Device and method for directly electrifying and purifying carbon nano tube

A carbon nanotube and weighing device technology, applied in the fields of carbon nanotubes, chemical instruments and methods, nanocarbons, etc., can solve the problems of uneven temperature distribution of reaction materials, low energy utilization rate, slow heating efficiency, etc., and achieve protection Graphite equipment, the effect of improving energy conversion efficiency and fast heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

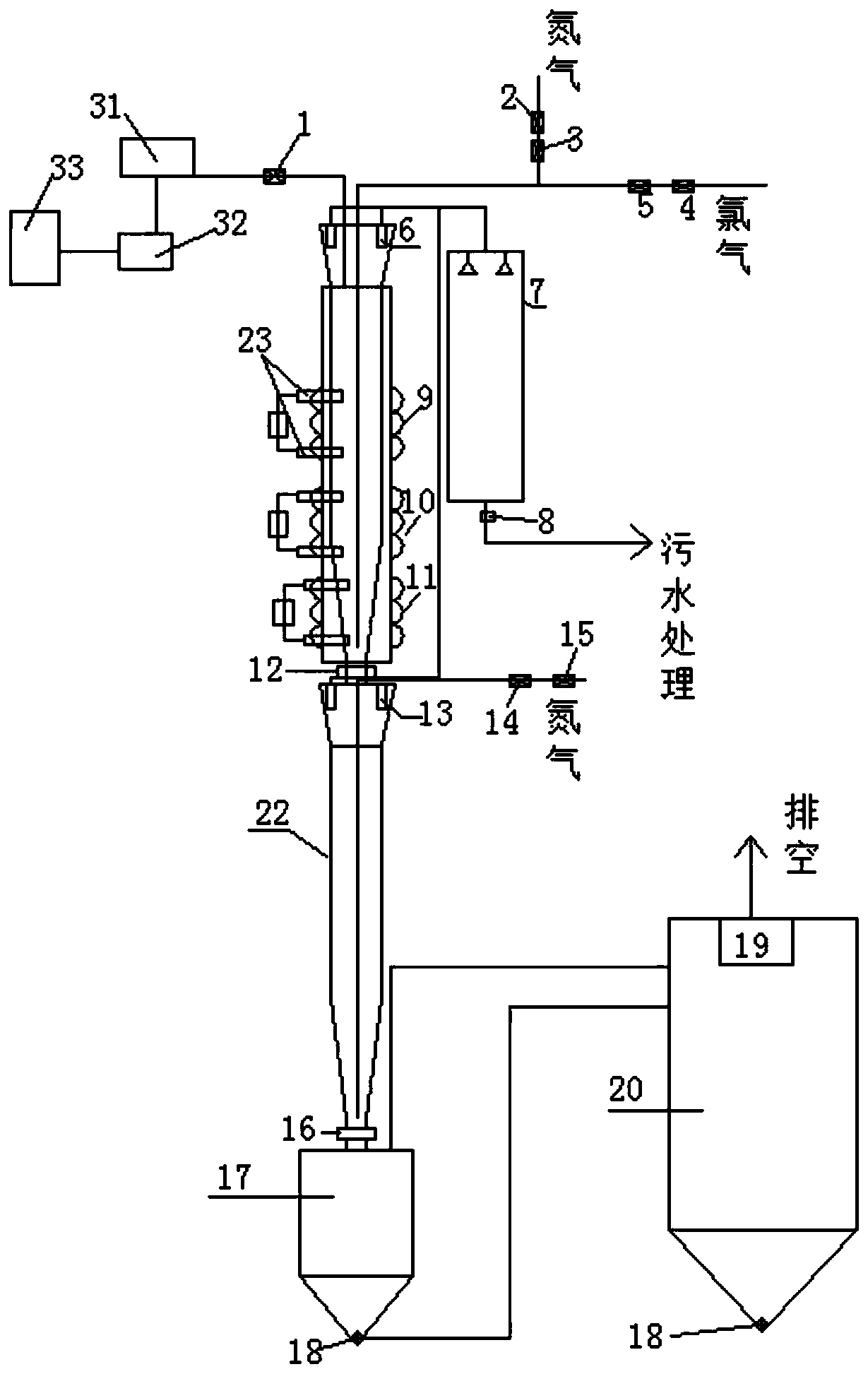

[0048] Embodiment 1 is carried out the device that electrification purifies carbon nanotube

[0049] A device for electrifying and purifying carbon nanotubes, including a main reactor, which includes a material preheating section 9, a low-temperature heating reaction section 10, a high-temperature heating reaction section 11, and a material cooling section arranged in sequence from top to bottom 22. The length ratio of the material preheating section 9, the low-temperature heating reaction section 10, the high-temperature heating reaction section 11, and the material cooling section 22 is 2:4:4:5; the heating form of the main reactor is to directly heat the carbon nanotube material power ups.

[0050] The upper end of the main reactor is connected with a feed valve 1, and the feed valve 1 is connected with a feed weighing device 31, and the feed weigh device 31 is connected with a constant pressure tank 32, and the constant pressure tank 32 is connected with a carbon nanotube ...

Embodiment 2

[0056] Embodiment 2 carries out the method for electrification purification to carbon nanotube

[0057] Since the device needs to be filled with part of the carbon nanotube material in the main reactor before operation, for this part of the filled material, the iron-cobalt-aluminum carbon nanotube material to be purified can be used, and the purified iron-cobalt-aluminum can also be used. Department of carbon nanotube materials.

[0058] (1) Under the protection of argon, 35 kilograms of iron-cobalt-aluminum-based carbon nanotube materials to be purified with a diameter of 4 mm are preloaded at the bottom of the main reaction;

[0059] (2) The system performs continuous vacuum pumping and argon replacement operation, and the oxygen content is detected to be lower than 0.15%;

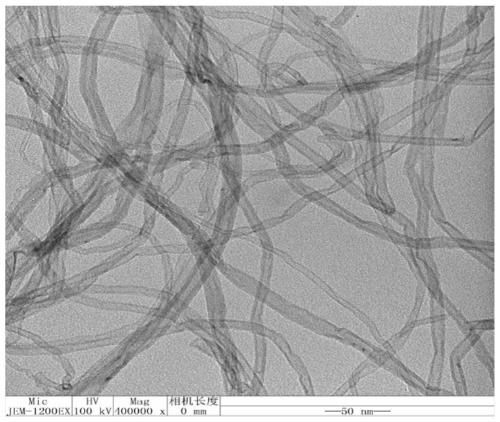

[0060] (3) Under the protection of argon, the carbon nanotube material in the reactor is energized, and the temperature of the low-temperature heating reaction section is controlled to be 1250°C, and th...

Embodiment 3

[0067] Embodiment 3: the method that carbon nanotube is carried out electrification purification

[0068] (1) Under the protection of argon, 50 kilograms of purified iron-nickel-magnesium-based carbon nanotube materials with a diameter of 9 mm are preloaded at the bottom of the main reaction;

[0069] (2) The system performs continuous vacuum pumping and argon replacement operation, and the detected oxygen content is lower than 0.1%;

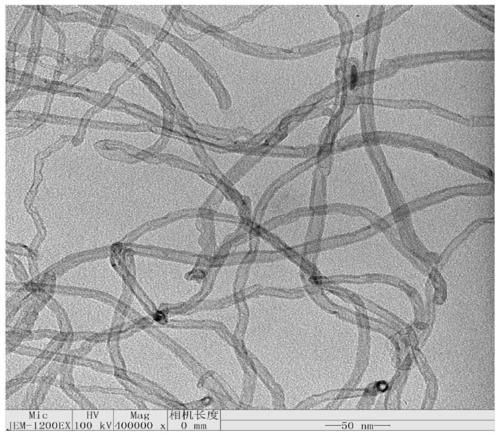

[0070] (3) Under the protection of argon, the carbon nanotube material in the reactor is energized, and the temperature of the low-temperature heating reaction section is controlled to be 1400°C, and the temperature of the high-temperature heating reaction section is 2230°C;

[0071] (4) The iron-nickel-magnesium-based carbon nanotube material to be purified is continuously transported from the carbon nanotube storage tank to the constant pressure tank through pipelines;

[0072] (5) Fe-Ni-Mg carbon nanotubes to be purified enter the main react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com