Producing equipment and method for inorganic material composite coating steel pipeline

A technology of inorganic materials and composite coatings, applied in mechanical equipment, pipeline protection, metal processing equipment, etc., can solve the problems of high production cost, thin porcelain layer, high production line cost, etc., and achieve low production cost, long service life, complete convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

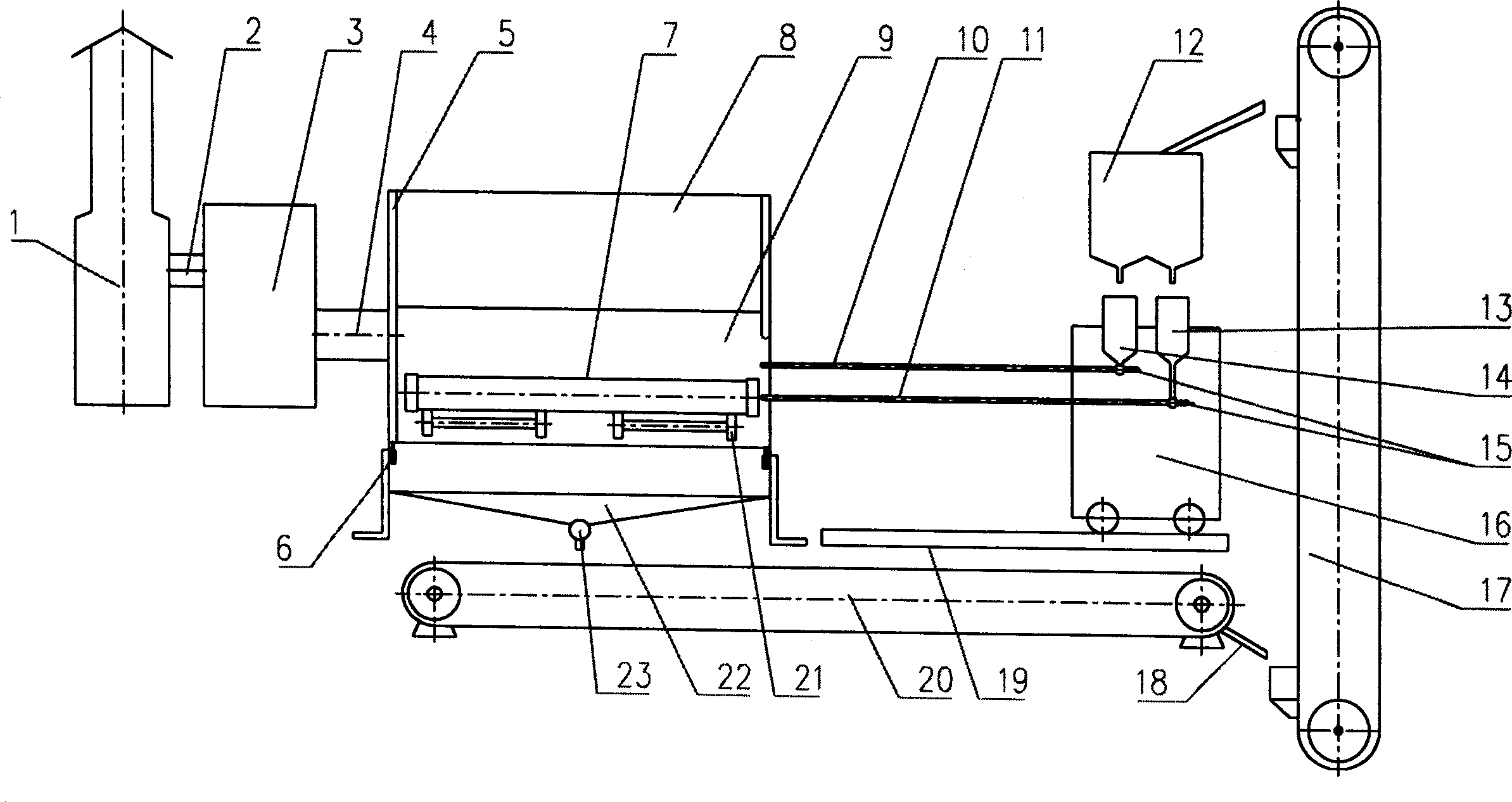

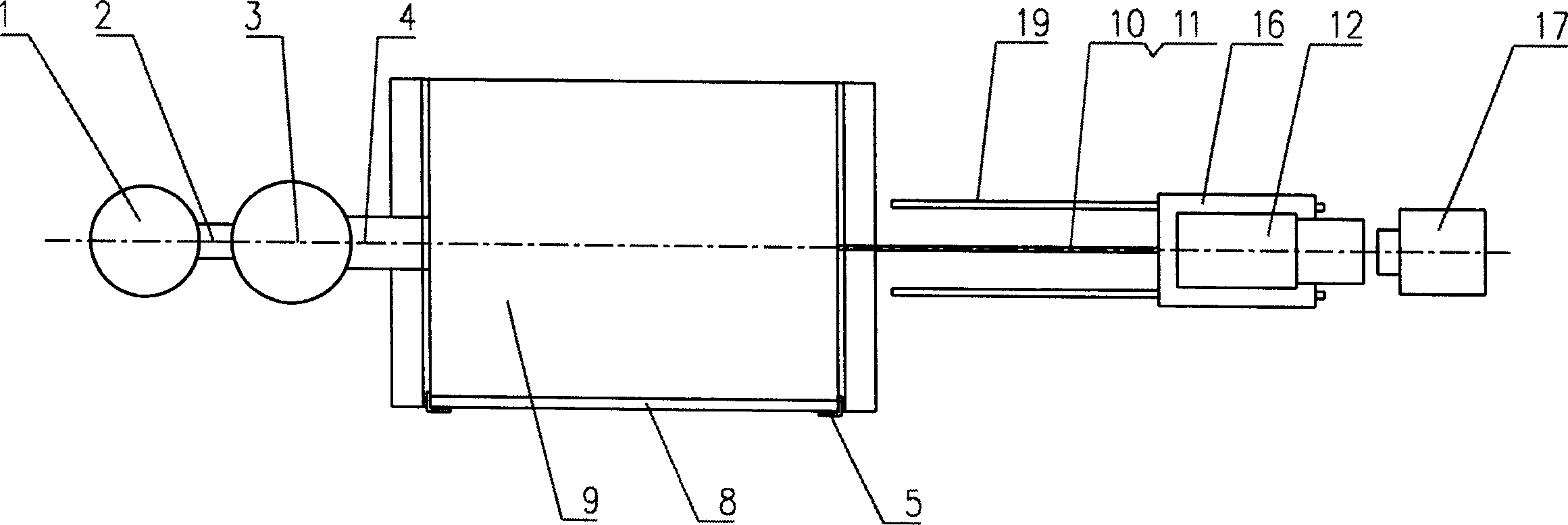

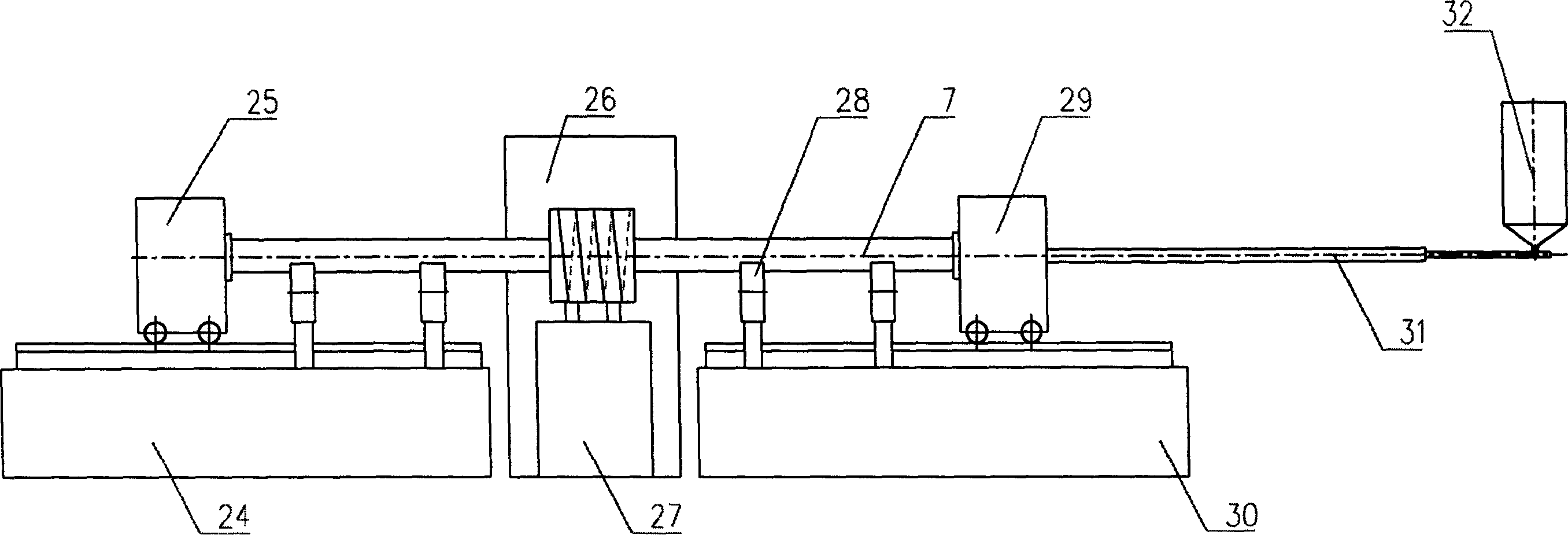

[0015] Example: figure 1 , figure 2 They are respectively the front view and attached view of the sandblasting section in the production equipment for steel pipelines with composite coating of inorganic materials according to the embodiment of the present invention. The sandblasting machine 9 both sides of cuboid are fixedly installed with track 5, and the sandblasting machine door 8 that can slide along track 5 is driven by electric push rod 6, is installed in sandblasting machine 9 bottoms and sandblasting machine lower sand storehouse 22 tops. Rotary turbine unit 21, a lower sand warehouse valve 23 is installed at the outlet of the lower sand warehouse 22 of the sandblasting machine, and the steel pipe 7 with socket is clamped on the rotary turbine unit 21 and can rotate together with the rotary turbine unit 21. The push rod 6 and the rotating wheel unit 21, the belt conveyor 20, the bucket elevator 17, and the sandblasting tank car 16 are respectively driven by a motor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com