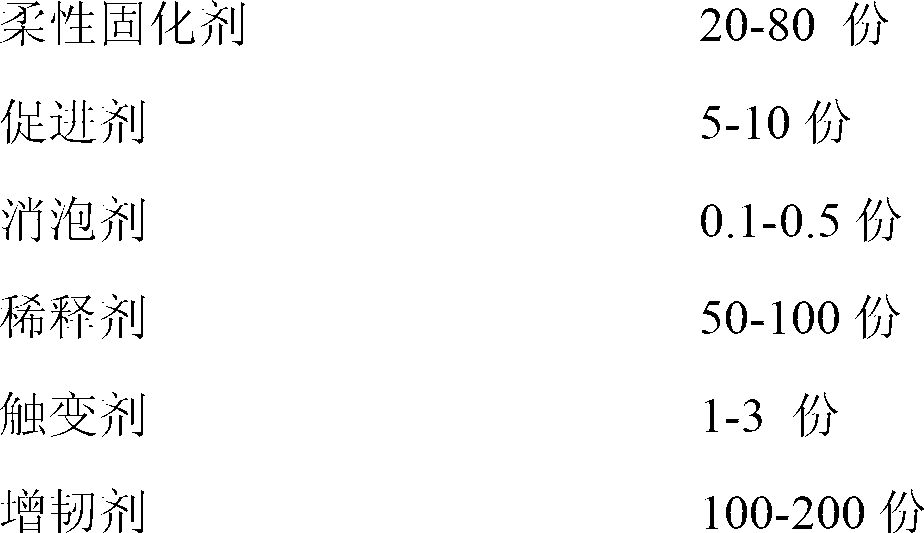

High-performance epoxy bitumen mixture easy to construct and maintain and preparation method thereof

The invention discloses a high-performance epoxy bitumen mixture easy to construct and maintain, comprising four components of A, B, C and D. The high-performance epoxy bitumen mixture easy to construct and maintain is characterized in that the component A mainly comprises epoxy resin, a toughening agent, an accelerating agent and a diluent agent; the component B mainly comprises a curing agent, an accelerating agent, a compatilizer and a diluent agent; the component C comprises bitumen; the component D comprises aggregates and mineral powder, wherein the ratio of the component A to the component B is 100:50 to 100:100; the ratio of the sum of the component A and the component B to the component C is 100:100 to 100:160; and the ratio of the sum of the component A, the component B and the component C to the component D is 6:94 to 7:93. The high-performance epoxy bitumen mixture easy to construct and maintain has the characteristics of excellent mechanical property, temperature resistance, water resistance, solvent corrosion resistance, fatigue durability, simple construction process and short maintenance time. The high-performance epoxy bitumen mixture easy to construct and maintain is suitable for paving and maintenance of road surfaces, such as steel bridge floors, cement concrete bridge floors, tunnels, expressways and the like. The invention also discloses a preparation method of the high-performance epoxy bitumen mixture easy to construct and maintain.

Owner:NANJING UNIV

Mixed silicon sol water inorganic zinc enriching paint

An inorganic water paint rich in Zn for steel contains the component A prepared from Zn powder, thickening agent and filler and the component B prepared from mixed silicon sol, deposition resistant, emulsion, surfactant and assistant. Its advantages are high resistance to salt fog and ageing, low cost and no environmental pollution.

Owner:SHANGHAI MAMPLE NEW MATERIAL

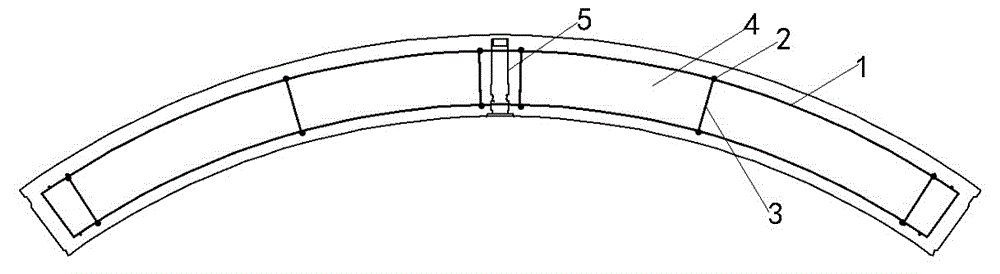

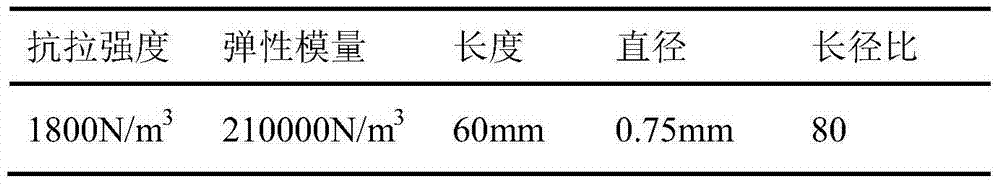

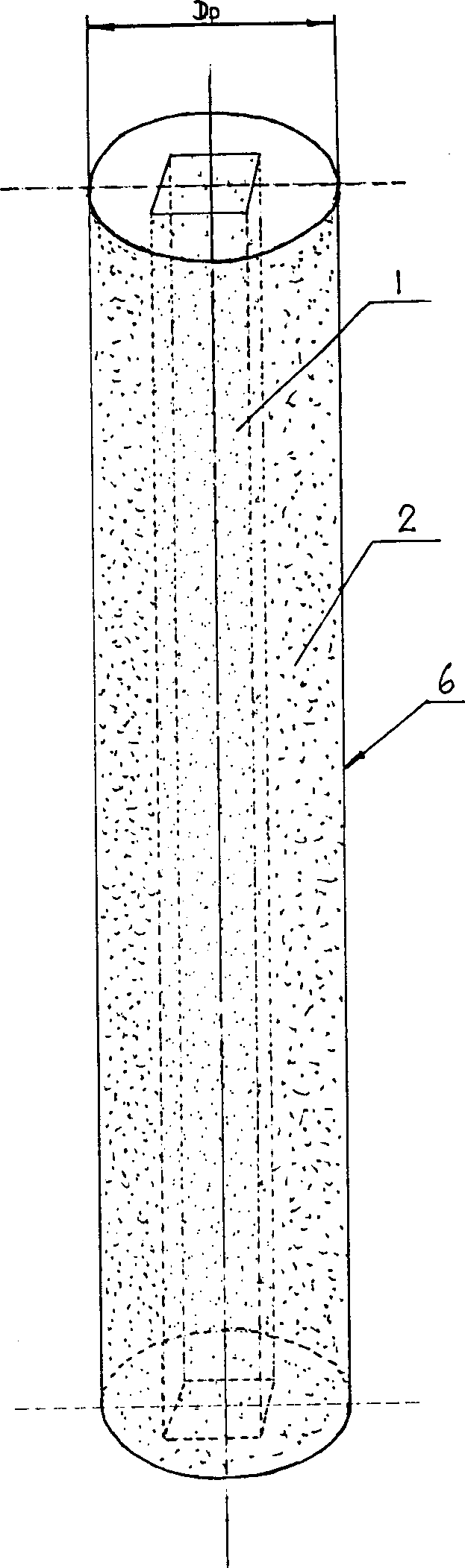

Ultra-high performance hybrid fiber concrete shield segment and preparation method thereof

InactiveCN105041336AReduce dosageReduce consumptionUnderground chambersTunnel liningCrack resistanceReinforced concrete

The invention discloses an ultra-high performance hybrid fiber concrete shield segment and a preparation method thereof. The ultra-high performance hybrid fiber concrete shield segment is of a reinforced concrete structure which consists of a steel skeleton and concrete, wherein the reinforcement ratio of used main reinforcements is 0.5%-1.0%, the distances of the main reinforcements are 150-300mm, the grades of steel reinforcements are not less than three, the smallest steel reinforcement distance of distributed reinforcements is 400mm, the biggest steel reinforcement distance of used distributed reinforcements is 2000mm, and the grades of the steel reinforcements are not less than two. The ultra-high performance hybrid fiber concrete shield segment is made from ultra-high performance hybrid fiber concrete, and comprises cementitious materials, sands, crushed stones, steel fibers, synthetic fibers, water reducer, defoamer and water. The ultra-high performance hybrid fiber concrete shield segment is less in dosage of the steel reinforcements and concrete and high in early strength, can prevent steam preservation, reduces energy consumption, and is green, energy-saving and environmentally friendly. The ultra-high performance hybrid fiber concrete shield segment is strong in anti-burst performance when having a fire, excellent in toughness and crack resistance and excellent in durability, enables edge joints not to easily break, and overcomes the defects of traditional segments.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

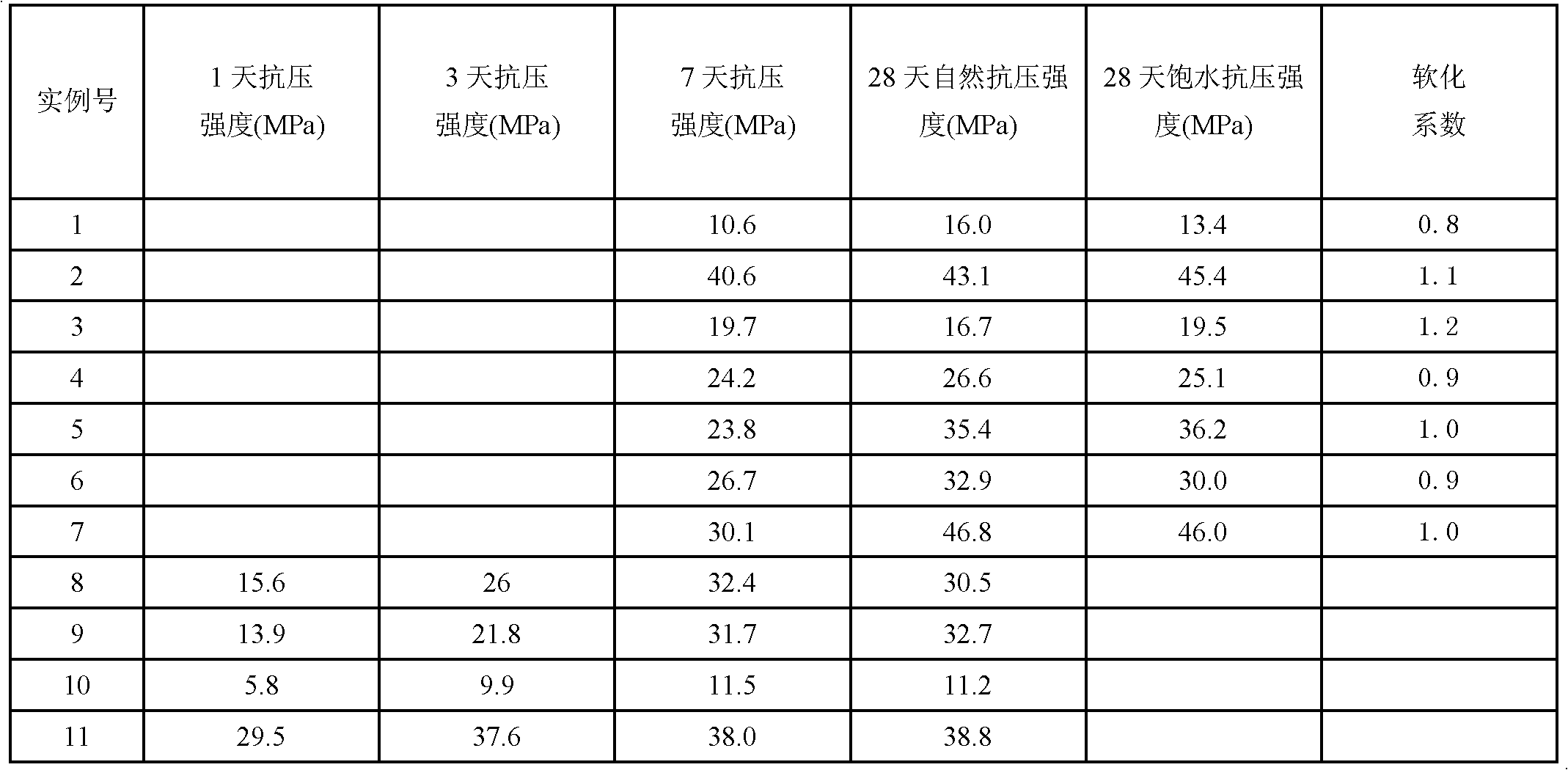

Method for curing lake dredged sediment containing heavy metal

InactiveCN103086670AShort maintenance timeReduce moisture contentSludge treatmentWater contaminantsResource utilizationPlastic film

The invention belongs to a treatment method of solid waste in environmental engineering, and particularly relates to a method for curing lake dredged sediment containing heavy metal. The method is characterized by comprising the steps of adding a curing agent prepared from waste gypsum, coal ash and cement in a mixing manner to lake dredged sediment containing heavy metal, evenly stirring, and covering a plastic film on the surface for molding for 1-3 days; and maintaining for 2-10 days under the conditions that the temperature is 20+ / -(3-6) DEG C and the relative humidity is 70-100% to obtain a solidified clod of which the unconfined compression strength is greater than or equal to 170.6kpa, wherein the weight ratio of the waste gypsum to the coal ash to the cement is 1 to (0.5-10) to (1-15); and the adding amount of the curing agent is 3-20% of mass of the lake dredged sediment containing the heavy metal. Industrial wastes such as the coal ash, the waste gypsum and the like are taken as curing agent materials of heavy metal polluted sediment; and resource utilization of the wastes such as the polluted sediment, the coal ash and the waste gypsum is achieved, so as to achieve the target of treatment of wastes with processes of wastes against one another.

Owner:HUBEI POLYTECHNIC UNIV

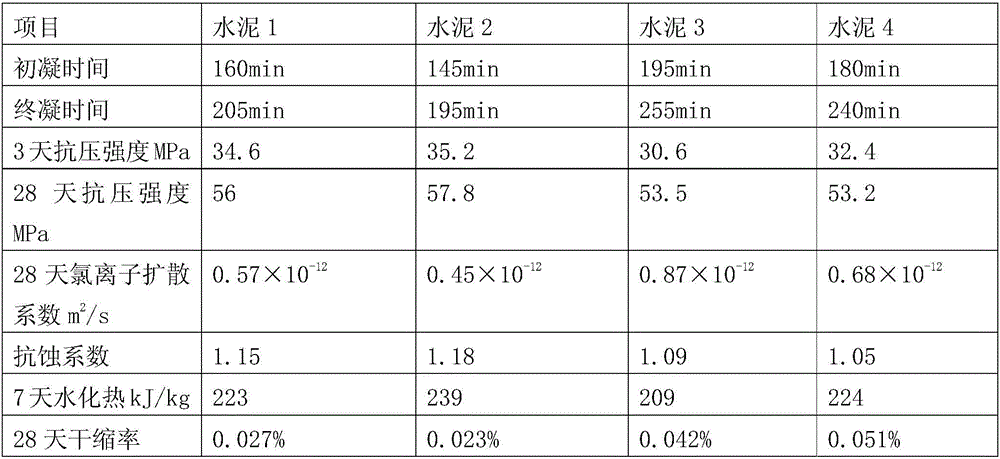

High early strength and high corrosion resistant Portland cement and preparation method thereof

ActiveCN106082724AReduce tricalcium contentExtended service lifeClinker productionMass ratioPortland cement

Belonging to the field of cement production and also relating to the field of building materials, the invention provides a high early strength and high corrosion resistant Portland cement and a preparation method thereof. The high early strength and high corrosion resistant Portland cement is mainly applied to engineering projects in complex marine environments and the west harsh environments. The high early strength and high corrosion resistant Portland cement is characterized by containing, by weight percentage, 60%-90% of a high iron and low calcium cement clinker mineral component, 2%-10% of an auxiliary functional component, 5%-25% of an auxiliary cementitious component, and 3%-7% of industrial gypsum. The high iron and low calcium cement clinker mineral component is mainly prepared from high iron and low calcium Portland cement clinker and high iron and low calcium Q phase cement clinker in a mass ratio of 5-15:1. The cement not only has strong seawater erosion resistance and high early strength, but also has the characteristics of low shrinkage and low hydration heat.

Owner:WUHAN UNIV OF TECH

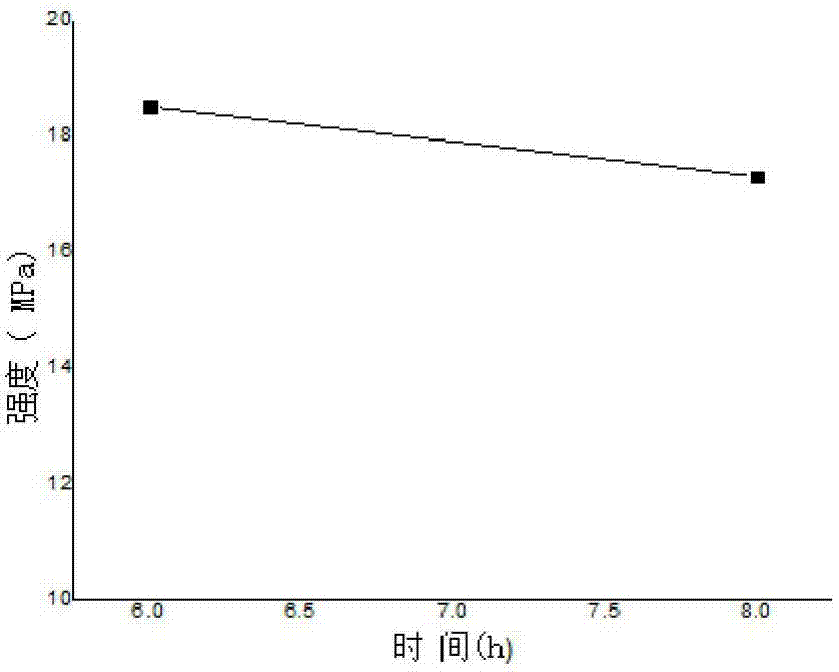

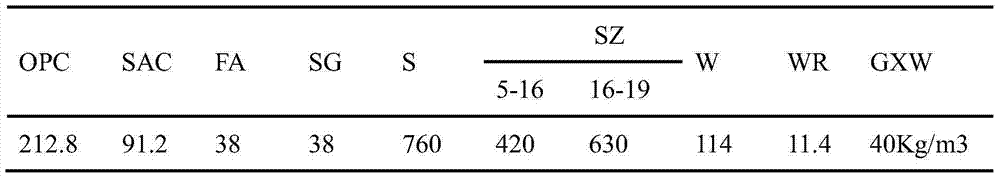

Steam-curing-free early-strength steel fiber concrete pipe segment and preparation method thereof

InactiveCN104773988AHarden fastSimplify maintenanceSolid waste managementFiberCALCIUM HYDROXIDE SOLUTION

The invention discloses a steam-curing-free early-strength steel fiber concrete pipe segment comprising ordinary Portland cement, early-strength sulphoaluminate cement, fly ash, slag, fine aggregate, coarse aggregate, water, a polycarboxylic acid type water reducer and end hook type steel fibers. The invention also discloses a preparation method of the steam-curing-free early-strength steel fiber concrete pipe segment. The steam-curing-free early-strength steel fiber concrete pipe segment is quick in coagulation and hardening and high in early strength, can reach the strength of 15MPa required by pipe segment demolding in 6-8 hours, and can be prepared into a concrete pipe segment for an underground structure by performing water curing in a 20 DEG C saturated calcium hydroxide solution for 24 hours and then performing natural curing for 28 days. The steam-curing-free early-strength steel fiber concrete pipe segment does not need steam curing, so that the curing mode of the pipe segment can be simplified, the curing time is shortened, a lot of manpower and resources are saved, and the popularization and application values are high.

Owner:SOUTHEAST UNIV +1

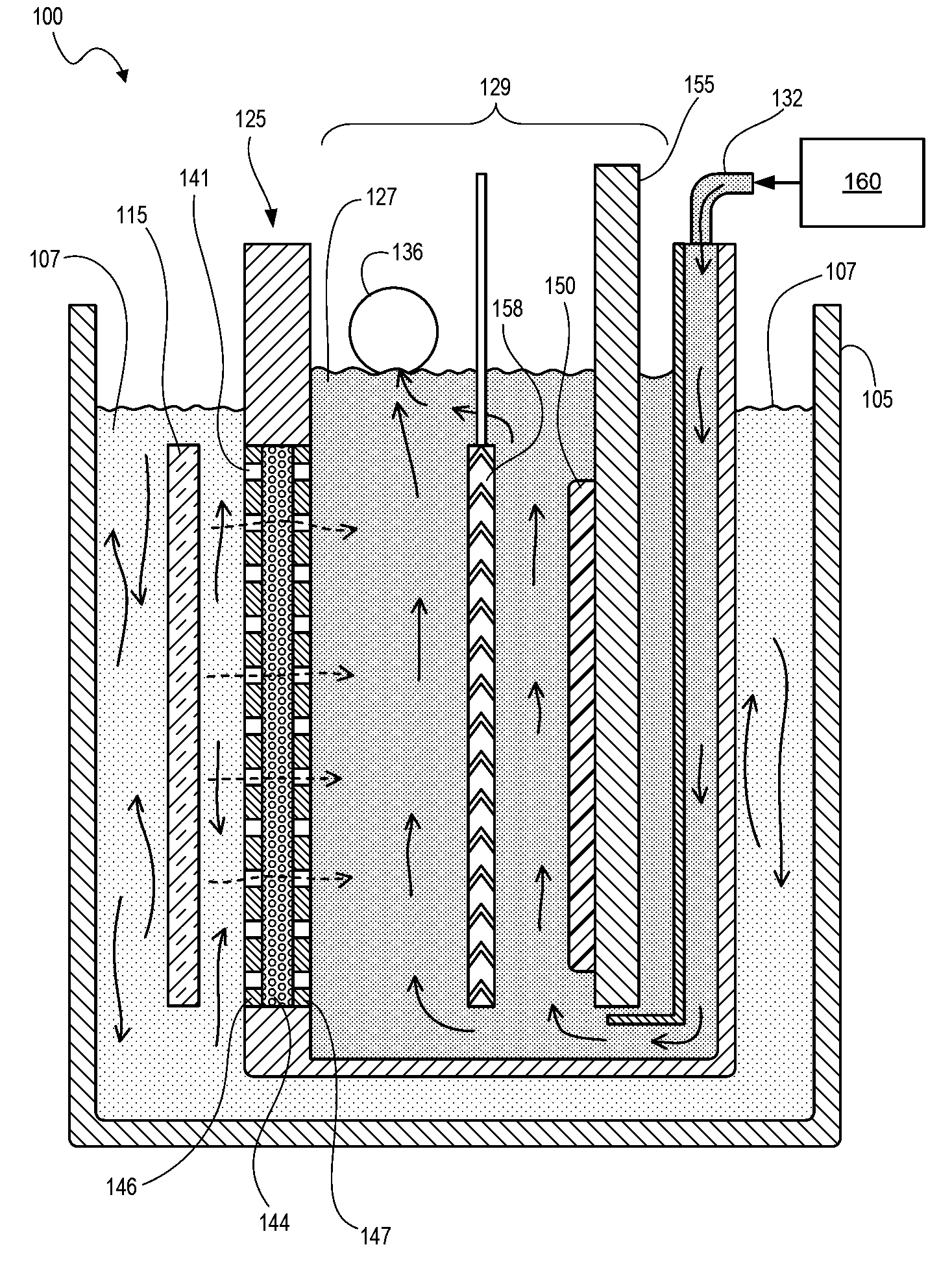

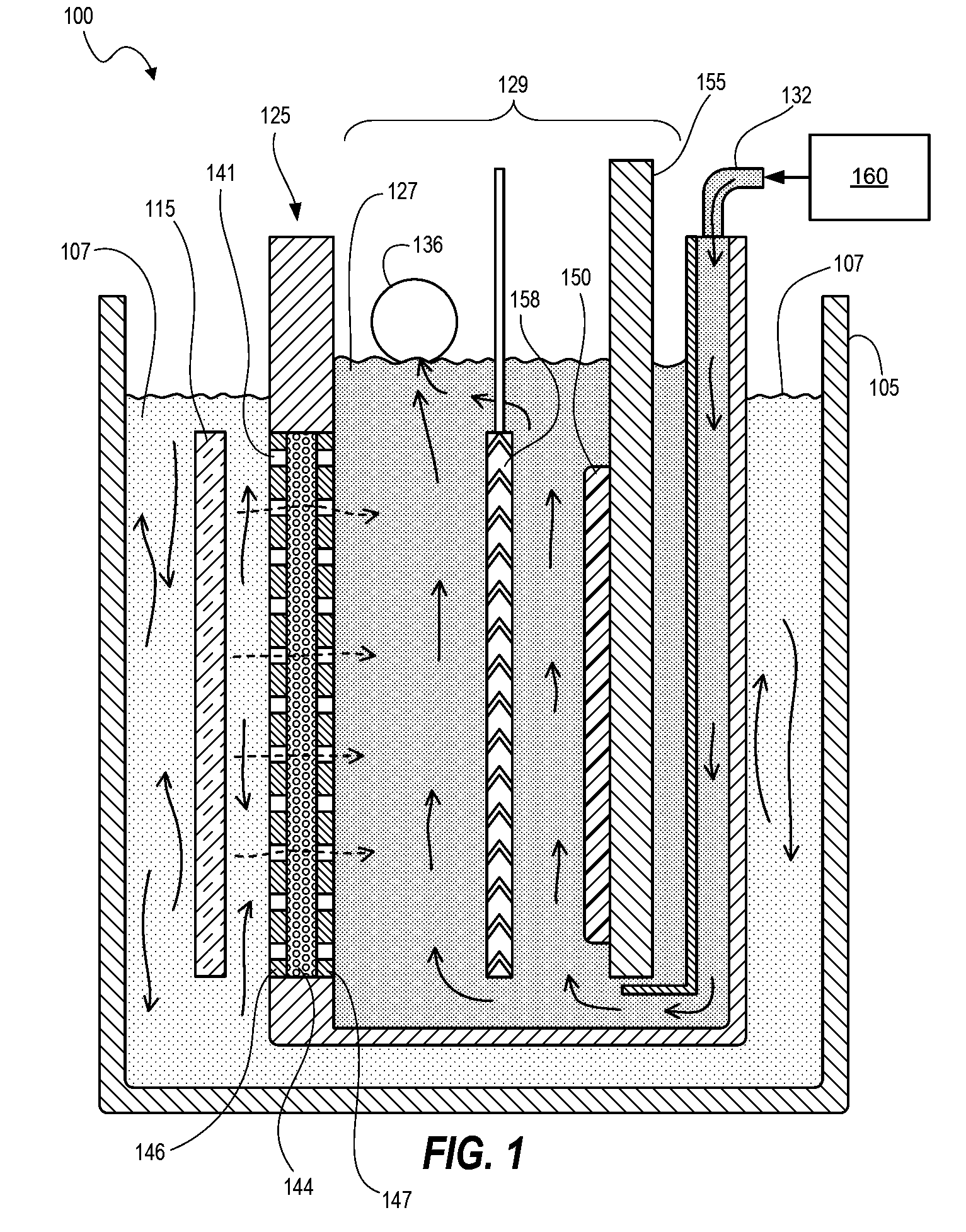

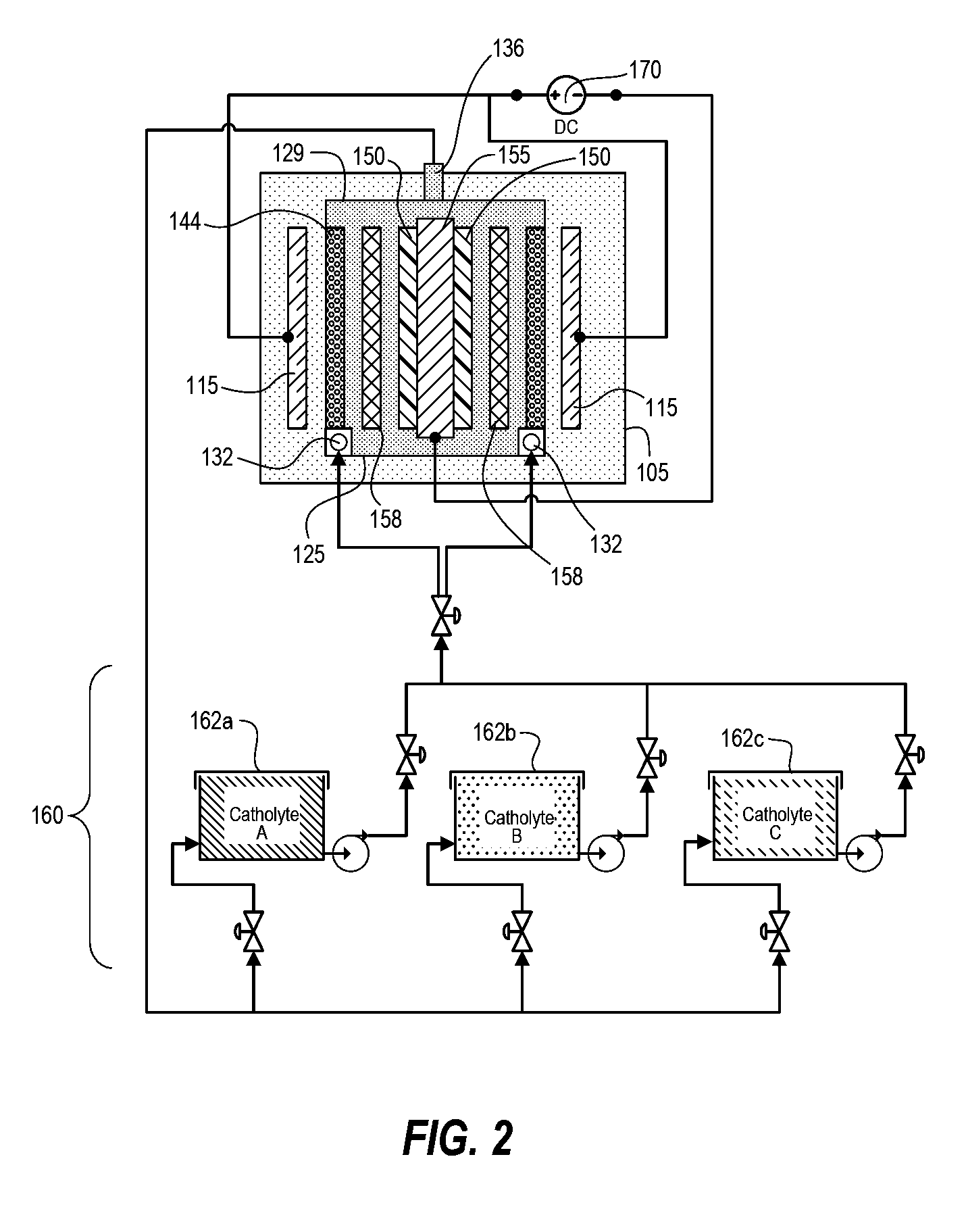

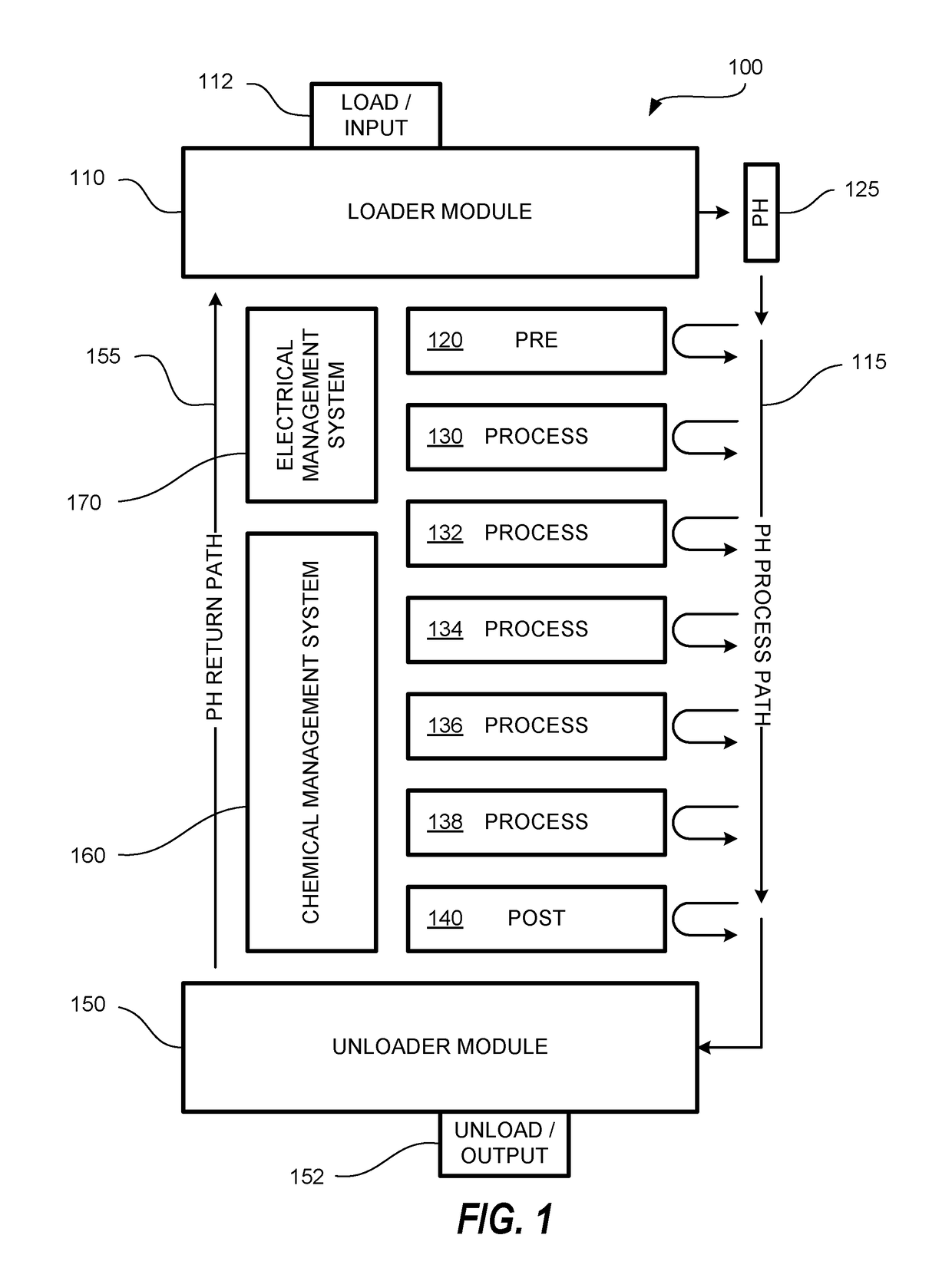

Electrochemical deposition apparatus with remote catholyte fluid management

ActiveUS20150129418A1Removal costRemove complexityCellsSemiconductor/solid-state device manufacturingFluid compartmentsElectrolytes fluids

Techniques disclosed herein include an electro-chemical deposition apparatus that provides an efficient circulation system, chemical management that provides reliable and uniform plating, and a configuration that provides short maintenance times and greater tool availability. Techniques include a processing tank containing an anolyte fluid, and one or more plating cells each having a catholyte fluid compartment with a circulation path that connects to a separate or remote catholyte reservoir. Thus, with such a configuration, a single pump can be used to flow catholyte (via manifolds) through one or more plating cells. Thus, with the catholyte reservoir maintained off board, instead of dumping catholyte over a weir into a reservoir, catholyte fluid—after flowing through a plating cell—is returned to the catholyte reservoir.

Owner:ASMPT NEXX INC

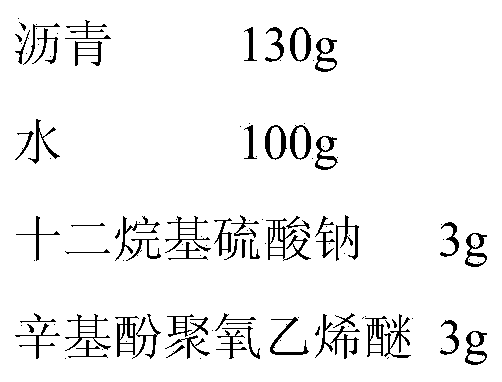

Waterborne polyurethane emulsified asphalt concrete as well as preparation method and application thereof

The invention discloses a waterborne polyurethane emulsified asphalt concrete which is prepared from the following raw materials: mineral aggregates, emulsified asphalt and waterborne polyurethane emulsion, wherein the weight ratio of the mineral aggregates, the emulsified asphalt and the waterborne polyurethane emulsion is 100:(1-20):(7-20). The invention also discloses a preparation method of the waterborne polyurethane emulsified asphalt concrete, and the preparation method comprises the following steps: mixing the waterborne polyurethane emulsion with the emulsified asphalt, and uniformly stirring, so that waterborne polyurethane modified emulsified asphalt is obtained; adding the waterborne polyurethane modified emulsified asphalt into the mineral aggregates, uniformly stirring, and carrying out maintenance on the obtained product; or uniformly stirring the mineral aggregates, the emulsified asphalt, and the waterborne polyurethane emulsion, and carrying out maintenance on the obtained product. The prepared waterborne polyurethane emulsified asphalt concrete not only has the advantages of cold-mixed asphaltic concrete, but also has excellent mechanical properties and stability; the waterborne polyurethane emulsified asphalt concrete is excellent in pavement performance, and can be used for greatly prolonging the service life of pavements; and the maintenance time is short, and the traffic can be implemented in 1-3 days, therefore, the waterborne polyurethane emulsified asphalt concrete can be applied to the preparation of asphalt concrete paving materials, asphalt pavement repair materials, slurry seals for maintenance and asphalt mortar for micro-surfacing and high-speed railways.

Owner:山东大山绿道工程科技有限公司

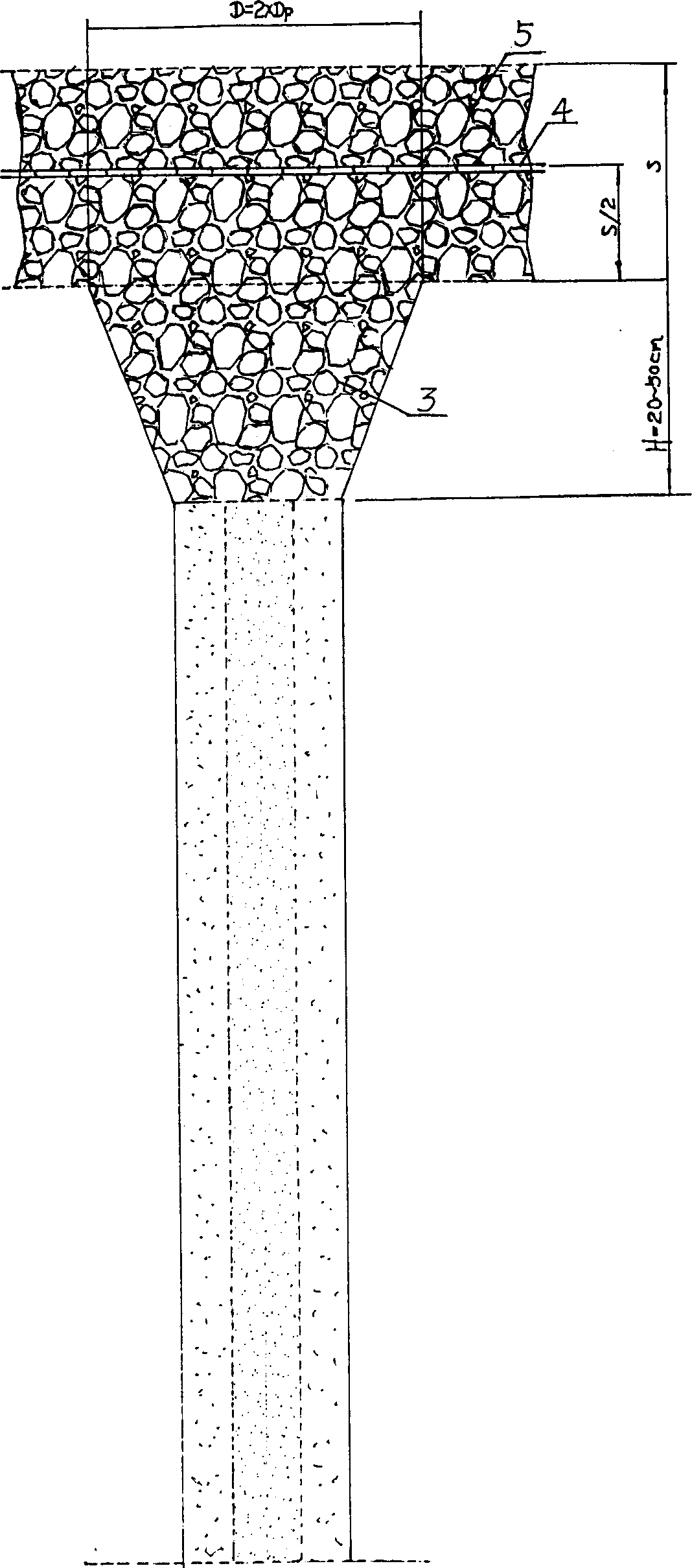

Novel method for reinforcing deep soft foundition-cencrete core sand stone pile compound foundition method

The invention relates to deep-thick soft foundation reinforcing new method-concrete core sand stone pile composite foundation. It is aimed at the current problem, and combines drainage consolidation method. It is used pre-form concrete pile as pile core to bear vertical load and transmit it to below solid ground. The medium coarse sand or brash chips are filled around to use as pile shell to increase core pile side surface friction resistance and vertical drainage. The pile body is laid with mattress layer to from new composite foundation. The method has the advantages of simple construction, fast pile forming speed, fast earth strength resuming, saving curing time and high strength. It can be applied to deep-thick soft earth foundation with high water and organic matter content, especially for irrigation works and traffic engineering.

Owner:南京水科院瑞迪科技集团有限公司

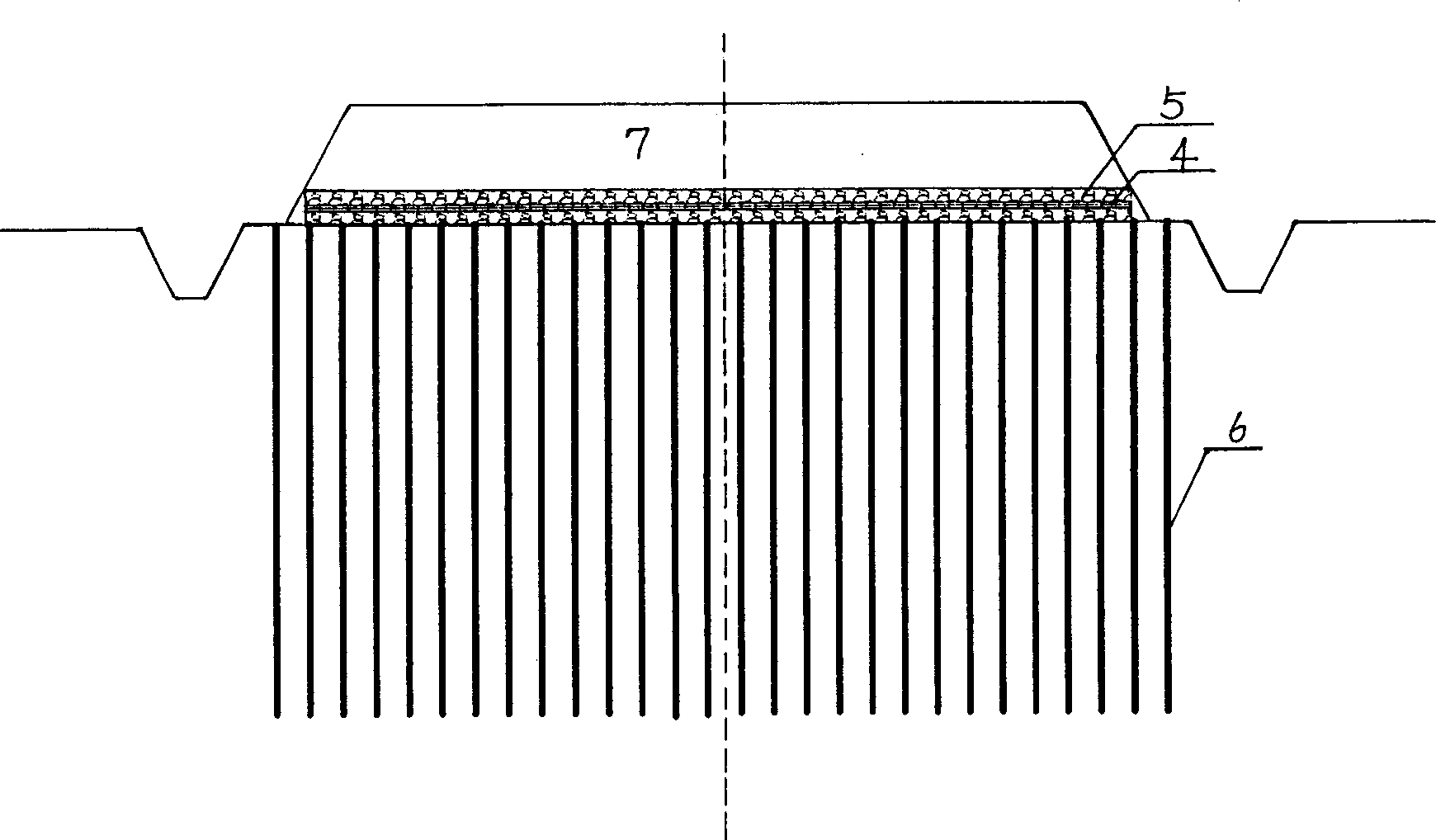

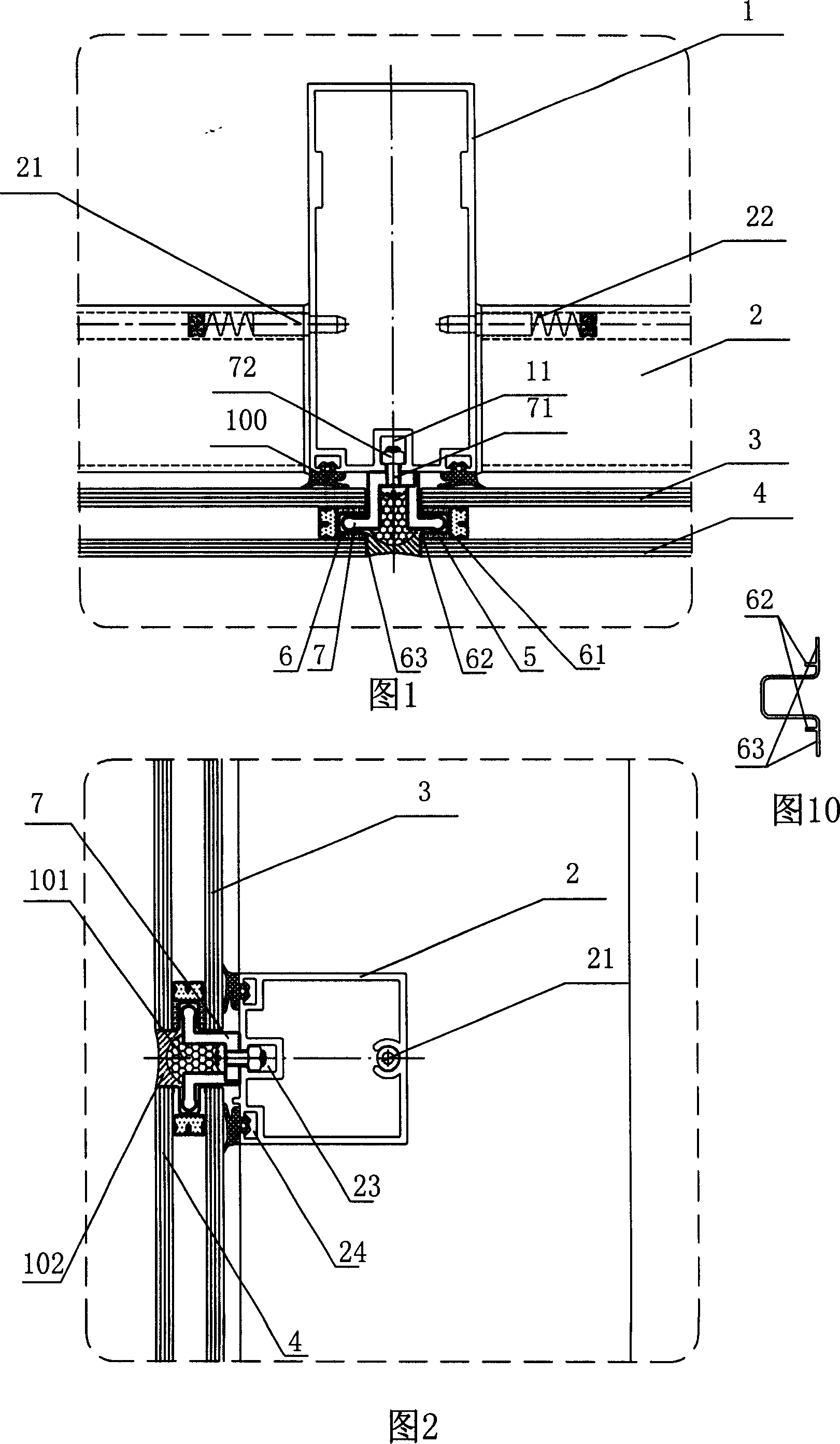

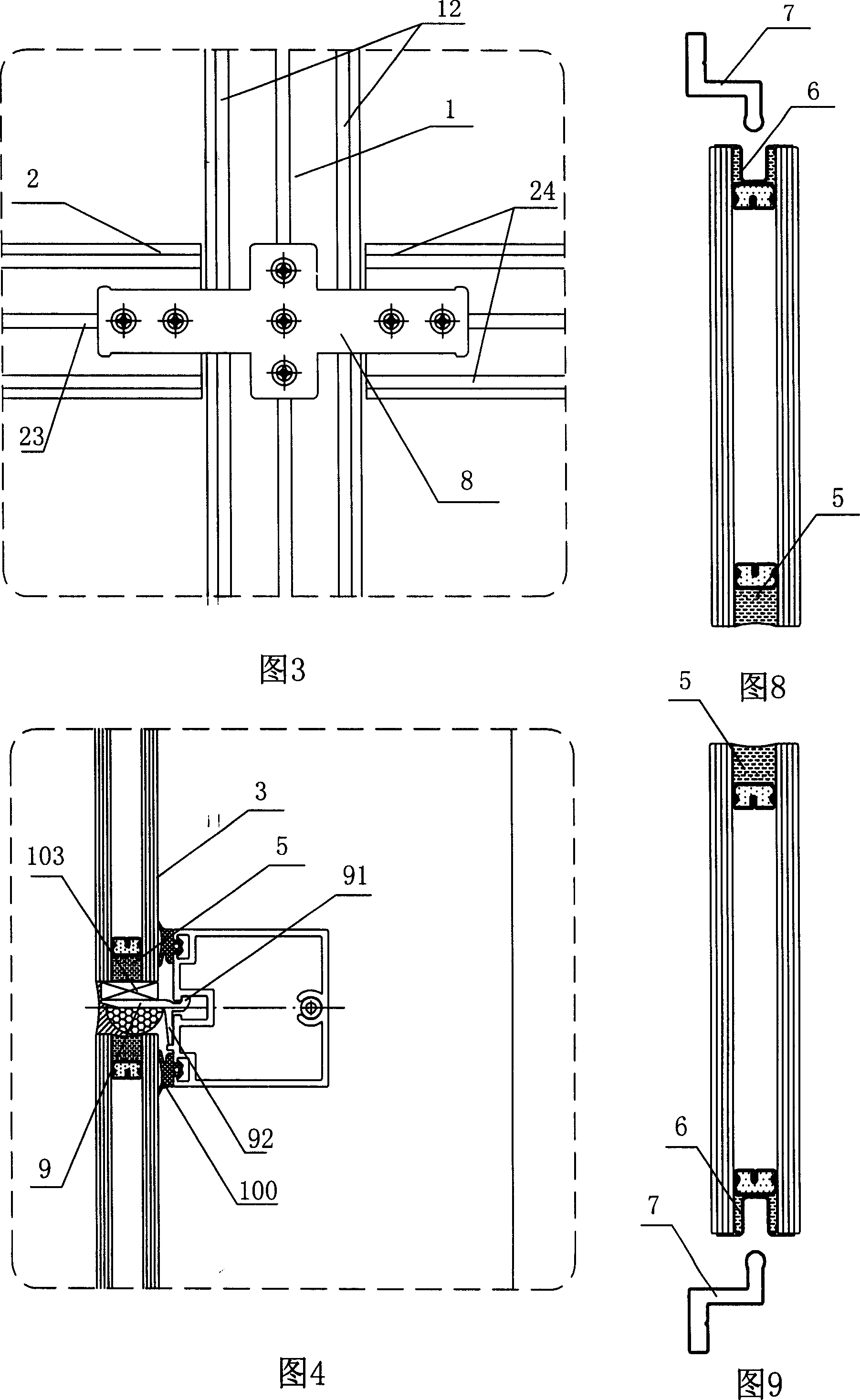

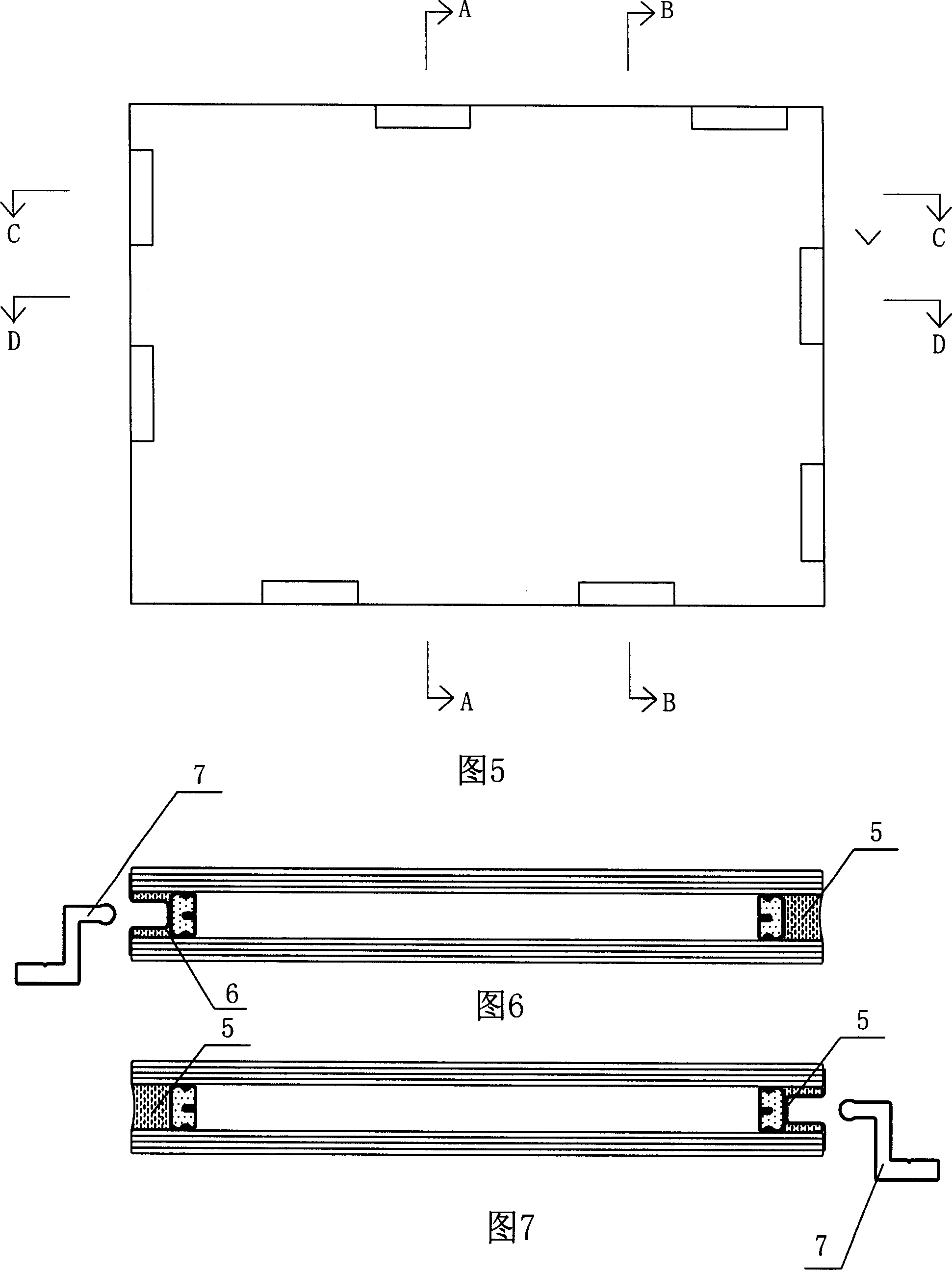

Hollow glass curtain wall with invisible frame and hollow glass plate for use in curtain wall

The invention provides a hidden framing hollow glass curtain wall, comprising upright pillar, cross beam and hollow glass block set on the upright pillar and cross beam. The hollow glass block contains inner glass plate and outer glass plate, round which there is structural glue used to connect inner and outer glass plates. There are inserting parts, whose length is far from less than the length of relative glass plate side, in the structural glue respectively. There are assembling slots in inserting parts and locating structure along the thickness direction of hollow glass plate. Connectors inserting into the assembling slots is set on said hidden framing hollow glass curtain wall and said connector is connected with upright pillar and cross beam. The invention changes the method that the glass of hidden framing glass curtain wall is formed to glass parts by structural glue necessarily and maintaining time for structural glue and relative machining procedure for structural glue and assistant frame is canceled so that unit cost is decreased largely. Construction process is quickened while quality danger generated by structural glue and assistant frame is reduced.

Owner:浙江中南幕墙科技股份有限公司

Secondarily-curable polyurethane modified epoxy asphalt mixture, preparation method therefor and application thereof

The present invention provides a secondarily-curable polyurethane modified epoxy asphalt mixture which is prepared by mixing 2-8 parts by mass of polyurethane modified epoxy asphalt with 92-98 parts by mass of mineral aggregates; the polyurethane modified epoxy asphalt consists of a component A, a component B, and a component C, wherein the component A is 100 parts of polyurethane modified epoxy resin; the component B consists of the following substances in parts by mass: 70-150 parts of a curing agent and 0-0.02 parts of an accelerator; and the component C is 50-200 parts of asphalt. The secondarily-curable polyurethane modified epoxy asphalt mixture provided by the present invention is suitable for paving a steel bridge deck and a cement concrete bridge deck and paving and repairing an asphalt pavement, and is used for special road sections such as an intersection and a bus stop.

Owner:中路交建(北京)工程材料技术有限公司

Composite fire-proof insulation board and preparation method thereof

InactiveCN102584130AReduce the ratioReduce production processCeramic shaping apparatusPolymer sciencePolystyrene

The invention discloses a composite fire-proof insulation board and a preparation method thereof. The composite fire-proof insulation board is prepared from the raw materials of 30-80kg of cement, 20-60kg of coal ash, 0.2-0.7m<3> of glazed hollow beads, 0.2-0.7m<3> of expandable polystyrene (EPS) particles, 0.2-1kg of methylcellulose and water, wherein, the weight of the water accounts for 50% of the weight of the raw materials. The composite fire-proof insulation board provided by the invention is characterized by short curing time and high early strength.

Owner:NANJING TIANYA NEW MATERIALS

Waterborne two-component quick-drying polymer cement waterproof mortar

The invention discloses a waterborne two-component quick-drying polymer cement waterproof mortar. The waterborne two-component quick-drying polymer cement waterproof mortar includes a powder materialand a liquid material, wherein the powder material is composed of the following components by mass percent: 35%-55% of Portland cement, 3%-12% of sulfur aluminum cement, 5%-25% of active filler, 25%-50% of ordinary filler, 0.2%-1.5% of anti-cracking fiber, and 0.1%-1.5% of an assistant; and the liquid material is composed of the following components by mass percent: 30%-50% of a polymer emulsion,0.1%-2% of an assistant, and the balance water; and the powder material and liquid material are mixed in a ratio of 2.5-4:1. Compared with the prior art, the invention realizes one-time thick coatingof polymer cement waterproof mortar, which can dry quickly, does not crack, and has good impermeability. The construction and maintenance time can be shortened to 4h, and the construction period is greatly shortened. The waterborne two-component quick-drying polymer cement waterproof mortar provided by the invention has the characteristics of high bonding strength, good resistance to water and alkali, and good weatherability, can be directly applied to construction on base planes without open water, and can be widely applied to basement, kitchen, toilet, bathroom, swimming pool, balcony, garden waterscape, interior and exterior wall integral waterproofing and seepage prevention, and other waterproofing projects.

Owner:KESHUN WATERPROOF TECH CO LTD

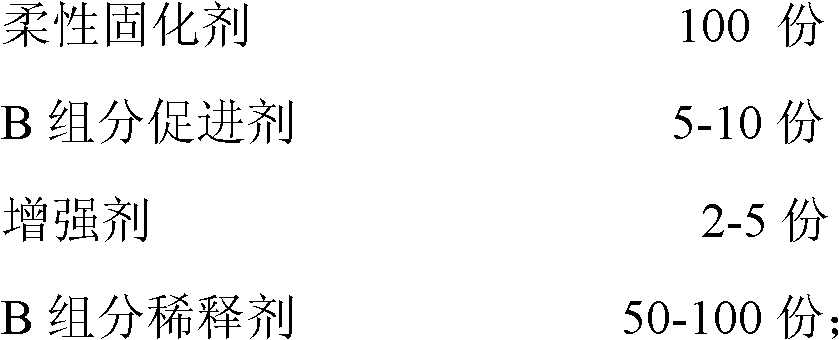

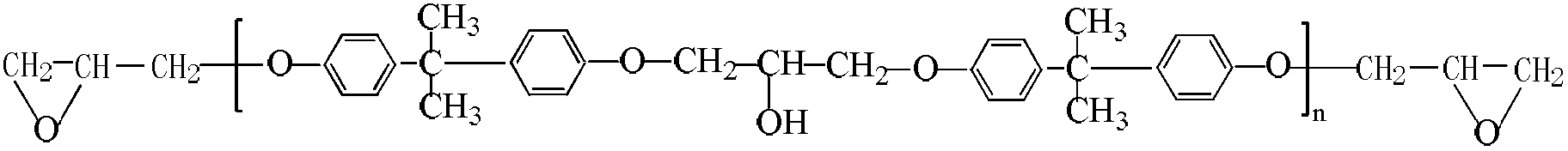

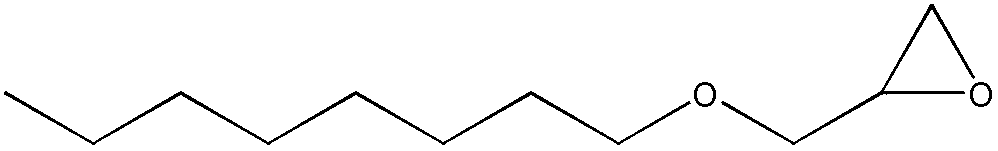

Cold mixed epoxy resin material and preparation method thereof

The invention relates to a cold mixed epoxy resin material, which comprises components A and B, wherein the component A mainly consists of epoxy resin and a reactive diluent, and the component B mainly consists of a flexible curing agent, an accelerating agent, a defoamer, a thinner, a thixotropic agent and a toughening agent; and the mass ratio of component A to component B is (100:200)-(100:350), and the components are mixed with an aggregate and mineral powder to obtain a cold mixed epoxy resin mixture, wherein the mass ratio of the sum of components A and B to component C is (6:94)-(7:93). The cold mixed epoxy resin material has excellent mechanical property, temperature resistance, water resistance, solvent resistance and fatigue resistance, and in addition also has the characteristics of being environment-friendly, low-carbon, simple in construction process, and short in curing time. The cold mixed epoxy resin material is mainly applicable to patching of epoxy asphalt road surfaces, and at the same time is also applicable to paving of road surfaces of high-grade highways, tunnels, airfield runways, cement concrete bridge floors and the like. The invention discloses a preparation method of the cold mixed epoxy resin material.

Owner:NANJING UNIV

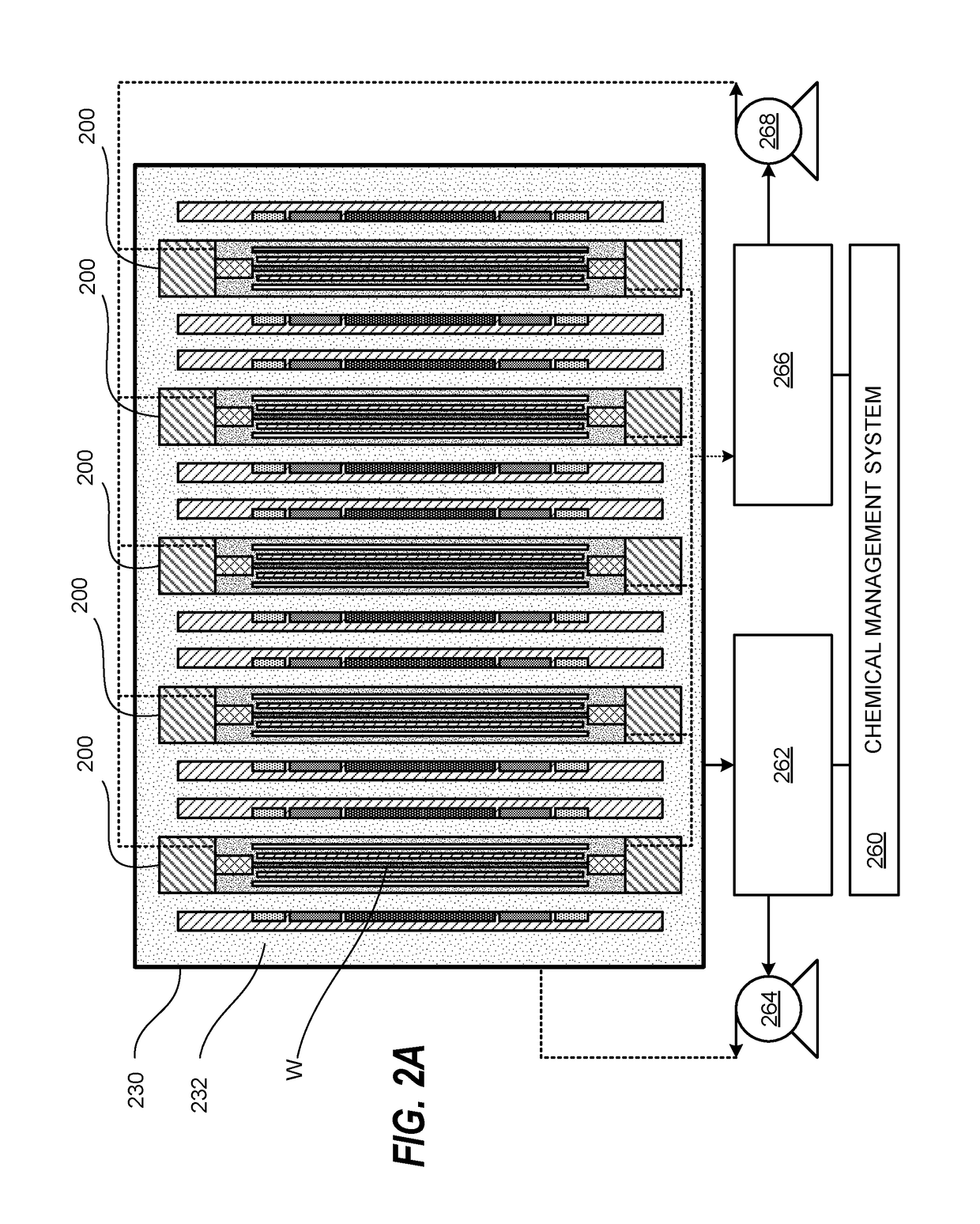

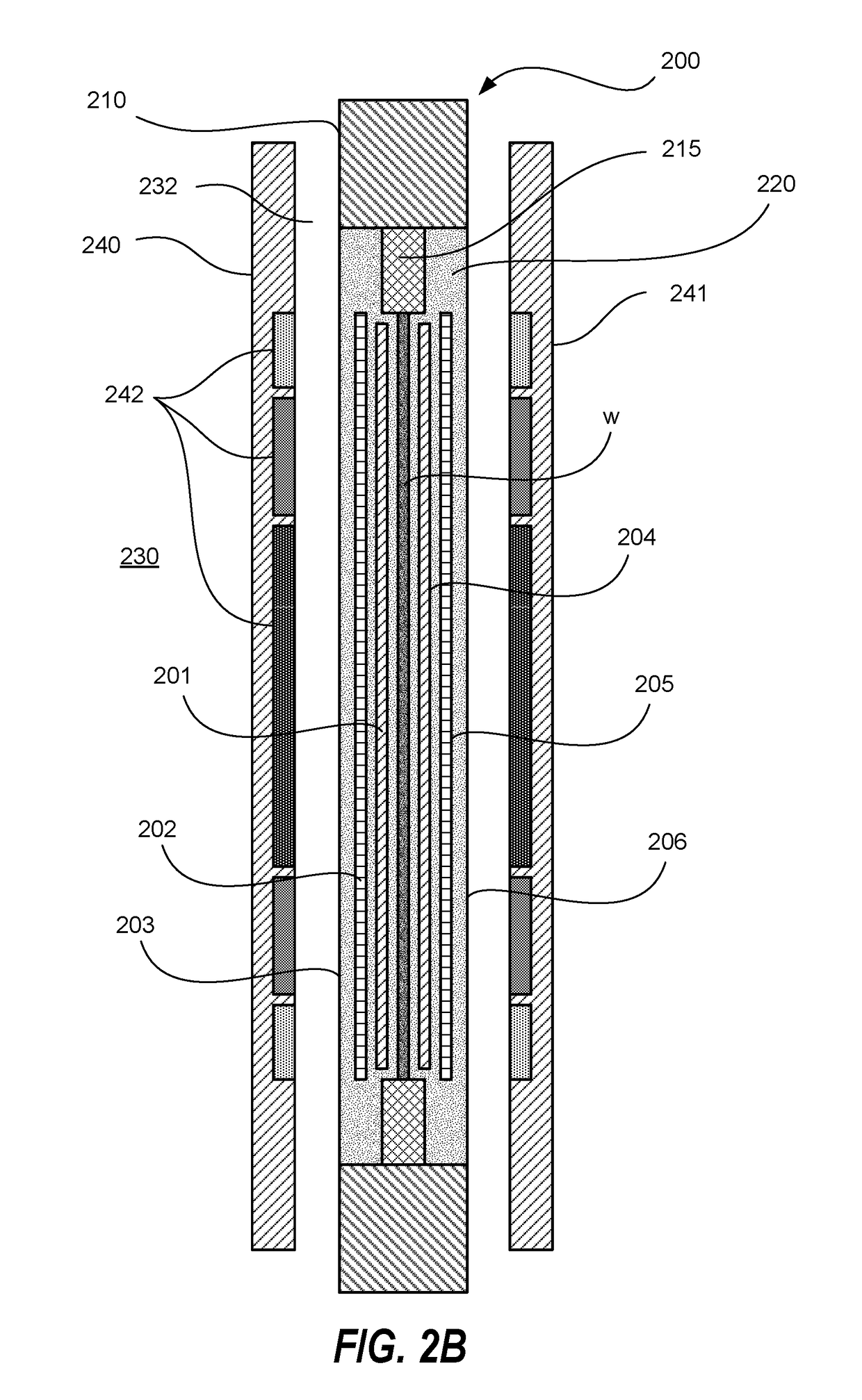

Wet processing system and method of operating

An electrochemical deposition system having two or more electrochemical deposition modules arranged on a common platform and configured for depositing one or more metals on a substrate is described. Each electrochemical deposition module includes an anode compartment configured to contain a volume of anolyte fluid, a cathode compartment configured to contain a volume of catholyte fluid, and a membrane separating the anode compartment from the cathode compartment. Each electrochemical deposition module further includes a workpiece holder configured to hold opposing edges of a flexible workpiece between first and second leg members via a clamping mechanism, and a loader module configured to position the flexible workpiece in the workpiece holder while holding the flexible workpiece using an air cushion on each opposing planar surface of the flexible workpiece.

Owner:TEL NEXX INC

Construction process for repairing concrete ground

InactiveCN102261034AStable structureNot easy to damageRoads maintainenceHigh intensityMaterial resources

The invention relates to a ground repairing technology and discloses a construction process for repairing concrete ground. The construction process for repairing the concrete ground comprises the following steps of: selecting the concrete ground, planing a deterioration layer, removing dust, cleaning and moistening by the use of water, mixing a high-strength non-shrinkage grouting material and water which accounts for 10-15% of the total weight with stirring to obtain a slurry, pouring the slurry into ground defect positions to repair and smoothen the ground, flattening the ground after solidification, pouring the slurry onto the surface of the whole concrete substrate to form a layer of 0.3cm-3cm thick, naturally drying for 10-14 hours, covering the layer with a maintenance pad, watering, followed by wet curing for several days, and removing the maintenance pad to finish the construction process. According to the technical scheme provided by the invention, apart from the full consideration of concrete ground situation and the impact of external environment such as temperature, climate and the like during the construction process, the high-strength non-shrinkage grouting material with high strength and good viscosity is used such that the repaired ground has a high hardening strength and is not easy to crush and damage, and manpower and material resources are saved.

Owner:张学

Method for source modification treatment of fluoro-gypsum

The invention discloses a method for source modification treatment of fluoro-gypsum which comprises the steps of, (1) raw material selection, charging composite active triggering agent and alkaline material into the fluoro-gypsum, wherein the mass fraction of each components are, fluoro-gypsum 93-97, composite active triggering agent 1-2, alkaline material 2-5, (2) agitating and mixing, transferring to rainproof yard, stewing, (3) stacking, trickling and maintaining. The modified fluoro-gypsum is applied to cement production.

Owner:WUHAN UNIV OF TECH

Quick-setting early-strength geopolymer grouting material and preparation method of same

The invention discloses a quick-setting early-strength geopolymer grouting material and a preparation method of same. The grouting material includes, by mass, 40-100 parts of a framework material, 0-20 parts of a doping framework material, 5-10 parts of an alkali activator, and 0.5-10 parts of a chemical additive. The grouting material has good durability, excellent groutability and short maintenance time, and is simple in preparation method.

Owner:CHANGAN UNIV

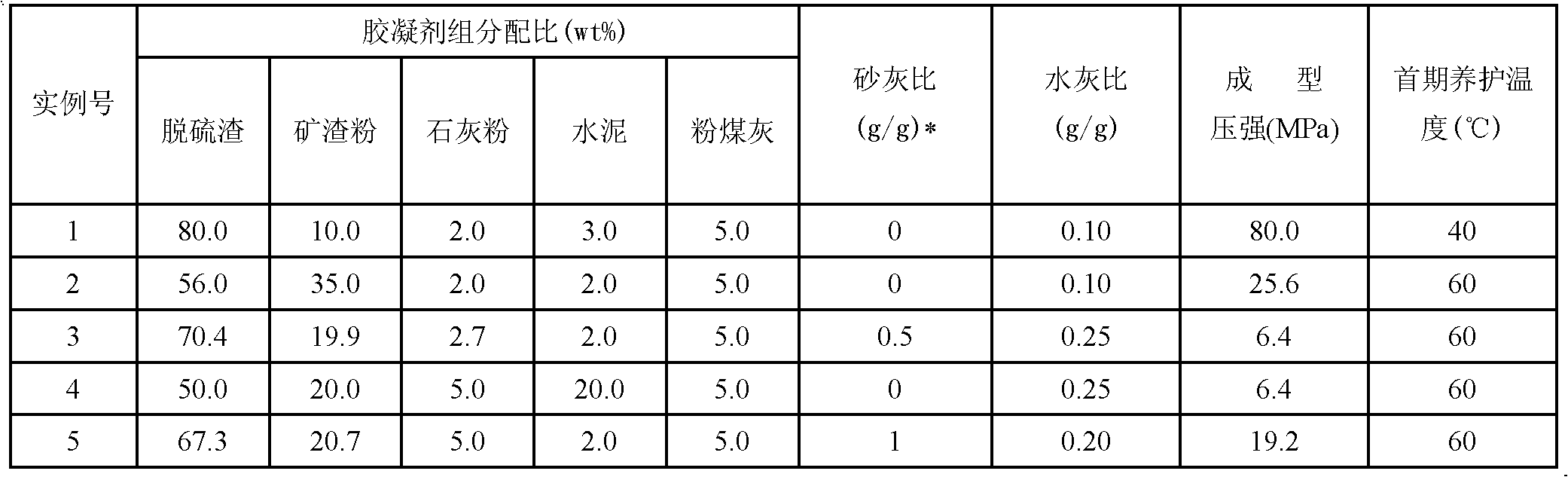

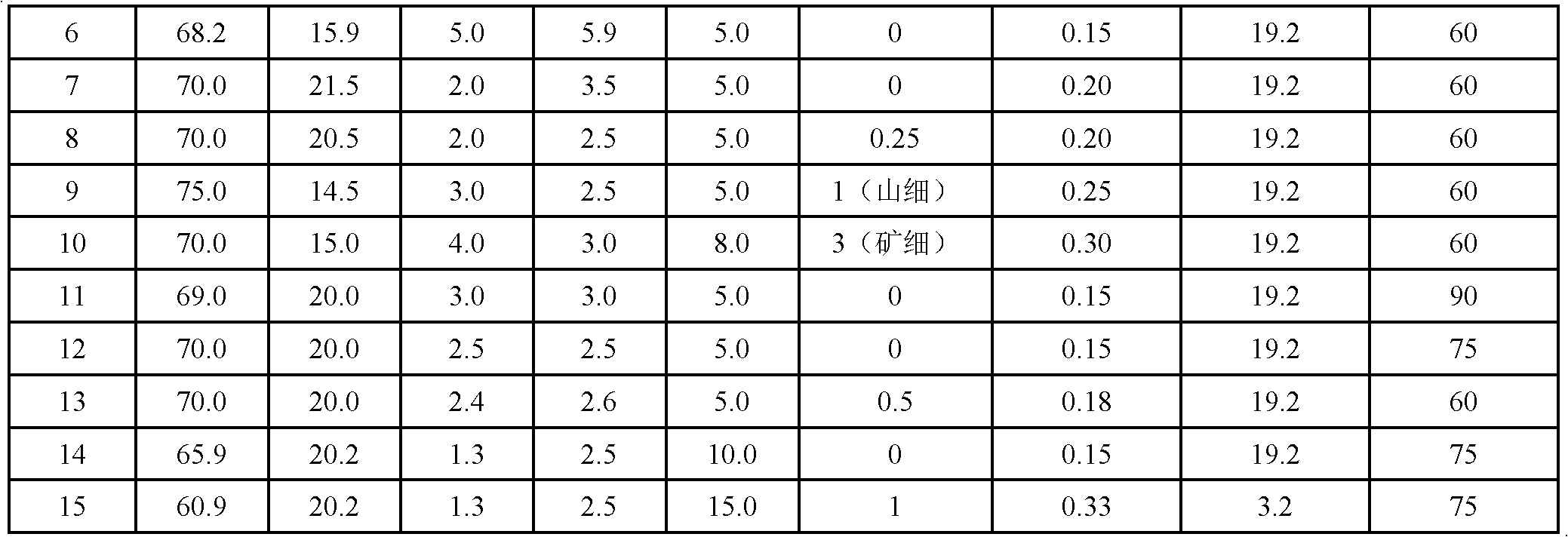

Method of preparing baking-free load-bearing bricks through steam curing of semidry desulfurization residues

The invention discloses a method of preparing baking-free load-bearing bricks through steam curing of semidry desulfurization residues, belonging to the technical fields of environmental engineering and preparation of construction material. According to the invention, a gelling agent is prepared from semidry desulfurization slag and multi-component powder and is uniformly mixed with inert sandy aggregate in a mixer, water accounting for 10 to 46% of the mass of solid powder is added and uniformly mixed with the solid powder, an obtained mixture undergoes pressure forming and demolding so as to obtain green bricks, and the green bricks are subjected to steam curing at a temperature of 40 to 90 DEG C for 1 to 7 d so as to obtain baking-free bricks with sufficient strength; the baking-free bricks can meet different strength requirements for load-bearing bricks of a model number in a range of MU10 to MU30, have excellent water resistance and can be used as exterior wall tiles. According to the invention, the problem that comprehensive utilization of semidry desulfurization gypsum is not easy due to complex composition of the semidry desulfurization gypsum is overcome; effective usage of solid waste in production of the baking-free bricks which cost less than conventional sintered clay bricks do has great significance to energy conservation and environmental protection.

Owner:HUNAN UNIV OF SCI & TECH

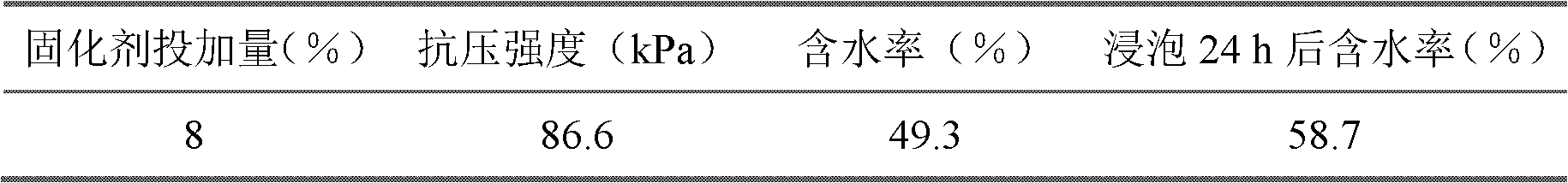

A treatment method for dewatered sludge in a domestic sewage treatment plant

InactiveCN102276128AHigh activityShort curing timeSludge treatment by de-watering/drying/thickeningSewageSewage treatment

The invention relates to a treatment method of dehydrated sludge in a domestic sewage treatment plant. The treatment method comprises the following steps: evenly mixing limestone, magnesia and bauxite which are weighed in a ratio of (40%-60%):(20%-30%):(20%-30%) by weight percent and then firing for 1-2 hours at the temperature of 900 DEG C-1200 DEG C so as to obtain a sludge solidifying agent; adding the sludge solidifying agent in the dehydrated sludge in the ratio of dehydrated sludge to sludge solidifying agent of (90%-95%):(5%-10%) by weight percent, and then stirring; after evenly mixing, paving the mixture obtained in the former step to the thickness of 20-30 cm in the open air, and placing for 48 hours so as to obtain a sludge solidifying body; and finally, performing landfill treatment. According to the invention, the solidifying time is short, and the adding amount of the sludge solidifying agent is less; by using the treatment method, sludge can be modified, and the stabilization of sludge is promoted; the bulking of the sludge solidifying body is small, the stability and mechanical strength of the sludge solidifying body are high, and secondary pollution can not be caused; and the solidifying technological process is simple and convenient for operation, and the investment and treatment costs are low, thus the treatment method in the invention can be widely applied to stabilization, reduction and innocent treatments of dehydrated sludge in a sewage plant.

Owner:SHANGHAI TONGJI CONSTR CO LTD

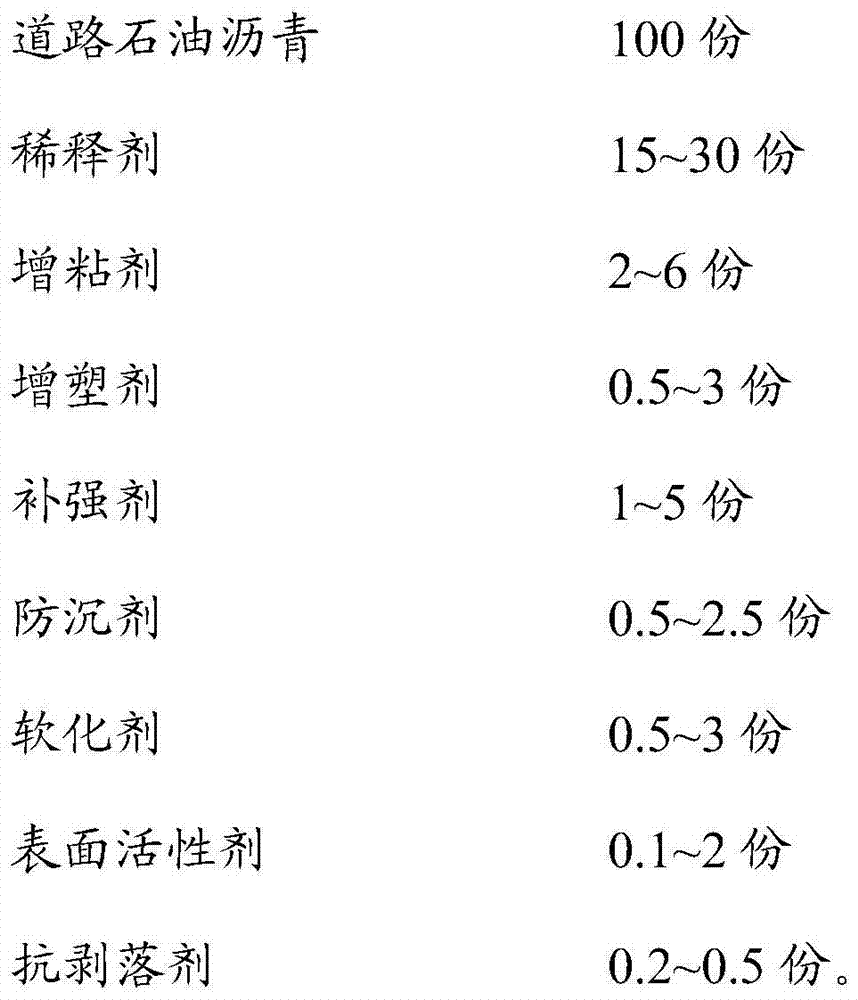

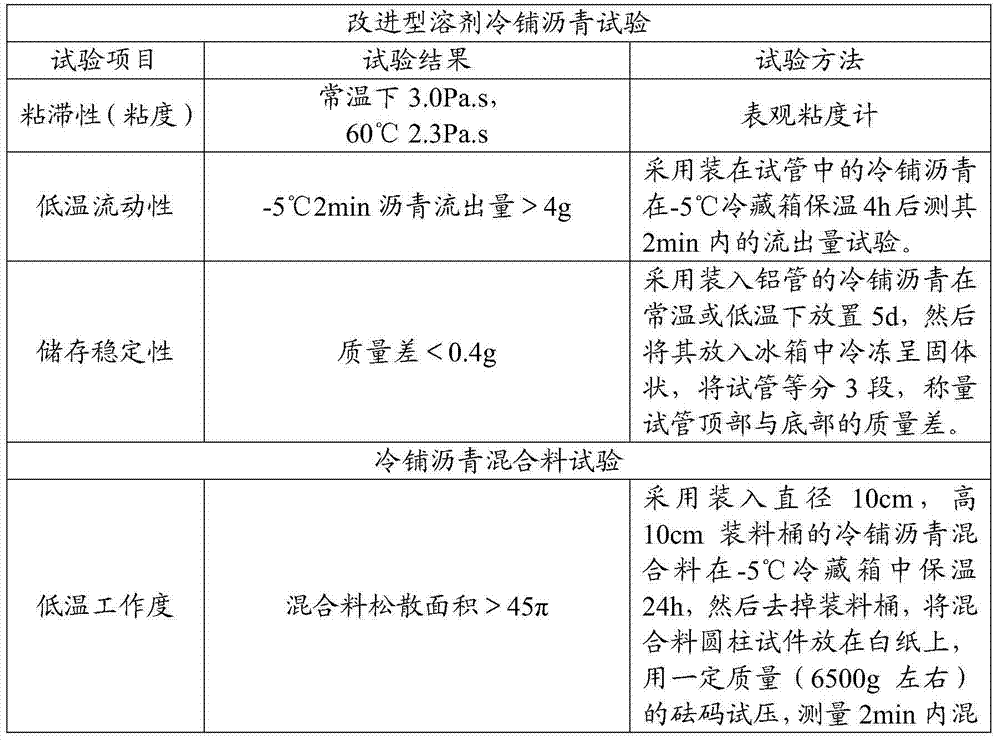

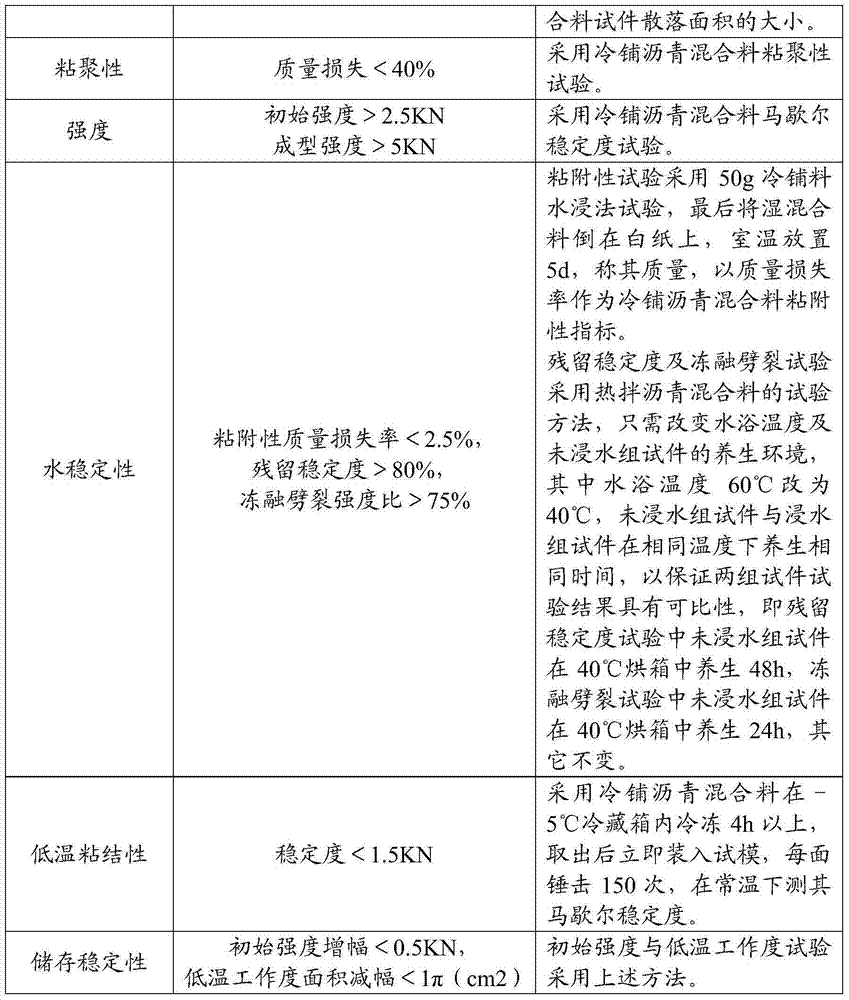

Improved solvent cold laid asphalt as well as preparation process and using method thereof

InactiveCN103923475AImprove adhesionImprove liquidityIn situ pavingsBuilding insulationsLiquid stateEngineering

The invention discloses an improved solvent cold laid asphalt as well as a preparation process and using method thereof. The improved solvent cold laid asphalt is at a liquid state under normal temperature or low temperature; cold oil and cold materials can be directly blended for construction on the spot without heating, and the construction can be carried out at high / low temperature seasons and rain / snow weather, and a large number of machinery and labor are not required in the construction process, the construction is simple and convenient and the repair effect is good; traffic can be immediately opened after repair without affecting the travel of people; the improved solvent cold laid asphalt is usually used for daily maintenance, such as pot slot repair and emergency repair; meanwhile, the improved solvent cold laid asphalt has the advantages of no deterioration, no layering and the like after being stored for a long time.

Owner:CHANGAN UNIV

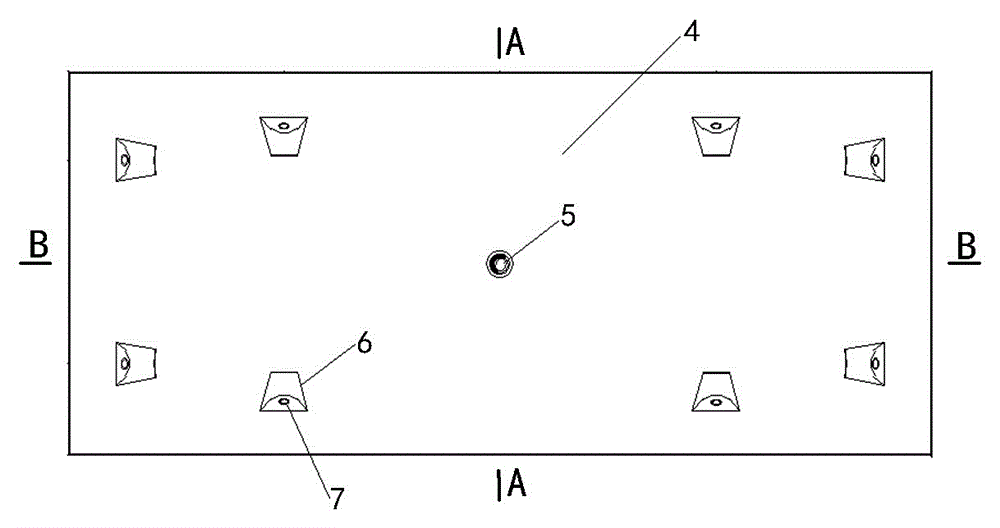

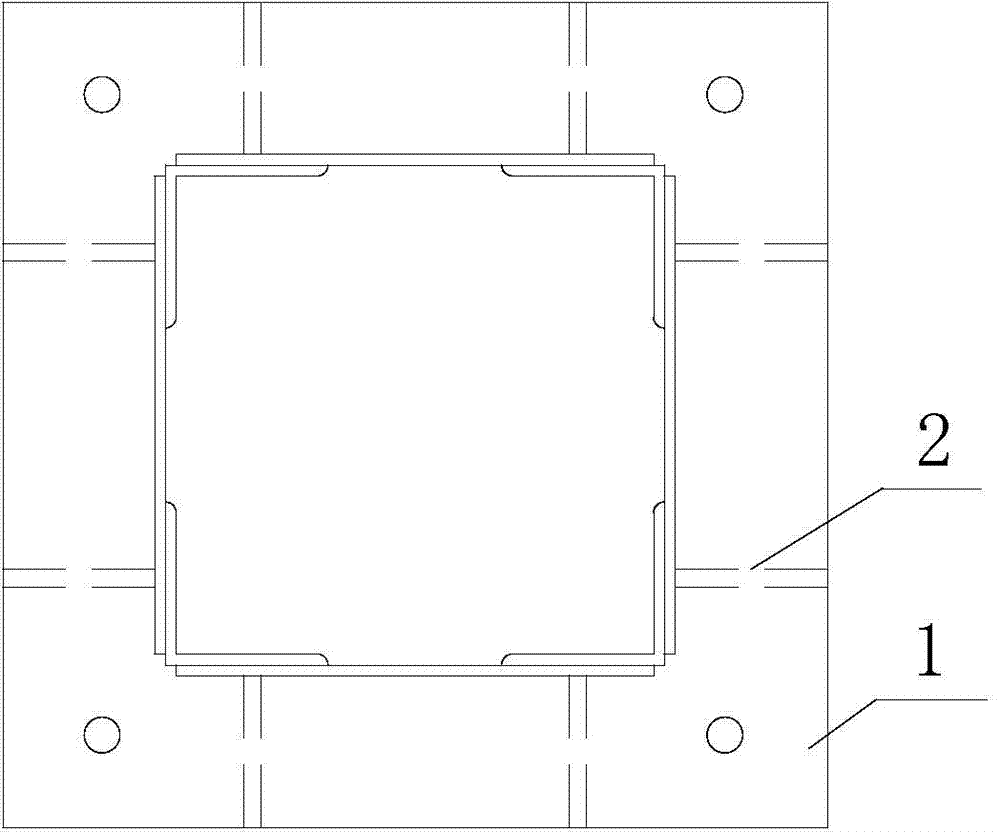

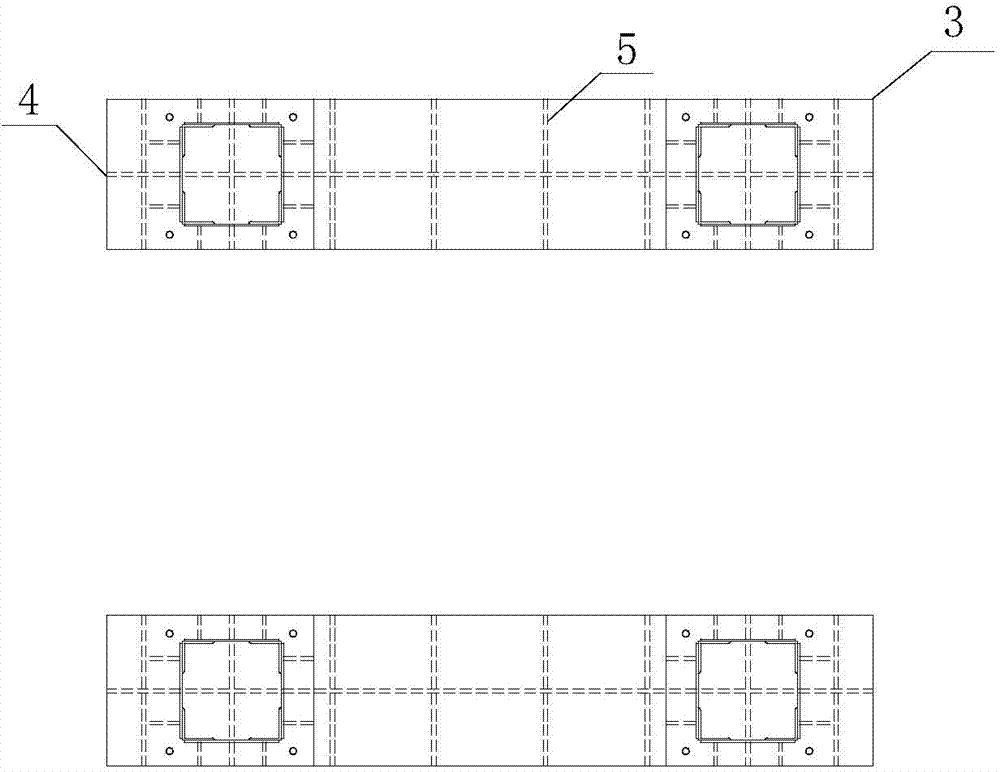

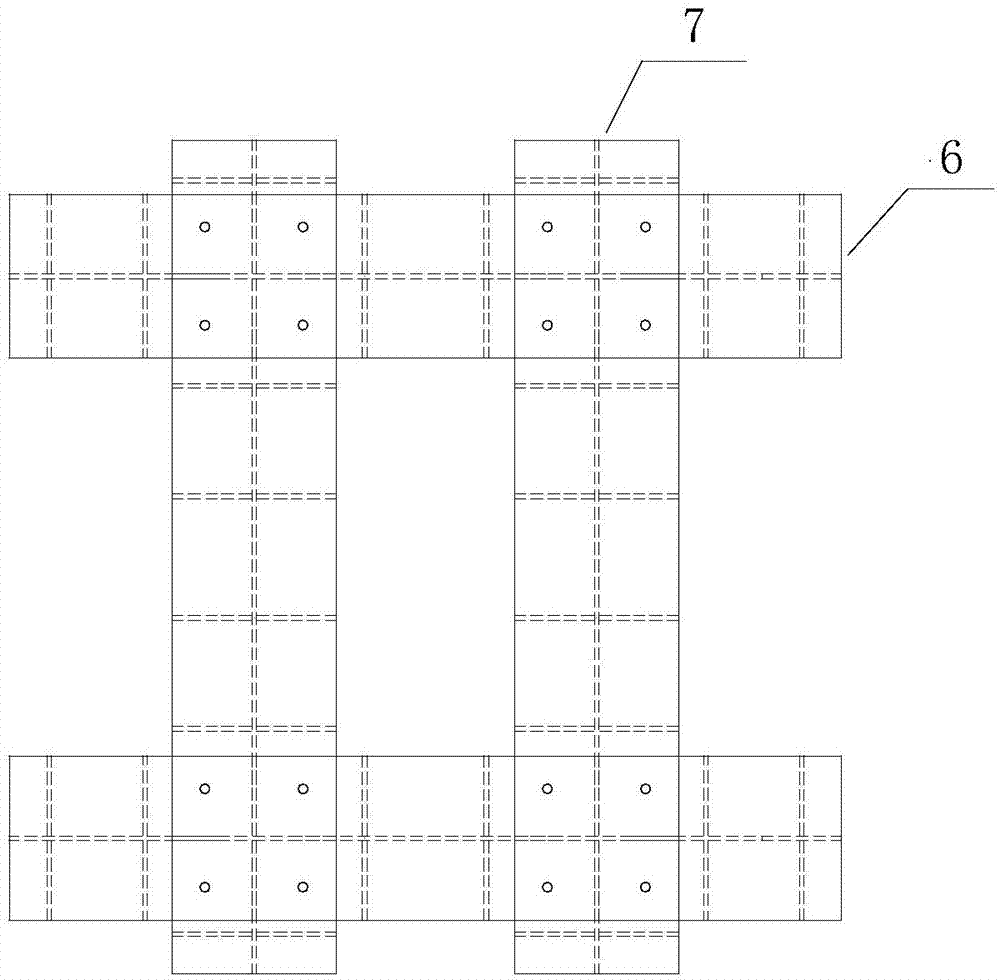

Steel platform tower crane foundation and construction method thereof

ActiveCN103485360AHigh precisionShort maintenance timeFoundation engineeringArchitectural engineeringTower crane

The invention discloses a steel platform tower crane foundation and a construction method thereof. The steel platform tower crane foundation comprises bored piles, steel latticework columns and a steel bearing platform. The steel latticework columns are fixed on the bored piles, and the steel bearing platform comprises four steel beams, wherein two of the four steel beams are lower steel beams, and the other two steel beams are upper steel beams. The upper steel beams are fixed on the lower steel beams to form a #-shaped structure, the lower steel beams are fixed on the steel latticework columns, and a tower crane is fixed on the upper steel beams. The steel platform tower crane foundation has the advantages that the tower crane foundation steel beams are machined in a factory, preformed bolt holes are drilled in a lofting mode according to the sizes of tower crane standard section bolts, and accuracy of the bolt holes is high; on-site assembling and disassembling are convenient, the tower crane can be installed as long as the foundation is installed, and maintenance time of concrete is eliminated; in the foundation disassembling process, only the bots need to be detached for hoisting, concrete does not need to be crushed, and disassembling is convenient; disassembled steel beams can be repeatedly used, and construction cost is saved.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

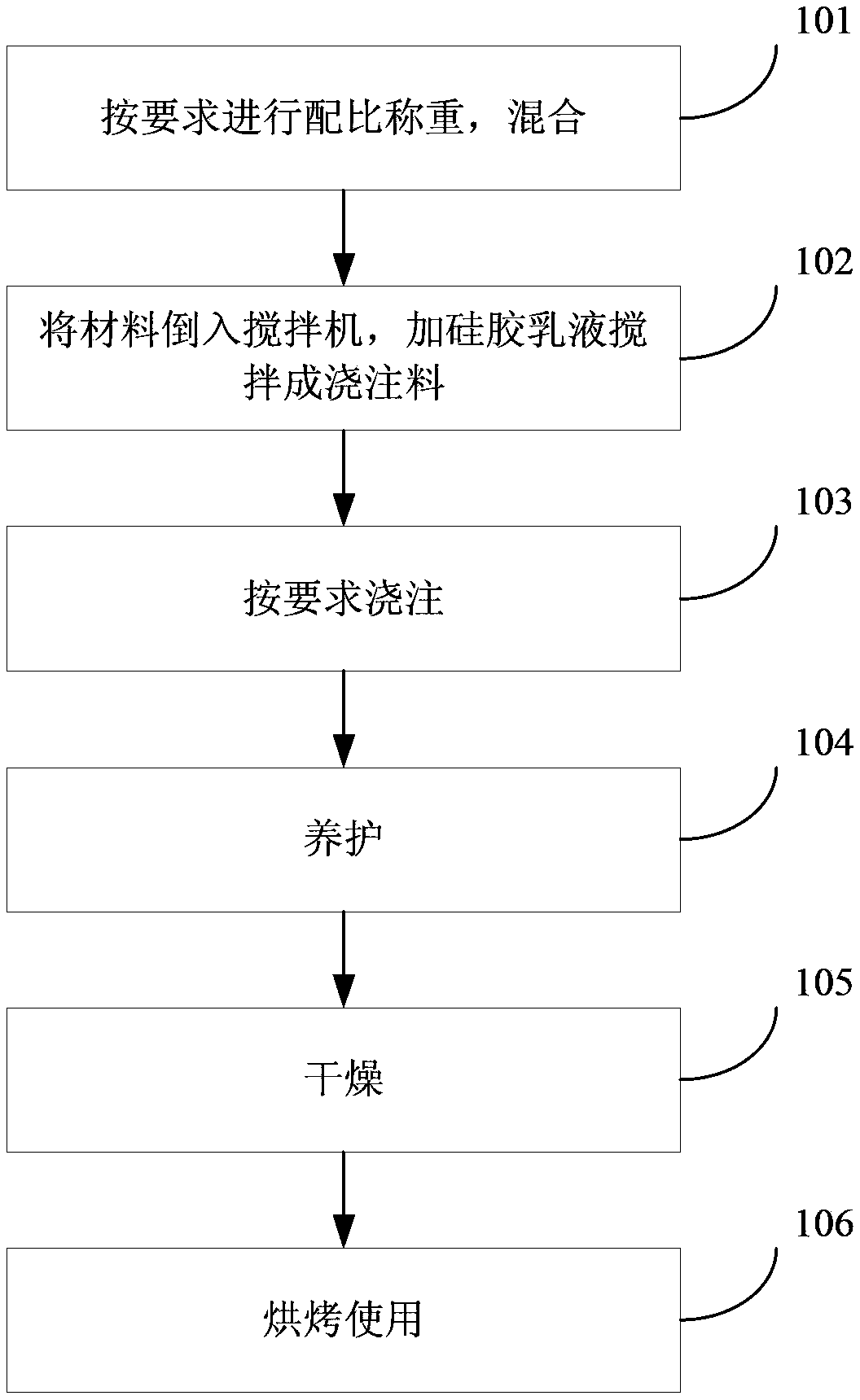

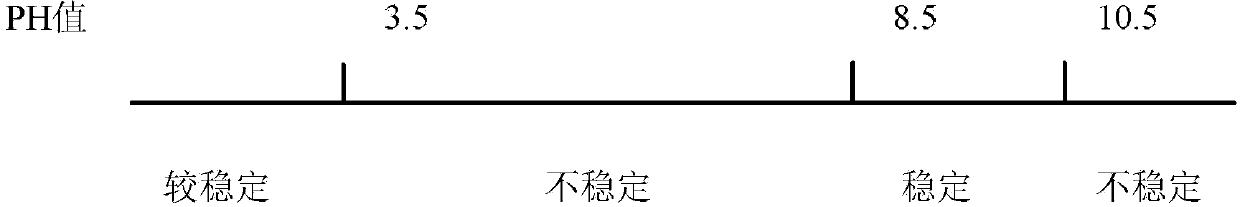

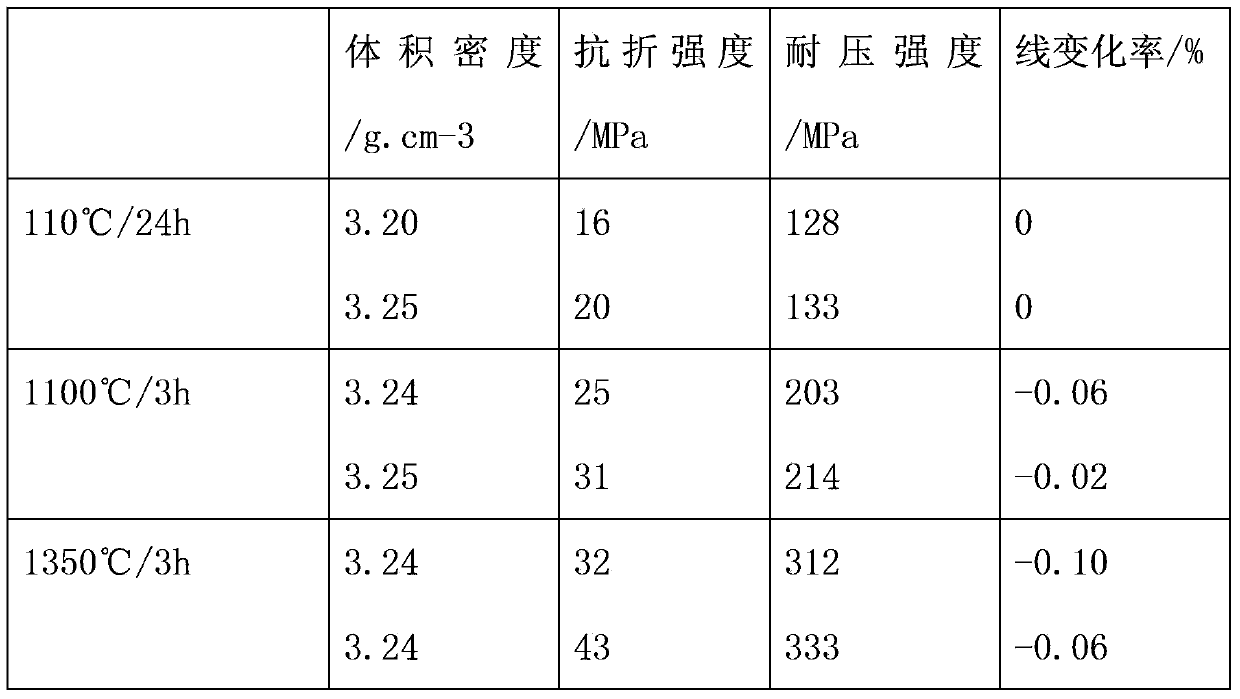

Refractory castable and using method thereof

The invention discloses a refractory castable and a using method thereof. The refractory castable is prepared by taking silica gel / sol as a binding agent and tartaric acid as an accelerating agent and adopting corundum, activated alumina micro powder, 96% of silicon oxide micro powder, pure calcium aluminate cement, steel fibers and an additive. The refractory castable has the characteristics of good flowability, stable curing, shorter curing time, high demoulding, medium temperature and high temperature strength, good thermal shock resistance and the like, and is an excellent refractory material required by thermal equipment in the industries such as metallurgy, machinery, electricity, petrochemistry and construction and by high temperature kilns.

Owner:ANHUI RUITAI NEW MATERIALS TECH

Low-shrinkage creep wet joint ultrahigh-strength concrete material and preparation method thereof

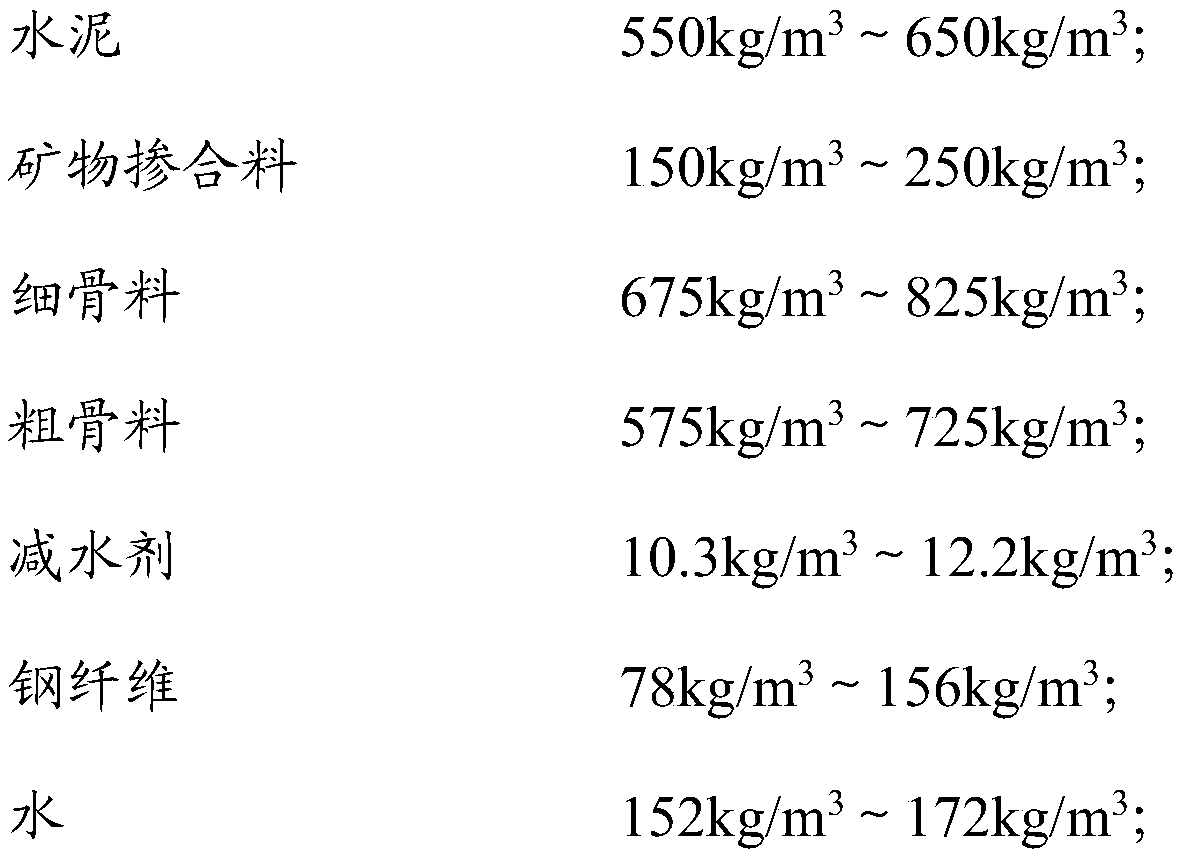

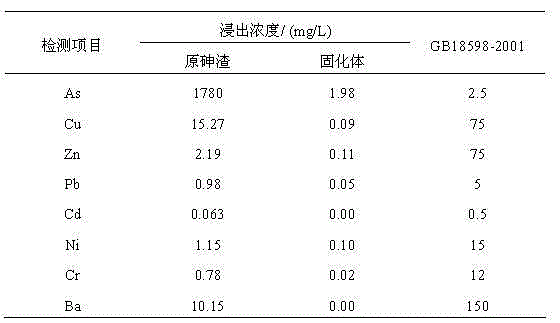

The invention relates to a low-shrinkage creep wet joint ultrahigh-strength concrete material and a preparation method thereof. The material comprises the following raw materials in proportion: 550kg / m<3> to 650kg / m<3> of cement, 150kg / m<3> to 250kg / m<3> of a mineral admixture, 675kg / m<3> to 825kg / m<3> of fine aggregate, 575kg / m<3>-725kg / m<3> of coarse aggregate, 10.3kg / m<3>-12.2kg / m<3> of a waterreducing agent, 78kg / m<3> to 156kg / m<3> of steel fibers, and 152kg / m<3> to 172kg / m<3> of water, wherein the mineral admixture is composed of an expanding agent and at least two of silica fume, superfine mineral powder, limestone powder, rice hull ash, metakaolin and fly ash microspheres, the coarse aggregate is any one or more of basalt, granite and diabase, the particle size is 5-10mm, and the needle sheet shape content is smaller than or equal to 1%. The low-shrinkage creep wet joint ultrahigh-strength concrete material prepared from the raw materials has the advantages of low shrinkage creep, good working performance, excellent mechanical properties, excellent durability and the like, is used for bridge wet joints, and can reduce the influence of shrinkage creep, guarantee the later durability and prolong the service life of bridges.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

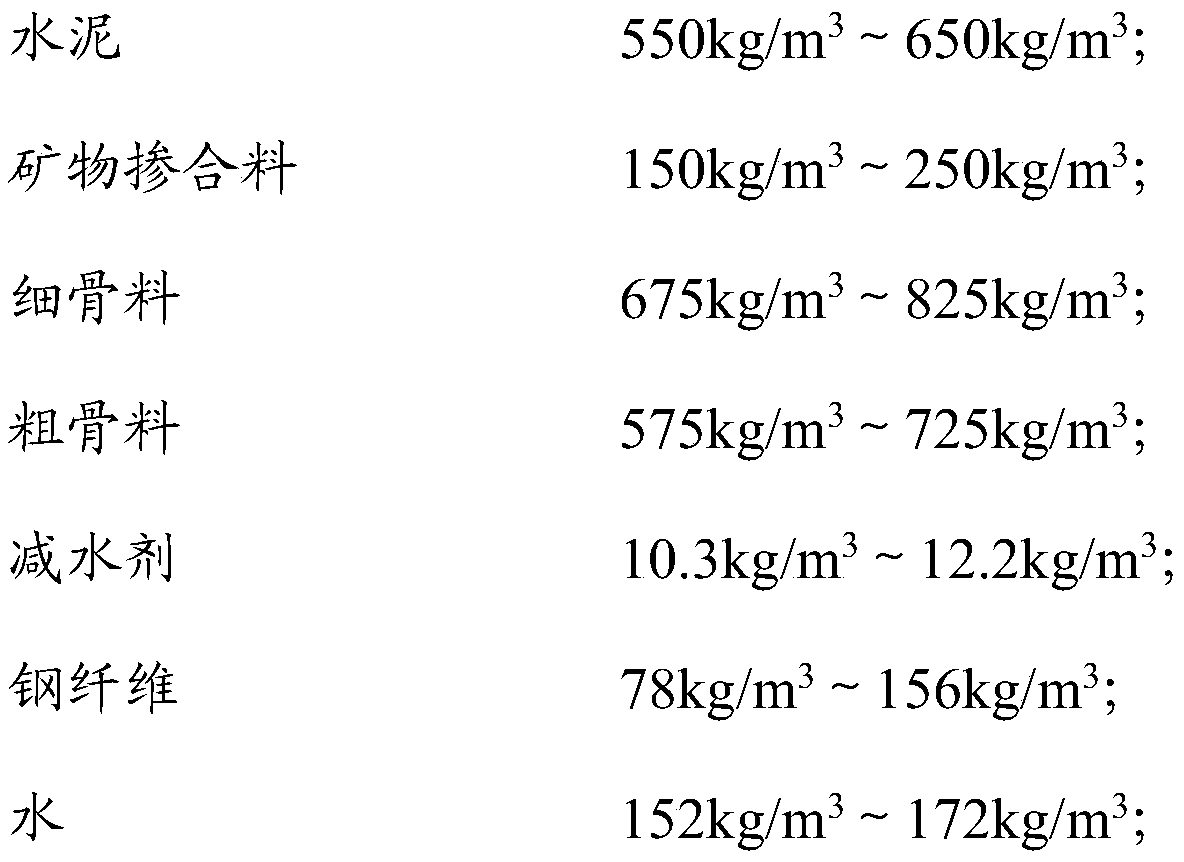

A low negative temperature post-tensioned beam prestressed pipeline grouting material

The invention belongs to the technical field of building materials, and in particular relates to a low negative temperature post-tensioned beam prestress pipeline mudjacking material. The material disclosed by the invention is prepared from cement, a poly-carboxylate water reducer, an anti-freezing component, a retardant component, a harness promoting component, mineral admixtures and an expanding agent through mixing and stirring; the material can be used for the construction of pipe mudjacking of a post-tensioned prestressing T beam and a continuous beam in the construction condition not lower than minus 10 DEG C; and the effect of the material is more obvious in the environment condition of shifts between positive and negative temperatures day and night. The strength of hardened mortarcan develop continuously in the conditions of low temperature and negative temperature, the maintenance time can be shortened greatly, the construction efficiency can be improved, and large energy consumption required by low and negative temperature construction can be reduced.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

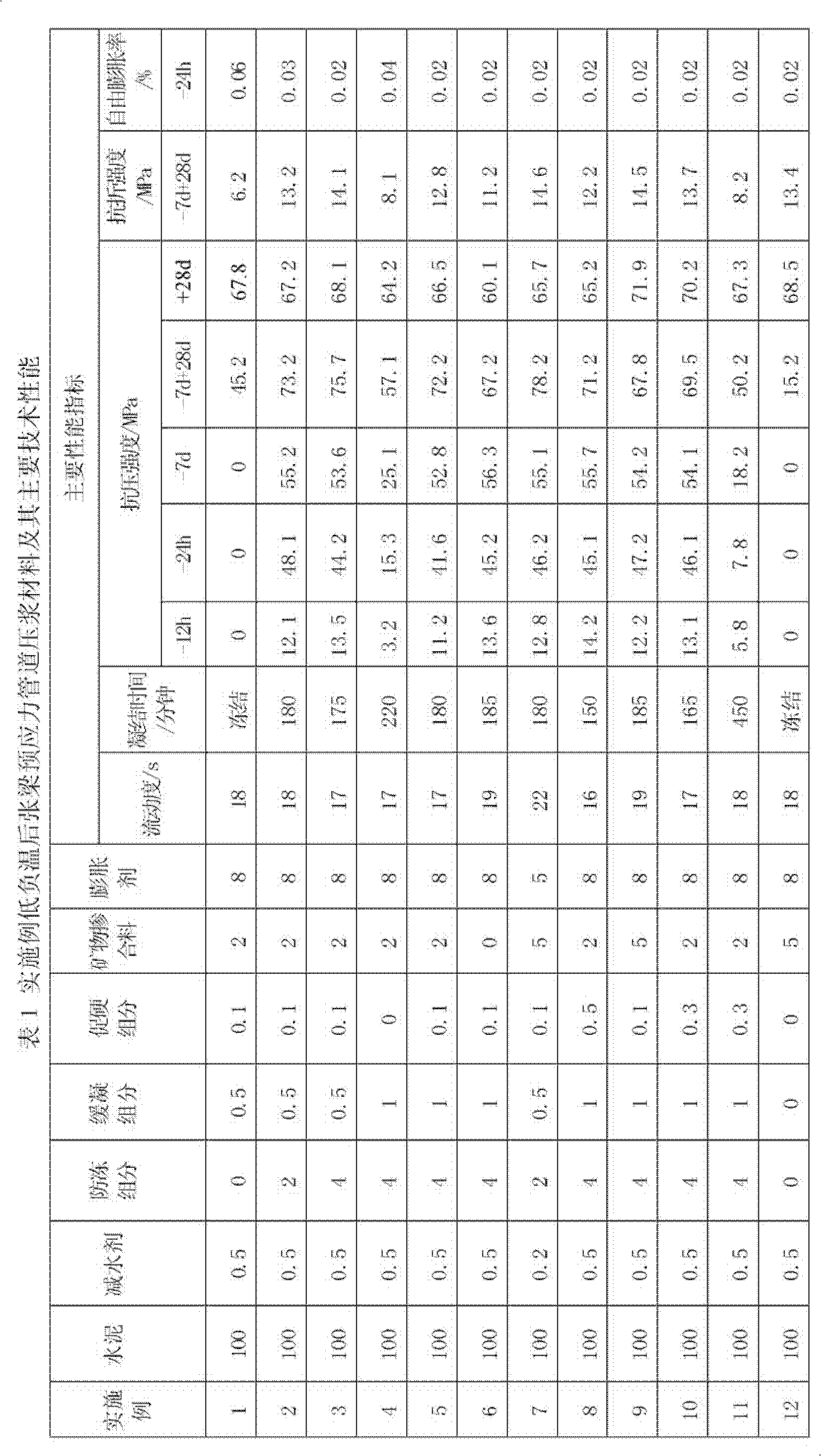

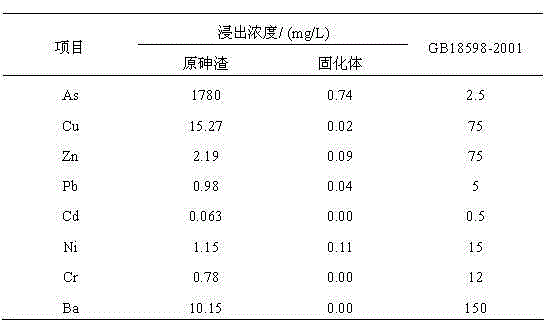

Stable curing method of arsenic sulfide waste slag

ActiveCN105215047AReduce leachingReduce contentSolid waste disposalTransportation and packagingCalcium hydroxideSlag

The invention discloses a stable curing method of arsenic sulfide waste slag. The method comprises the following steps: (1) heavy metal sludge is added in arsenic sulfide slag to be treated for stirring to obtain a slurry material; (2) calcium hydroxide powder is added in the slurry material obtained in the step (1) in the stirring state for continuous stirring until red substances in the slurry material are all disappeared; (3) yellow sand and cement are added in the material obtained by stirring in the step (2); and (4) the stirring material obtained in the step (3) is cooled to the normal temperature, is transferred to a forming mold for molding, is taken out from the mold, and is maintained at the normal temperature to obtain a curing body accordant with the landfill standard. The method uses the heavy metal sludge as an arsenic stabilizing agent for treating wastes by wastes; the sources of such materials as heavy metal sludge, lime, cement and yellow sand needed to treat the strong-acid arsenic sulfide waste slag are wide; other medicaments are not needed to be added; and compared with other methods, the method is lower in treatment cost.

Owner:YANGZHOU JIEJIA IND SOLID WASTE HANDLING CO LTD

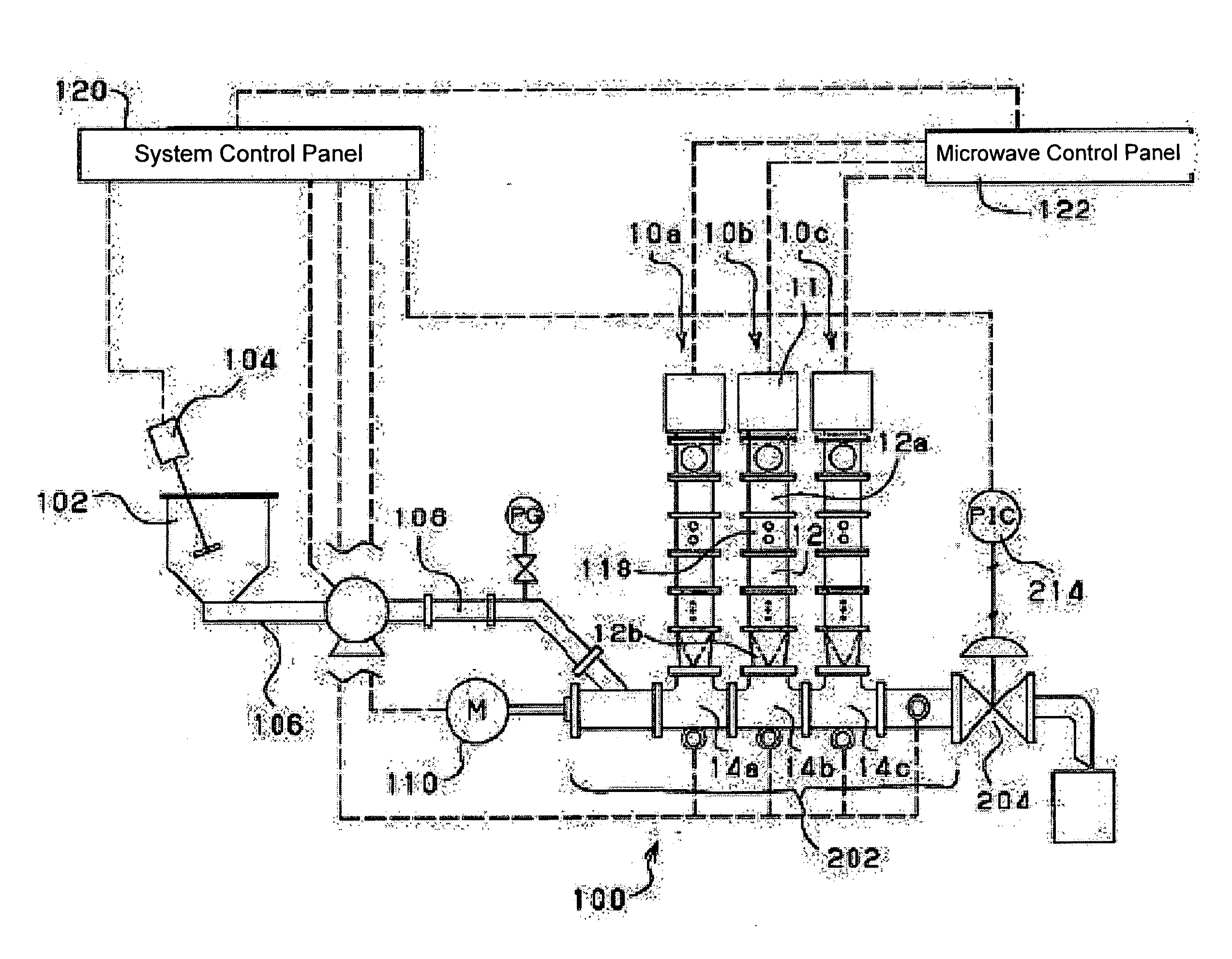

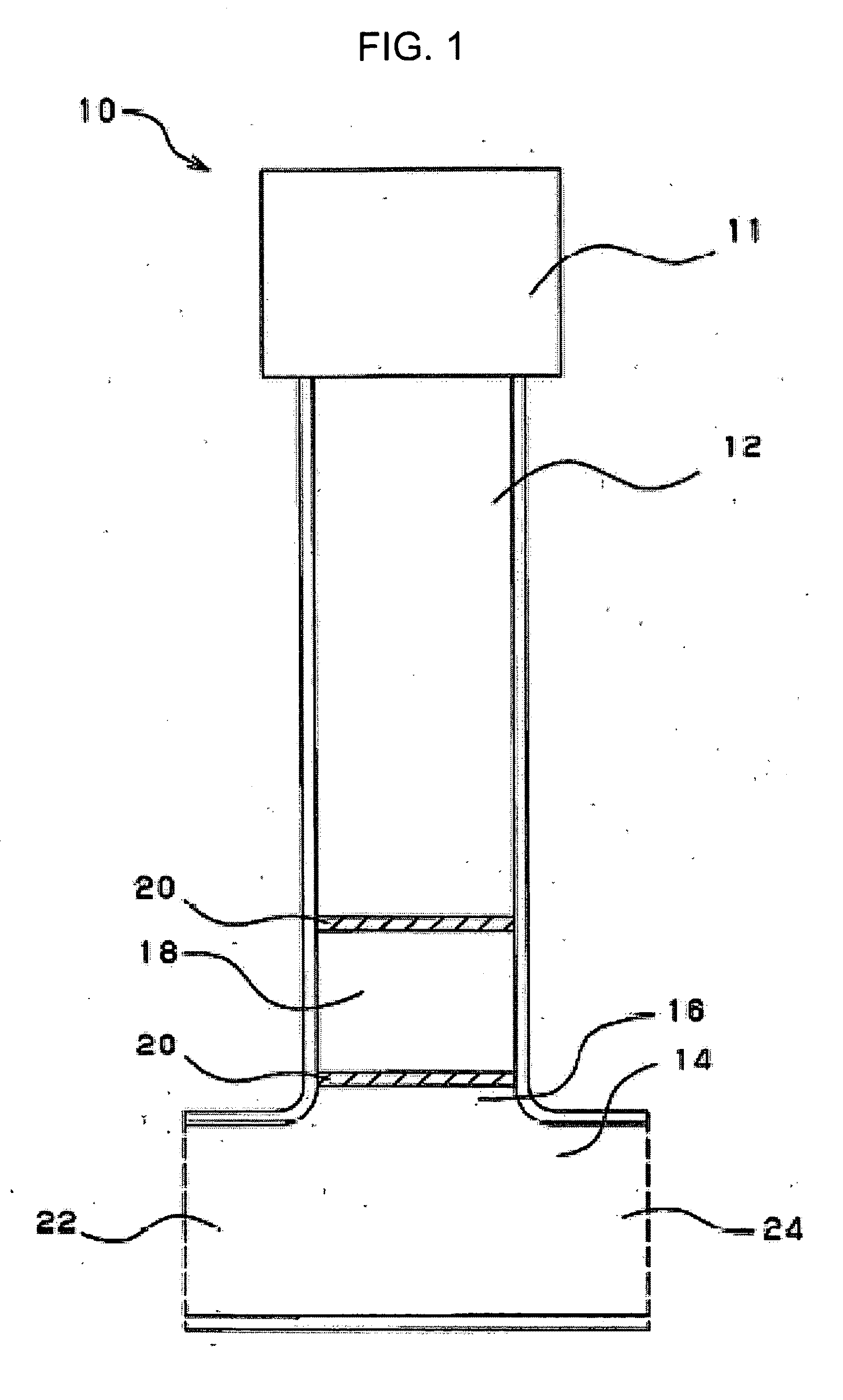

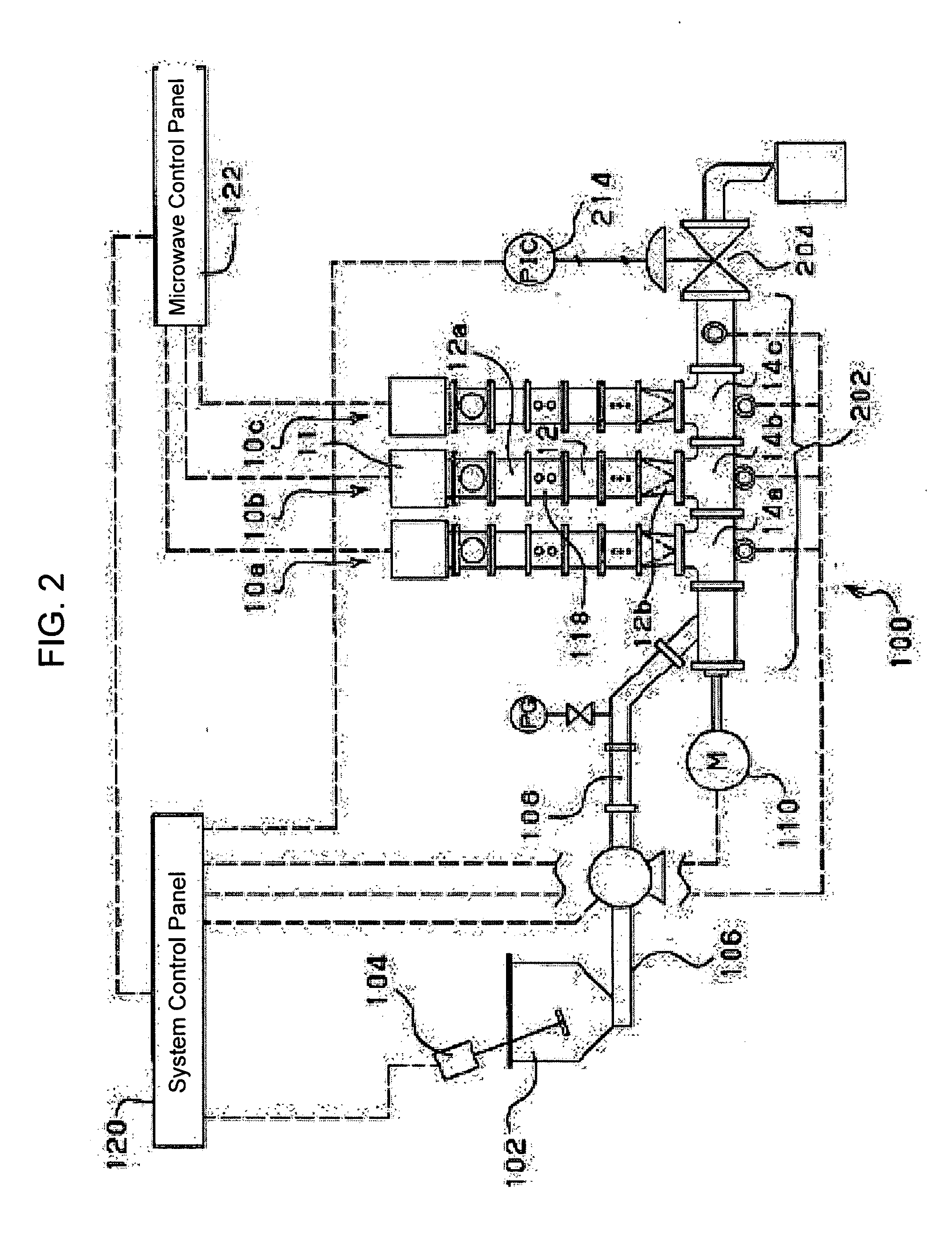

Microwave radiating device, connecting type microwave radiating device, and methods of producing sugar ingredient from plant materials

InactiveUS20110263843A1High popularitySufficiently conductiveSugar derivativesPurification by electrical meansElectricityAdditive ingredient

The present invention provides a microwave radiating device which treats a radiated material by microwave irradiation; and further provides a method of producing a sugar ingredient from a plant material.The microwave radiating device of the present invention is equipped with an irradiating means which has a microwave radiating source, and containers which accept radiated material inside. Further, the container of the device has supply means which provides radiated material to the container, and discharge means which discharges radiated material from the container, and a microwave receiving section which makes microwaves that irradiate from radiating means, penetrate into the container through the medium of dielectric material. Further, there is provided at least one layer that is composed of non-dielectric material, between the atmosphere of the inner side and the outer side of the container. Yet, irradiating means and the above container are connected in a removable mode.

Owner:JAPAN CHEM ENG&MACHINERY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com