Patents

Literature

183results about How to "Reduce the difficulty of on-site construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

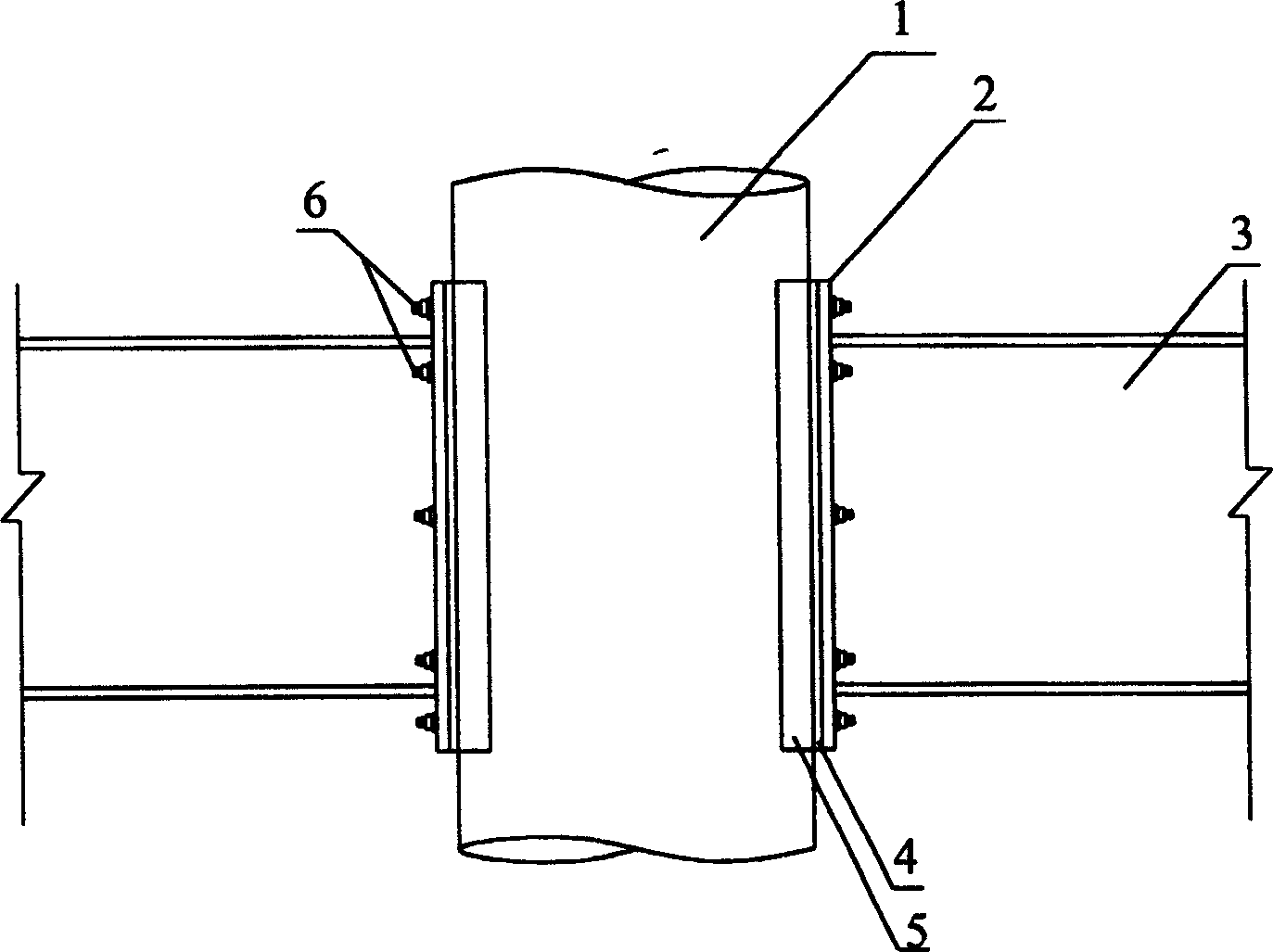

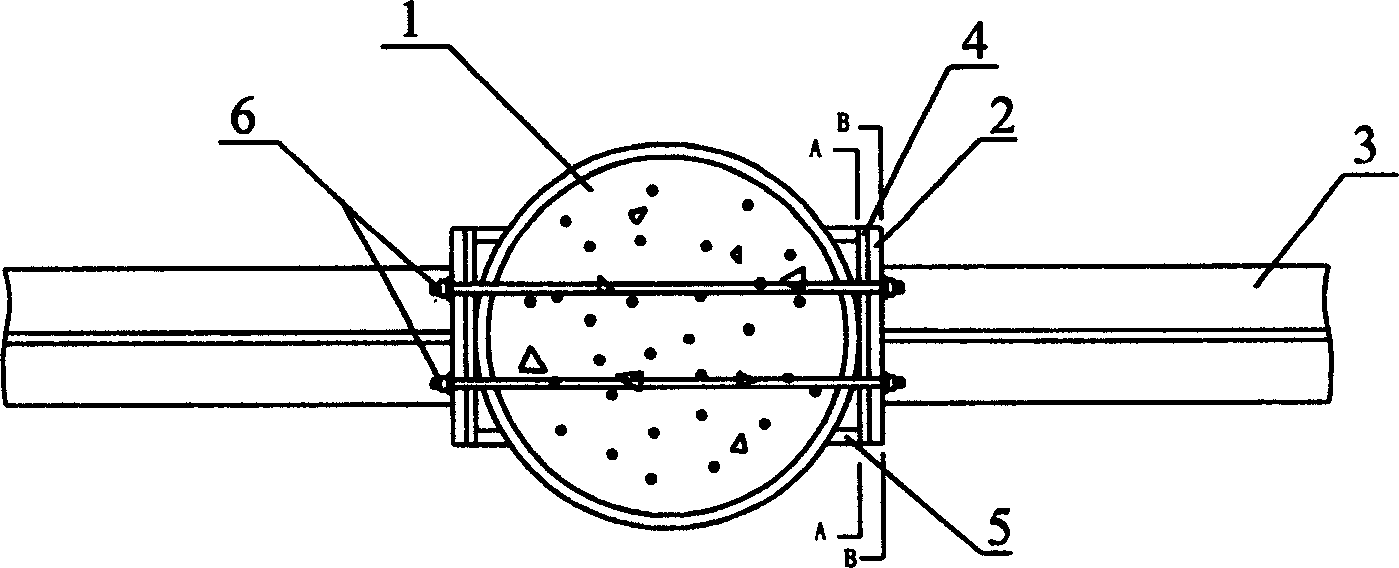

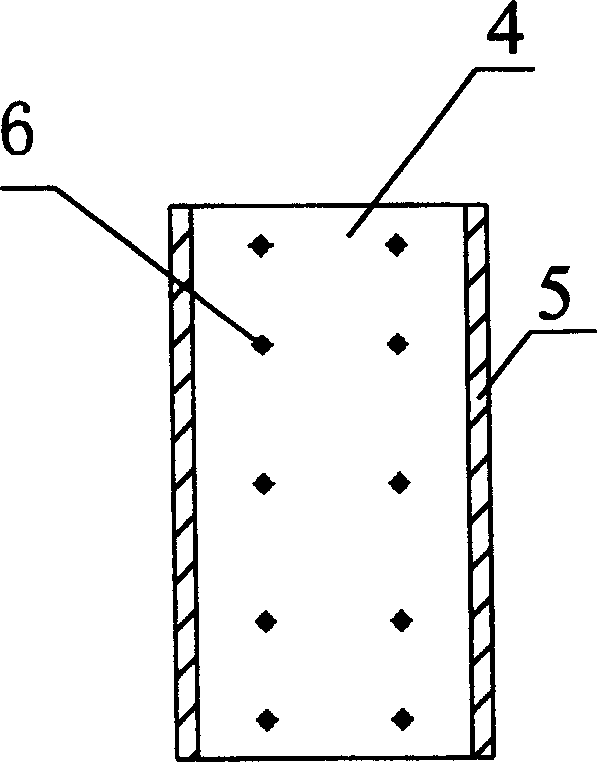

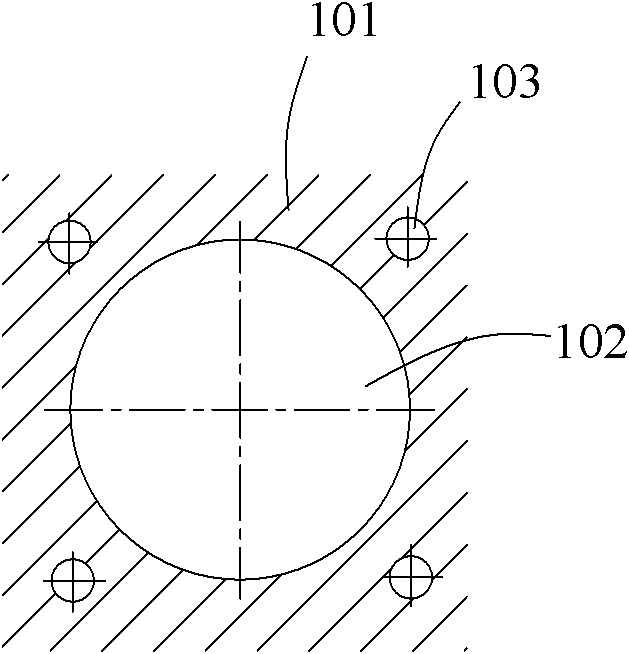

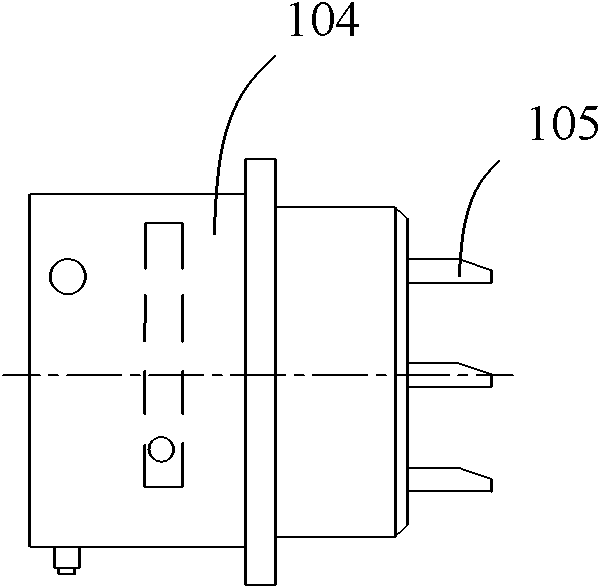

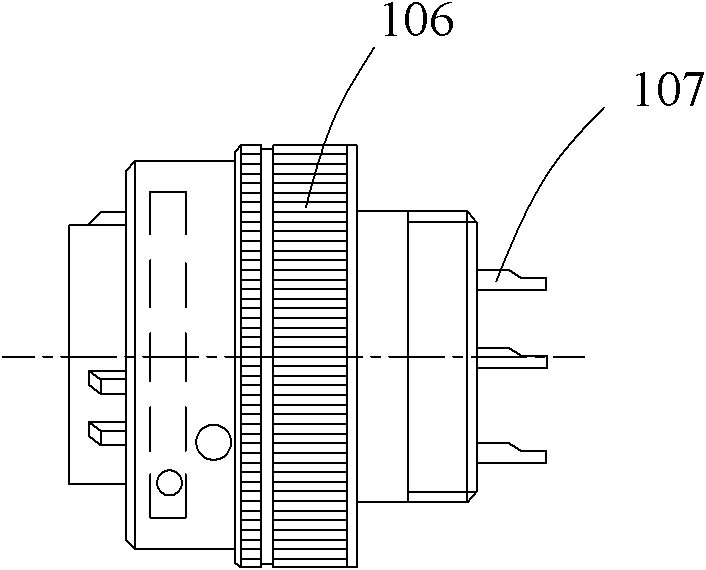

Round steel pipe concrete column joint for beam column connection and method for manufacturing the same

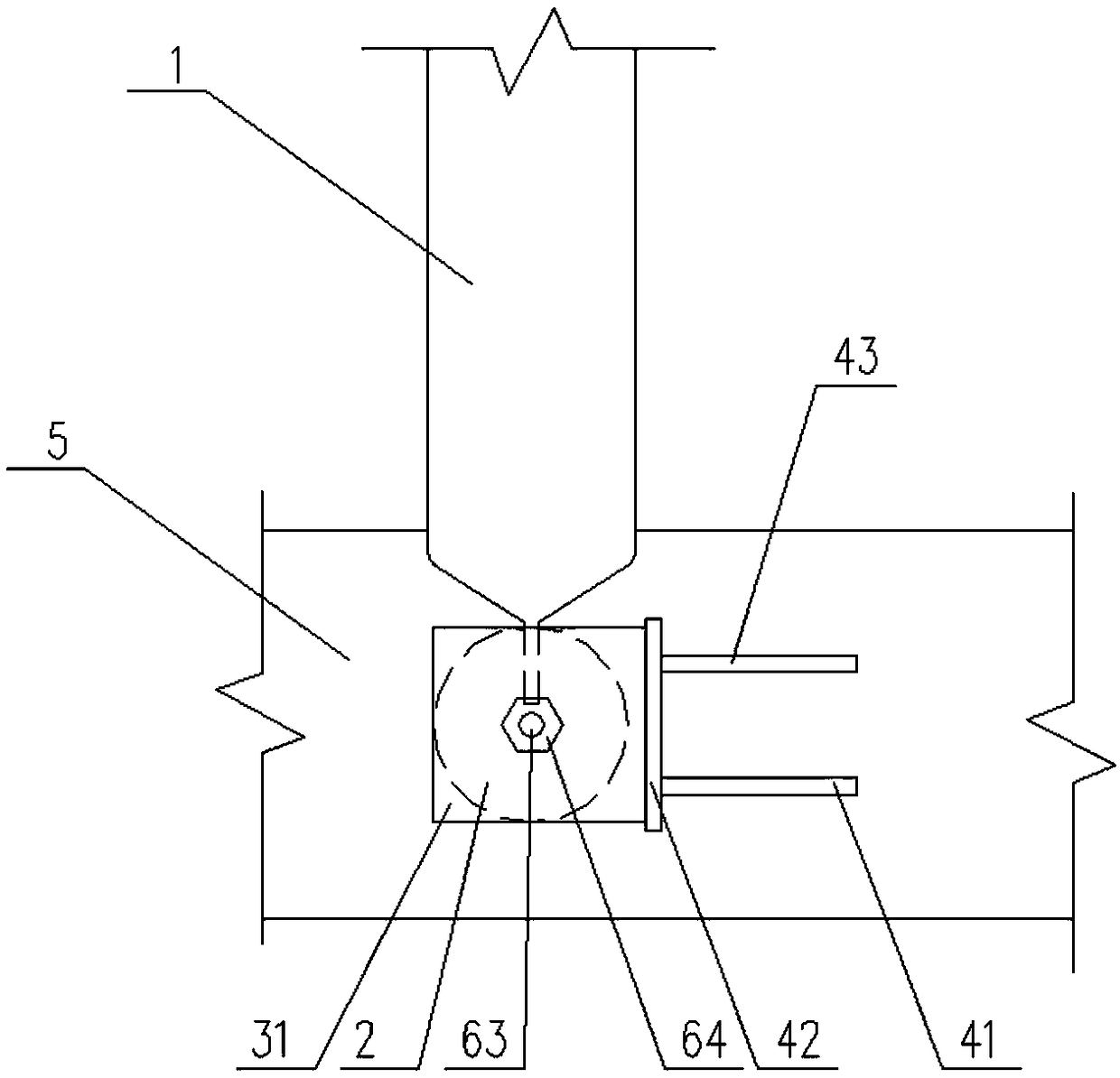

The invention discloses a kind to use in beam column the connection round steel pipe coagulation earth pyramid pitch point and its the manufacture method, it mainly included the round steel pipe coagulation earth pyramid and the steel girder which connected with this column, the round steel pipe coagulation earth pyramid and filled in in this round steel pipe including the round steel pipe the concrete, in carried with steel pipe coagulation earth pyramid connection steel girder Liang is equipped with an end board, this steel pipe coagulation earth pyramid with stated between the end board to be equipped with the belt rib level the steel plate, level the steel plate solidified on the round steel pipe, carried the board, level the steel plate as well as the round steel pipe through as soon as passed through core excels in the bold fastening in together. The invention cost inexpensive, mechanics performance good, design succinct convenient, the construction difficulty is small, also can avoid the scene welding, improves the connection quality and the construction benefit.

Owner:HUNAN UNIV

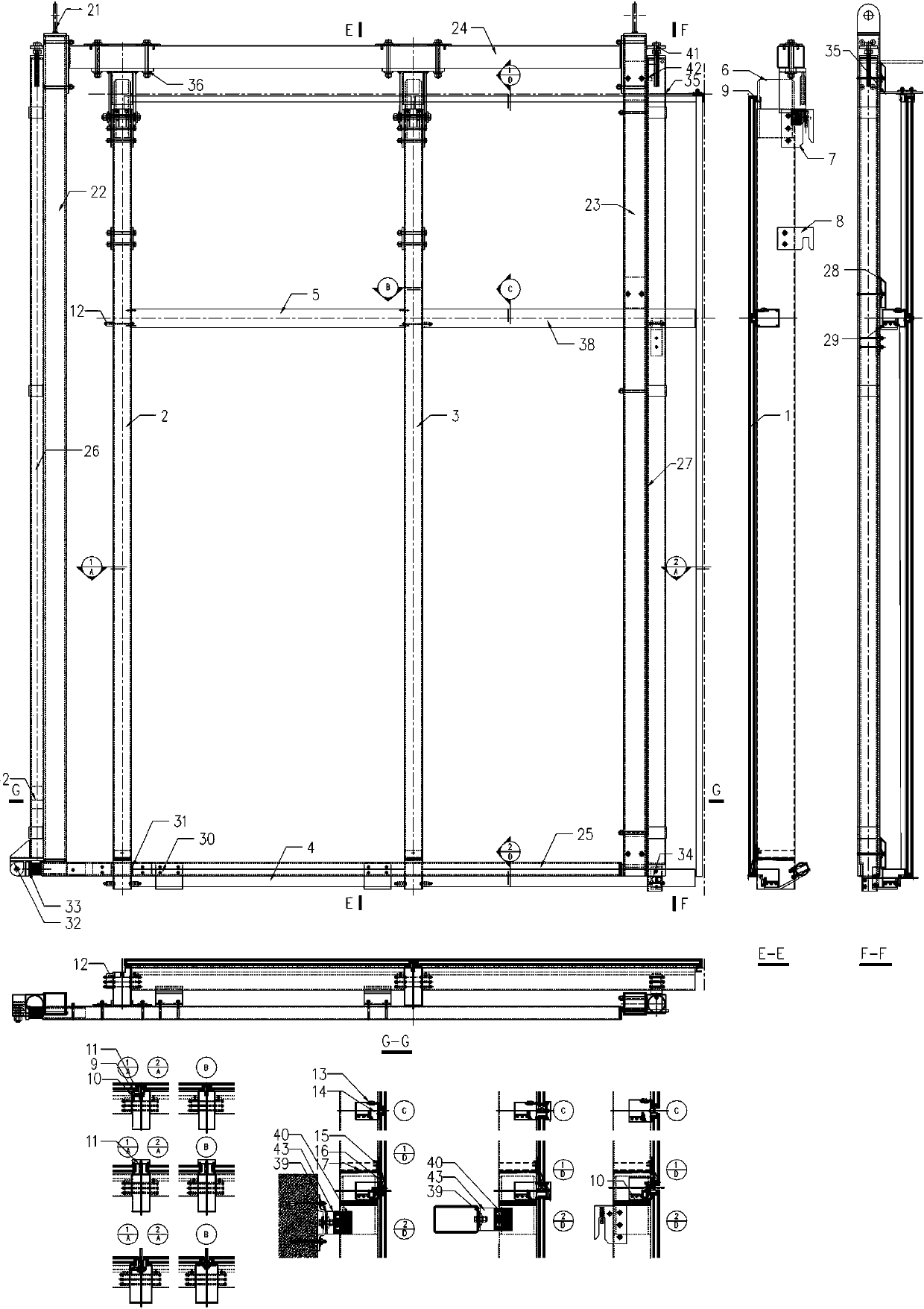

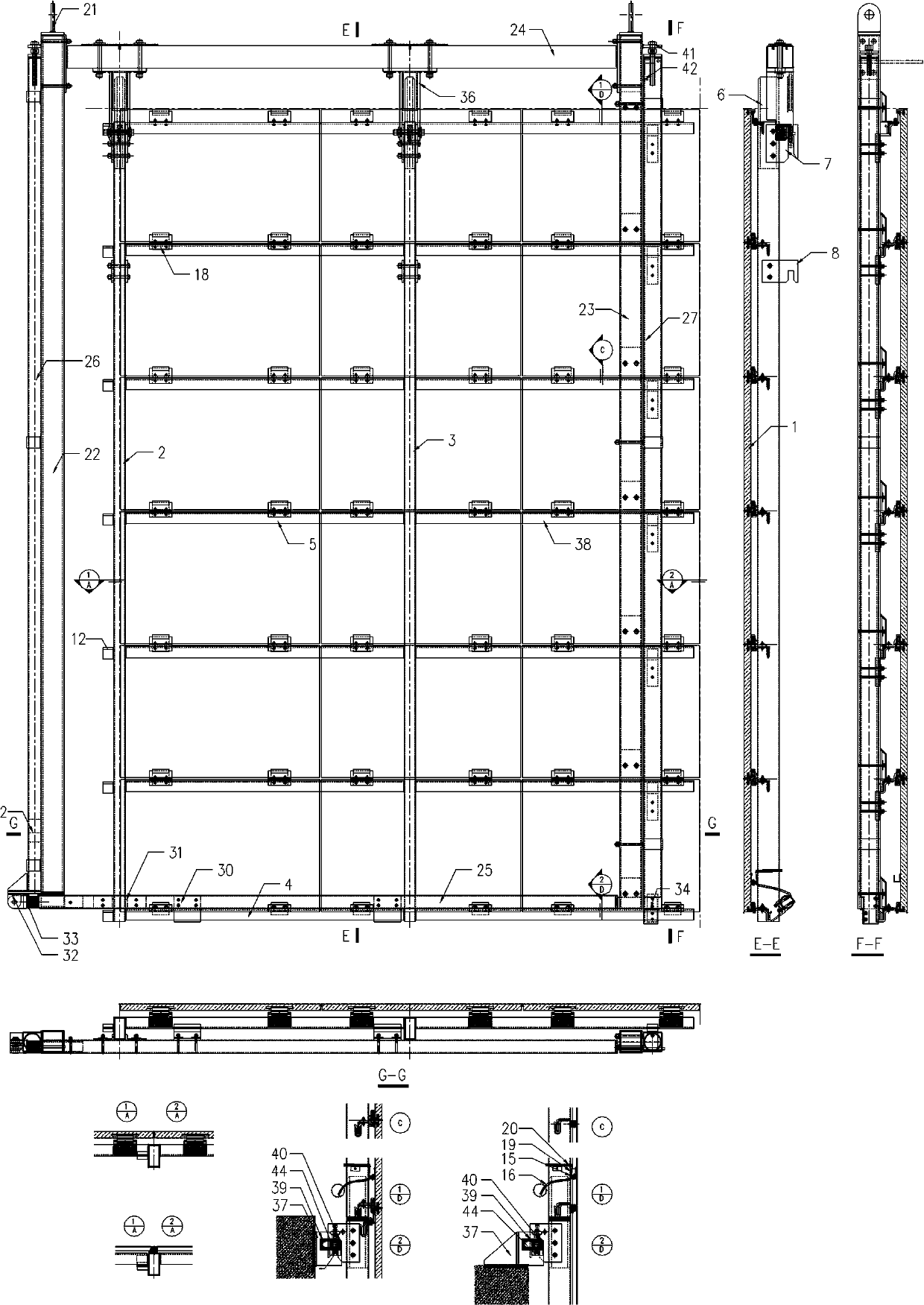

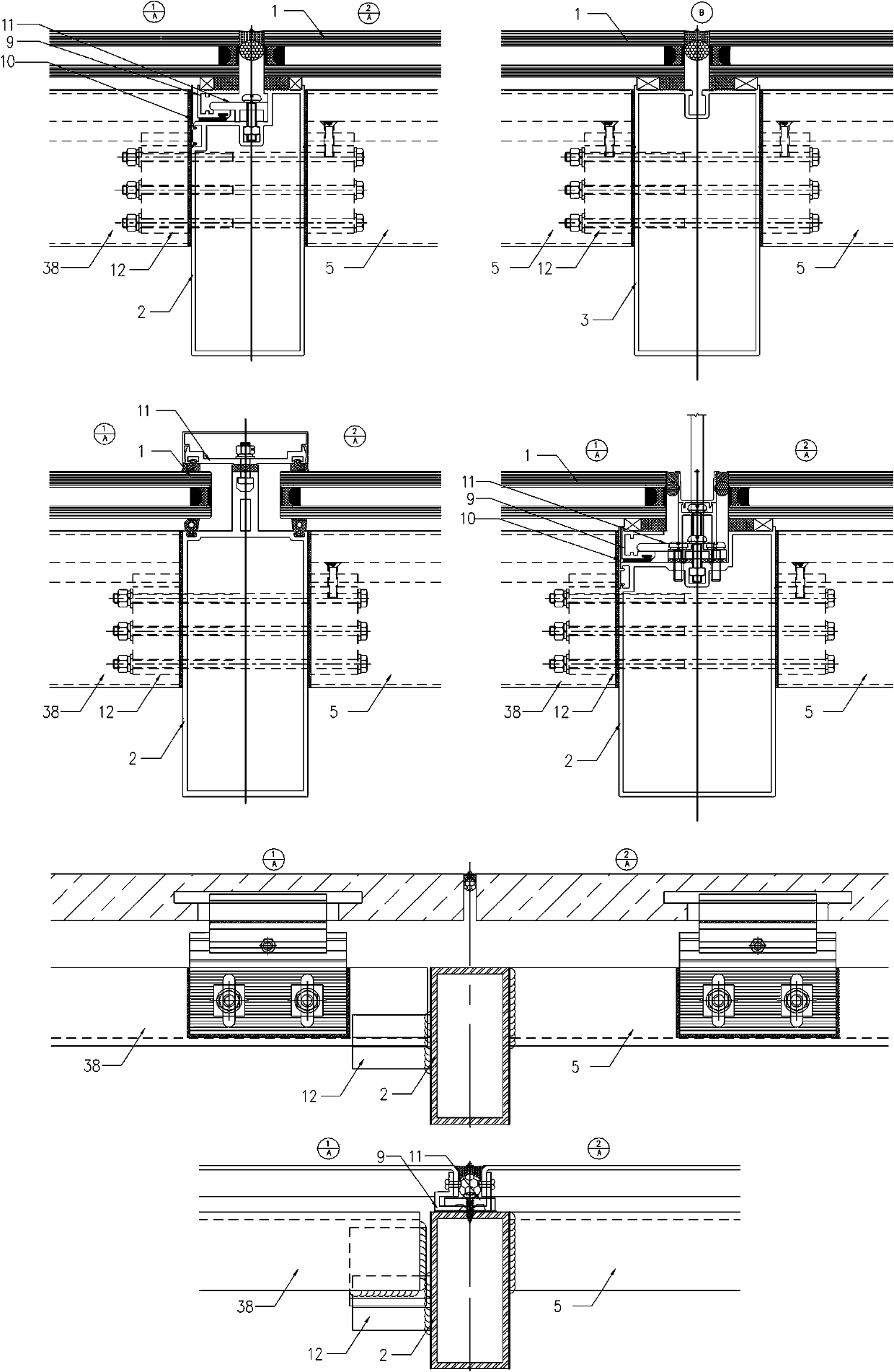

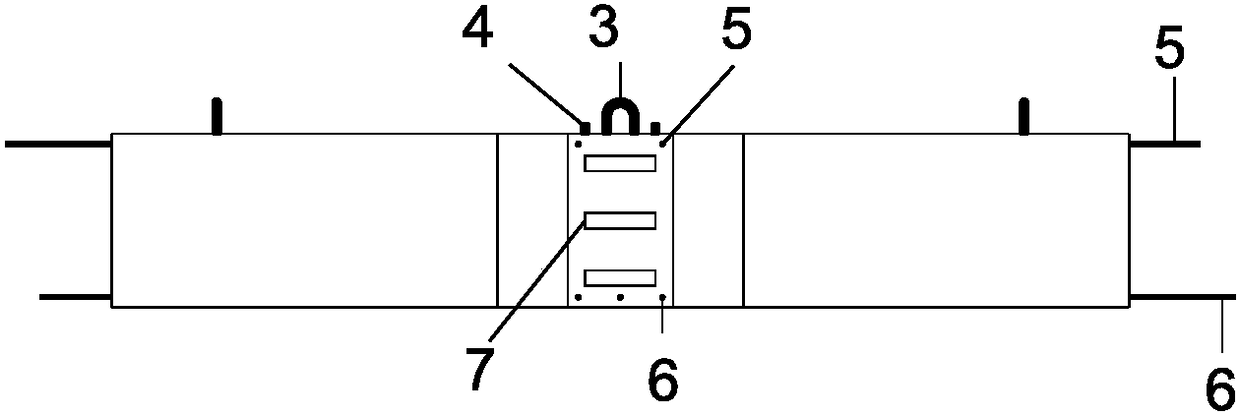

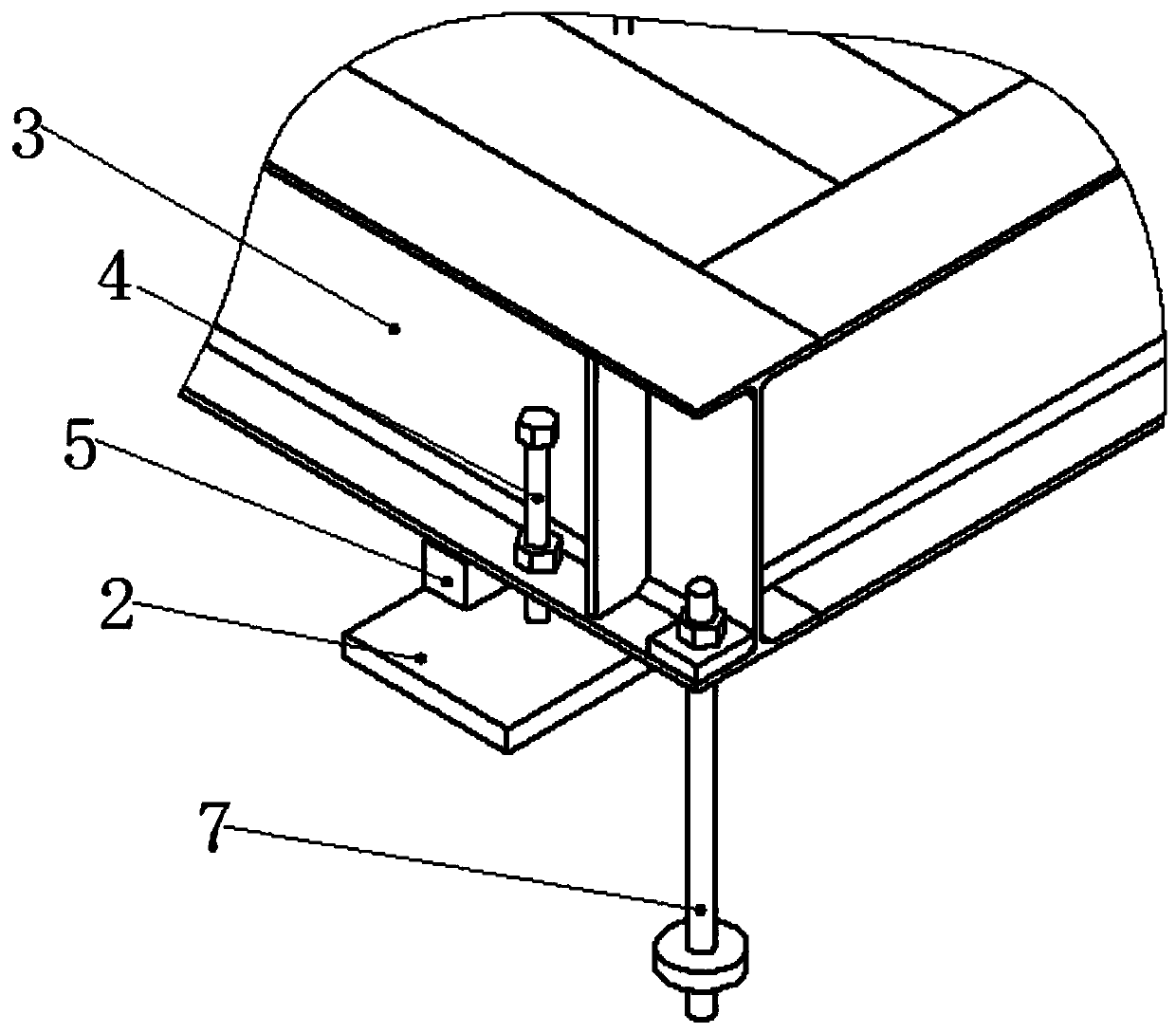

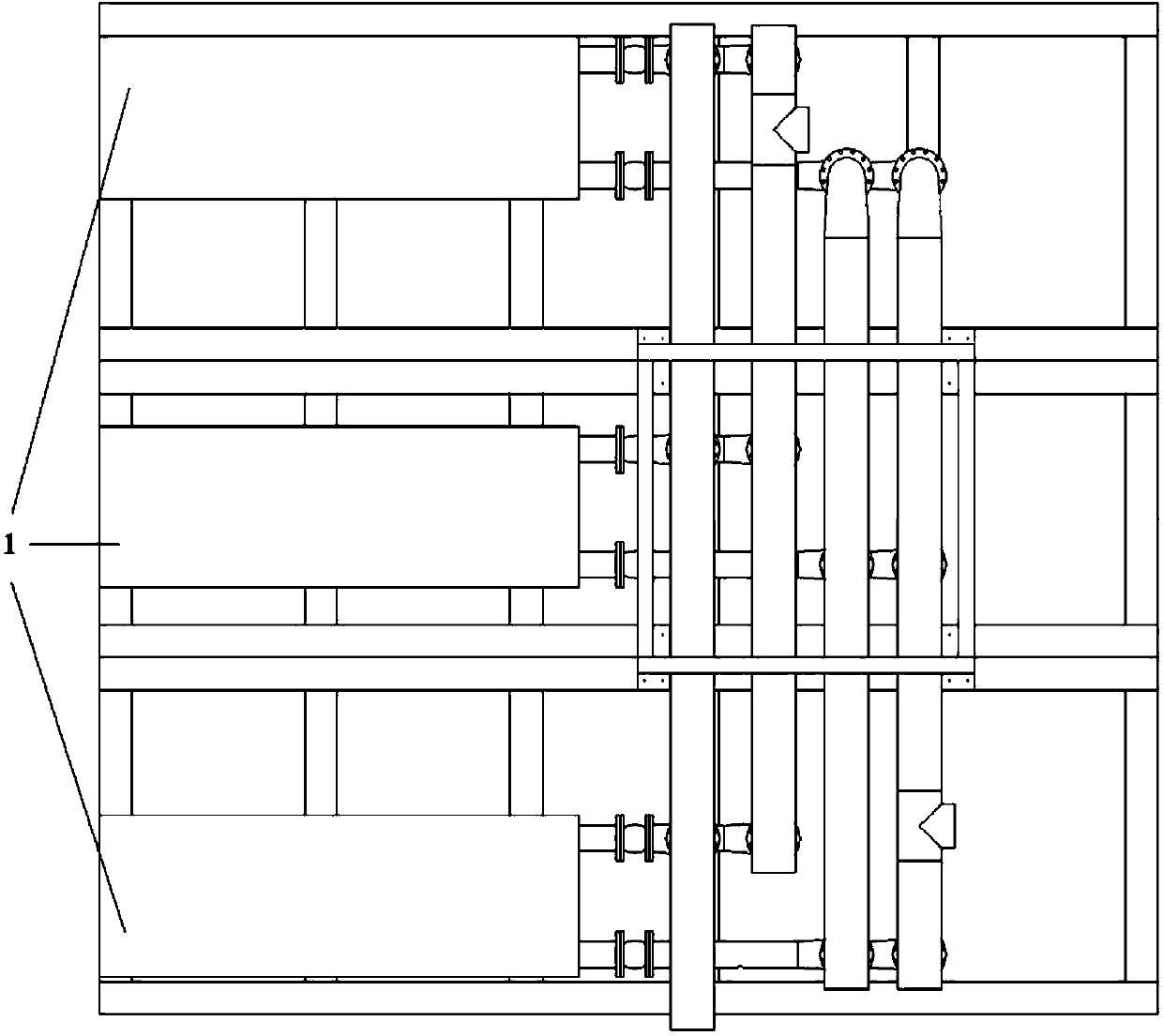

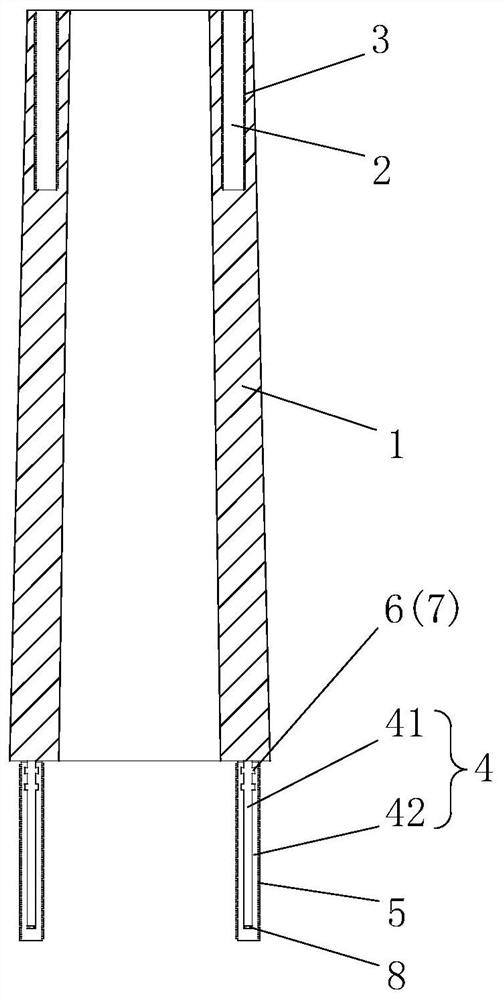

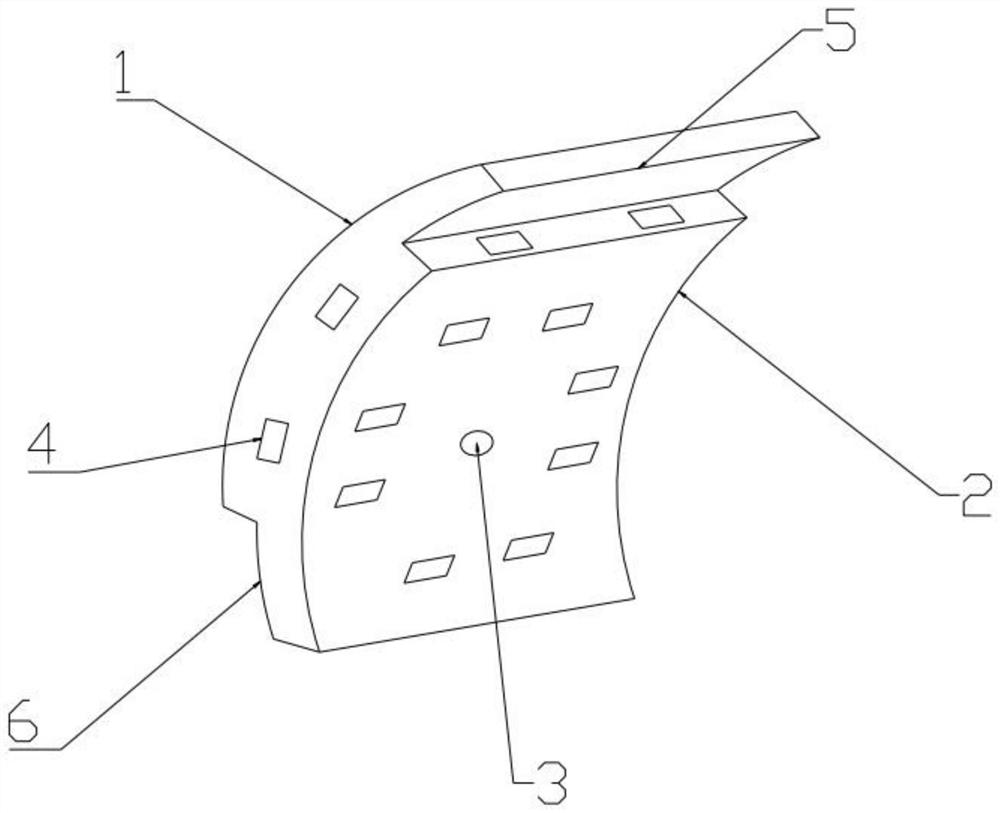

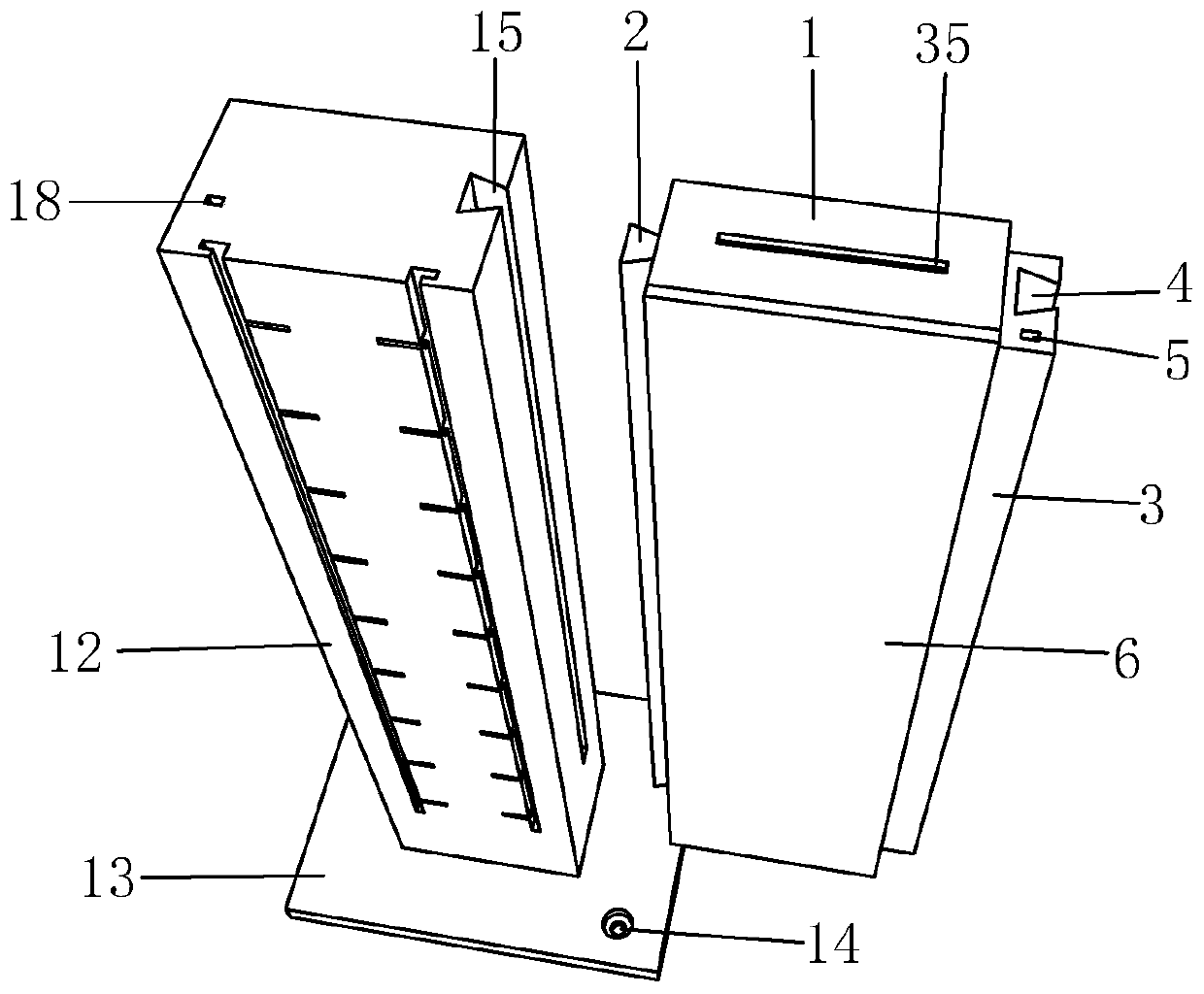

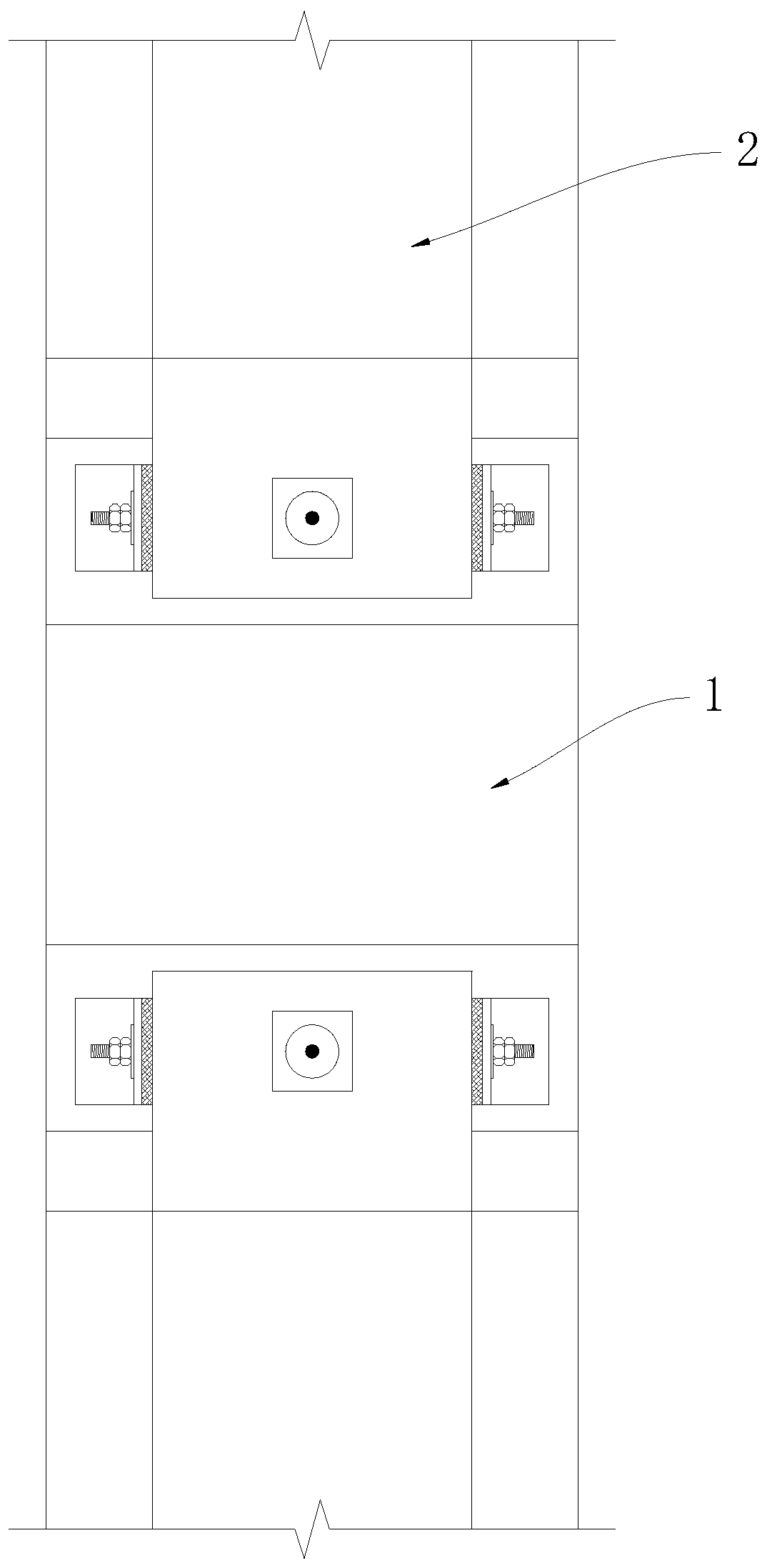

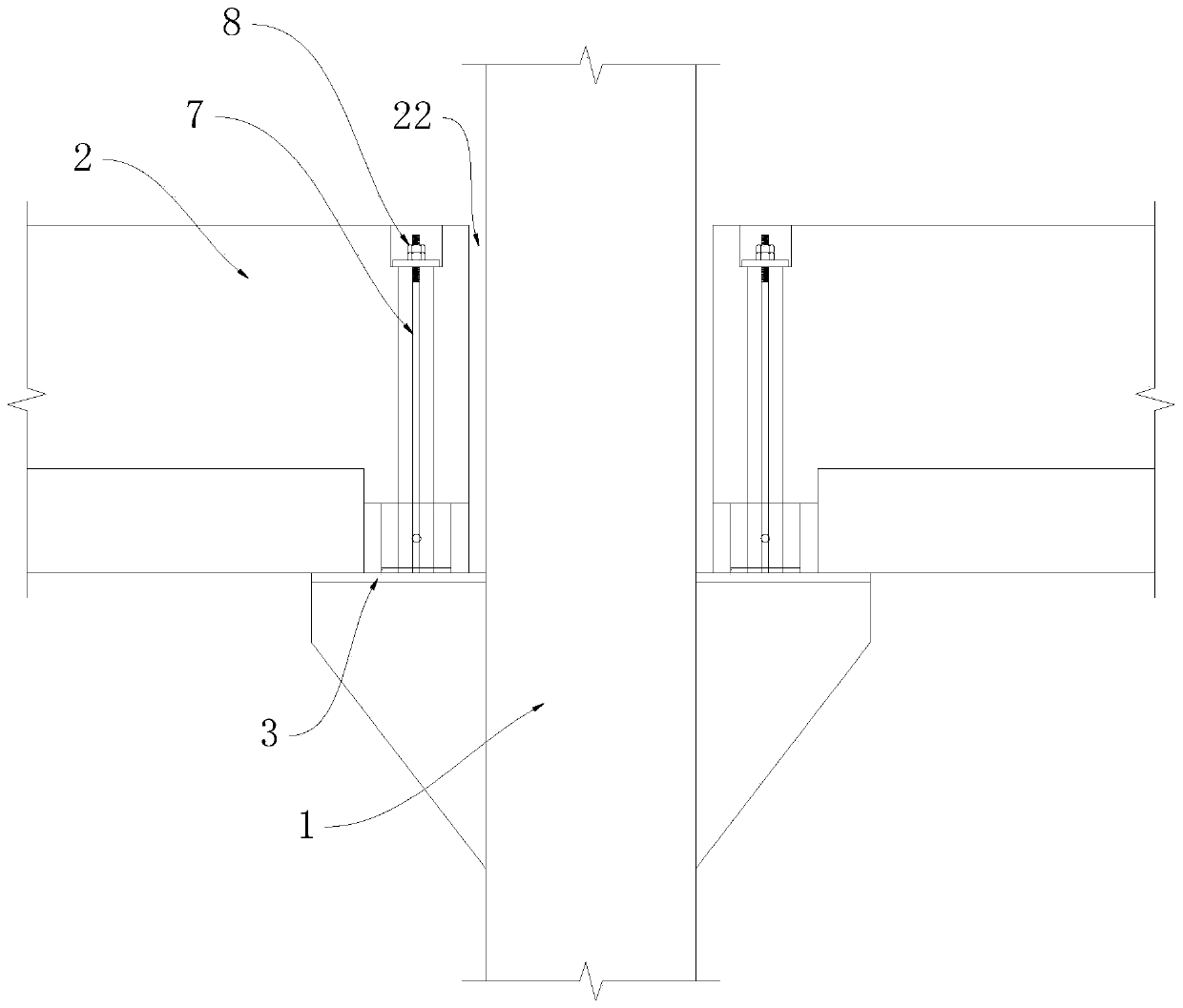

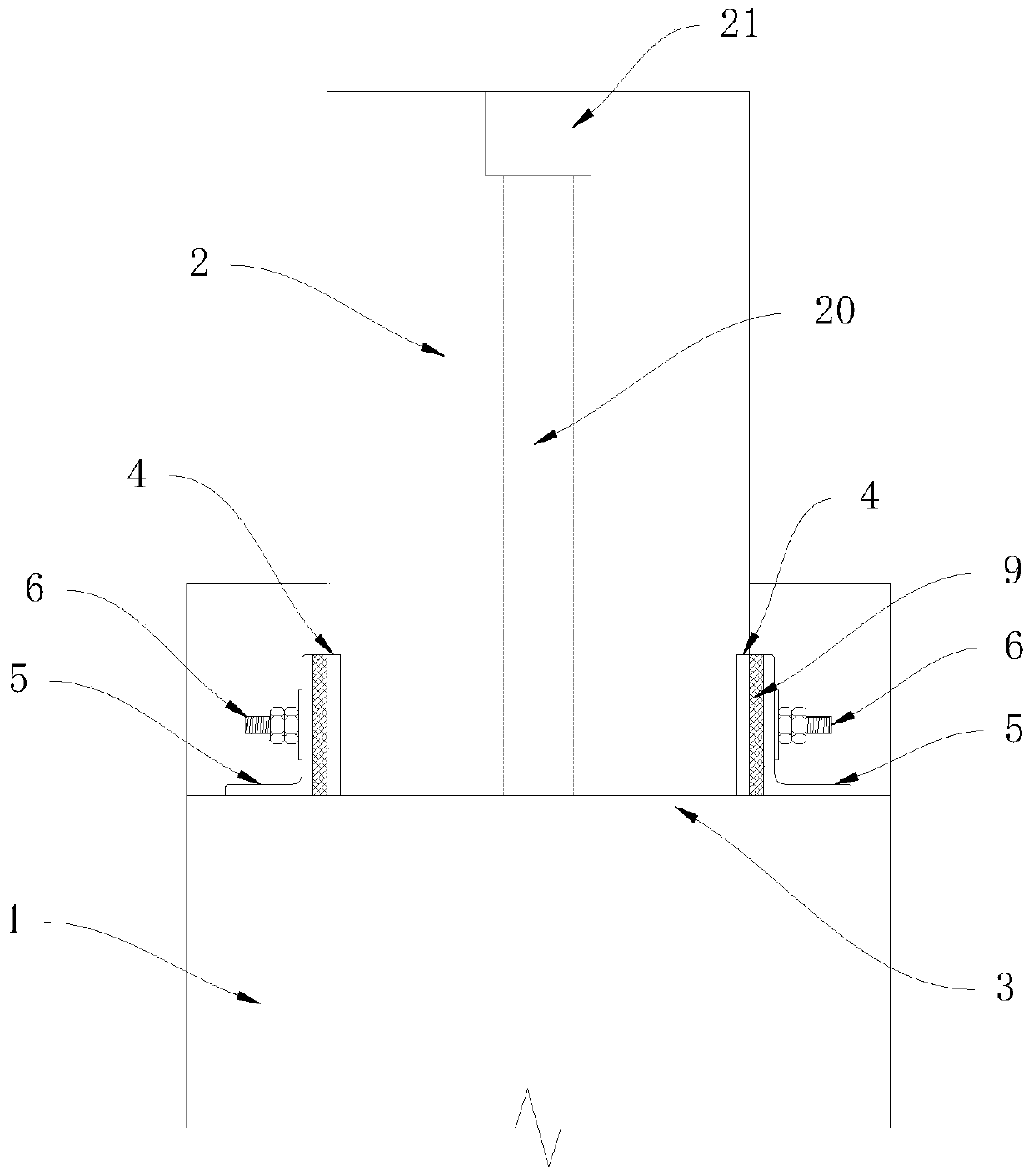

Frame type unit curtain wall adopting auxiliary installing rack, tooth profile angle and tooth profile support

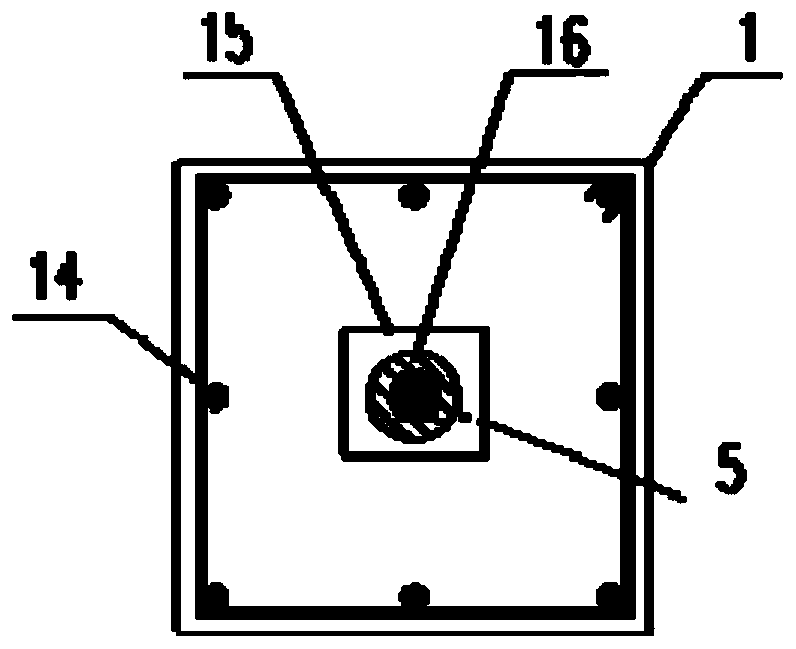

The invention relates to the field of curtain walls of buildings, in particular to a frame type unit curtain wall adopting an auxiliary installing rack, a tooth profile angle and a tooth profile support. The frame type unit curtain wall adopting the auxiliary installing rack comprises a panel (1), end columns (2), middle columns (3), end cross beams (4), middle cross beams (5), inserting cores (6), an auxiliary frame (9), a cover plate and the like. The frame type unit curtain wall adopting the auxiliary installing rack, the tooth profile angle and the tooth profile support are long in service life, low in cost, good in machinability, short in field construction period and good in sealing performance.

Owner:何志胜

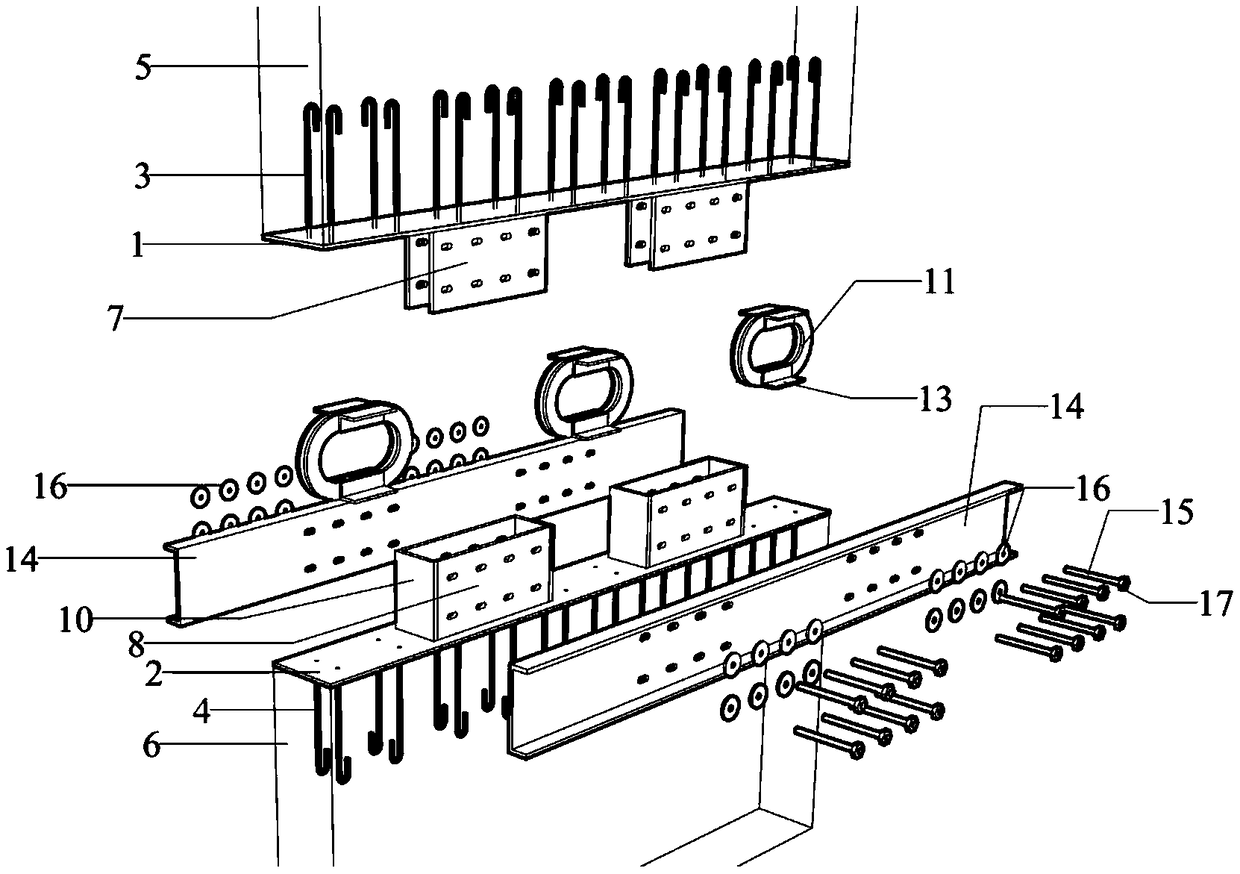

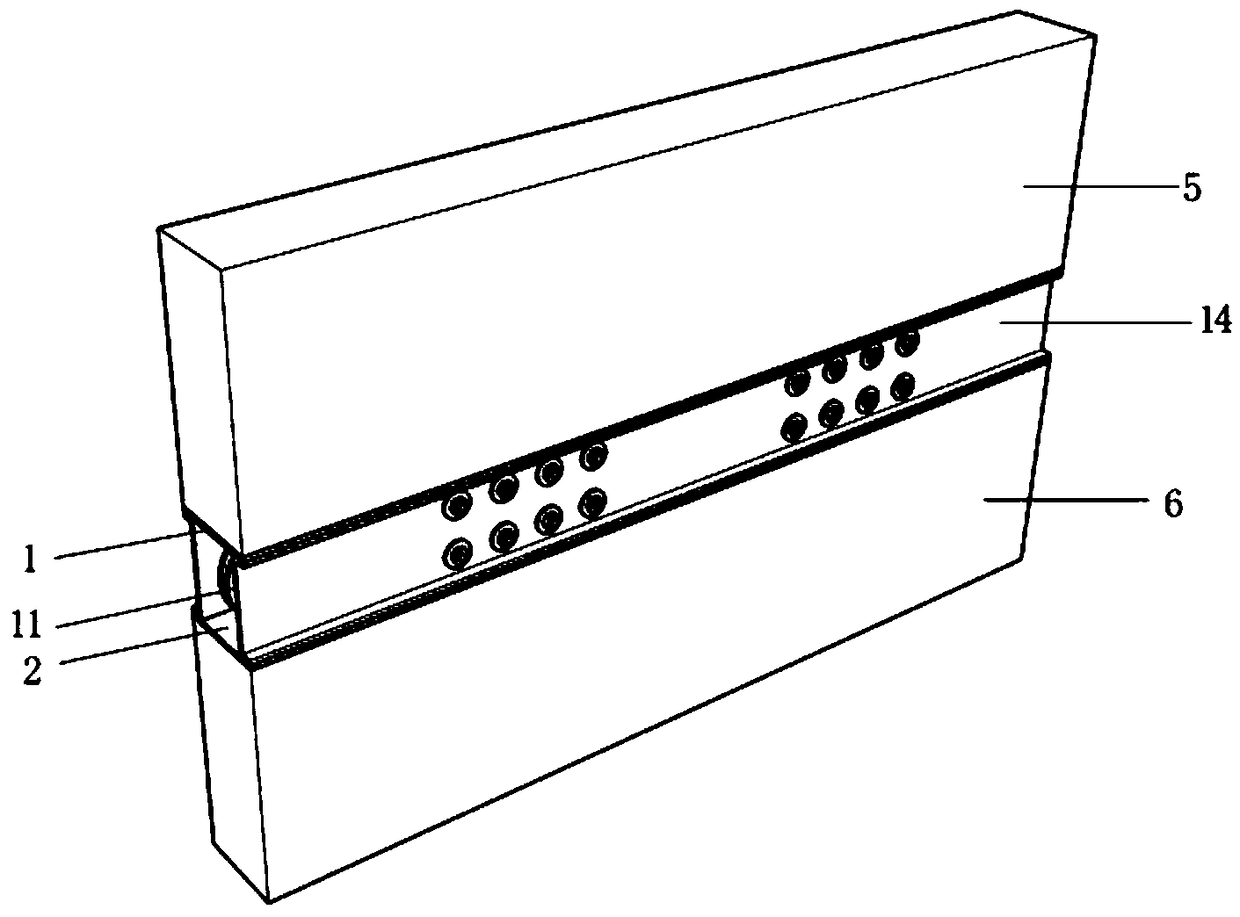

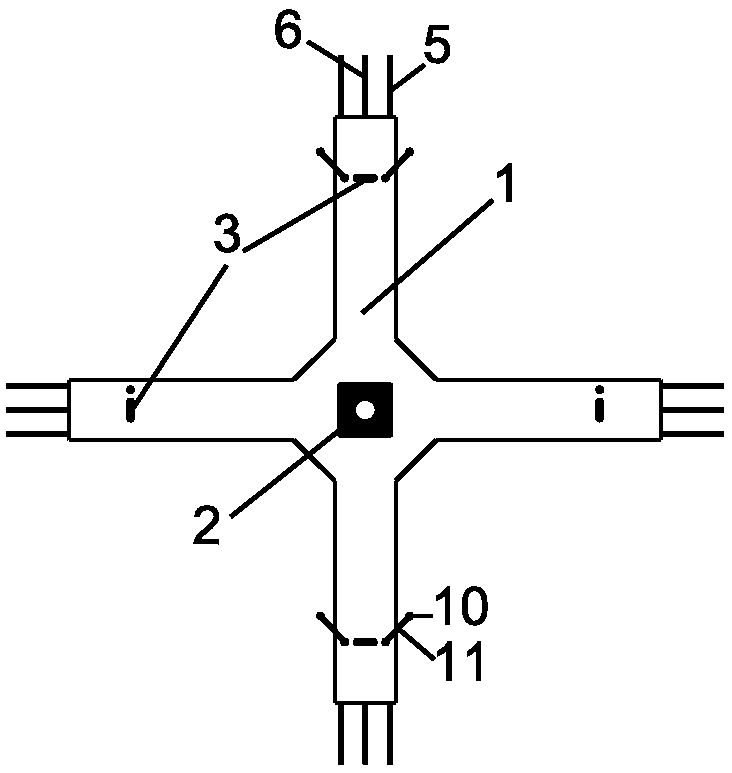

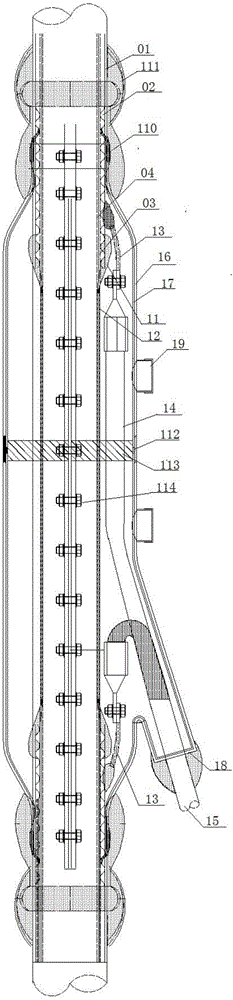

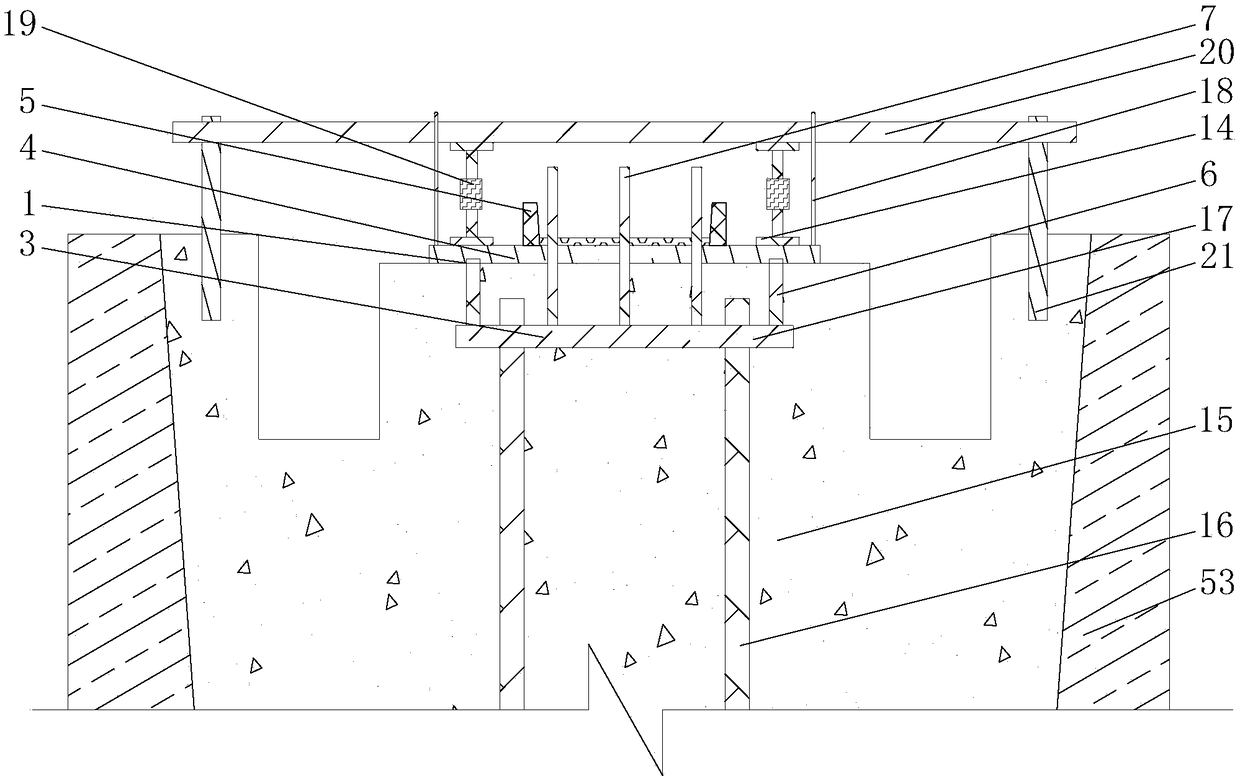

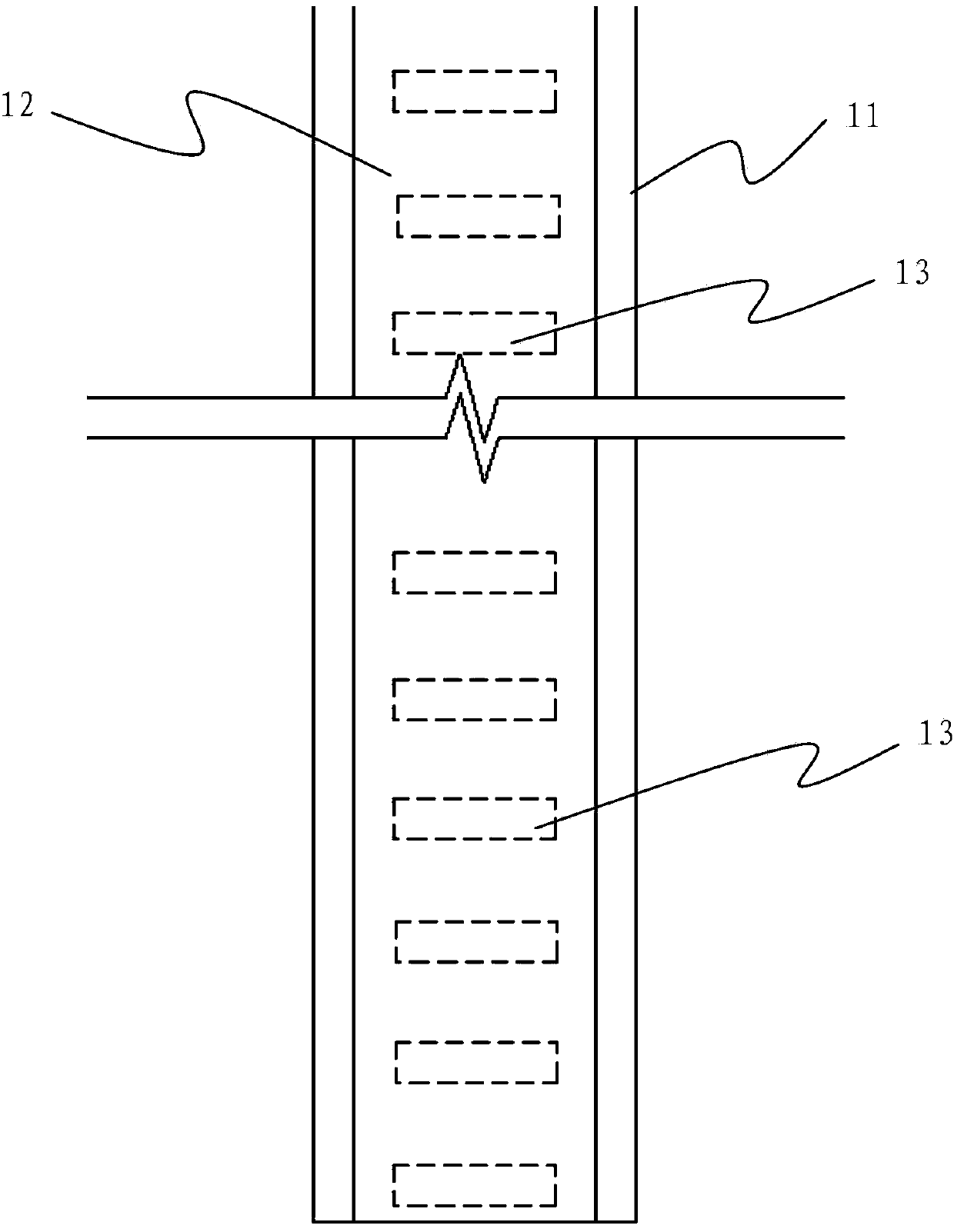

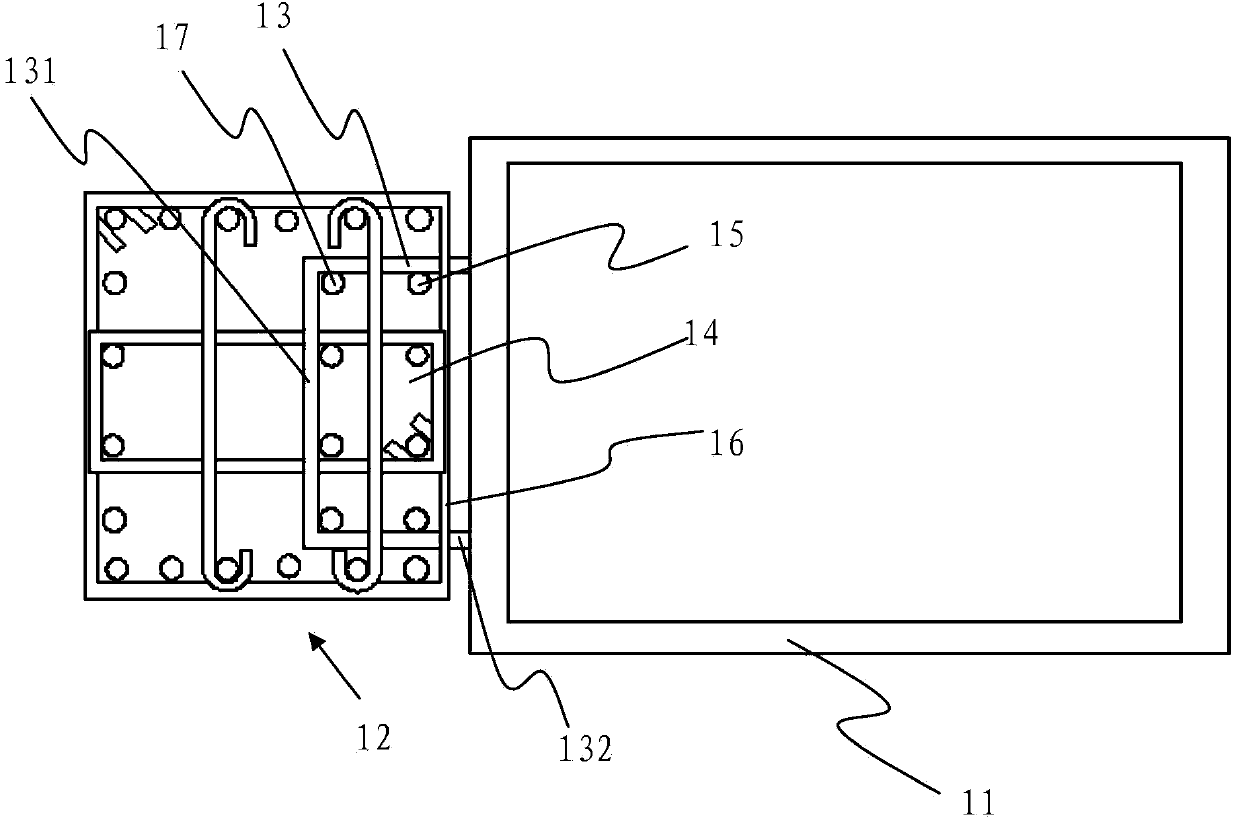

Fabricated type shear wall vertical connection energy dissipation structure and construction method thereof

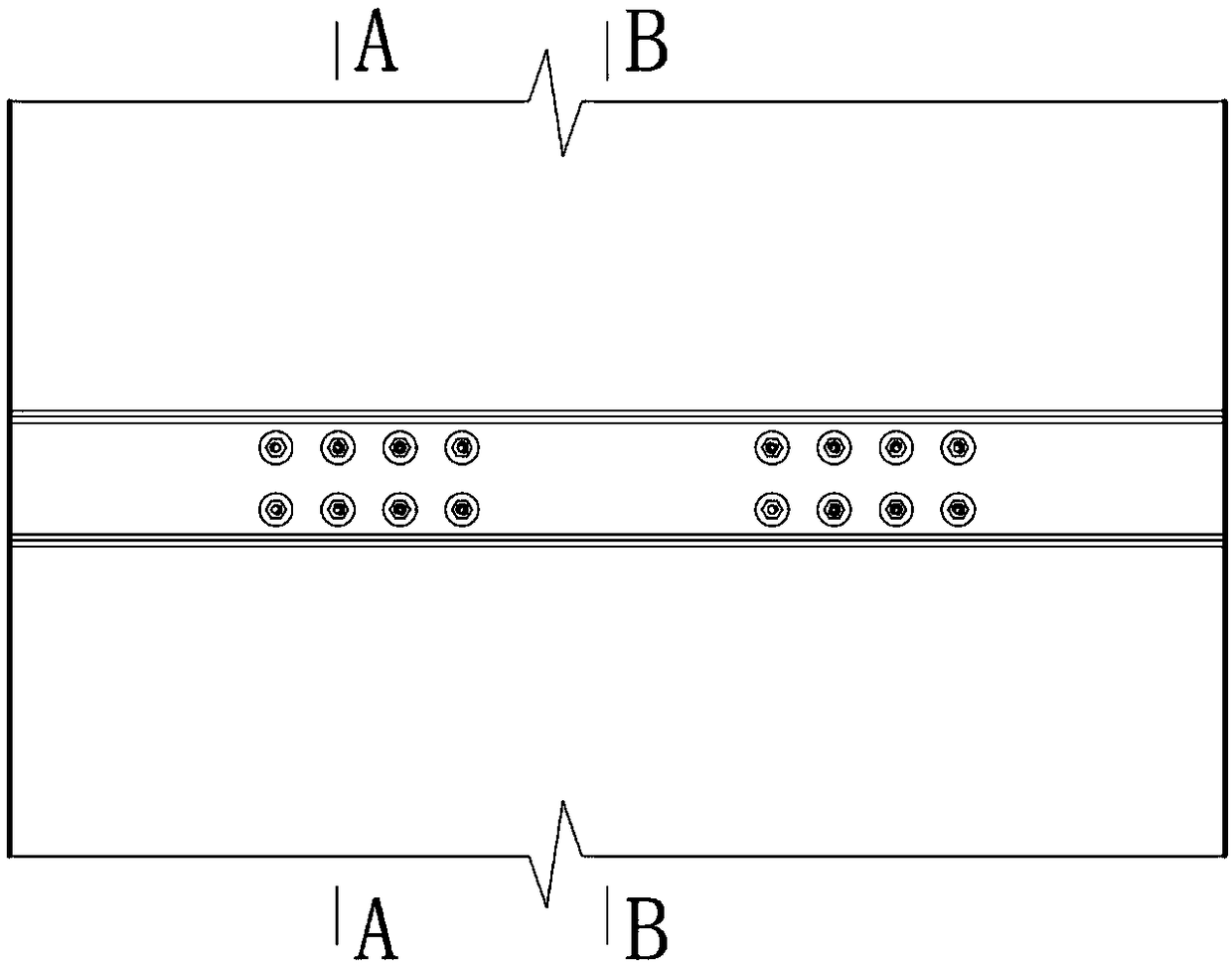

PendingCN109440973AImprove prefabrication rateEase of industrial productionWallsProtective buildings/sheltersEngineeringRebar

The invention provides a fabricated type shear wall vertical connection energy dissipation structure and a construction method thereof, and belongs to the technical field of building engineering. Thefabricated type shear wall vertical connection energy dissipation structure comprises a first shear wall prefabricated part, a second shear wall prefabricated part and lateral groove shaped steel parts. The first shear wall prefabricated part comprises a first horizontal steel plate, a plurality of first anchoring reinforcing steel bars, a first shear wall and a plurality of plug steel plate parts, and bolt holes are formed in the plug steel plate parts. The second shear wall prefabricated part comprises a second horizontal steel plate, a plurality of inserted groove steel plate parts, a plurality of second anchoring reinforcing steel bars and a second shear wall, bolt holes are formed in the inserted groove steel plate parts, and bolt holes are formed in the lateral groove shaped steel parts. According to the fabricated type shear wall vertical connection energy dissipation structure and the construction method thereof, the prefabricating ratio is low, industrial production is facilitated, the site construction difficulty can be reduced, the construction efficiency can be improved, the construction quality can be guaranteed, and the mounting precision and effectiveness of connection can be guaranteed and the action of energy dissipation and seismic mitigation is achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

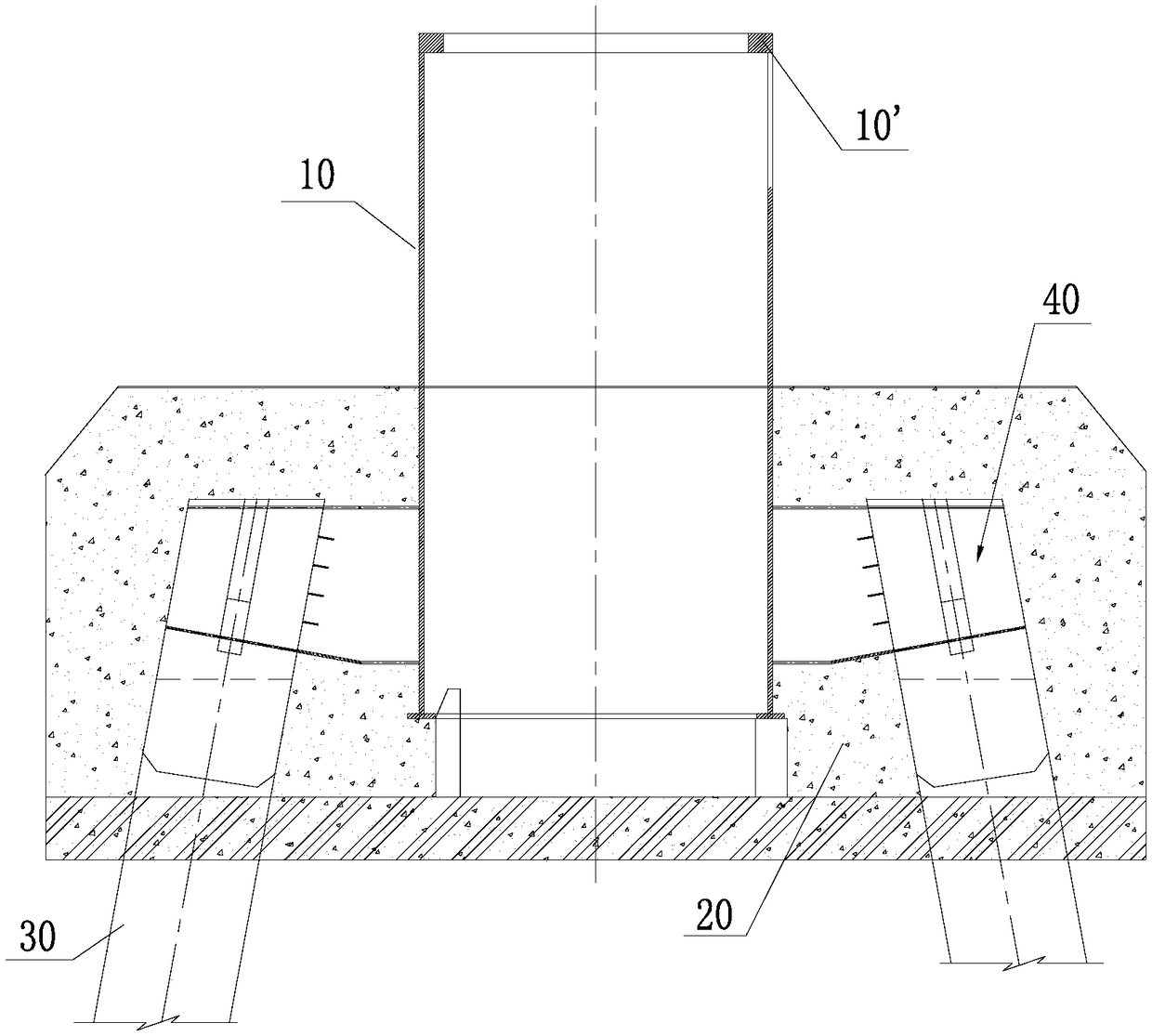

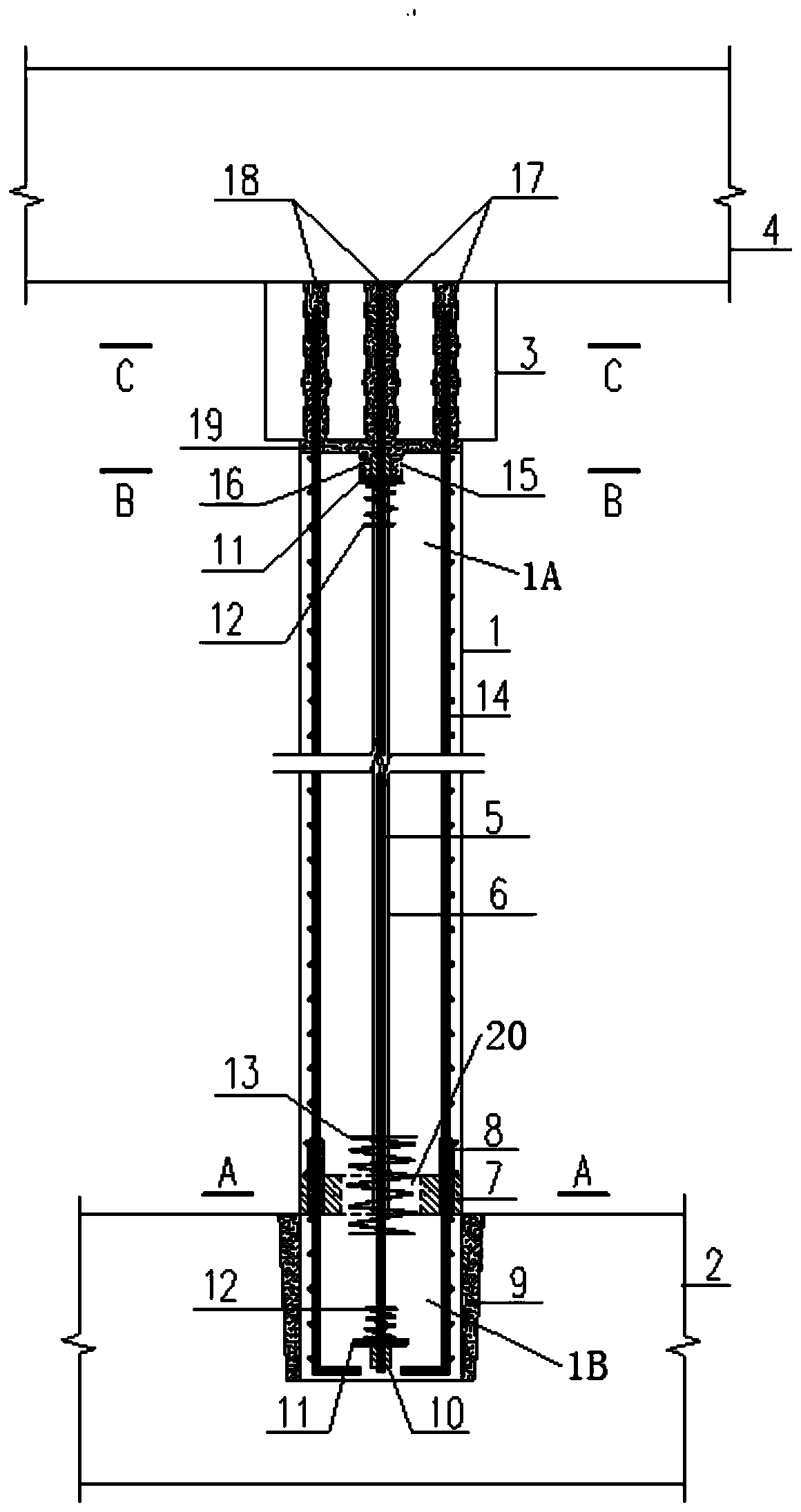

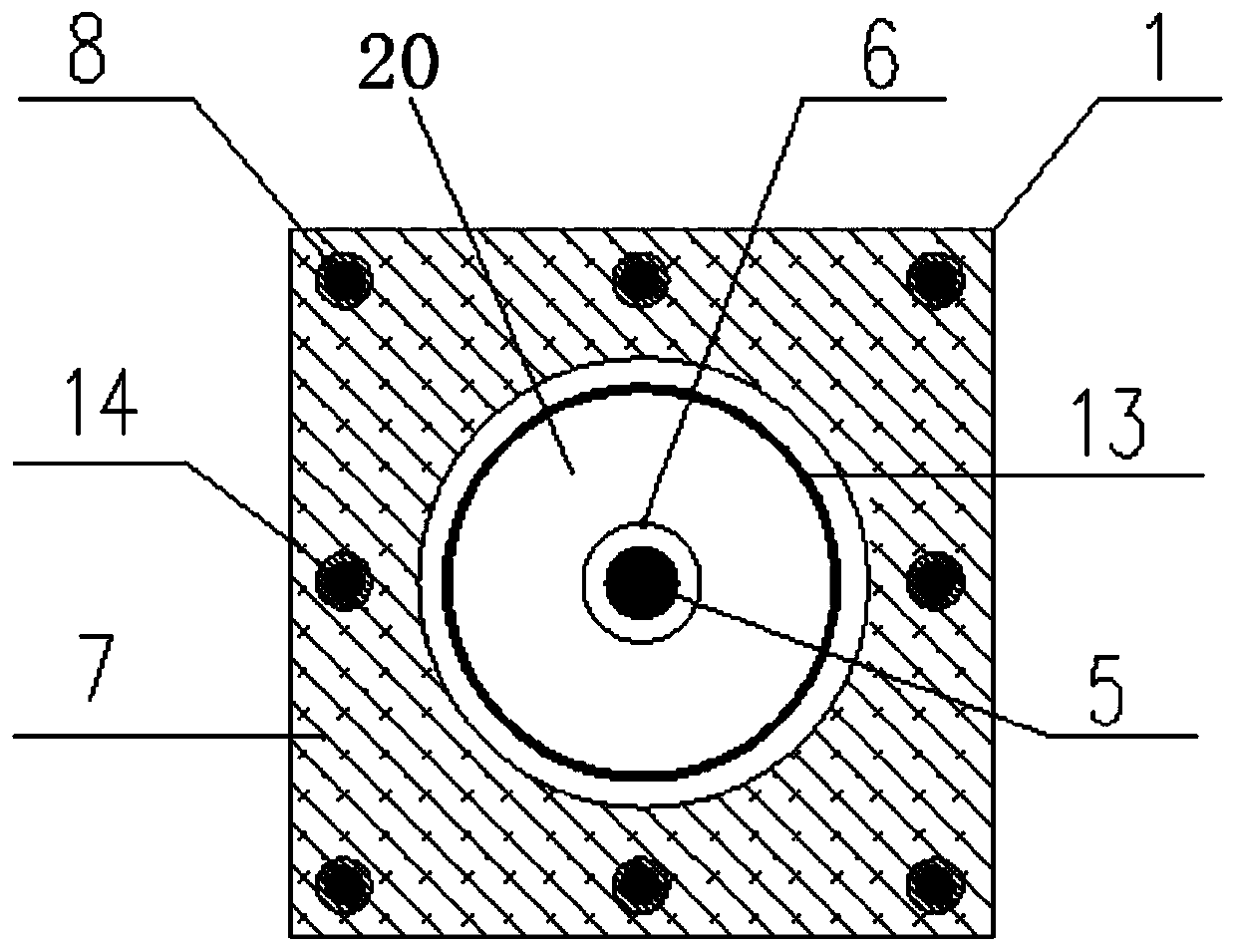

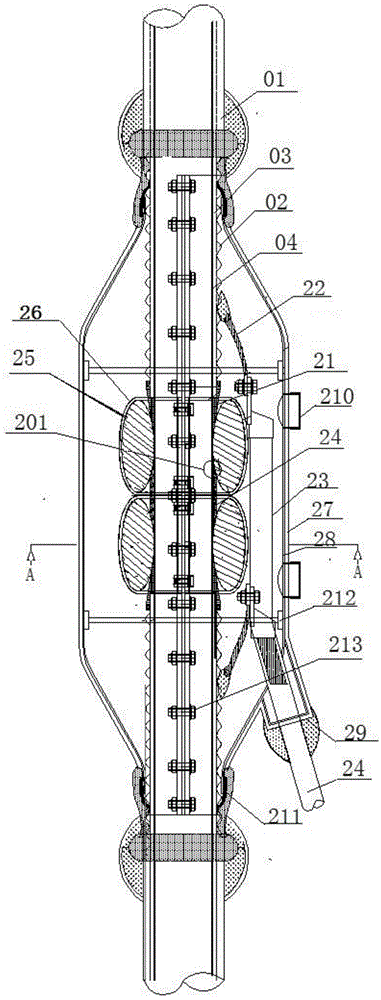

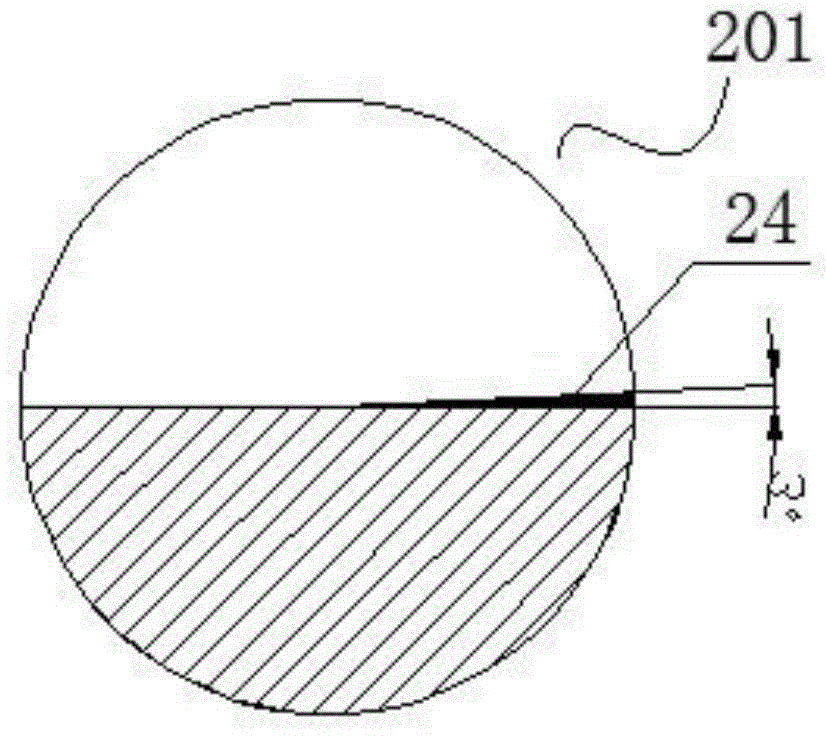

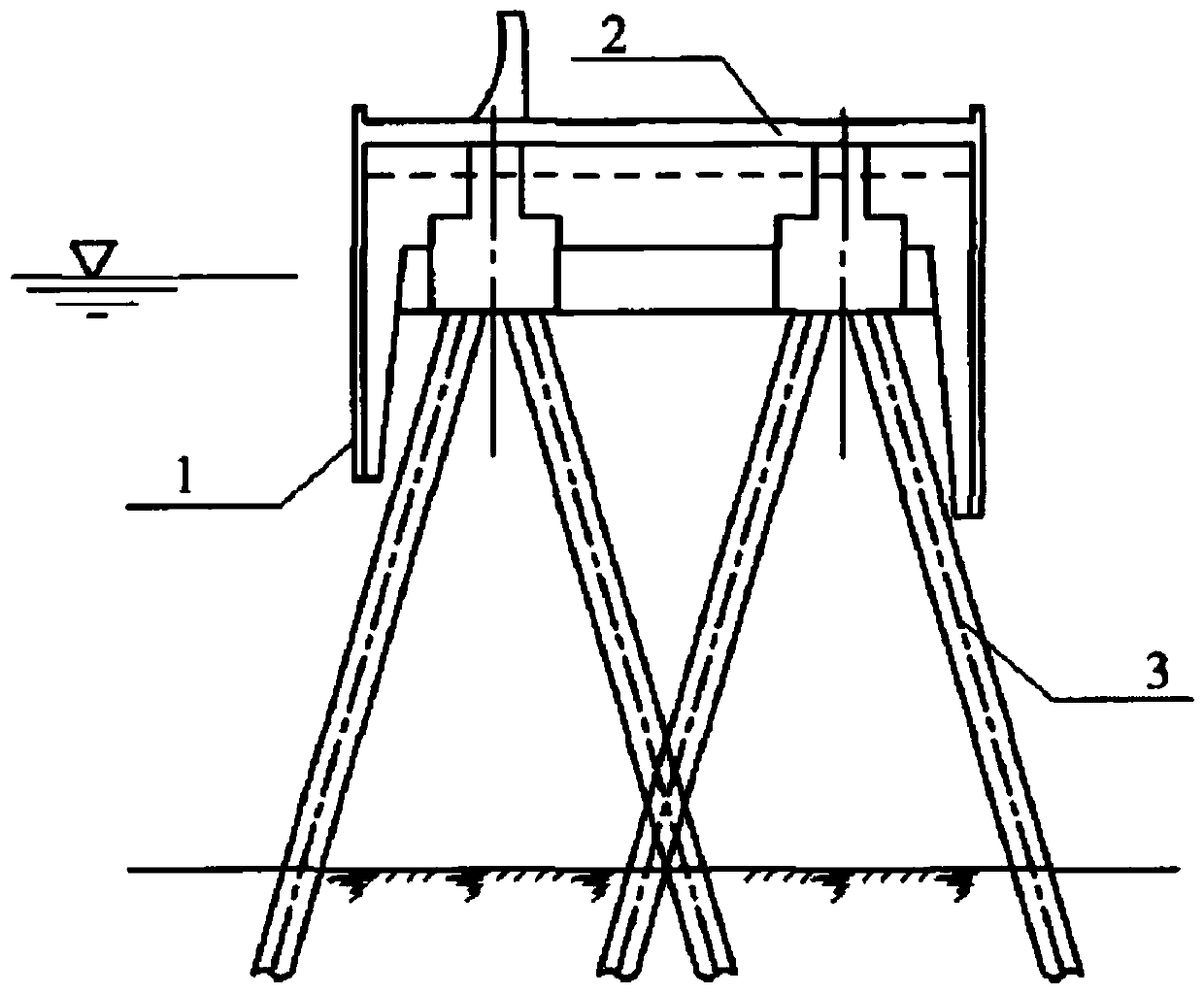

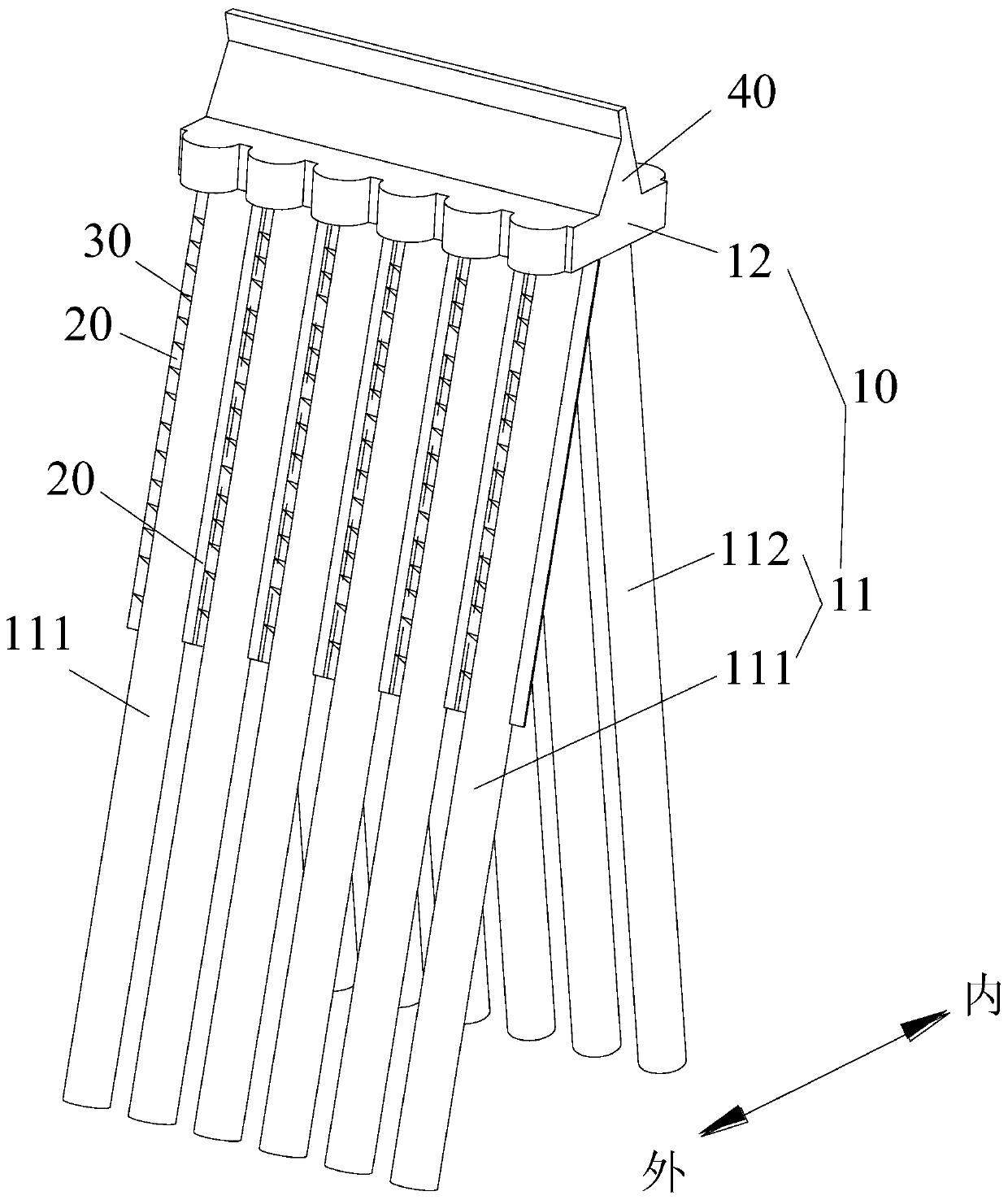

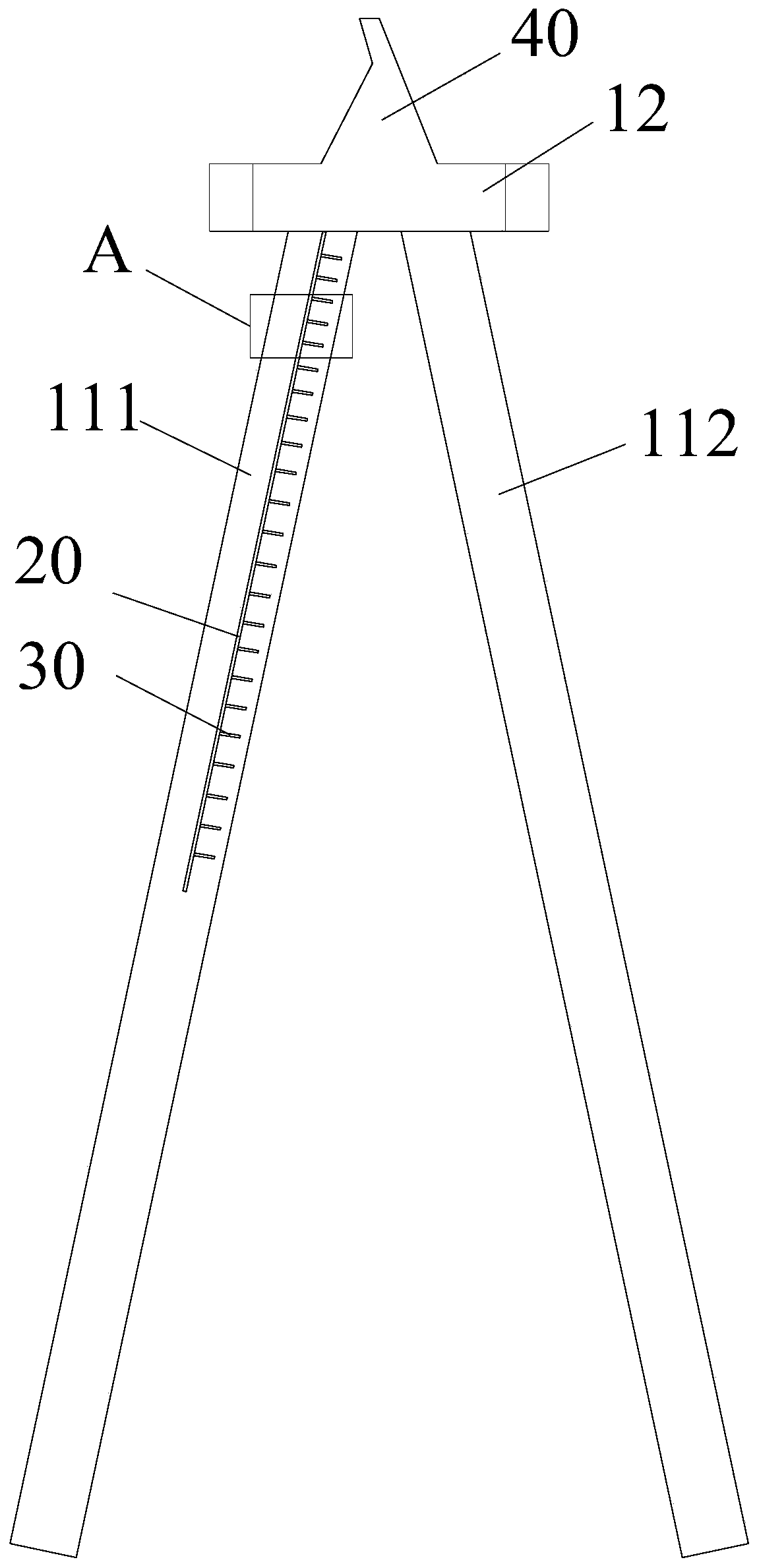

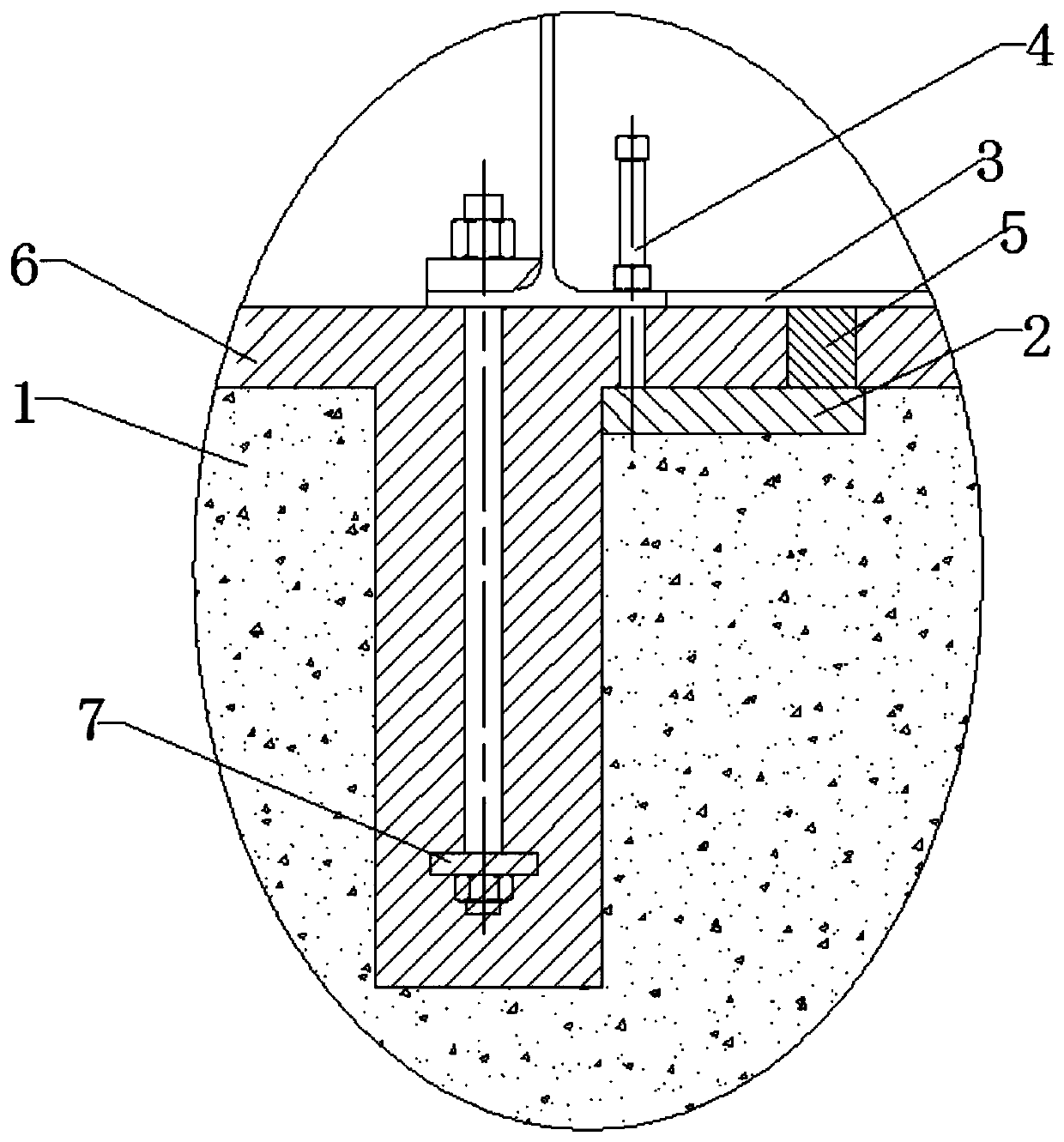

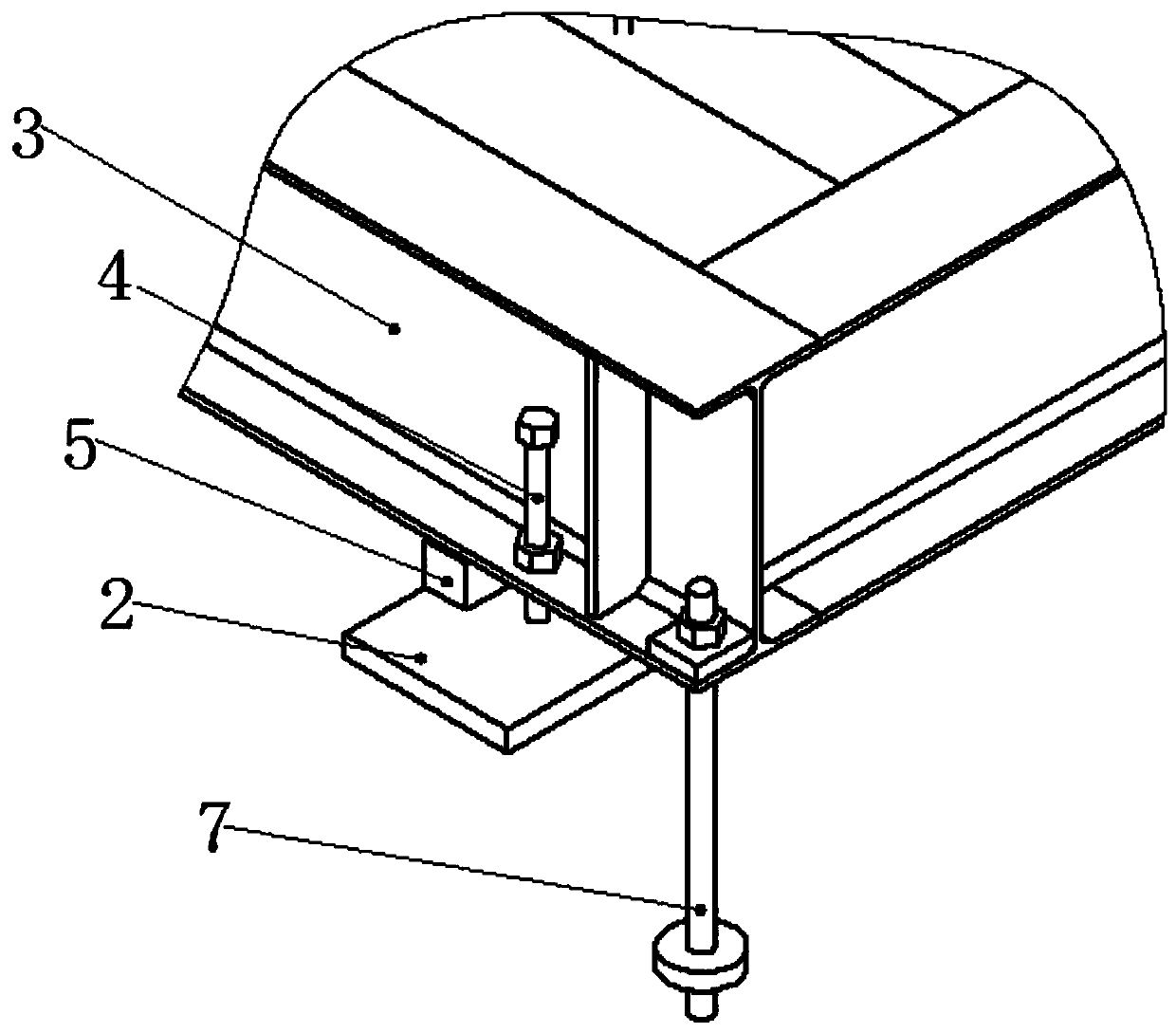

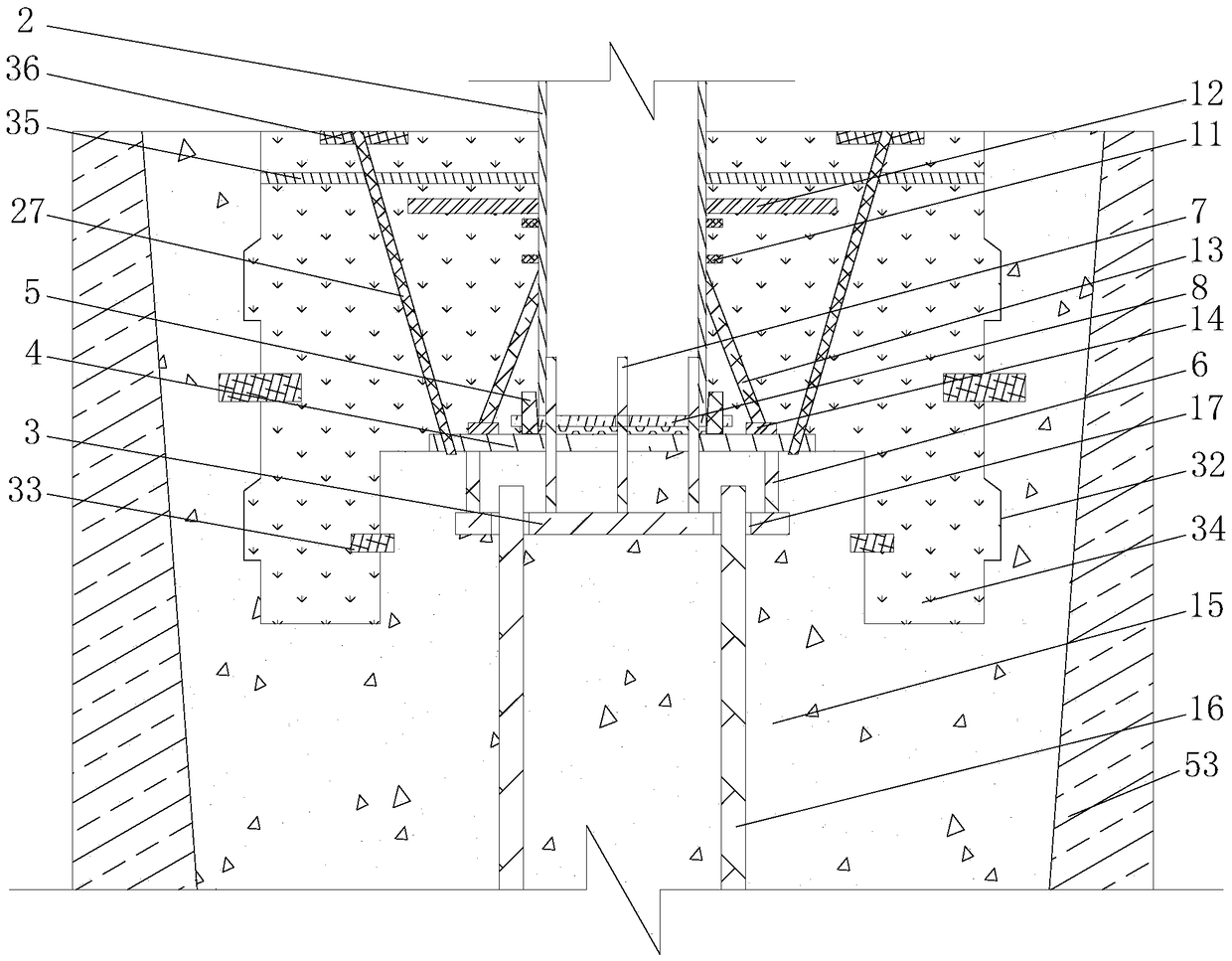

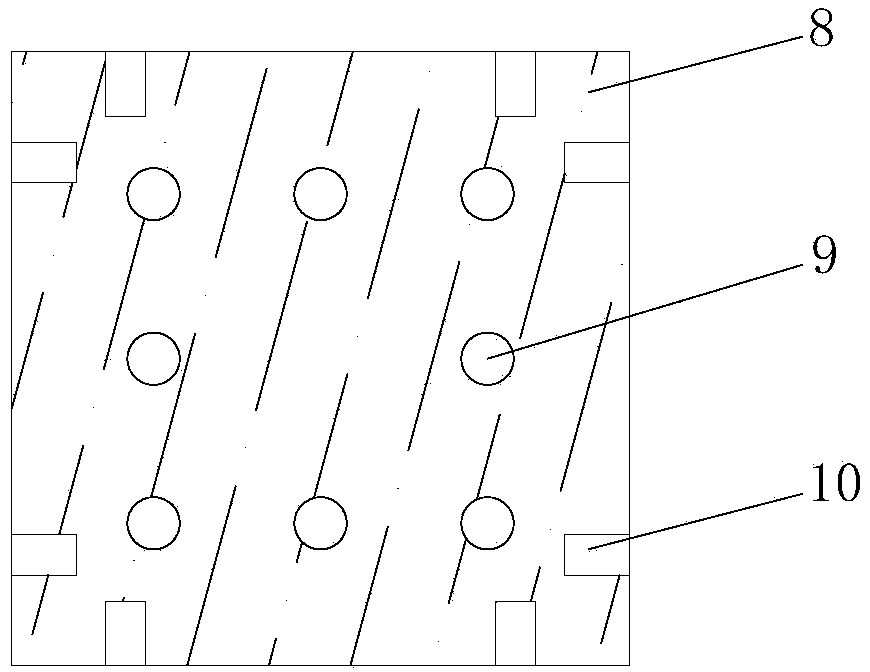

Offshore wind power fabricated type bearing table foundation and construction method thereof

PendingCN108643221ALower the volumeReduce the difficulty of on-site constructionFoundation engineeringElectricityPre stress

The invention discloses an offshore wind power fabricated type bearing table foundation and a construction method thereof. The bearing table foundation comprises a bearing table, an anchor rod mechanism and a plurality of foundation steel pipe piles; the bearing table is a cylindrical prefabricated concrete bearing table, a plurality of cylindrical pile holes are preserved in the bottom face of the bearing table, and a ring-shaped anchor rod groove is reserved in the middle of the top face; the anchor rod mechanism is a pre-stressed anchor rod cage, the height of the pre-stressed anchor rod cage is matched with the depth of the anchor rod groove, the diameter of the pre-stressed anchor rod cage is matched with the diameter of a draught fan tower barrel transition section, and the pre-stressed anchor rod cage comprises a flange base plate, a lower anchor plate and a plurality of pre-stressed anchor rods; the anchor rod mechanism is embedded into the anchor rod groove and is integrally solidified with the bearing table in a manner of filling slurry into the anchor rod groove after the flange base plate is leveled; and the multiple foundation steel pipe piles are all straight piles, the tops of the multiple foundation steel pipe piles are inserted into the multiple pile holes in a one-to-one corresponding manner, and then the bearing table and the foundation steel pipe piles are solidified into a whole in a manner of filling the slurry into the pile holes. By means of the offshore wind power fabricated type bearing table foundation and the construction method, the pouring quantity of concrete on site can be obviously reduced, the construction difficulty is greatly reduced, and the construction working efficiency is improved.

Owner:CCCC THIRD HARBOR ENG +2

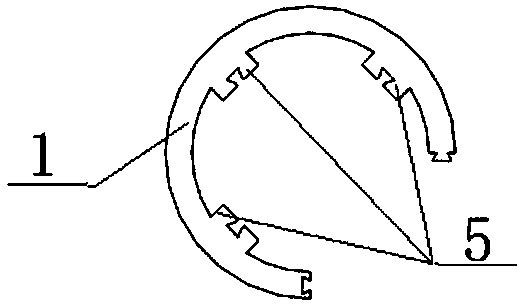

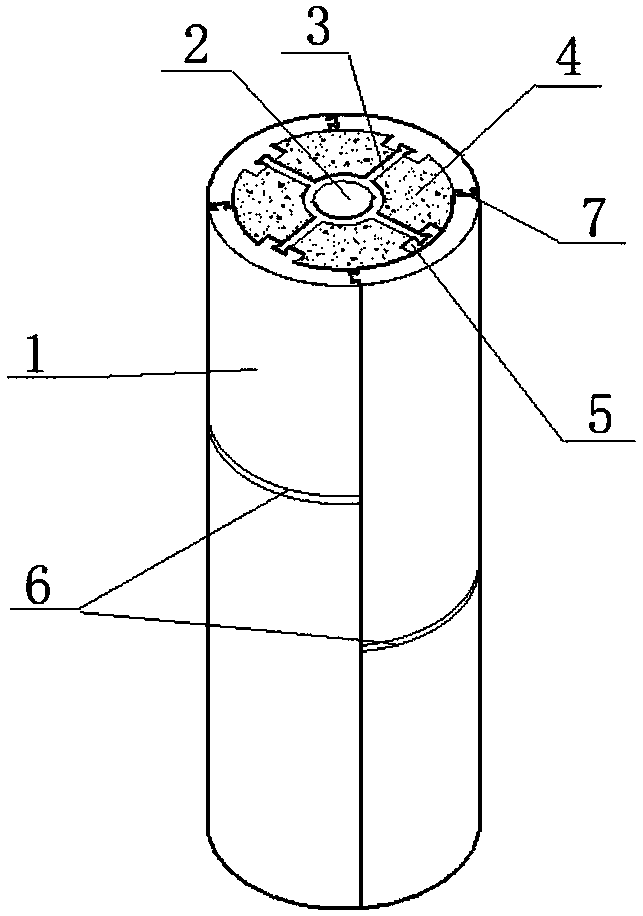

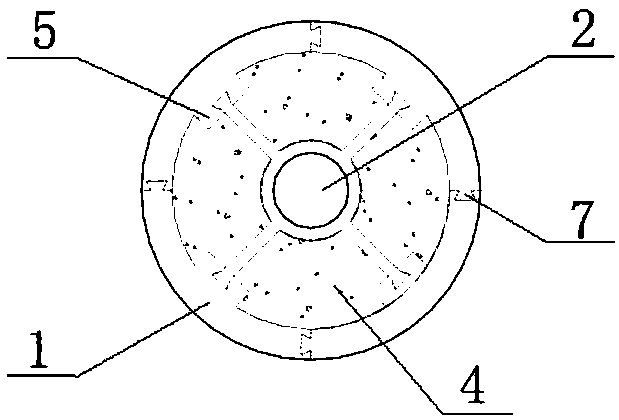

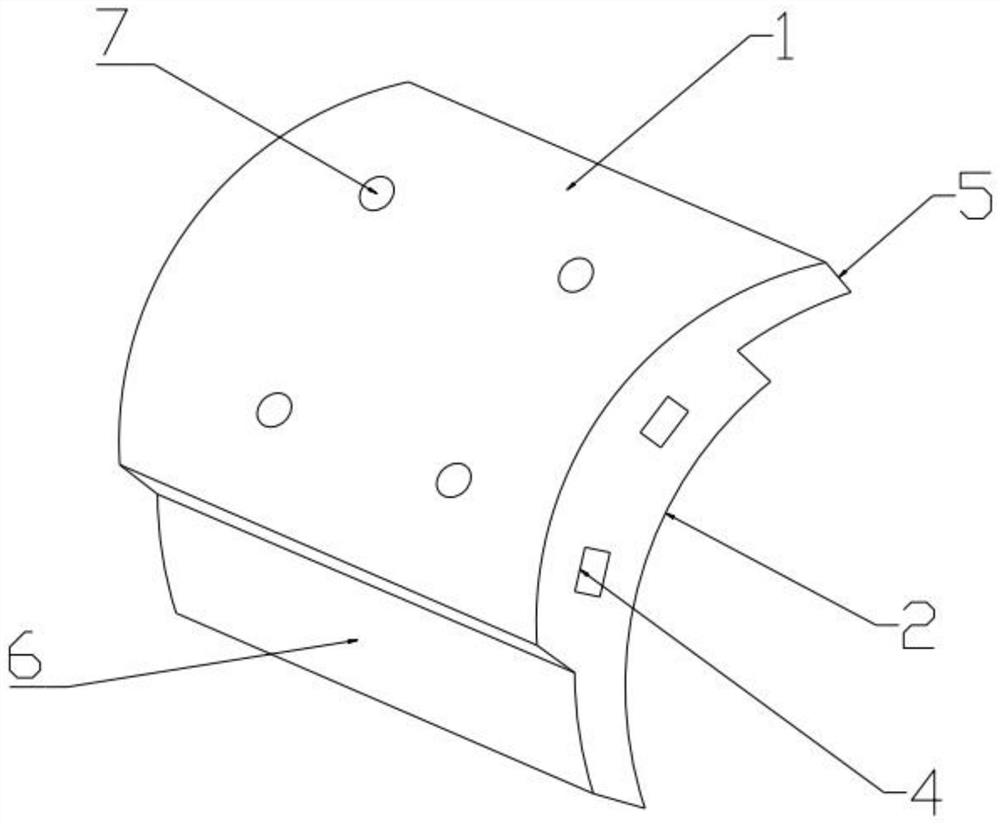

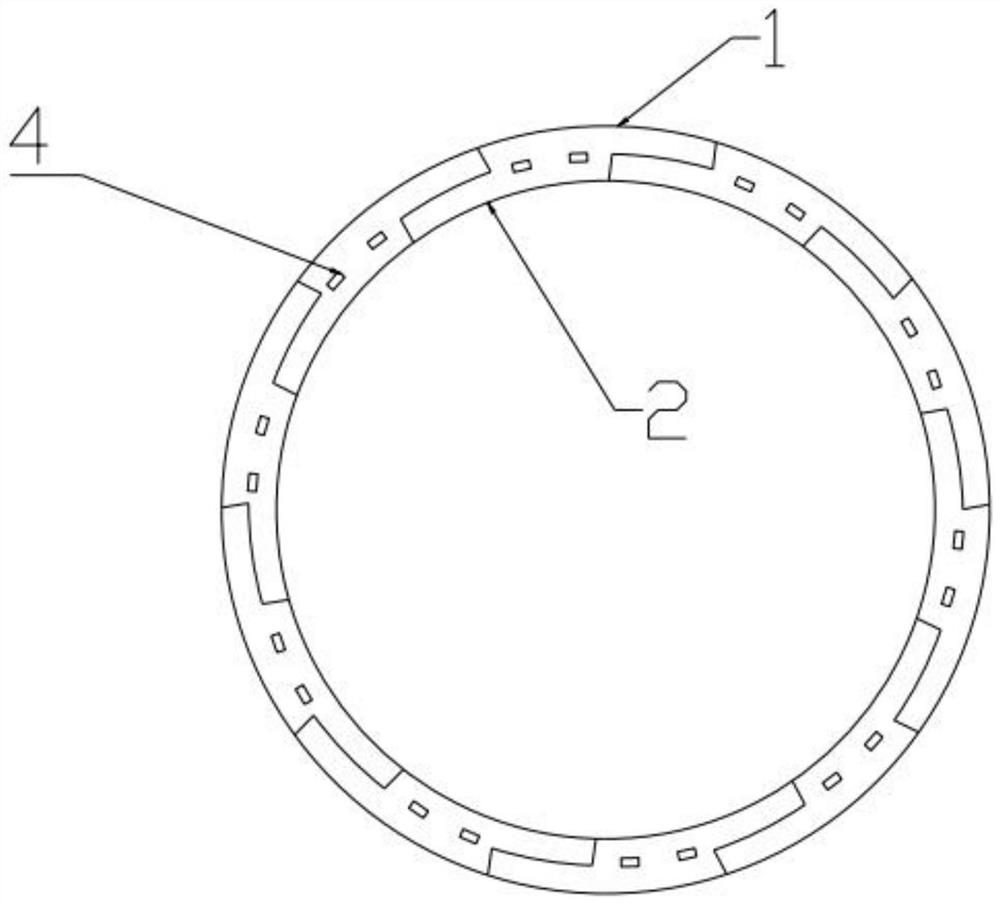

Circular hollow interlayer splicing column and construction method thereof

The invention relates to a circular hollow interlayer splicing column and a construction method thereof, and belongs to the technical field of building steel structure construction. The circular hollow interlayer splicing column comprises an outer circular pipe column formed by vertically inserting and fixing at least two skeleton units, and an inner circular pipe column member fixed in the outercircular pipe column; the inner wall of the outer circular pipe column is welded with at least one anti-drop groove; the inner tubular column member comprises an inner circular pipe column concentrically arranged with the outer circular pipe column, and a plurality of equal length steel partition plates welded perpendicularly along the outer wall of the inner circular pipe column; the steel partition plates are spaced apart from each other and anti-drop heads matched with the anti-drop grooves are arranged at ends of steel partition plates; the inner circular pipe column is fixed by insertingthe anti-drop heads of the steel partition plates into the anti-drop grooves of the outer circular pipe column; and the heights of the skeleton units at the left side and the right side of the bottomlayer is inconsistent in the vertical direction and the two skeleton units are staggered up and down. By adopting the circular hollow interlayer splicing column, the problems that the connection modeof the existing circular hollow interlayer splicing column is inconvenient in on-site construction operation, the connecting member is complicated in design and construction, and pitch points are insufficient in stiffness, and difficult in welding at present are solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Assembly type framework beam anchor cable supporting structure and construction method thereof

PendingCN108442391AReduce installationEasy constructionExcavationsBulkheads/pilesFalseworkSurface layer

The invention provides an assembly type framework beam anchor cable supporting structure. The assembly type framework beam anchor cable supporting structure comprises an assembly type framework beam,pre-stress anchor cables and an alien soil spraying face; the assembly type framework beam is composed of mutually connected prefabricated cross beams; through-length rebars are arranged in the prefabricated cross beams; lifting hooks and fixing rebars are pre-buried in the two ends of cross beams and vertical beams; an anchor cable hole is formed in the center of each prefabricated cross beam; through-length rebar joints between the prefabricated cross beams are mutually connected through mechanical connection joints; concrete is poured at the joints between the prefabricated cross beams to form a whole; the pre-stress anchor cables pass through the anchor cable holes and are fixed to the prefabricated cross beams by anchorage devices; and the lifting hooks on the prefabricated cross beams are connected with soil nails through slings. The assembly type framework beam anchor cable supporting structure is suitable for rock side slope supporting, construction is convenient, prefabricatedframework beam components can be directly fixed to a supporting surface layer, and scaffold installing is omitted; and the assembly type framework beam is adopted, the components are prefabricated ina factory, and the field construction difficulty is reduced; and meanwhile, a cast-in-situ segment template support can be directly fixed to the prefabricated components, and the construction speed is increased.

Owner:DALIAN UNIV OF TECH

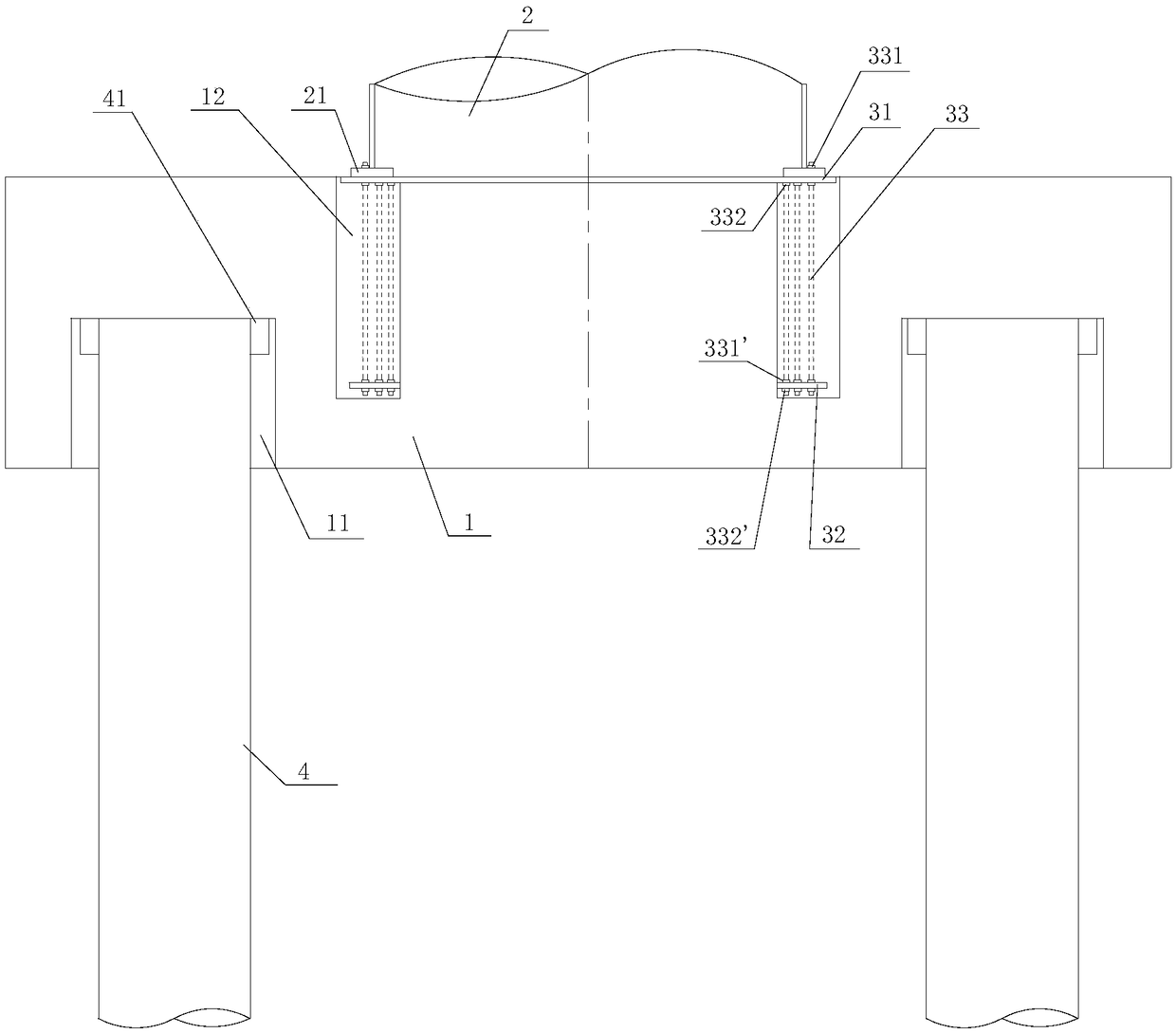

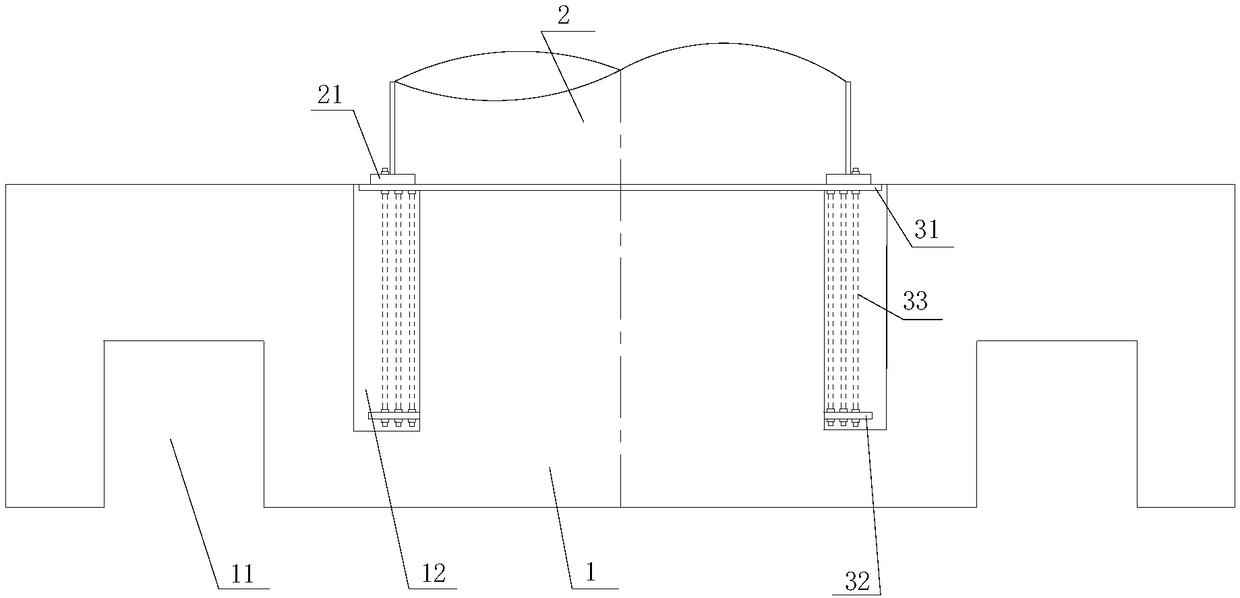

Partially bonded prestress assembly self-reset bridge pier column node and method

ActiveCN110359363ABuild fastImprove construction qualityBridge structural detailsBridge erection/assemblyPre stressEngineering

The invention relates to a partially bonded prestress assembly self-reset bridge pier column node and a method. The node comprises a pier column, wherein a main body of the pier column is fabricated by concrete; the lower end of the pier column is inserted into a foundation and fixedly connected with the foundation; the upper end of the pier column is fixedly connected with a capping beam; a prestressed reinforcement is arranged in the pier column; a central axis of the pier column is coincided with that of the prestressed reinforcement; the lower end of the prestressed reinforcement is inserted into the foundation along with the pier column; the middle of the prestressed reinforcement is arranged in the pier column; the upper end of the prestressed reinforcement penetrates out of the piercolumn and is inserted into the capping beam; the lower end of the prestressed reinforcement is bound and fixed to the pier column; the upper end of the prestressed reinforcement is bound and fixed to the capping beam; the middle of the prestressed reinforcement is arranged in a prestressed reinforcement duct of the pier column; the upper end of the prestressed reinforcement duct penetrates through the pier column; the lower end of the prestressed reinforcement duct is positioned in the pier column; and the lower end of the prestressed reinforcement is fixedly connected with the pier column through an anchor piece. The disadvantages of long construction cycle and high cost due to adoption of an external dissipative element and post tensioned application of prestress can be avoided, and the probability of brittle failure of the pier column is reduced.

Owner:SHANDONG JIANZHU UNIV

False cable joint

InactiveCN104065021ARealize the cross-connection functionReduce the influence of induced voltageCable terminationsInterconnectionEngineering

The invention discloses a false cable joint, applied to the laying process of a long cable to replace part of real joints to achieve cross interconnection. During the manufacture of the false cable joint provided by the invention, the cable at the position where a joint needs to be arranged is stripped in three modes, wherein the first mode is stripping from an outer insulating layer of the cable to a semiconductive buffer band and then recovering insulation and waterproofness of the cable; the second mode is stripping from an outer insulating layer of the cable to an outer semiconductive layer, wrapping the outer semiconductive layer by an annular stress cone or a semiconductive band and an insulating tape in layers to homogenize field intensity distribution and limit an electric field within a safe range, and then recovering insulation and waterproofness of the cable; the third mode is only stripping part of an outer insulating layer, earthing a shielding sheath and then recovering insulation and waterproofness of the cable. Cross interconnection is achieved by replacing the real joints with the false joints to reduce influence of induced voltage of the metal sheath of the long cable, and thereby required investment for joints in a cable laying project is reduced on basis of not changing a traditional design philosophy of cross interconnection .

Owner:李超 +2

Wave-permeable breakwater

PendingCN109763455AReduce weightReduce the difficulty of on-site constructionBreakwatersQuaysEngineeringBuilding construction

The invention provides wave-permeable breakwater which comprises pile bases and wave baffle plates, wherein the pile bases comprise pile base bodies and bearing platforms which are arranged at tops ofthe pile base bodies; the wave baffle plates are arranged on the pile base bodies. By adopting the technical scheme of the invention, the wave baffle plates can extend into any position of water, andthe wave-permeable breakwater is remarkable in wave elimination effect, small in construction difficulty and low in construction cost.

Owner:WATER TRANSPORT PLANNING & DESIGN INST +1

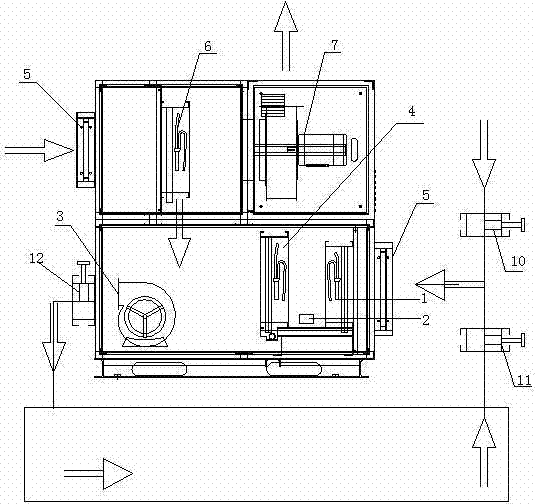

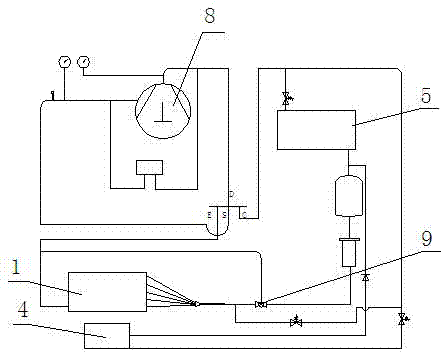

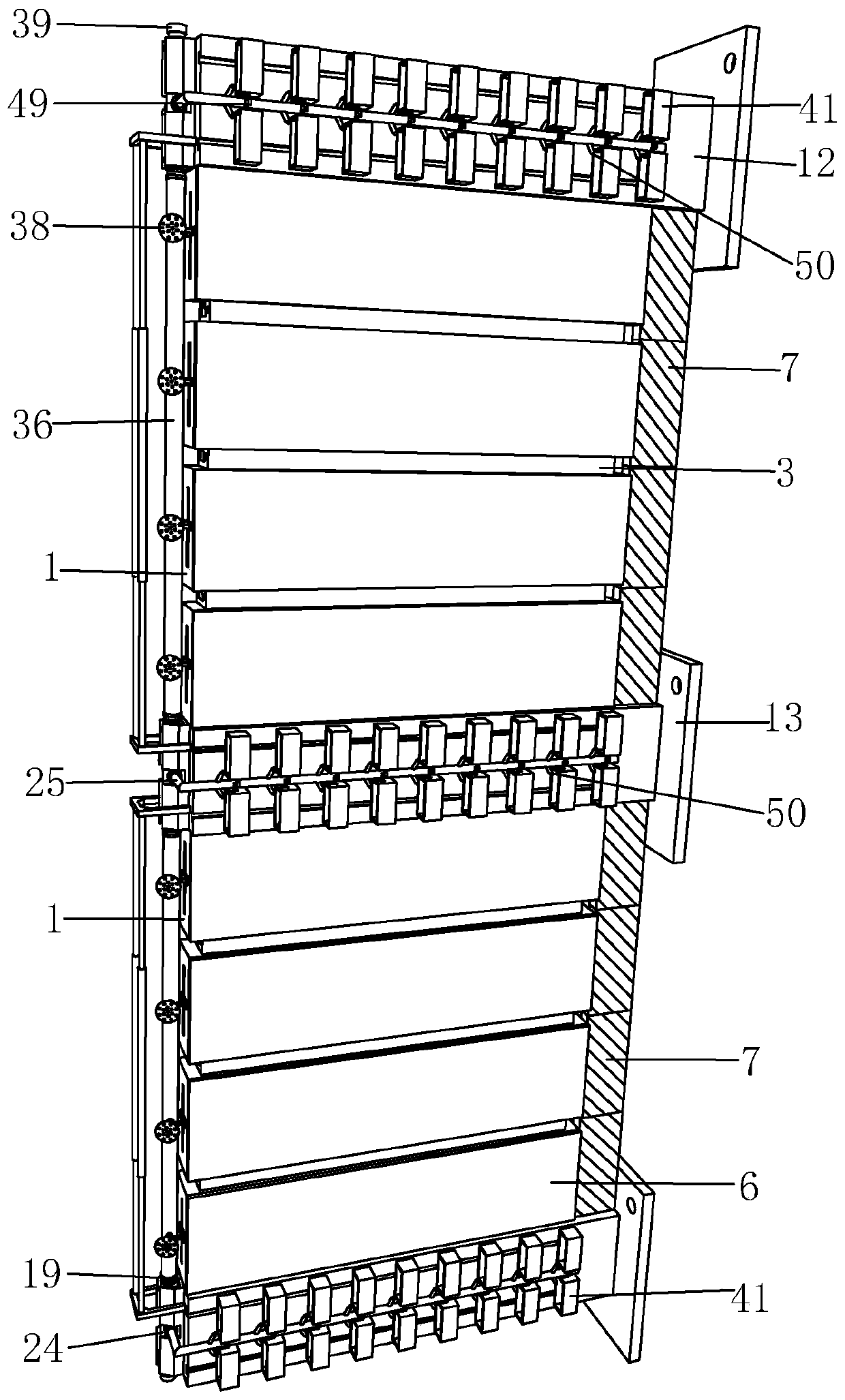

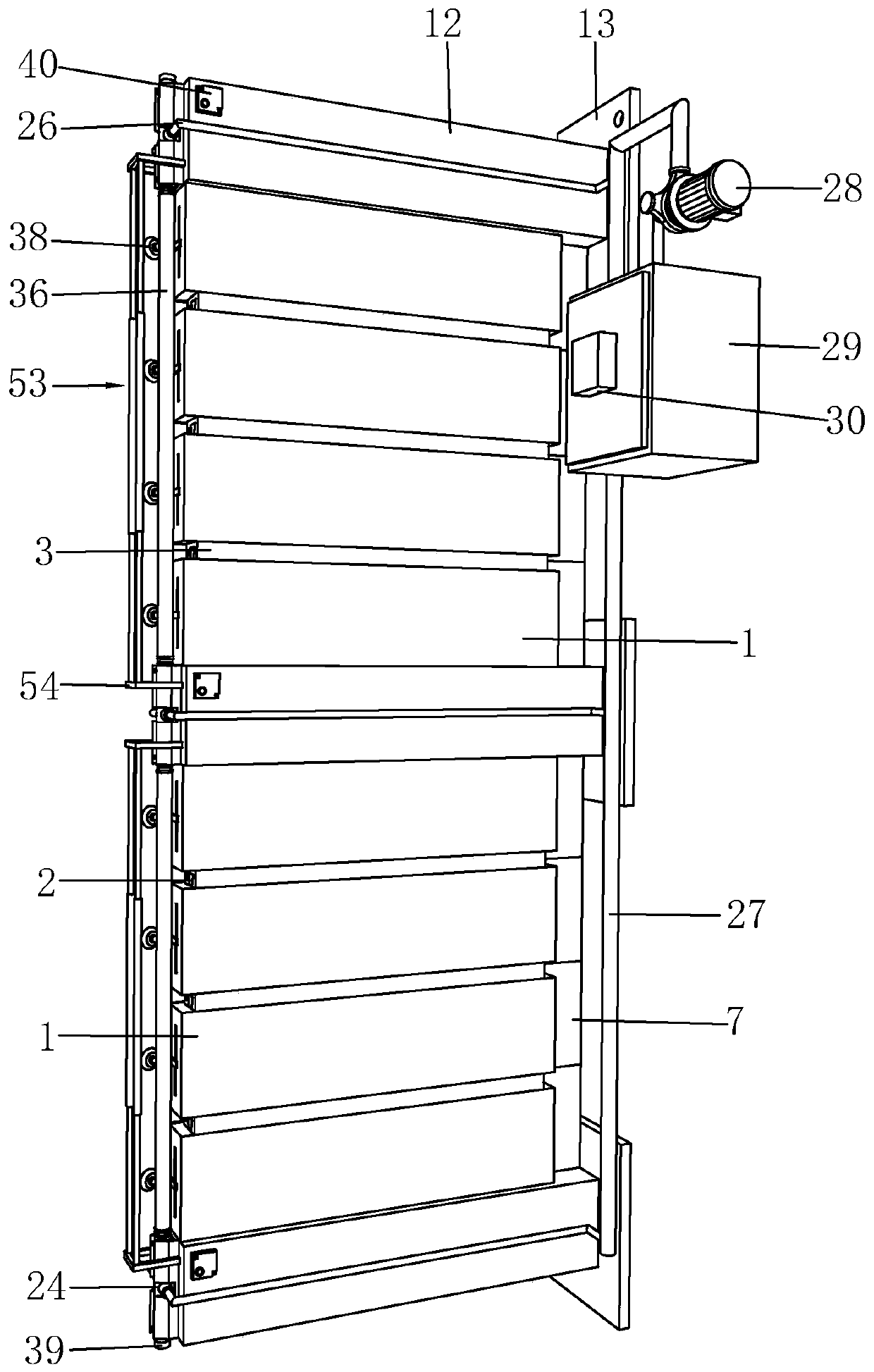

Intelligent temperature and humidity control integrated machine and control method for same

InactiveCN103363598AQuality assuranceReduce the difficulty of on-site constructionSpace heating and ventilation safety systemsLighting and heating apparatusComputer control systemProcess engineering

The invention relates to the field of air temperature and humidity regulation, in particular to an intelligent temperature and humidity control integrated machine and a control method for the same. The intelligent temperature and humidity control integrated machine comprises a heat pump system, a thermal circulation fan, a speed regulation fan and air valves. Condensers of the heat pump system include a main condenser and an auxiliary condenser, and the auxiliary condenser is connected with the main condenser in parallel. The control method for the intelligent temperature and humidity control integrated machine includes that a temperature and humidity sensors detect real-time temperature and humidity values of a drying room, and data are inputted into a computer control system; the computer control system compares the real-time temperature and humidity values of the drying room to set values and controls a temperature and humidity regulation circulation system to run. The intelligent temperature and humidity control integrated machine and the control method have the advantages that energy waste can be effectively reduced, the dehumidification efficiency is high, and temperature regulating and humidity stabilizing effects can be realized.

Owner:杭州迈驰除湿净化设备有限公司

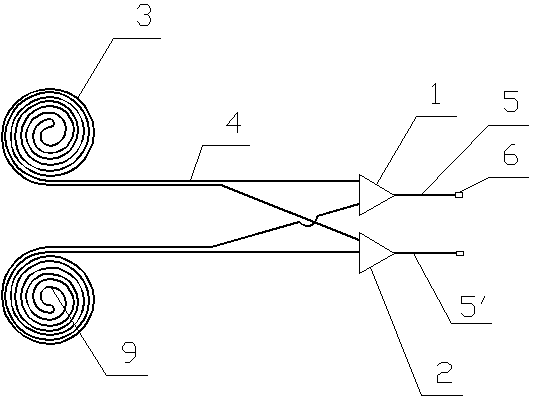

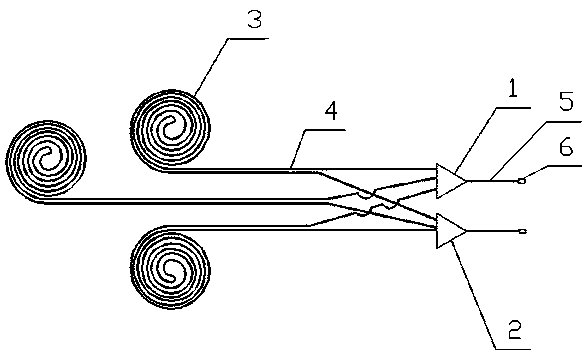

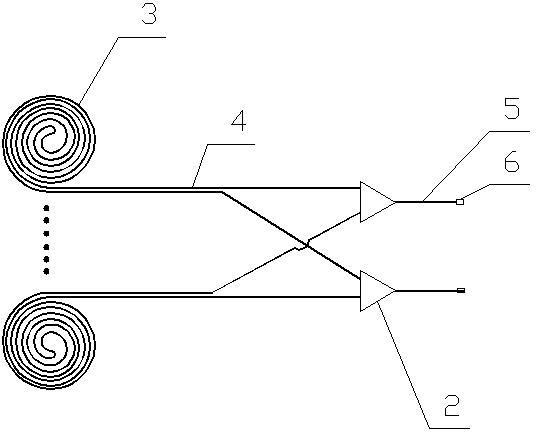

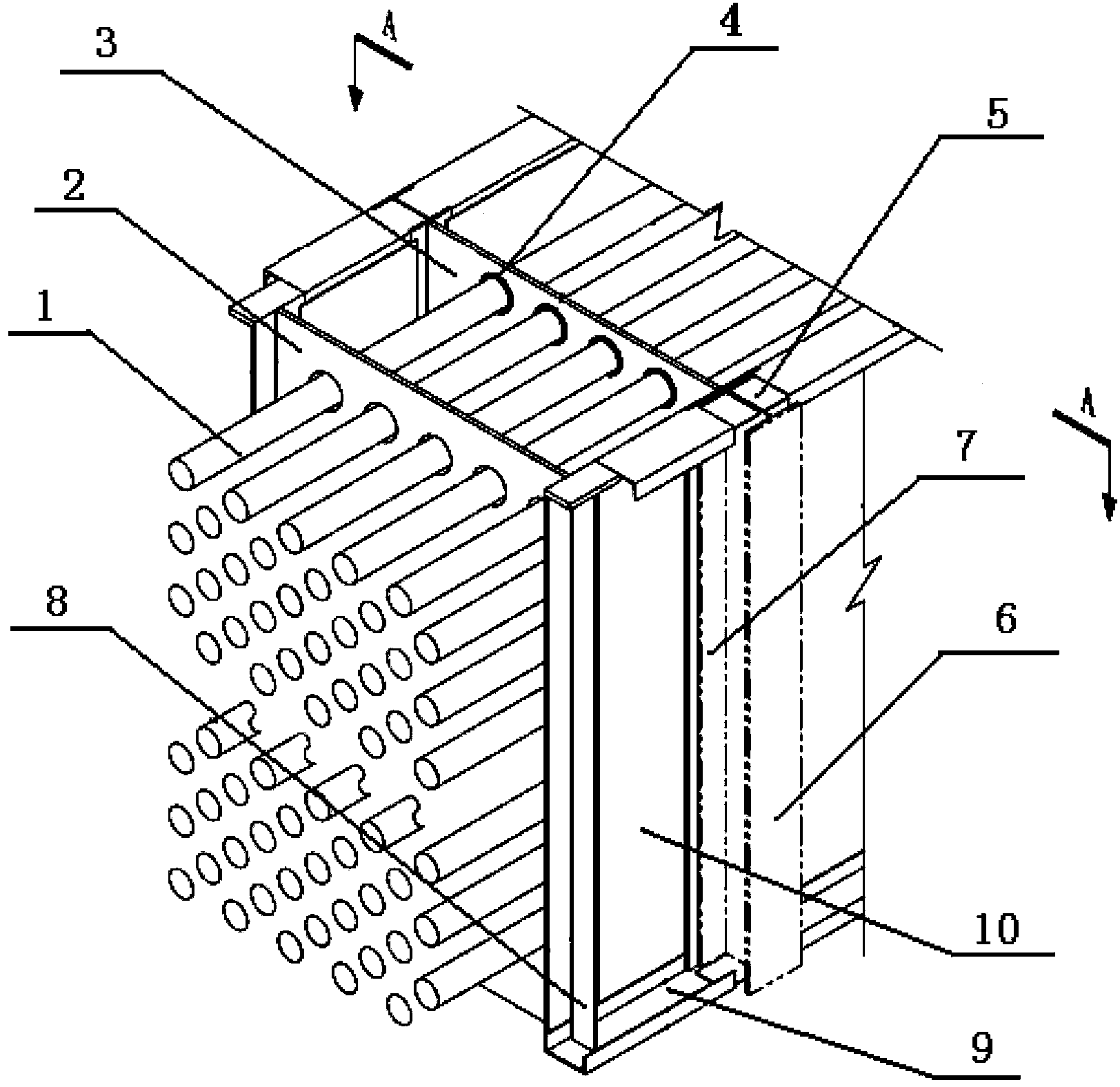

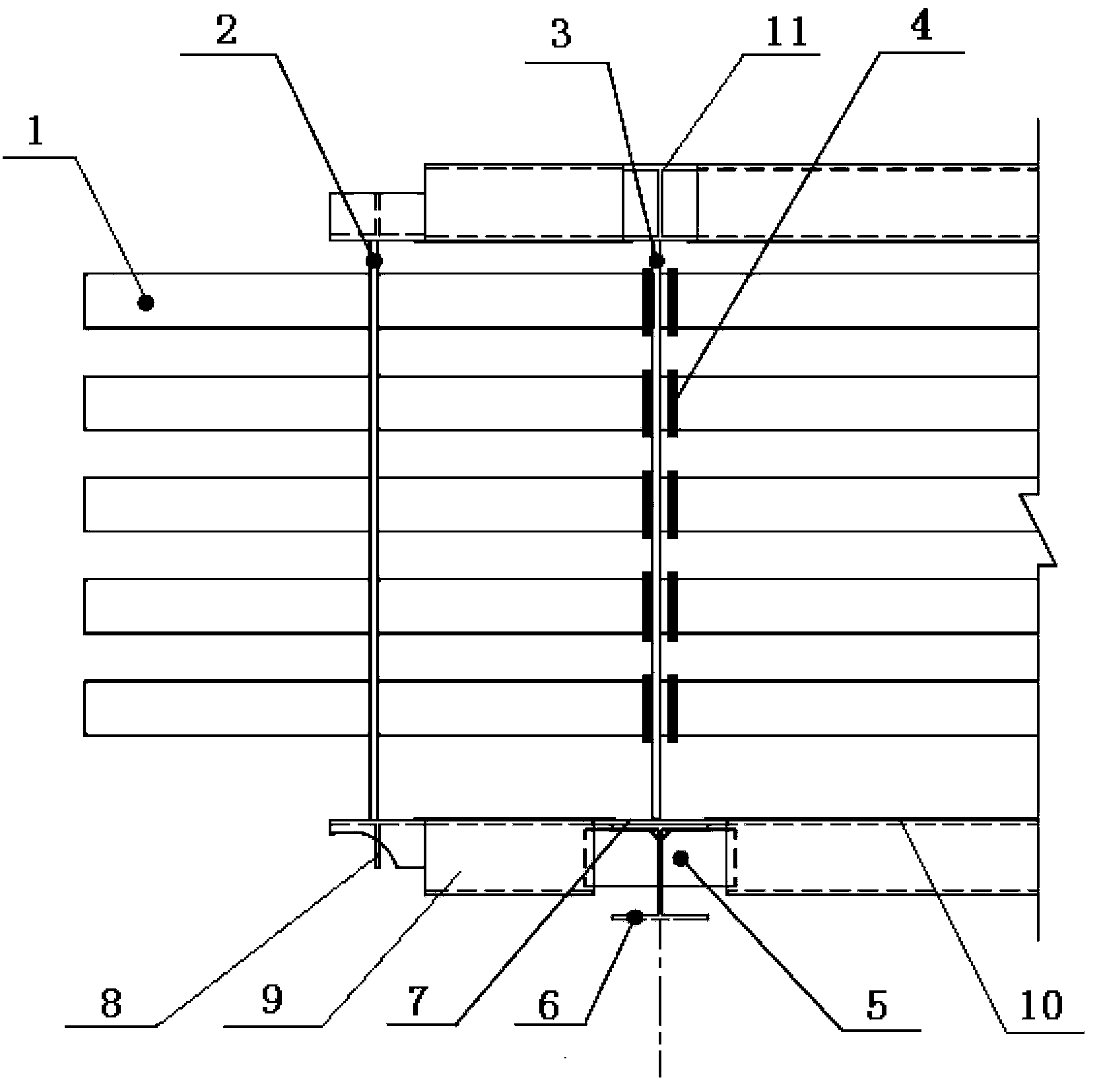

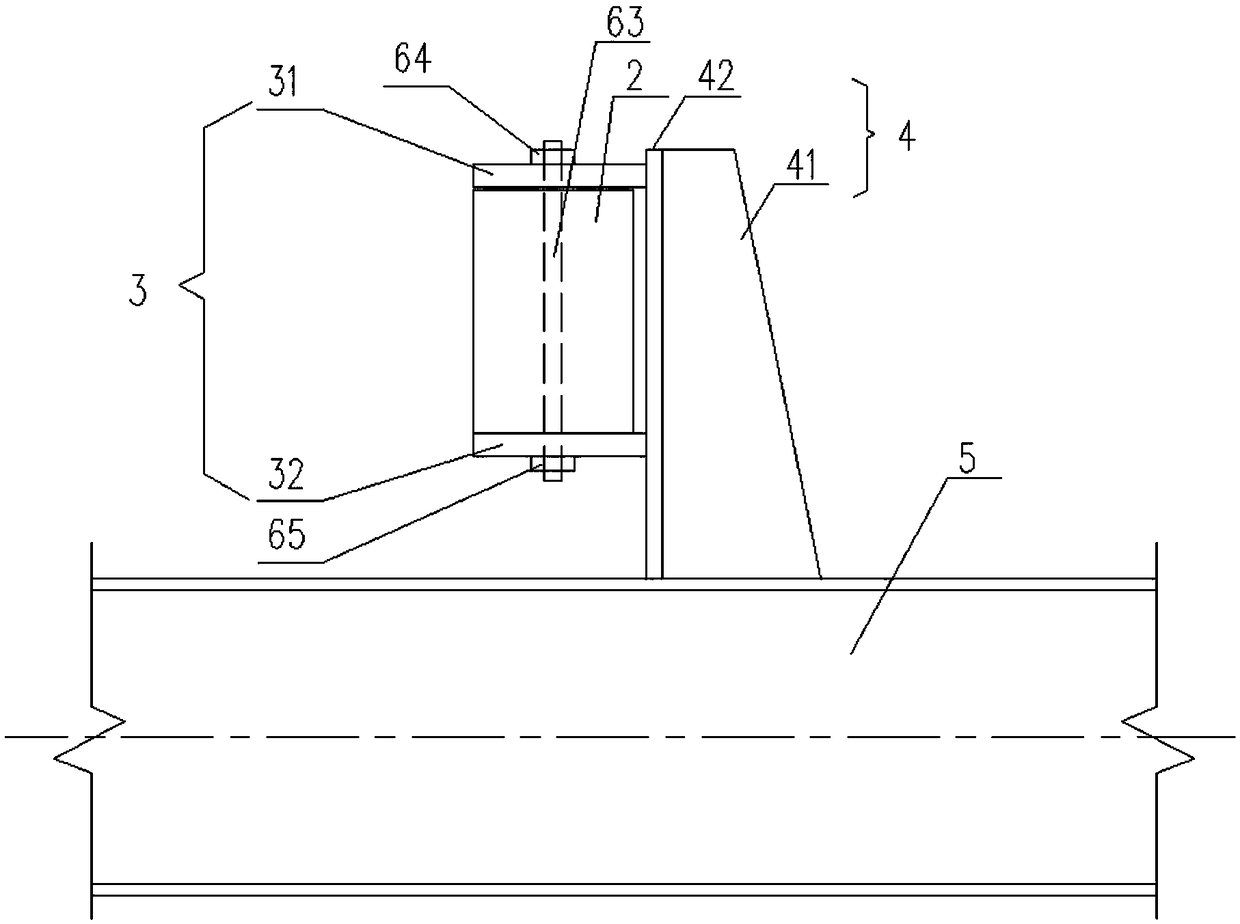

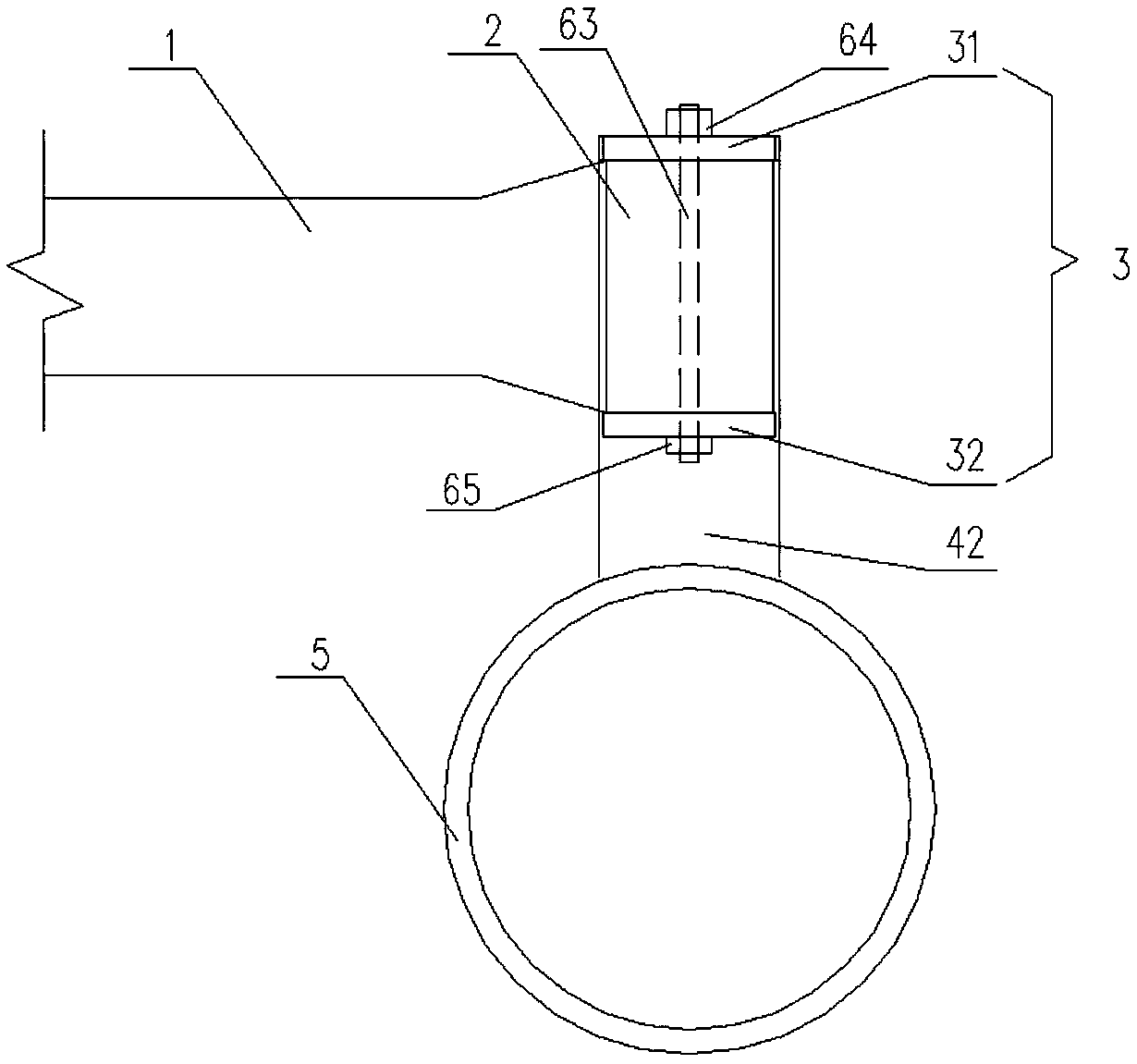

Phase-change heat exchange pipe bundle with optimized structure and production process of phase-change heat exchange pipe bundle

InactiveCN104315906AReduce the difficulty of on-site constructionIncrease profitEvaporators/condensersIndirect heat exchangersCapillary TubingProcess engineering

The invention discloses a production process of a phase-change heat exchange pipe bundle with an optimized structure. The production process includes that each single capillary pipe is bent from the middle of the length direction, and bending diameter is not smaller than four times of diameter of each capillary pipe; two parallel capillary pipes are formed after bending and wound to form a capillary pipe disc; each capillary pipe disc formed by the corresponding single capillary pipe is bundled by using a bundling wire; two joints set apart by each capillary pipe disc are welded on an air distributing head and a liquid returning head respectively. The production process is an extension of patented technology ZL2012202753539, aims to overcome the defects of the patented technology and improve the production process and is an optimized improvement on the patented technology. By adopting the production process to manufacture a pipe bundle coiler, automatic welding can be realized, manufacturing speed of a factory can be increased by more than five times, and speed of an on-site construction laying link can be increased by more than five times.

Owner:陈万仁

Power station generating set oil groove signal extension apparatus

InactiveCN102255419AAchieving pressure resistanceAchieve impact resistanceSupports/enclosures/casingsInterior spacePower station

The invention relates to a power station generating set oil groove signal extension apparatus which comprises a pedestal and a panel. The pedestal and the panel are in sealed connection to form internal space. A central section of the pedestal extends a conduit which communicates with the internal space. An end of the conduit is in threaded connection with a first cable jacket. The panel is provided with a plurality of second cable jackets. A plurality of signal cables fixed by the first cable jacket go through the conduit and the internal space, and go out from the second cable jackets. The signal lead out apparatus of the present invention has the advantages of novel design, vibration proof, impact resistance, high grade of sealing pressure, high reliability, reduction of interference to an oil groove sensor signal by electromagnetic field, reduction of site construction difficulty, improvement of site construction efficiency and cost saving. Thereby, the signal extension apparatus of the present invention is especially suitable for extension of a power station generating set large bearing oil groove sensor signal.

Owner:SHENZHEN TESTECK TECH

Installation method of skid-mounted reciprocating compressor unit

PendingCN110042858AReduce construction difficultyLower operating costsFoundation engineeringEngineeringJackscrew

Owner:SHANDONG KERUI COMPRESSOR

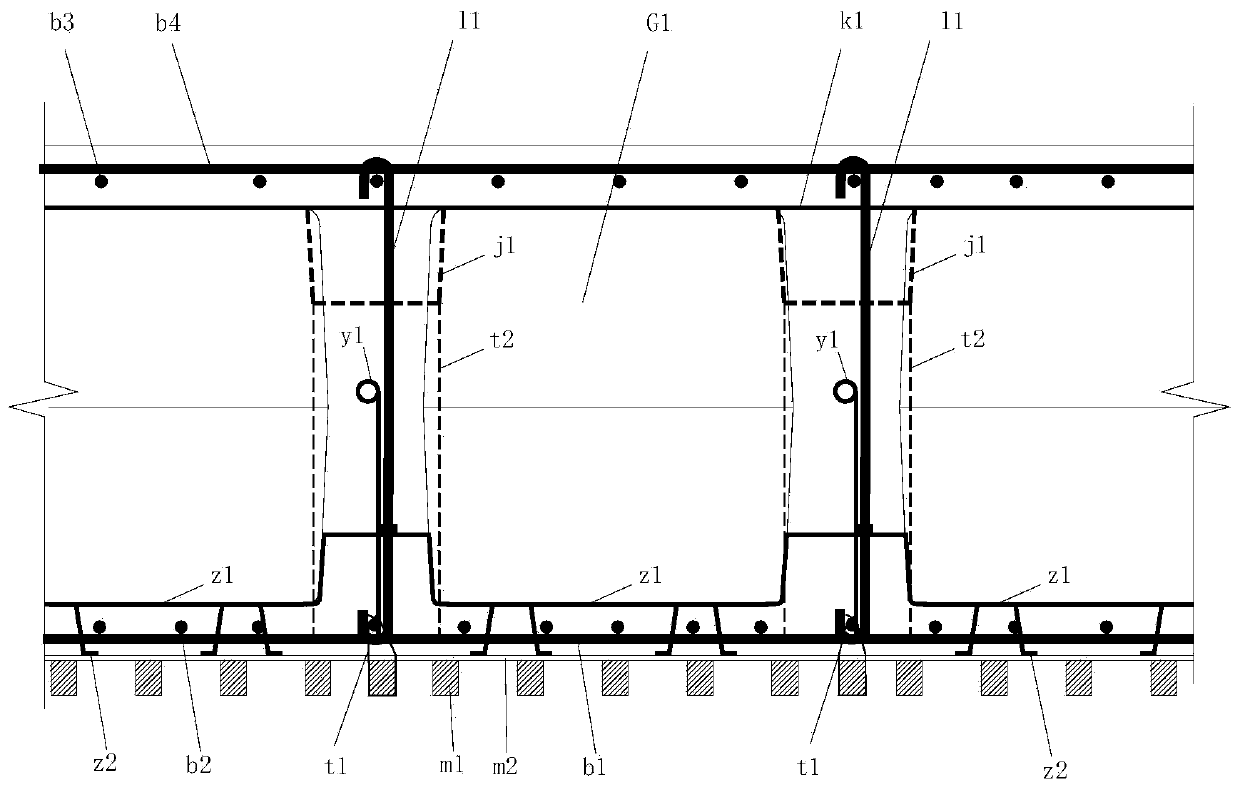

Prestress thick plate hollow floor construction method

The invention relates to a prestress thick plate hollow floor construction method. The method comprises the steps: according to hollow floor design parameters, deepening the geometric dimension and arrangement parameters of a built-in hollow square box; determining arrangement parameters of an anti-floating tie bar; mounting a formwork; locating a hidden beam, a column cap, a multi-ribbed beam, ahigh-injection alloy square box and a reserved embedded facility and performing scribing; installing the hidden beam, column cap ribs, a plate bottom reinforcing steel bar, prestressed ribs and the reserved embedded facility; connecting the plate bottom reinforcing steel bar with the bottom template; laying a hollow square box bottom positioning device; laying a hollow square box; laying an anti-floating steel bar layer, and placing an upper positioning device; connecting the upper positioning device with the plate bottom reinforcing steel bar; placing a plate top reinforcing steel bar cushionblock, laying plate top reinforcing steel bars on the plate top reinforcing steel bar cushion block and performing binding, and tying the plate top reinforcing steel bars and the plate bottom reinforcing steel bars through tie bars; pouring concrete, and performing vibrating and maintaining; performing prestress tensioning, grouting and anchor sealing; and dismantling the formwork. The construction quality of the prestress hollow floor can be improved, and the field construction difficulty is reduced.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

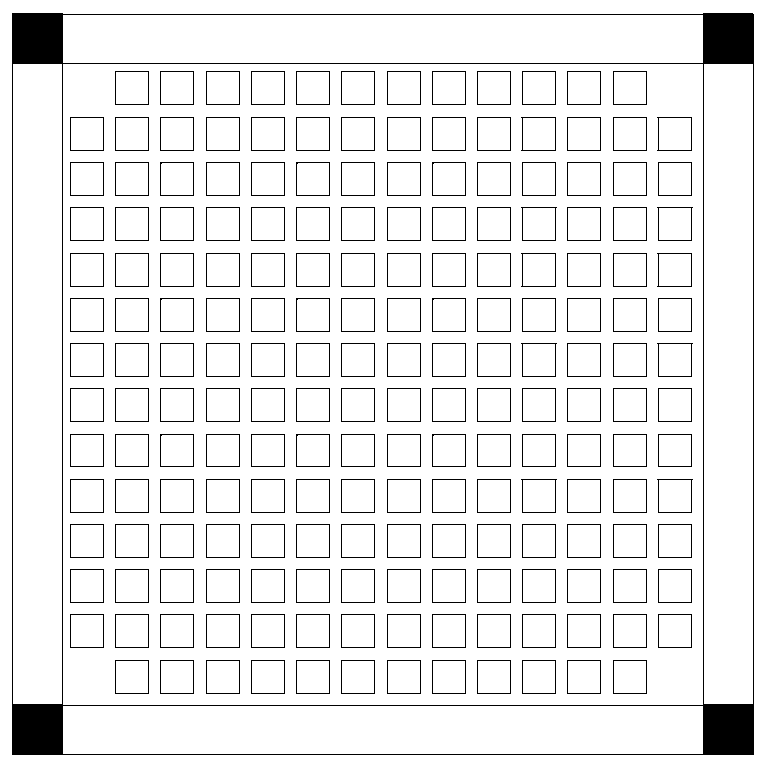

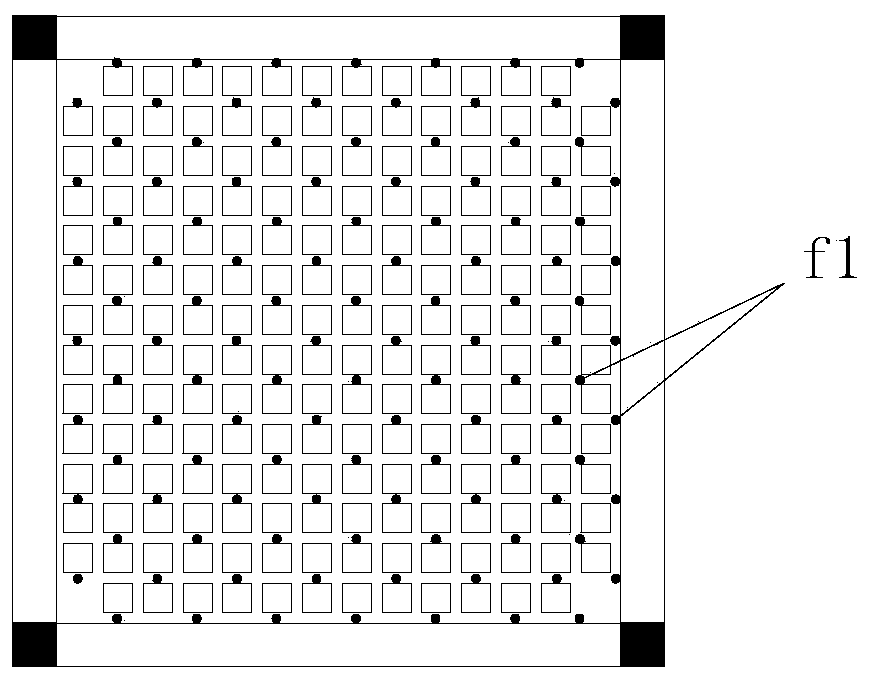

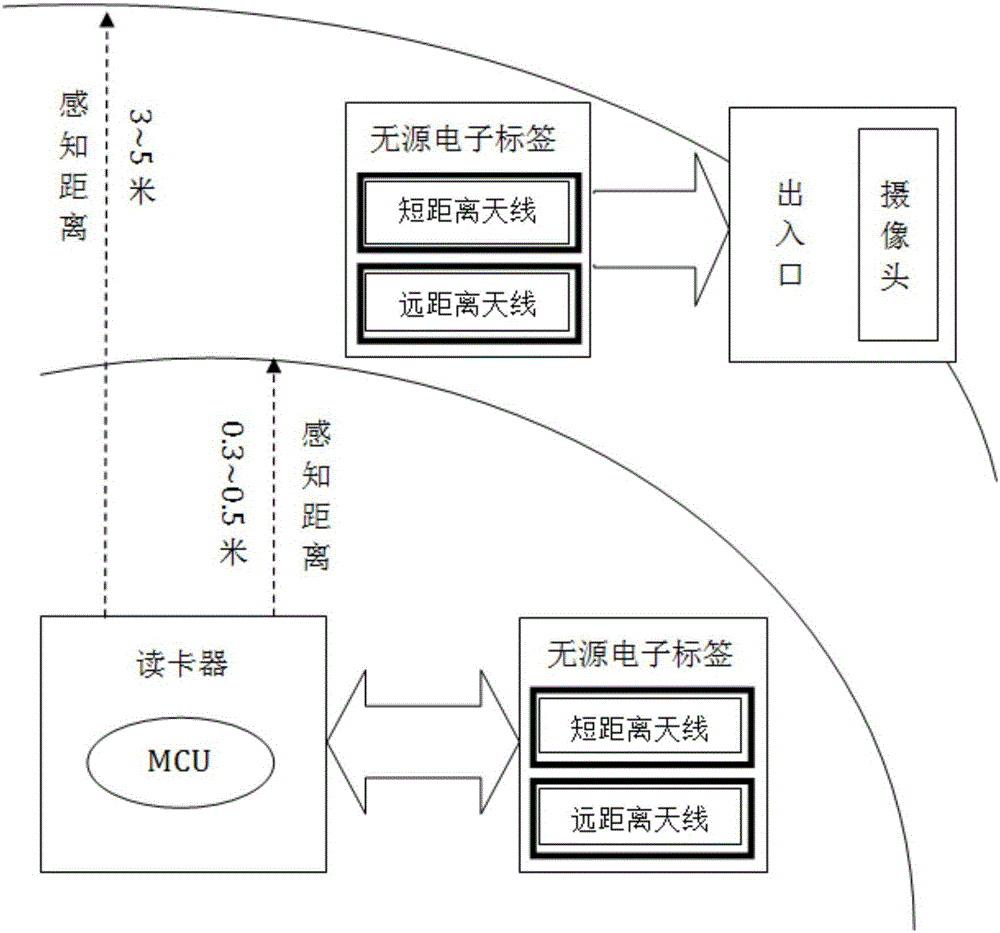

Passive electronic tag reading and writing system

PendingCN106446748ARead and write implementationReduce in quantitySensing by electromagnetic radiationButt jointShortest distance

The invention provides a passive electronic tag reading and writing system which is used for monitoring and identifying the moving track of target items within an area to be detected. Passive electronic tags are attached to the target items. The passive electronic tag reading and writing system comprises a plurality of passive electronic tags, a matrix control switch, a card reader and a plurality of array antennas, the card reader and the array antennas are in a one-to-many butt joint relationship, the passive electronic tags are provided with internal antennas and chips, and the internal antennas include short-distance antennas and long-distance antennas. The passive electronic tag reading and writing system is free from complicated wiring and simple to mount.

Owner:紫光智云(江苏)物联网科技有限公司

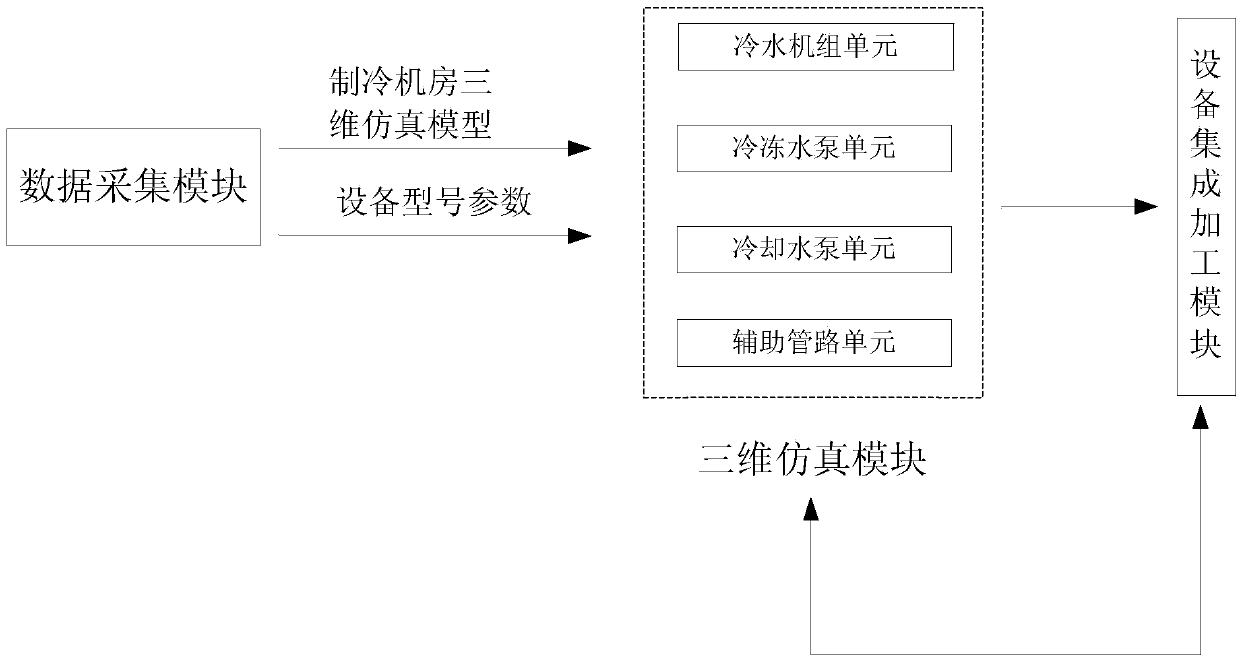

Integration system and method for integrated refrigeration station

ActiveCN103471190ASmall footprintPrecise positioningLighting and heating apparatusAir conditioning systemsThree dimensional simulationModeling and simulation

The invention discloses an integration system and method for an integrated refrigeration station. The integration system comprises a data collecting module, a three-dimensional simulation module and a equipment integration machining module. The data collecting module collects information and transmits the same to the three-dimensional simulation module. The three-dimensional simulation module comprises a water chilling unit, a cooling water pump unit, a refrigerating water pump unit and an auxiliary pipeline unit. The auxiliary pipeline unit is used for performing three-dimensional simulation modeling and simulation coordination on auxiliary pipelines and corresponding pipeline supports. The equipment integration machining module performs simulation coordination on three-dimensional models of the water chilling unit, the cooling water pump unit and the refrigerating water pump unit to obtain an ultimate three-dimensional simulation model of the integrated refrigeration station, and entity machining of the integrated refrigeration station is performed according to the three-dimensional simulation model. By the system and the method, floor space of the refrigeration station is reduced, equipment positioning and transportation are facilitated, filed construction difficulty is lowered, equipment of the refrigeration station operates coordinately, and the refrigeration station greatly approaches from an engineering project to a system integrated product.

Owner:BEIJING SATELLITE MFG FACTORY

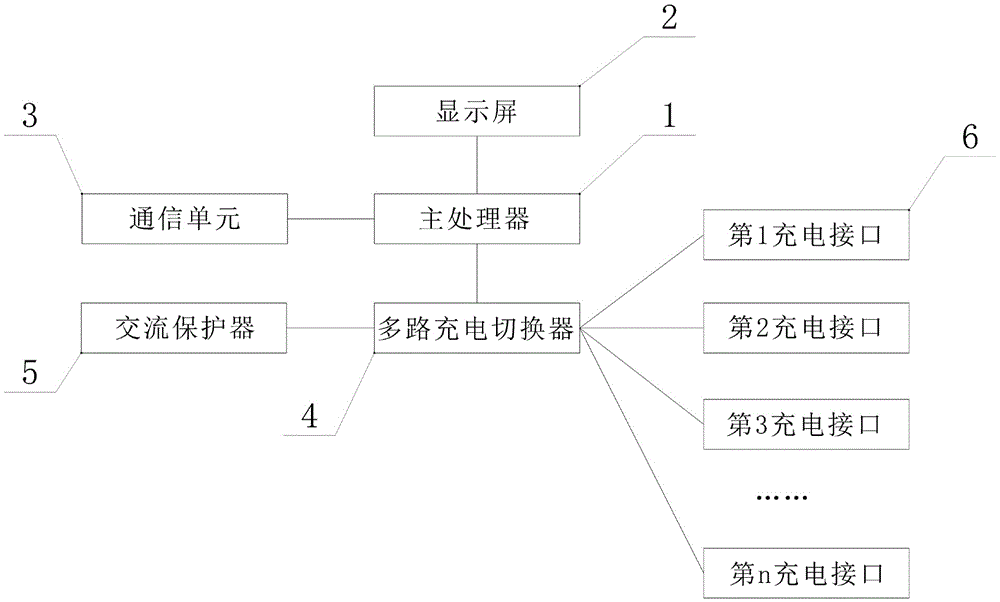

Multi-interface charge scheduling method and system

ActiveCN105576748AReduce the burden onReduce the difficulty of on-site constructionCharge equalisation circuitElectric powerCharge currentCommunication unit

The invention discloses a multi-interface charge scheduling method and system. The system comprises a main processor, a communication unit, a multi-path charge switcher and charge interfaces, wherein the main processor is used for judging the sequence that an electric vehicle user requests charging, and calculating power distribution during charging; the communication unit is used for transmitting and receiving data of a client, and communicating with the main processor through a CAN bus; the multi-path charge switcher is used for controlling outputting of multi-path charge currents, and adjusting charge powers distributed to one or more electric vehicles according to the command of the main processor to reach the effect of charging a plurality of electric vehicles; the charge interfaces are the interfaces connected when the electric vehicles are charged; the main processor is connected with the communication unit and the multi-path charge switcher; and the multi-path charge switcher is connected with the charge interfaces. According to the method, one charge pile can simultaneously charge the plurality of electric vehicles and queue up the electric vehicles in order; and resource waste and charge efficiency reduction caused by residual charge power are avoided; and the system can reach the effect of charging the plurality of electric vehicles with one charge pile, reduces the network burden and reduces the on-site construction difficulty.

Owner:GUILIN ZHONGJIE NEW ENERGY TECH CO LTD

Construction method for large-section embedded stiff column base

Owner:HANGZHOU JIANGRUN TECH LIMITED

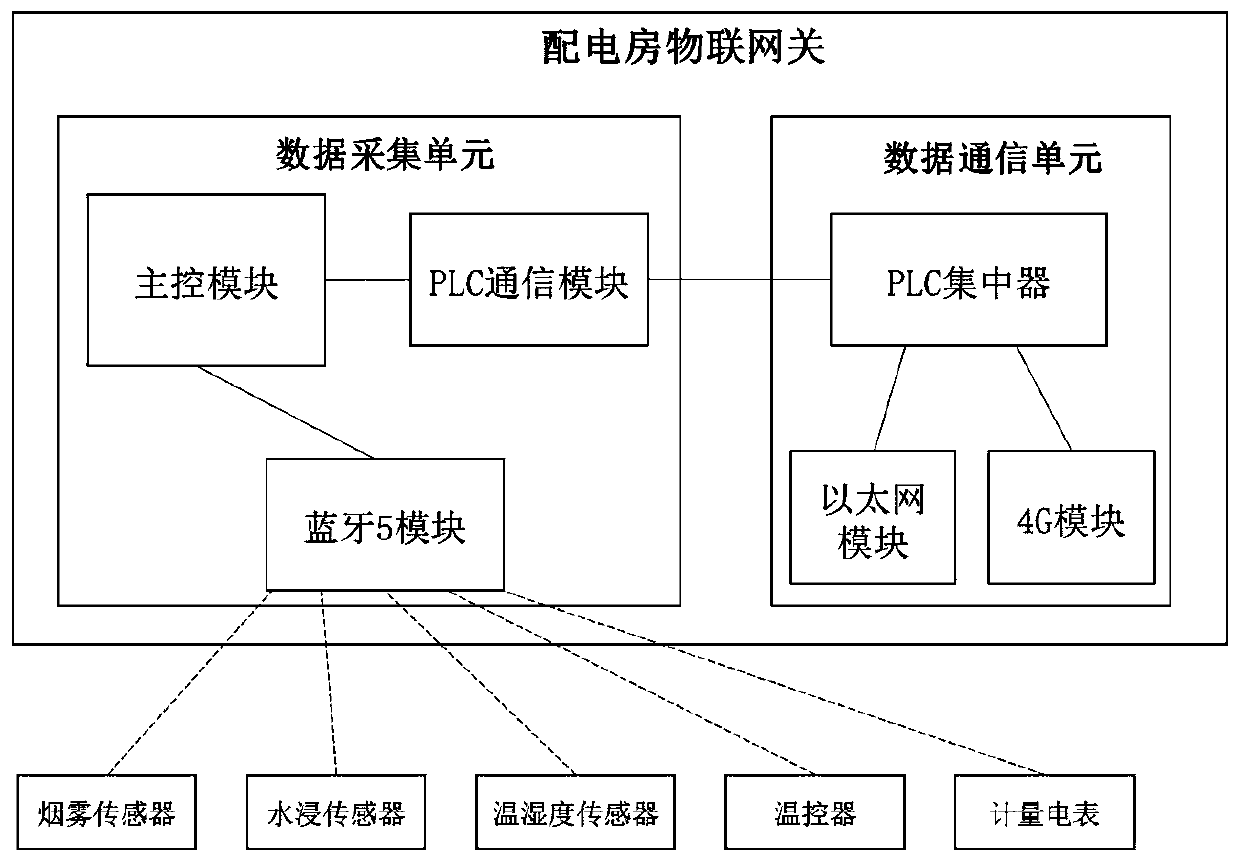

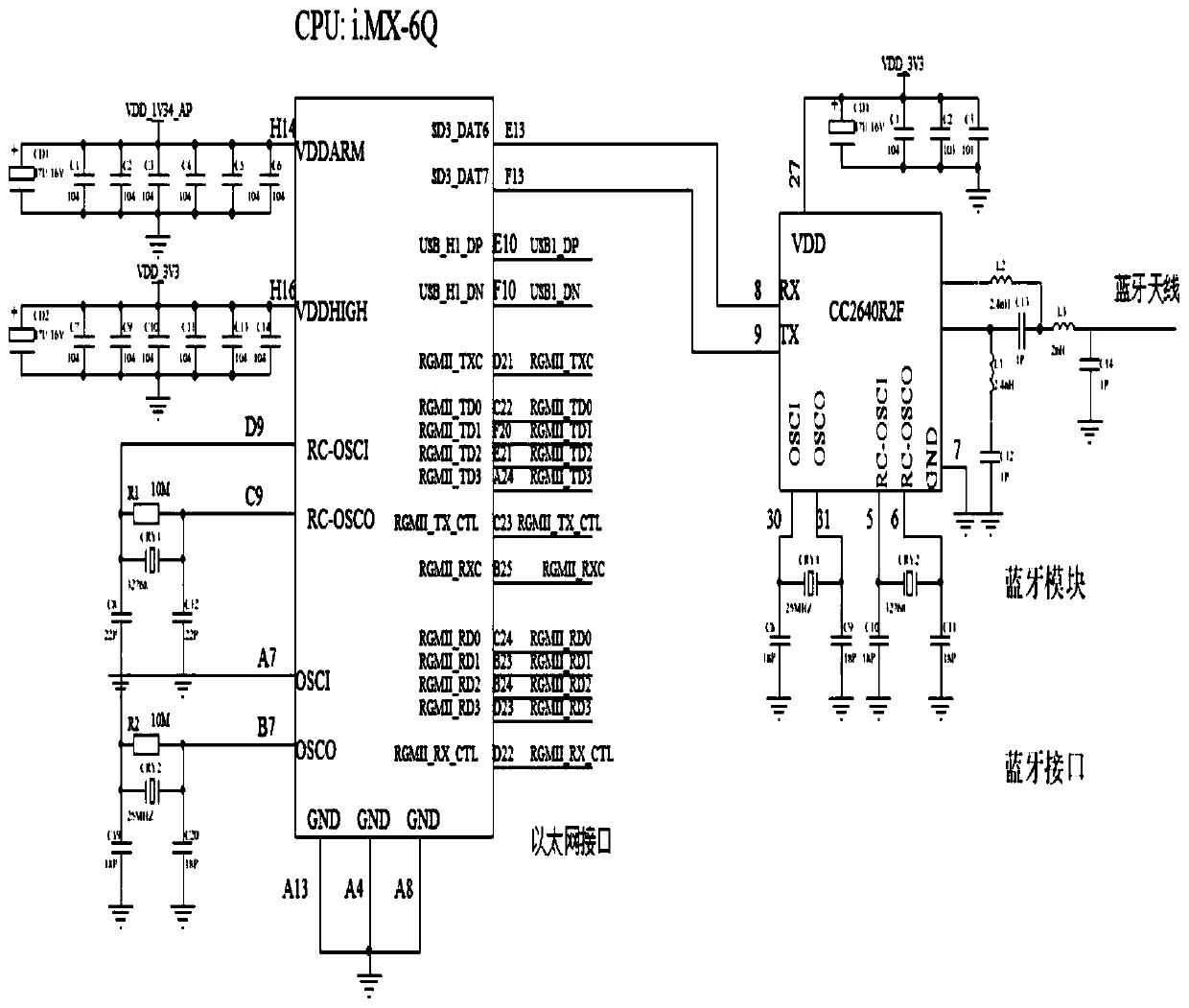

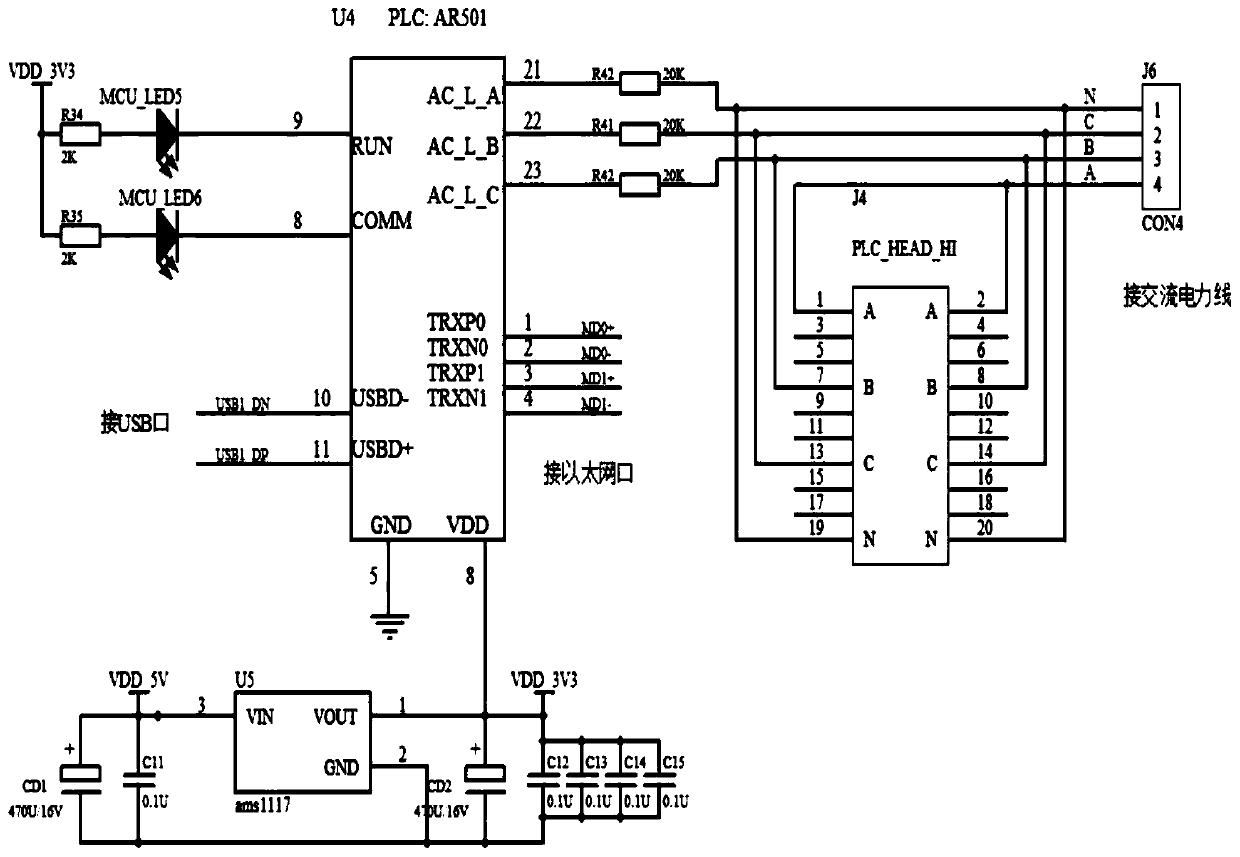

Internet of Things gateway of switch board room

InactiveCN110517474AReduce the difficulty of on-site constructionIncrease success rateElectric signal transmission systemsSub-station arrangementsIot gatewayCommunication unit

The invention discloses an Internet of Things gateway of a switch board room. The Internet of Things gateway comprises a data collection unit and a data communication unit, the data collection unit comprises a main control module, a PLC communication module and a Bluetooth 5 module; the data communication unit comprises a PLC concentrator, an Ethernet module and a 4G module; the main control module is in signal connection with a smoke sensor, a water sensor, a temperature and humidity sensor, a temperature controller and a metering electricity meter through the Bluetooth 5 module; and the maincontrol module is in signal connection with the PLC concentrator through a PLC communication module, and the PLC concentrator is in signal connection with the Ethernet module and the 4G module. In the scheme, by improving the data collection mode of the sensor and improving the gateway uploading mode, the site construction difficulty is greatly reduced, and the success rate of data collection andthe success rate of data uploading in harsh environments are improved.

Owner:深电能科技集团有限公司

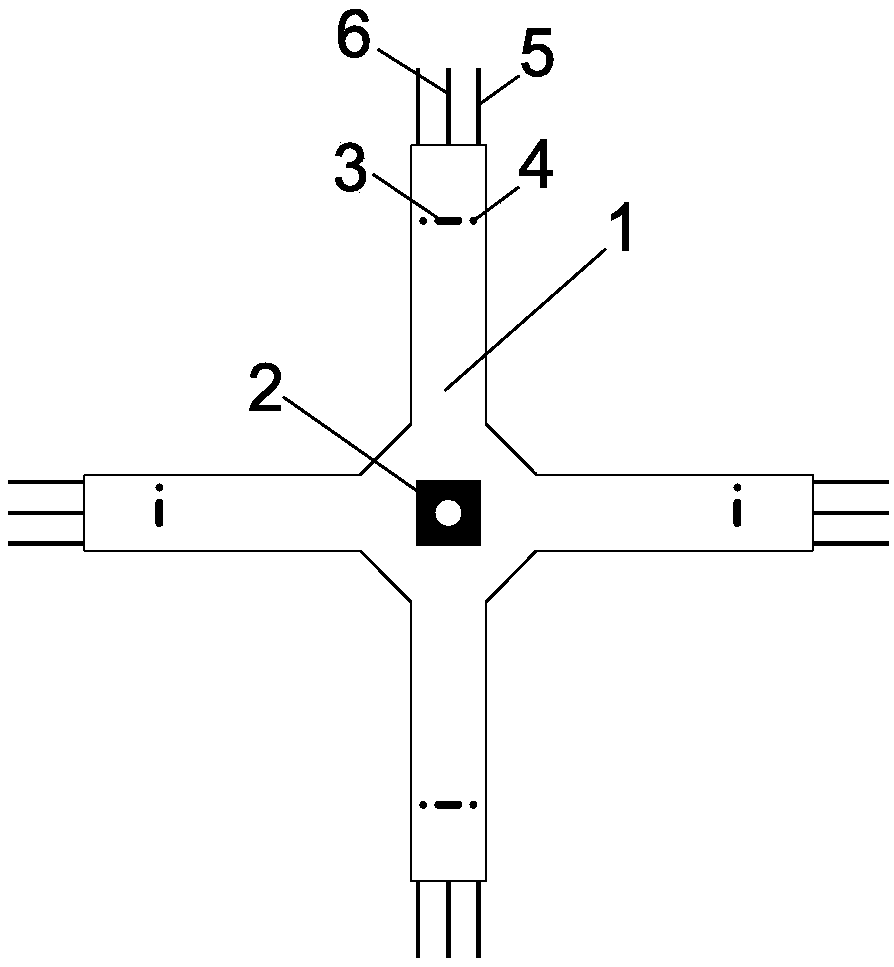

Grouting steel pipe connection device structure and connection method

ActiveCN106245765ALow skill level requiredSimple connection structureBuilding material handlingRebarMaterials science

The invention relates to the field of steel structure buildings, in particular to a grouting steel pipe connection device structure and a connection method. The produced grouting steel pipe connection device can be used for connecting steel pipe structures in the steel structure buildings. The steel pipe connection method adopting the grouting steel pipe connection device can serve as the method for connecting the steel pipe structures in the steel structure buildings. The structure comprises a high-strength steel bar with anchor hooks, an anchorage positioning steel plate, steel bar penetrating holes, an inner clamping ring, a lower connected steel pipe, a grouting hole and an upper connected steel pipe. By arranging the grouting steel pipe connection device between the ordinary connected steel pipes, the steel pipes are connected through a grouting method. The grouting steel pipe connection device can be prefabricated in a plant. Welding is not needed during on-site construction, the connection structure is simple, the requirement for the technical level of constructors is not high, the on-site construction difficulty is low, the construction quality can be guaranteed easily, environmental friendliness is achieved, energy is saved, and the requirement for current green buildings is better met.

Owner:SHENYANG SANXIN IND

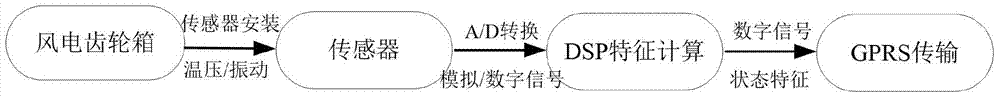

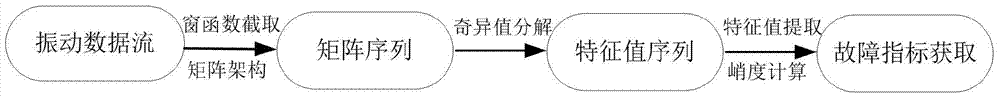

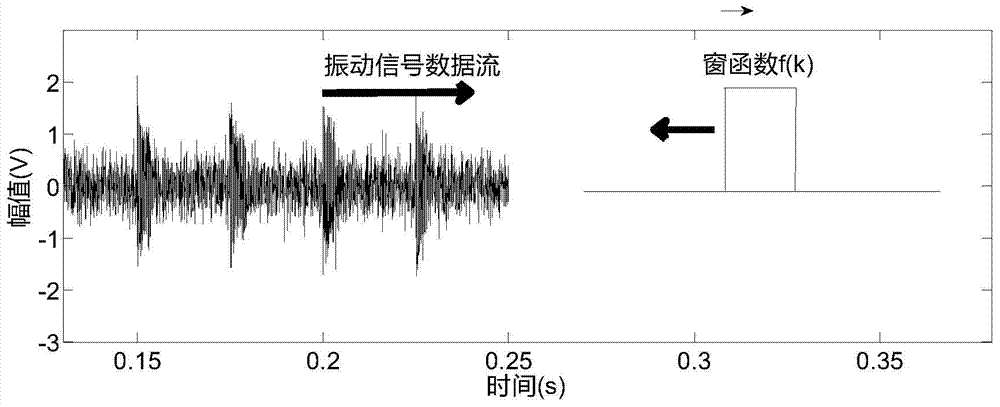

GPRS-based wind power gear box remote monitoring and diagnosis method

ActiveCN104764487AReduce the difficulty of on-site constructionLow costMachine gearing/transmission testingElectricityDiagnosis methods

The invention discloses a GPRS-based wind power gear box remote monitoring and diagnosis method. The GPRS-based wind power gear box remote monitoring and diagnosis method obtains the on-line operating temperature, pressure and vibration signals according to the design operating conditions of a wind power gear box and converts the signals into digital signals, and feature signals reflecting the operation health state of equipment are calculated and obtained through a DSP processing module and sent to a GPRS module; the GPRS module transmits feature diagnostic information to a remote control center through the serial port communication technology, the virtual serial port technology and the mobile network entry technology and realizes remote monitoring and diagnosis of the wind power gear box. The GPRS-based wind power gear box remote monitoring and diagnosis method can realize low-cost and low-threshold remote on-line monitoring and diagnosis through the GPRS technology, largely reduces the on-site construction difficulty and network distribution cost of an on-line system and has important engineering value.

Owner:ZHEJIANG UNIV

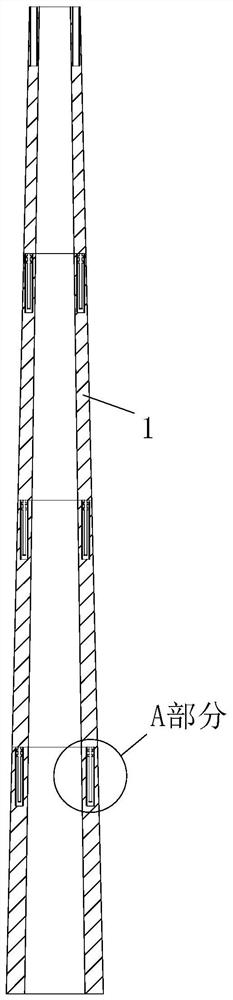

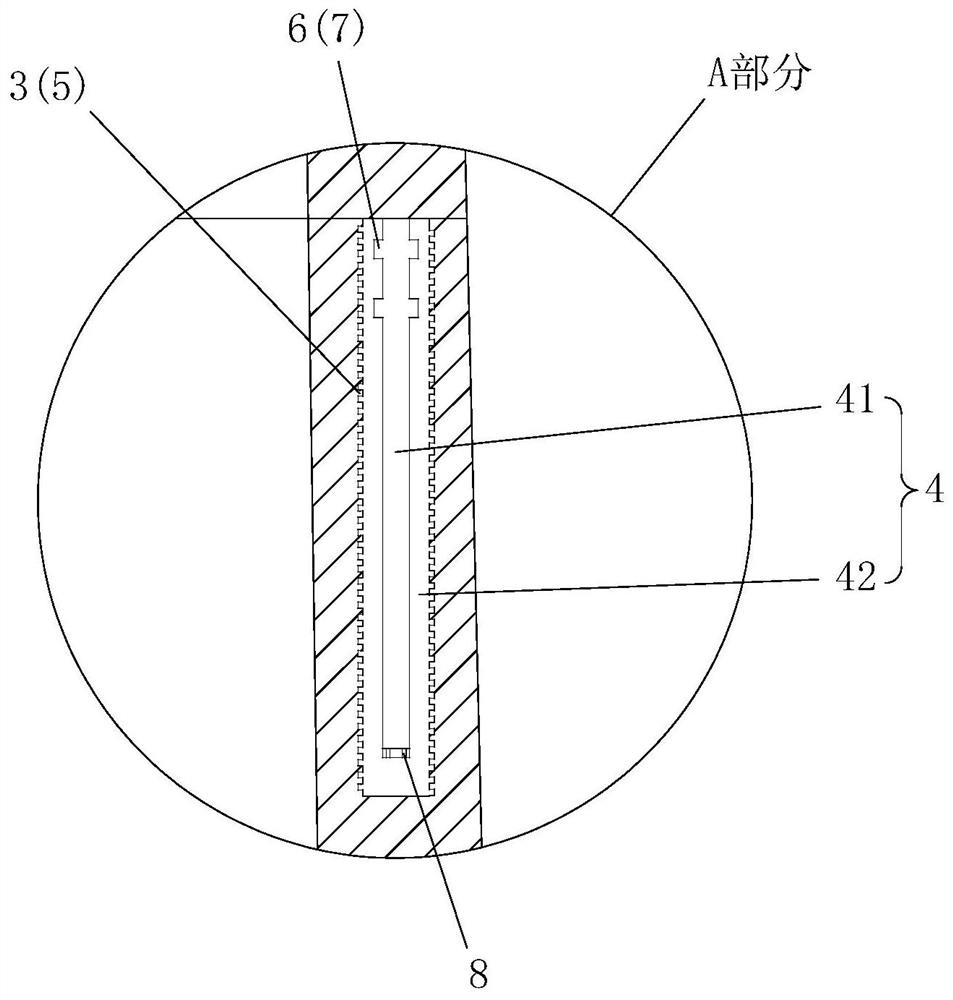

Annular concrete pole and segmented assembling method thereof

InactiveCN111852162AEasy to transportReduce the difficulty of on-site constructionBuilding constructionsTowersScrew thread

The invention discloses an annular concrete pole and a segmented assembling method thereof. The annular concrete pole is composed of multiple segments of branch pole bodies. Multiple columnar holes are formed in the axial direction of the top end face of each segment of branch pole body. Threaded grooves are formed in the hole walls of the columnar holes. Multiple inserting rods are arranged on the bottom end face of each segment of branch pole body. The positions of the inserting rods are in one-to-one correspondence to the positions of the columnar holes. Each inserting rod is composed of aninner core shaft and an outer shaft sleeve, the inner core shafts are fixedly connected with the bottoms of the branch pole bodies, the inner walls of the outer shaft sleeves are rotationally connected with the inner core shafts, and the outer diameter of each outer shaft sleeve is equal to the inner diameter of each columnar hole. Threaded strips are arranged on the outer walls of the outer shaft sleeves and can be completely screwed into the threaded grooves. According to the annular concrete pole, the segmented assembling method is adopted, transporting is convenient, and the field construction difficulty is reduced; and during assembling, only the branch pole bodies need to be lifted and aligned, threaded connection of adjacent segments can be completed through the self gravity of thebranch pole bodies, connecting firmness is guaranteed, and the field assembling efficiency is greatly improved.

Owner:安徽凯越电力杆塔有限公司

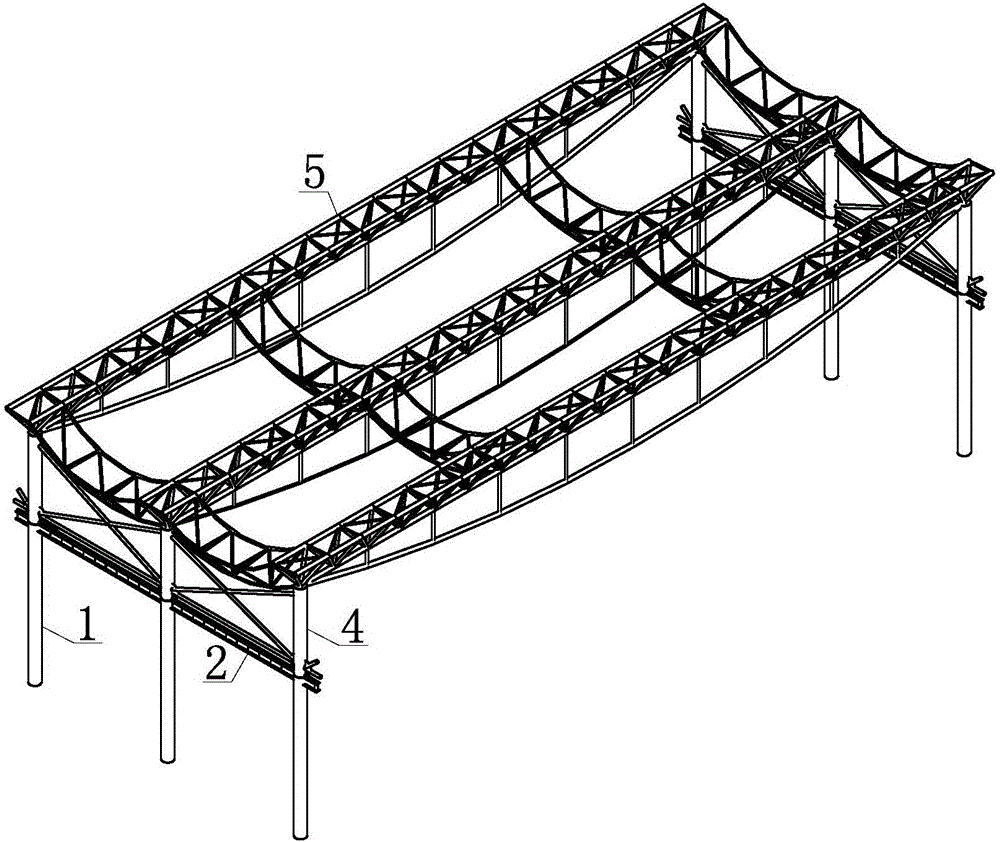

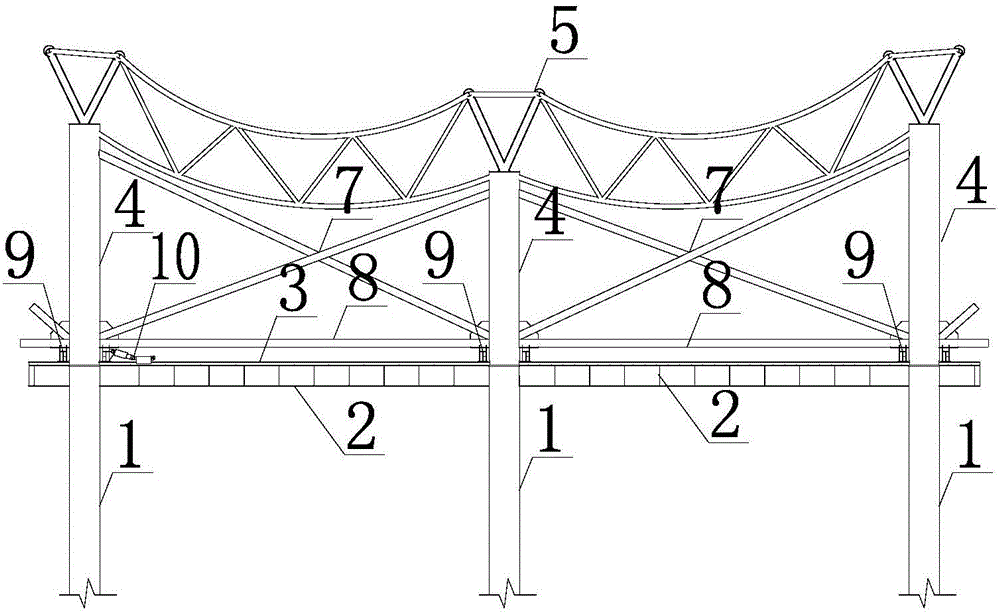

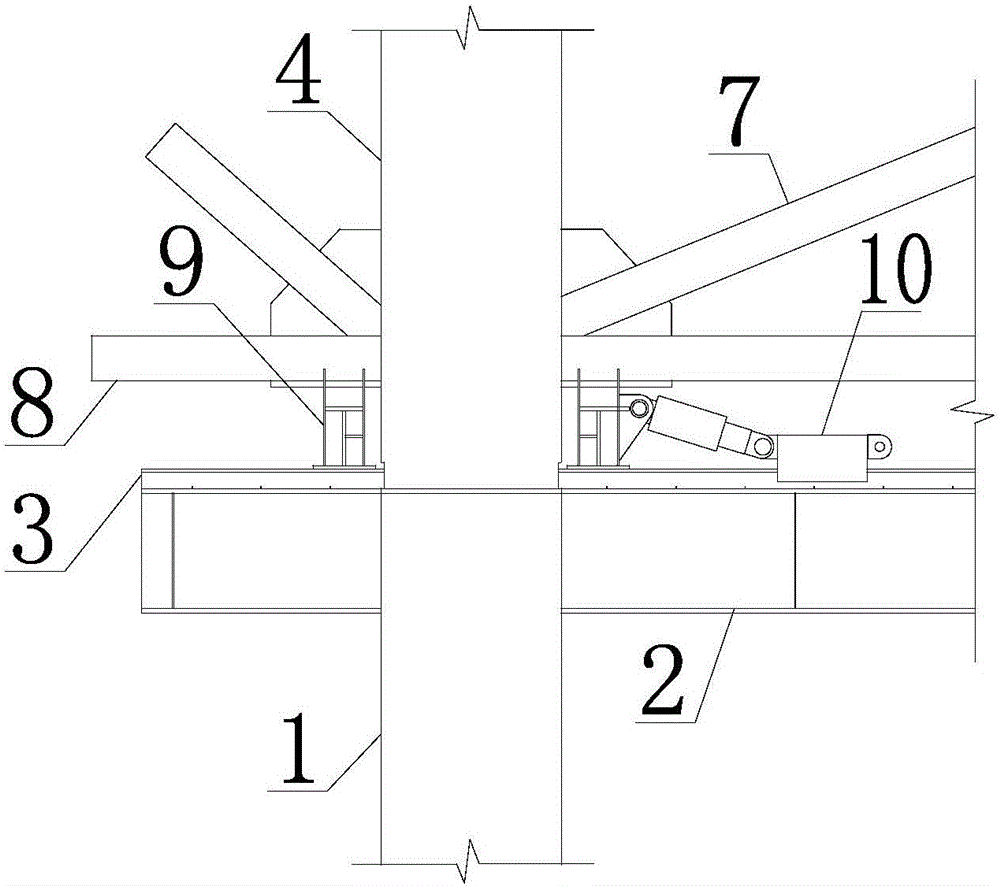

High-position equal-elevation with-column slipping structure and method for large-span space structure

InactiveCN106592984AStrong process controllabilityReduce wasteBuilding material handlingSpatial structureGravity center

The invention belongs to the field of steel structure buildings, and particularly relates to a high-position equal-elevation with-column slipping structure and method for a large-span space structure. The slipping structure comprises supporting steel columns and inter-column beams perpendicularly and fixedly connected with the supporting steel columns. Slipping rails are laid on the inter-column beams and slidably provided with slipped steel columns. Slipping shoes are fixedly arranged on the two sides of the slipped steel columns. The slipping shoes on one sides of the slipped steel columns are connected with hydraulic jacking and pushing devices arranged on the slipping rails. By adoption of the high-position equal-elevation with-column slipping structure and method, the problems that the large-span space structure is high in roof gravity center and poor in stability under the condition that solid web columns have no lateral support, and column base slipping is difficult to implement are solved.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

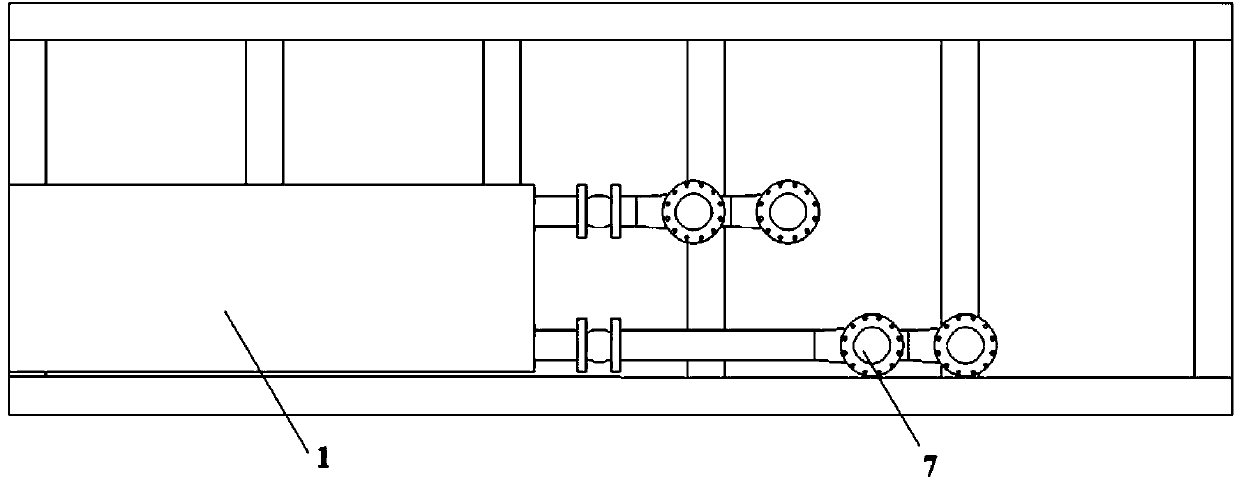

Modularizing transformation method of convection section of ethylene cracking furnace and convection section module of the ethylene cracking furnace

ActiveCN104130797AReduce workloadImprove manufacturing qualityThermal non-catalytic crackingManufacturing qualitySmoke

The invention provides a modularizing transformation method of a convection section of an ethylene cracking furnace and a convection section module of the ethylene cracking furnace. According to the method, a first bearing column is reused; all parts in the convection section are prefabricated into an integrated convection section module; and the convection section module is installed on the first bearing column to complete the transformation of the convection section module. The convection section module consists of a heat exchange tube bundle, a tube sheet, a smoke-insulating plate, a modularized steel structure and a liner. The tube sheet is arranged on an end of the convection section module. The smoke-insulating plate is disposed on an inner side of the tube sheet. The tube sheet and the smoke-insulating plate are arranged at an interval in the length direction of the convection section module. The modularized steel structure is fixedly connected to the first bearing column. By means of the transformation method, locally modularizing transformation of the convection section of the ethylene cracking furnace is achieved without replacement of the first bearing column so that equipment such as a top bench, a fan and a steam drum is unnecessary to move. The method can improve manufacturing quality, can shorten a construction period, can reduce construction difficulty and can reduce installation cost.

Owner:SINOPEC ENG +1

Clamping plate type support of aluminum alloy hub-type joint net frame

PendingCN109138164ASimple structureSave steelExtraordinary structuresEngineeringUltimate tensile strength

The invention provides a clamping plate type support of an aluminum alloy hub-type joint net frame. The technical problem that a screw rod is not subjected to shearing force is solved. According to the adopted technical scheme, the splint type support comprises a maintaining part, a locking assembly, and a connecting part, wherein the maintaining part is provided with a fixing end plate and further provided with a first sealing end plate and a second sealing end plate which are arranged on one side face of the fixing end plate in parallel, and a positioning groove suitable for placing a hub joint is enclosed among the two sealing end plates and the fixing end plate; the locking assembly includes a perforating part passing through the first sealing end plate, the hub joint and the second sealing end plate in sequence in the axial direction of the hub joint, and locking parts arranged at the two ends of the perforating part; and the connecting part is suitable for connecting the maintaining part to a to-be-connected object. Cover plate seals in the prior art is replaced by adopting a clamping type sealing structure, seals are in rigid connection, the overall structural strength of the support is enhanced, thus the perforating part can withstand a certain degree of shearing resistance, and the structural strength of the support is greatly enhanced.

Owner:HUADIAN HEAVY IND CO LTD

Connecting method and connecting structure for box-type steel pipe column and shear wall end post

ActiveCN103774758AImprove connection strengthImprove seismic performanceShock proofingRebarUltimate tensile strength

The invention discloses a connecting method and a connecting structure for a box-type steel pipe column and a shear wall end post. The connecting method comprises the following steps: the box-type steel pipe column is provided; a plurality of shear resisting connecting bonds are fixedly connected onto one side of the box-type steel pipe column; a rebar structure for bonding a shear wall end post enables the vertical rebar part of the shear wall end post to be arranged in the shear resisting connecting bonds in a penetrating manner; form erecting is performed and the shear wall end post is poured. A row of shear resisting connecting bonds is fixed at a side part of the box-type steel pipe column, the vertical rebar part of the shear wall end post is arranged into the shear resisting connecting bonds in a penetrating manner, and a plurality of composition steel bars are arranged in the shear wall end post in a matching manner, so the shear wall end post is tightly buckled onto the shear resisting connecting bonds, and meanwhile, a reliable connection effect of shear resisting and pulling resisting between shear resisting connecting bonds and the shear wall end post can be played. The connecting strength between the box-type steel pipe column and the shear wall end post can be enhanced, the entire anti-seismic property of the structure is enhanced, and compared with a like method, the method provided by the invention has the advantages that the on-site construction difficulty is low, the construction quality is high, the working period is shortened and the cost is reduced.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Prefabricated subway shield segment and detection and installation method thereof

PendingCN113279781AAvoid pollutionAvoid noise pollutionUnderground chambersOptically investigating flaws/contaminationLaser scanningMechanical engineering

The invention provides a prefabricated subway shield segment and a detection and installation method thereof, and belongs to the technical field of subway shield segments and installation methods thereof. The problems that a traditional shield segment is large in site construction pollution, the grouting speed of the shield segment is low, and the gap filling effect is poor are solved. A first step structure and a second step structure which are matched with each other are arranged at the two ends of the shield segment, first grouting holes are formed in the inner arc face, at least three second grouting holes are formed in the outer arc face, the first grouting holes and the second grouting holes form a communicating pipeline in the shield segment, bolt holes are formed in the two sides and the inner arc face of the shield segment, and bolt holes are formed in the end faces of the first step structure and the second step structure. Shield segments are prefabricated in a factory and then spliced in a staggered joint mode, primary grouting treatment is carried out, a three-dimensional laser scanner is adopted for scanning, and SBS modified asphalt is used for joint sealing treatment. The grouting hole channel is formed in each shield segment, the grouting speed is high, the three-dimensional laser scanner is used for detecting and caulking, and the waterproofness is effectively improved.

Owner:CCCC SECOND HARBOR ENG

Construction method of drip irrigation type ecological fence

ActiveCN111101746AStable structureVariable lengthSelf-acting watering devicesFencingEnvironmental resource managementDrip irrigation

The invention discloses a construction method of a drip irrigation type ecological fence. The construction method comprises the following steps that (a) baffles are assembled; (b) a warning board is assembled; (c) assembling is carried out to form a wall; (d) supporting piles are placed in place; (e) the supporting piles are fixed; (f) a pipeline is mounted; and (g) a planting basket is installed.The construction method is simple to operate, easy to construct, low in difficulty, high in construction efficiency, labor-saving, convenient and fast, high in construction quality, stable in ecological fence structure, variable in length, high in adaptability, large in shielding range, good in effect, reusable after being disassembled, high in resource utilization rate and cost-saving; and a three-dimensional greening mode is adopted, attractiveness can be improved, raised dust can be adsorbed, and the dust reduction effect is achieved.

Owner:浙江恒山建设有限公司

Dry connection structure and method of precast concrete column

PendingCN109723144AReduce the difficulty of on-site constructionShorten construction timeBuilding constructionsPrecast concreteBuilding construction

The invention discloses a dry connection structure of a precast concrete column. The dry connection structure comprises a precast column and a precast beam, wherein column embedded parts are precast on the precast column, beam embedded parts are precast at the two sides of the precast beam respectively, the outer sides of the beam embedded parts are provided with angle irons, the vertical faces ofthe angle irons are spirally fixed with the beam embedded parts through first bolts, the planes of the angle irons and the bottom face of the precast beam all abut against the beam embedded parts, second bolts penetrates through the precast beam, the top end of the precast beam is provided with nuts, the lower ends of the second bolts are spirally fixed with the column embedded parts, and the upper ends of the second bolts are spirally fixed with the nuts. The dry connection structure of the precast concrete column has the advantages that the angle irons and the embedded parts are constructedthrough the preset design, the assembly connection of the precast concrete columns can be achieved only through a dry connection mode on site; compared with the prior art, the site construction difficulty is greatly reduced, the construction time is effectively shortened, and the construction cost is saved better.

Owner:深圳市特区建工科工集团盛腾科技有限公司

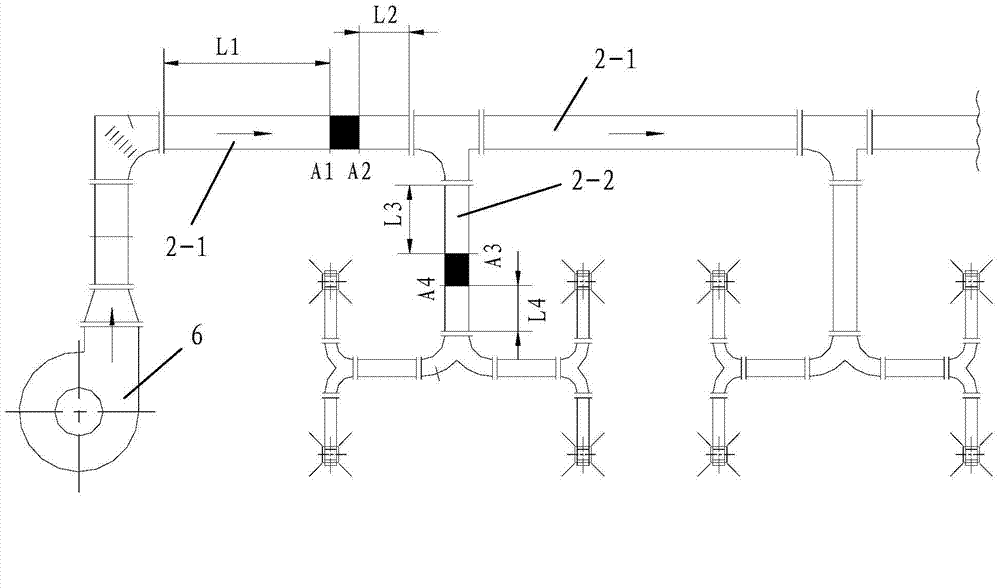

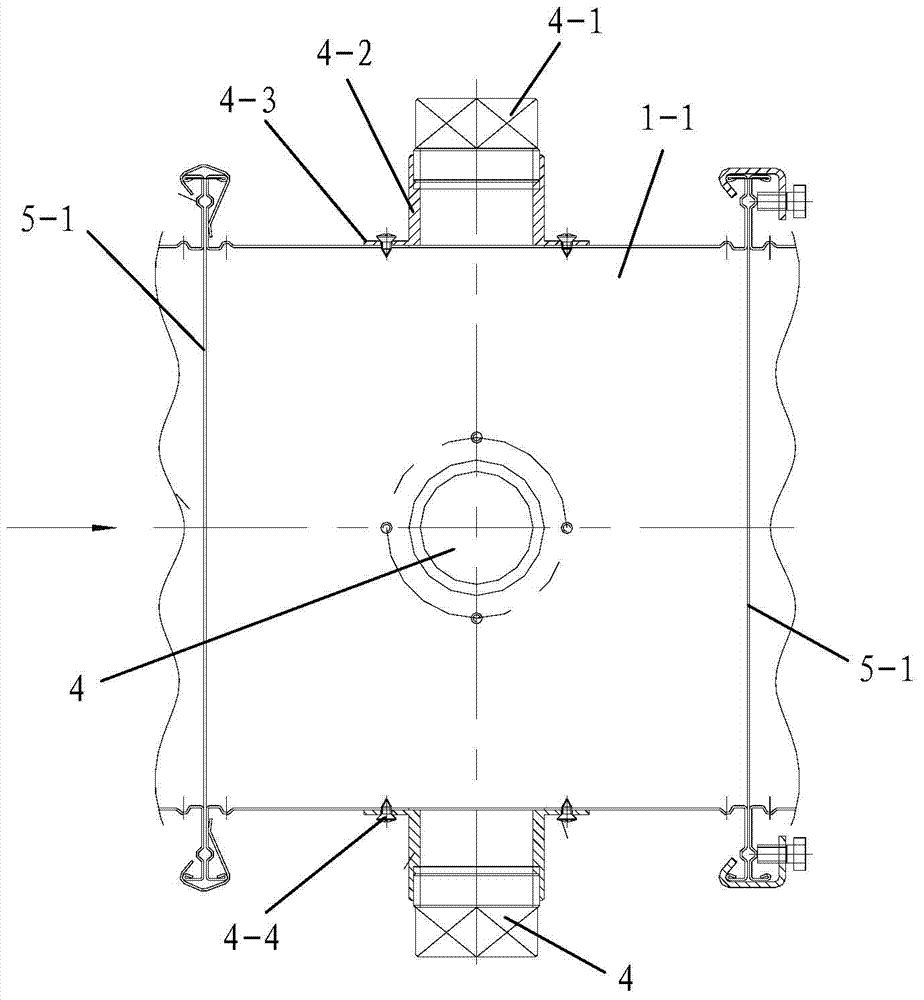

Hole-opening method for measuring holes for testing performances of ventilation and air conditioning system

ActiveCN104772497ASimple stepsReasonable designMetal working apparatusTest performanceTest requirements

The invention discloses a hole-opening method for measuring holes for testing performances of a ventilation and air conditioning system. The hole-opening method comprises the following steps: I, determining positions of measuring sections and the measuring holes: according to pre-designed test requirements of the ventilation and air conditioning system, determining quantity of to-be-tested test sections on a to-be-tested flue, the position of each test section as well as quantity of to-be-opened measuring holes in each test section and hole position of each measuring hole; II, opening and sealing measuring holes: respectively opening all measuring holes in the to-be-tested flue, and sealing each measuring hole as follows: 201, opening holes: drilling by adopting drilling equipment; 202, sealing the measuring holes: sealing processed and formed measuring holes by adopting a sealing part. The hole-opening method disclosed by the invention is simple in step, reasonable in design, convenient to realize, high in working efficiency, good in using effect and capable of simply, conveniently and quickly completing a hole-opening process of measuring holes of an air hose, and guaranteeing the performance test effects of the ventilation and air conditioning system.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com