Patents

Literature

625results about How to "Resolve connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-person human body posture estimation method

ActiveCN111339903AImprove recognition rateAvoid interferenceImage enhancementImage analysisPattern recognitionHuman body

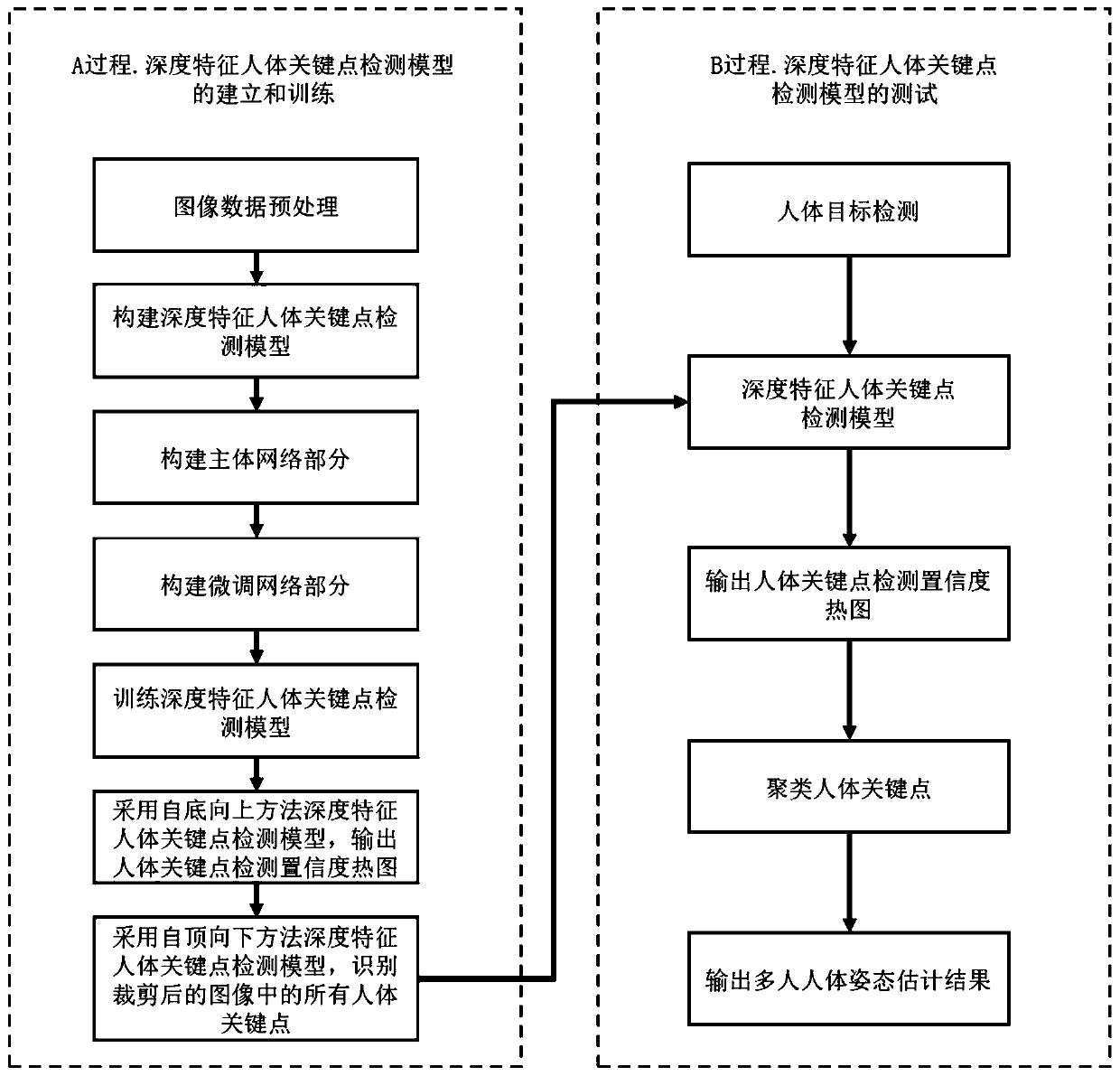

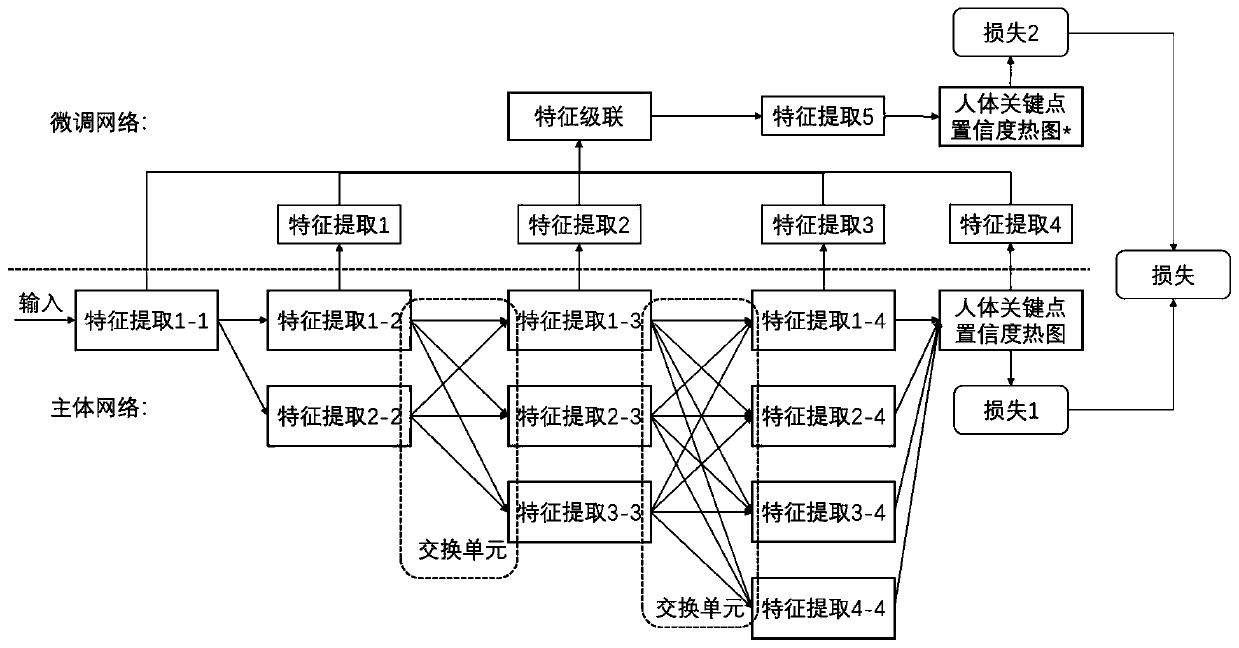

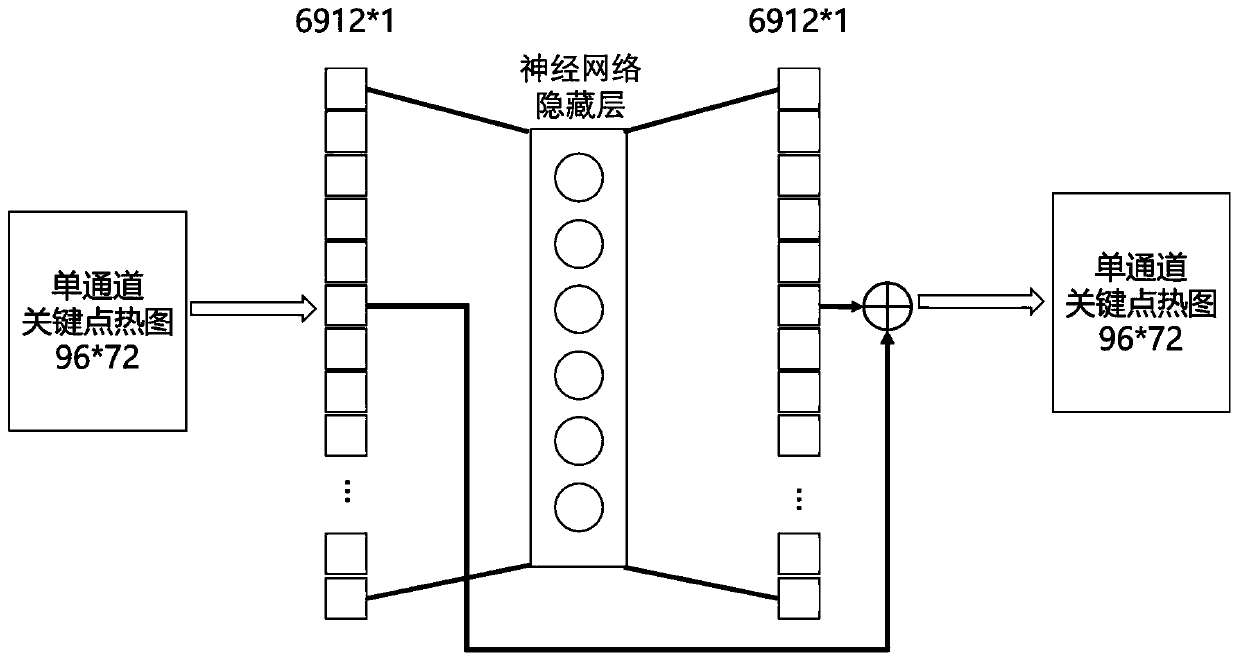

The invention discloses a multi-person human body posture estimation method, and relates to processing of a recording carrier for identifying graphics. The method is a multi-person human body postureestimation method based on depth features. According to the method, a depth feature human body key point detection model composed of a main body network and a fine tuning network is constructed; a depth feature human body key point detection model is trained by adopting a two-stage training method combining a bottom-up method and a top-down method; finally, the human body key points are detectedby using a depth feature human body key point detection model trained in two stages. Redundant key points which do not belong to a target person are removed through human body key point clustering processing, then a multi-person human body posture estimation result is output, and the defects that in the existing multi-person human body posture estimation method technology, under the condition thatcrowds are dense, the target human body shielding interference robustness is poor, and the human body key point detection accuracy is low are overcome.

Owner:HEBEI UNIV OF TECH

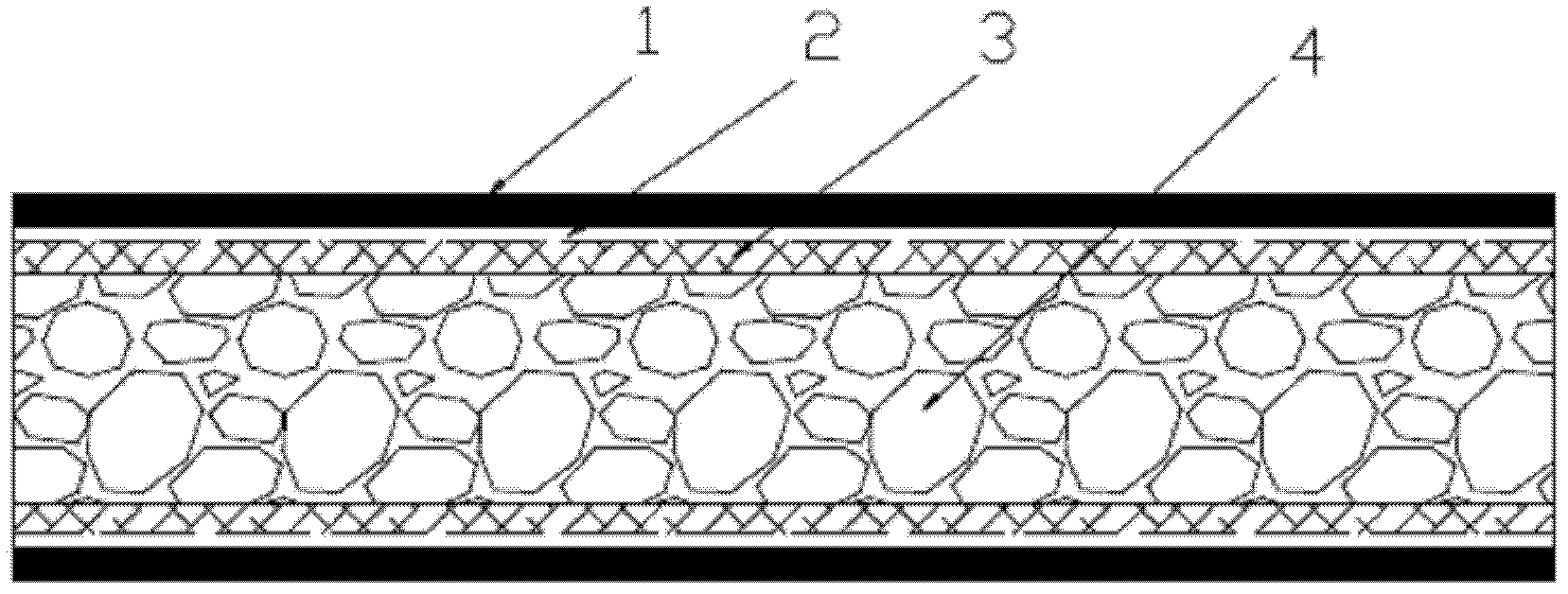

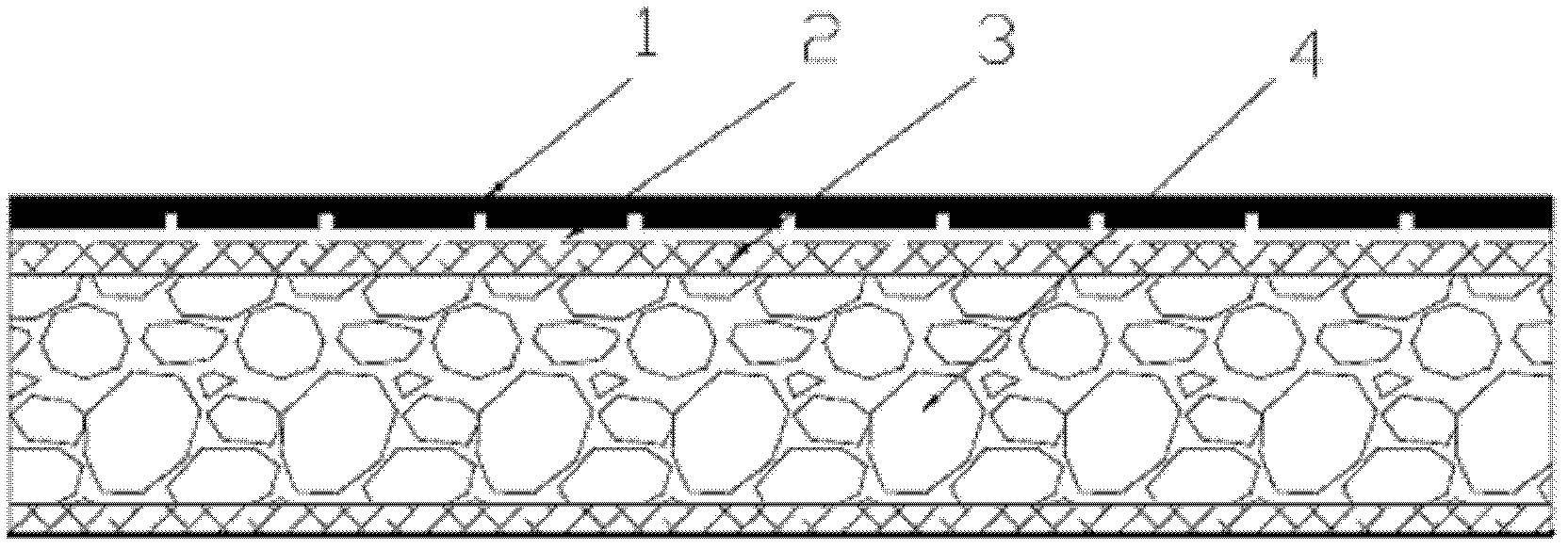

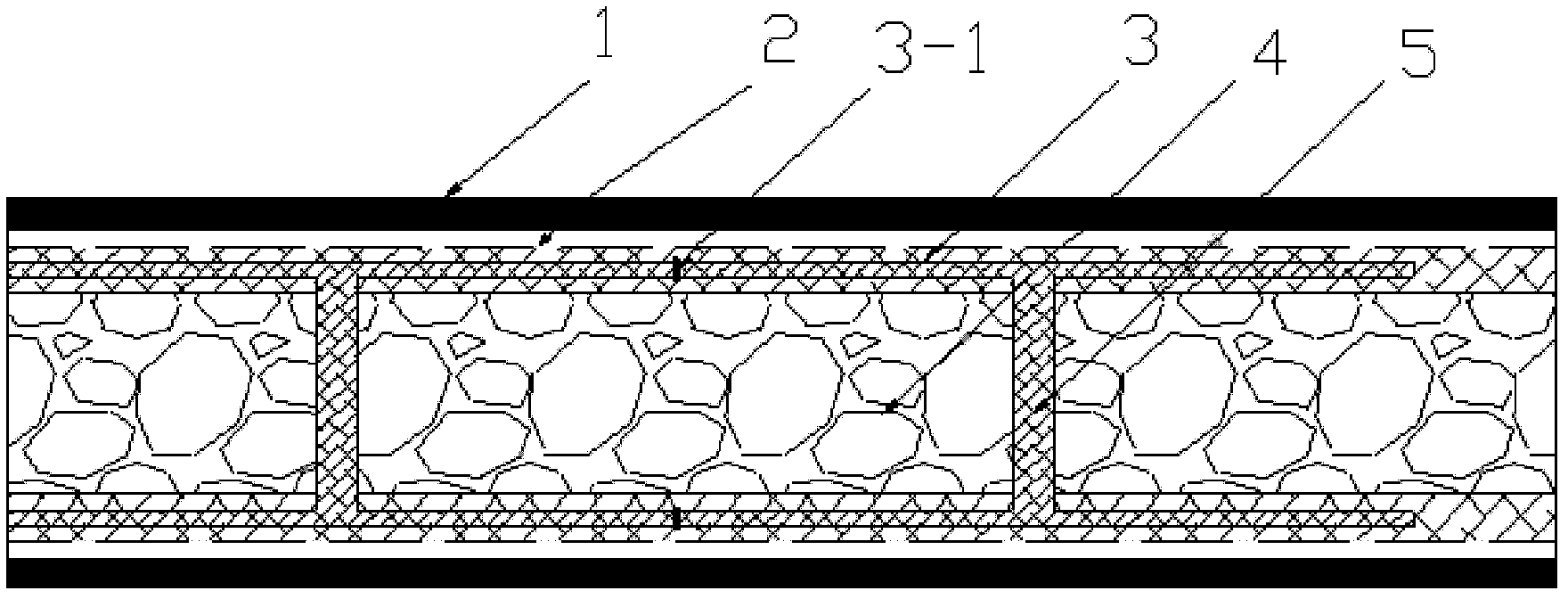

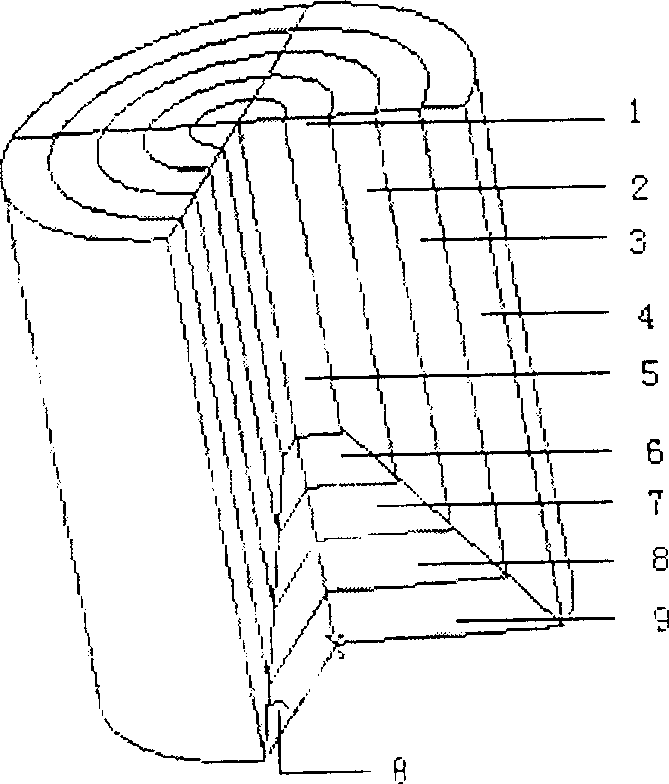

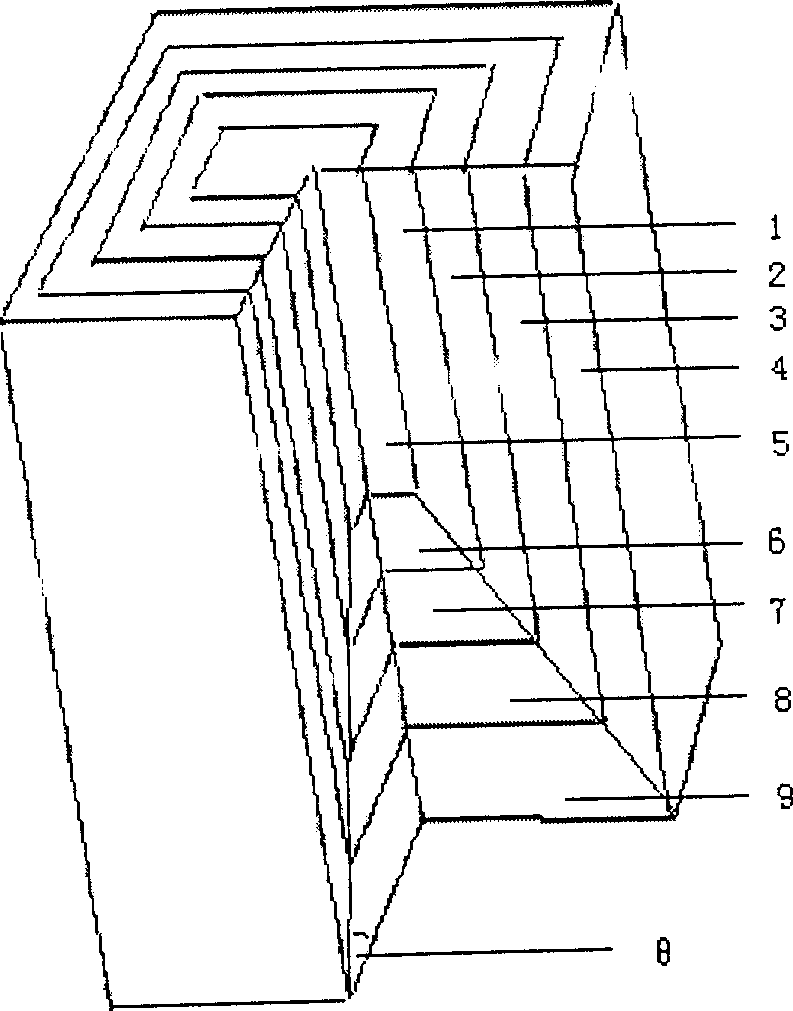

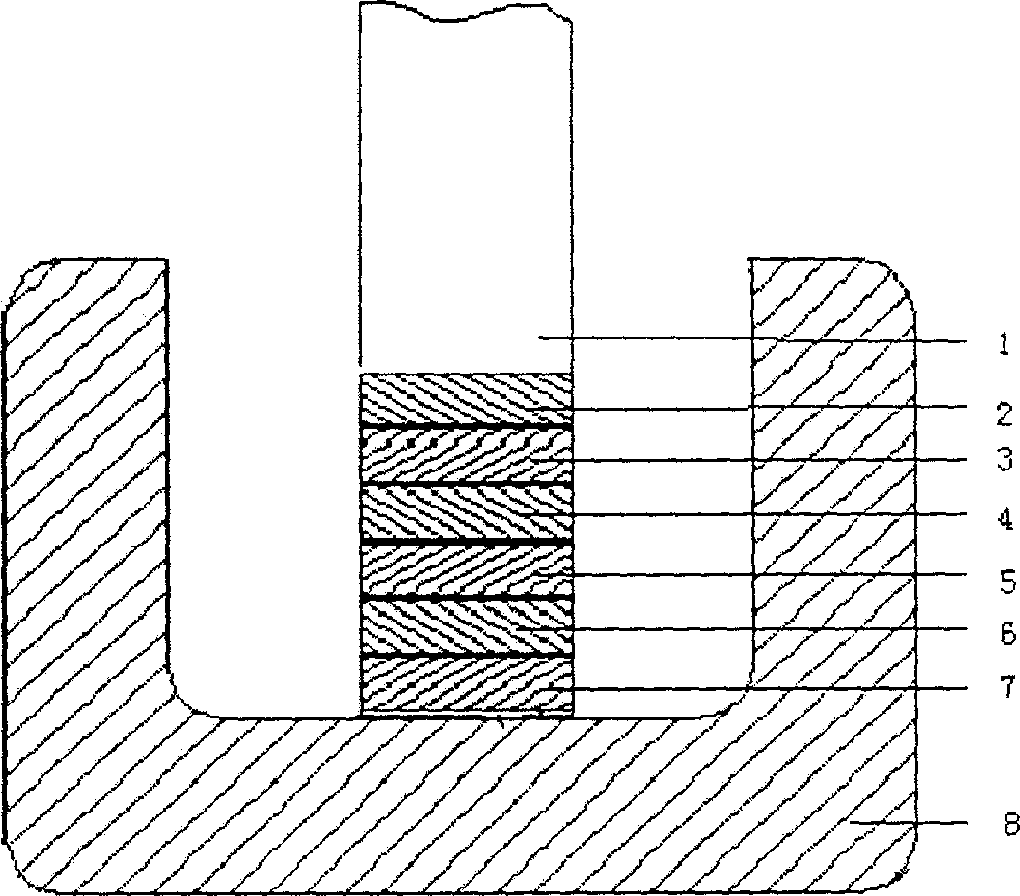

Composite material plate, preparation method and use of composite material plate

InactiveCN103009728AIncrease stiffnessSolve wear resistanceSynthetic resin layered productsLaminationWear resistancePolydicyclopentadiene

The invention relates to a composite material plate. The composite material plate comprises a sandwich layer, two covering layers coating the outer surface of the sandwich layer, and a polydicyclopentadiene layer arranged on the outer surface of at least one of the covering layers. The invention also relates to a preparation method and a use of the composite material plate. According to the composite material plate, outside of a fiber reinforced material is coated by the polydicyclopentadiene layer, so that the problem that a conventional fiber reinforced resin-based composite material is easily suffered from layering failure and is poor in abrasive resistance when being subjected to an impact load is solved. The composite material plate can be widely applied to loading or load-bearing components on mine, railway and road transportation heavy vehicles and goods hoppers. The composite material plate material can be obtained through a reaction injection molding process combined with a vacuum auxiliary molding process, and is suitable for industrial production.

Owner:蓝星环境工程有限公司

Carbon, ceramic-nonmetallic material and metal material connection method

InactiveCN1528714ASimple processEasy to implementLiquid/solution decomposition chemical coatingSuperimposed coating processCeramic particleSolderability

The invention is a method to link carbon and ceramic nonmetallic materials with metallic material, firstly adopting nonmetallic material surface metalizing technique to form a layer electro-conductive metallic substrate on the nonmetallic material basal body, then electroforming to deposit a 1-10nm thick metallic or compound coat on the substrate, and for improving thermal expansion matching performance of nonmetallic and metallic materials, adding reinforcing bodies like second-phase ceramic particles or crystal tassels, etc to the electroforming solution, where the thermal expansion coefficient of compound electroformed coat is controlled at 4-12X10 to the power -6 / deg.C. It uses weldable and plastic processing performances of metallic electroformed coat, to realize the effective linkage of metalized modified nonmetallic material with metallic material structural component by welding or other mechanical linking methods.

Owner:SHANGHAI JIAO TONG UNIV

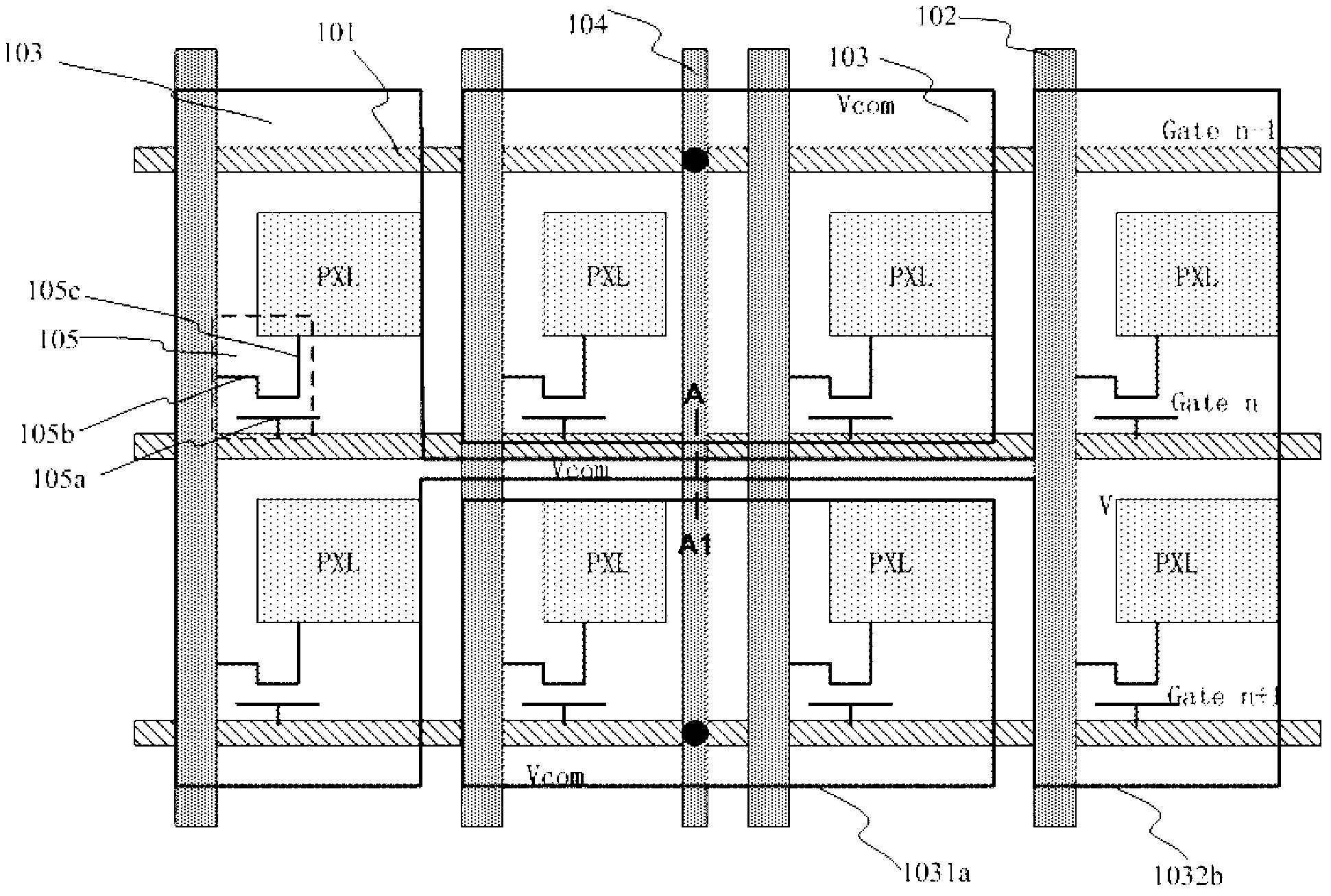

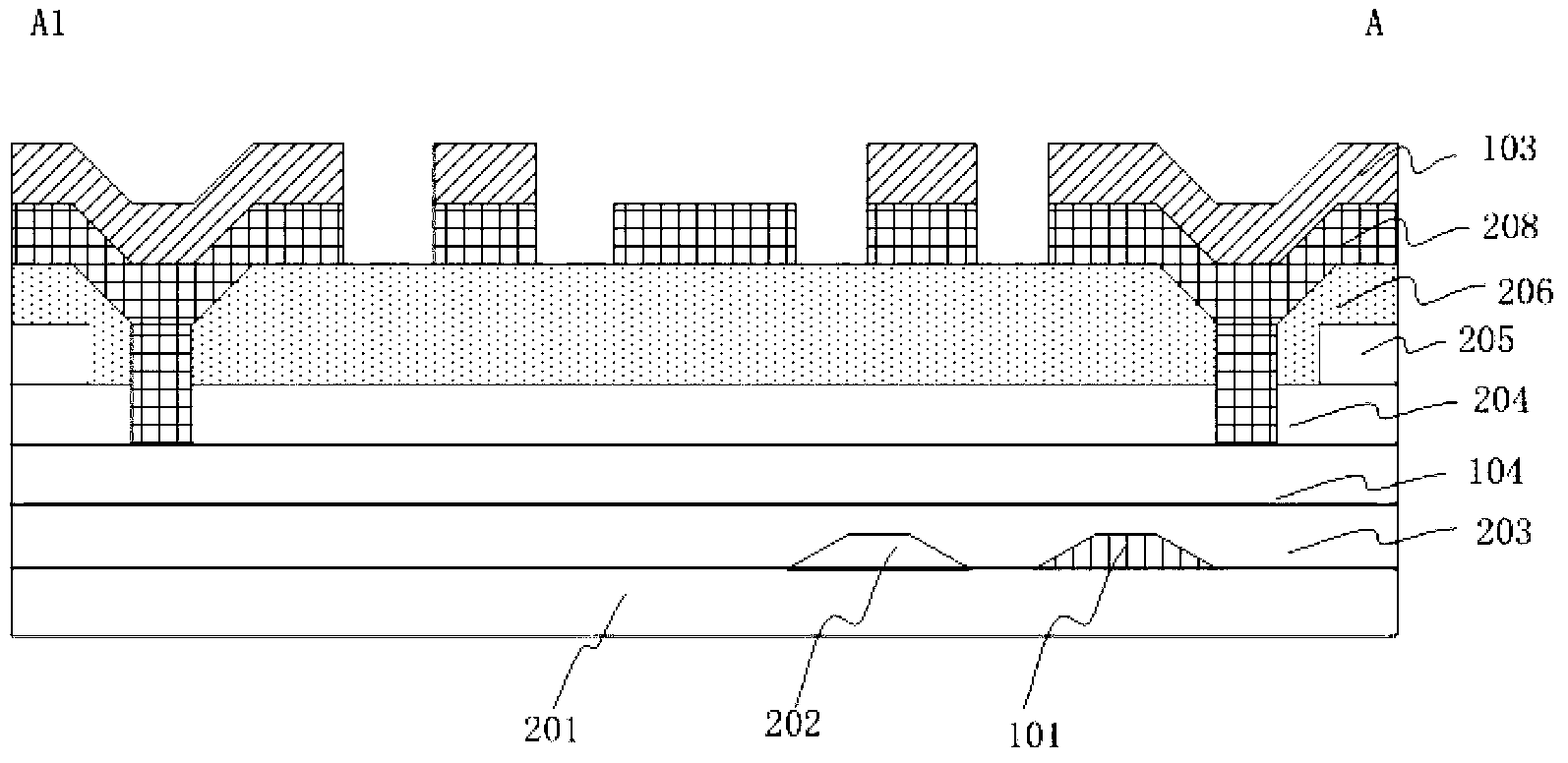

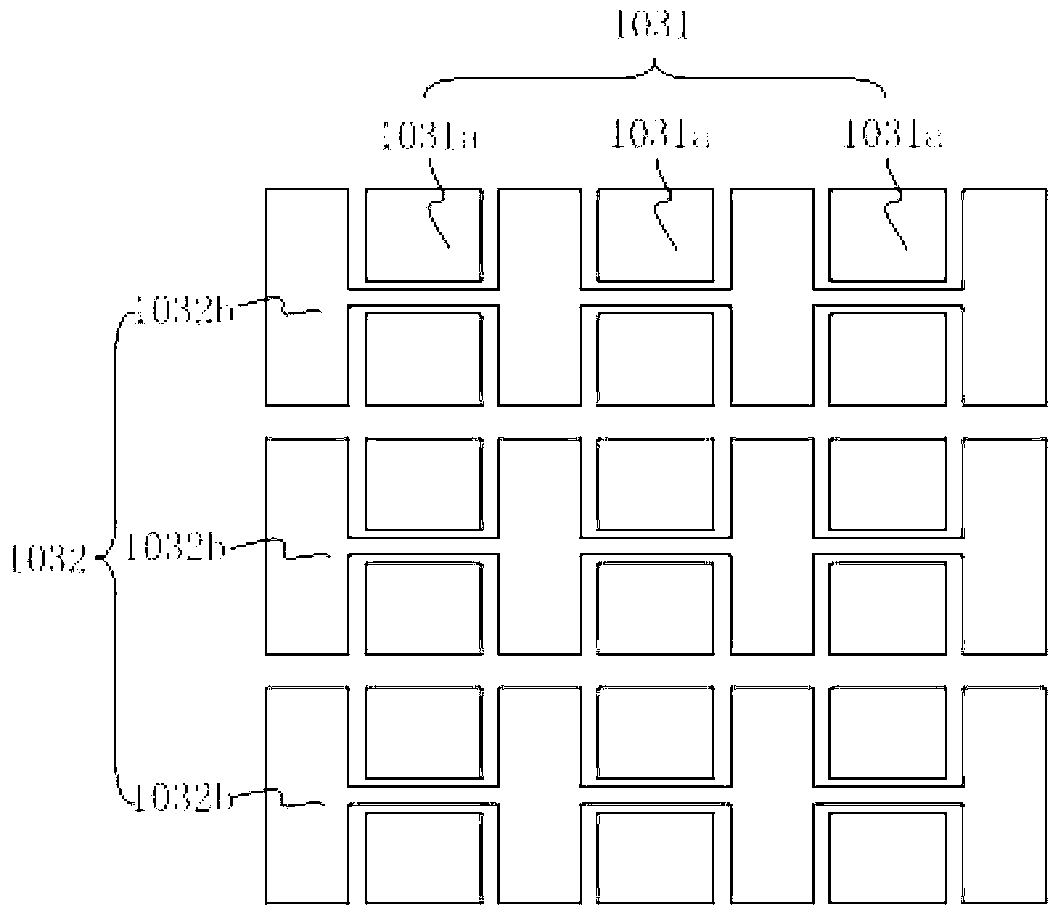

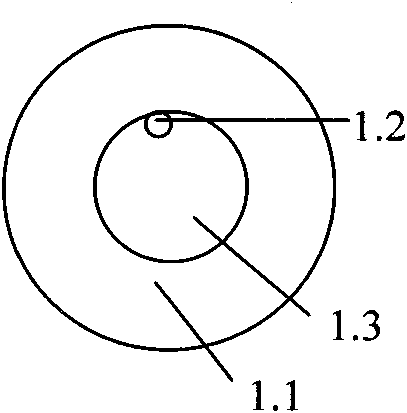

Capacitor-embedded touch screen and capacitor-embedded displaying device

ActiveCN103257769AResolve connectionNon-linear opticsInput/output processes for data processingDriven elementCapacitance

An embodiment of the invention provides a capacitor-embedded touch screen and a capacitor-embedded displaying device, and aims to solve the problem about common electrode split connection based on normal pixel design. The capacitor-embedded touch screen comprises an array substrate, grid lines, data lines and common electrode layers are arranged on the array substrate, wherein the common electrode layers comprise a plurality of touch driving element units and a plurality of touch sensing electrode units which are mutually insulated, the touch driving element unit comprise a plurality of touch driving sub-electrodes, the touch sensing electrode units comprise a plurality of touch sensing sub-electrodes, the touch driving sub-electrodes are connected with one of the touch sensing sub-electrodes in a bridging manner along the direction of the data lines and directly connected with the other touch sensing sub-electrode along the direction of the grid lines, or the touch driving sub-electrodes are connected with one of the touch sensing sub-electrodes in a bridging manner along the direction of the grid lines and directly connected with the other touch sensing sub-electrode along the direction of the data lines.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

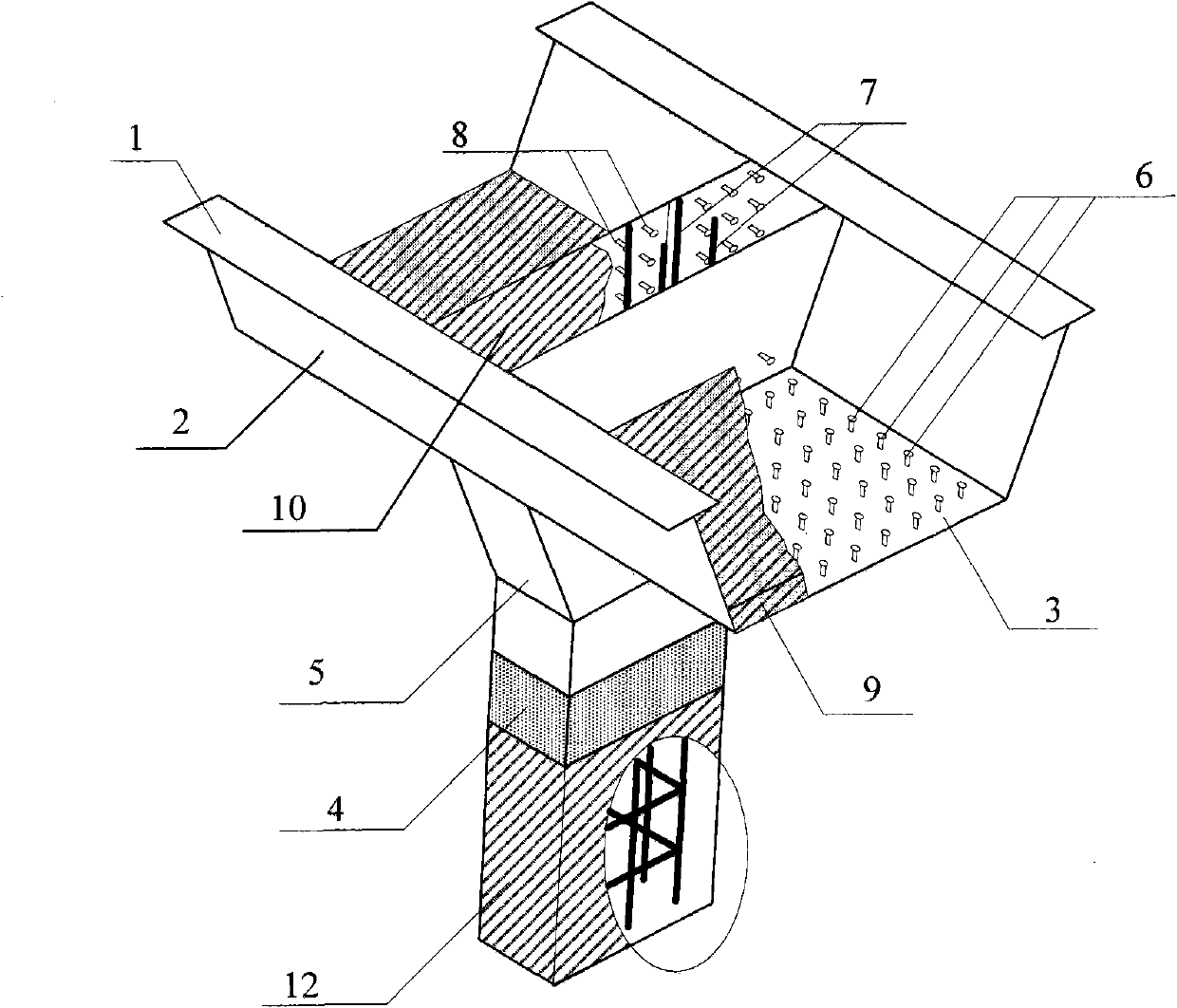

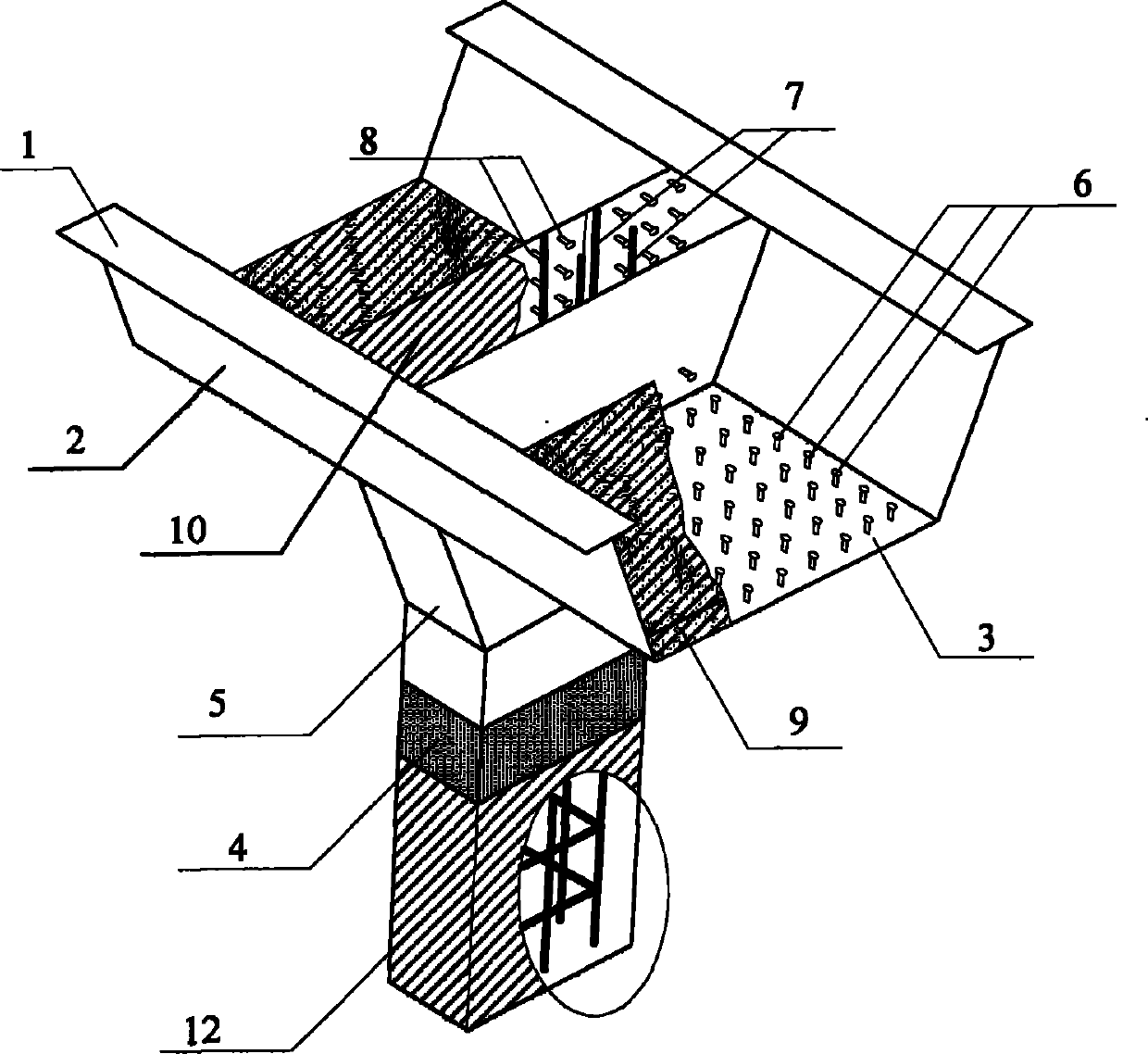

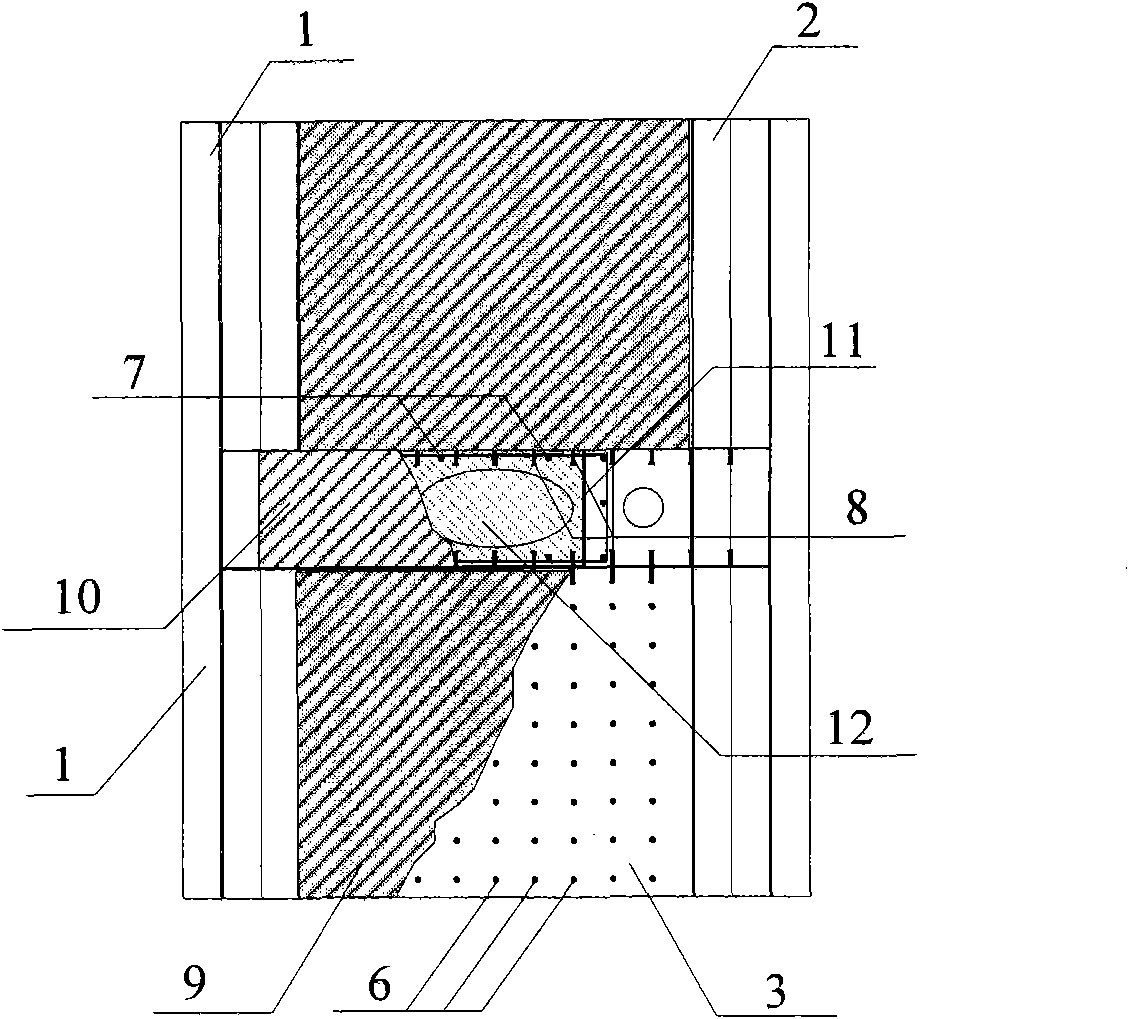

Round steel pipe concrete column joint for beam column connection and method for manufacturing the same

The invention discloses a kind to use in beam column the connection round steel pipe coagulation earth pyramid pitch point and its the manufacture method, it mainly included the round steel pipe coagulation earth pyramid and the steel girder which connected with this column, the round steel pipe coagulation earth pyramid and filled in in this round steel pipe including the round steel pipe the concrete, in carried with steel pipe coagulation earth pyramid connection steel girder Liang is equipped with an end board, this steel pipe coagulation earth pyramid with stated between the end board to be equipped with the belt rib level the steel plate, level the steel plate solidified on the round steel pipe, carried the board, level the steel plate as well as the round steel pipe through as soon as passed through core excels in the bold fastening in together. The invention cost inexpensive, mechanics performance good, design succinct convenient, the construction difficulty is small, also can avoid the scene welding, improves the connection quality and the construction benefit.

Owner:HUNAN UNIV

Graphene-enhanced Al-based composite solder auxiliary soldering method

InactiveCN105382440AHigh thermal conductivityLow densityWelding/cutting media/materialsSoldering mediaReduction treatmentGas phase

The invention relates to a solder auxiliary soldering method, in particular to a graphene-enhanced Al-based composite solder auxiliary soldering method. The method solves the problems that existing graphene is poor in aluminum base enhancing effect and poor in dispersibility. The method comprises the steps that an oxidized graphene suspension and an aluminum solder suspension are mixed, dried and then placed into a plasma enhanced chemical vapor deposition vacuum device for reduction treatment, then, the mixture is pressed into foils, the graphene / aluminum-based solder foils are placed between to-be-soldered faces of metal to be soldered for vacuum soldering, and the graphene-enhanced Al-based composite solder auxiliary soldering method is completed. The method is used for graphene-enhanced Al-based composite solder auxiliary soldering.

Owner:HARBIN INST OF TECH

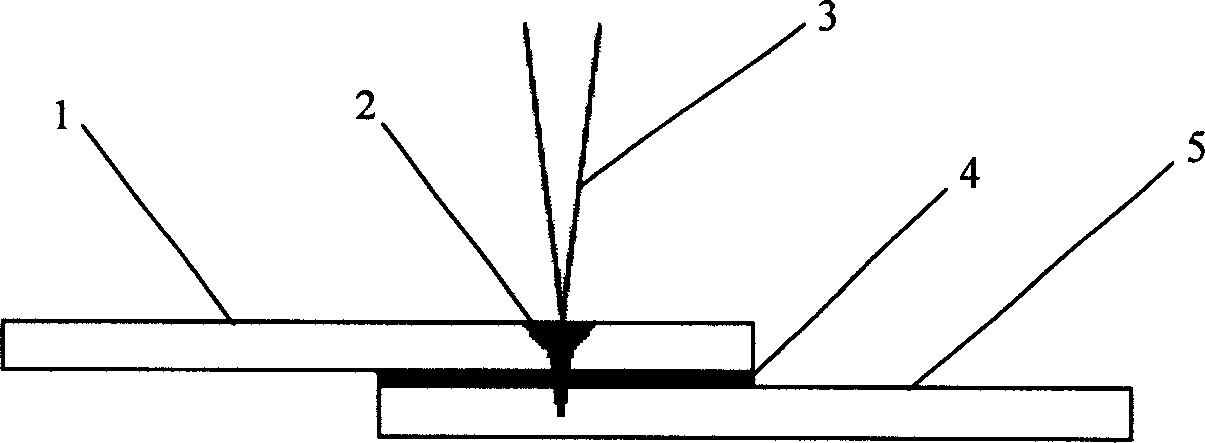

Glue welding connection method

InactiveCN1663729AIncreased shear strengthReduce material lossWelding apparatusFatigue IntensityEngineering

The invention is the glue welding method and belongs to the material engineering technology field. It relates to the new jointing method adopting glue joint and welding. The procedure is: coat a layer of glue on the overlap areas of the surfaces of the two layers of the waiting materials, then adopt welding hot resource overlapping to realize fine joint of the adapters. The invention can fulfill the effective integrate of mechanic joint, metallurgy joint and chemical joint, improve the loading capacity, the fatigue intensity, the cut intensity, solve the problem of hard jointing of same or different metals, reduce the material wastage and meet the demand of the practical project. The invention is suitable for the jointing of magnesium alloy, Al alloy, Ti alloy and steel and obtains the joints with fine performance.

Owner:DALIAN UNIV OF TECH

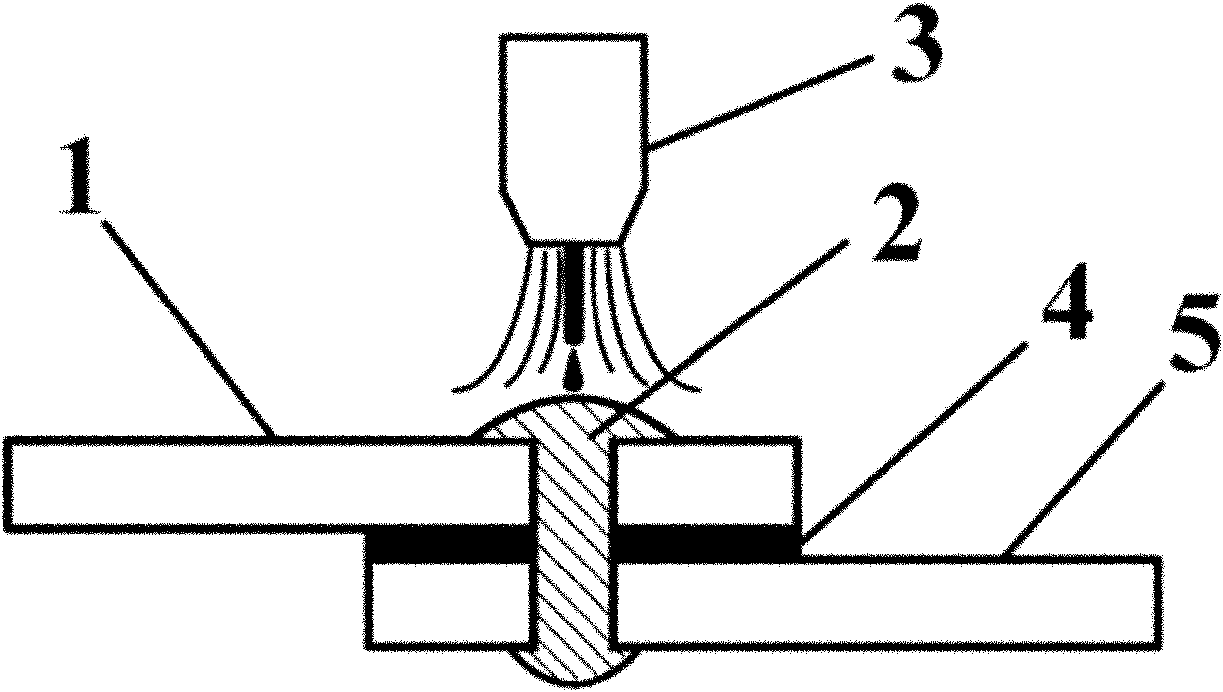

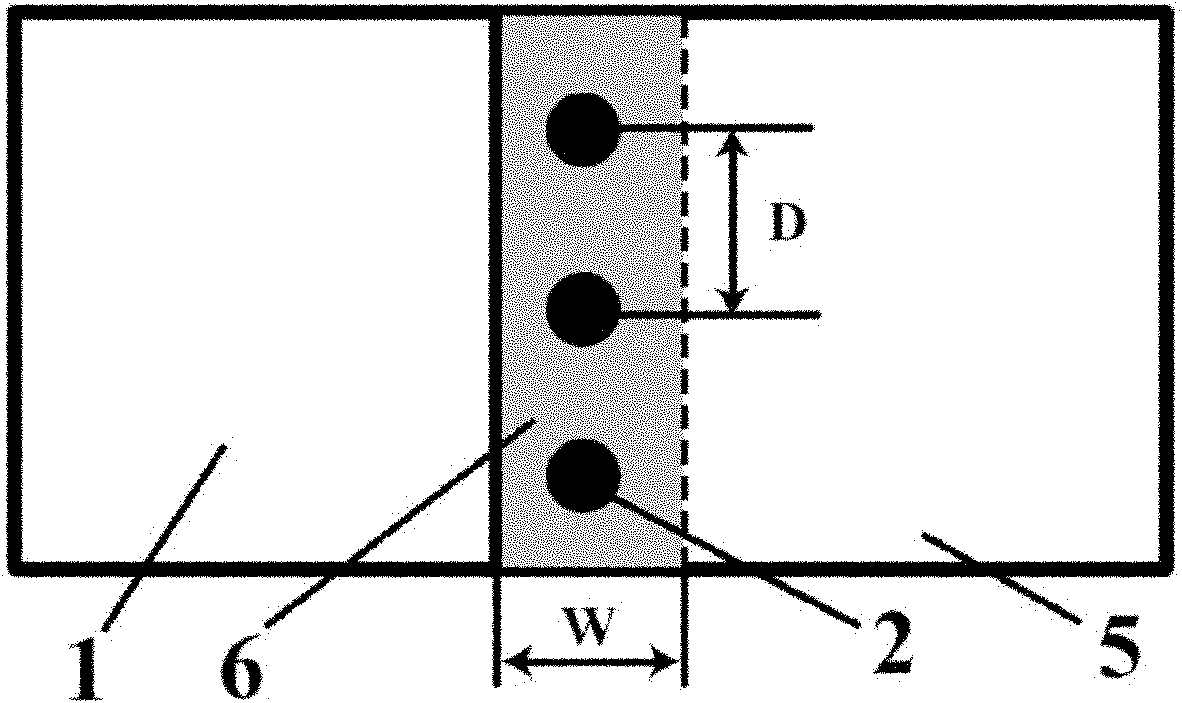

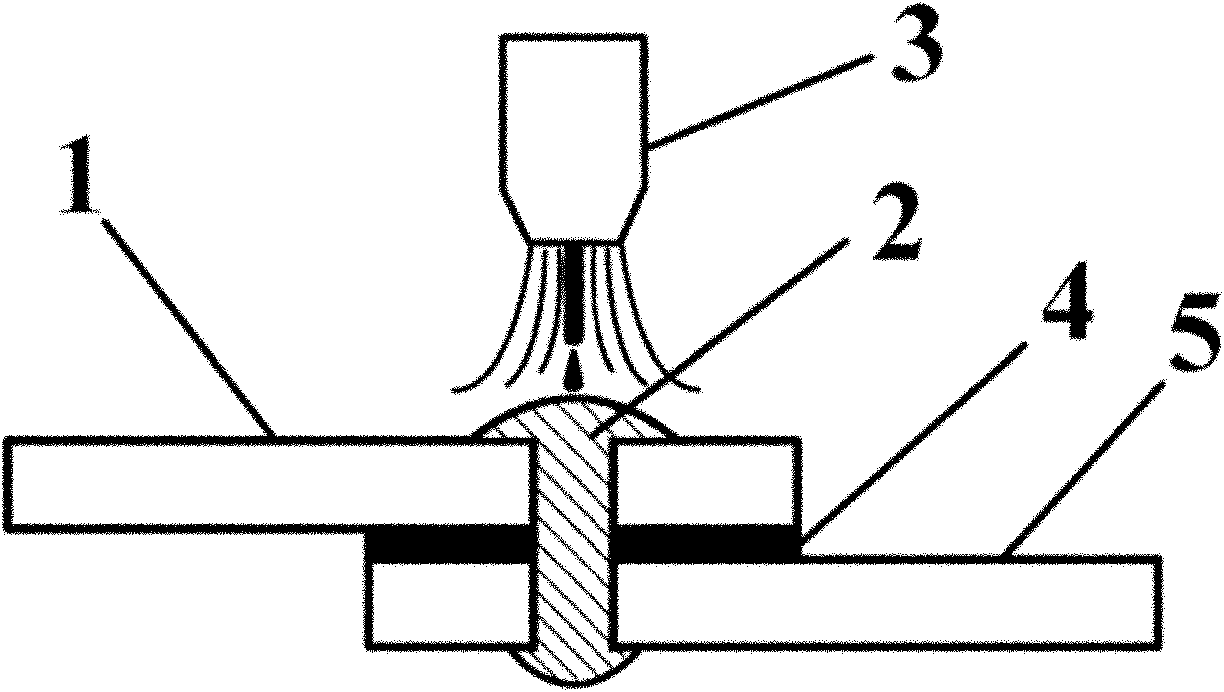

Adhesive jointing and electric arc spot welding combined connection method for metals

InactiveCN102059460AHigh solder joint strengthImprove stabilityArc welding apparatusJoint surfaceElectric arc

The invention belongs to the technical field of material engineering and relates to a connection technique for metals, in particular to a welding and adhesive jointing combined connection technique for metals, which comprises: applying adhesive for structural curing on the joint surfaces of materials to be welded; jointing the materials; and welding. The technique is characterized in that: an adhesive layer which is 0.02 to 1 millimeter thick is uniformly applied between the jointing surfaces of the materials to be connected; after joining, through holes with an aperture of 3 to 10 millimeters are formed on a jointed part at 15 to 50 millimeter intervals along a joint, and performing double-sided filler wire spot welding at the holed part with an arc weld; and heating the jointed parts between which a glue layer is applied to 50 to 500 DEG C before welding and after welding, and keeping the temperature for 10 to 180 minutes. The method can increase the strengths of the welded spots, avoid surface collapse caused by other adhesive bonding, improve the bearing load, fatigue strength and shearing performance of difficult-to-weld welded structure made of one kind of metal and different kinds of metals, and meet actual engineering needs.

Owner:DALIAN UNIV OF TECH

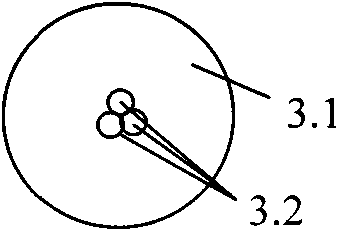

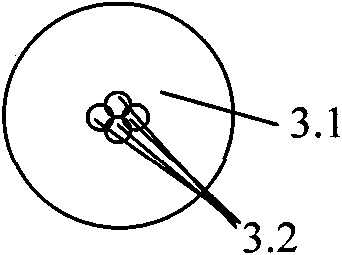

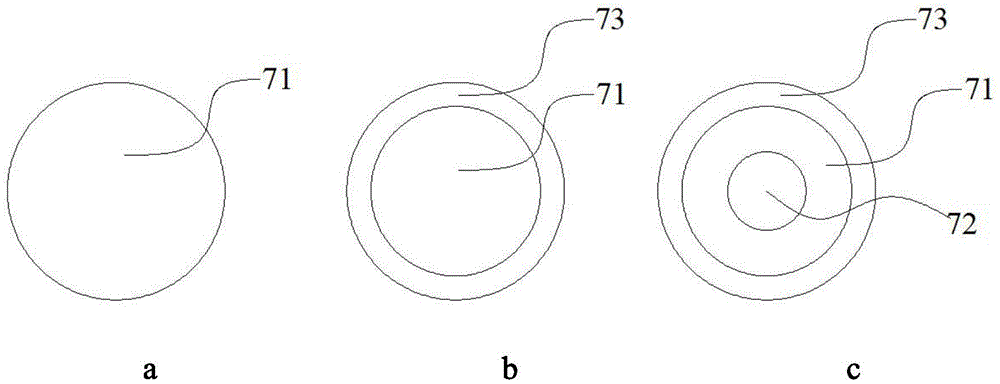

Capillary pipe optical fibre and standard optical fibre connecting method

InactiveCN101339275AResolve connectionEasy to manufactureCladded optical fibreCoupling light guidesLight energyCoupling

The invention provides a connecting method for a capillary optical fiber and a standard optical fiber, which comprises the following steps: stripping and washing the coating layer at one end of the capillary optical fiber, the standard optical fiber or a multimode optical fiber respectively and cutting a tidy optical fiber head face; fusing and welding through an optical fiber welder; preheating for Delta t seconds at the position where a welding point leans a distance of delta from the standard optical fiber or the multimode optical fiber (the value range of Delta is 0.1 - 3.5mm, the value range of Delta t is 3 - 12 seconds); implementing fused biconical taper to form a tapered light energy distribution area; carrying out optical power monitoring to one end of the capillary optical fiber in the process of fused biconical taper so as to form a tapered coupling area; sheathing a quartz protection sleeve outside of the tapered coupling area and sealing the both ends of the quartz protection sleeve with the standard optical fiber and the capillary optical fiber. The method solves the connection problem of the standard optical fiber and the hollow capillary optical fibers with the same diameter but different cross-sectional area ratio, and has the advantages of easy manufacturing and high light-wave conversion efficiency.

Owner:HARBIN ENG UNIV

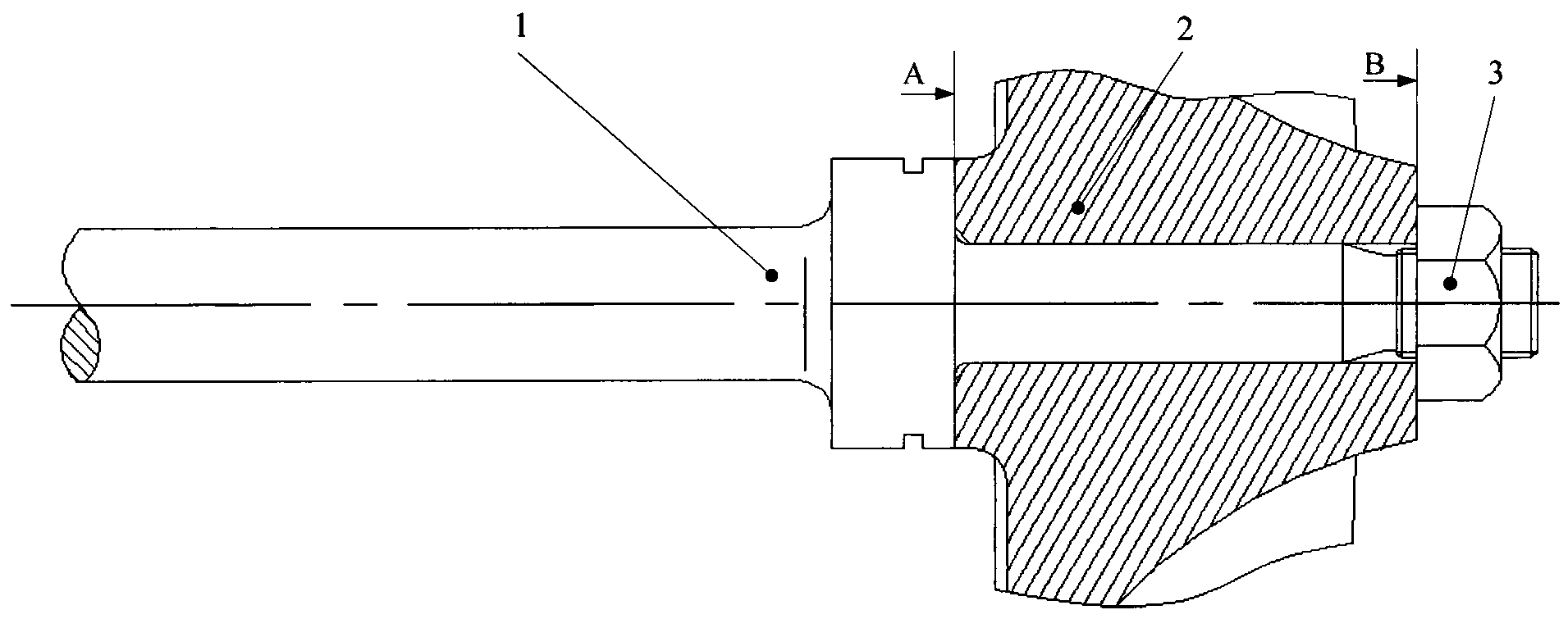

Threaded interference fitting method and threaded interference fitting structure for turbine impeller and rotary shaft

ActiveCN103244194APersistent and reliable connectionGuaranteed connection strengthBlade accessoriesMachines/enginesImpellerAluminium alloy

The invention relates to a threaded interference fitting method and a threaded interference fitting structure for a turbine impeller and a rotary shaft. Through reasonable design of a threaded connecting structure and process diameters of a titanium aluminum turbine impeller and a 42CrMo rotary shaft, machining of titanium aluminum turbine impeller inner threads and a titanium aluminum turbine impeller matching end face and 42CrMo rotary shaft outer threads and a 42CrMo rotary shaft matching end face, threaded assembling of the titanium aluminum turbine impeller and the 42CrMo rotary shaft is achieved by heating a threaded connecting part of the titanium aluminum turbine impeller or cooling a threaded connecting part of the 42CrMo rotary shaft, blind holes of connected turbine rotary shafts are machined, elastic cylindrical pins are fitted in the blind holes, and other parts of the connected turbine rotary shafts are machined according to structural parameters of turbine rotary shafts. The advantages of threaded connection and interference fitting are combined, durable and reliable connection of the titanium aluminum alloy turbine impeller and 42CrMo alloy rotary shaft, and the connection strength requirements of the booster turbine impeller and the rotary shaft are satisfied.

Owner:CHINA NORTH ENGINE INST TIANJIN

Coupling method for suspended-core optical fibers

InactiveCN101852894AHigh light conversion efficiencyResolve connectionCoupling light guidesCouplingOptical power

Owner:HARBIN ENG UNIV

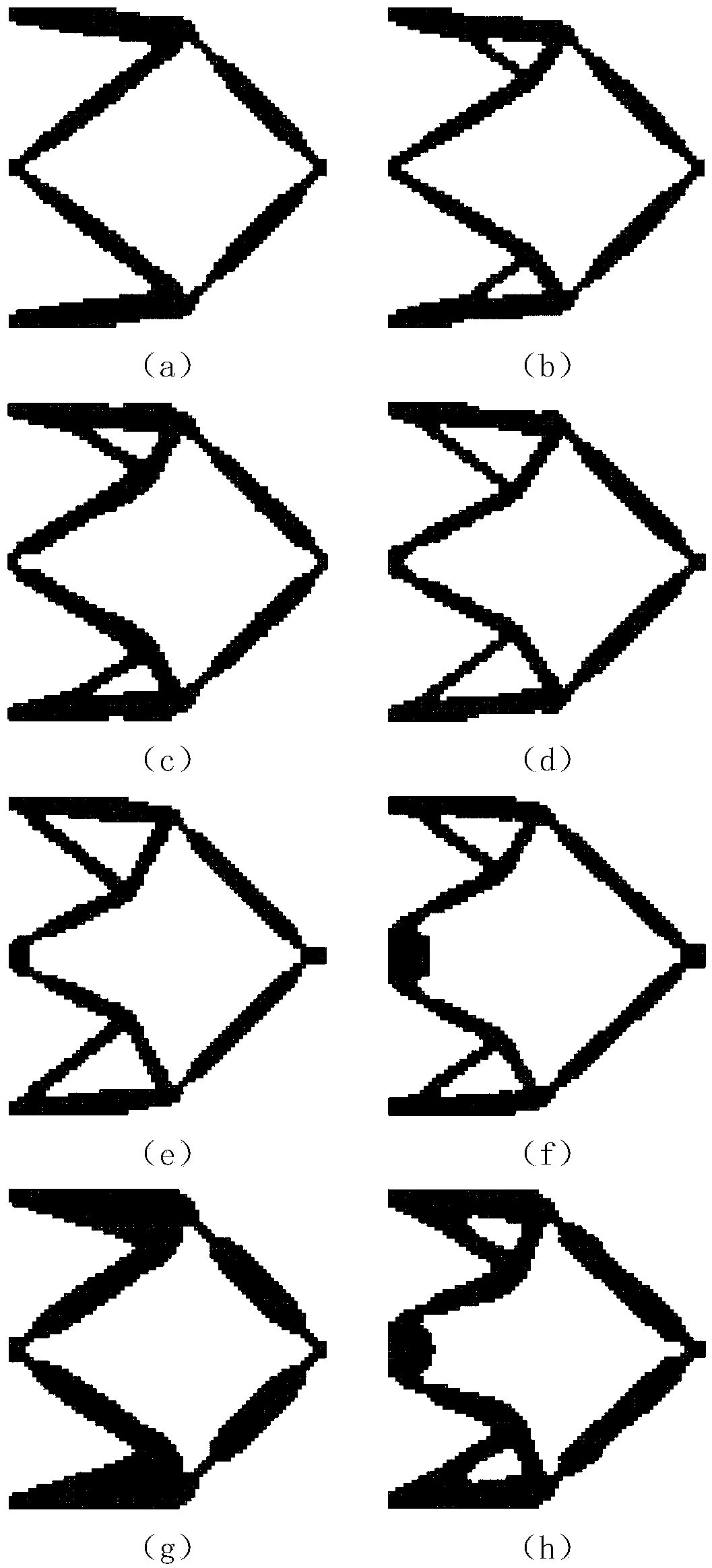

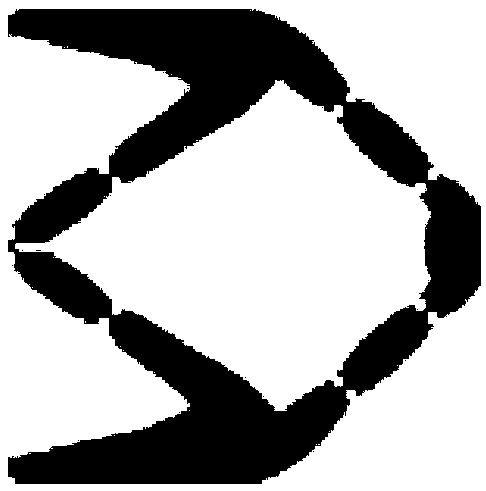

A flexible mechanism topology optimization design method based on adaptive constraint

ActiveCN109583091AResolve connectionMeet the design requirementsGeometric CADDesign optimisation/simulationElement modelElement analysis

The invention discloses a flexible mechanism topology optimization design method based on self-adaptive constraint. The method is used for solving the problem of single hinge existing in flexible mechanism topology optimization. The method comprises the following steps that an initial design area is given, finite element grids are divided, a finite element model of a current effective structure isformed, and meanwhile a mapping relation data file of a maximum design area grid model and the finite element model of the current effective structure is generated and stored; Performing finite element analysis to obtain displacement vector data under an actual load and a unit virtual load; Establishing a function expression of adaptive constraint based on the mutual strain energy, the flexibility, the volume and the mechanism comprehensive flexibility function change rate, establishing an approximate optimization model, converting the model into an approximate quadratic mathematical programming model, and obtaining a topological variable solution; And automatically updating the structure topological variable, and reading the structure grid and the model data to form a new structure system finite element model. The above steps are repeated, and the optimal topology can be obtained when the iteration process converges.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

13 Cr oil well-pipe test material object preparation method

ActiveCN101149319AImprove technical effectQuality assurancePreparing sample for investigationMaterial strength using tensile/compressive forcesAlloyEngineering

The invention relates to a welding method for the collet between the 35CrMo or 30CrMo and the oil drilling vitta, bushing made by the 13Cr martensitic stain less steel. The two ends of the oil drilling vitta are machined to welding groove and many uniformly plug welding holes are machined at the position of 100mm far from the welding groove; two of tested collets are welded into the groove, which is welded with the test pipe, the inner and out of the other end are machined with screw thread to connect with the test equipment; the plug welding root is welded with the collet and the side is connected with the test pipe; or it and / or pipes are set with a ring of reinforced tendon, which the material is the low alloy high strength steel and welded with the collet and test pipe by the angle welding line. In the condition of high temperature, pressure and loading, the joint head is welded well, so it solves the problem of connecting between the 13Cr pipe and collet and has high reliability and successful ration, low period to improve the working efficiency and decrease the cost comparing to the screw + glue sealing structure.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

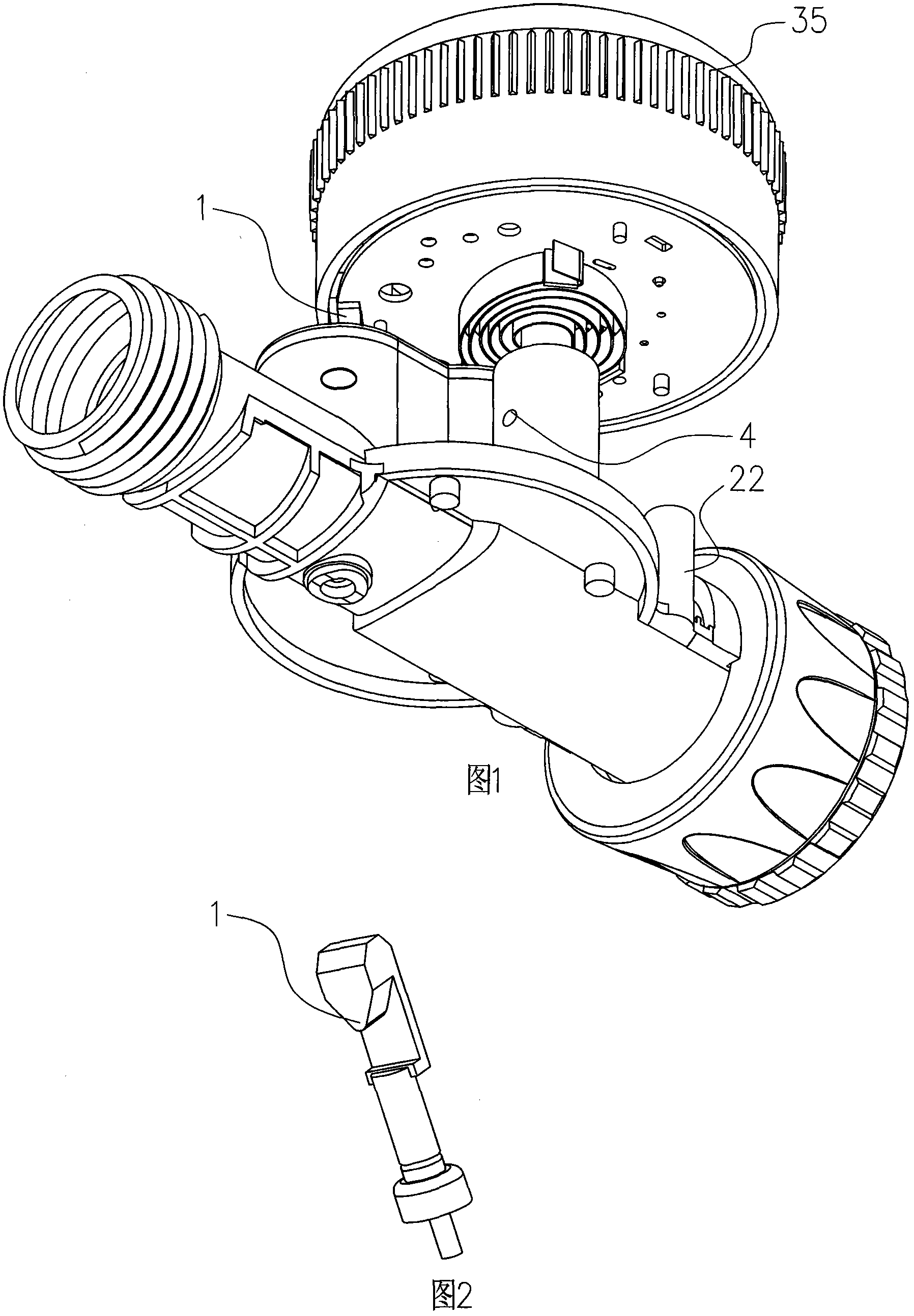

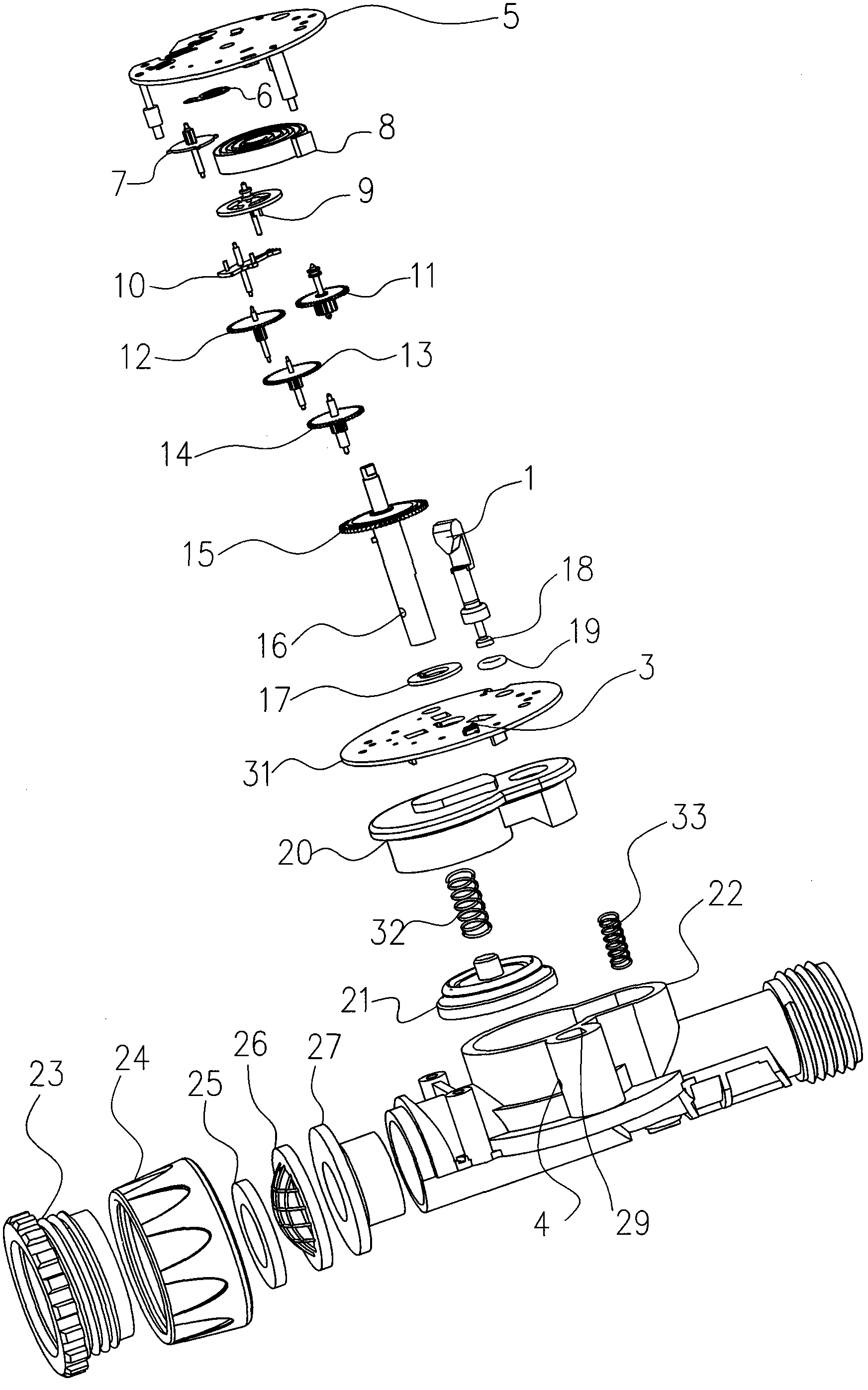

Faucet joint with clamps and combination thereof with timer and sprinkler

ActiveCN103518593ASave sizeWide applicabilityWatering devicesCultivating equipmentsWater flowEngineering

The invention relates to a faucet joint with clamps and a combination thereof with a timer and a sprinkler and also relates to a utility method for irrigation waterflow for environmental protection and gardening. The faucet joint and the combination have the advantages that operation is facilitated and application range is widened; the faucet joint and the combination can be applied to the field of supplies special for one-handed persons; an operator can easily mount a faucet into the faucet joint by holding the joint with a hand and pulling up the faucet into the faucet joint with no need of pressing the clamps, and the clamps directly open to mount the faucet under the action of chamfers; the faucet can be taken out by hands pressing the clamps; the faucet joint can be optionally combined with various joints and devices as an independent product; each of the left and right clamps is provided with a return spring which is a compression spring having large elasticity, and with the return spring, the faucet joint is applied to large-sized products; with elastic wires (66), the faucet joint is applied to medium-sized products; with elastic bands which have small size and elasticity, the faucet joint is applied to small-sized products; a bubbler (63) is provided with a plurality of channels which are equal in size and each which is provided with a pipe, the channels alternately vary in density and shape, and accordingly bubbling is better; the quality of products is improved comprehensively. The faucet joint with the clamps is easily connected to various faucets, not only can be connected to inner screw thread faucets, but also can be connected to external screw thread faucets.

Owner:NINGBO DAYE GARDEN IND

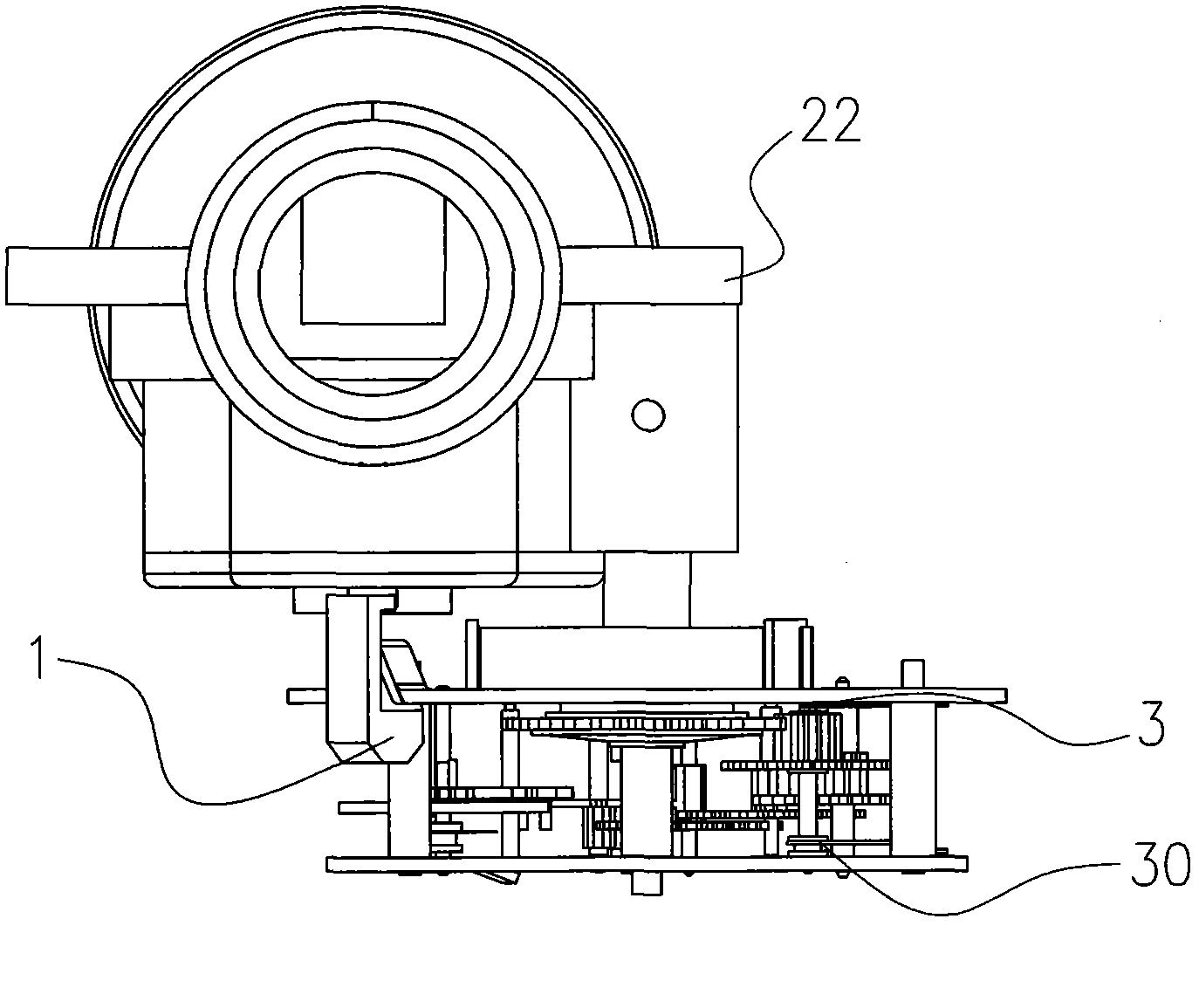

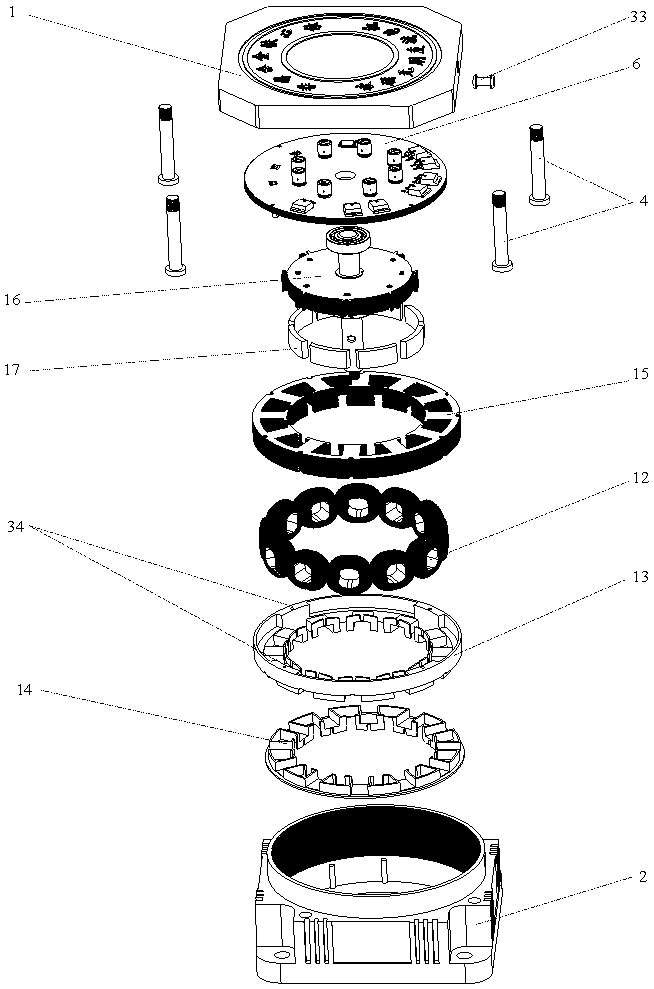

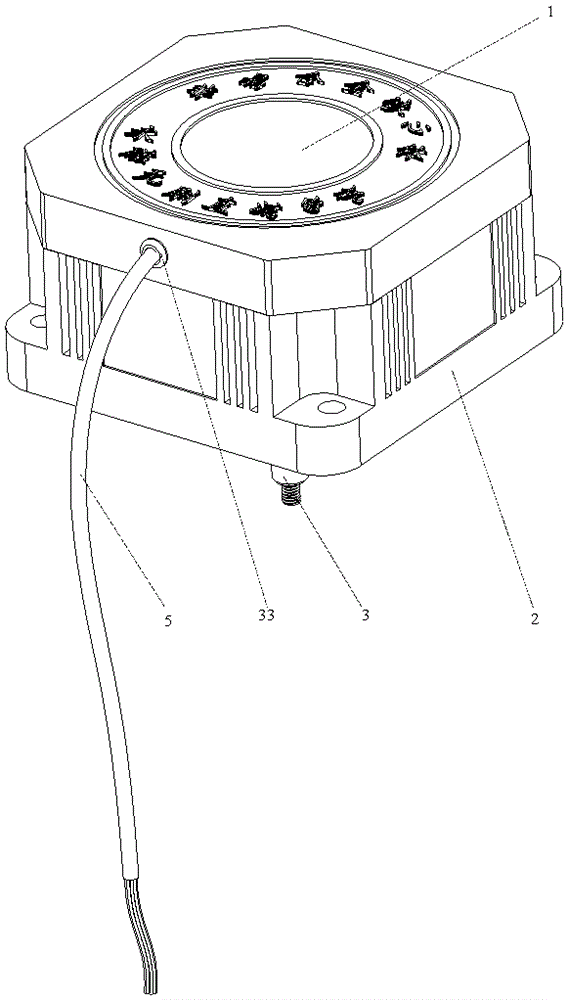

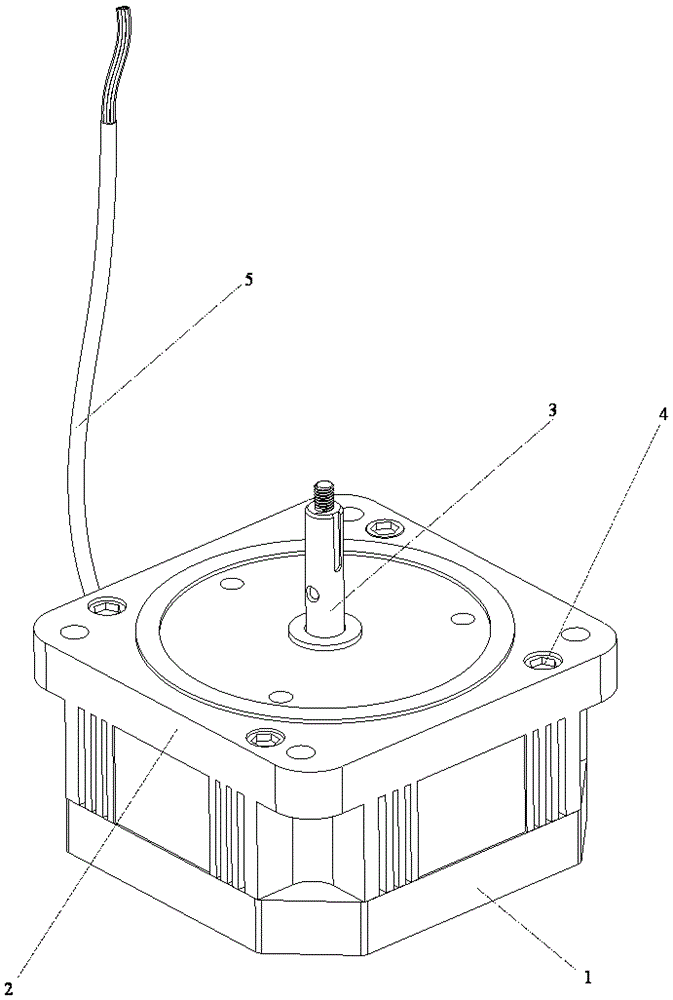

Amorphous alloy iron core permanent magnet brushless direct-current motor

ActiveCN106208545AImprove reliabilityImprove efficiencyAssociation with control/drive circuitsSupports/enclosures/casingsHall elementStator coil

An amorphous alloy iron core permanent magnet brushless direct-current motor consists of the two portions including a motor body and a controller, wherein the motor body portion comprises a motor upper end cap, a motor lower end cap, a motor output shaft, a shaft sleeve, an upper framework, a lower framework, a stator coil, a stator iron core body, a rotor iron core body and neodymium iron boron permanent magnet block, and the controller portion comprises an aluminum metal based printing circuit board, a control cable, a double-core single chip microcomputer, a power VMOS tube and a Hall element. The amorphous alloy iron core permanent magnet brushless direct-current motor is characterized in that both the stator iron core body and the rotor iron core body are formed by superposing iron based amorphous alloy sheets, the stator iron core body is fixed through joint supporting of the upper framework and the lower framework, the stator coil is made by winding an anaerobic copper line, all of controller elements and circuits are integrated on the aluminum metal based printing circuit board, an outer thread is carved on the supporting aluminum metal cylinder of the aluminum metal based printing circuit board, the cylinder is screwed into the inner wall thread of the motor lower end cap during installation to form a motor body and controller mechanical-electrical integrated structure.

Owner:彭希南

Ceramet material with gradient function for electrolyzing Al

The present invention relates to aluminum electrolysis, and is especially inert ceramet anode. The ceramet material has structure of at least two layers and is rod shaped, plate shaped or cup shaped. The ceramic phase is spinelle type composite oxide; and the metal phase is made of Cu, Ni, Co, Fe, Ag, Pt, Au and other metal or their binary or multiple-element alloy. The composite material with gradient function has excellent comprehensive performance under electrolysis, and the anode of the composite material needs no frequent replacement. Using the composite material of the present invention can alter the electrolytic bath structure, raise production efficiency, lower aluminum ingot producing cost, improve environment, and reduce power consumption.

Owner:CENT SOUTH UNIV +1

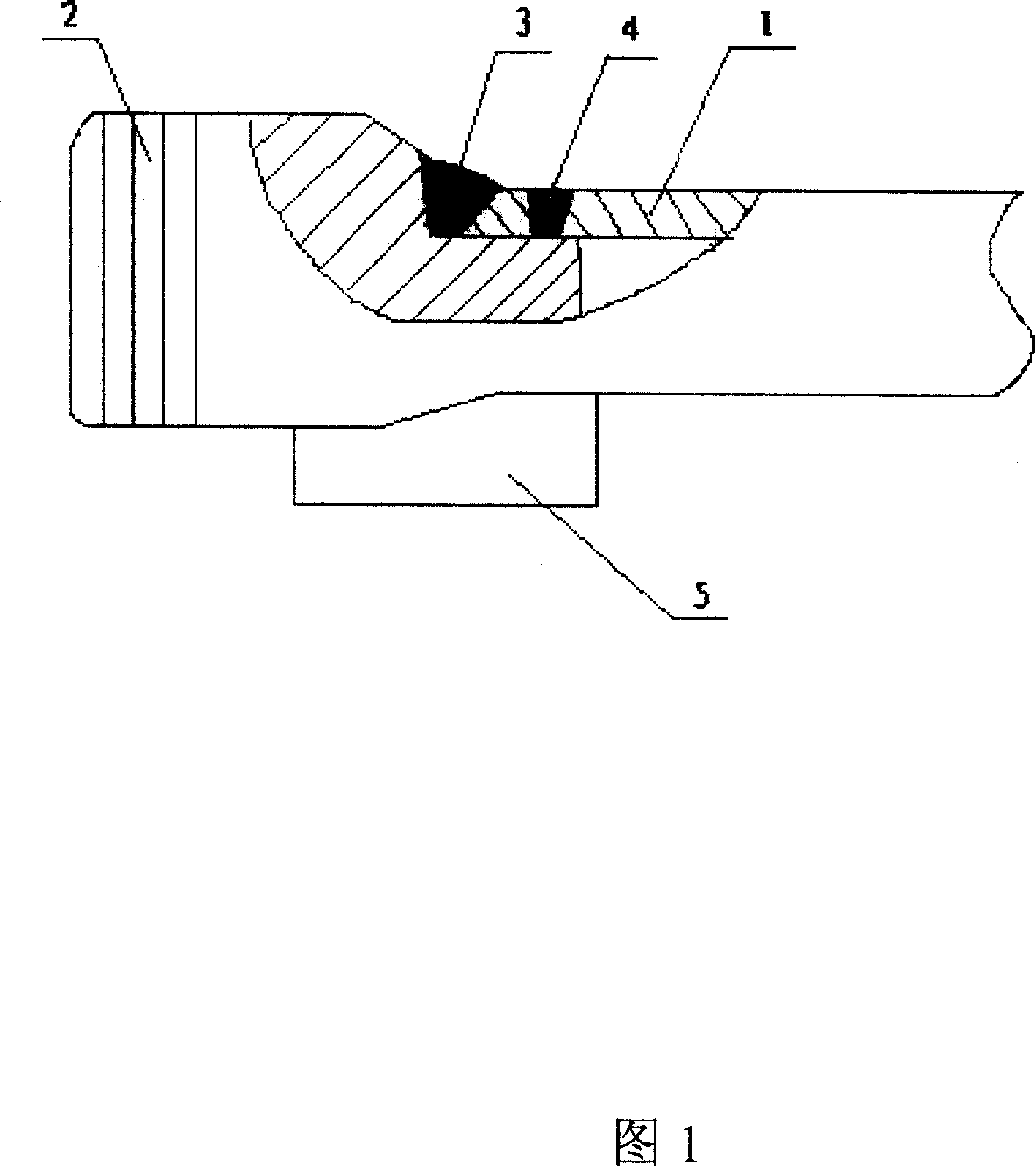

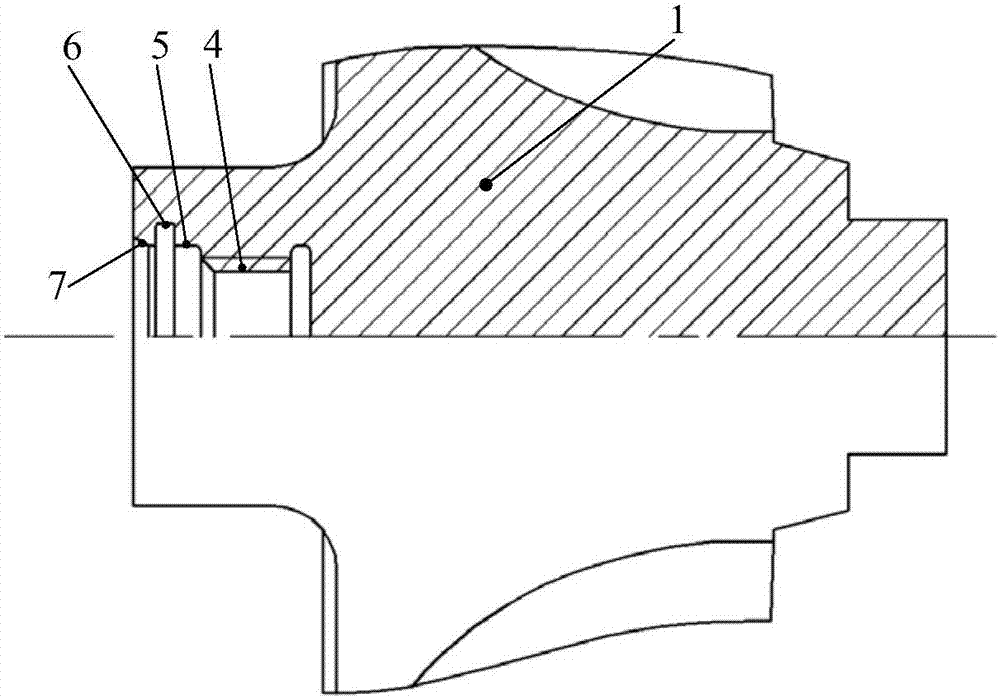

Runoff type supercharger turbine rotating shaft structure and molding process thereof

InactiveCN106988784AFirmly connectedResolve connectionBlade accessoriesMachines/enginesTurbochargerOptical axis

The invention relates to a runoff type supercharger turbine rotating shaft structure and a molding process thereof. The runoff type supercharger turbine rotating shaft structure comprises a turbine, a rotating shaft and a self-locking ring, the turbine is provided with an internal thread blind hole, a polished hole, a ring slot and a guide chamfer, the rotating shaft is provided with an external thread, a positioning shaft shoulder, a polished shaft and a ring slot, and the self-locking ring is an elastic opening ring and is provided with a guide chamfer. By reasonably determining the structure sizes of the turbine, the rotating shaft and the self-locking ring, the turbine, the rotating shaft and the self-locking ring are machined, and then the turbine, the rotating shaft and the self-locking ring are assembled to further form a complete turbine rotating shaft. By means of the runoff type supercharger turbine rotating shaft structure and the molding process, the problems in turbine rotating shaft connection when new materials such as ceramic and a titanium-aluminum alloy are adopted in the supercharger turbine can be effectively solved, reliable connection of the supercharger turbine rotating shaft can be achieved, and the connecting strength and rigidity of the turbine rotating shaft are sufficiently guaranteed.

Owner:CHINA NORTH ENGINE INST TIANJIN

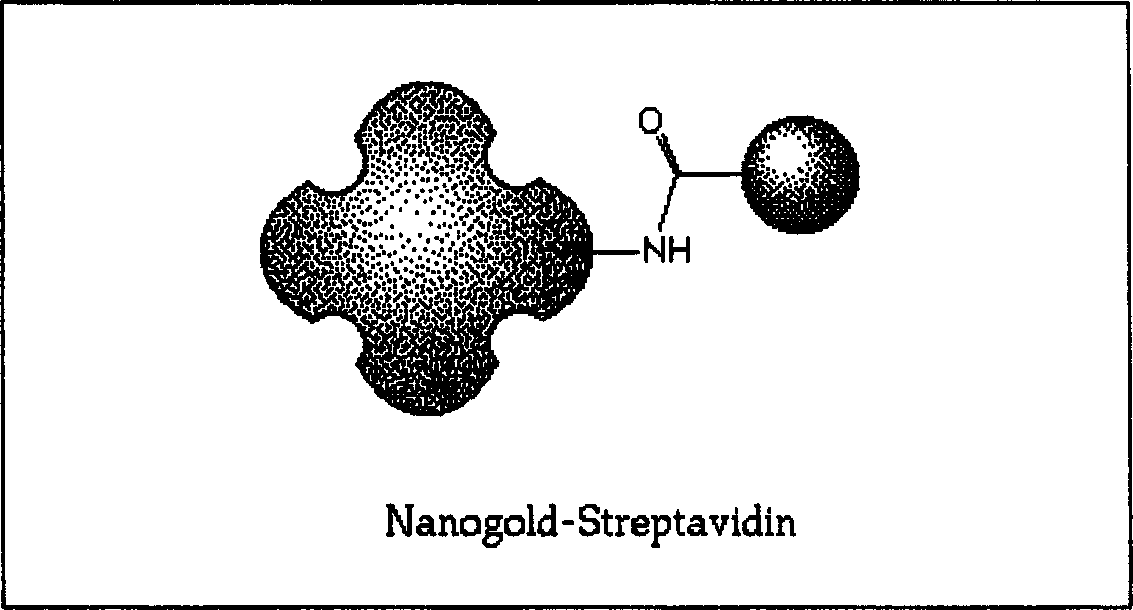

Marking probe of nano microparticle and affinity element and its preparation method as well as application

InactiveCN1415759AResolve connectionSolve the key problems of detectionMicrobiological testing/measurementBiotin-streptavidin complexRegulation of gene expression

A nanopartide and its avidin probe are disclosed. Said gene probe for detecting the mutation or non-mutation of DNA is prepared from nanoparticles or colloidal particles and avidin, streptavidin, or antibiotin through preparing colloidal gold and preparing the compound. Its advantges are high sensitivity, specificity and speed.

Owner:上海华冠生物芯片有限公司

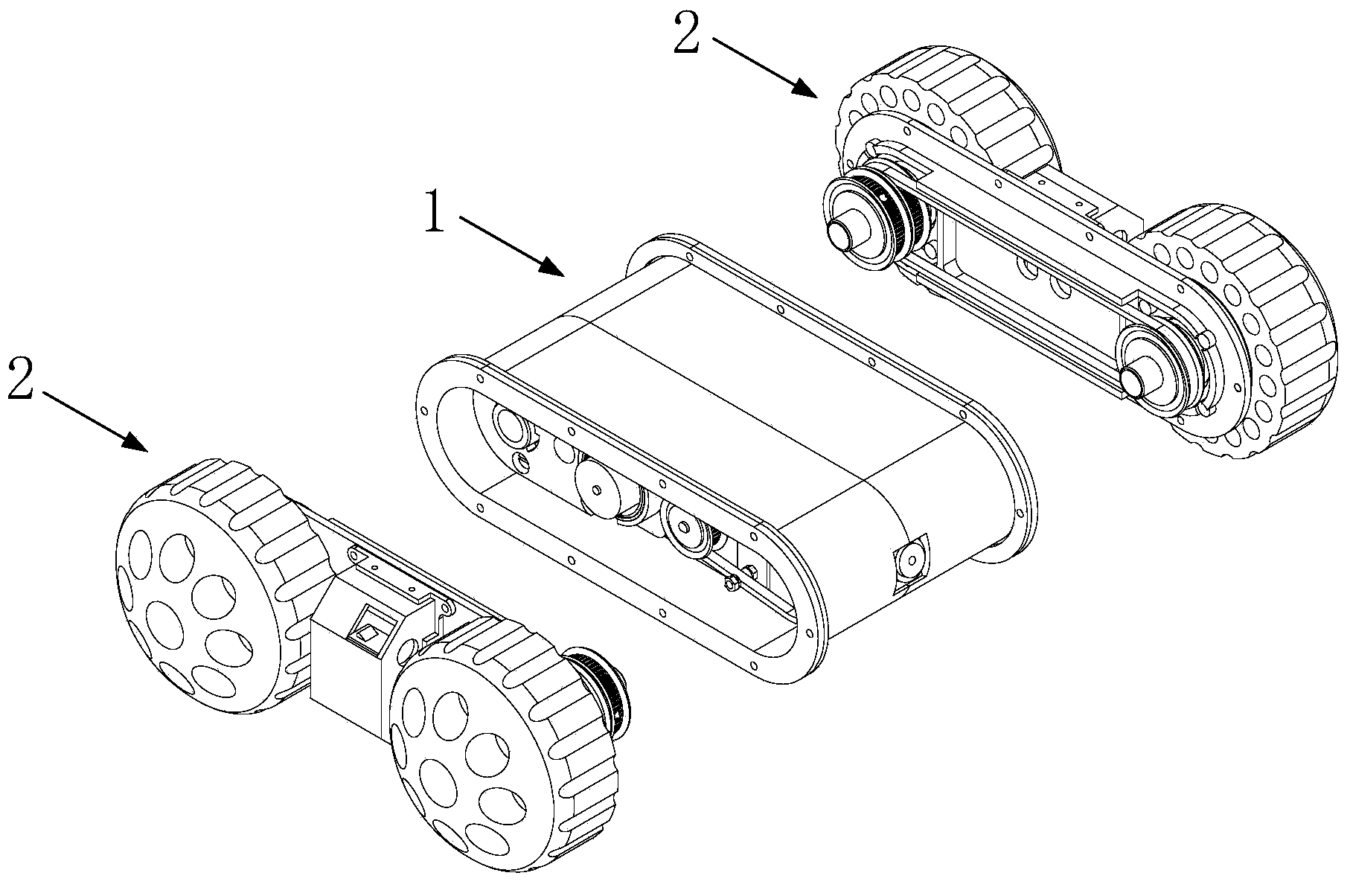

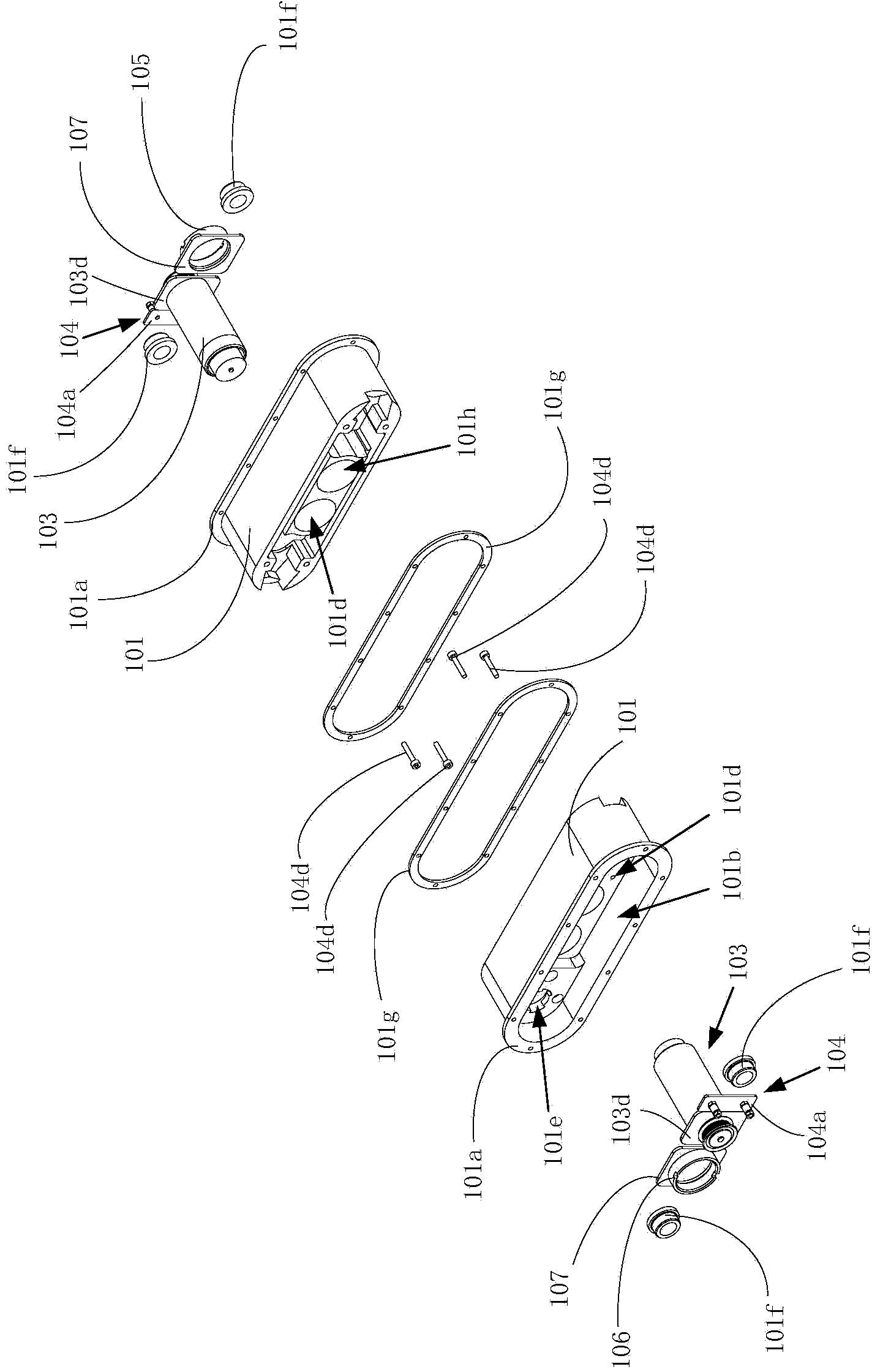

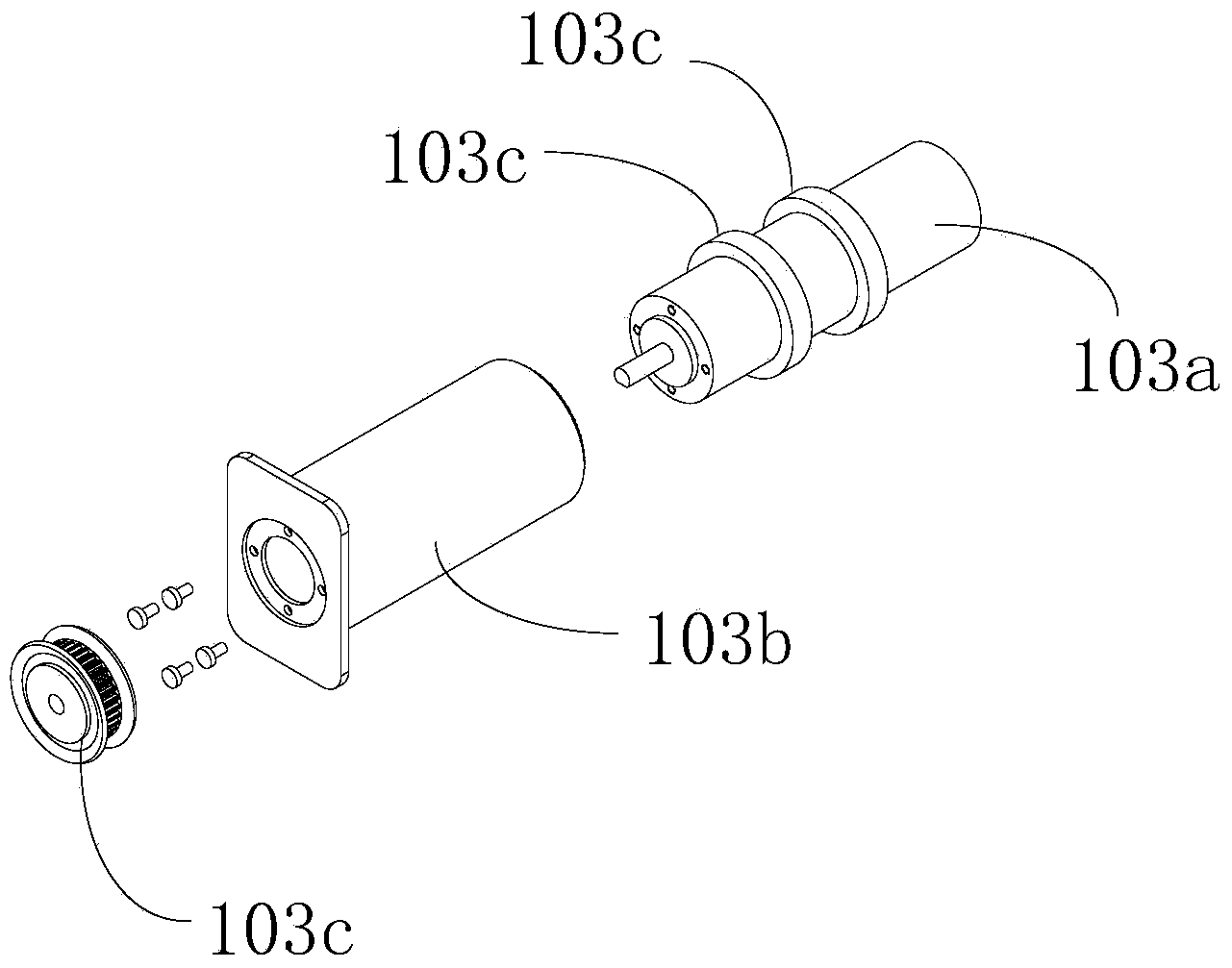

Throwable scout robot

The invention discloses a throwable scout robot comprising a car module and motion modules mounted on two sides of the car module. The car module is made of rubber, driving motors are mounted on two sides of the car module and drive transmission mechanisms composed of belts and transmission wheels so as to transmit power, and motion wheel trains on the transmission mechanisms can rotate. The driving motors and the transmission mechanisms are arranged in grooves of the car module. The motion modules and the car module are connected through skirts of the car module and connecting main boards of the motion modules, so that flexible connection is realized. The car module is provided with a plurality of form cavities used for mounting task loads inside. The throwable scout robot has the advantages of compact structure and the advantages that impact caused by falling can be resisted by its structure so as to prevent damage and complete subsequent scout tasks within a throwing height range (throwing height of an object of 2kg is approximate to 6 meters) of a normal adult.

Owner:BEIHANG UNIV

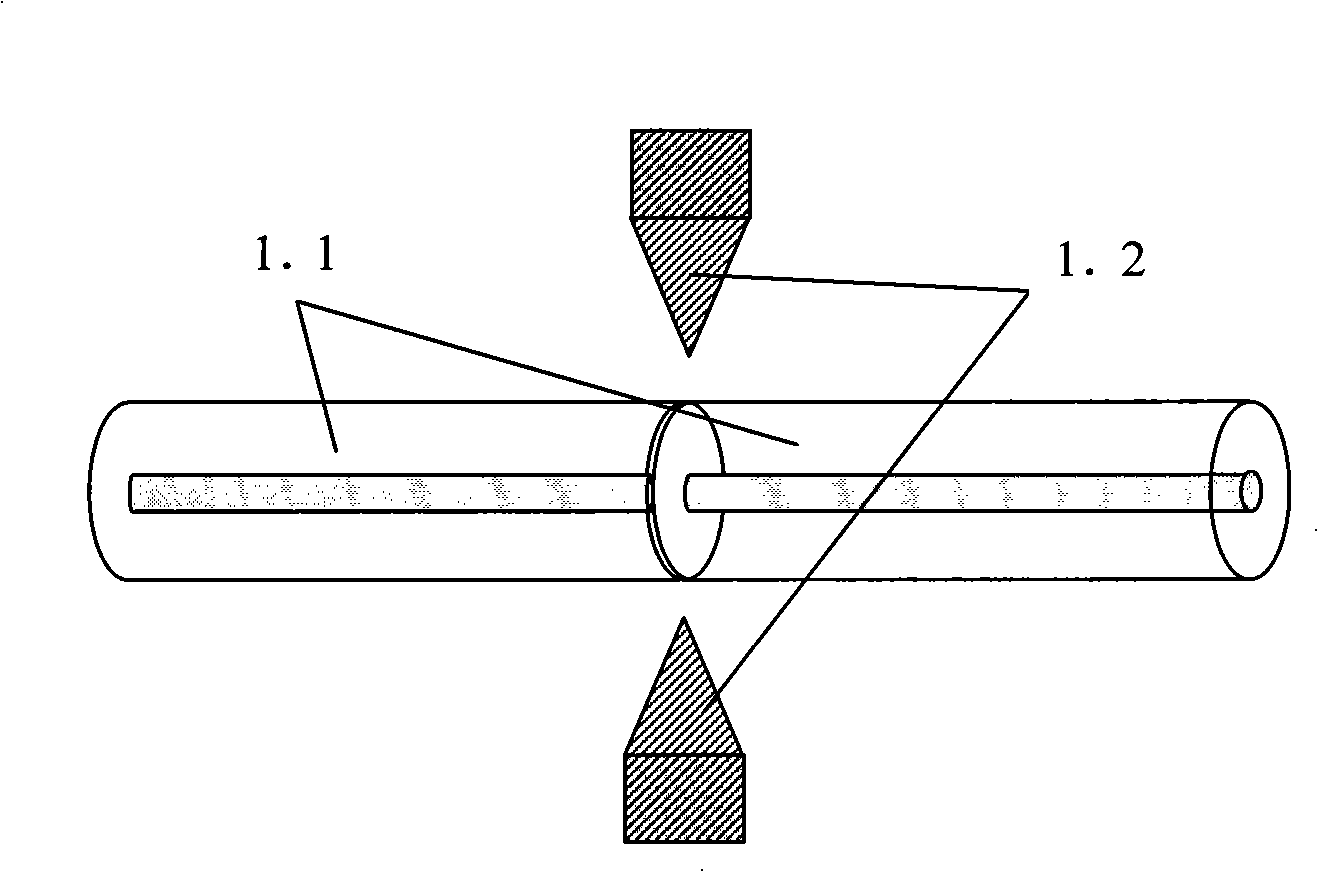

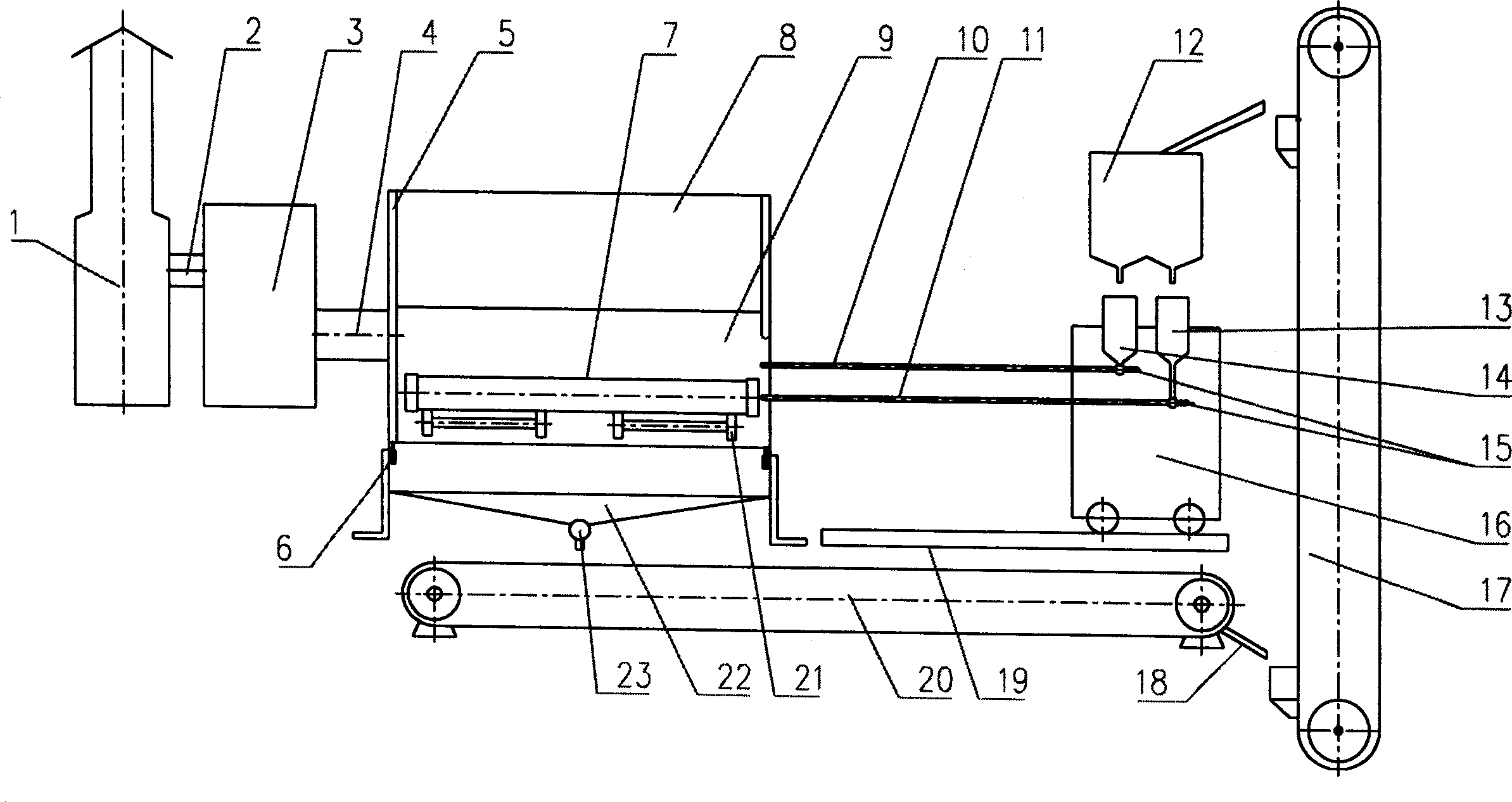

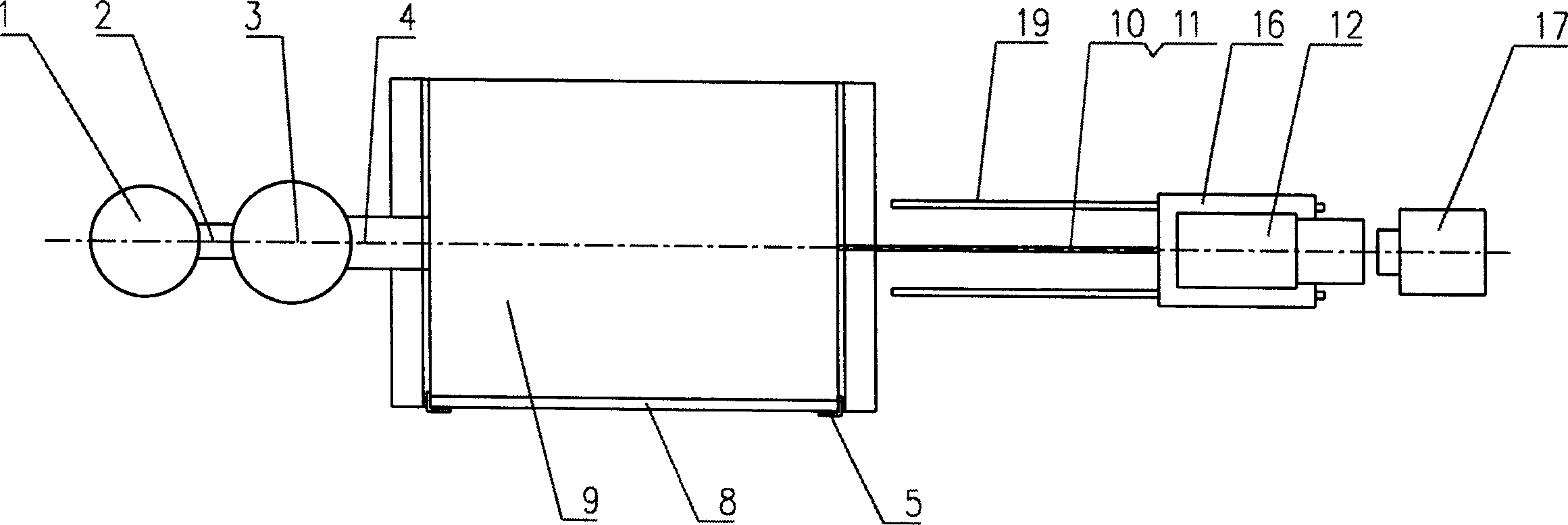

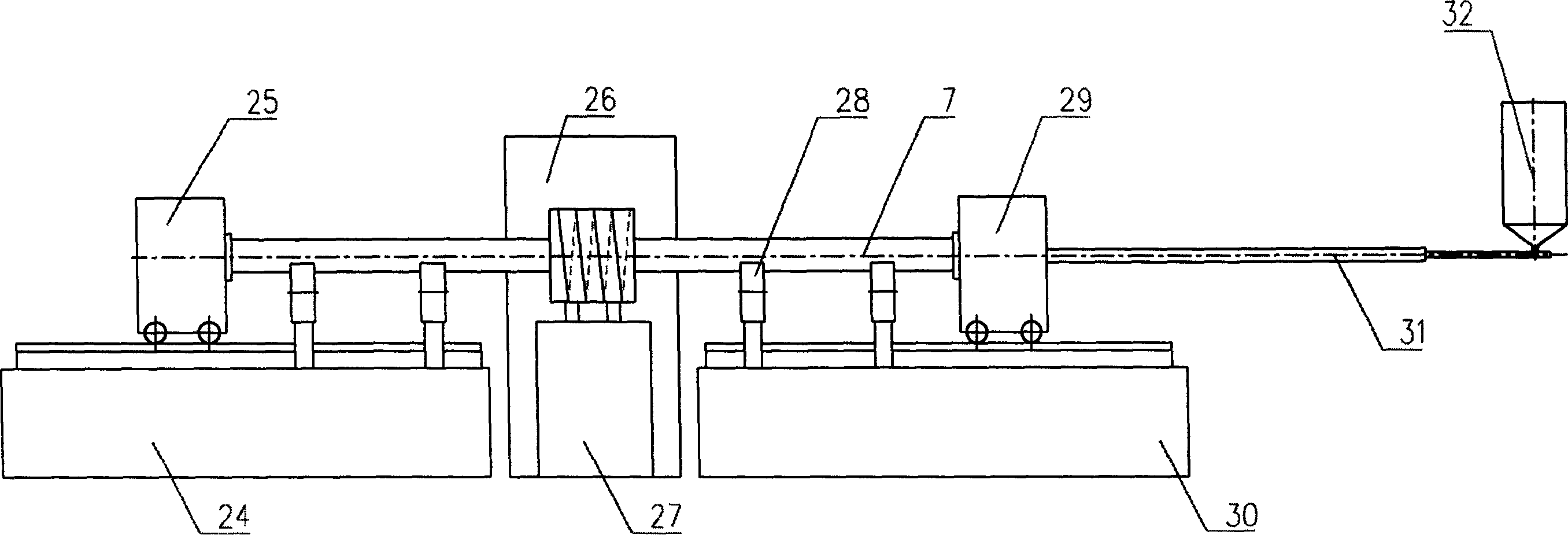

Producing equipment and method for inorganic material composite coating steel pipeline

InactiveCN1821649AImprove wear resistanceImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationBogieBucket elevator

The present invention relates to production equipment and method for steel pipe with composite inorganic material coating. The production equipment includes mainly one sand blasting section comprising deduster, sand blaster, sand blasting pipeline, belt conveyer, bucket type lifter, sand bin, etc.; and one enamel baking section comprising drawing bogie, medium frequency heating furnace, medium frequency machine, rack, glaze feeder, etc. It features the sand blasting process while turning the steel pipe, and the simultaneous heating, glaze spraying and enamel baking process. The present invention has simple technological process and low production cost, and the produced ultra long steel pipe has high wear resistance, high corrosion resistance and long service life.

Owner:北京中冶设备研究设计总院有限公司

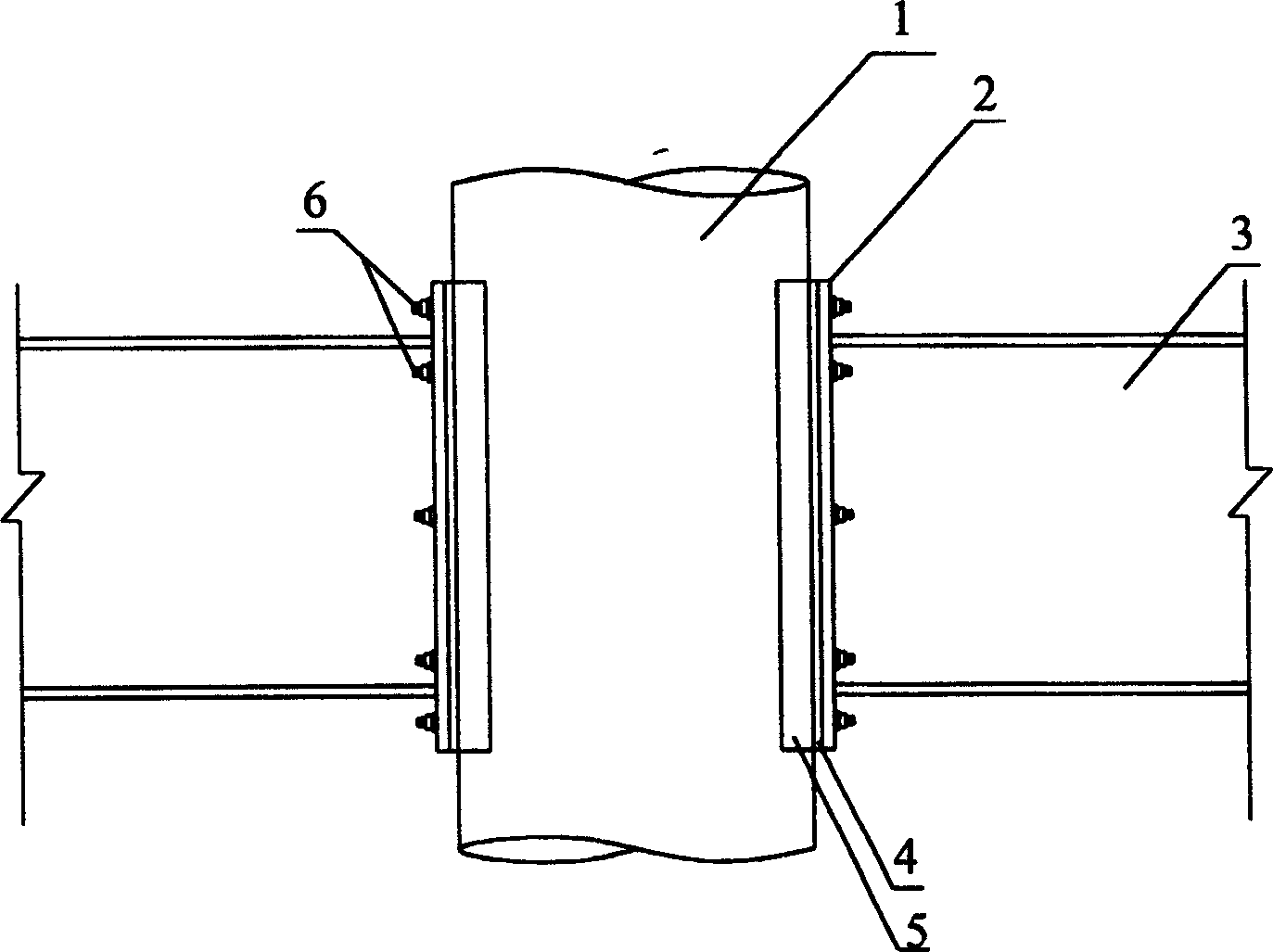

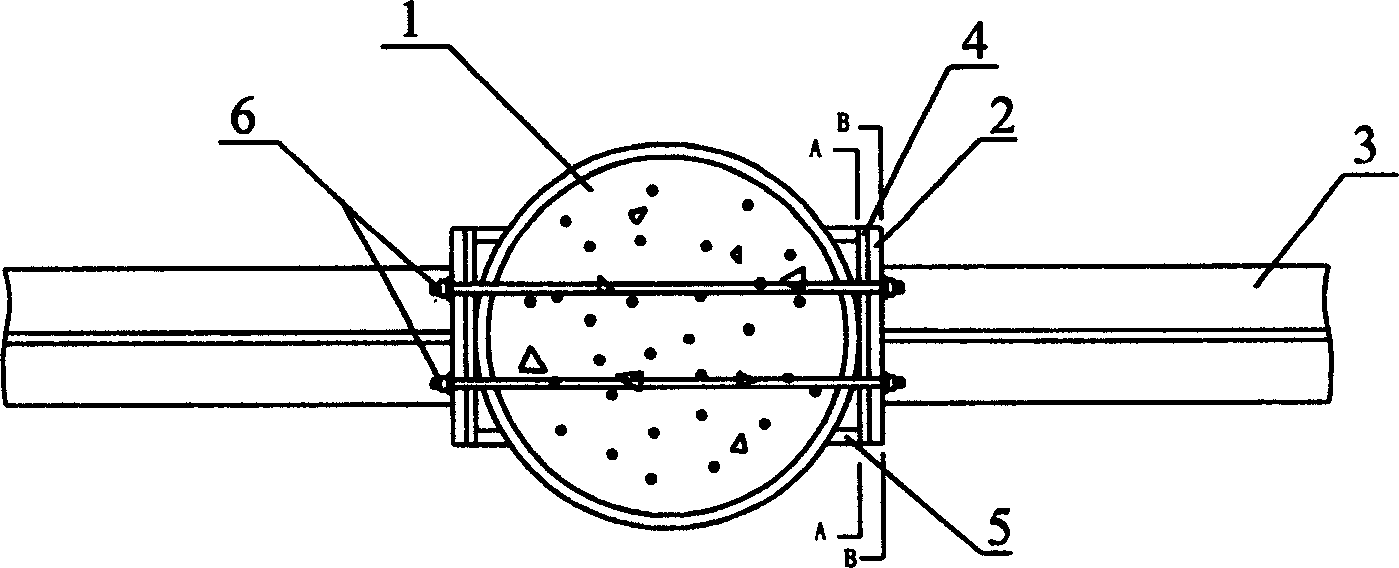

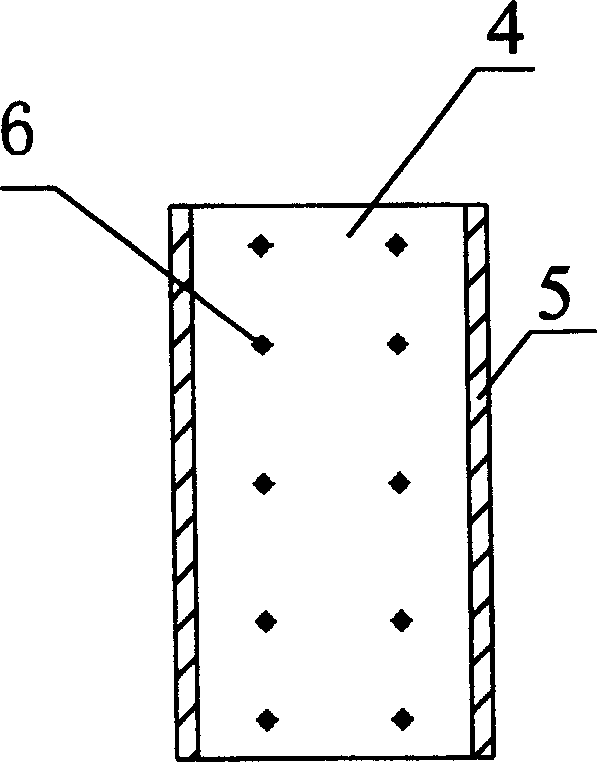

Reinforced electric hot melting belt and connecting structure and method thereof for connecting reinforced plastic electric hot melting belt with plastic pipeline

The invention relates to a screen mesh or metal hole plate-reinforced plastic electric hot melting belt used for connecting a plastic pipeline. The screen mesh or metal hole plate-reinforced plastic electric hot melting belt comprises a thermoplastic plastic plate belt, wherein a conductive metal net is pressed and embedded on a plate surface at one side of the plastic plate belt; two ends of the metal net in a length direction are provided with outgoing wire electrodes connected with the metal net; and at least one layer of reinforced screen mesh or metal hole plate is compounded in the plastic plate belt. A connecting structure for connecting the plastic pipeline with the electric hot melting belt comprises a coating electric hot melting belt, filling solders and a lapping electric hot melting belt, wherein the coating electric hot melting belt is coated and fusion-welded on the outer wall surfaces of two connected pipe end connecting areas in a manner of two-end butting or is adhered and fusion-welded on the inner wall surfaces of two connected pipe end connecting areas, and a gap suitable for welding is arranged at an abutting joint; the filling solders are used for welding and filling the gap of the abutting joint of the coating electric hot melting belt; and the lapping electric hot melting belt is used for fusion-welding a surface area of the abutting joint of the coating electric hot melting belt. A connecting method for connecting the plastic pipeline is comprised in the invention.

Owner:EZHOU XINGXIN BUILDING MATERIALS

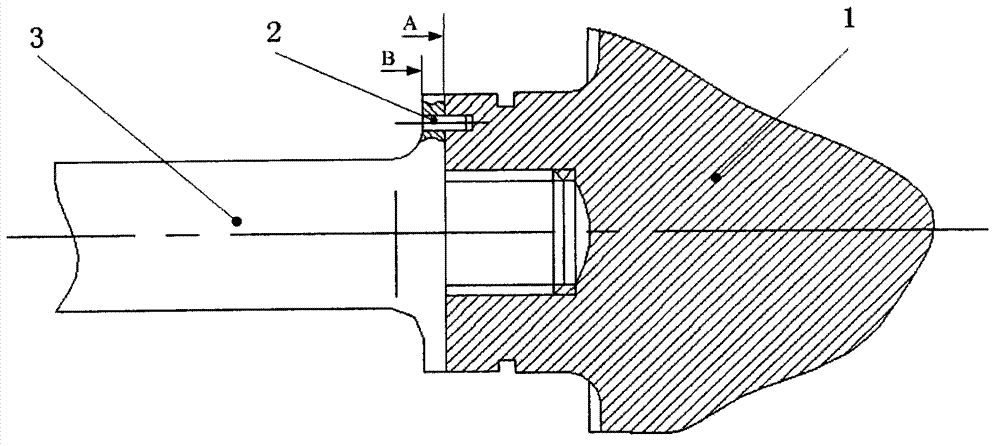

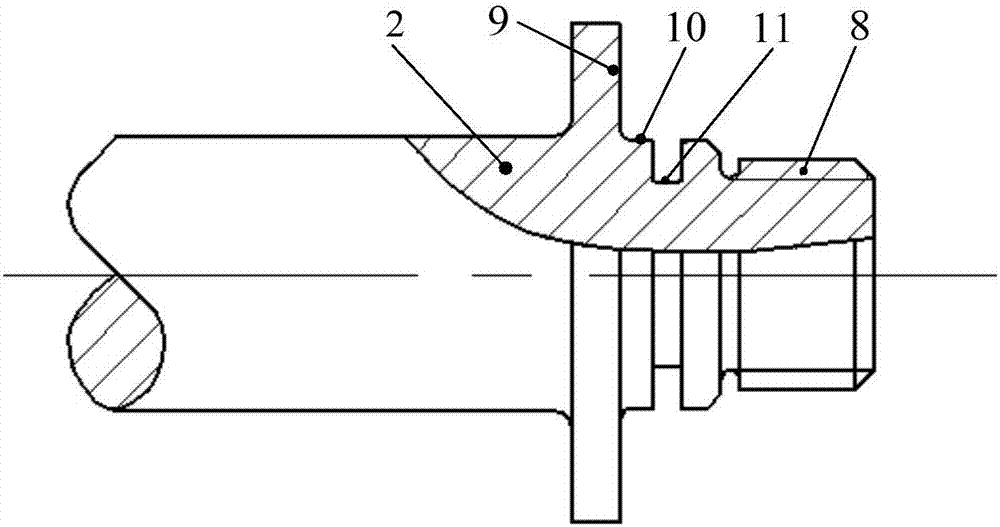

Through-hole connection method and connection structure of titanium aluminum turbine impeller and rotating shaft

ActiveCN103321685AMeet the needs of engineering applicationsGuaranteed connection strengthBlade accessoriesMachines/enginesInterference fitImpeller

The invention relates to a through-hole connection structure and connection method of a titanium aluminum supercharger turbine impeller and a rotating shaft. The connection structure comprises the rotating shaft, the titanium aluminum turbine impeller and a shaft end locking nut. A through hole is formed in the center of the titanium aluminum turbine impeller. A thread is arranged at the end portion of the rotating shaft. Seen from the end of a turbine, the rotating direction of the thread is the same as the rotating direction of the turbine rotating shaft during working. The lower portion of the thread is the rotating shaft connection portion. The rotating shaft connection portion penetrates through the through hole of the turbine impeller. The rotating shaft connection portion and the turbine impeller through hole are in transition fit or interference fit. The shaft end locking nut is installed on the thread of the end portion of the rotating shaft. As for the connection problem of the titanium aluminum turbine impeller and the rotating shaft, the through-hole connection and threaded locking structure are adopted, the durable and reliable connection between the titanium aluminum turbine impeller and the 42CrMo rotating shaft can be achieved, the requirements for the connection strength of the supercharger turbine impeller and the rotating shaft are met, and meanwhile the connection structure has the advantages of being simple in structure, easy to machine and the like.

Owner:CHINA NORTH ENGINE INST TIANJIN

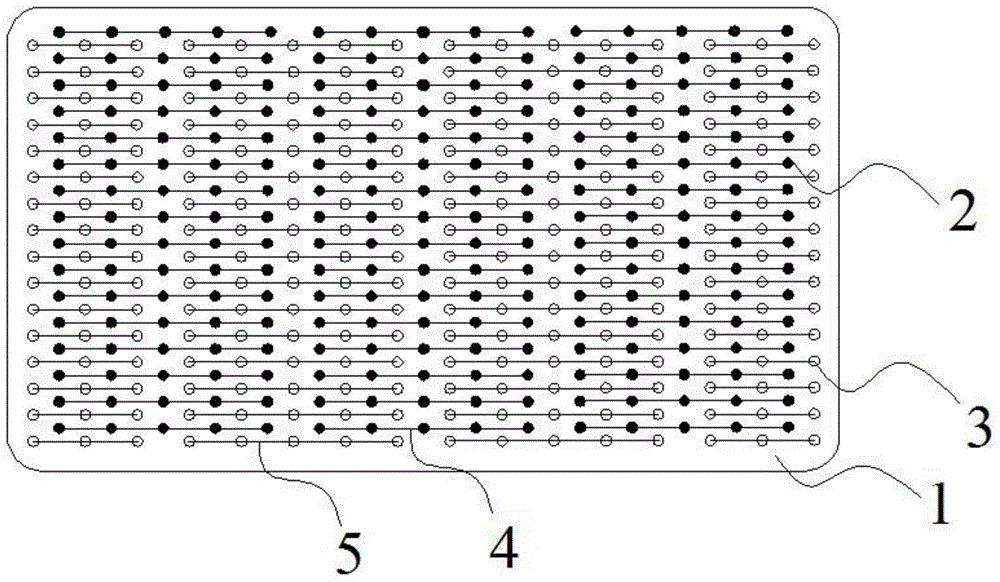

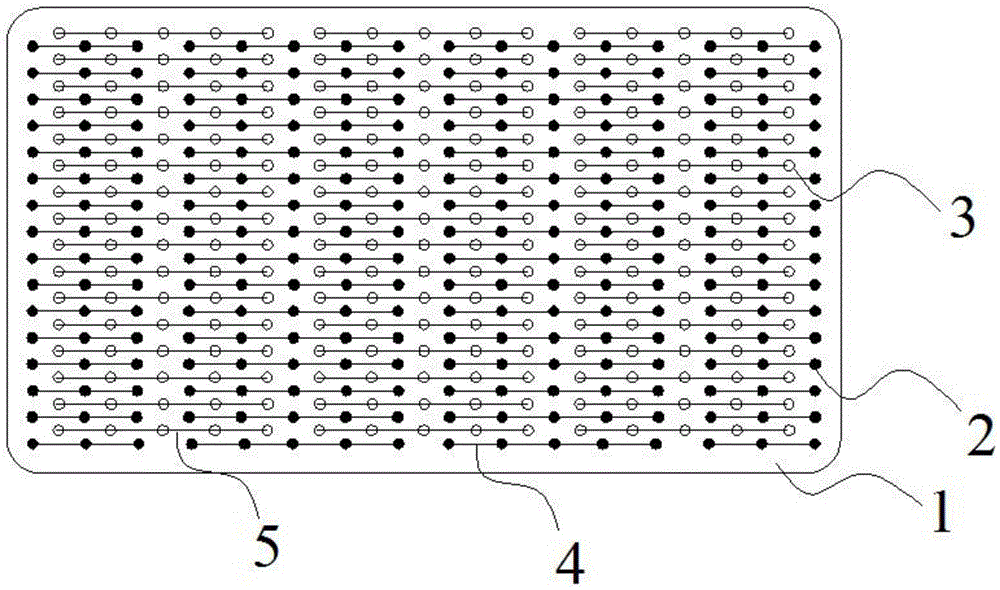

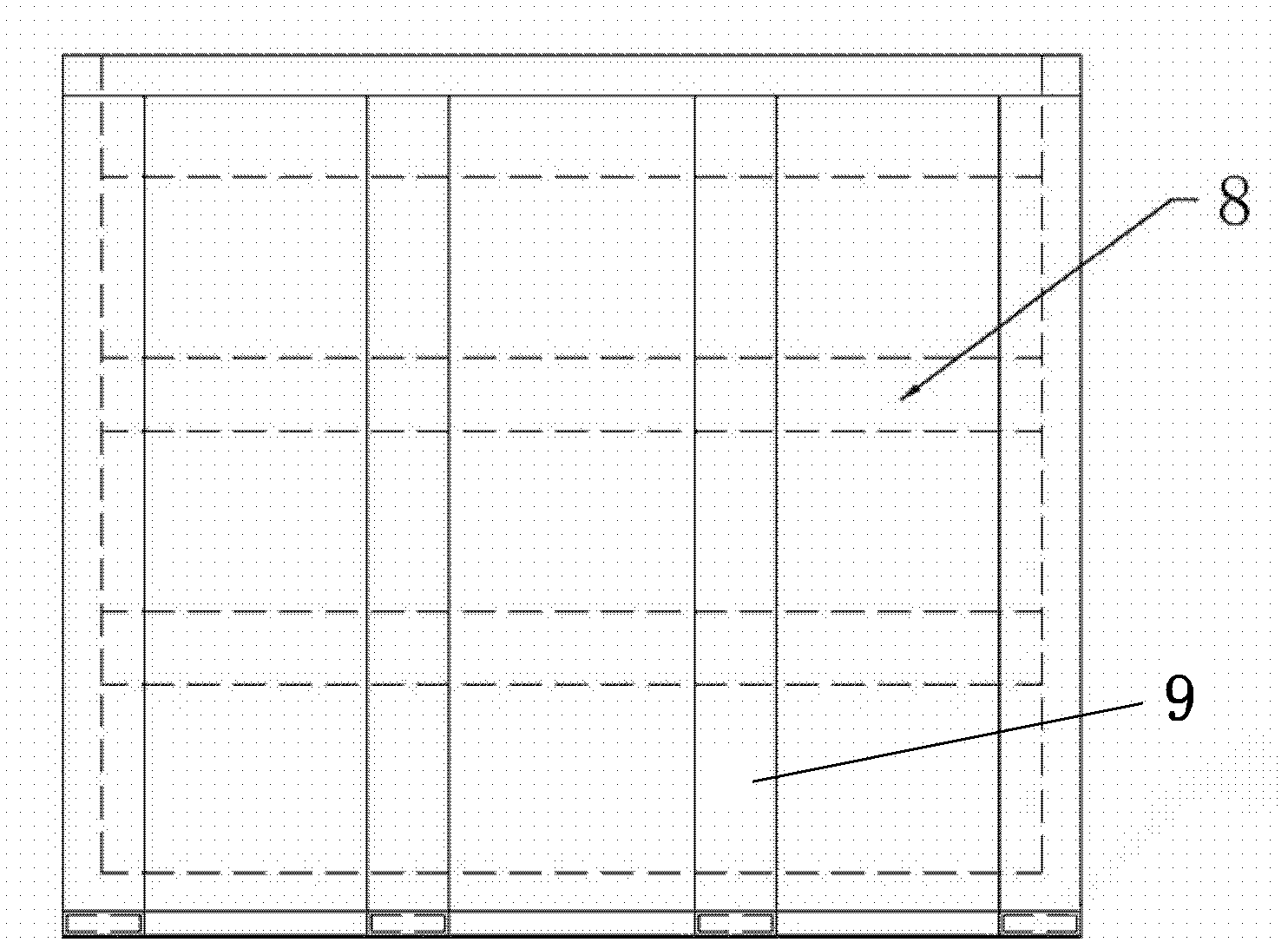

Main-grid-free efficient back-contact solar battery and assembly and manufacturing technology thereof

ActiveCN104576778AReduce the difficulty of serial connectionLow costFinal product manufacturePhotovoltaic energy generationElectricityFill factor

The invention relates to the field of solar batteries, in particular to a main-grid-free efficient back-contact solar battery and assembly and a manufacturing technology of the main-grid-free efficient back-contact solar battery and assembly. The main-grid-free efficient back-contact solar battery comprises a solar battery piece and an electric connection layer. The backlight surface of the solar battery piece is provided with an electrode P and an electrode N, wherein the electrode P is connected with a P-type doped layer, and the electrode N is connected with an N-type doped layer. The solar battery is characterized in that the electric connection layer comprises a plurality of conductive fine grid lines, the conductive fine grid lines are partially connected with the electrode P on the backlight surface of the solar battery piece, and the remaining conductive fine grid lines are connected with the electrode N on the backlight surface of the solar battery piece. The conductive fine grid lines are each of a multi-segment structure. The main-grid-free efficient back-contact solar battery and assembly and the manufacturing technology of the main-grid-free efficient back-contact solar battery and assembly have the advantages that the usage amount of silver paste is reduced, and the cost is lowered; as the multi-segment conductive fine grid lines are arranged, series resistance is lowered, and the transmission distance of fill factors is shortened; efficiency is improved, and meanwhile the stress on the battery piece by the conductive fine grid lines can be effectively reduced.

Owner:JOLYWOOD SUZHOU SUNWATT

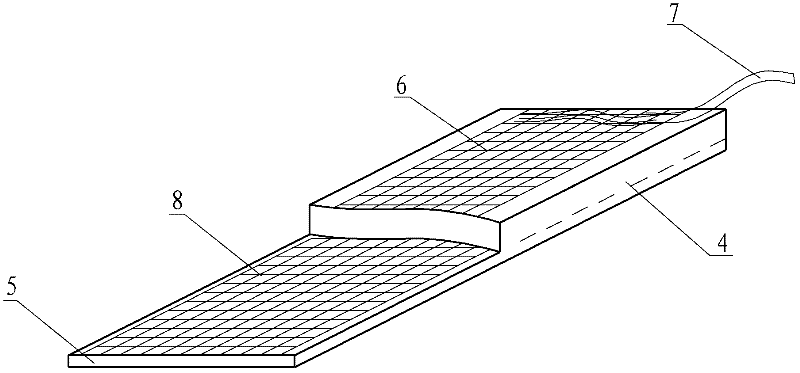

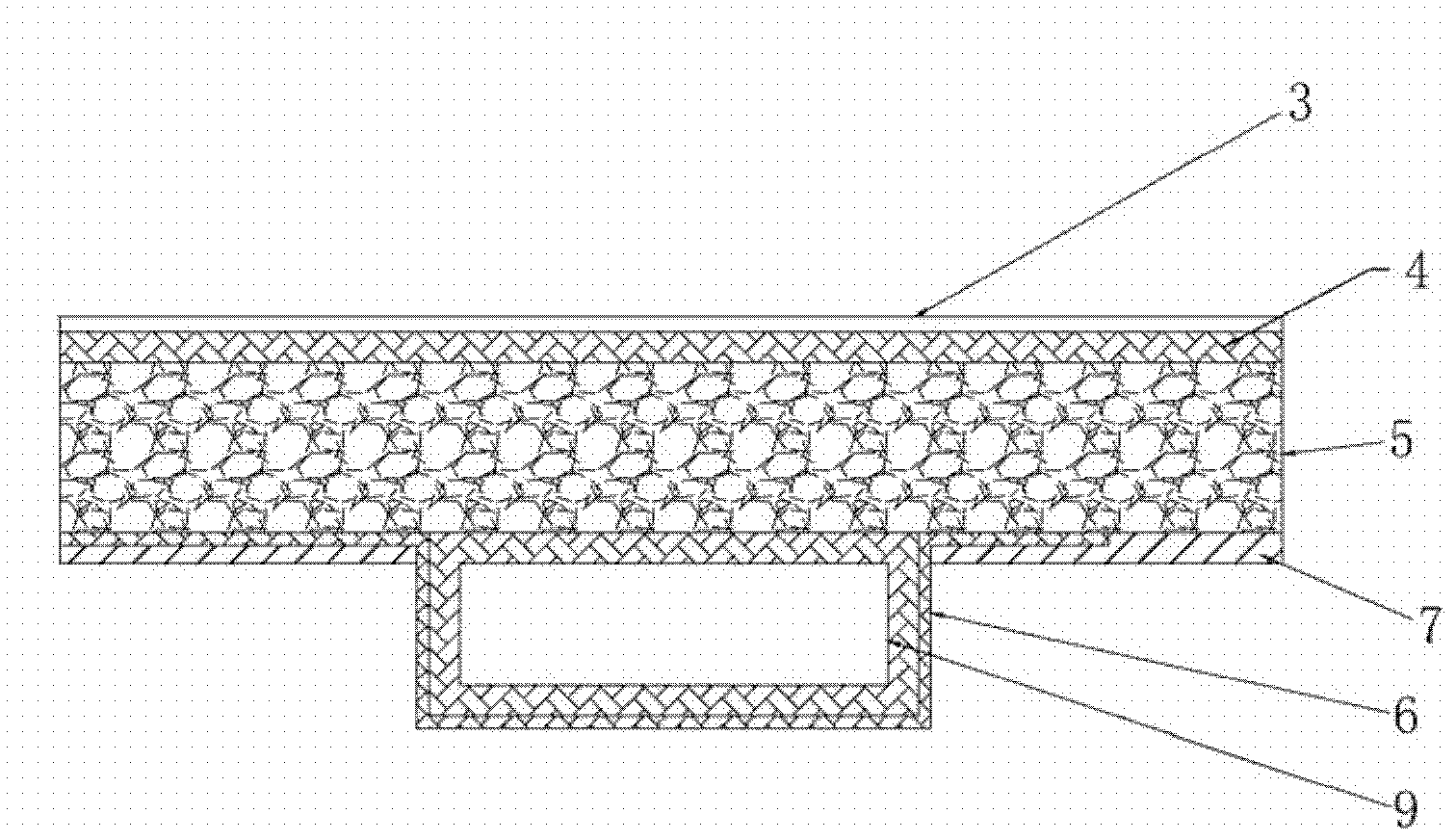

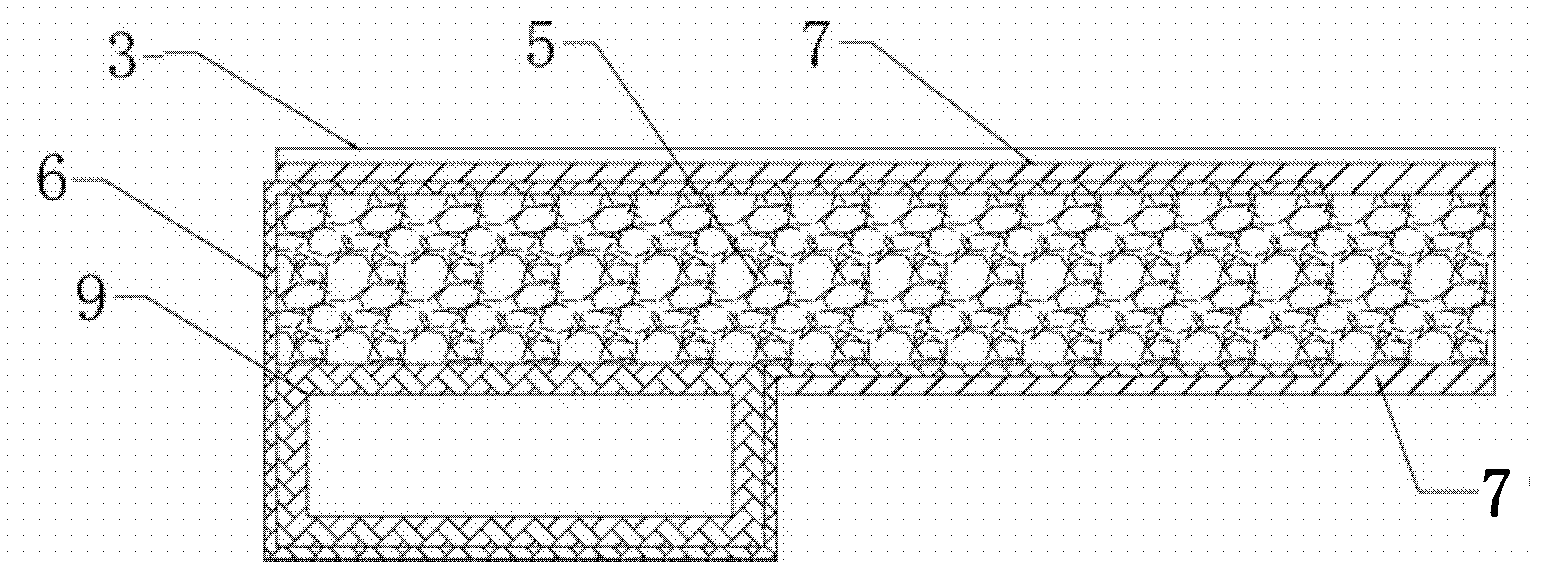

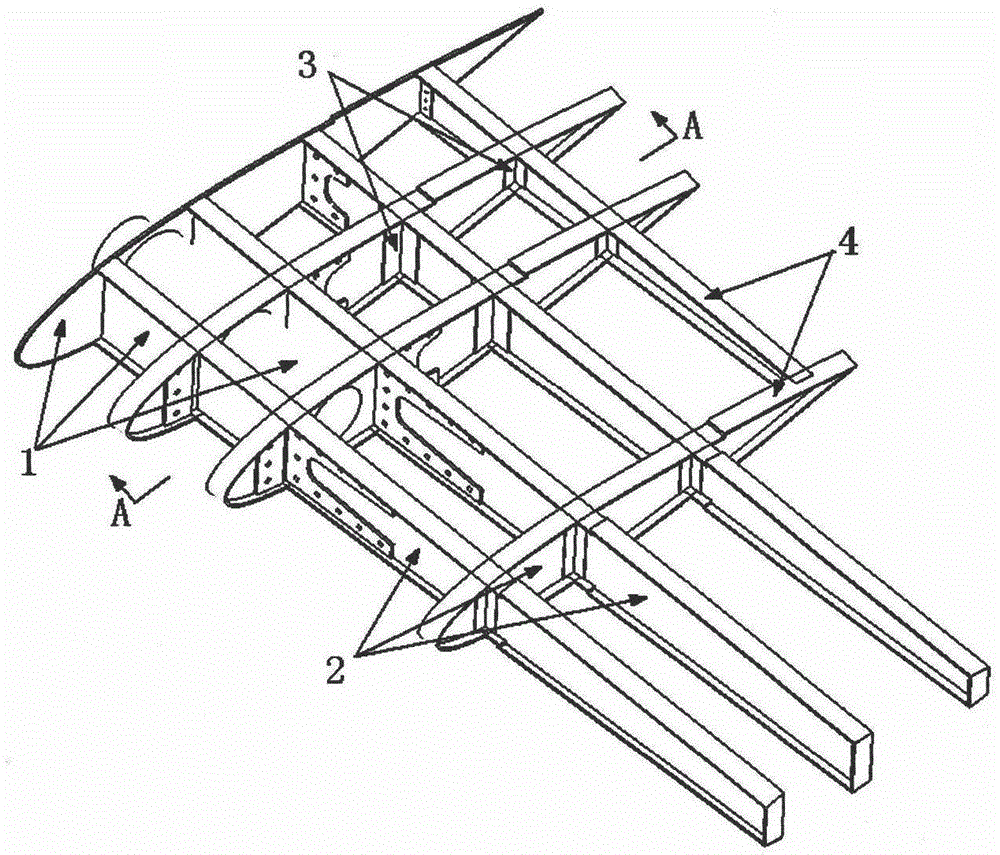

Composite board and preparation method thereof, and dumper compartment

InactiveCN103010316AAddressing Layered FailuresSolve wear resistanceSynthetic resin layered productsWood layered productsEngineeringPolydicyclopentadiene

The invention discloses a composite board which comprises two skin layers, wherein an intermediate layer is formed between the two skin layers and an inner stiffening beam is arranged between the two skin layers, a core material is filled in the intermediate layer, an outer stiffening beam is arranged between the core material and at least one skin layer, and a polydicyclopentadiene layer is arranged outside the at least one skin layer. The invention also discloses a preparation method of the composite board. The invention further discloses a dumper compartment comprising the composite board. The dumper compartment has the characteristics of strong bearing capacity, remarkable weight reducing effect, oil consumption saving, carbon dioxide emission reducing, long service life and the like.

Owner:蓝星环境工程有限公司

Rigid connection method for steel beam and concrete pier

The invention discloses a rigid connection method for a steel beam and a concrete pier, and belongs to the technical field of bridgework and combined structures. The rigid connection method is characterized in that: a steel sleeve extending outwards is arranged under a steel main beam; a steel sleeve is arranged on the top of a pier; the pier and the beam are fixedly connected through the connection between the steel sleeves; and the inner walls of the steel sleeves are provided with stud connecting pieces to prevent the steel sleeves from locally flexing and facilitate coaction of the steel sleeves and the concrete. The rigid connection method comprises the following steps of: hoisting the main beam provided with the steel sleeve extending outwards to the top of the pier with the steel sleeve, and taking connection measures; positioning a reinforcement cage in a pillar, and casting the concrete to the lower side of the upper wing edge of the main beam to form rigid connection nodes. The axial force on the top of the pier is mainly borne and transmitted through the concrete in a node core area; the bending moment of the top of the pier is mainly borne and transmitted through a diaphragm plate, tensioned steel bars and the concrete in the node core area; and the shear force is mainly transmitted by a web plate of the main beam and the concrete. The steel sleeves can make most unfavorable sections move outwards so as to improve the bearing capacity and tensility of the node area.

Owner:TSINGHUA UNIV

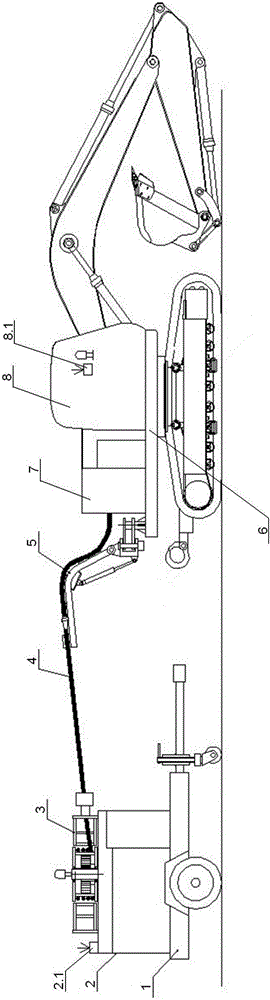

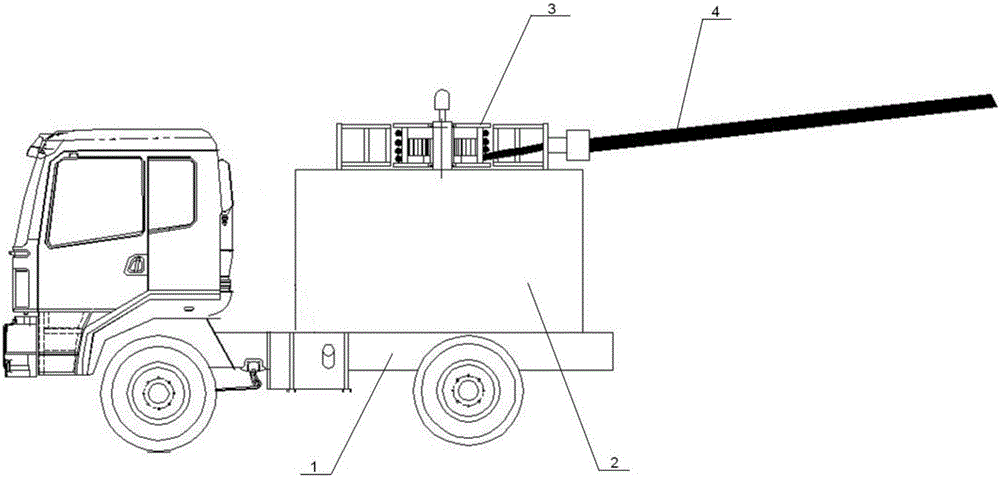

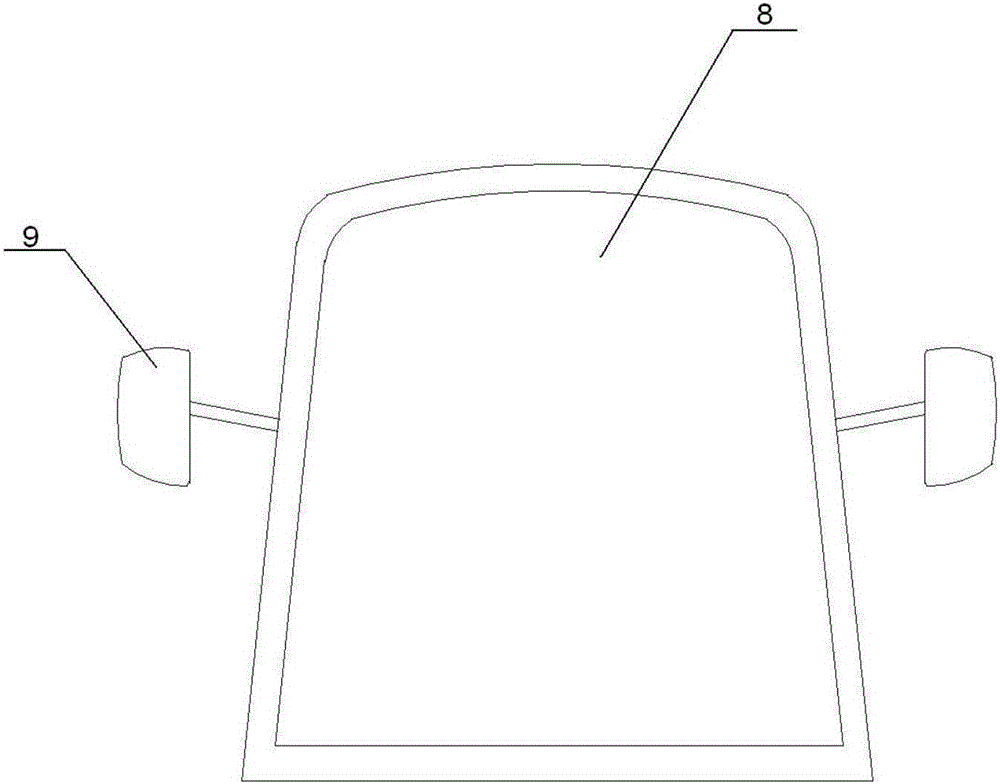

Externally-powered electric engineering machinery

ActiveCN105926707AResolve connectionEasy to useSoil-shifting machines/dredgersMobile vehicleEngineering

The invention provides externally-powered electric engineering machinery. The externally-powered electric engineering machinery comprises a mobile power supply vehicle and an electric engineering machine. The mobile power supply vehicle comprises a mobile vehicle body. A power unit and a cable take-up and pay-off device are mounted on the vehicle body. The electric engineering machine comprises an engineering vehicle body capable of moving freely, wherein an electric motor, a power control device, an operation control center and a power collection arm are arranged in the vehicle body. By adopting the externally-powered electric engineering machinery, the problem of cable connection between power supply equipment and electric equipment when electric engineering machinery moves to work is solved; it is guaranteed that cables do not hinder free movement of the electric equipment within a certain scope, and reliable electric power supply is guaranteed; and the externally-powered electric engineering machinery is good in work rotation capability and high in environmental adaptability, and the advantages are more obvious in working regions with oil and gas shortage. Meanwhile, the power supply equipment and the electric equipment can conduct signal communication, and use safety of the cables is ensured.

Owner:杭州蓝力电动科技有限公司

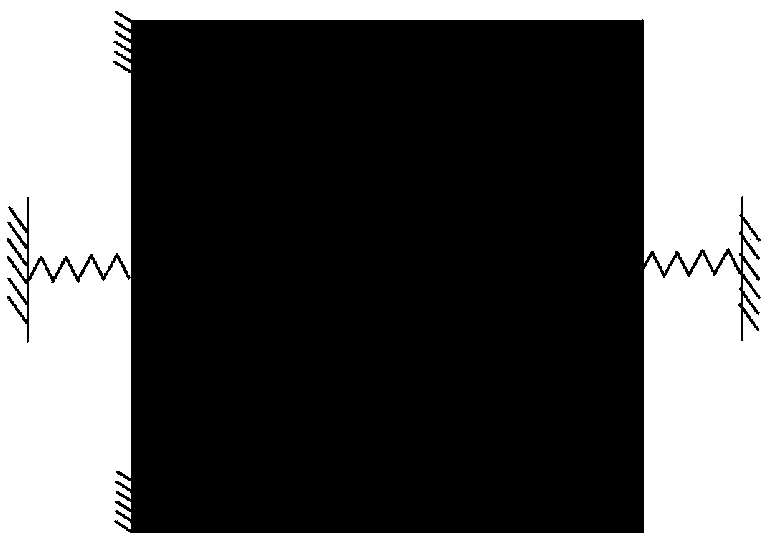

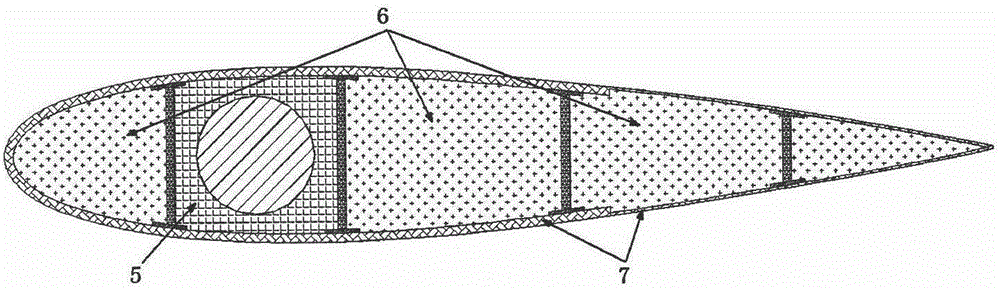

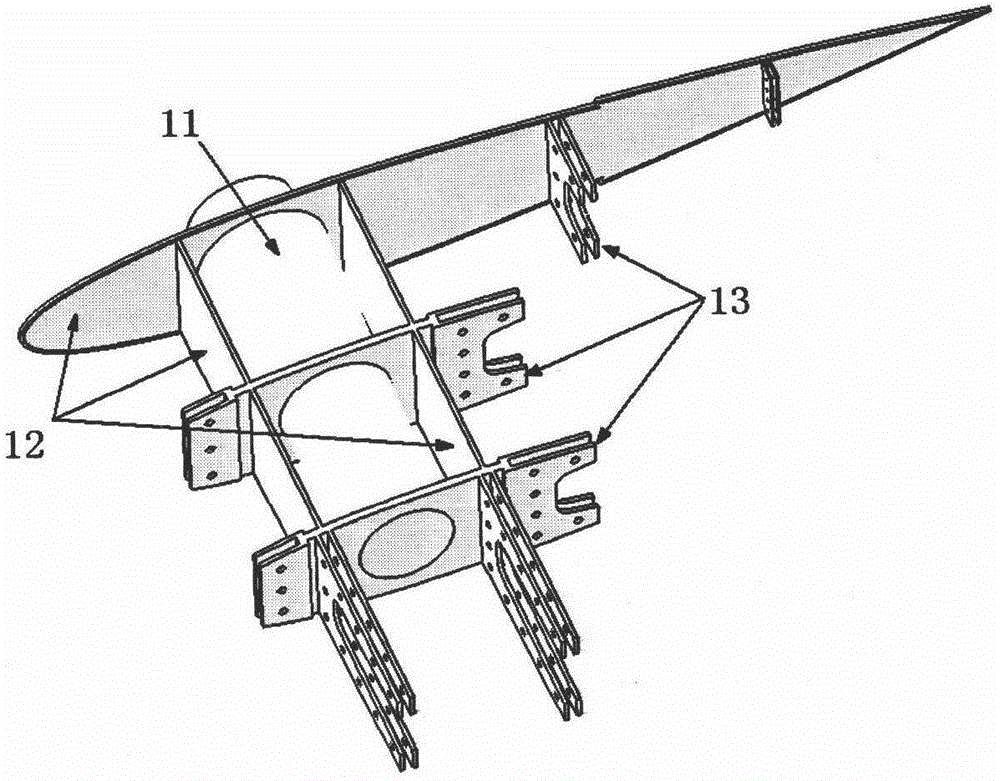

Solid composite rudder blade high in rigidity and low in weight

ActiveCN105599889AAdequate structural strength requirementsSufficient stiffness requiredSteering ruddersSurface layerSteel frame

The invention discloses a suspension rudder blade applied to a water surface vehicle or an underwater vehicle. The rubber blade comprises a rudder stock area steel frame (1), a composite framework (2), a damping and / or sound-absorbing material (5), buoyancy filling core materials (6) and composite skin (7), and the rudder stock area steel frame (1) is fixedly connected with the composite framework (2), so that an overall framework structure of the rudder blade is formed, and the surface layer of the overall framework structure of the rudder blade is coated with the composite skin (7), so that a watertight structure is formed, gaps between the overall framework structure of the rudder blade and the composite skin (7) are filled with the buoyancy filling core materials (6), and the space around a rudder stock of the rudder stock area steel frame (1) is filled with the damping and / or sound-absorbing material (5). The solid composite rudder blade high in rigidity and low in weight has the advantages of being high in bending resistance / torsional resistance, resistant to corrosion, low in underwater weight and low in noise.

Owner:NAVAL UNIV OF ENG PLA

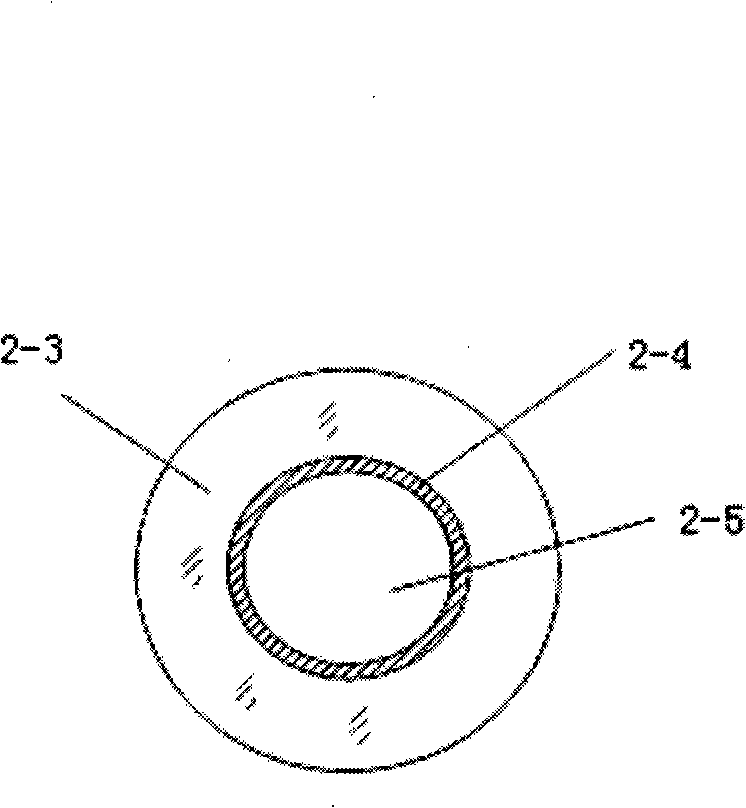

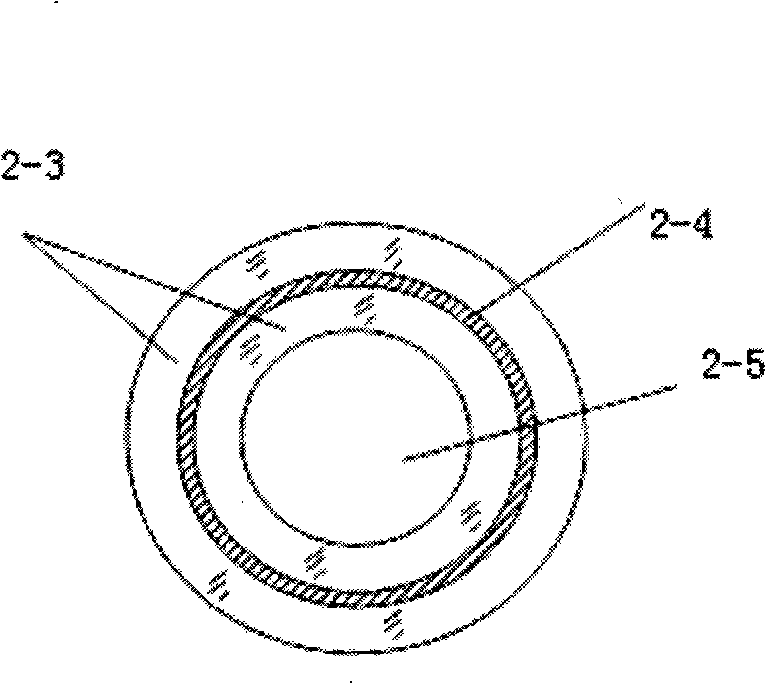

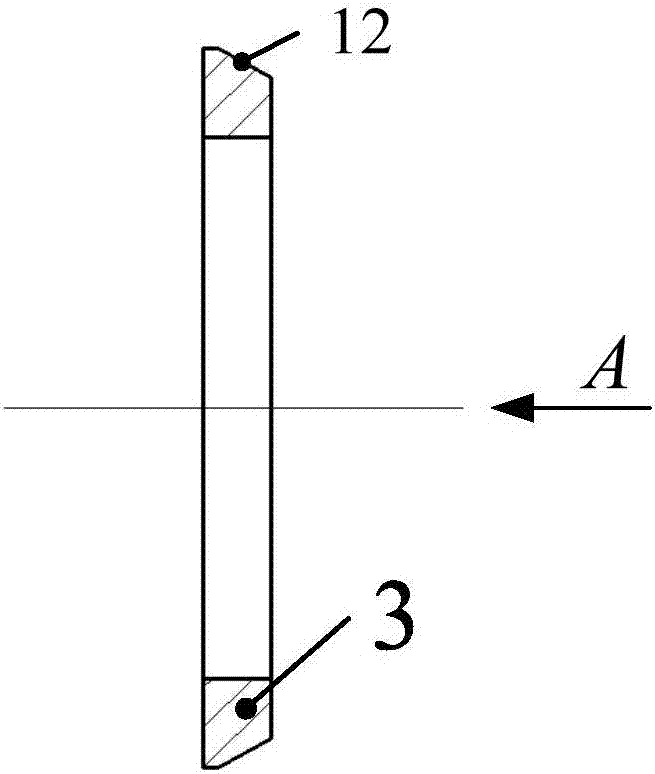

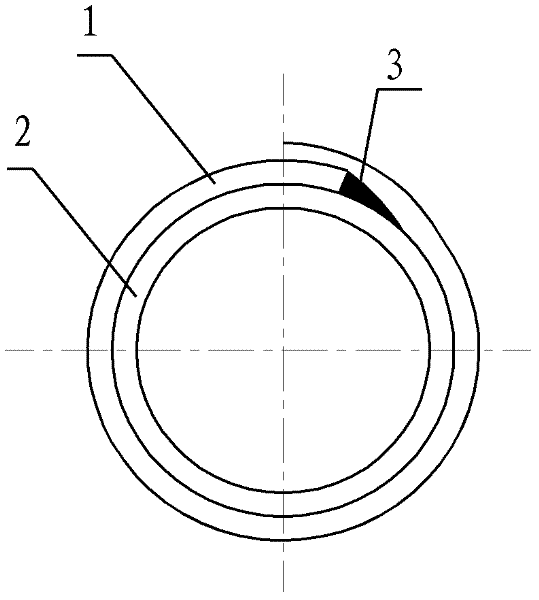

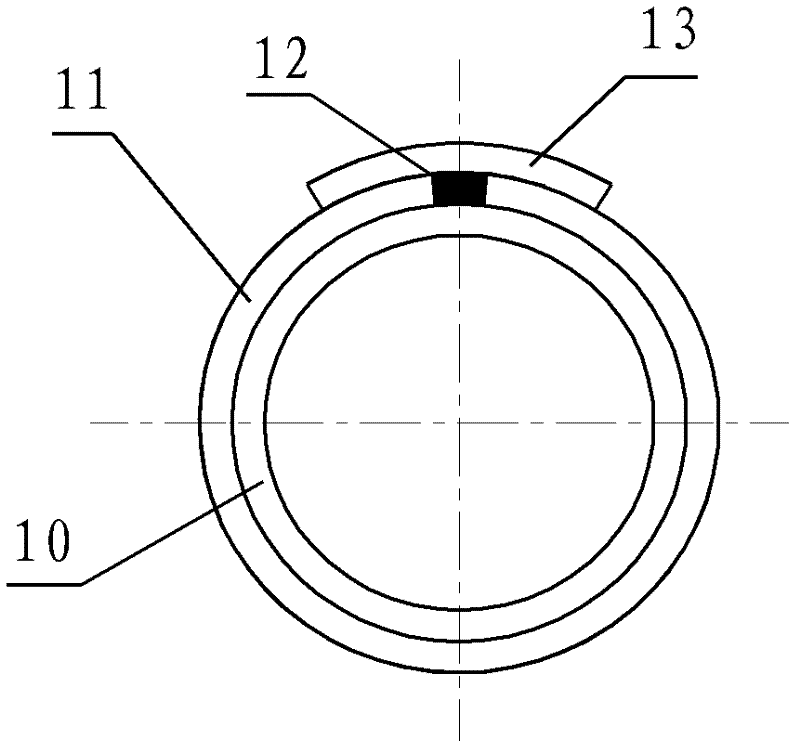

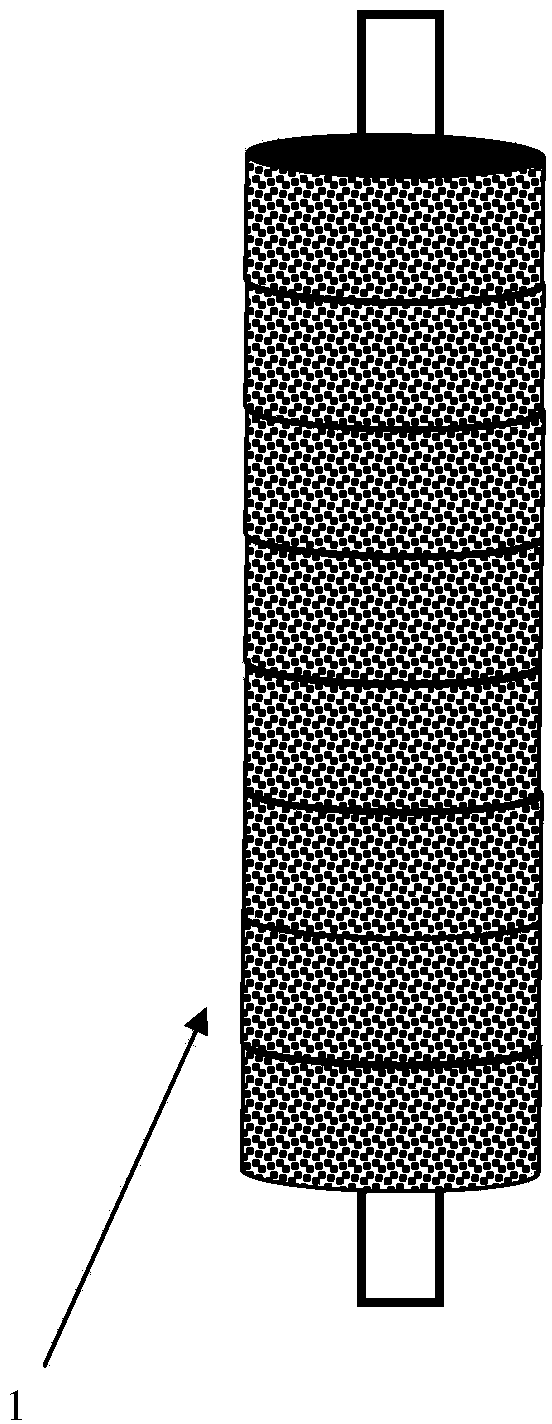

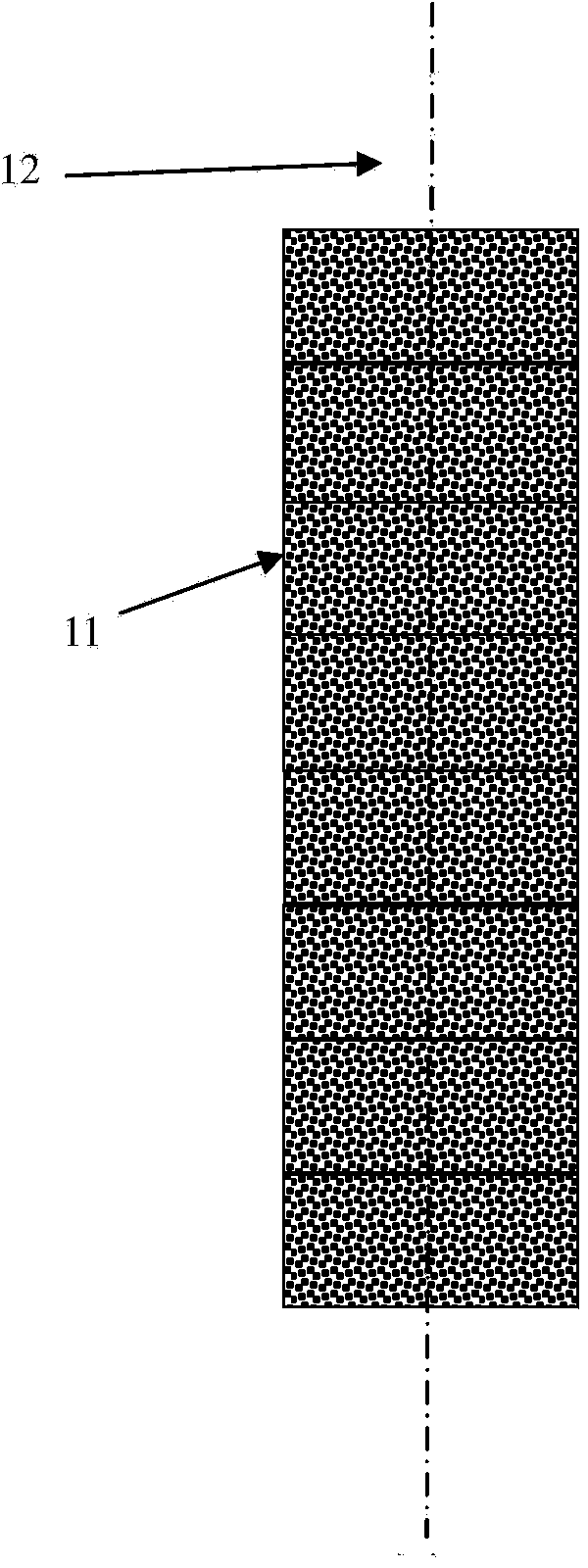

Positive displacement air thermal absorber with rotary heat absorption body

ActiveCN104197537AIncrease in sizeAvoid volatilitySolar heat devicesSolar thermal energy generationEngineeringHot Temperature

The invention discloses a positive displacement air thermal absorber with a rotary heat absorption body. A thermal absorber piece comprises a plurality of rotary heat absorption rods (1); each heat absorption rod (1) comprises a plurality of heat absorption cylinders (11) and a rotating shaft (12); the heat absorption cylinders (11) are hollow concentric cylindrical bodies, and are integrally made of silicon carbide foam ceramic; clamping grooves (13) are formed in the inner walls of the heat absorption cylinders (11); the rotating shaft (12) is cylindrical; convexes (14) are arranged in the exterior of the rotating shaft (12); the clamping grooves (13) are in close fit with the convexes (14); the rotating shaft (12) is integrally made of compact high-temperature resistance ceramic or heat-resistant alloy steel; the axis of the rotating shaft (12) is reclosed with the axes of the heat absorption cylinders (11); the heat absorption cylinders (11) are connected with the exterior of the rotating shaft (12) in a sleeving manner. The positive displacement air thermal absorber can acquire high-temperature air of which the temperature range is 700 DEG C-1300 DEG C, and the pressure is normal or higher than 1MPa, accumulates heat utilizing sensible heat of the air thermal absorber at the same time, and can be used for a cavity type non-pressure or non-pressure air thermal absorber, and an external cylindrical non-pressure air thermal absorber.

Owner:恒基能脉新能源科技有限公司

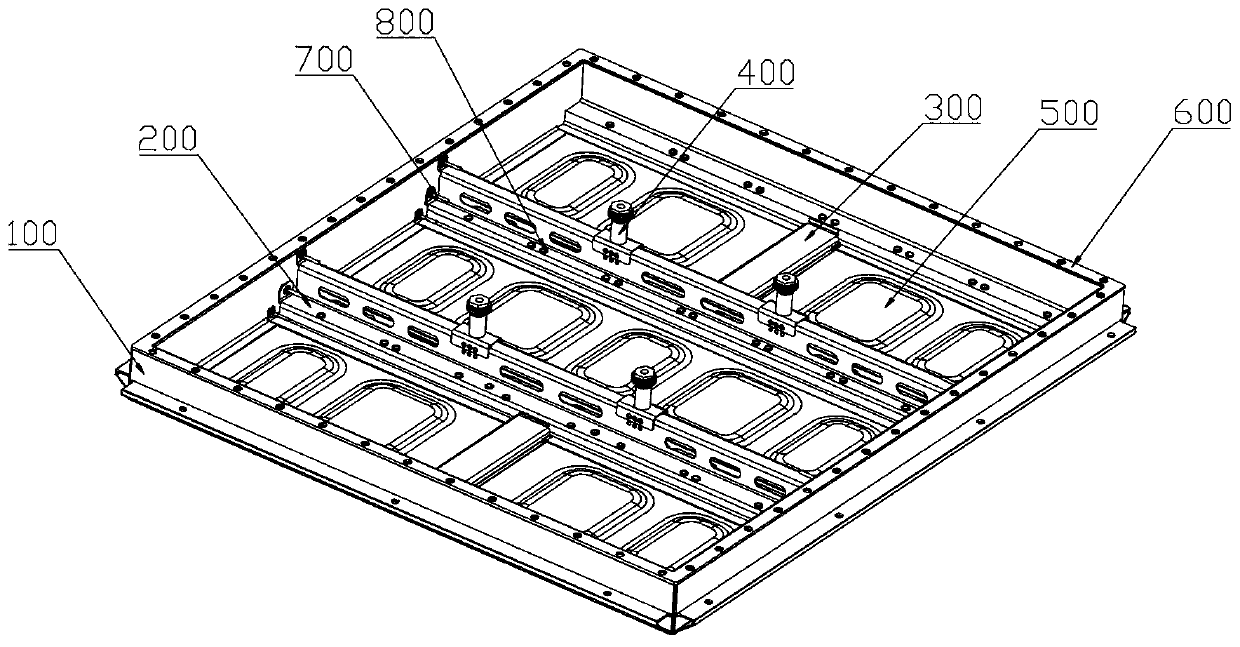

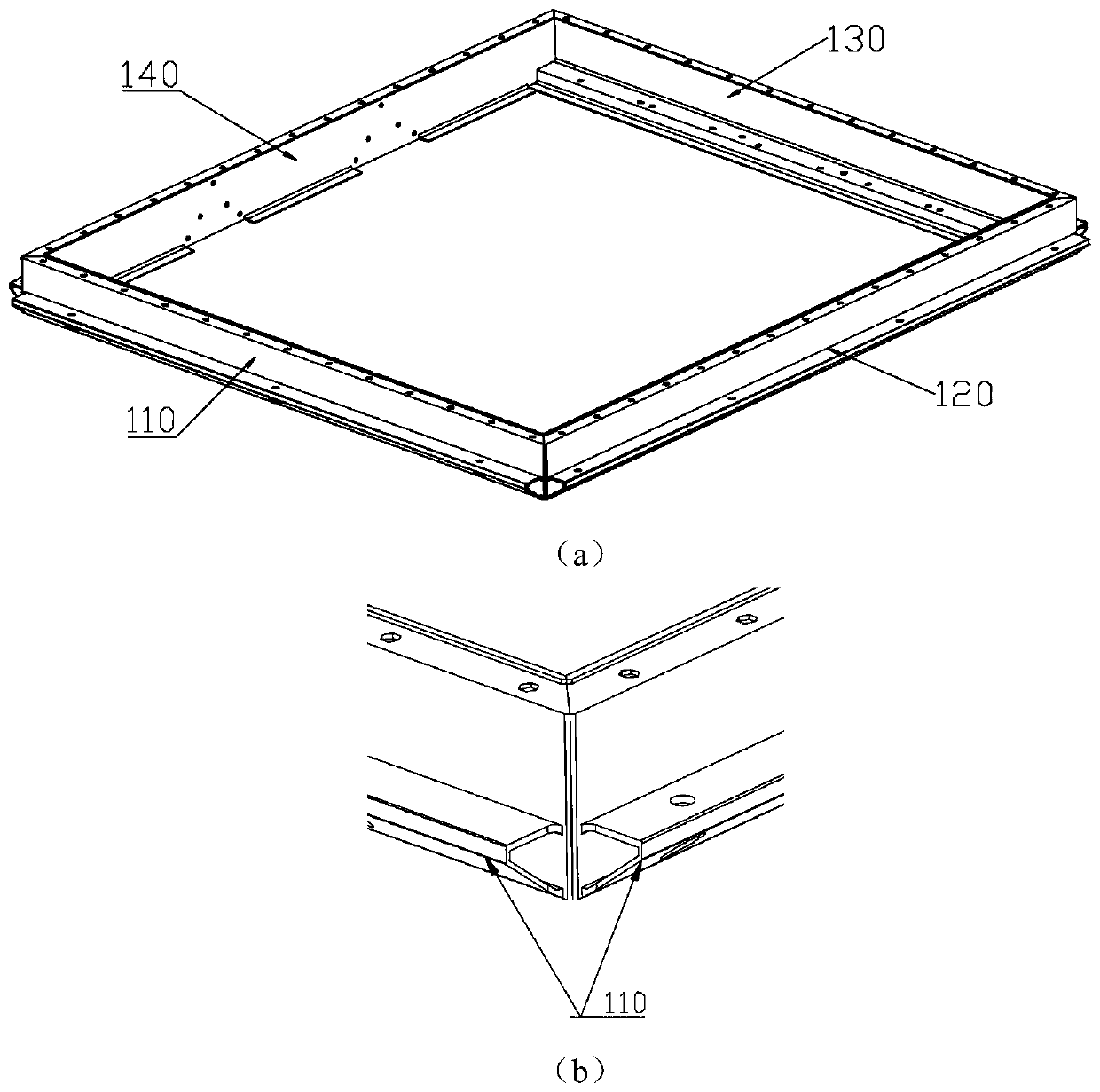

Lower shell of steel-aluminum hybrid battery pack

The invention discloses a lower shell of a steel-aluminum hybrid battery pack. The lower shell comprises a frame structure, cross beams, longitudinal beams, bottom plates and middle lifting lugs; themiddle lifting lugs penetrates through the cross beams and the bottom plates from top to bottom and are fixed to the cross beams and the bottom plates, and each of the middle lifting lugs comprises amiddle lifting lug body of a cylindrical hollow structure, wherein the top end of the middle lifting lug body is matched with a middle lifting lug nut, and the lower end of the middle lifting lug bodyis sequentially installed in a middle lifting lug reinforcing plate and a middle lifting lug sleeve in a penetrating mode; the frame structure is formed by splicing four frames, the four frames are divided into two groups, and each group of frames are the same in structure and are oppositely arranged; the cross beams are formed by embedding an inverted U-shaped thin-wall structure with a lightening hole into an inverted T-shaped thin-wall structure with a lightening hole, and the frame structure is made of aluminum alloy; the cross beams, the longitudinal beams, the middle lifting lugs and the bottom plates are all made of steel. According to the invention, the advantages of aluminum alloy and high-strength steel are fully absorbed, the lightweight and low-cost design of the battery packbox body is realized, the welding deformation is small, the connection strength is high, and the processing efficiency is high.

Owner:JIANGSU UNIV

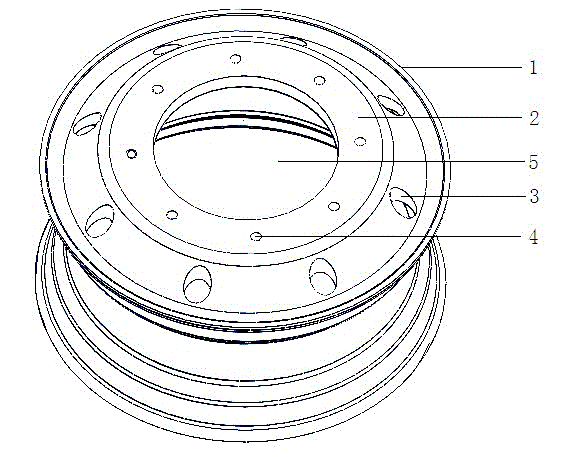

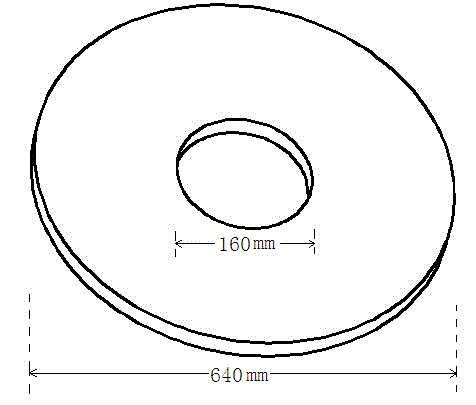

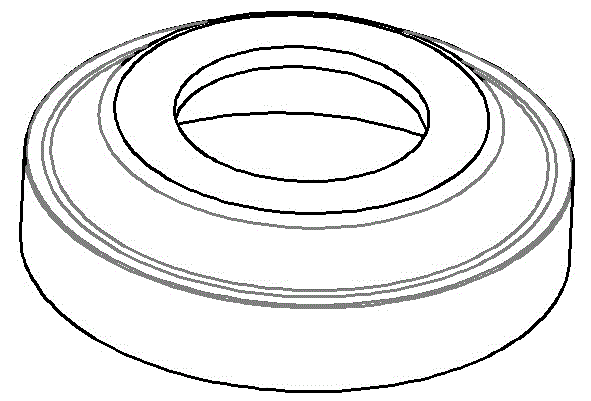

Integral aluminum alloy spinning hub and manufacturing method thereof

The invention discloses an integral aluminum alloy spinning hub and a manufacturing method thereof. The method mainly comprises the steps of (1) selecting an aluminum alloy medium-thickness panel as an initial blank; (2), forming the middle material of the aluminum alloy panel to be a hub and pre-forming the edge material of the aluminum alloy panel to be a rim by adopting strong bending spinning; (3) splitting the preformed rim to be a rim front piece blank and a rim rear piece blank by adopting splitting spinning; (4) respectively forming the front piece blank and the rear piece blank to a rim front piece and a rim rear piece by adopting strong thinning spinning. The spinning hub produced by the process is high in material use rate, and the material is subjected to plastic deformation for multiple times and is high in strength; a workblank does not need to be precast, forged or cast, the process is simple, the machining cost is low and the production efficiency is high. The front piece and the rear piece do not need welding and screw connection and have stable mechanical performance and high safety performance.

Owner:SHANGHAI HUIRU MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com