Threaded interference fitting method and threaded interference fitting structure for turbine impeller and rotary shaft

A technology of turbine impeller and threaded connection, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problem of difficulty in ensuring the long-term stability of the connection strength of the titanium-aluminum alloy turbine impeller and the 42CrMo alloy rotating shaft, and achieve the connection strength. Durable and reliable, durable and reliable connection, the effect of ensuring connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

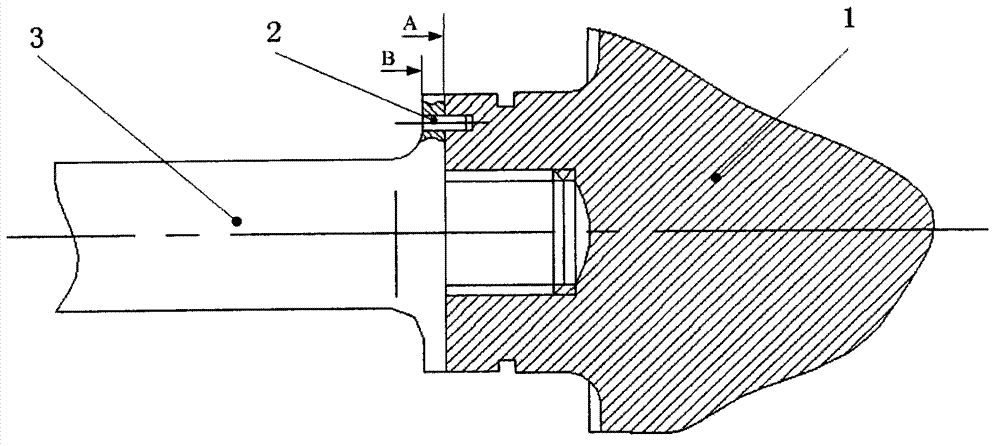

[0019] A connection structure between a turbine impeller and a rotating shaft, including a rotating shaft and a turbine impeller, the end of the rotating shaft is threaded, and the direction of rotation of the thread is the same as that of the turbine, and the connection between the turbine impeller and the rotating shaft has an interference fit with the thread on the end of the rotating shaft thread.

[0020] Preferably, straight pin holes are arranged on the rotating shaft and the turbine impeller, and the straight pins are used to connect the turbine impeller and the rotating shaft.

[0021] Preferably, the cylindrical pin holes are arranged symmetrically in the circumferential direction, and the number is 3-6.

[0022] Preferably, the cylindrical pin hole penetrates the rotating shaft and extends into the turbine impeller by 3-5 mm.

[0023] A thread interference connection method between a titanium-aluminum supercharger turbine impeller and a rotating shaft, comprising t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com