Round steel pipe concrete column joint for beam column connection and method for manufacturing the same

A technology for steel pipe concrete columns and concrete columns, which is applied in the direction of columns, joists, girders, etc., can solve problems such as brittle failure and difficult construction, and achieve the effects of avoiding stress concentration, reducing construction difficulty and workload, and flexible node application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

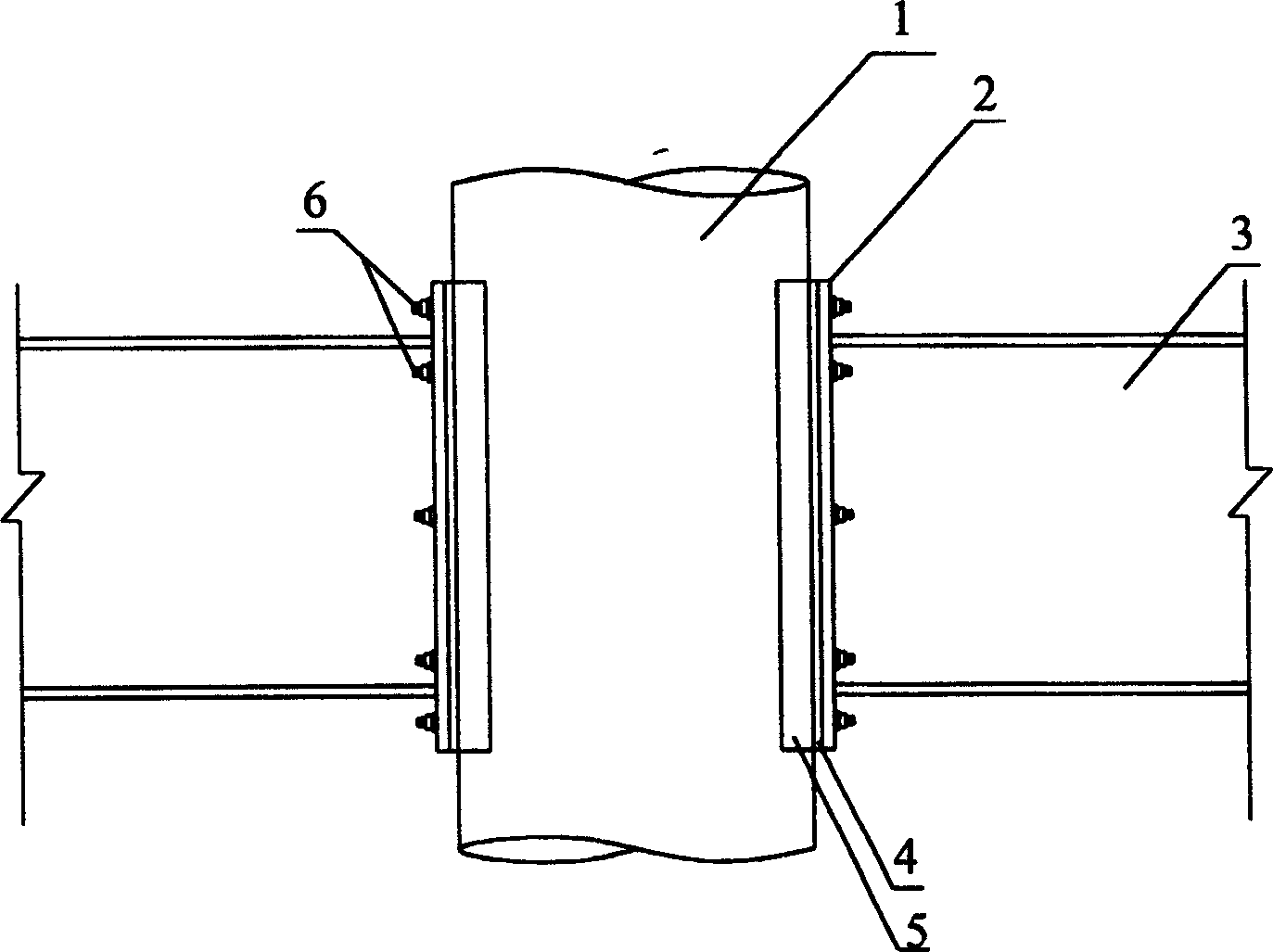

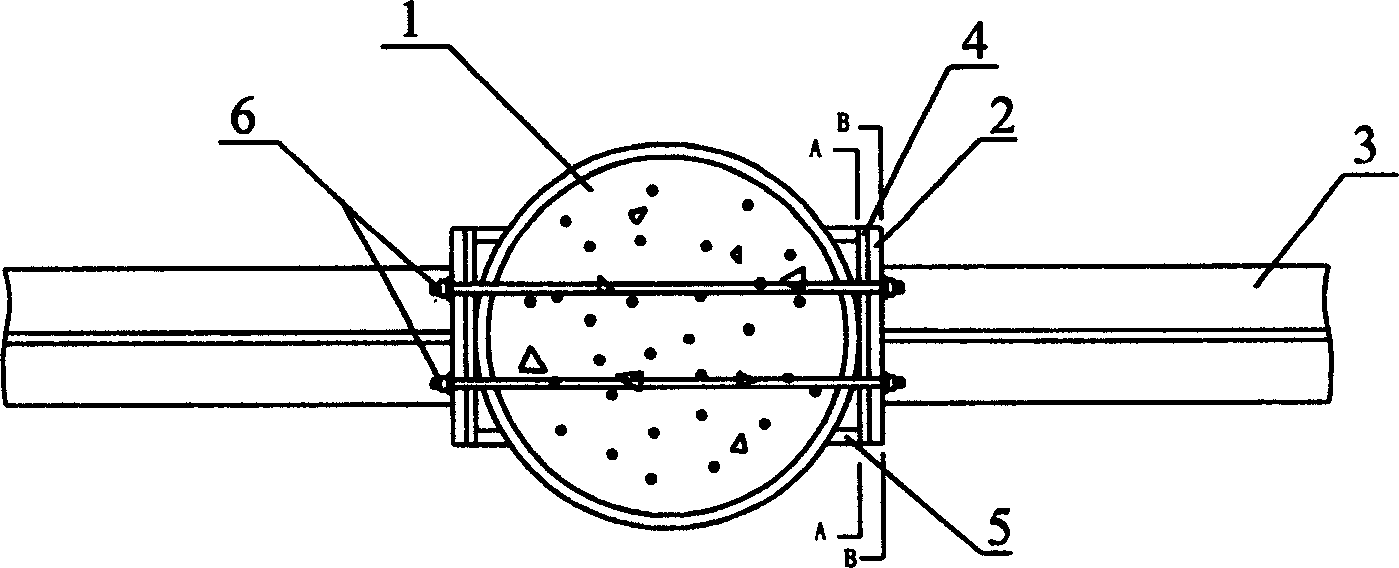

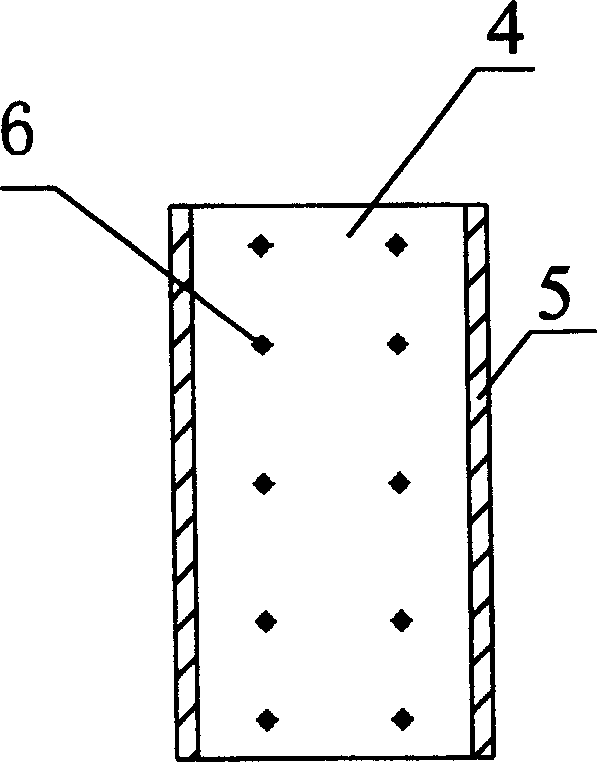

[0032] Embodiment 1: as Figure 1 to Figure 4 As shown, the present invention is a circular steel pipe concrete column joint for beam-to-column connection, which mainly includes a circular steel pipe concrete column and a steel beam 3 connected with the column. The circular steel pipe concrete column includes a circular steel pipe 1 and a circular steel pipe filled For the concrete in 1, an end plate 2 is provided on the beam end of the steel beam 3 connected to the circular steel pipe concrete column, and a leveling steel plate 4 with a leveling vertical rib 5 is arranged between the steel pipe concrete column and the end plate 2, and the leveling The steel plate 4 is fixedly connected to the round steel pipe 1, and the end plate 2, the leveling steel plate 4 and the round steel pipe 1 are connected together by a high-strength bolt 6 passing through the center of the column.

[0033] The construction steps of the present invention are: 1. stack the end plate 2 and the levelin...

Embodiment 2

[0034] Embodiment 2: as Figure 5 to Figure 8 As shown, the present invention is a circular steel pipe concrete column joint for beam-to-column connection, which mainly includes a circular steel pipe concrete column and a steel beam 3 connected with the column. The circular steel pipe concrete column includes a circular steel pipe 1 and a circular steel pipe filled For the concrete in 1, an end plate 2 is provided on the beam end of the steel beam 3 connected to the circular steel pipe concrete column, and a leveling steel plate 4 with a leveling transverse rib 7 is arranged between the steel pipe concrete column and the end plate 2, and the leveling The steel plate 4 is fixedly connected to the round steel pipe 1, and the end plate 2, the leveling steel plate 4 and the round steel pipe 1 are connected together by a high-strength bolt 6 passing through the center of the column.

[0035] The construction steps of the present invention are: 1. stack the end plate 2 and the level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com