Hollow glass curtain wall with invisible frame and hollow glass plate for use in curtain wall

A glass curtain wall and glass plate technology, which is applied in the field of hollow glass curtain walls and hollow glass plates for curtain walls, can solve problems such as no calculation, complicated calculation of opening profiles, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

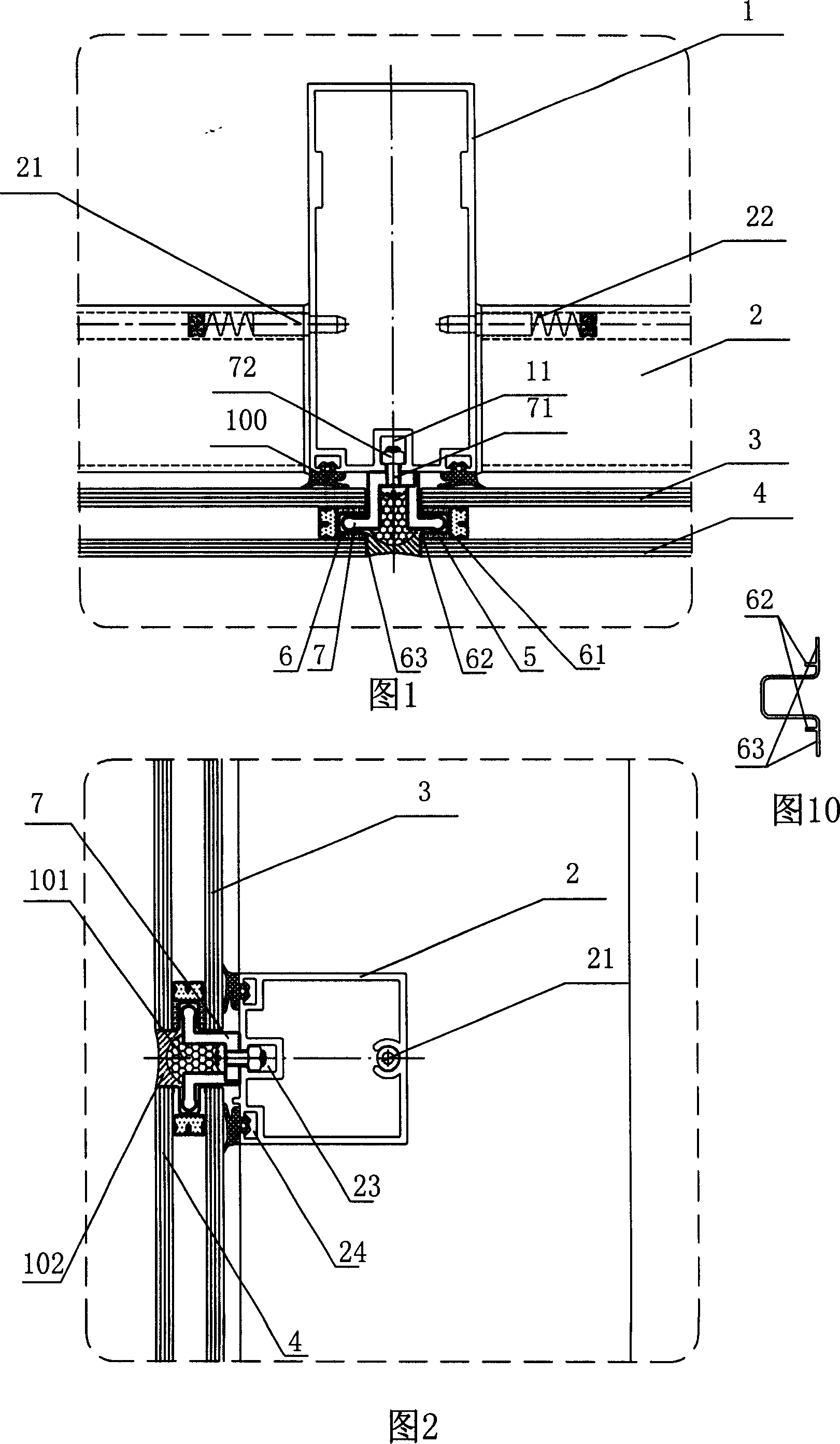

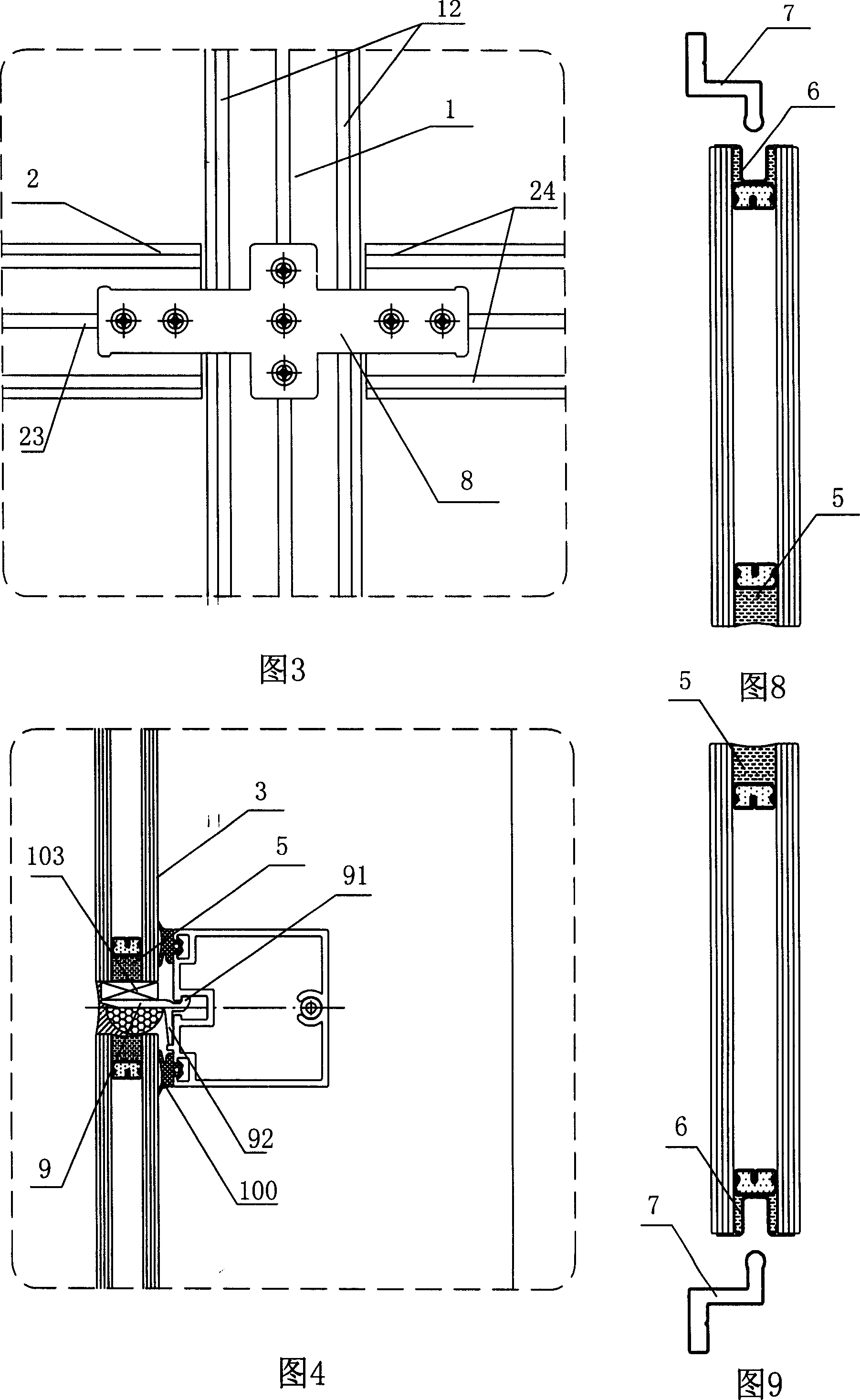

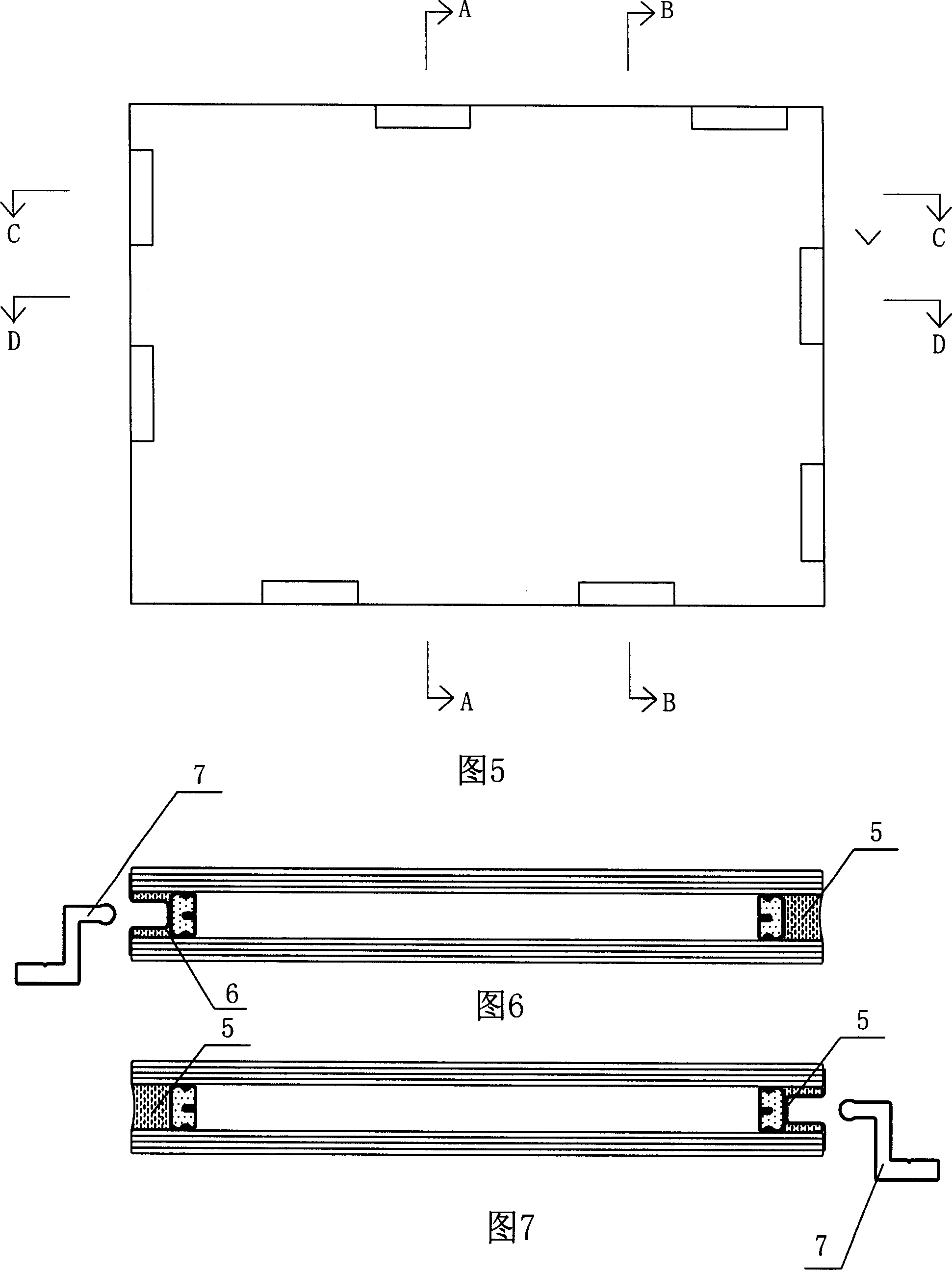

[0017] Refer to attached picture. The present invention includes a column 1 and a beam 2, and a hollow glass plate installed on the column and the beam, the hollow glass plate includes an inner glass plate 3 and an outer glass plate 4, and the surrounding glass plate between the inner glass plate and the outer glass plate There is structural glue 5 connecting the inner glass plate and the outer glass plate, and inserts 6 are respectively set in the surrounding structural glue. The length of the inserts is much smaller than the side length of the side of the glass plate where they are located, and the inserts are provided with installation grooves. 61, the insert is also provided with a positioning structure 62 in the thickness direction of the hollow glass plate, and the frameless hollow glass curtain wall is provided with a connecting piece 7 inserted in the installation groove, and the connecting piece is connected with a column or a beam.

[0018] The length of the insert i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com