Connection joint structure of prefabricated sandwich side wall and prefabricated laminated bottom plate and construction method of connection joint structure of prefabricated sandwich side wall and prefabricated laminated bottom plate

A technology for connecting nodes and prefabricated panels, which is used in infrastructure engineering, underwater structures, artificial islands, etc. It can solve the problem that the relative position cannot be fine-tuned at the construction site, and the connection strength, mechanical performance, tensile and shear resistance cannot be guaranteed. and weak bending resistance, to achieve the effect of ensuring assembly accuracy and welding quality, improving construction efficiency and quality, and improving shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

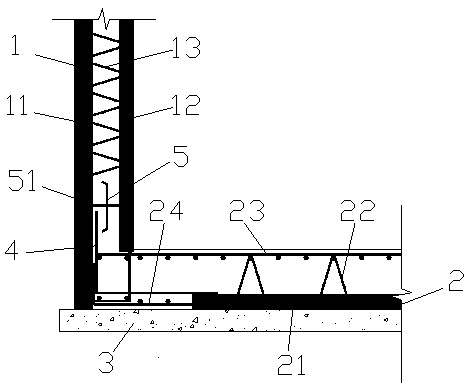

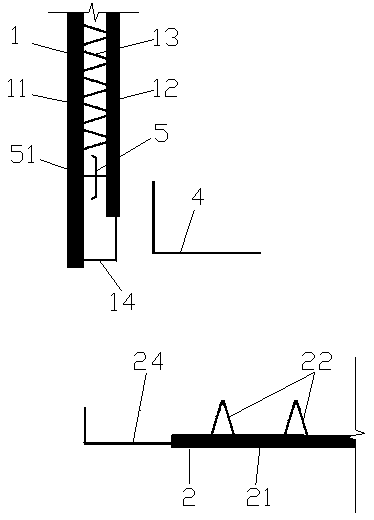

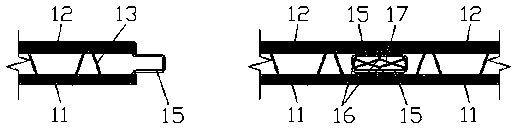

[0045] Please refer to figure 1 , figure 2 , a connection node structure between a prefabricated sandwich side wall and a prefabricated laminated floor according to the present invention, comprising a vertically arranged prefabricated sandwiched sidewall 1 and a prefabricated laminated floor 2 horizontally arranged below the prefabricated sandwiched sidewall 1, the prefabricated sandwiched sidewall 1 Including two prefabricated panels 11 and 12 inside and outside, connected by erecting trusses 13 between them, a horizontal water-stop steel plate 5 is arranged in the middle of the bottom of the prefabricated sandwich side wall 1, and horizontal short steel bars are evenly distributed on both sides of the water-stop steel plate 5 51. There is a gap between the end of the horizontal short steel bar 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com