Refractory castable and using method thereof

A refractory castable and content technology, applied in the field of refractory castables, can solve the problems of difficulty in control, poor flowability of castables, decreased erosion resistance, etc., and achieves good thermal shock resistance, high strength at medium and high temperatures, and good fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

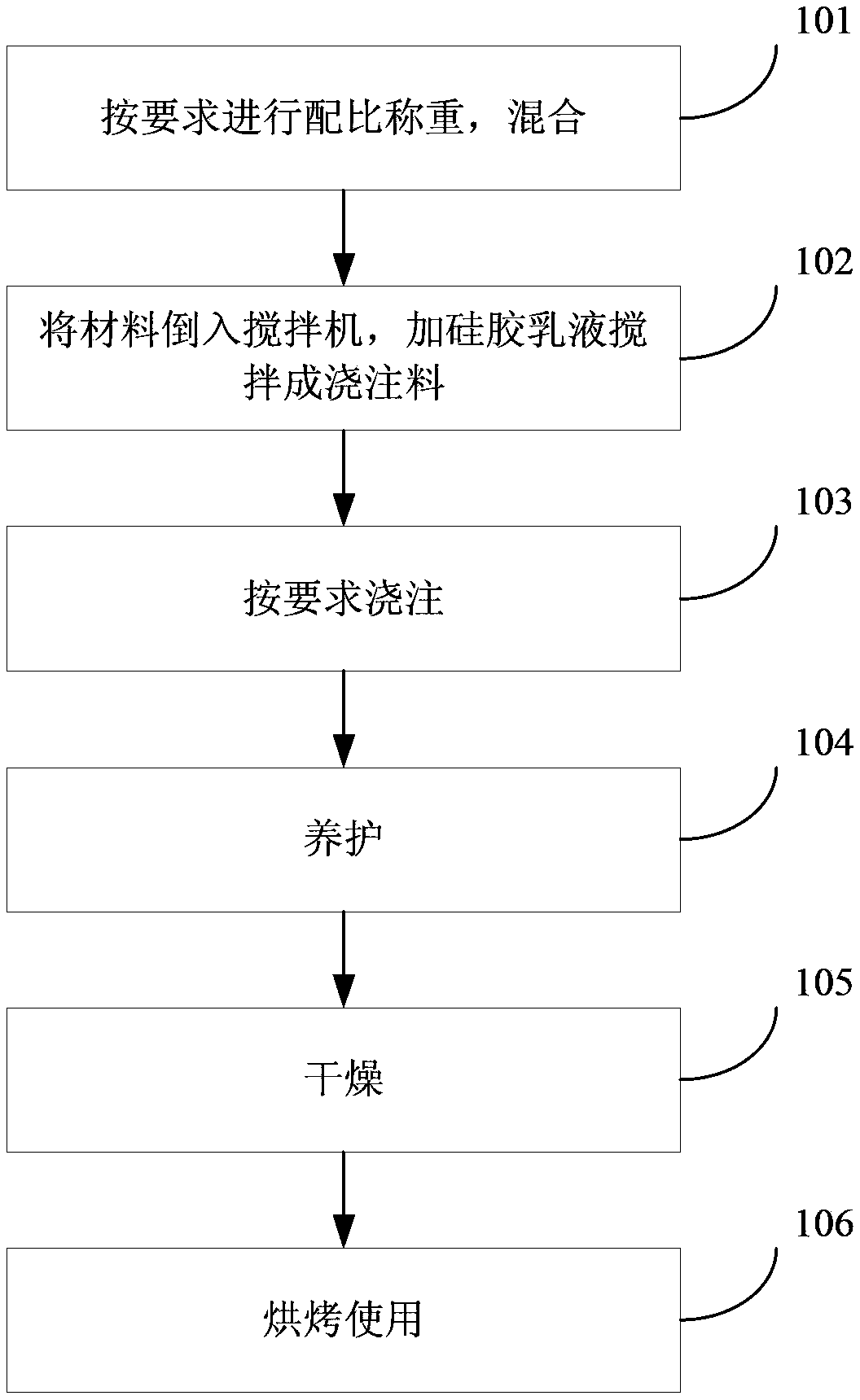

[0058] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

[0059] Embodiment 1 of the present invention provides a refractory castable, its components and weight percentages include: corundum 5-3mm: 25%-35%; 3-1mm: 10%-20%; 1-0mm: 10%- 20%; 200 mesh: 20% to 30%; activated alumina powder: 1% to 5%; silicon oxide powder: 2% to 7%; cement: 3% to 5%; steel fiber: 1% to 3%; Sodium hexametaphosphate: 0.1% ~ 0.2%; tartaric acid: 0.01% ~ 0.02%; 35% silica gel: water = 1:1:3% ~ 5%. The present invention adopts corundum (brown corundum, dense corundum) as the main aggregate, which has a high melting point (2050° C.), high hardness (Mohs hardness 9), excellent high-temperature mechanical properties, stable chemical properties and good wear resistance.

[0060] The present invention adopts corundum (brown corundum, dense corundum) as the main aggregate, which has a high melting poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com