Preparation method of FeCrAl cladding layer on molybdenum alloy matrix

A molybdenum alloy and substrate technology is applied in the field of preparation of FeCrAl coating on a molybdenum alloy substrate, which can solve the problems of weak bonding force between the coating and the substrate, poor coating performance, etc., and achieve the effects of improving oxidation resistance, compact structure and large output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] After cleaning and drying the pure molybdenum substrate, put it into the vacuum chamber of the multi-target magnetron sputtering ion plating equipment. The targets are 2 316l stainless steel targets, 2 pure chromium metal targets, and 1 pure aluminum metal target. Evacuate the vacuum chamber to 9×10 -5 After Torr, argon gas is introduced, and the flow rate is 15 sccm. Perform ion bombardment cleaning for 20 minutes: adjust the negative bias to -400V, turn on the four target currents at the same time, I 316l 0.3A, I Cr 0.8A, I Al 0.3A; then deposit 20min of chromium primer: adjust the negative bias to -120V, adjust the four target currents, I 316l 0.3A, I Cr 1.0A, I Al 0.3A; deposit 150min of FeCrAl coating: adjust the negative bias to -40V, adjust the four target currents, I 316l for 2A, I Cr 0.5A, I Al 0.6A.

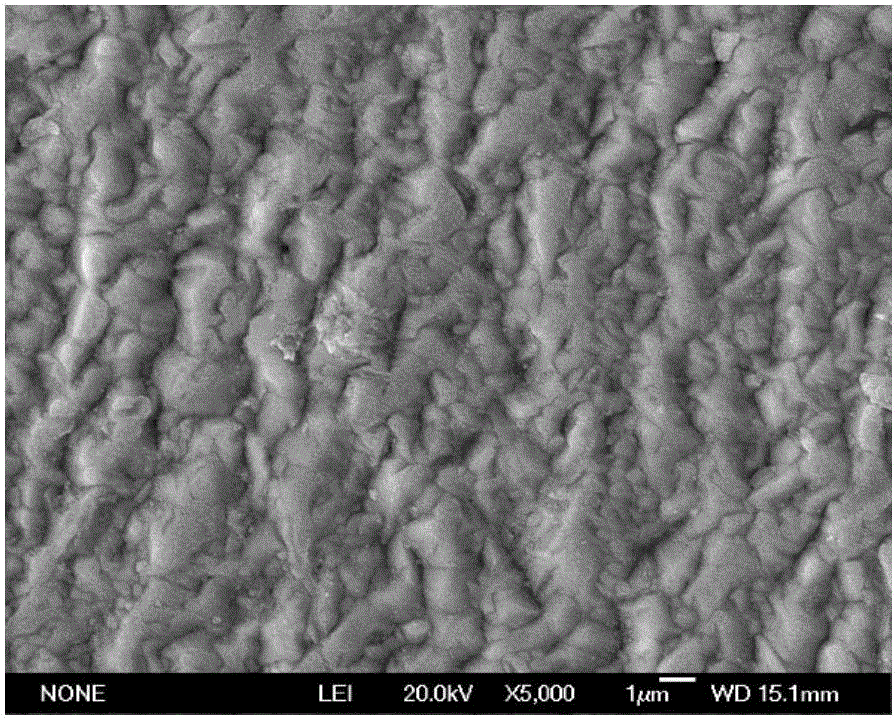

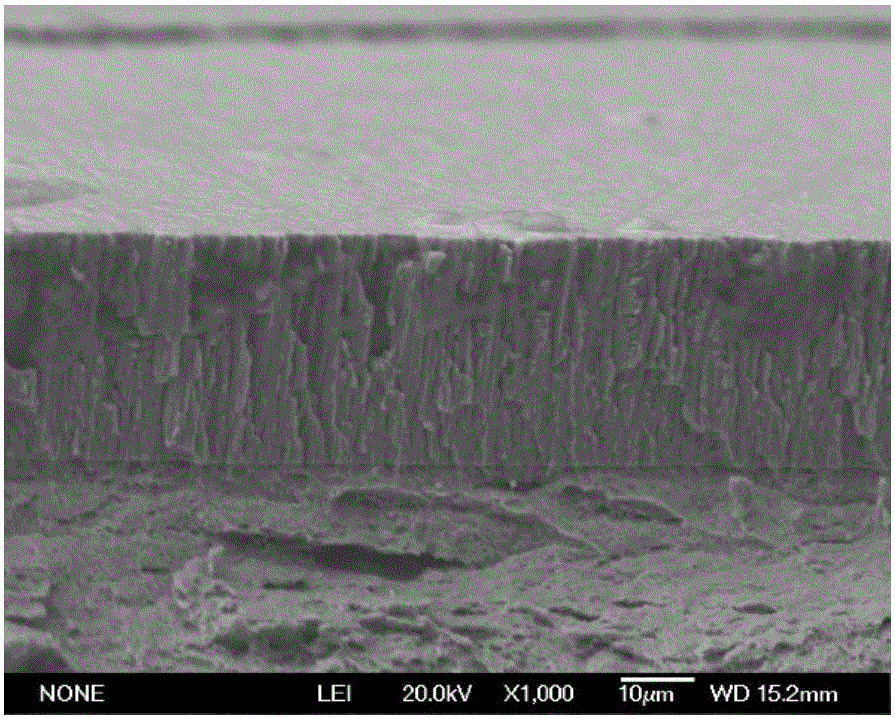

[0030] The composition of the FeCrAl coating obtained by this process is: Fe-24.4Cr-3.7Al, the thickness is 11.4μm, the bonding force is 55MPa, and the ...

Embodiment 2

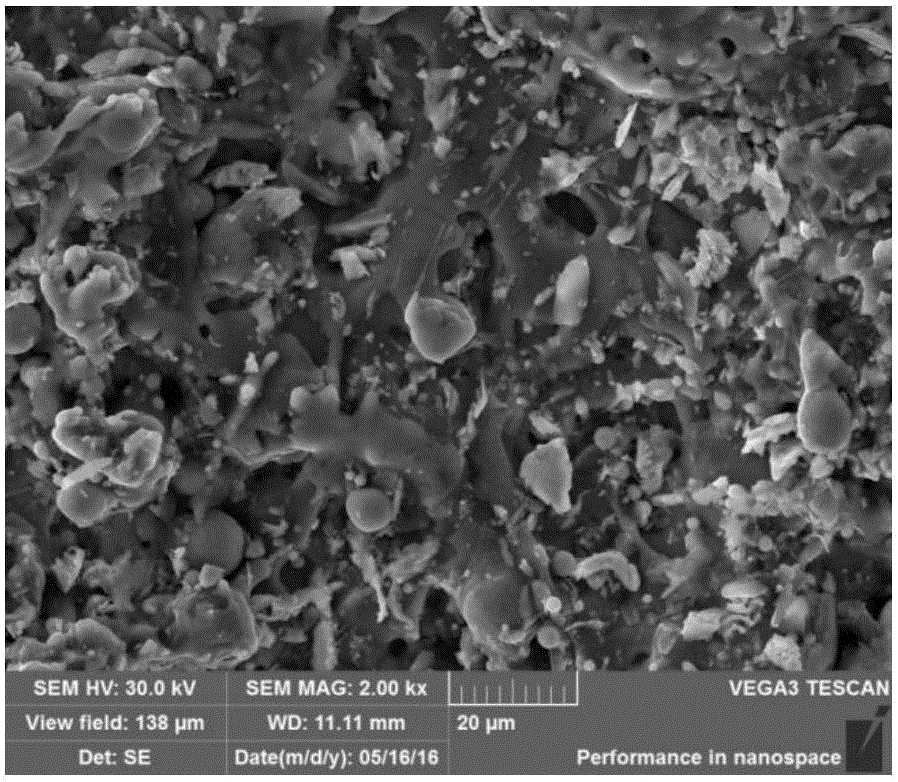

[0032] After cleaning and drying the molybdenum-zirconium alloy substrate, put it into the vacuum chamber of the multi-target magnetron sputtering ion plating equipment. The targets are two 316l stainless steel targets, one pure chromium metal target, and one pure aluminum metal target. Evacuate the vacuum chamber to 1 x 10 -5 After Torr, argon gas is introduced, and the flow rate is 24 sccm. Perform ion bombardment cleaning for 12 minutes: adjust the negative bias voltage to -480V, and turn on the four target currents at the same time, I 316l 0.5A, I Cr 0.3A, I Al 0.5A; then deposit 5min of chromium primer: adjust the negative bias to -120V, adjust the four target currents, I 316l 0.8A, I Cr for 2A, I Al 0.8A; deposit FeCrAl coating for 30min: adjust negative bias to -90V, adjust four target currents, I 316l 5A, I Cr for 3A, I Al for 3A.

[0033]The composition of the FeCrAl coating obtained by this process is: Fe-29.4Cr-6.4Al, the thickness is 3.7μm, the bonding for...

Embodiment 3

[0035] After cleaning and drying the molybdenum-yttrium alloy substrate, put it into the vacuum chamber of the multi-target magnetron sputtering ion plating equipment. The targets are two 316l stainless steel targets, one pure chromium metal target, and one pure aluminum metal target. Evacuate the vacuum chamber to 4 x 10 -5 After Torr, argon gas is introduced, and the flow rate is 28 sccm. Perform ion bombardment cleaning for 30 minutes: adjust the negative bias voltage to -320V, turn on the four target currents at the same time, I 316l 0.8A, I Cr 0.5A, I Al 0.3A; then deposit 8min of chromium primer: adjust the negative bias to -150V, adjust the four target currents, I 316l 0.3A, I Cr for 3A, I Al 0.3A; deposit 380min of FeCrAl coating: adjust the negative bias to -60V, adjust the four target currents, I 316l 5A, I Cr 1.4A, I Al for 2A.

[0036] The composition of the FeCrAl coating obtained by this process is: Fe-25Cr-4.2Al, the thickness is 49μm, the bonding force...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com