Patents

Literature

38results about How to "Simple and stable process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

White light-emitting device

InactiveUS20050093422A1Simple processImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesGreen-lightLength wave

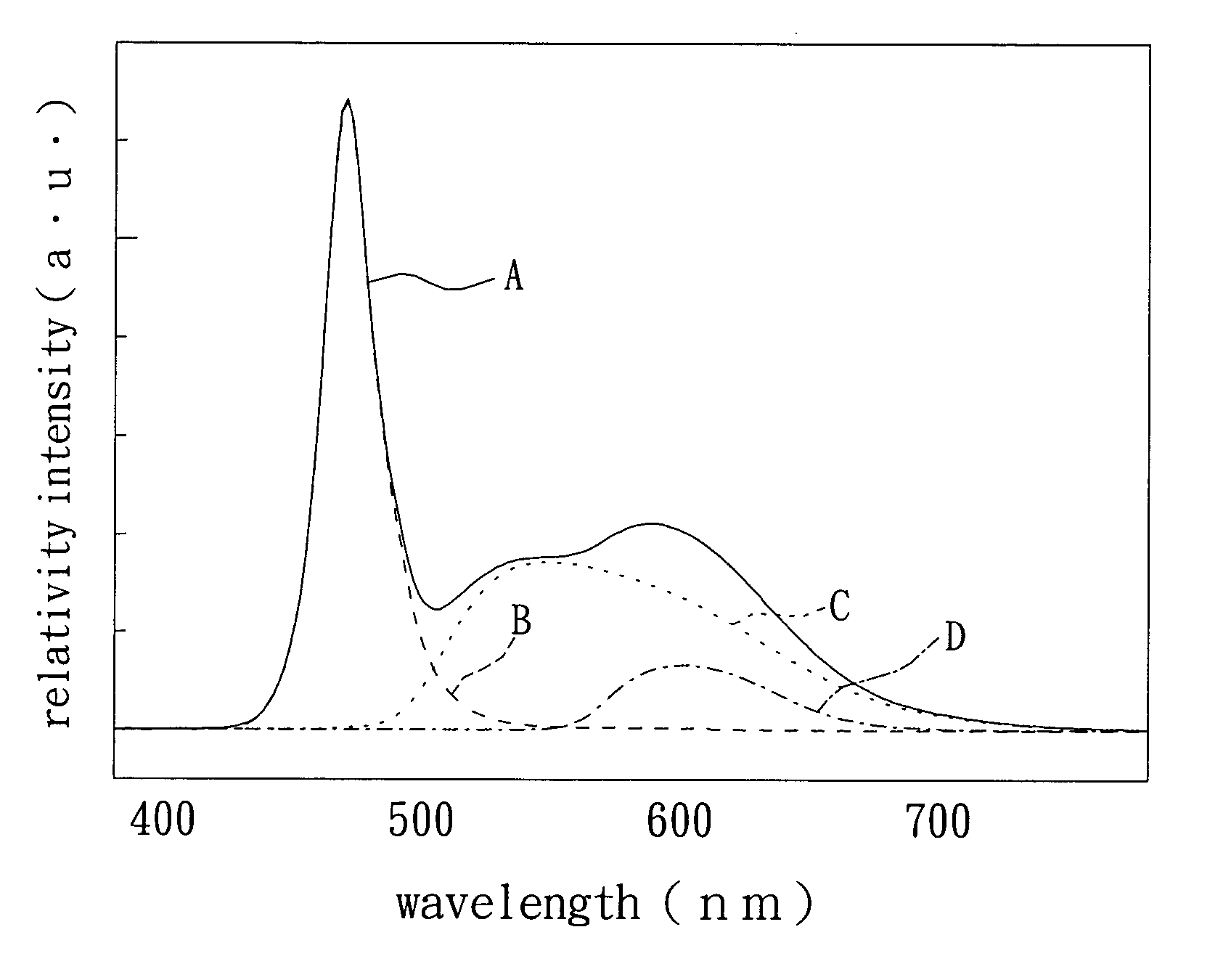

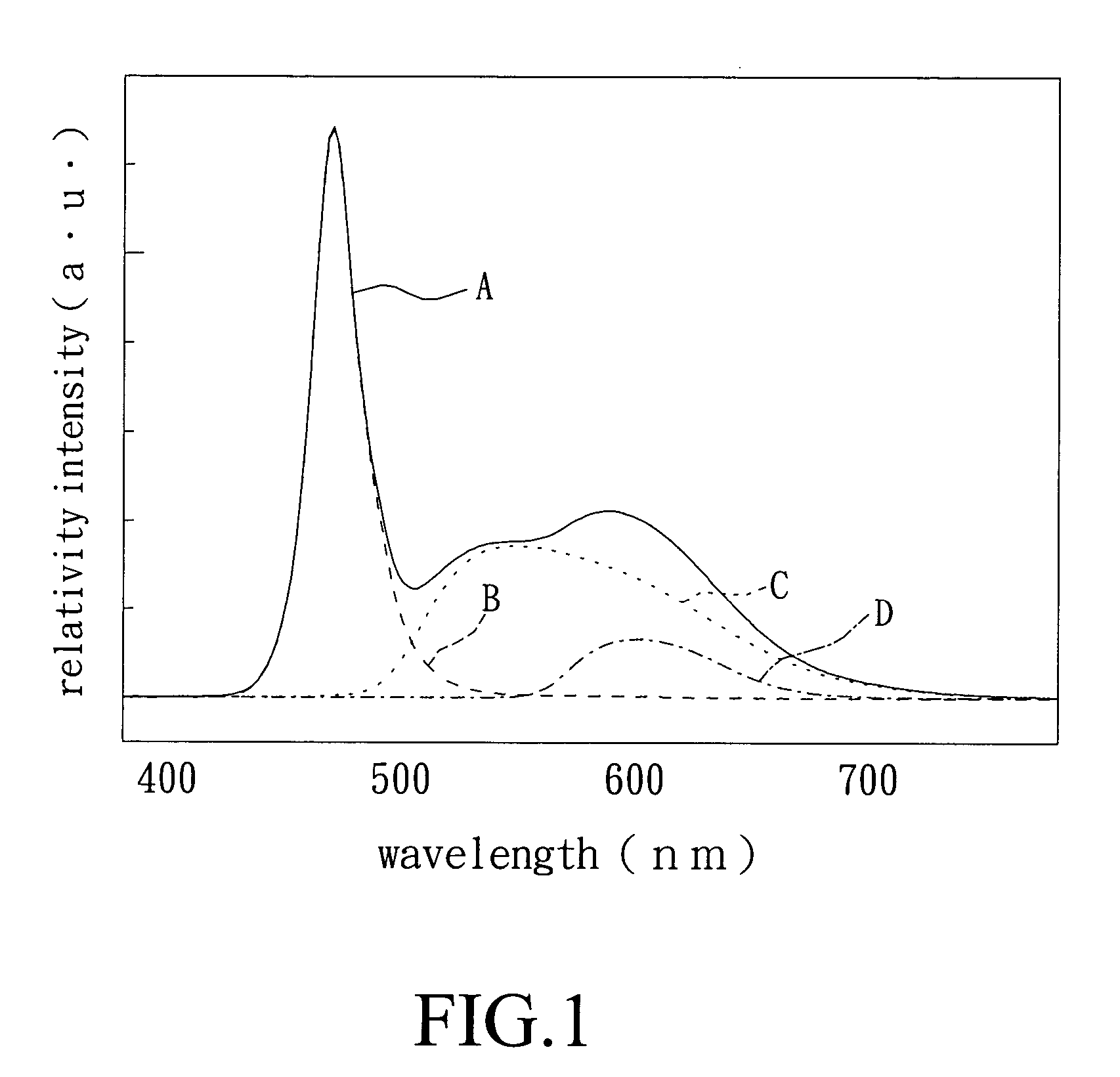

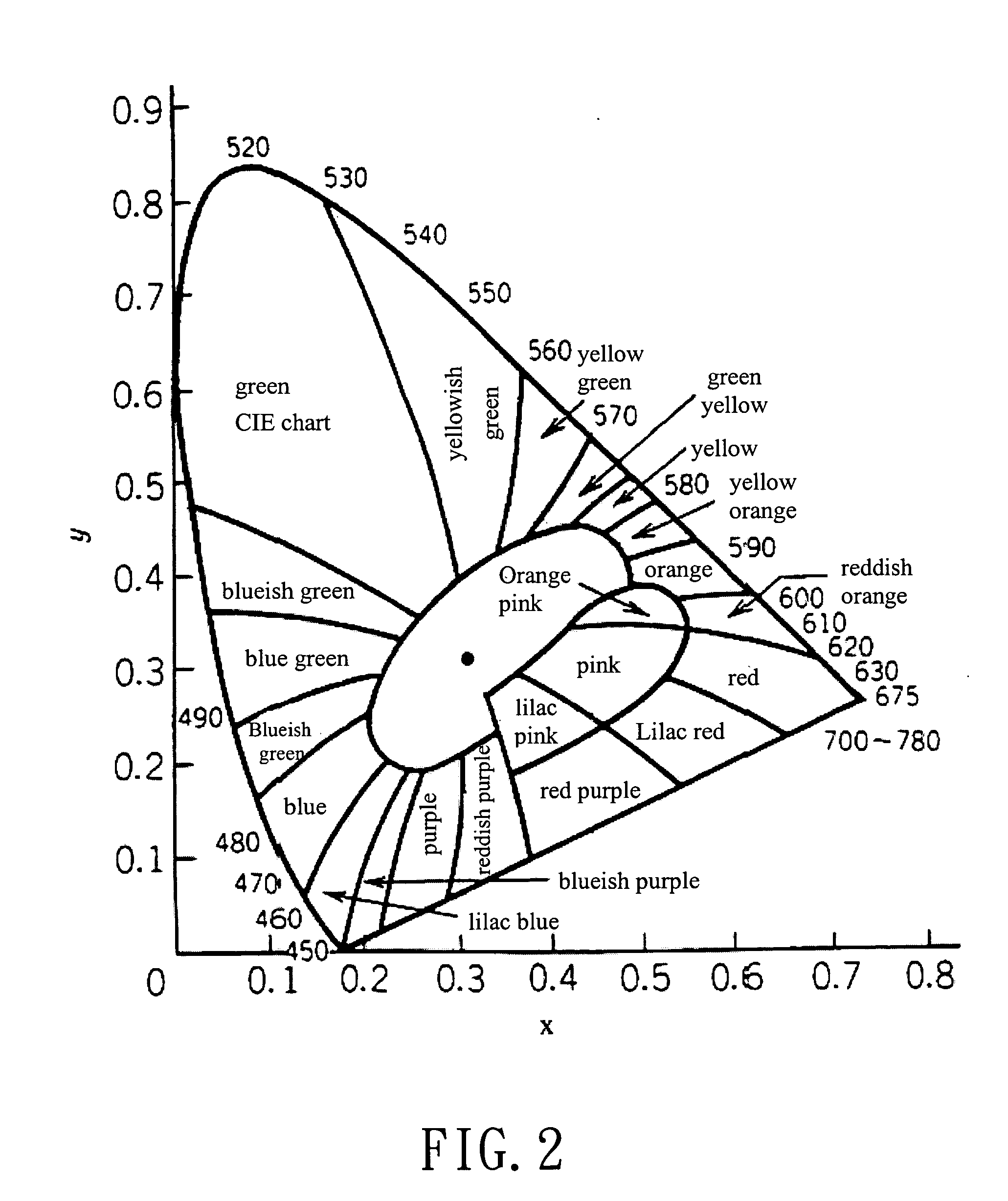

A white light-emitting device comprising a blue or blue-green light-emitting diode emitting light of 450-500 nm wavelength, and two phosphor materials capable of emitting a yellow light with 520 to 580 nm wavelength, and a red light with 580 to 640 nm wavelength, respectively. The light-emitting diode and the two phosphor materials are packaged together to form the white light-emitting device.

Owner:LITE ON TECH CORP

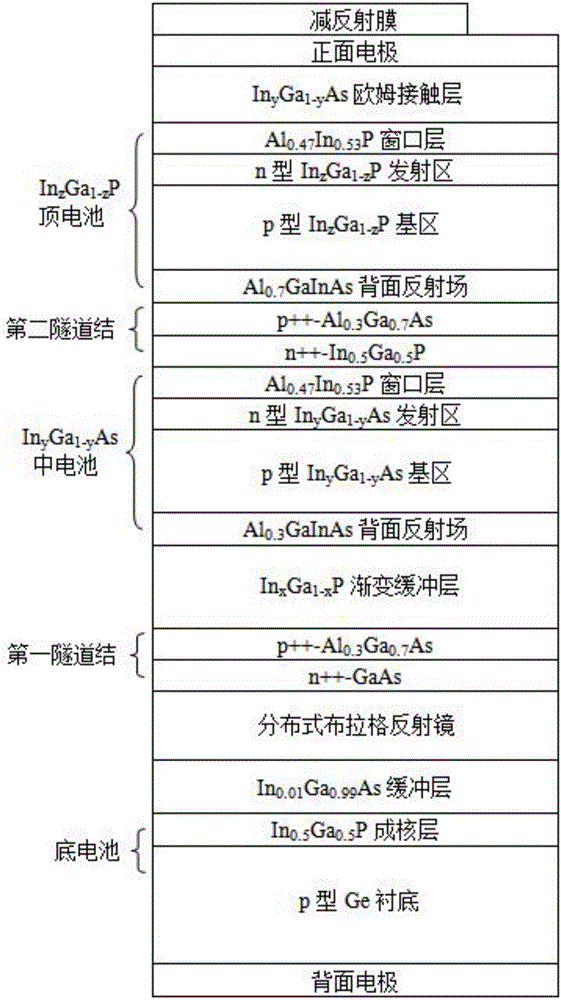

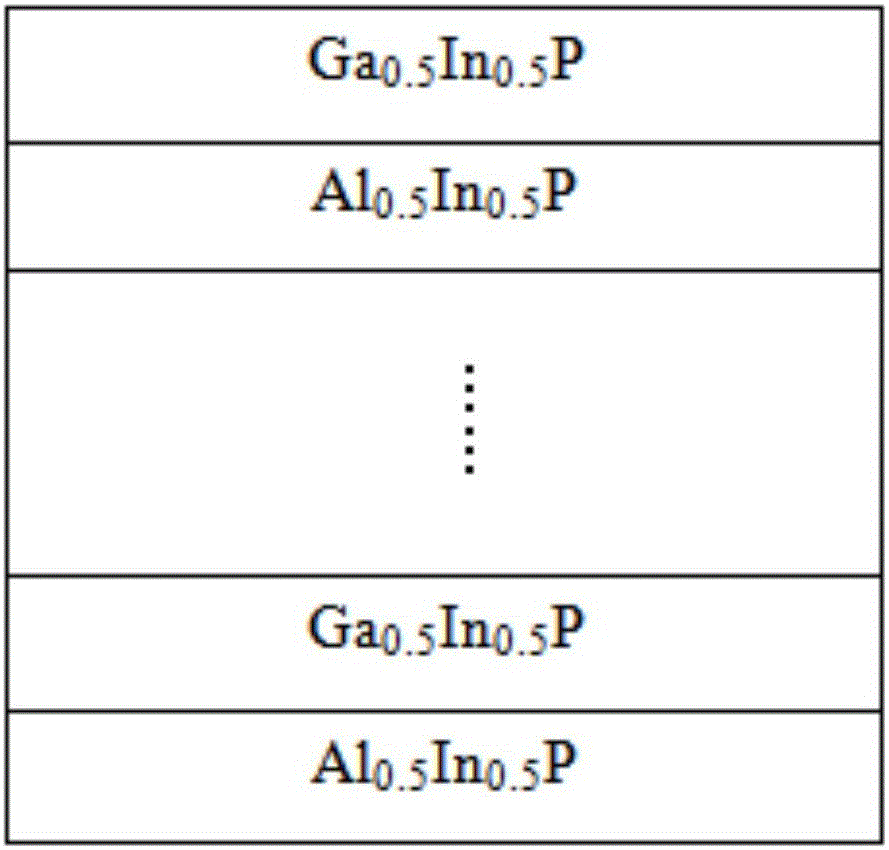

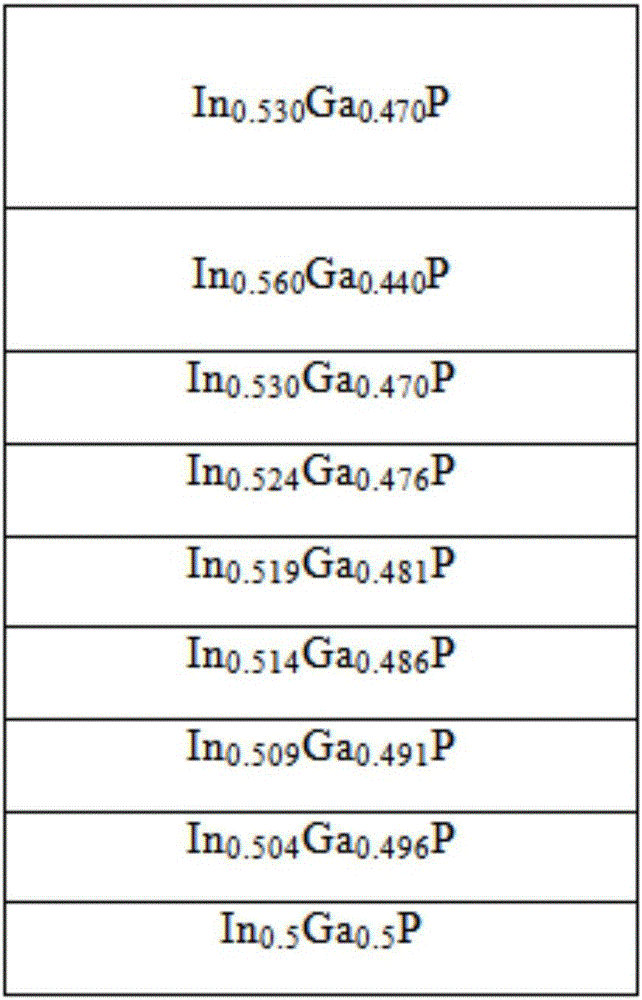

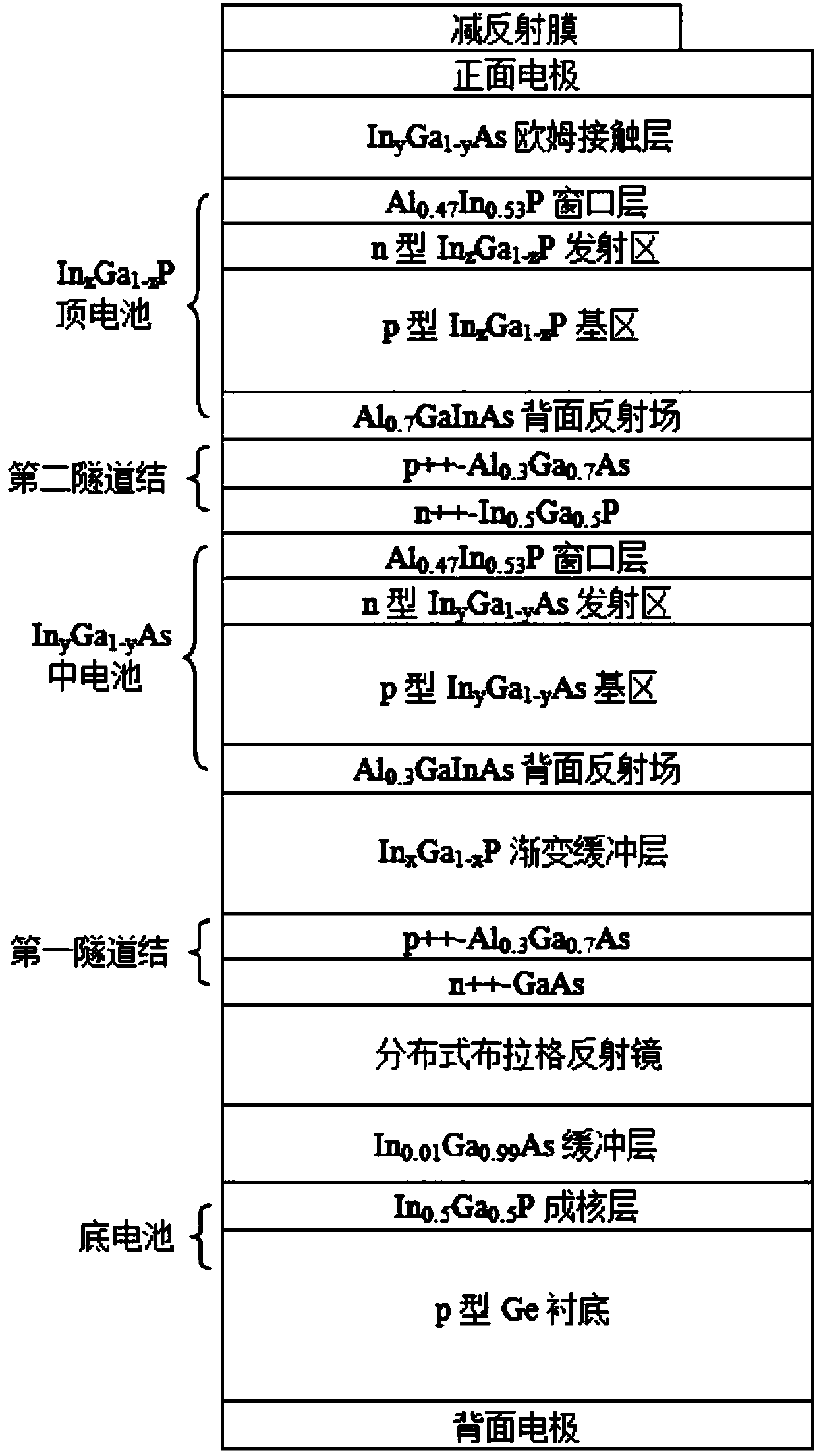

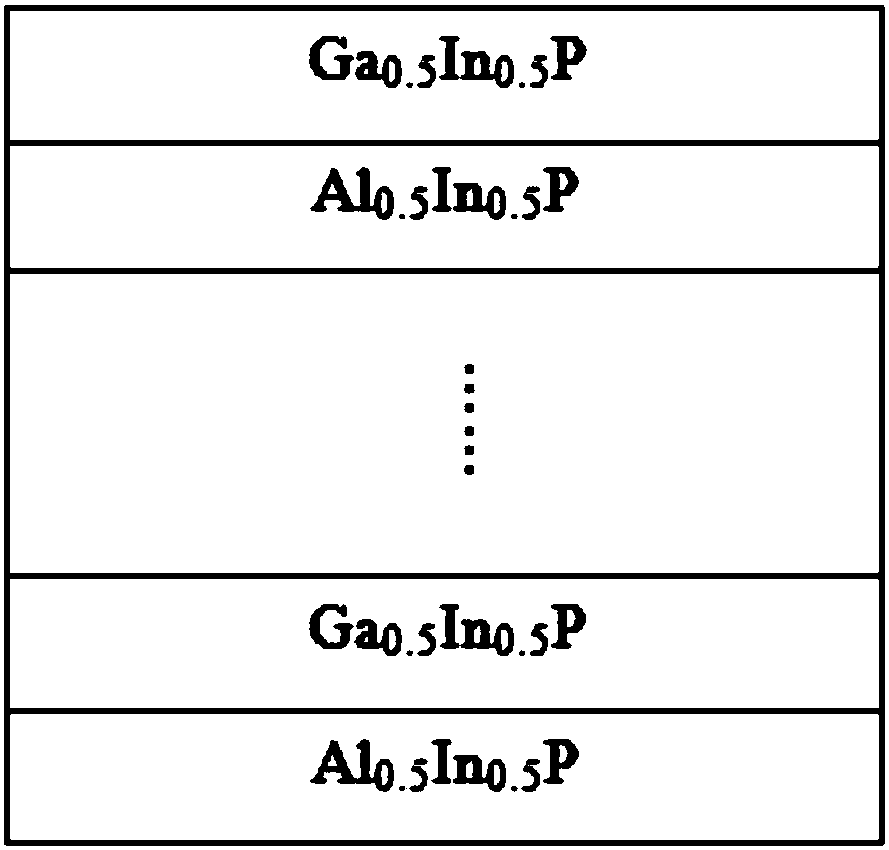

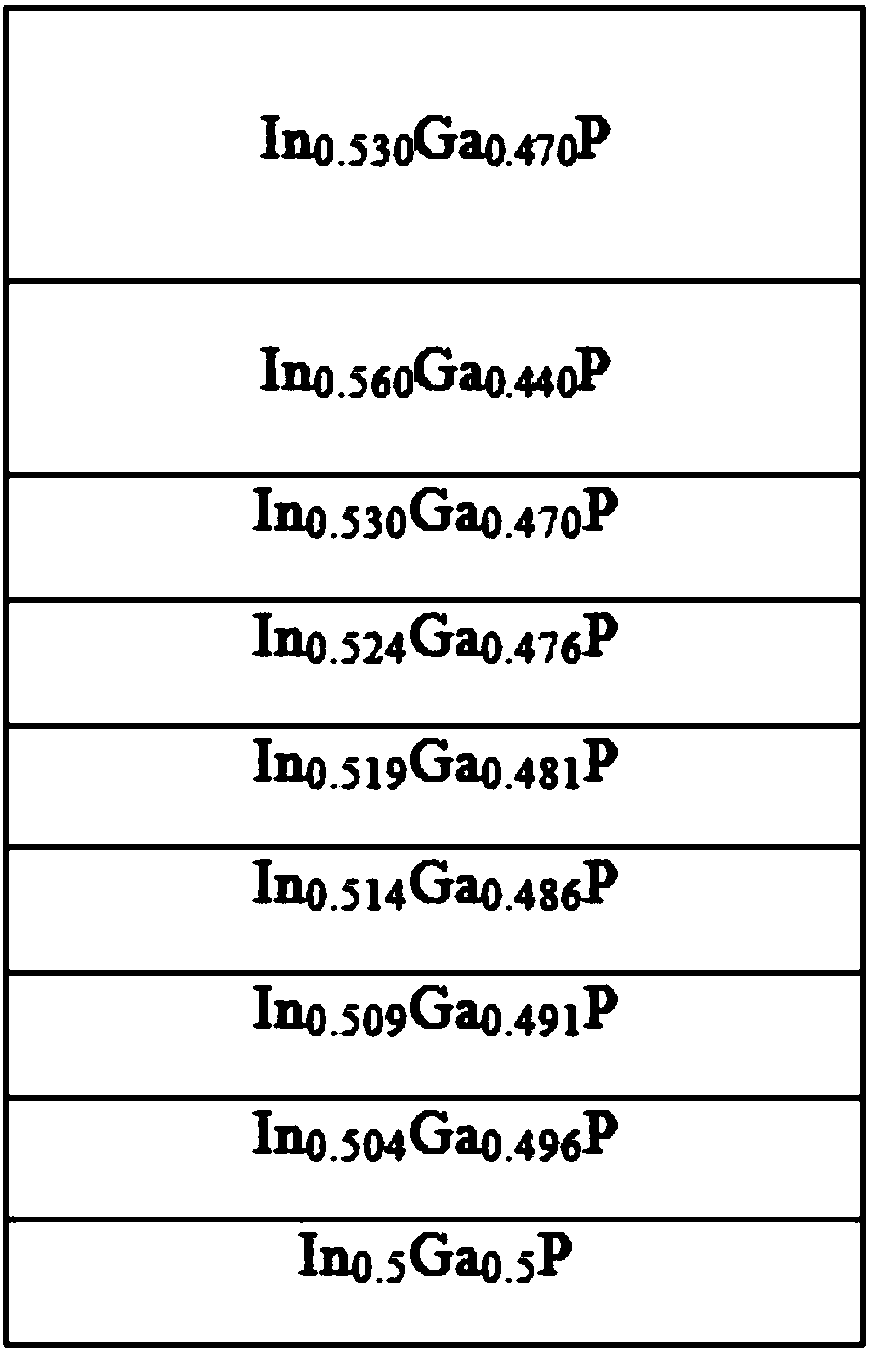

Micro-lattice mismatch quantum well solar cell and manufacturing method therefor

ActiveCN106067493AImprove photoelectric conversion efficiencyIncrease currentSemiconductor devicesLattice mismatchQuantum well

The invention discloses a micro-lattice mismatch quantum well solar cell and a manufacturing method therefor. The solar cell adopts p type Ge as material for a substrate; an In0.5Ga0.5P nucleating layer, an In0.01Ga0.99As buffer layer, a distributed type Bragg reflector, a first tunnel junction, an InxGa1-xP gradual change buffer layer, an InyGa1-yAs middle cell, a second tunnel junction, an InzGa1-zP top cell, an InyGa1-yAs Ohmic contact layer, a front side electrode and an antireflection film are orderly laminated on an upper surface of the substrate in a bottom-to-top manner; a back side electrode is made on a lower surface of the p type Ge substrate. According to the micro-lattice mismatch quantum well solar cell and the manufacturing method therefor, InyGa1-yAs and InzGa1-zP that are in a micro-lattice mismatch relation with the p type Ge substrate are respectively used as middle cell material and top cell material; an InyGa1-yAs / Ga0.92In0.08N0.028As quantum well structure is added, the InxGa1-xP gradual change buffer layer is adopted for eliminating defects such as dislocation and the like caused by micro-lattice mismatch, the distributed type Bragg reflector is adopted for improving a utilization rate of solar photons by the InyGa1-yAs middle cell, electric current density of the middle cell and the top cell can be improved finally, and photoelectric conversion efficiency of the cell can be raised.

Owner:ZHONGSHAN DEHUA CHIP TECH CO LTD

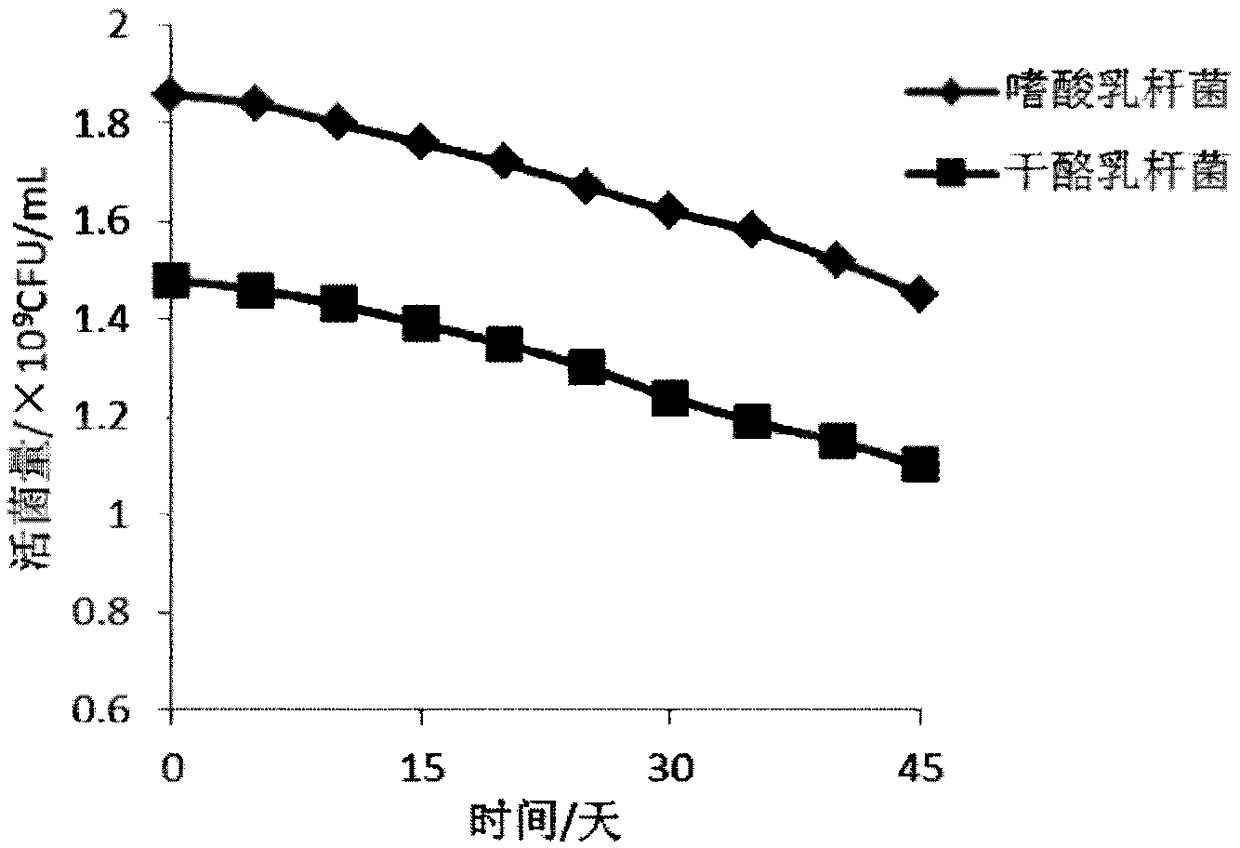

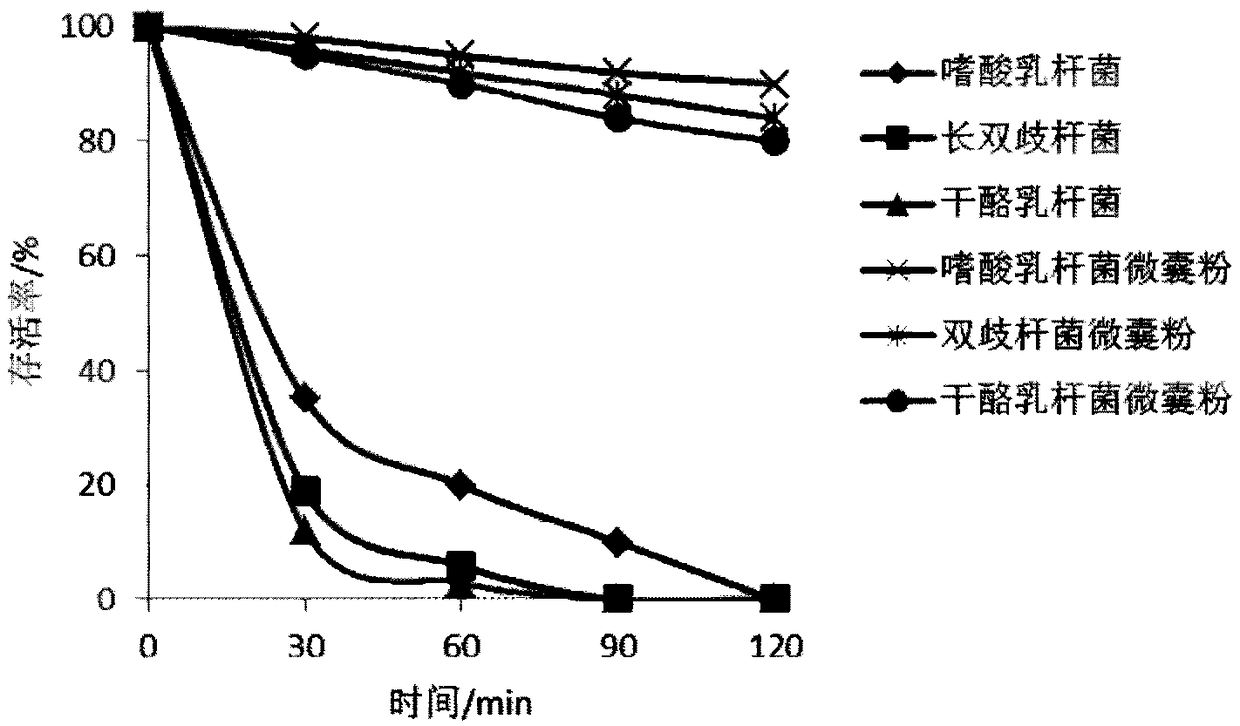

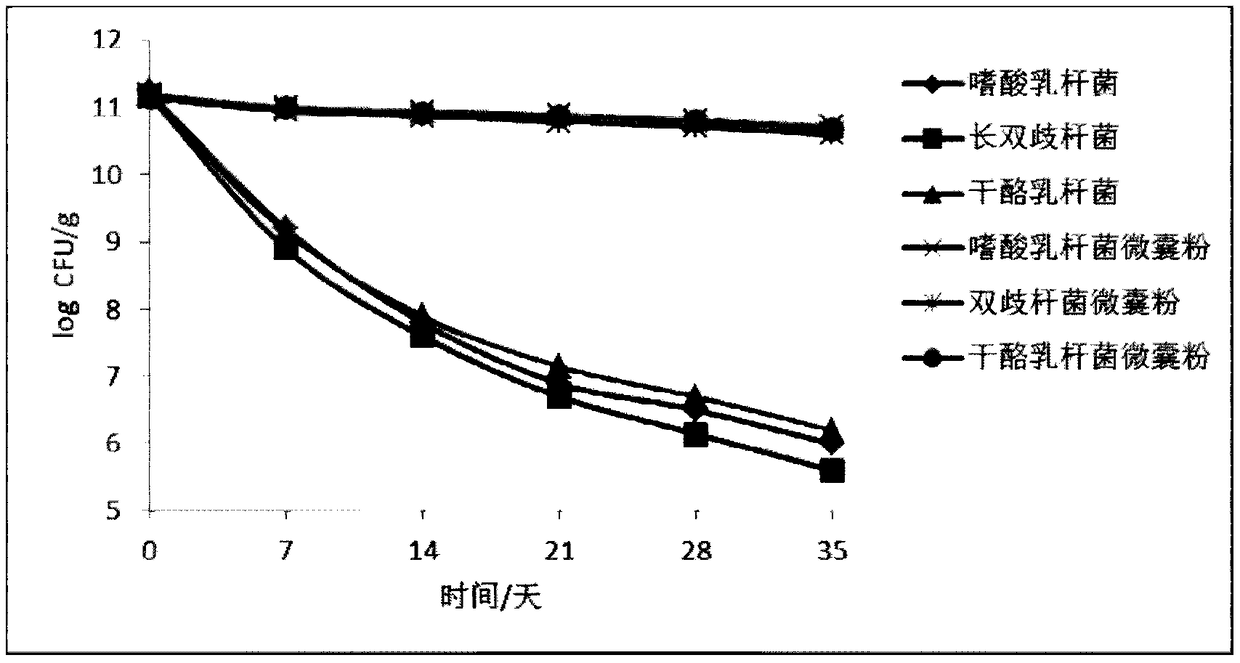

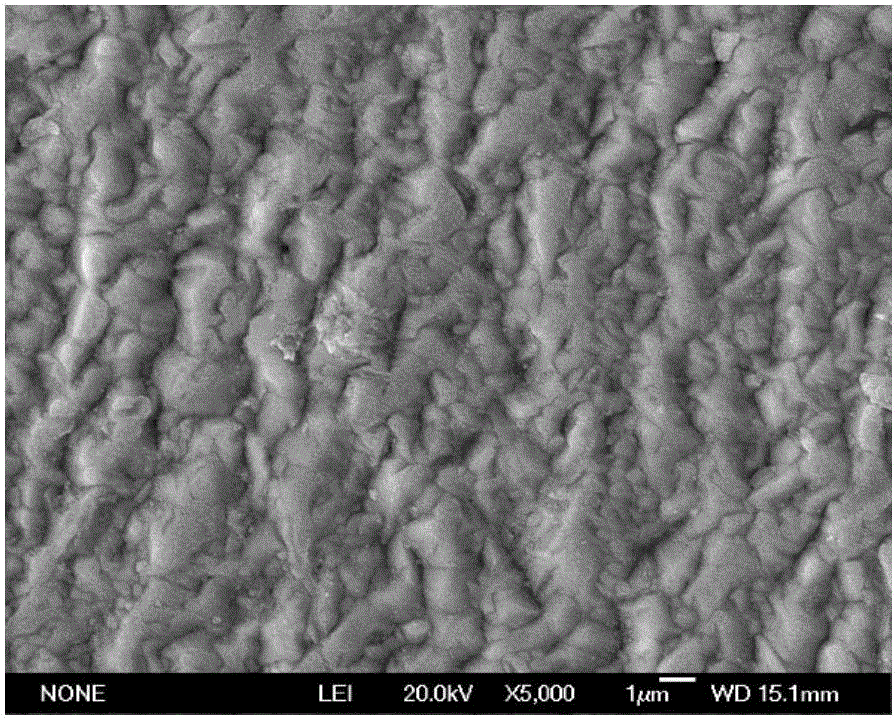

Probiotics microcapsule capable of keeping activity of strains and preparation method thereof

ActiveCN108618151ABiologically active and stableIncreased durabilityBacteria material medical ingredientsPharmaceutical non-active ingredientsFreeze-dryingTremella

The invention discloses a probiotics microcapsule capable of keeping activity of strains and a preparation method thereof. The probiotics microcapsule is of a composite wall material structure which is composed of a first wall material and a second wall material, wherein the first wall material is protein plant polysaccharide complex gel which is prepared from casein, malt extract and xylooligosaccharide, can effectively block damages, on a core material, of light, heat, oxygen, metal ions and the like, and achieves positive promoting effect on stability of an embedded material; the second wall material is a plant polysaccharide composite which is prepared from tremella polysaccharide, rhizoma bletillae polysaccharide, bighead atractylodes rhizome polysaccharide, guar gum and pectin, and can greatly reduce influences, on biological activity of probiotics strains of the core material, of a vacuum freeze-drying and processing process; and meanwhile, when the second wall material coats the first wall material, the first wall material containing a great number of proteins can improve film-forming property and embedding effect of the second wall material, so that the performance of thecomposite wall material is integrally improved, and therefore, the composite wall material can protect the biological activity of the core better, and remarkably improves the stability of the core material.

Owner:NINGBO YUFANGTANG BIOTECH

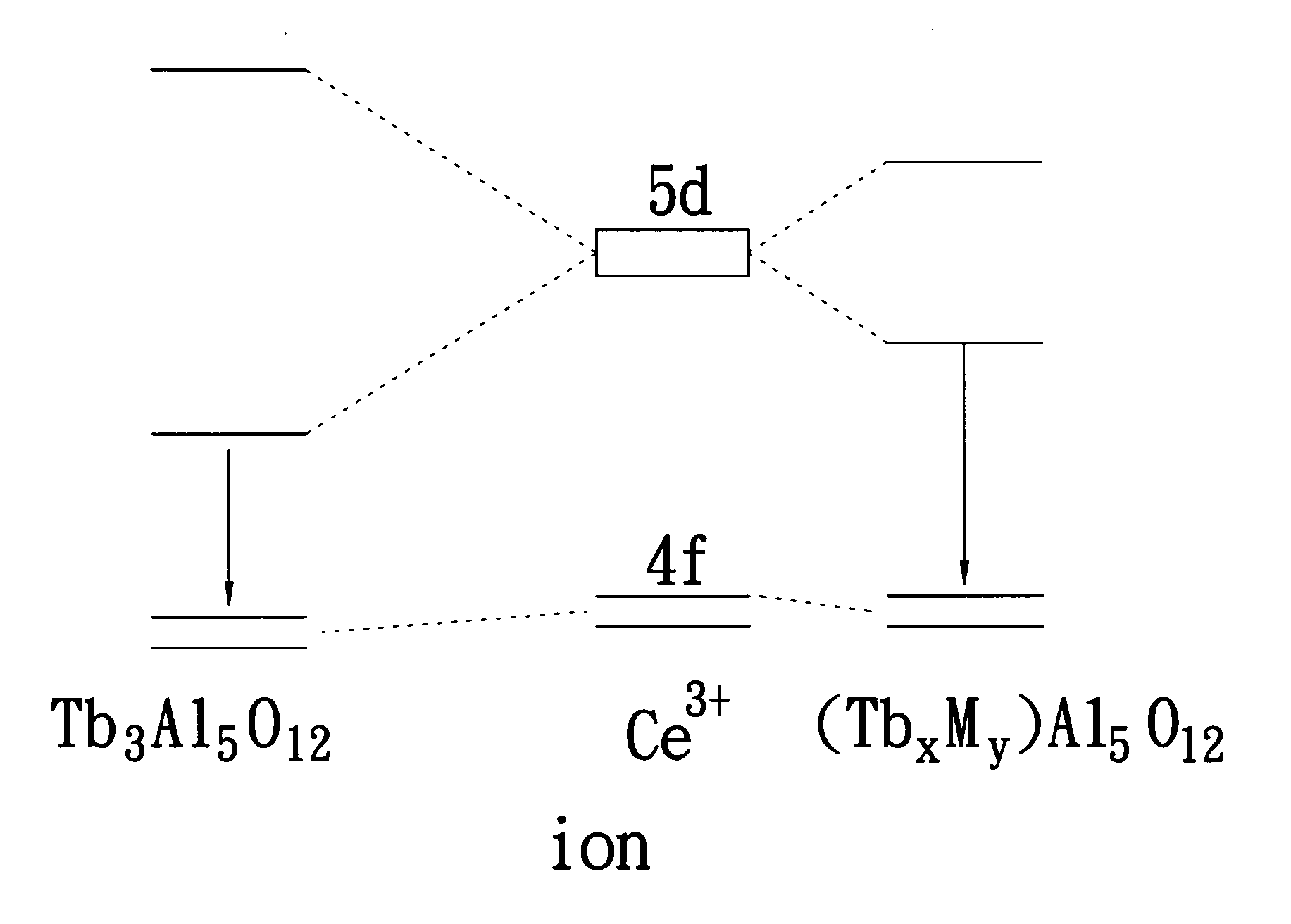

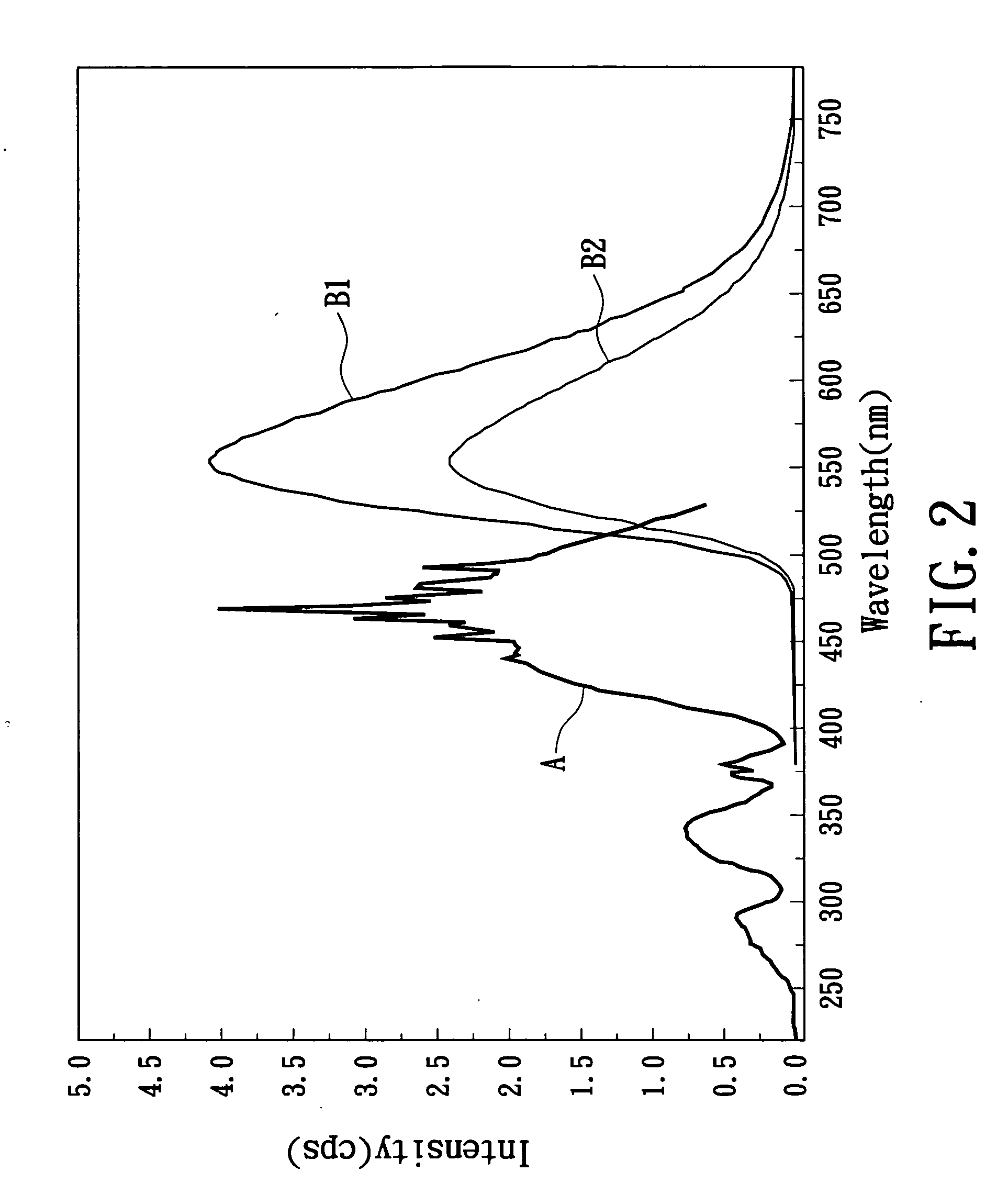

Yellow phosphor material and white light-emitting device using the same

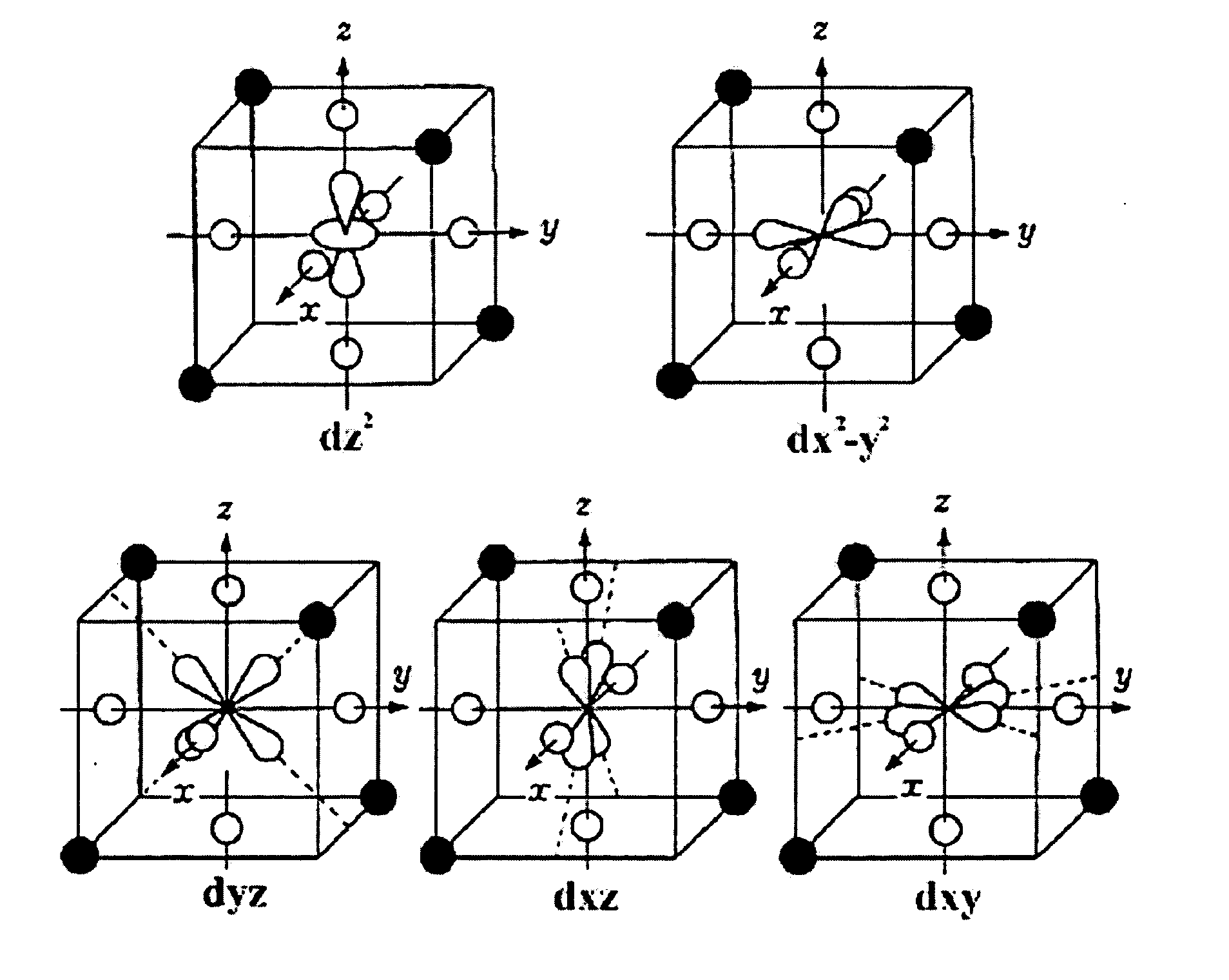

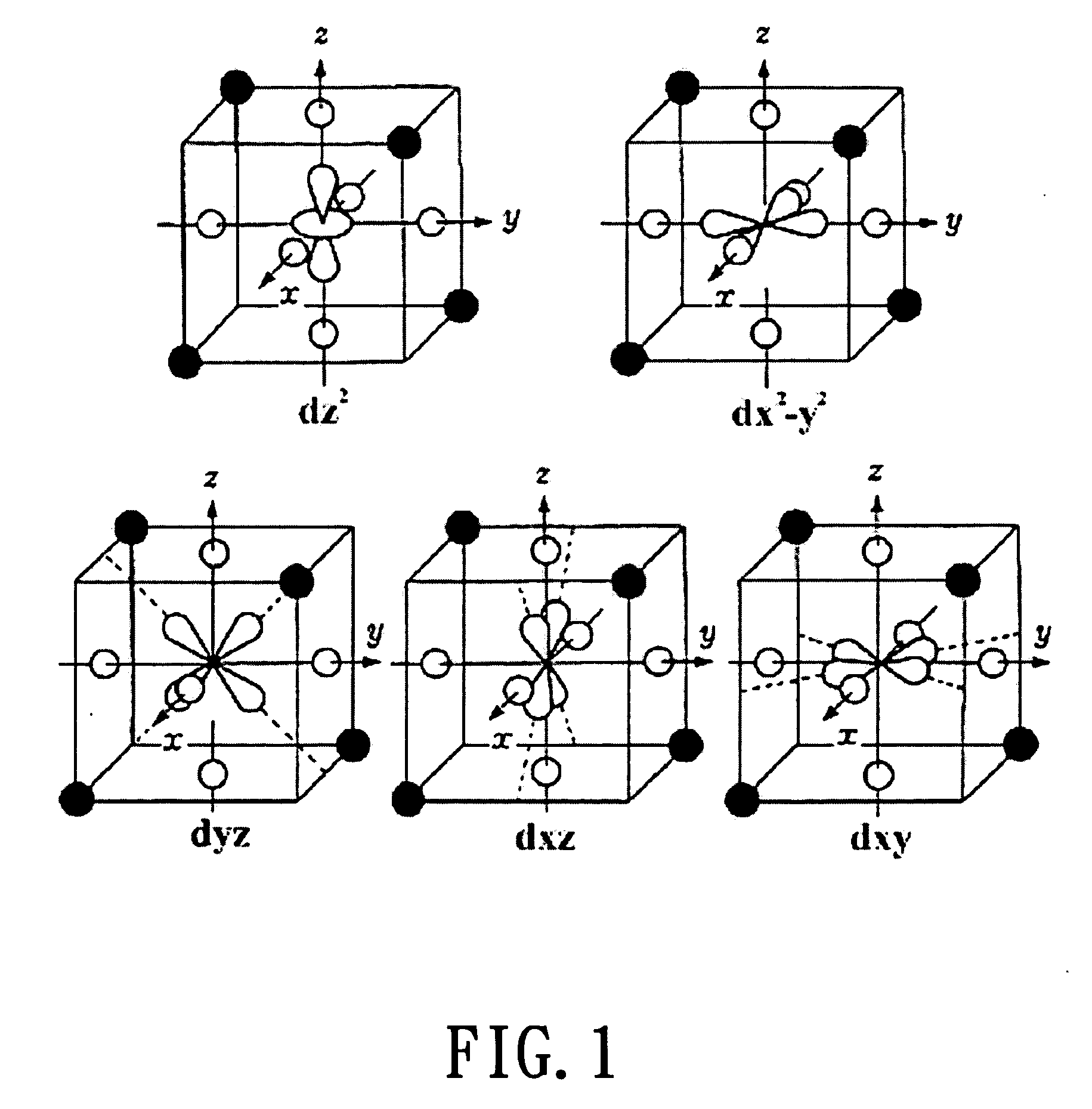

InactiveUS20050099786A1Improve efficiencyEasy to usePoint-like light sourceGas discharge lamp usageExcited statePhosphor

A yellow phosphor material has a host with a formula (TbxMyCez)Al5O12, wherein x+y+z=3 , 3>x>0 and y≠0 and a Ce activator. M is selected from the group consisting of Sc, Y, Dy, Ho, Er, Tm, Yb, and Lu. By changing the diameter of metal ions, the crystal field thereof may be modulated to thereby alter the energy level of the excited state to which the activator is transferred upon irradiation by a specific wavelength of light. The phosphor can be used with a blue LED to form a white light source.

Owner:LITE ON TECH CORP

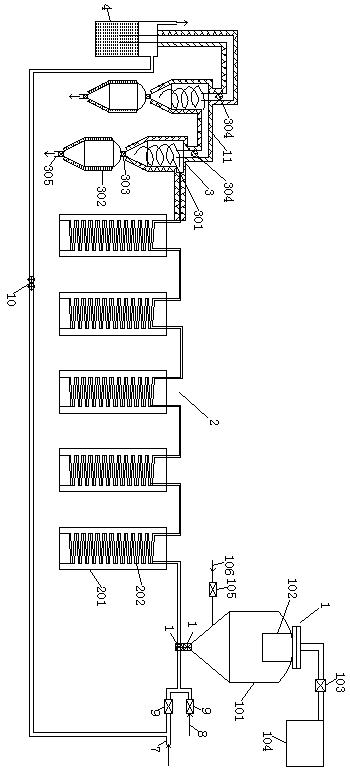

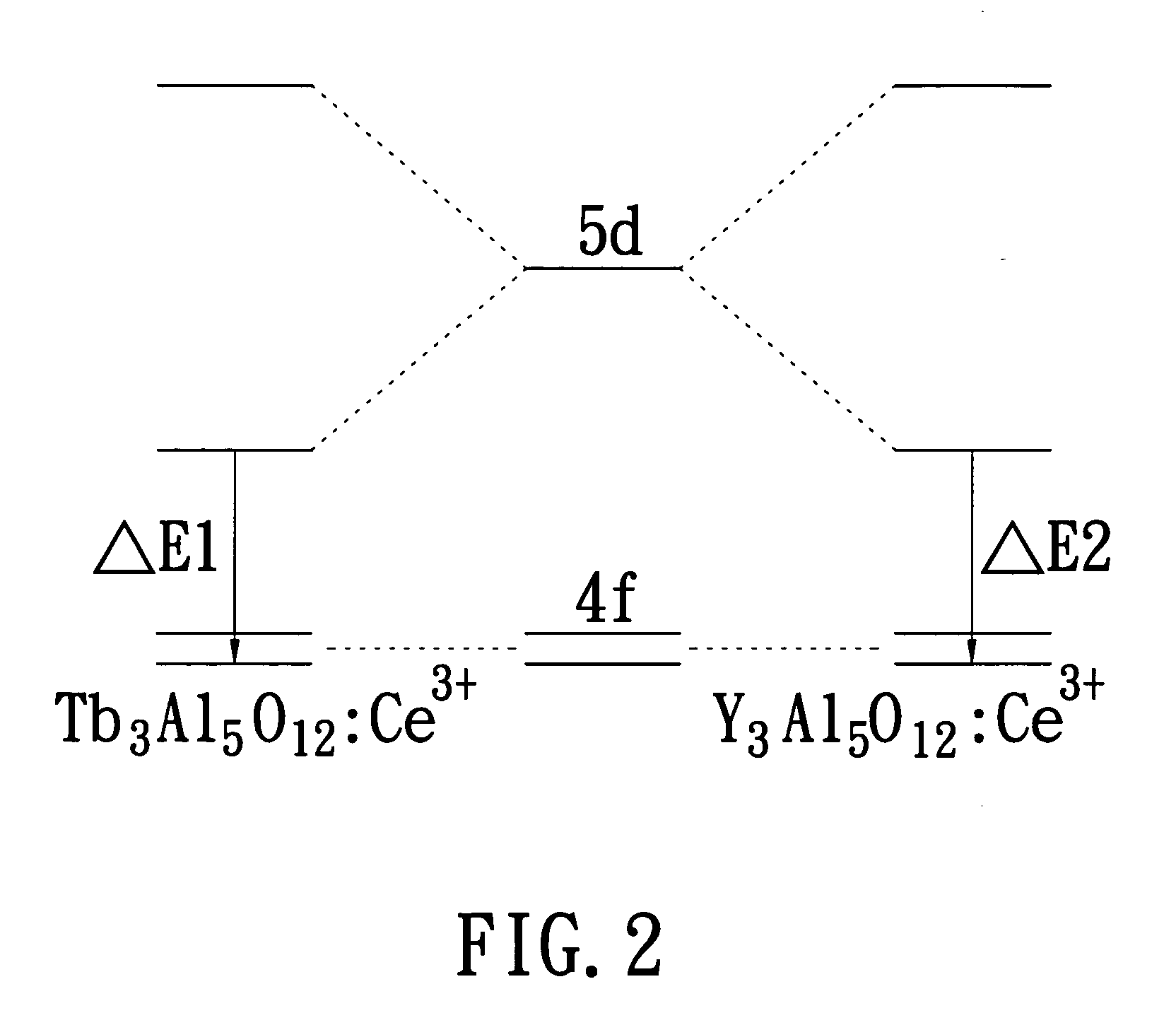

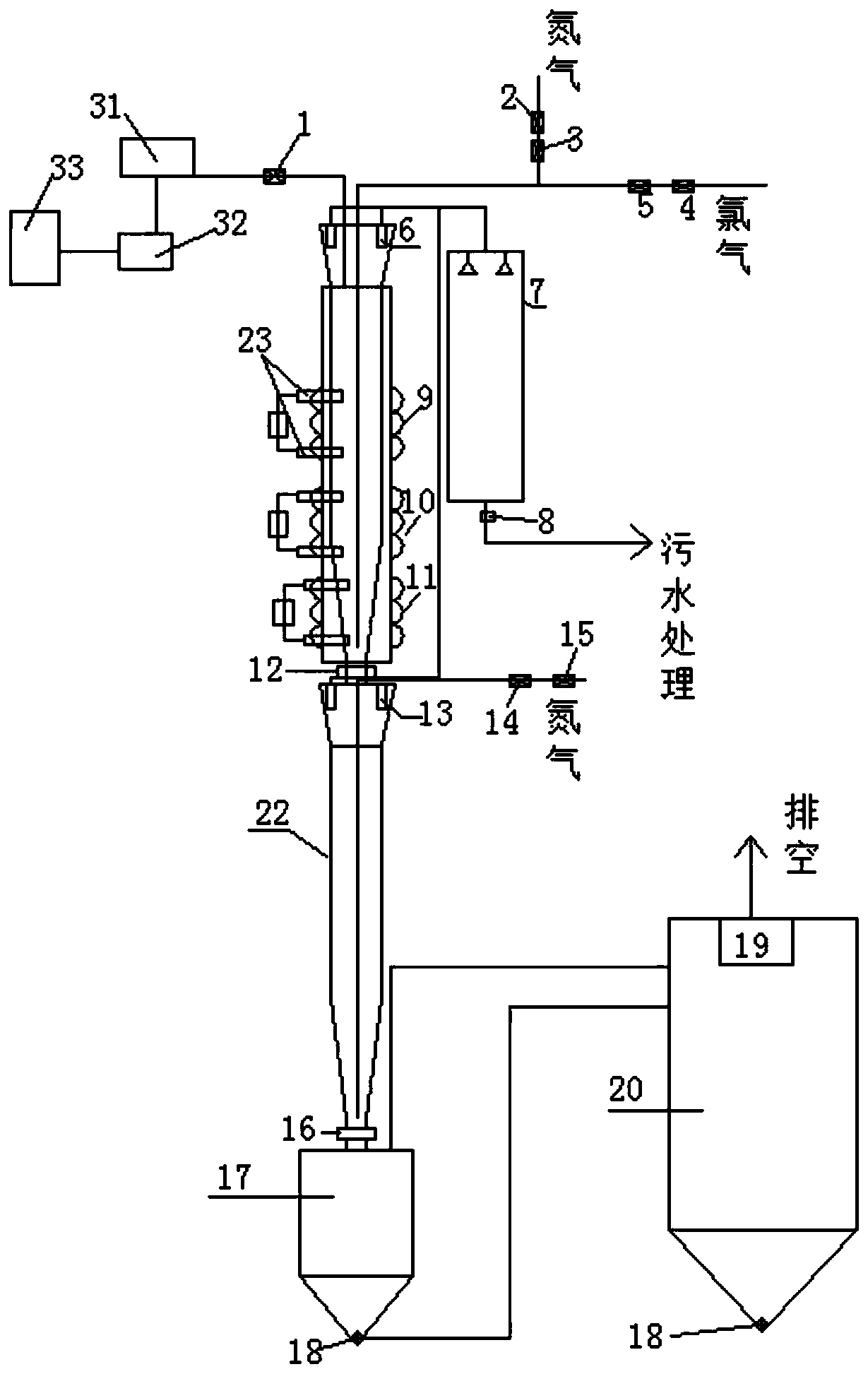

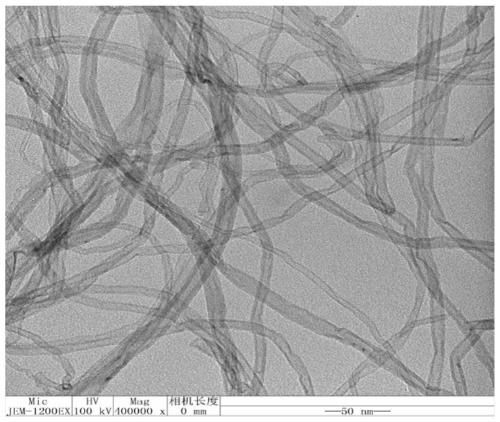

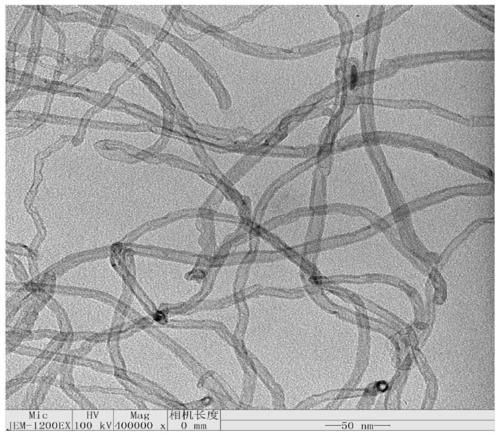

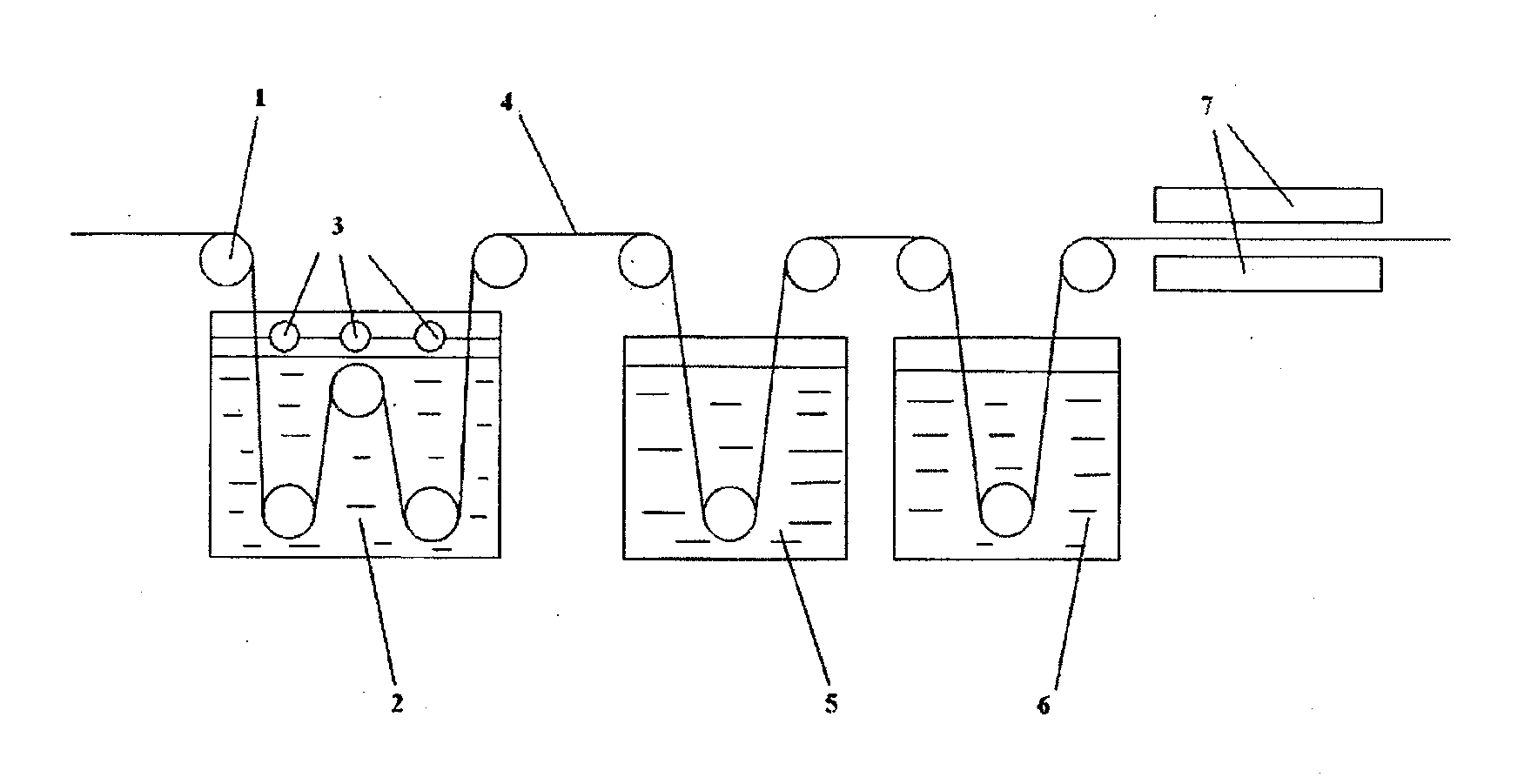

Method and device for continuously preparing high-purity carbon nano tubes

The invention relates to a method and device for continuously preparing high-purity carbon nano tubes. The method comprises the following steps: (1) performing inert gas replacement on carbon nano tubes, passing through a pressurized seal pneumatic conveying device via a quantitative dumping device, and entering a gradient heating device at a normal temperature in a dense-phase flow form under drive of mixed gases of protective carrier gas and acid gas; (2) preheating and reacting the carbon nano tubes in the gradient heating device; (3) separating the purified carbon nano tubes from tail gases by virtue of a two-stage gas-solid separation device, cooling the carbon nano tubes by a cooling device in the gas-solid separation device, and enabling the carbon nano tubes to enter a high-puritycarbon nano tube collection device via a feeding hole; and (4) enabling the tail gases to enter a tail gas treatment device, feeding the protective gas to a protective gas inlet via a recycling pressure stabilizing device; and feeding impurity tail gases into a tail gas collection device. According to the method disclosed by the invention, the carbon nano tubes with the high purity of 99.9% or higher can be obtained, and the device disclosed by the invention is simple in operation, simple and stable in process, low in operating cost and stable in product quality.

Owner:SHANDONG DAZHAN NANO MATERIALS

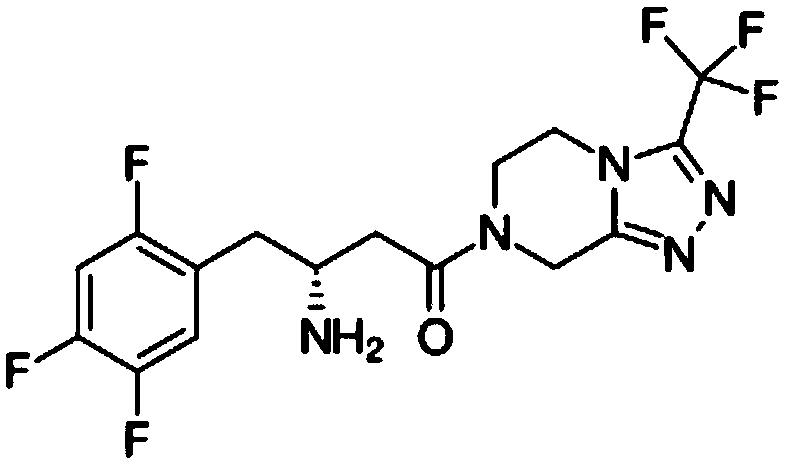

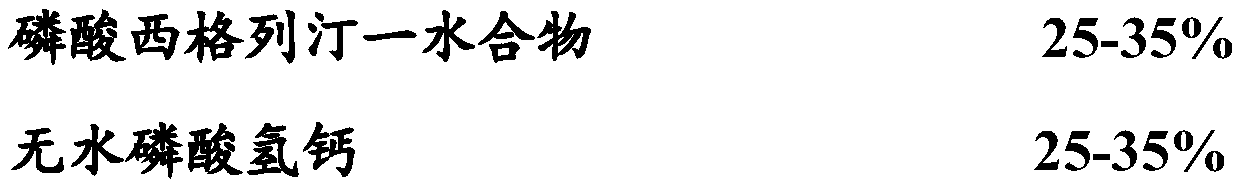

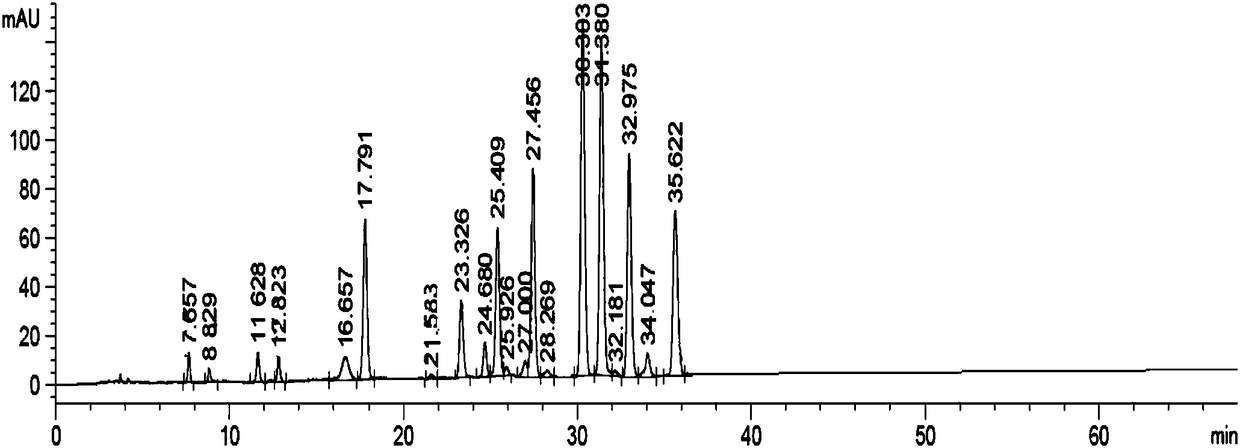

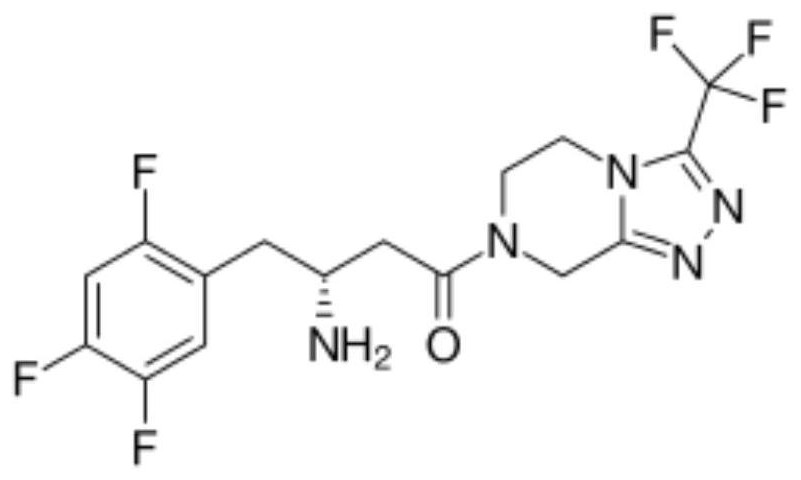

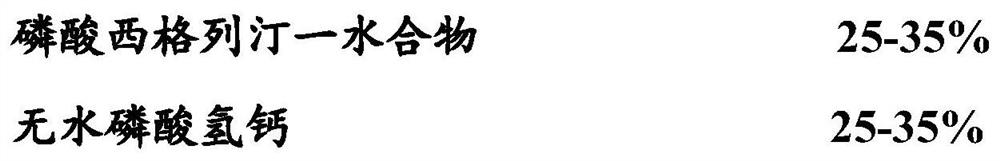

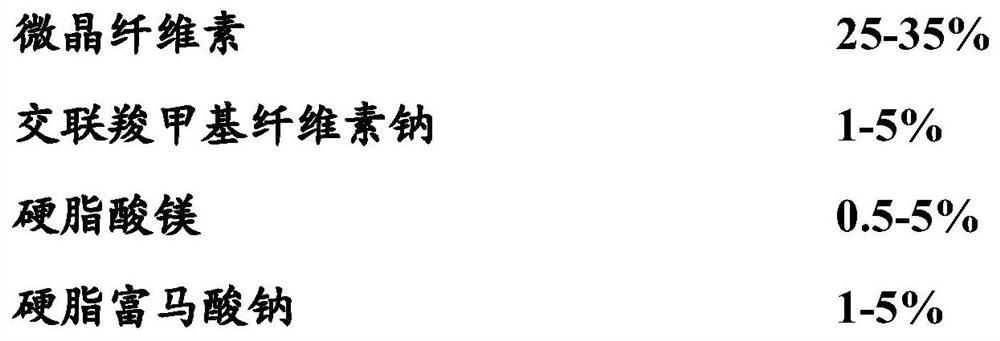

Medicinal composition containing sitagliptin or pharmaceutically acceptable salt thereof and preparation method thereof and application

ActiveCN109157522AQuality improvementIncrease contentOrganic active ingredientsMetabolism disorderSitagliptinHydrogen phosphate

The invention relates to a medicinal composition. The medicinal composition comprises sitagliptin, pharmaceutically acceptable salt thereof and / or hydrate of the salt, and anhydrous calcium hydrogen phosphate. The medicinal composition is further used for preparing a solid preparation, and is especially prepared into a tablet by a direct tabletting method. Through selection of the medicinal composition, especially selection of the specific anhydrous calcium hydrogen phosphate as a raw material, the quality control way of the medicinal composition using the sitagliptin, the pharmaceutically acceptable salt thereof and / or the hydrate of the salt as an active component can be significantly improved, and even production of related impurities in the medicinal composition can be significantly improved so as to improve the stability of the medicinal composition and relevant dosage forms.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD

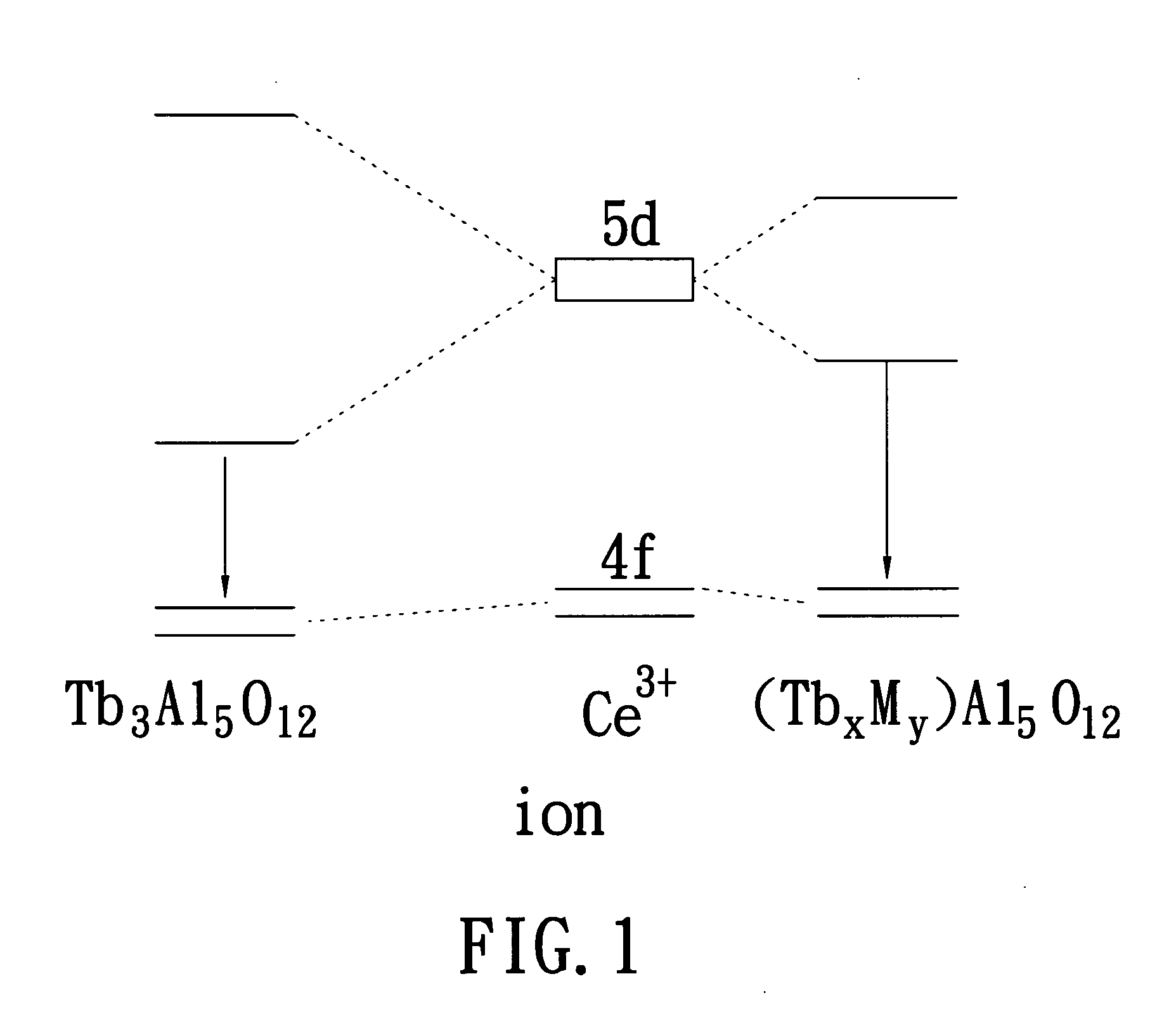

Phosphor material and white light-emitting device using the same

InactiveUS20050205874A1Easy to useImprove efficiencySolid-state devicesGas discharge lamp usageExcited stateGreen yellow

A white light-emitting device comprising a blue-violet or blue LED and a phosphor material capable of emitting a yellow-green to orange-yellow light upon excitation by the light emitted by the LED. The light from the LED and the phosphor material are mixed in an appropriate ratio to produce a white light. The phosphor material has a general formula (YxMyCez)Al5O12, where x+y=3, x, y≠0, 0.5>z>0, and M is selected from the group consisting of Tb, Lu, and Yb, with (YxMy)Al5O12 serving as a host and Ce as an activator. By changing the composition of the metal elements in the host, the crystal field is modulated to thereby alter the energy level of the excited state to which the activator is transferred upon irradiation by a specific wavelength of light, leading to the change in the emitting wavelength of the phosphor material.

Owner:LITE ON TECH CORP

Device and method for directly electrifying and purifying carbon nano tube

InactiveCN111410188ASimplify complex structuresSave a lot of spaceCarbon nanotubesChemistryProcess engineering

The invention relates to the technical field of carbon nano tube purification, in particular to a device and a method for directly electrifying and purifying a carbon nano tube. The device comprises amain reactor, the main reactor comprises a material preheating section, a low-temperature heating reaction section, a high-temperature heating reaction section and a material cooling section which are sequentially arranged from top to bottom, the upper end of the main reactor is connected with a feeding valve, the feeding valve is connected with a feeding weighing device, the feeding weighing device is connected with a constant-pressure tank, and the constant-pressure tank is connected with a carbon nano tube storage tank; the invention discloses a device and a process method for directly electrifying and heating a carbon nano tube material in a reactor and then continuously purifying carbon nano tubes by adopting chlorine or hydrogen chloride gas. According to the continuous industrial purification device, graphite is adopted as an inner container of a reactor, a pouring material frame is combined, carbon nano tubes in the reactor are directly powered on, and acid gas and granular carbon nano tubes are used for reaction purification.

Owner:甘海半导体材料(上海)有限公司 +1

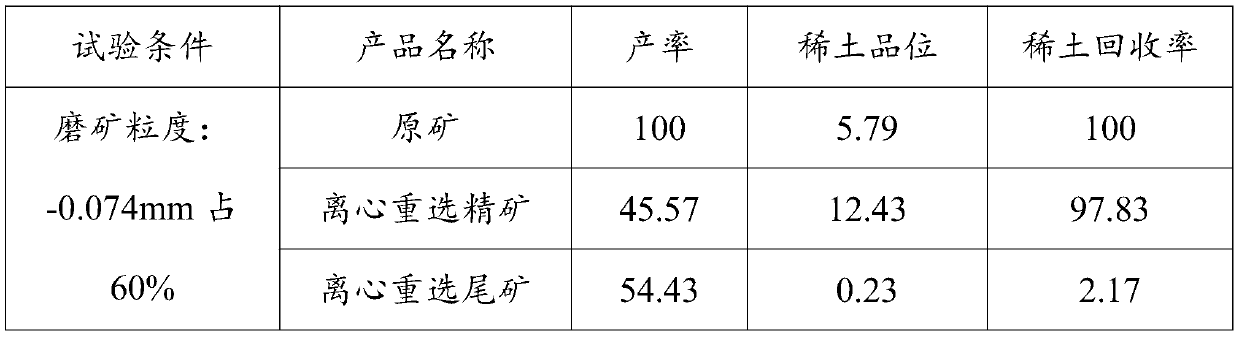

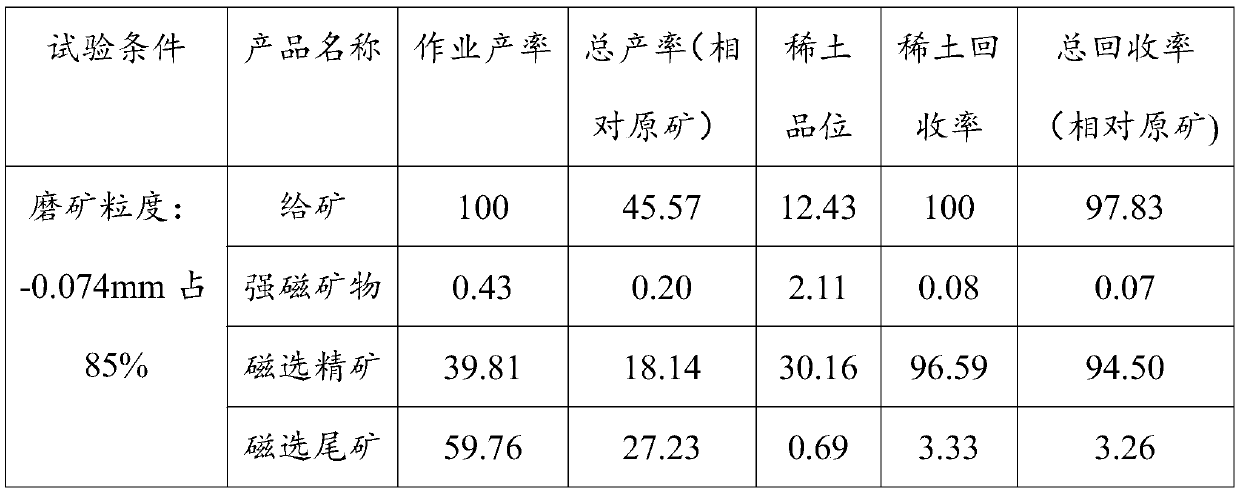

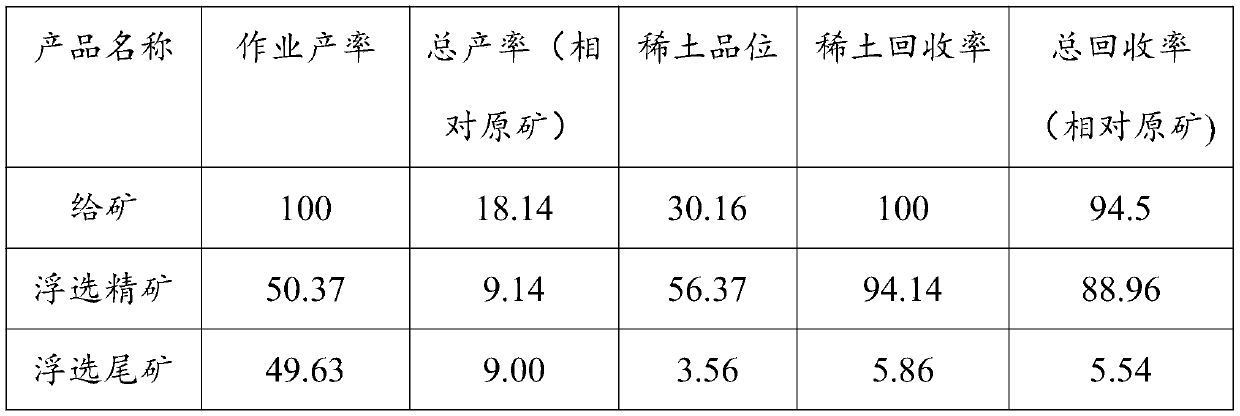

Beneficiation method applied to superconduction magnetic separation of rare earth ore

InactiveCN111346742AReduce the amount of oreReduce volumeHigh gradient magnetic separationCentrifugesMining engineeringWater resources

The invention discloses a beneficiation method applied to superconduction magnetic separation of a rare earth ore, and aims to solve the technical problems of higher economical loss and resource wastecaused by lower recovery rate of a rare earth resource in a traditional rare earth beneficiation process. The substantial process of the beneficiation method is as follows: firstly, a raw ore of therare earth ore is crushed and grinded; the tailing discarding is performed on the rare earth ore in advance by centrifugal reselection; then, a reselected concentrate is grinded, and a superconductionmagnetic separator is used for superconduction weak magnetic separation to remove high-magnetism mineral impurities; then, superconduction strong magnetic separation is performed to obtain a rare earth rough concentrate; and finally, flotation is performed on the rare earth rough concentrate to obtain a high-grade rare earth concentrate. The beneficiation method greatly improves the sorting precision and efficiency, and reduces consumption of a total flotation medicament and consumption of a water resource through a breakthrough-developed reselection-superconduction magnetic separation-flotation process, so that the energy consumption and the operation cost are reduced, efficient sorting and utilization of the rare earth resource are implemented, and the grade and recovery rate of the rare earth ore are greatly improved.

Owner:JIANGXI UNIV OF SCI & TECH

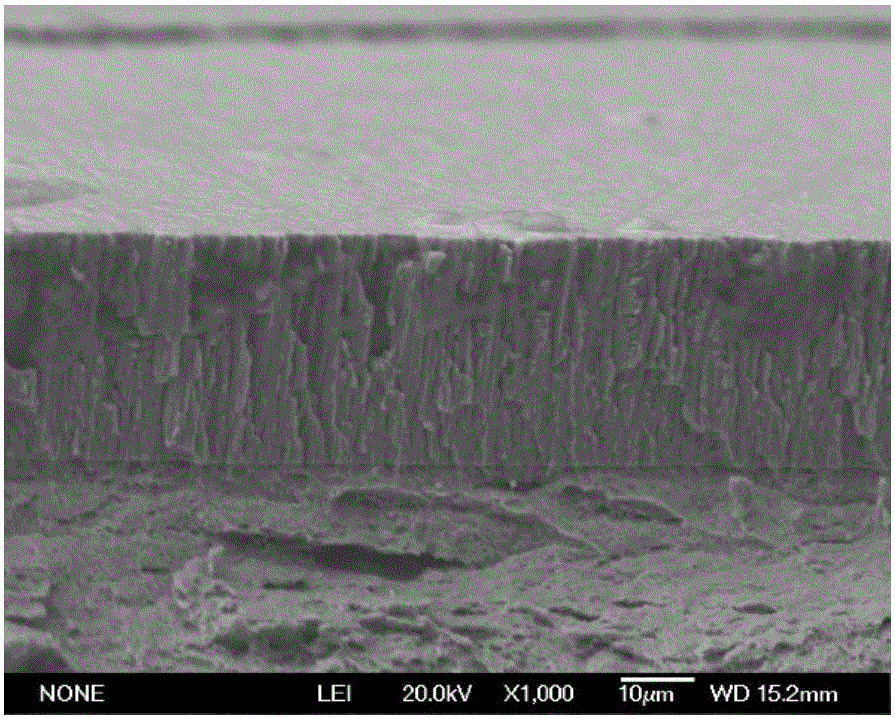

Preparation method of FeCrAl cladding layer on molybdenum alloy matrix

ActiveCN105862003APrecise adjustment of coating compositionWill not oxidize and volatilizeVacuum evaporation coatingSputtering coatingIon bombardmentAlloy

The invention discloses a preparation method of a FeCrAl cladding layer on a molybdenum alloy matrix. The molybdenum alloy matrix is cleaned and dried and then placed into a vacuum chamber of magnetron sputtering ion plating equipment, a target material at least comprises a 3161 stainless steel target, a pure chromium metal target and a pure aluminum metal target, the vacuum chamber is vaccumized, then, ion bombardment cleaning is performed on the molybdenum alloy matrix, a chromium bottom coating is deposited on the surface of the molybdenum alloy matrix after cleaning is performed, and finally a FeCrAl cladding layer is deposited on the chromium bottom coating. The preparation method has the advantages that the technology is simple, rapid and stable, cladding layer components are precisely controlled, and industrial production is easily achieved. The obtained FeCrAl cladding layer is well combined with the molybdenum alloy matrix, the structure is compact, and the molybdenum alloy matrix is not oxidized.

Owner:XIAN UNIV OF TECH

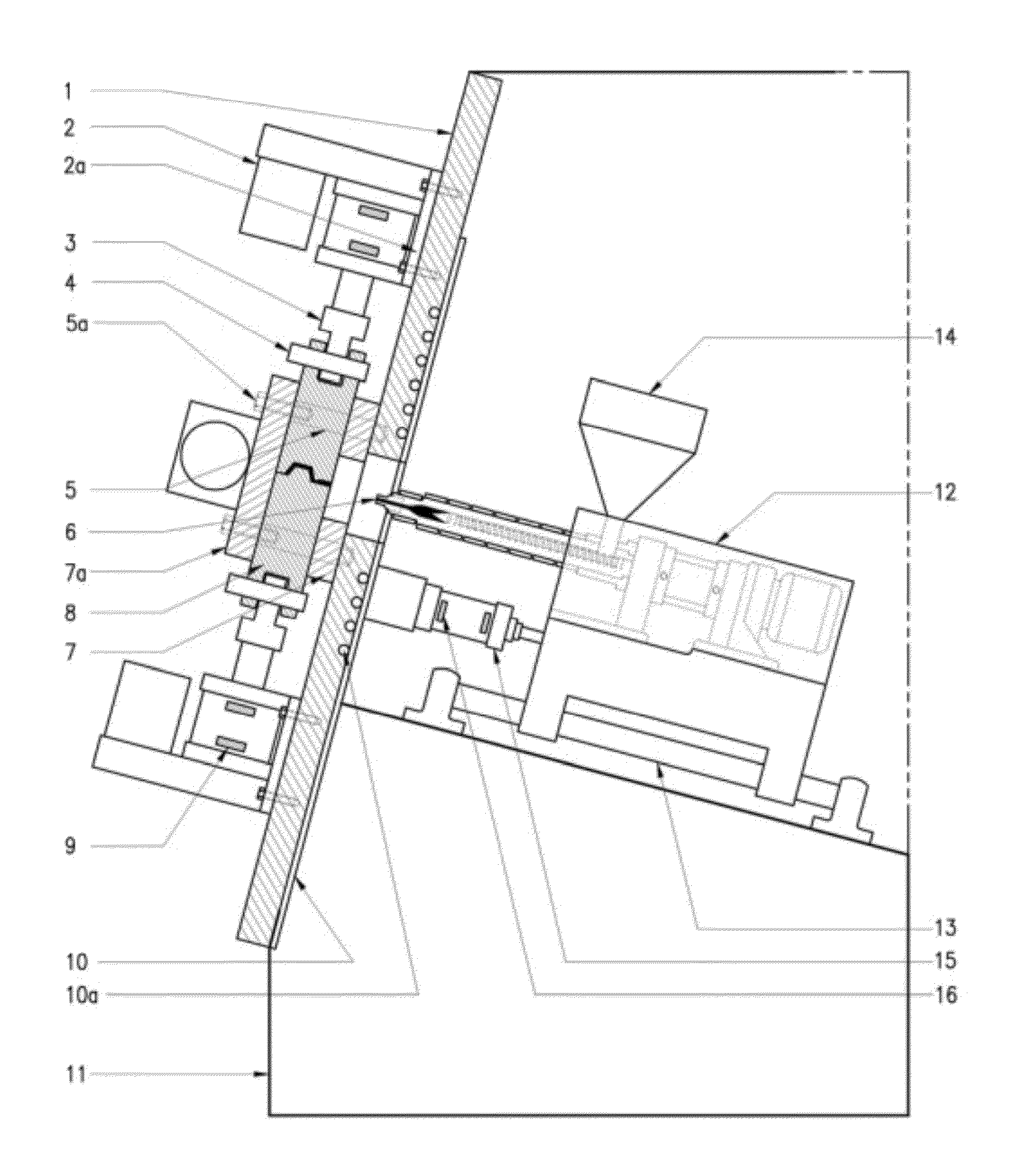

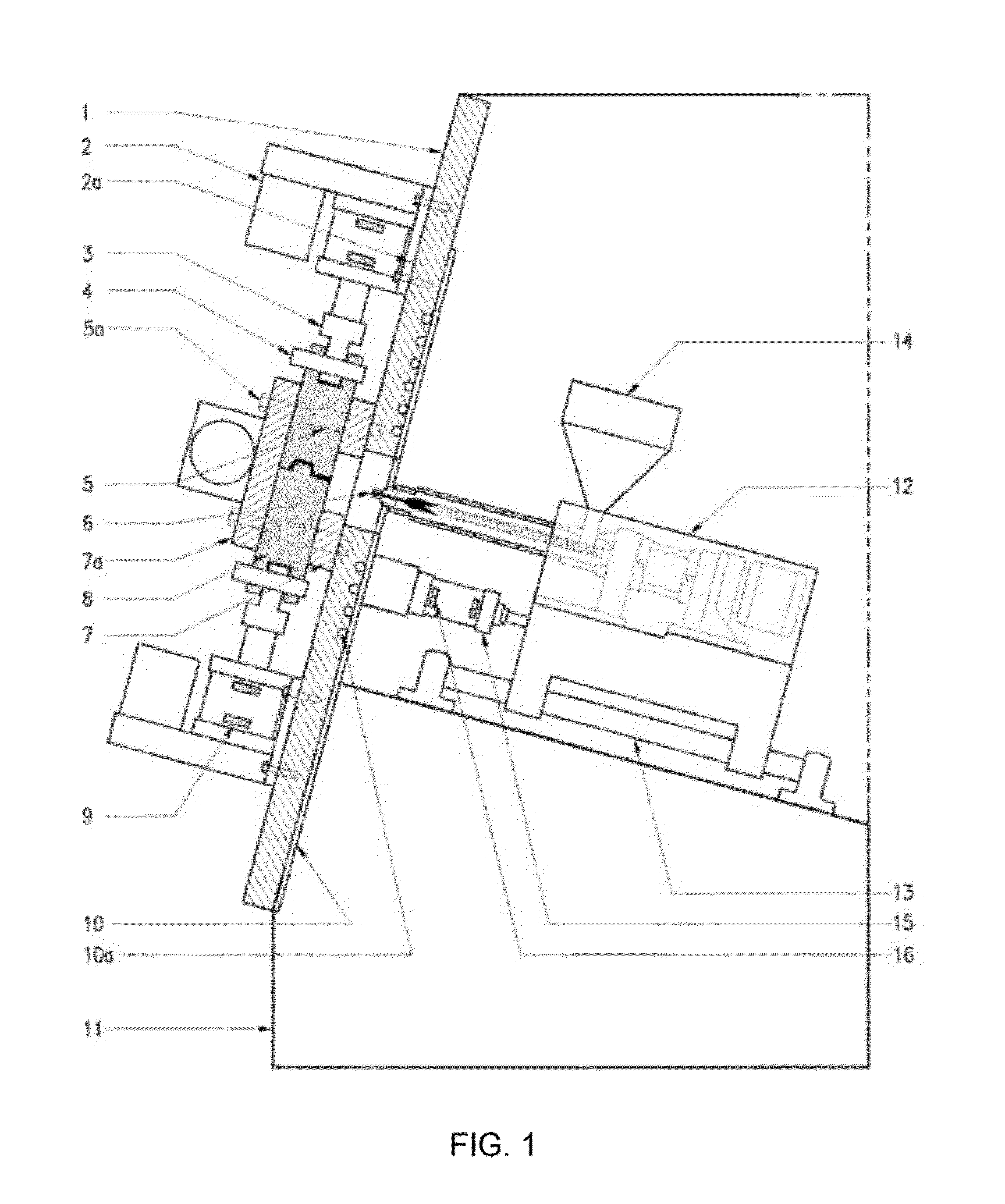

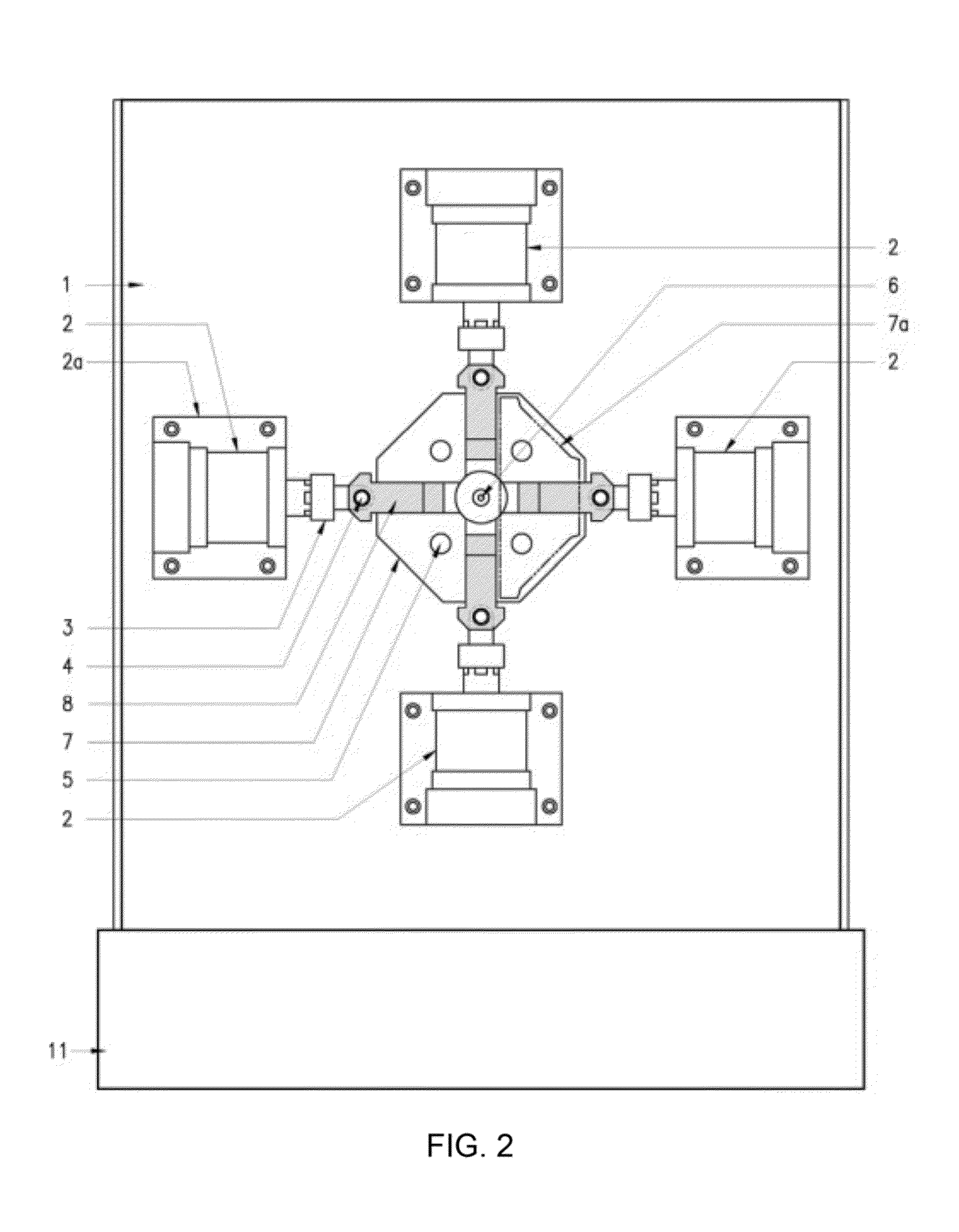

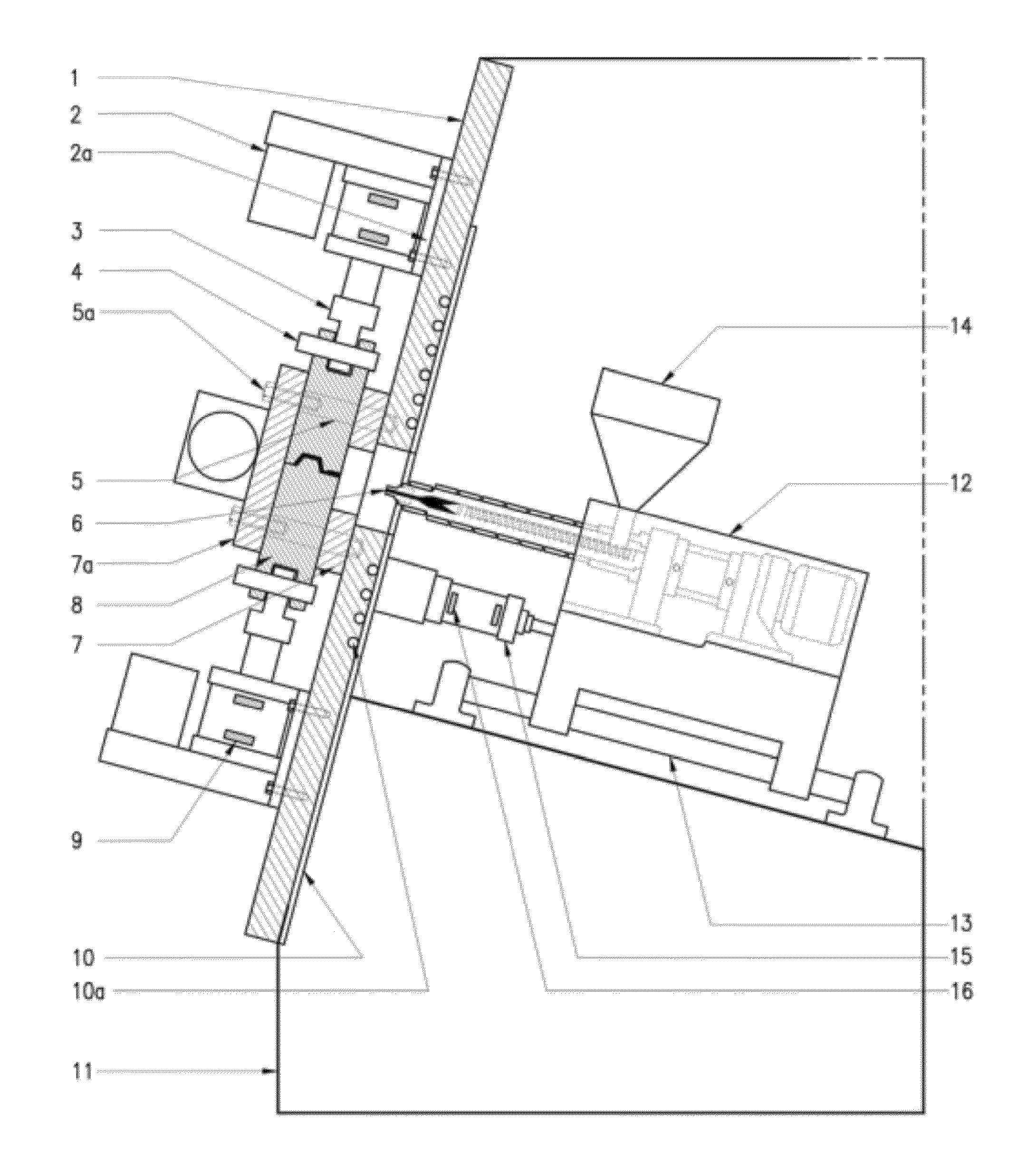

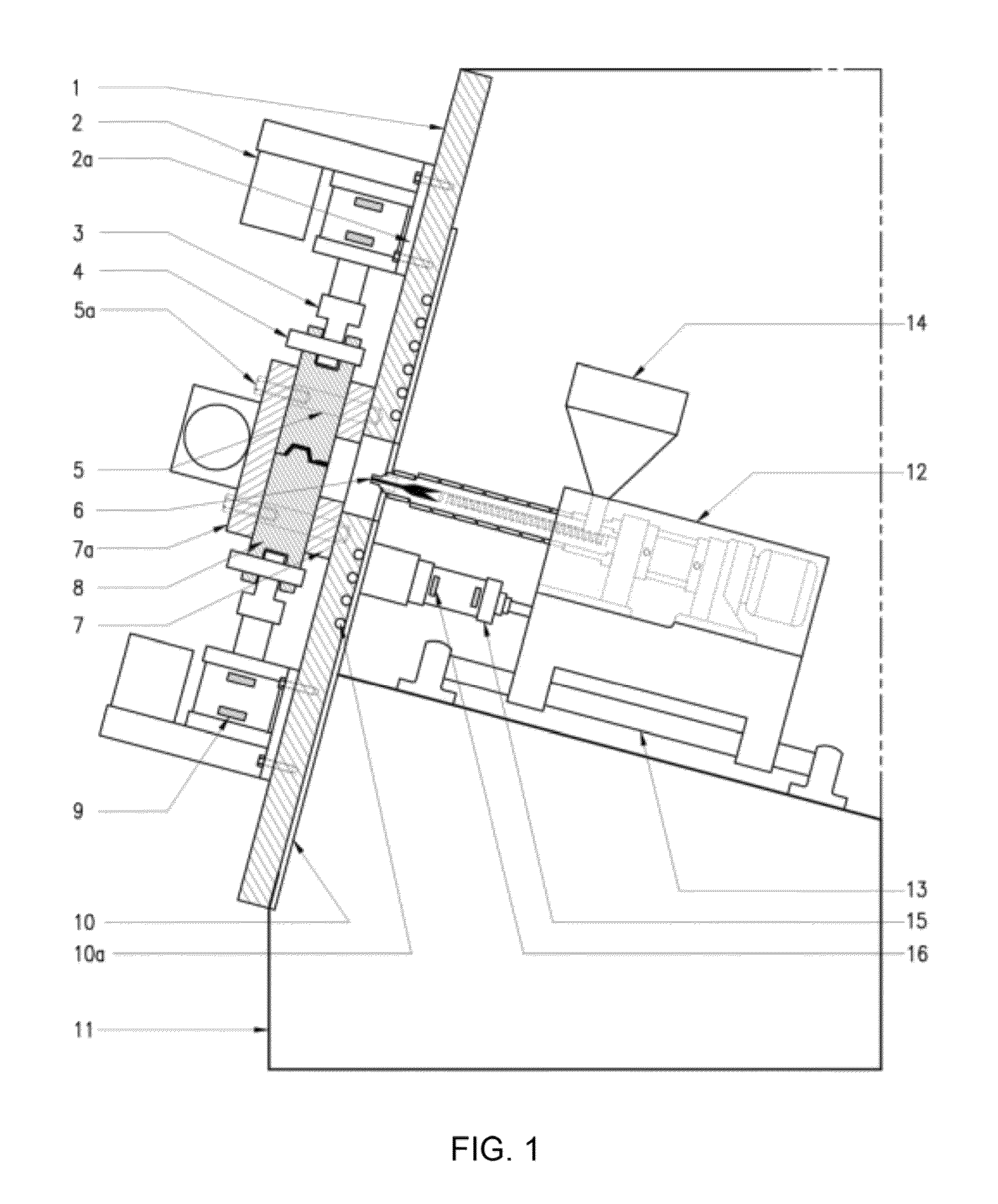

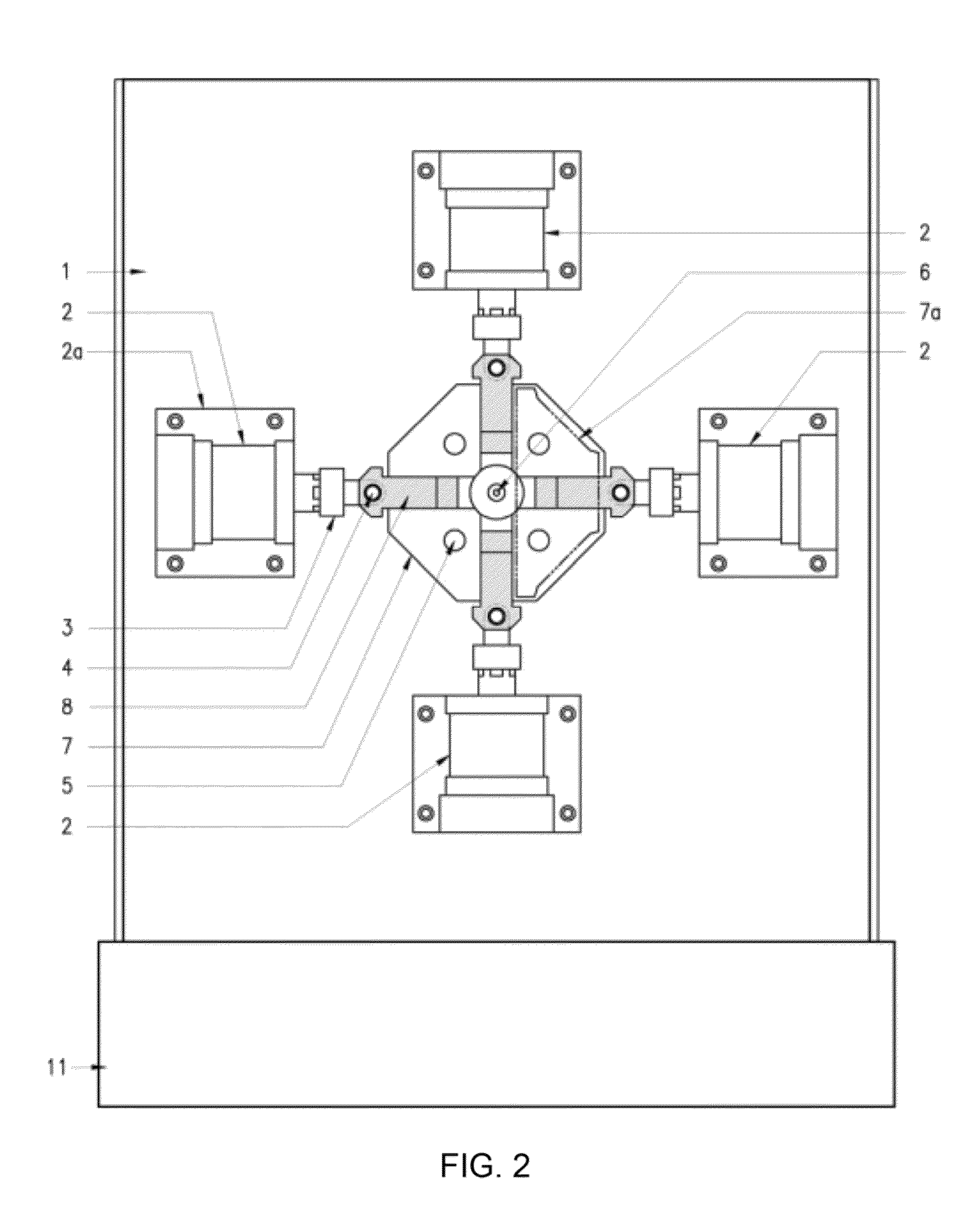

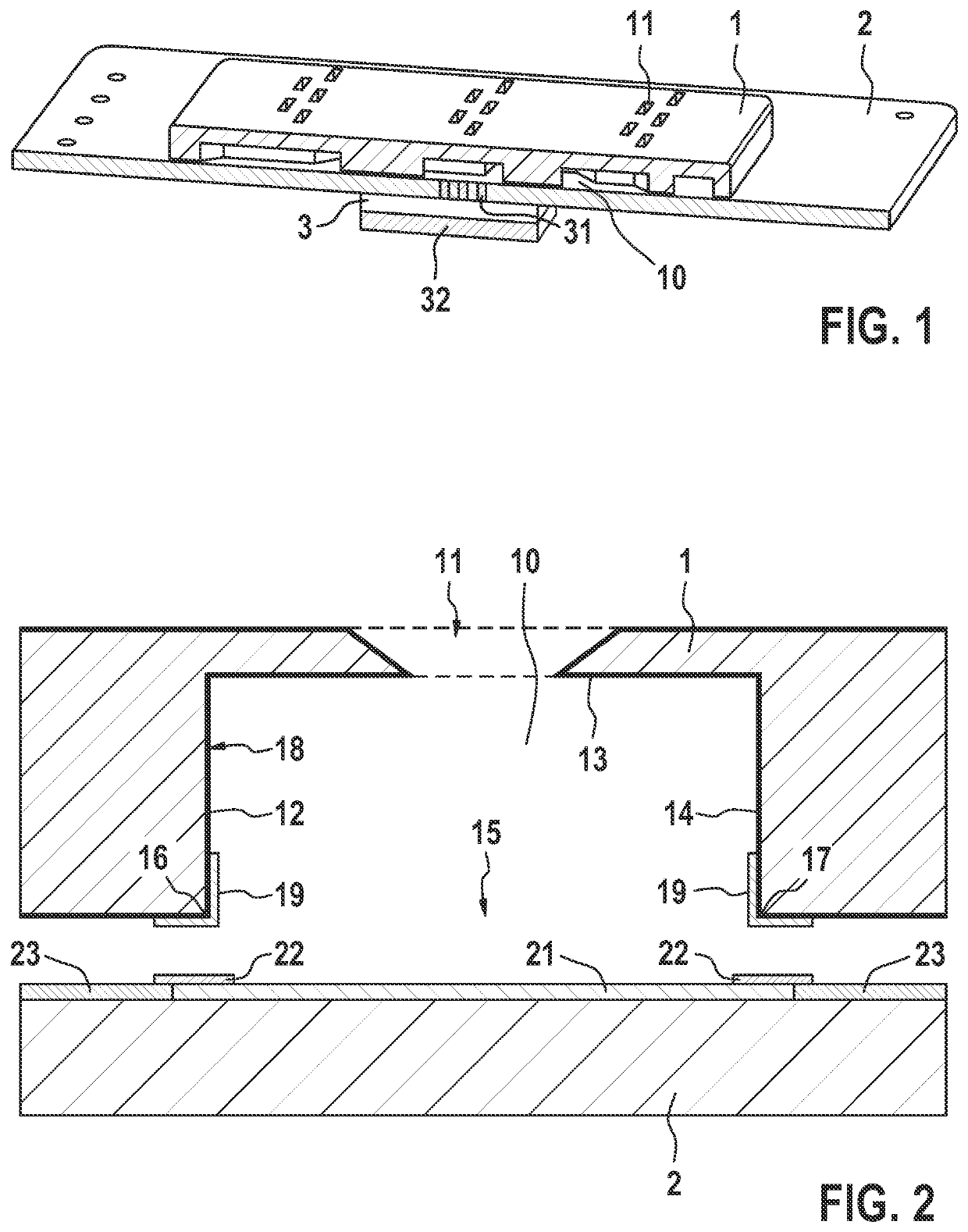

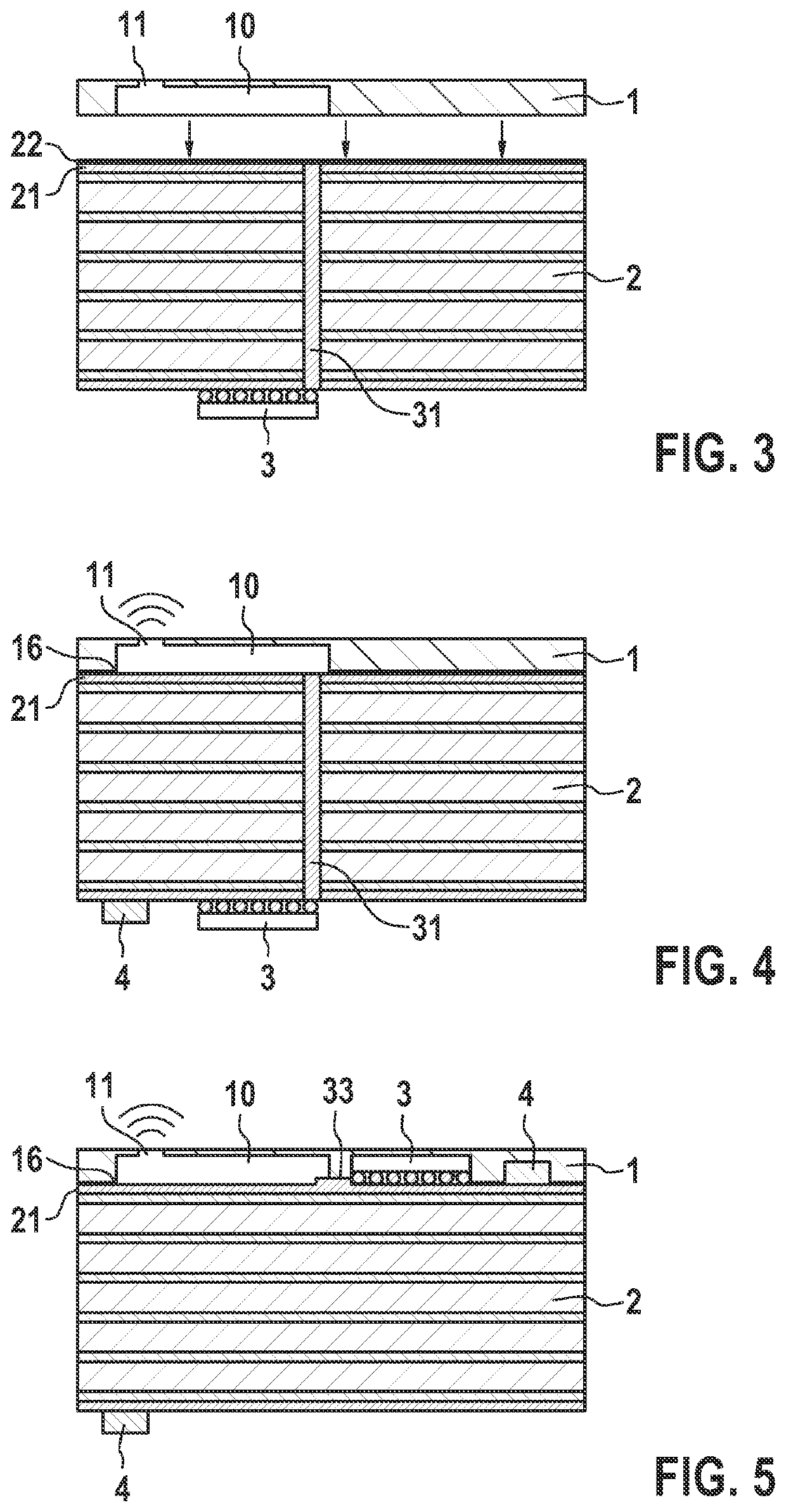

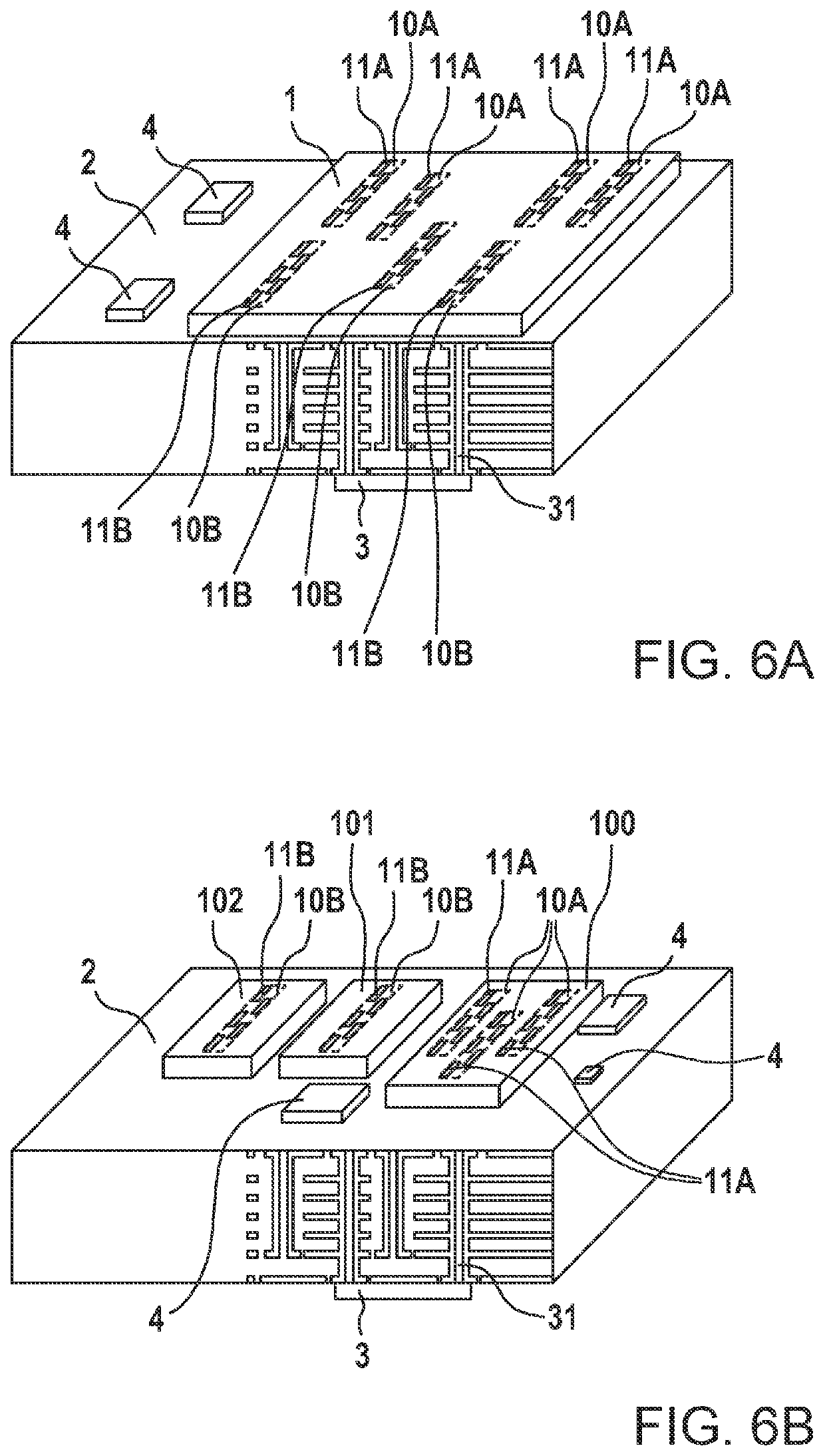

Electrical all-dimensional numerical control injection molding machine

ActiveUS20140141112A1Increase chanceEasy to operateAuxillary shaping apparatusNumerical controlPlastic materials

An electric all-dimensional numerical control injection molding machine is applicable to production of injection products with high precision and complex three-dimensional shapes. The machine comprises a machine base, a main board, four sets of electric mould guiding devices, a cross-shaped chute mould assembly, and an injection device assembly. The electric mould guiding devices are mounted on a front face of the machine. A slider mould is disposed in a chute of a cross-shaped mould base, is connected to a shaft of an electric driver, and implements mould opening and closing functions by means of linear movement of the shaft of the electric driver. An injection system of the machine is used for injecting plasticized, fused, and homogenized plastic materials into a mould cavity of the mould.

Owner:LIU JUN

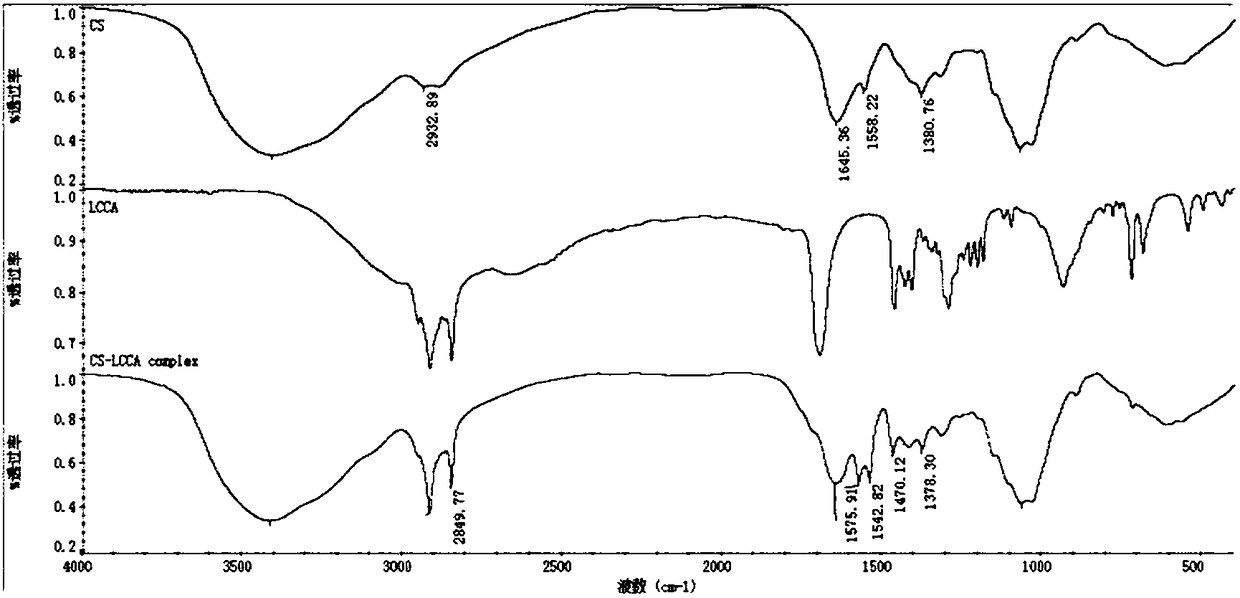

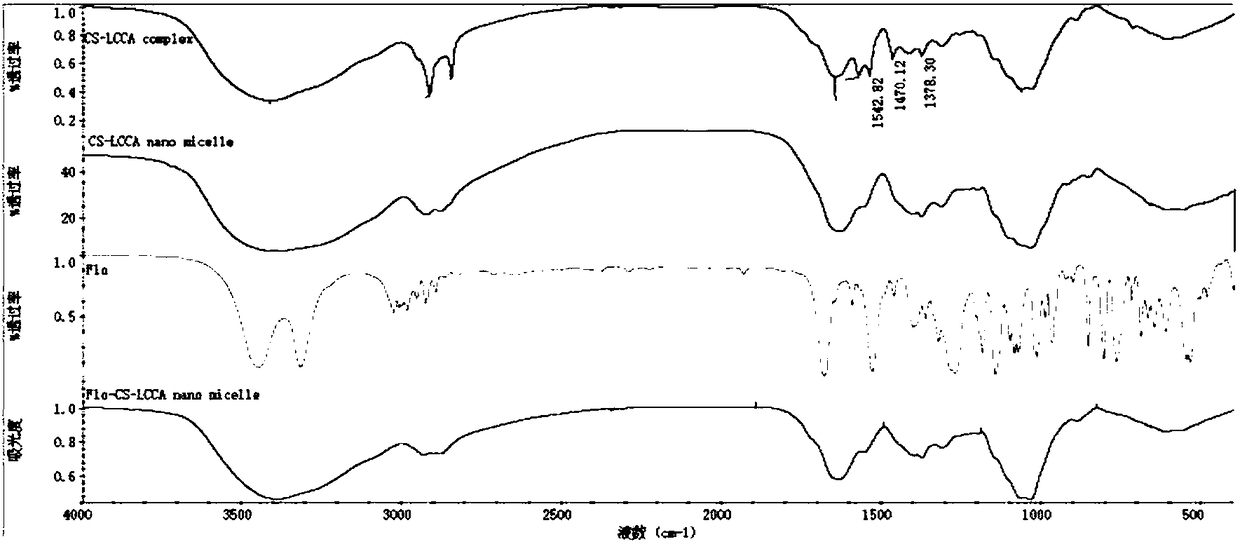

Method for preparing florfenicol-chitosan/long-chain carboxylic acid nano-micelle freeze-dried powder

InactiveCN108379593AGood curative effectReduce adverse reactionsAntibacterial agentsPowder deliveryFreeze-dryingCarboxylic acid

The invention discloses a method for preparing florfenicol-chitosan / long-chain carboxylic acid nano-micelle freeze-dried powder. The method comprises the following steps of (1) dissolving to obtain asolution I of chitosan derivatives; 2) dissolving the long-chain carboxylic acid to prepare a solution II; (3) mixing the solution I and the solution II, adding a catalyst, controlling the pH of a system, and reacting under ultrasonic conditions to obtain a mixing solution of the chitosan-long-chain carboxylic acid self-assembled nano-micelle and the catalyst; (4) making the mixing solution subjected to centrifugation, dialysis treatment, freeze-drying and washing to obtain the chitosan-long-chain carboxylic acid nanomicelle; (5) mixing the chitosan-long-chain carboxylic acid nano-micelle withflorfenicol under the ultrasonic conditions, and filtering and drying to obtain a solid product of the florfenicol-chitosan / long-chain carboxylic acid nano-micelle. The method has the advantages of convenient operation, stability, abundant raw material sources and the like. The self-assembly and ultrasonic pulverization method is adopted, so that the micelle is more dense and the performance is more stable, and the economic development potential is good.

Owner:QINGDAO UNIV OF SCI & TECH

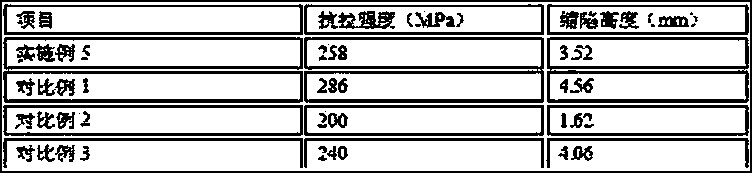

Modifier for thin-wall and high-strength gray cast iron and melting method thereof

ActiveCN108642366AReduce manufacturing costStable productionProcess efficiency improvementSolubilityManganese

The invention discloses a modifier for thin-wall and high-strength gray cast iron and a melting method thereof. The modifier comprises the following components with contents in percentage by weight: 3.0-8.0% of rare earth, 15.0-30.0% of silicon, 10.0-18.0% of chromium, 1.0-4.0% of zirconium, 7.0-14.0% of manganese, 0.2-1.5% of calcium, the balance iron and 24.5-63.8% of inevitable trace elements.The modifier is low in melting point, high in solubility, and not liable to form hard spots; the components are uniform and not liable to generate segregation after being melted, and the casting is stable in quality; the particle sizes of the modifier used in a tapping ladle are 3-5mm, and the modifier is not liable to be involved into molten slag in the ladle or attached onto the wall of the ladle; the amount of graphite in cast iron can be increased, and the sharp corners of the flake graphite are passivated, so that the mechanical property of the casting is improved; and the modifier obtained by the new modifier melting method meets the strength requirement of high-strength gray cast iron, and reduces the shrinkage performance; and meanwhile, the adding amount of molybdenum-chromium alloy can further be replaced or reduced.

Owner:FIRST TRACTOR

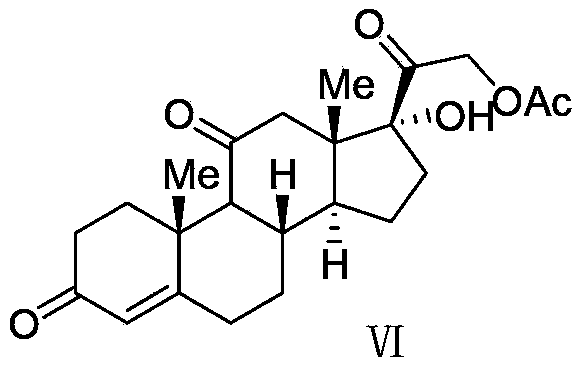

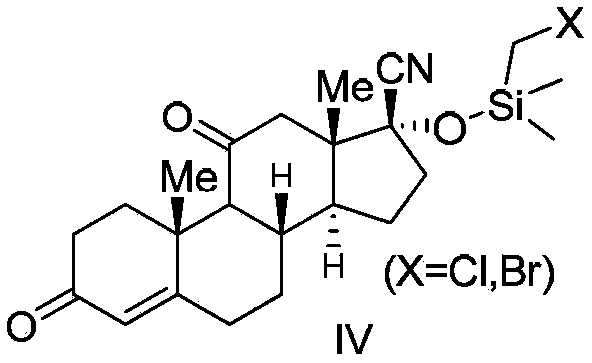

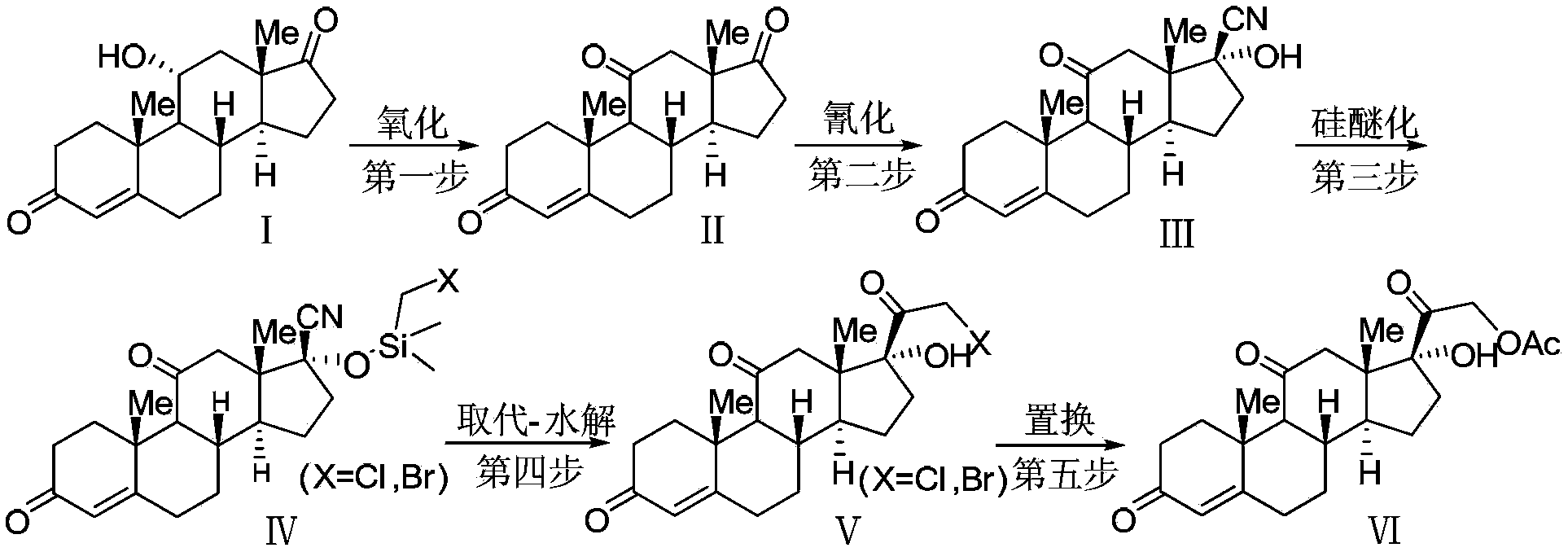

Cortisone acetate intermediate, preparation method and use thereof in preparation of cortisone acetate

InactiveCN104098642ARaw materials are cheap and easy to getSimple and stable processSteroidsSynthesis methodsCortisone acetate

The invention discloses a cortisone acetate synthesis method and an intermediate compound IV used in cortisone acetate synthesis. The cortisone acetate synthesis method has the advantages of cheap and easily obtained raw materials, short route, convenient operation and high yield. The reaction route of the cortisone acetate synthesis method is shown in the specification.

Owner:沈敬山

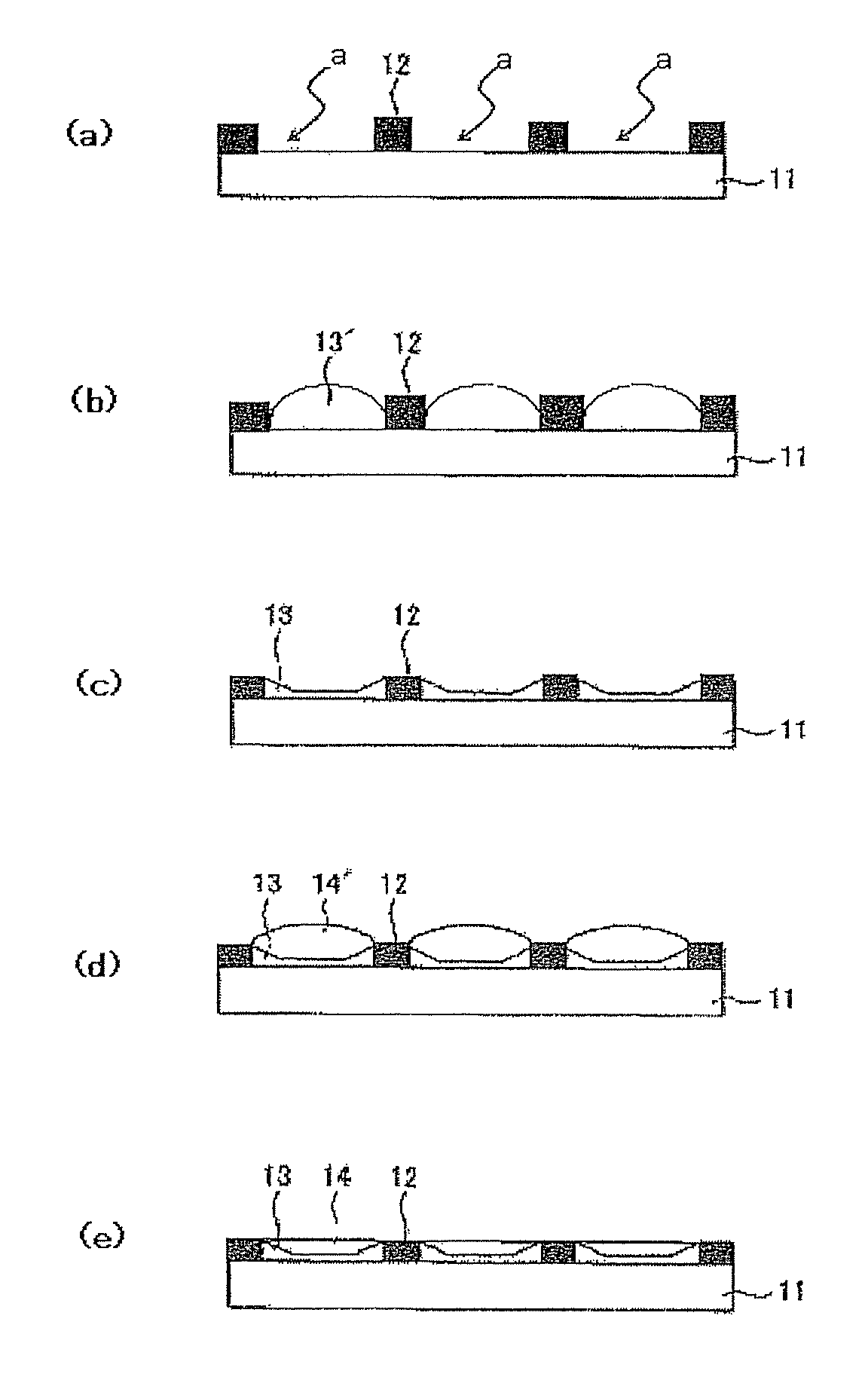

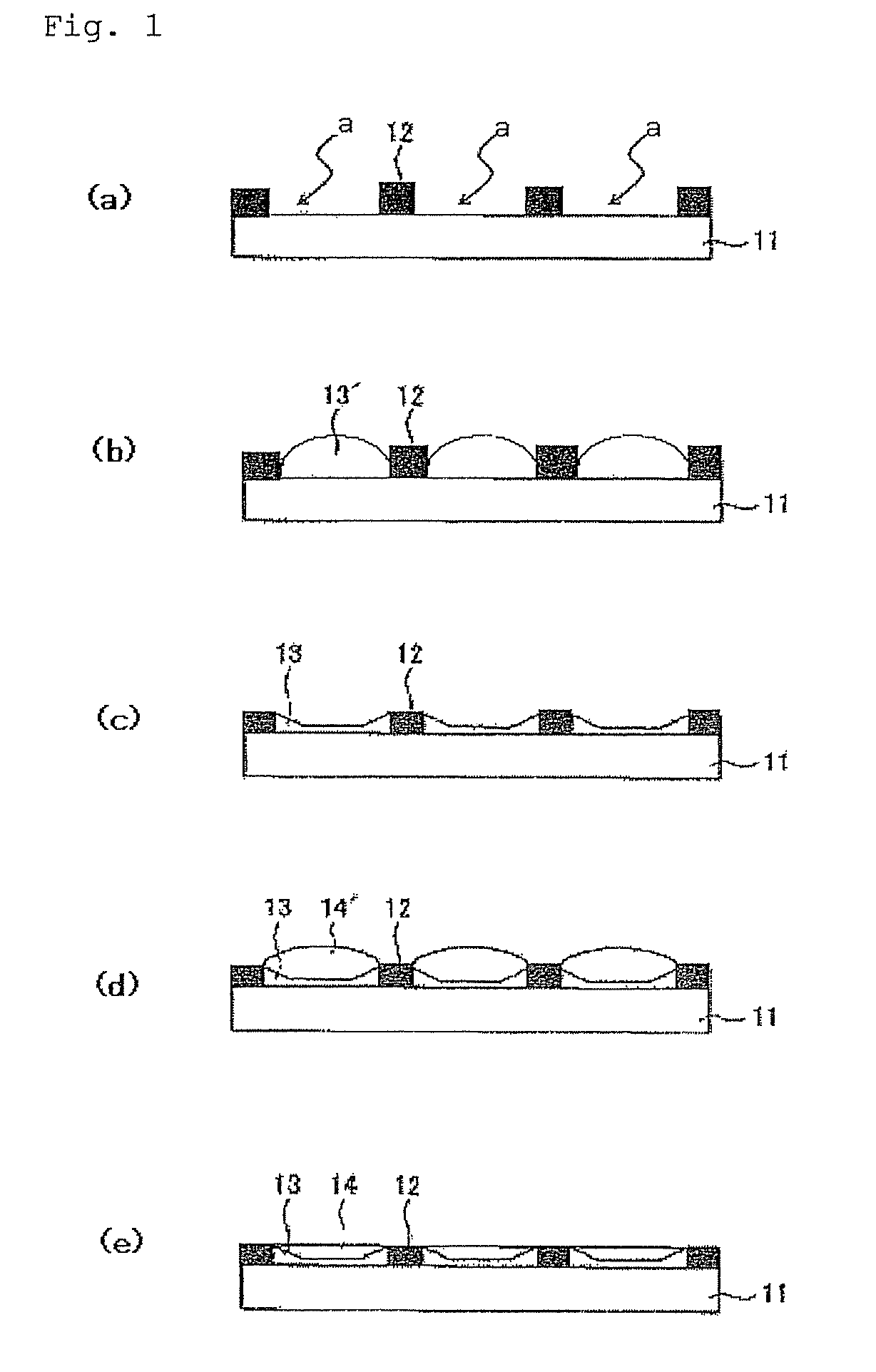

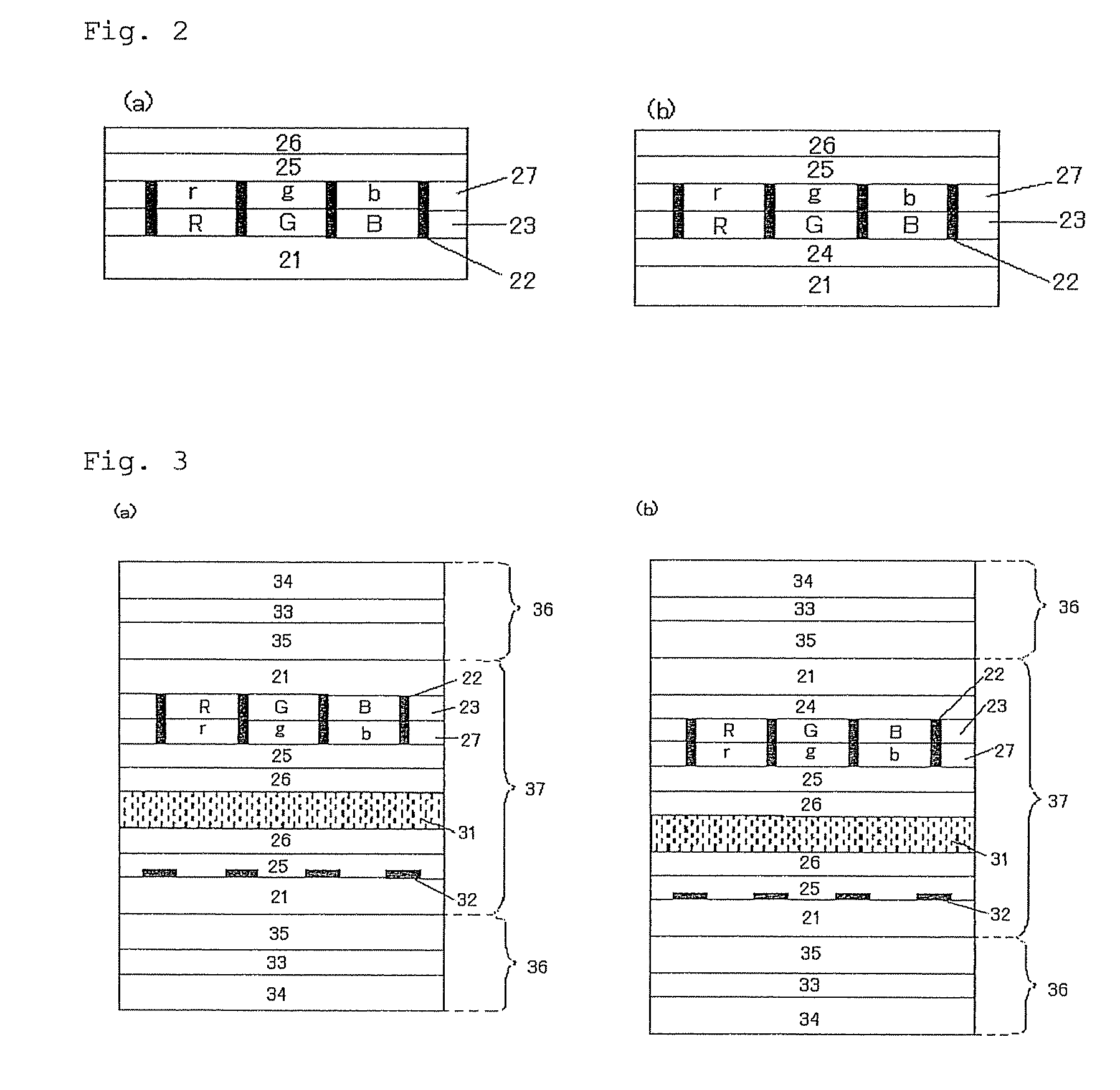

Liquid crystal display device and color film plate, and processes for producing the same

InactiveUS8094271B2Simple and stable processIncrease production capacitySpecial surfacesCoatingsLiquid-crystal displayColor film

A novel liquid crystal display device is disclosed. The liquid crystal display device comprises a first substrate, a second substrate, liquid crystal held between the first substrate and the second substrate, patterned layers divided into fine areas, disposed on the first substrate, comprising at least a patterned color filter layer and a patterned first optically anisotropic layer laminated in the direction of the normal line of the substrate, and a barrier wall disposed at a boundary portion of the adjacent fine areas of the patterned layers.

Owner:FUJIFILM CORP

Preparation method of folium sennae extract for health food

InactiveCN108157962AIncrease contentImprove protectionNatural extract food ingredientsMedicinal herbsSide effect

The invention belongs to the technical field of preparation of drugs, and particularly relates to a preparation method of a folium sennae extract for health food. The preparation method comprises: (1)crushing: crushing a herb folium sennae into coarse powder or fine powder according to the requirement; (2) extracting: carrying out ultrasonic extraction on the crushed herb by using water as solvent; (3) concentrating and impurity removing: carrying out concentrating and impurity removing on the filtrate by using a membrane filtration device, carrying out ultra-filtration treatment with a filtration membrane, and collecting the product concentrated liquid; and (4) drying: carrying out freeze drying on the collected product concentrated liquid, and carrying out pressure reducing freeze drying to obtain the solid powder. According to the present invention, the method has advantages of simple process, low energy consumption, short production period and easily controlled cost, and does notuse organic reagents and acid-alkali solutions so as not to cause environmental pollution; and the obtained folium sennae extract has characteristics of high effective component content and less side-effect component, and can be used for industrial production.

Owner:四川健之源科技有限公司

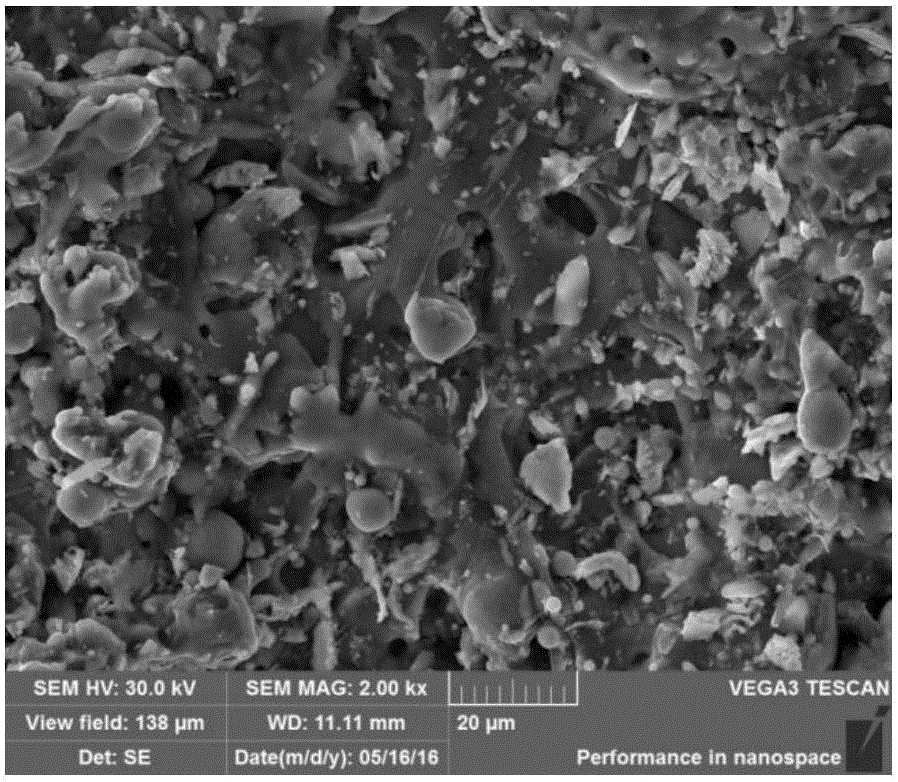

Nano titanium carbide particle reinforced ADC12 aluminum matrix composite and preparation method thereof

The invention discloses a nano titanium carbide particle reinforced ADC12 aluminum matrix composite and a preparation method thereof. The preparation method comprises the steps that nano titanium carbide powder and aluminum powder are put into a ball mill to be subjected to ball milling, and mixed powder composed of the nano titanium carbide and the aluminum is obtained; an aluminum ingot is put into a smelting furnace, aluminum-silicon intermediate alloy is added into the smelting furnace, then, copper is added into the smelting furnace, finally, the mixed powder composed of the nano titaniumcarbide and the aluminum is added into the smelting furnace, a refining agent is added for deslagging and degassing, a molten liquid sample is analyzed and adjusted, chemical elements comprise 9.6-12.0% of silicon, 1.5-3.5% of the copper, 1.0-3.0% of the nano titanium carbide and the balance aluminum, drossing and casting molding are conducted, and a blank needing to be subjected to post-treatment is obtained; and the blank needing to be subjected to post-treatment is put into a heat treatment furnace to be heated and subjected to heat preservation, and then is taken out of the heat treatmentfurnace to be subjected to water quenching, after water quenching, heating and heat preservation are conducted again, and a finished product is obtained. The microstructure of an ADC12 aluminum matrix is perfected, and the mechanical property is improved. The technology is simple, convenient and stable, the preparation cost is low, and environmental friendliness is achieved.

Owner:常熟市恒泰精密金属制品有限公司

Broken-wall saccharomyces cerevisiae culture with bean pulp as base material and preparation method of culture

InactiveCN104489263AHigh content of small peptidesImprove immune activityMicroorganism lysisAnimal feeding stuffBiotechnologySmall peptide

The invention relates to a broken-wall saccharomyces cerevisiae culture with bean pulp as a base material and a preparation method of the culture. The broken-wall saccharomyces cerevisiae culture is prepared by virtue of the following steps: taking the bean pulp as the base material, adding nutritional accessories and inoculating with an active dry yeast, and performing fermentation cultivation, thereby obtaining a high-density saccharomyces cerevisiae culture; next, adjusting the pH value, adding a compound enzyme, a cosolvent and water and preserving heat for enzymolysis and wall breaking; drying to obtain the broken-wall saccharomyces cerevisiae culture of which the content of small peptides is 10%-30% and the content of amino acid nitrogen is 0.5%-2%. The preparation method of the culture comprises preparing the high-density saccharomyces cerevisiae culture, performing enzymolysis and wall breaking, drying the semi-finished product and determining the finished product. The broken-wall saccharomyces cerevisiae culture with the bean pulp as the base material has the advantages of soybean peptides and yeast cultures, and is high in immunocompetence, good in palatability and high in protein digestibility; the culture is a good-quality vegetable protein feed and is capable of taking the place of animal protein feeds such as fish meal and plasma proteins; the preparation method is simple and stable in process, easy to operate and control, suitable for large industrial production and low in cost.

Owner:湖北邦之德牧业科技有限公司

Yeast culture and preparation method thereof

The invention relates to a yeast culture and a preparation method thereof. The preparation method comprises the following steps: carrying out high-density fermentation on white spirit lees used as a base material through yeast strains to obtain yeast high-density fermented white spirit lees, and regulating the pH value of the yeast high-density fermented white spirit lees; adding a yeast autolysis agent for mixing, and adding water for regulating the humidity; then, carrying out heat-insulating cultivation; and finally, drying to obtain the yeast culture with a conventional shape, wherein thecontent of amino nitrogen in the yeast culture is 0.3-1.2%. In the invention, the yeast culture prepared by using the white spirit lees as the base material has the advantages of high amino nitrogen content, low price and wide application range, enables waste materials to be used as resources, and belongs to an energy-saving and environment-friendly advanced industrial feed product. The preparation method of the yeast culture of the invention has the advantages of simple and stable processes, easy operation and control and low cost and is suitable for large-scale industrial production.

Owner:JIANGSU GOSIGN BIO FEED

Molybdenum-containing composite nitride antifriction coating and preparation method thereof

InactiveCN106256922APrecise regulation of periodic structuresApplicable to different application environmentsVacuum evaporation coatingSputtering coatingFriction reductionNitrogen gas

The invention discloses a molybdenum-containing composite nitride antifriction coating. The molybdenum-containing composite nitride antifriction coating is a CrTiAlN / MoN coating with a layered periodic structure and has a modulation period of 3-8nm. The invention also discloses a preparation method of the molybdenum-containing composite nitride antifriction coating. The preparation method comprises cleaning and drying a workpiece, putting the workpiece into a vacuum chamber, carrying out vacuum-pumping, feeding argon into the vacuum chamber, carrying out ion bombardment cleaning, feeding nitrogen into the vacuum chamber, carrying out coating deposition and taking out the workpiece after a temperature in the vacuum chamber is reduced to the room temperature. The molybdenum-containing composite nitride antifriction coating has a layered periodic structure and the layered periodic structure guarantees high hardness and high bonding strength of the coating, is conducive to lubrication phase molybdena formation in friction wear and realizes coating lubrication and friction reduction. Compared with the traditional nitride coating, the molybdenum-containing composite nitride antifriction coating has a lower friction coefficient and a lower specific wear rate in a temperature range of the room temperature to 700 DEG C and can satisfy high speed dry cutting technology requirements on cutter coating wear resistance and thermal properties.

Owner:XIAN UNIV OF TECH

Preparation method of optical colorful polyester film using microwave technique

A process for preparing an optical colored polyester film using microwave technique comprises the following steps: microwave dyeing treatment by passing a polyester film through a disperse dye suspension with steady water phase in a dye-pool comprising a microwave generator; rinsing with water; rinsing with solvent; finally drying treatment, and then uniform optical colored films with various colors are obtained. The optical colored films are used as optical filters or optical protection films and as glass window films for automobile, and domestic and office windows.

Owner:PENG BO +2

A kind of microlattice mismatch quantum well solar cell and its preparation method

ActiveCN106067493BImprove photoelectric conversion efficiencyIncrease currentSemiconductor devicesLattice mismatchDislocation

Owner:ZHONGSHAN DEHUA CHIP TECH CO LTD

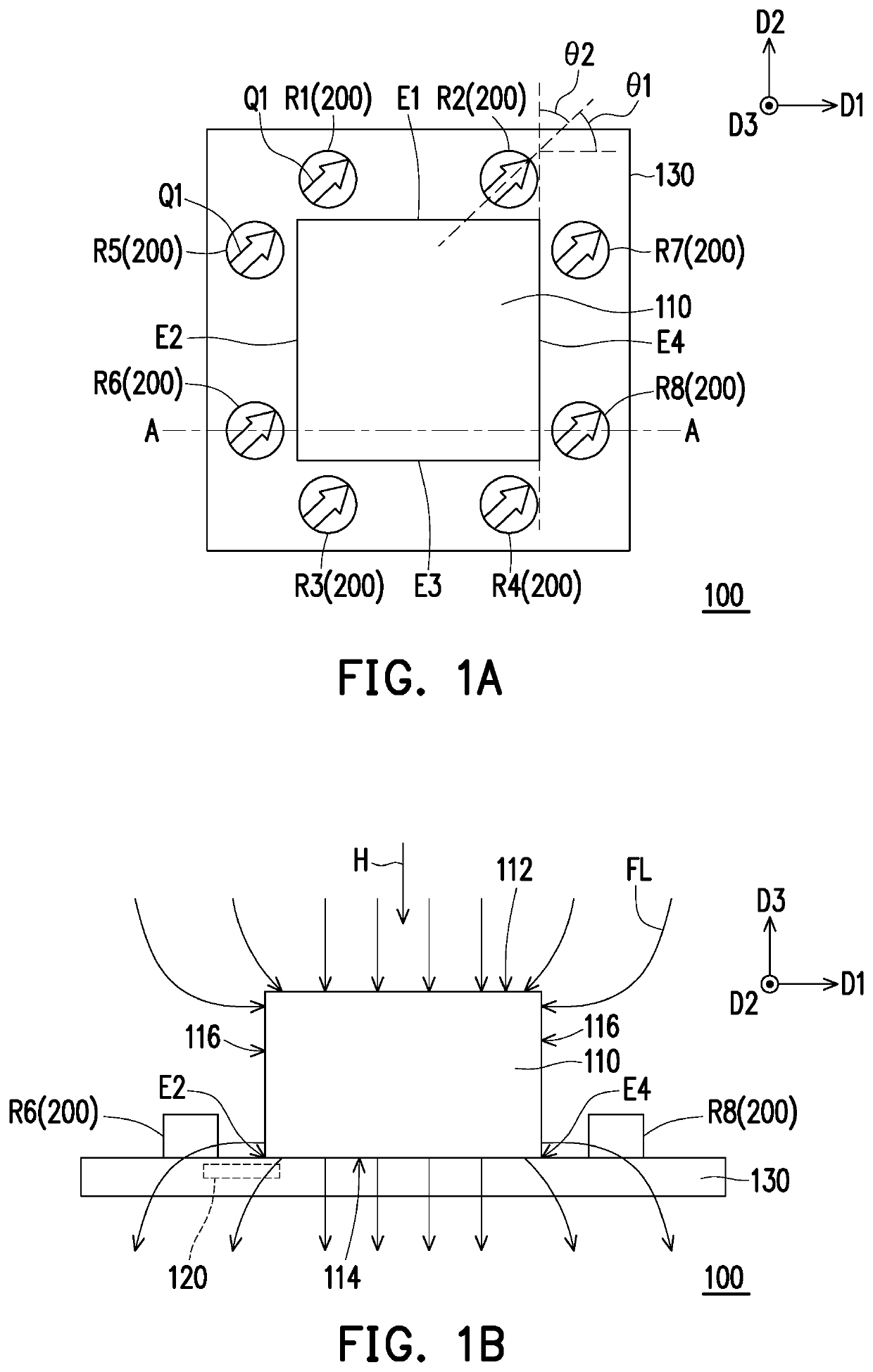

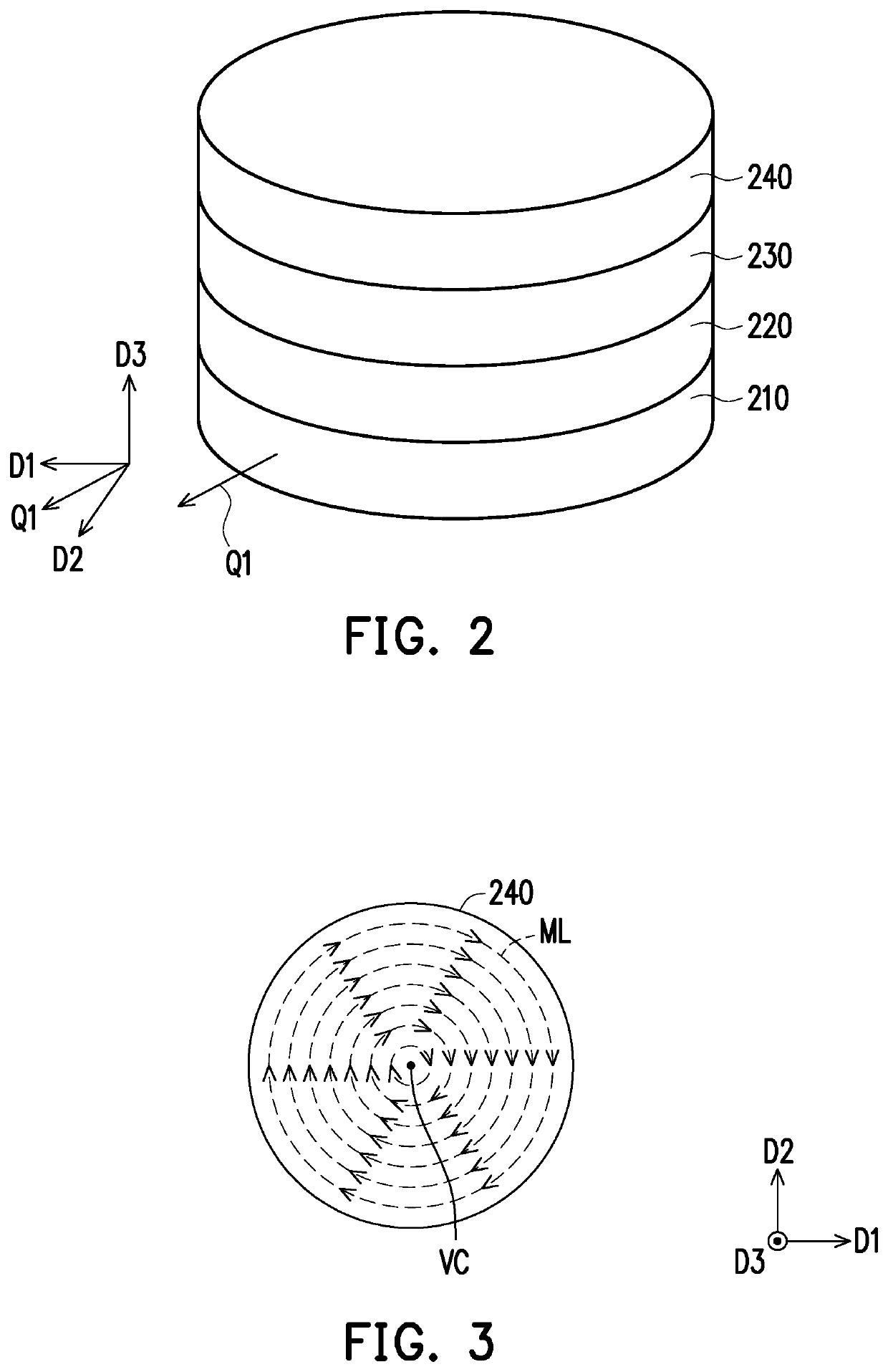

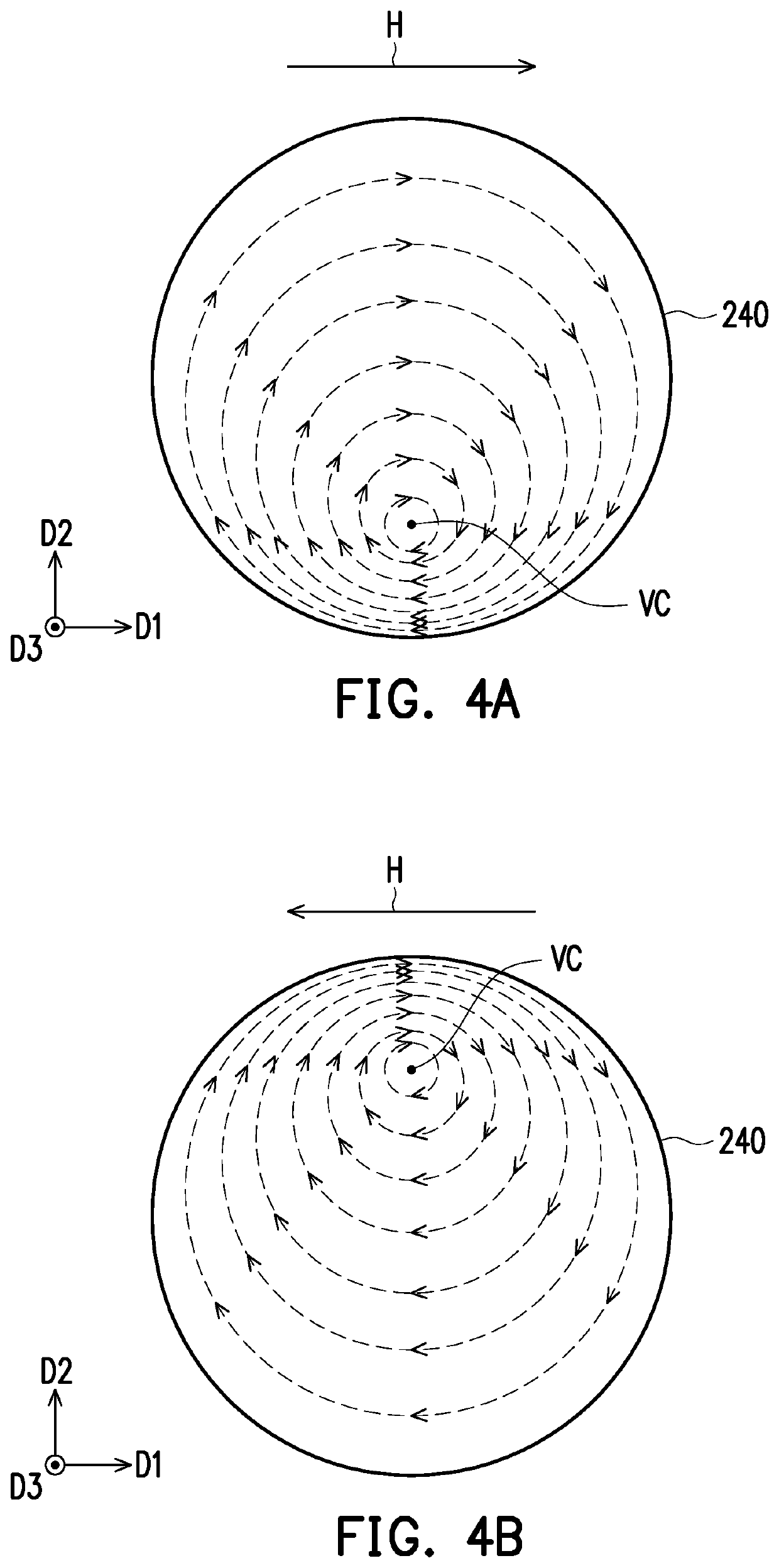

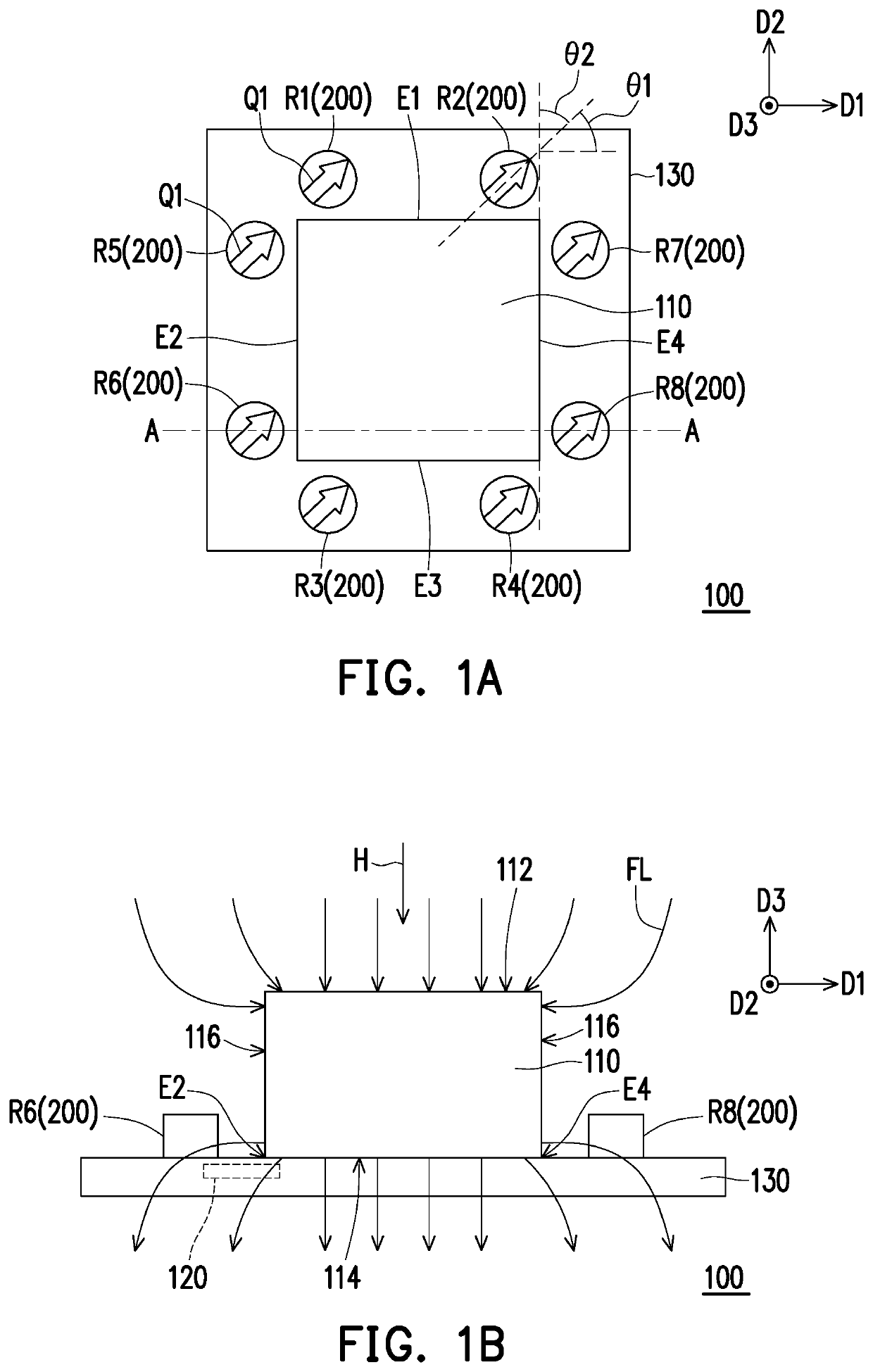

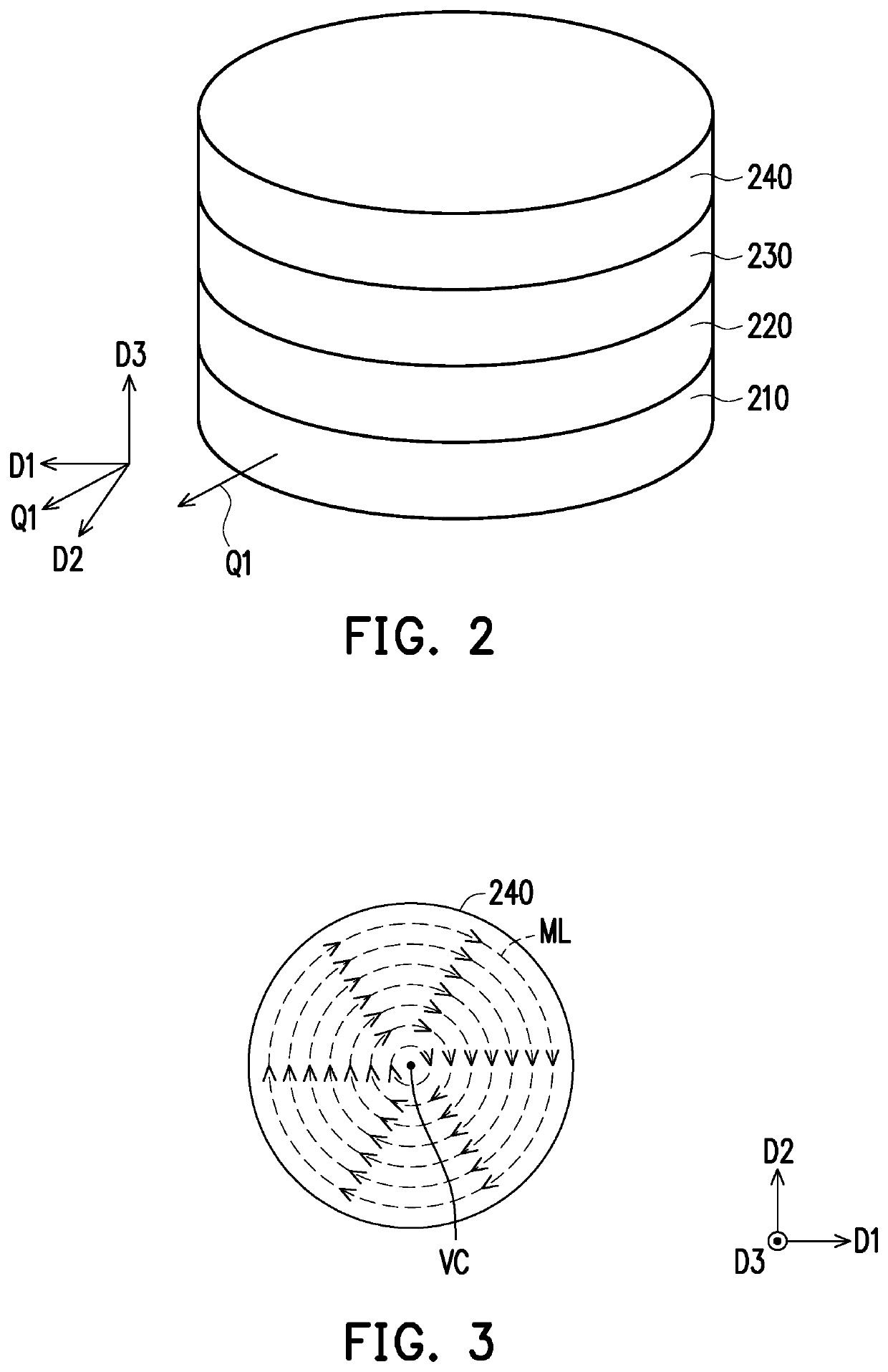

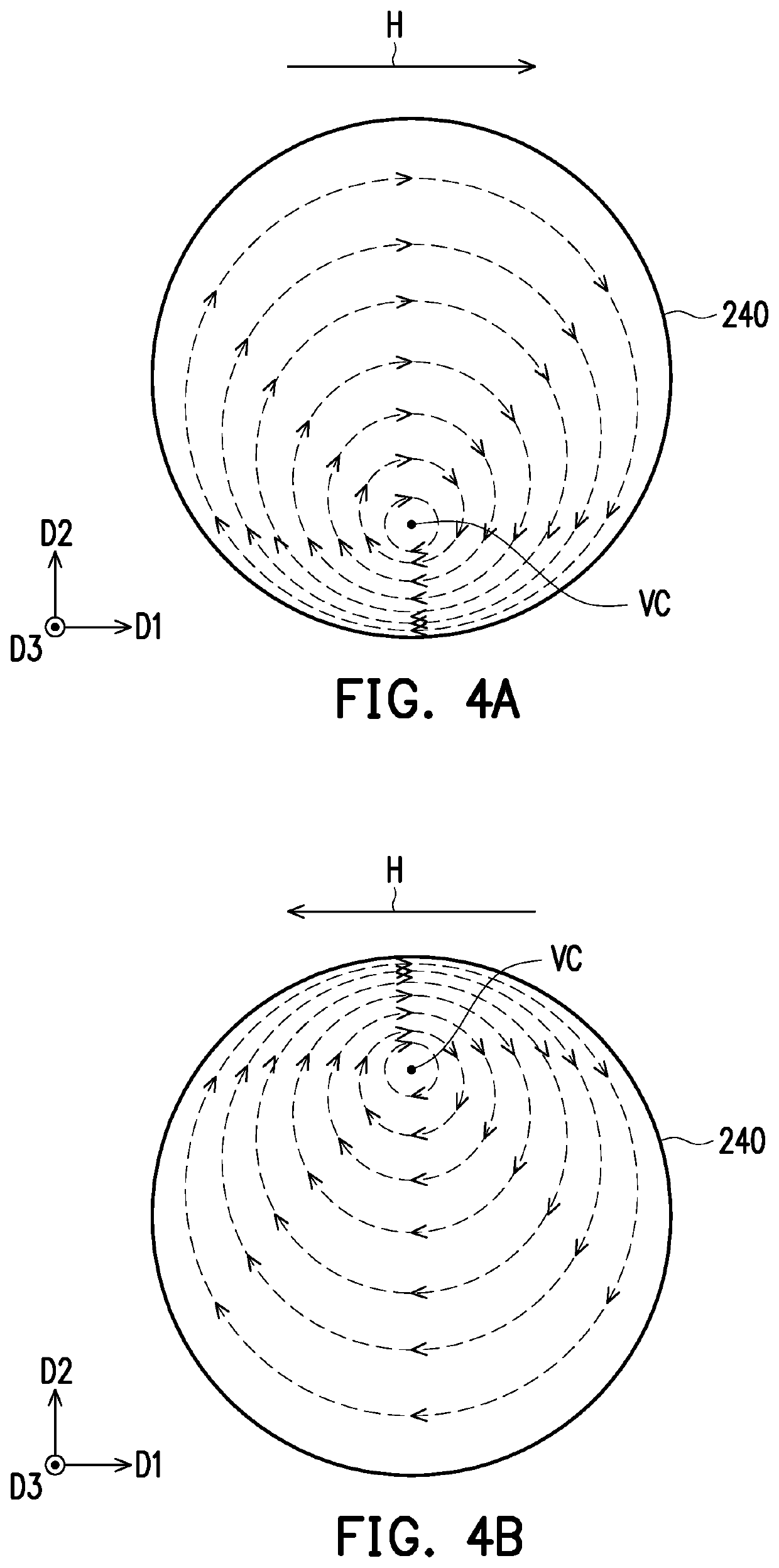

Magnetic field sensing device

ActiveUS20200057119A1Manufacturing process is simple and stableReduce manufacturing costMagnetic sensor arraysMagnetic fluxMaterials science

A magnetic field sensing device including a magnetic flux concentrating module and a plurality of vortex magnetoresistors is provided. The magnetic flux concentrating module has a first side, a second side, a third side and a fourth side, wherein the first side is parallel to the third side, the second side is parallel to the fourth side, and the first side is not parallel to the second side. The vortex magnetoresistors are disposed beside the first to the fourth sides. The vortex magnetoresistors have a same pinning direction. The pinning direction is inclined with respect to the first side and the second side. The vortex magnetoresistors are configured to be connected to form a plurality of different Wheatstone bridges, so as to sense magnetic field components in a plurality of different directions, respectively.

Owner:ISENTEK INC

Pharmaceutical composition containing sitagliptin or its pharmaceutically acceptable salt and its preparation method and use

ActiveCN109157522BQuality improvementIncrease contentOrganic active ingredientsMetabolism disorderSitagliptinHydrogen phosphate

The invention relates to a pharmaceutical composition, comprising sitagliptin, its pharmaceutically acceptable salt and / or the hydrate of the salt, and anhydrous calcium hydrogen phosphate. The pharmaceutical composition is further used for the preparation of solid preparations, especially tablets by direct compression. By selecting the pharmaceutical composition of the present invention, especially selecting specific anhydrous calcium hydrogen phosphate as a raw material, it is possible to significantly improve the composition of sitagliptin, its pharmaceutically acceptable salt and / or the hydrate of the salt as the active ingredient. The quality control method of the pharmaceutical composition can even significantly improve the generation of related impurities in the pharmaceutical composition, so as to improve the stability of the pharmaceutical composition and related dosage forms.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD

Electrical all-dimensional numerical control injection molding machine

An electric all-dimensional numerical control injection molding machine is applicable to production of injection products with high precision and complex three-dimensional shapes. The machine comprises a machine base, a main board, four sets of electric mould guiding devices, a cross-shaped chute mould assembly, and an injection device assembly. The electric mould guiding devices are mounted on a front face of the machine. A slider mould is disposed in a chute of a cross-shaped mould base, is connected to a shaft of an electric driver, and implements mould opening and closing functions by means of linear movement of the shaft of the electric driver. An injection system of the machine is used for injecting plasticized, fused, and homogenized plastic materials into a mould cavity of the mould.

Owner:LIU JUN

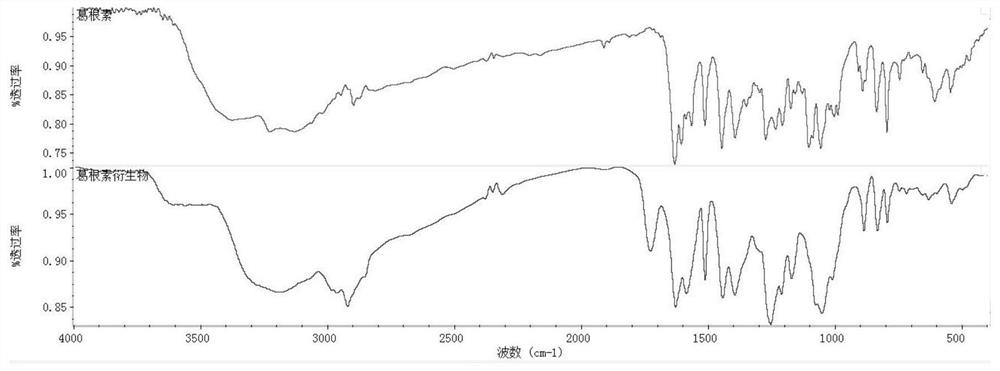

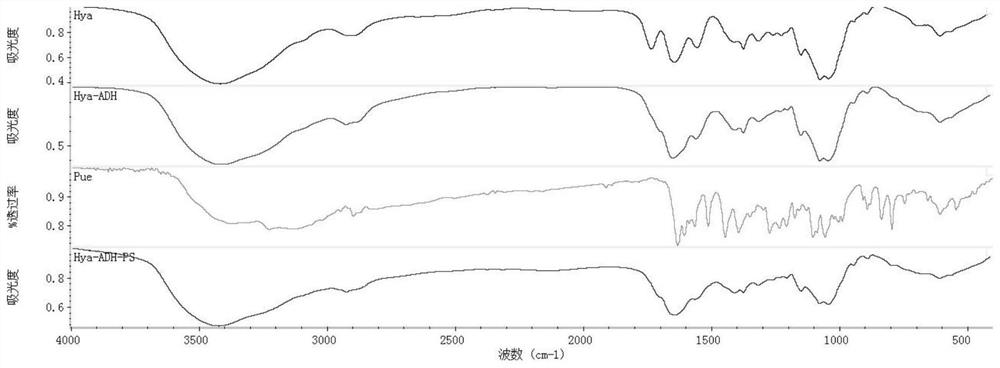

A kind of preparation method of puerarin hyaluronic acid nano-micelle

InactiveCN108635589BGood curative effectReduce adverse reactionsOrganic active ingredientsMetabolism disorderMedicinePuerarin

The invention discloses a preparation method of puerarin and hyaluronic acid nano-micelles. The method comprises the following steps that 1, a solution I of a hyaluronic acid derivative is obtained through dissolution; 2, ADH is dissolved to prepare a solution II; 3, the solution I is added into the solution II drop by drop, the system pH is adjusted, and after reaction, a hyaluronic acid-ADH intermediate is obtained through centrifugal separation and drying; 4, the hyaluronic acid-ADH intermediate and a puerarin derivative are fully dissolved, and then a catalyst is added into the mixture toprepare the puerarin and hyaluronic acid nano-micelles; 5, the puerarin and hyaluronic acid nano-micelles are added into an organic dispersion phase, the puerarin and hyaluronic acid nano-micelles andpuerarin are mixed, dialysis treatment is conducted, and finally, a solid product of the puerarin and hyaluronic acid nano-micelles is obtained. The method has the advantages that operation is convenient, the preparation technology is simple and stable, and the production cost is low; by means of the study, the curative effect of the puerarin is improved, adverse reaction of the puerarin is reduced, and a novel production technology is provided for developing a novel puerarin replacement medicine.

Owner:QINGDAO UNIV OF SCI & TECH

Method for manufacturing a radar sensor

PendingUS20220196792A1Reduce manufacturing costHigh bulk densityAntenna supports/mountingsSemiconductor/solid-state device detailsTransceiverPlastic materials

A method for manufacturing a radar sensor. In the method, a circuit board is provided. A surface of the circuit board is equipped with a radar transceiver. A waveguide structure made of plastic material is provided. Waveguide channels including at least one metallic conductively coated side wall in the waveguide structure and an open side are formed. The waveguide structure is soldered to a surface of the circuit board, the open side being oriented in the direction of the circuit board.

Owner:ROBERT BOSCH GMBH

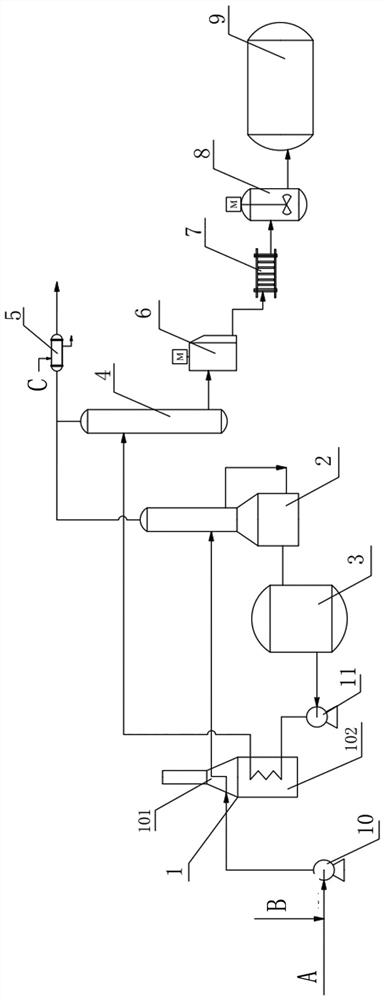

A preparation method and production device for producing fuel oil from bio-heavy oil

ActiveCN109280562BHigh calorific valueProduction environmental protectionPhysical/chemical process catalystsFuelsTube furnaceProcess engineering

The invention discloses a preparation method and a production device for producing fuel oil from biological heavy oil, belonging to the technical field of fuel oil preparation. According to the preparation method of bio-heavy oil production fuel oil of the present invention, the bio-heavy oil production fuel of the present invention is obtained after the bio-heavy oil is heated and evaporated by a tube furnace and an evaporation tower, dehydrated and desalted, and catalyzed esterified, and then added with a coating agent after homogeneous filtration Oil, using the characteristic of high surface tension of the coating agent, coats the homogenized material into multiple small molecular mass substances with the coating agent. The prepared fuel oil has high calorific value, low sulfur and low phenol, low viscosity, low pour point and flash point, the production process is green and environmentally friendly, and the process flow is simple and stable. The production device for producing fuel oil from bio-heavy oil based on the preparation method has simple process flow, stable operation, and has the characteristics of high preparation efficiency, low cost and high safety.

Owner:SHANDONG HENGDAO OIL CHEM

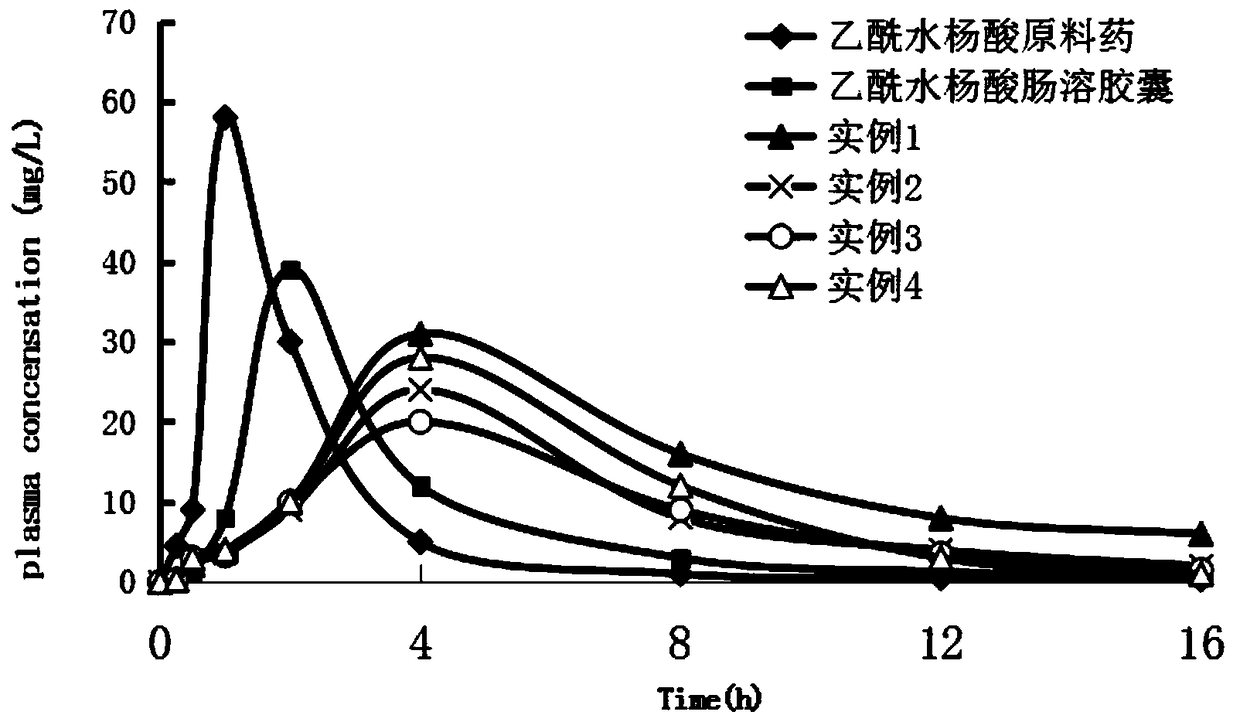

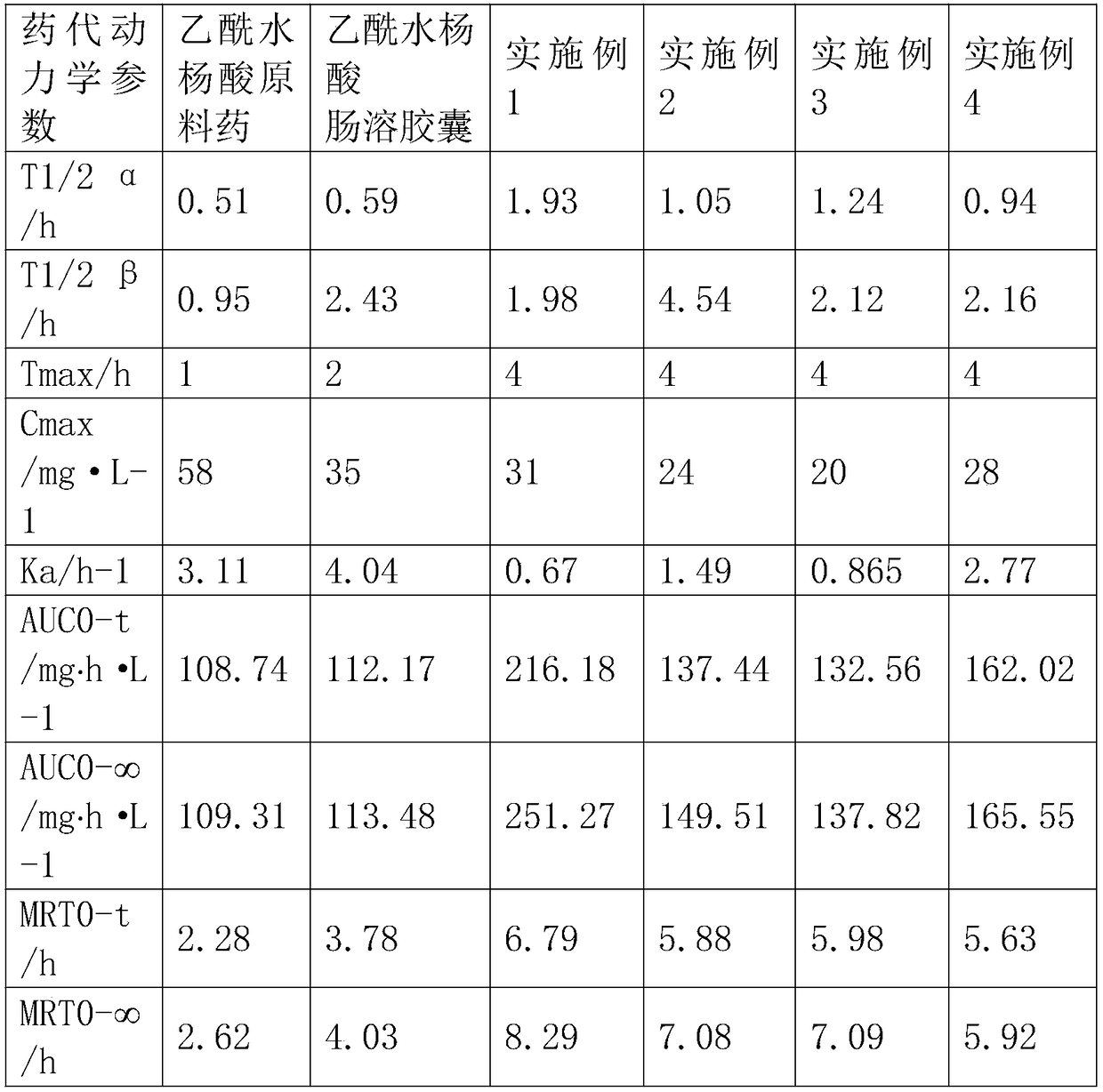

Preparation method of acetylsalicylic acid colon positioning bioadhesion type sustained release capsules

InactiveCN108743565AImprove bioavailabilityReduce adverse reactionsOrganic active ingredientsNervous disorderManufacturing technologyMicrosphere

The invention discloses a preparation method of acetylsalicylic acid colon positioning bioadhesion type sustained release capsules. The preparation method particularly comprises the following steps: (1) dissolving to obtain a medicine sustained release material solution and mixing the medicine sustained release material solution and ASA; (2) pouring the mixture into a disperse phase solution, adding an emulsifier, and performing high-pressure homogenization, complete emulsification and vacuum defoaming; (3) guiding into a spray drying granulating machine to prepare acetylsalicylic acid sustained release powder microspheres; (4) sieving the prepared acetylsalicylic acid sustained release powder microspheres, mixing the sieved acetylsalicylic acid sustained release powder microspheres, carrier auxiliary materials and filling agents uniformly and preparing granules with ethanol as a wetting agent; and (5) performing granulation and low-temperature vacuum drying on the granules, putting into enterosoluble hollow capsules and packaging to obtain the acetylsalicylic acid colon positioning bioadhesion type sustained release capsules. The preparation method has the advantages of convenience in operation, simple, convenient and stable preparation technology, low manufacturing cost and the like. The prepared product provides a new preparation technology for improving the bioavailabilityof the ASA and the prevention and treatment effect of cardiovascular diseases as well as reducing adverse effect, and has great social benefit and economic benefit.

Owner:QINGDAO UNIV OF SCI & TECH

Magnetic field sensing device

ActiveUS11035913B2Simple and stable processReduce manufacturing costMagnetic sensor arraysElectrical resistance and conductanceMagnetic flux

A magnetic field sensing device including a magnetic flux concentrating module and a plurality of vortex magnetoresistors is provided. The magnetic flux concentrating module has a first side, a second side, a third side and a fourth side, wherein the first side is parallel to the third side, the second side is parallel to the fourth side, and the first side is not parallel to the second side. The vortex magnetoresistors are disposed beside the first to the fourth sides. The vortex magnetoresistors have a same pinning direction. The pinning direction is inclined with respect to the first side and the second side. The vortex magnetoresistors are configured to be connected to form a plurality of different Wheatstone bridges, so as to sense magnetic field components in a plurality of different directions, respectively.

Owner:ISENTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com