Method and device for continuously preparing high-purity carbon nano tubes

A carbon nanotube, high-purity technology, applied in the fields of carbon nanotubes, chemical instruments and methods, nanocarbons, etc., can solve the problems of continuous production resistivity increase, inability to continuous production, large amounts of sewage, etc., to ensure purification. effect, low operating cost and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 A method for continuously preparing high-purity carbon nanotubes

[0035] Specific steps are as follows:

[0036] (1) The carbon nanotubes are replaced by inert gas first, and then pass through the quantitative feeding device and pass through the positive pressure dense phase conveying device. Driven by the mixed gas of protective carrier gas and acid gas, they enter the gradient heating at room temperature in the form of dense phase flow. device;

[0037] The inert gas is argon, the argon flow rate is 4L / min, and the carbon nanotubes are iron-based multi-walled carbon nanotubes with an ash mass concentration of 2.5%; the protective carrier gas is nitrogen, and the acid gas is chlorine; the carbon nanotubes The feed rate is 100g / min, the flow of nitrogen is 4 L / min, the flow of chlorine is 4L / min; the mixed gas pressure in the positive pressure dense phase delivery device is 1.5Mpa;

[0038] (2) The carbon nanotubes are preheated and reacted in the quartz coil...

Embodiment 2

[0043] Example 2 A method for continuous preparation of high-purity carbon nanotubes

[0044] Specific steps are as follows:

[0045] (1) The carbon nanotubes are replaced by inert gas first, and then pass through the quantitative feeding device and pass through the positive pressure dense phase conveying device. Driven by the mixed gas of protective carrier gas and acid gas, they enter the gradient heating at room temperature in the form of dense phase flow. device;

[0046] The inert gas is helium, the helium flow rate is 4L / min, and the carbon nanotubes are cobalt-based multi-walled carbon nanotubes with an ash mass concentration of 2%; the protective carrier gas is nitrogen, and the acid gas is chlorine; the carbon nanotubes The feed rate is 100g / min, the flow of nitrogen is 4 L / min, the flow of chlorine is 4L / min; the mixed gas pressure in the positive pressure dense phase conveying device is 3Mpa;

[0047] (2) The carbon nanotubes are preheated and reacted in the quart...

Embodiment 3

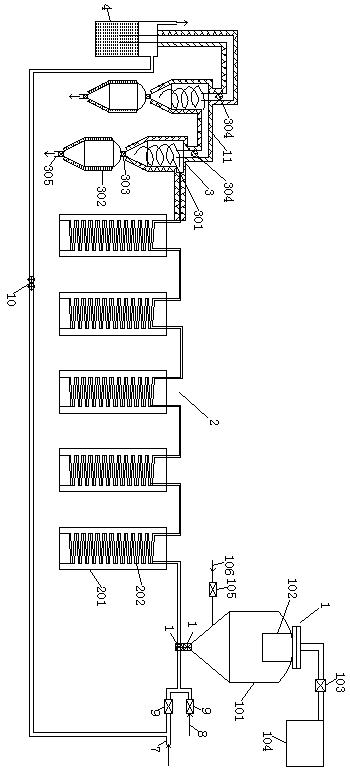

[0052] Example 3 A device for continuous preparation of high-purity carbon nanotubes

[0053] Such as figure 1 As shown, the device for continuously preparing high-purity carbon nanotubes includes a gas replacement device 1, a gradient heating device 2, a gas-solid separation device 3 and a tail gas treatment device 4;

[0054] The gas replacement device 1 includes a CNT storage tank 101. The top of the CNT storage tank 1 is provided with a replacement filter blowback device 102. The replacement filter blowback device 102 is connected to a vacuum pump 104 through a vacuum shut-off valve 103. The bottom of the CNT storage tank 101 is provided with nitrogen gas. Air inlet pipe 105, nitrogen inlet pipe 105 is provided with inlet valve 106, the bottom opening of CNT storage tank 101 is provided with quantitative feeder 5, quantitative feeder 5 is connected with dense-phase conveying device 6, protective carrier gas pipe 7 The flow controller 9 and the acid gas pipe 8 are all conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com