Patents

Literature

758results about How to "Improve bending efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

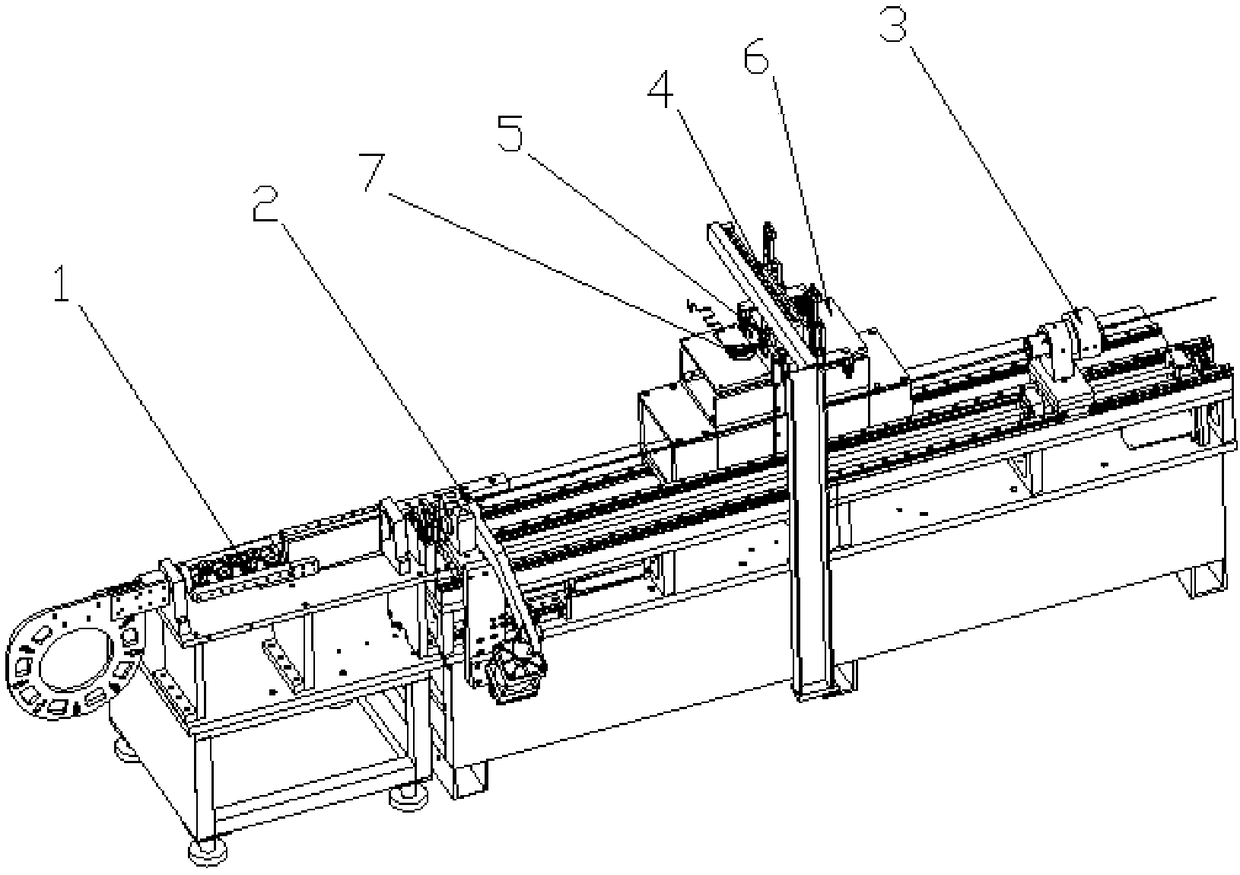

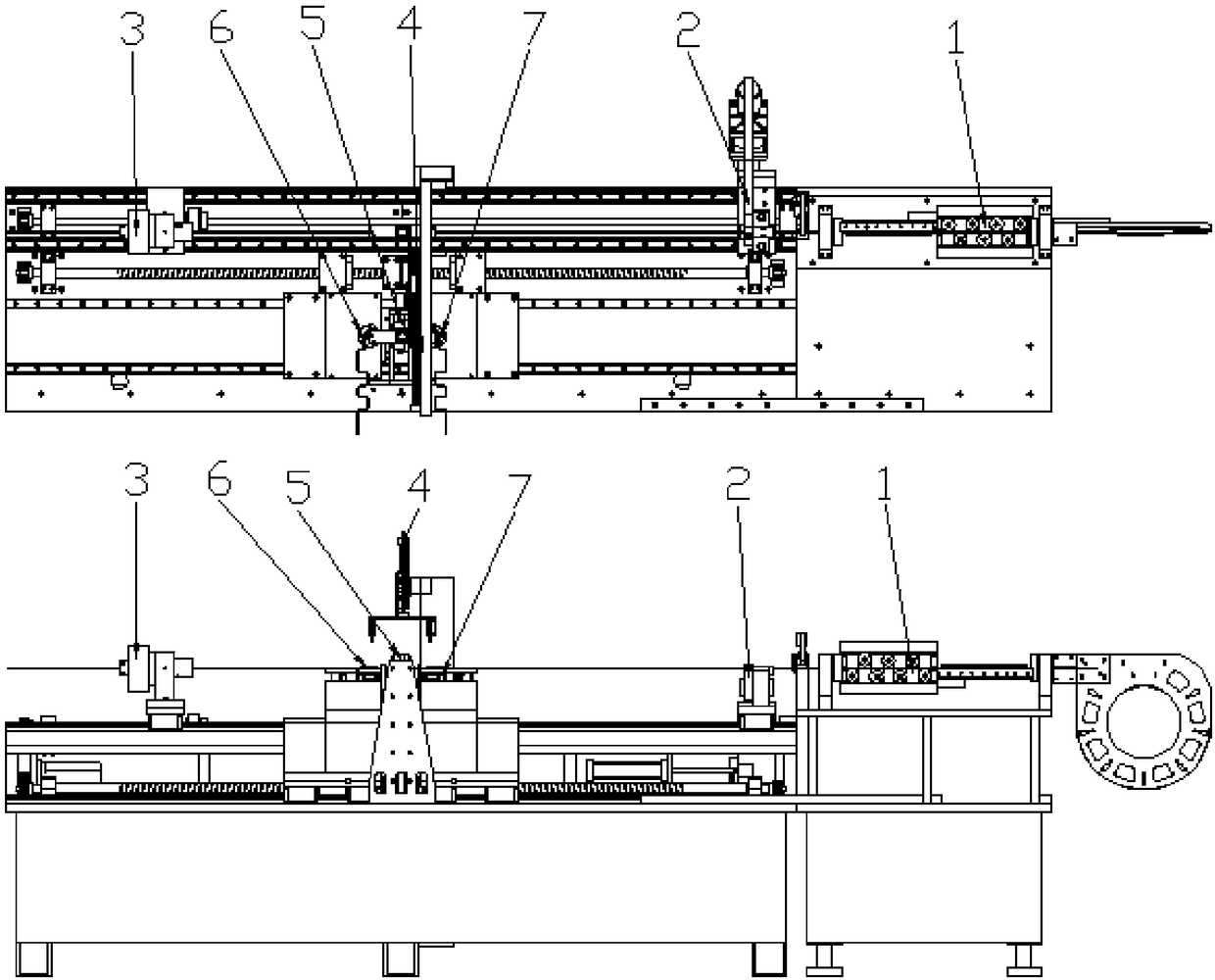

Automatic pipe bending device and pipe bending process thereof

The invention discloses an automatic pipe bending device and a pipe bending process thereof, belonging to the technical field of mechanical processing and manufacturing. The technical scheme adopted by the invention is as follows: under the automatic control of an automatic control platform, a loading claw of a pipe loading machine firstly shifts a single pipe into a rotating fixture of a pinch device, the pinch device drives the pipe to move forward through a heater, the heater heats a bent part of the pipe to 1200-1350 DEG C, the bent part is moved to a bending mold, a follower plate and a movable jaw clamp the pipe, the movable jaw and the bending mold rotate to a bending angle around a rotating shaft, the follower plate and the movable jaw are reset after the pipe is released, the above process is repeated until the bending of the whole pipe is finished, and an unloading manipulator carries out unloading operation, thus finishing the bending process. The system can automatically finish pipe operations such as loading, feeding, heating, rotating, bending, unloading and the like, so that the pipe can be automatically bent and molded, the molding process is more accurate, and theyield is high; and the number of times for transporting the pipe in the processing process is reduced, and the productivity is improved.

Owner:西安德卡汽车系统有限公司

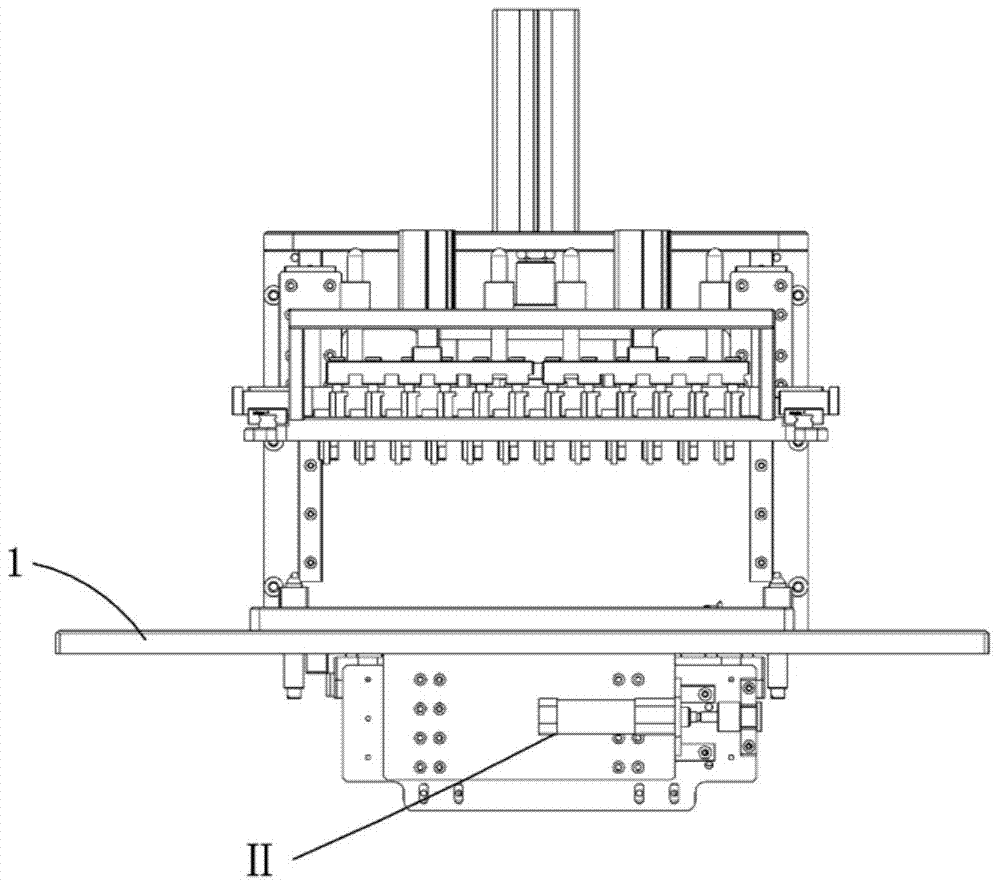

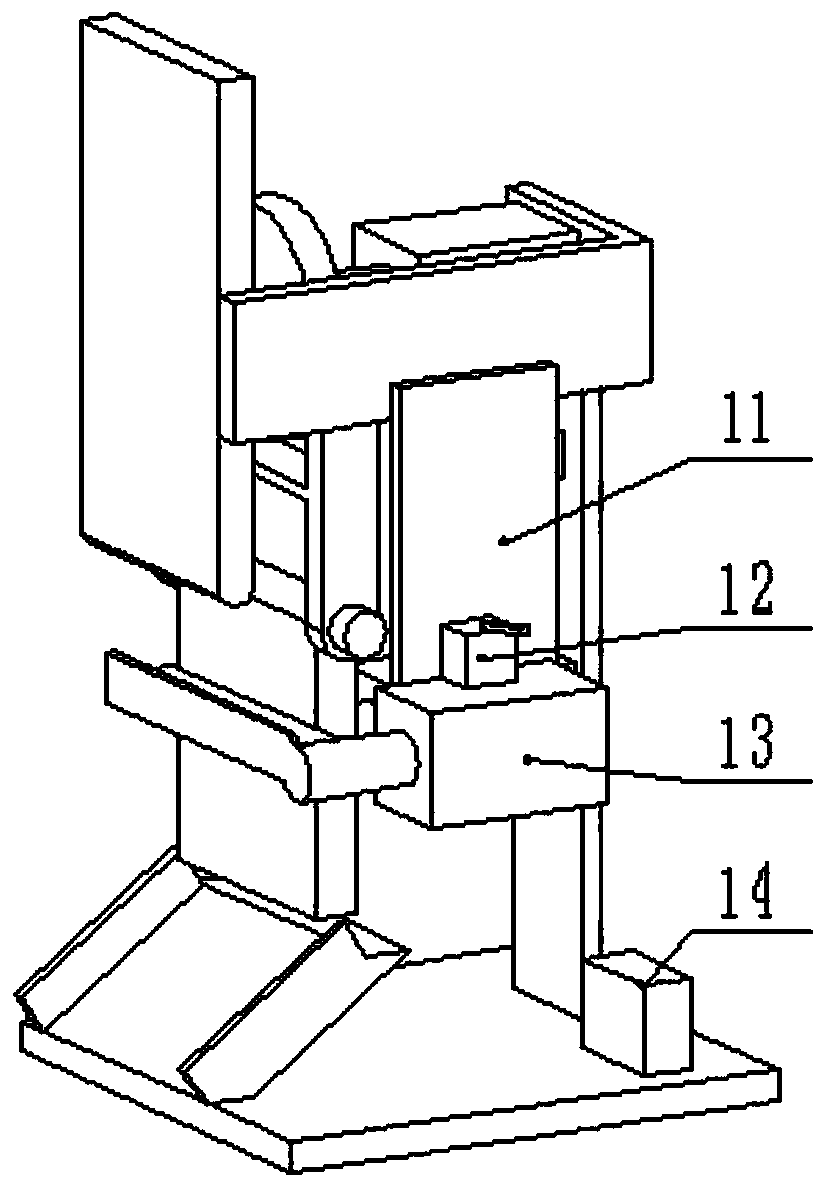

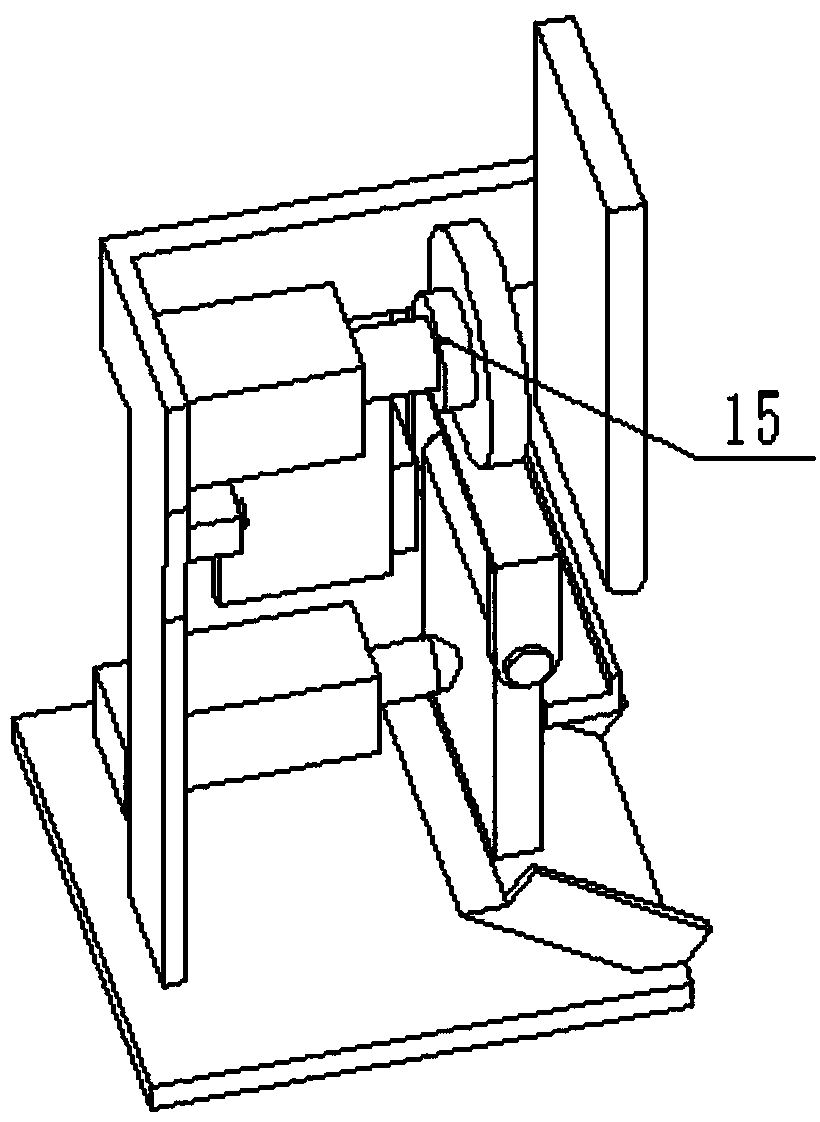

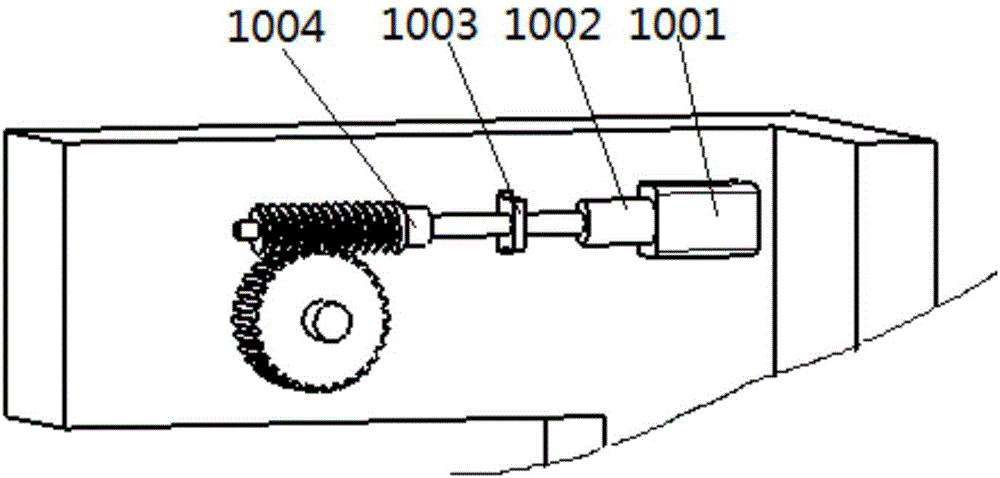

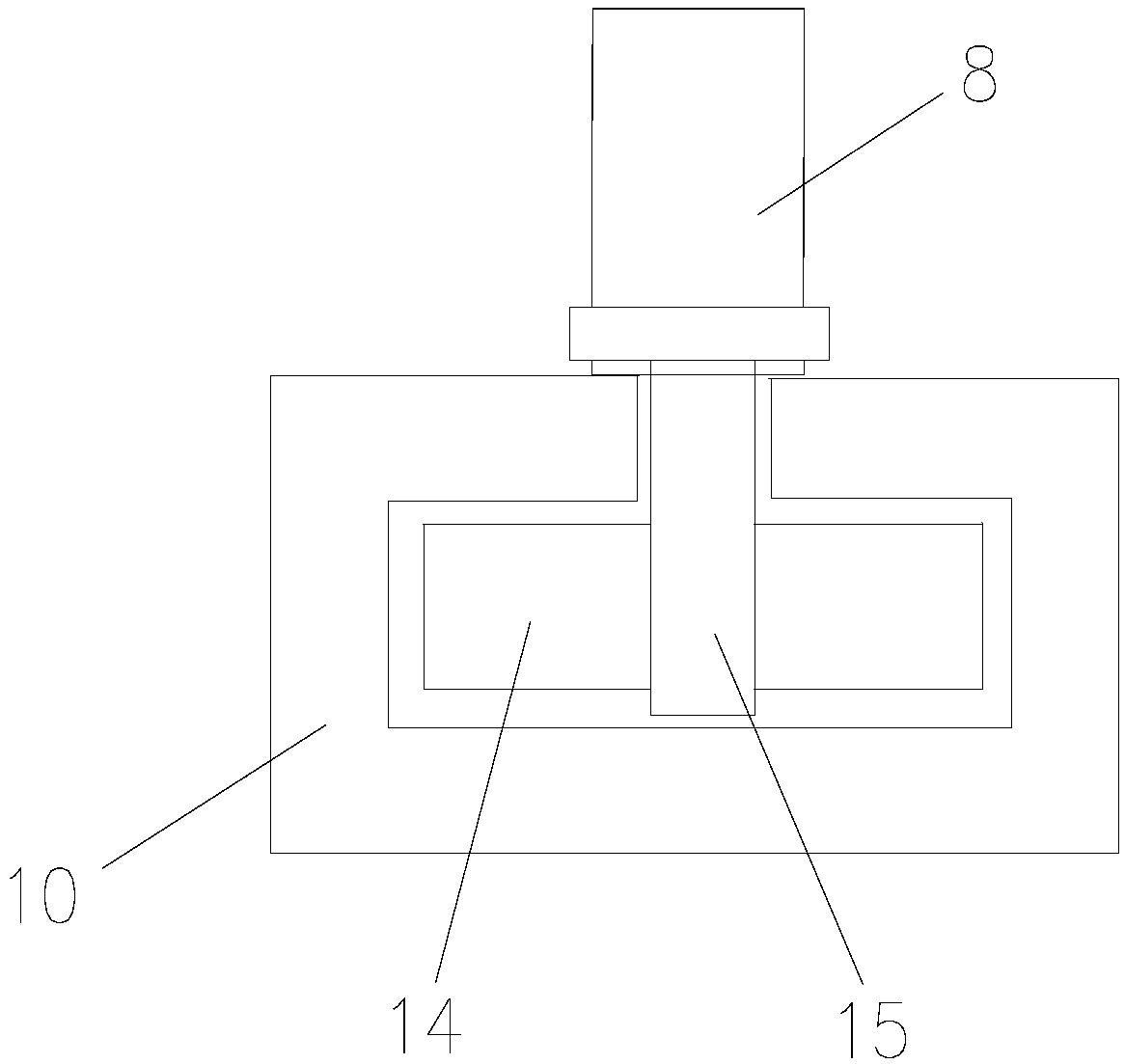

Flexible flat cable bending mechanism

ActiveCN104242019AEasy to moveWith anti-bounce functionLine/current collector detailsEngineeringVertical cylinder

The invention relates to the field of bending equipment, in particular to a flexible flat cable bending mechanism. The flexible flat cable bending mechanism comprises a panel, a carrier plate, an upper mold device and a lower mold device, wherein the carrier plate is arranged on the panel; a product is positioned on the carrier plate; the upper mold device is arranged on the upper portion of the panel; the lower mold device is arranged on the lower portion of the panel; the upper mold device is driven by a vertical cylinder and a transverse cylinder so that a pre-pressing block and a bending stopping block can reach standard operation positions, and preparations are made for bending of flexible flat cables; the upper mold device is also provided with a bending stopping block micro-adjusting mechanism; bending positions can be slightly adjusted by the bending stopping block micro-adjusting mechanism so that the bending precision of the flexible flat cables is high; a horizontal pushing block which is driven by a horizontal cylinder of the lower mold device drives a connecting plate to move along a horizontal sliding track in the left-right direction, and a bending mold is driven to move in the left-right direction; and under the driving effect of a lifting cylinder, a fixing seat can be pushed to move along a lifting sliding track in the up-down direction, and the bending mold is driven to move in the up-down direction. By the flexible flat cable bending mechanism, the flexible flat cables of a plurality of groups of connecting plates can be bent. The bending mechanism is stable and reliable and is high in bending precision, so that the production efficiency and the yield are improved, and the production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

Wire bending device

The invention discloses a wire bending device. The wire bending device comprises a frame; a first belt conveying component; a vertical plate; a second belt conveying component opposite to a first conveying belt up and down and bonded with the first conveying belt to form a wire feeding mechanism for clamping and conveying wires; a driving component; a wire bending component including a first air jaw cylinder, two first clamping jaws mounted at a free end of the first air jaw cylinder, a rotating cylinder for driving the first air jaw cylinder to swing between a position on the outer side of the tail end of the wire feeding mechanism and a position far from the tail end of the wire feeding mechanism, and a first lifting cylinder for driving a cylinder body of the rotating cylinder to move in the height direction of the frame; a wire clamping component; and a cutting component. In the wire bending device, the wire bending process is automatically finished, so that the wire bending efficiency is improved; and meanwhile, the wires are cut after being bent to possibly guarantee levelness of two ends of the wires.

Owner:DONGGUAN SENJIA MACHINERY

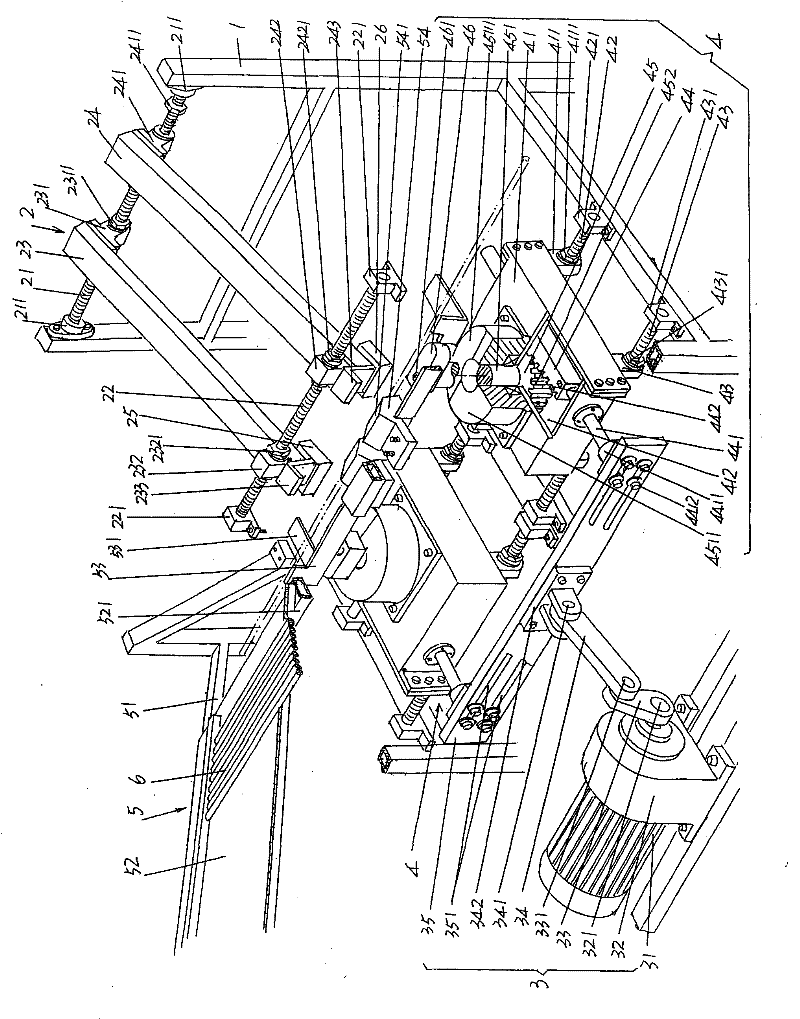

Plate bending method for intelligent numerical control bending machine

ActiveCN106077168ARealize automatic crawlingNo human intervention requiredMetal-working feeding devicesPositioning devicesAutomatic controlEngineering

The invention discloses a plate bending method for an intelligent numerical control bending machine and belongs to the technical field of bending machines. The machine comprises a rack, a worktable, a bending device and a base. The rack and the bending device are arranged on the base. The machine further comprises a material blocking device, a discharging device, a feeding device, a positioning device, a material conveying device and a numerical control system. A machined piece is conveyed to the worktable through the feeding device and clamped by the discharging device to move on the worktable, and the machined piece can be positioned in the X-axis direction. The material blocking device and the positioning device are matched to position the machined piece in the Y-axis direction. The material conveying device conveys the machined piece to a machining station for bending machining and controls the machined piece to rotate to be subjected to multi-edge bending, and the machined piece is pushed to get away from the worktable through the discharging device after machining is completed; and the numerical control system is used for completing automatic control over the whole bending process. The intelligent numerical control bending machine is high in work efficiency and automation degree, full-automatic multi-edge forward and reverse bending can be achieved on the machined piece, use is convenient, and the labor force can be sufficiently liberated.

Owner:JIANGSU HAIJIAN

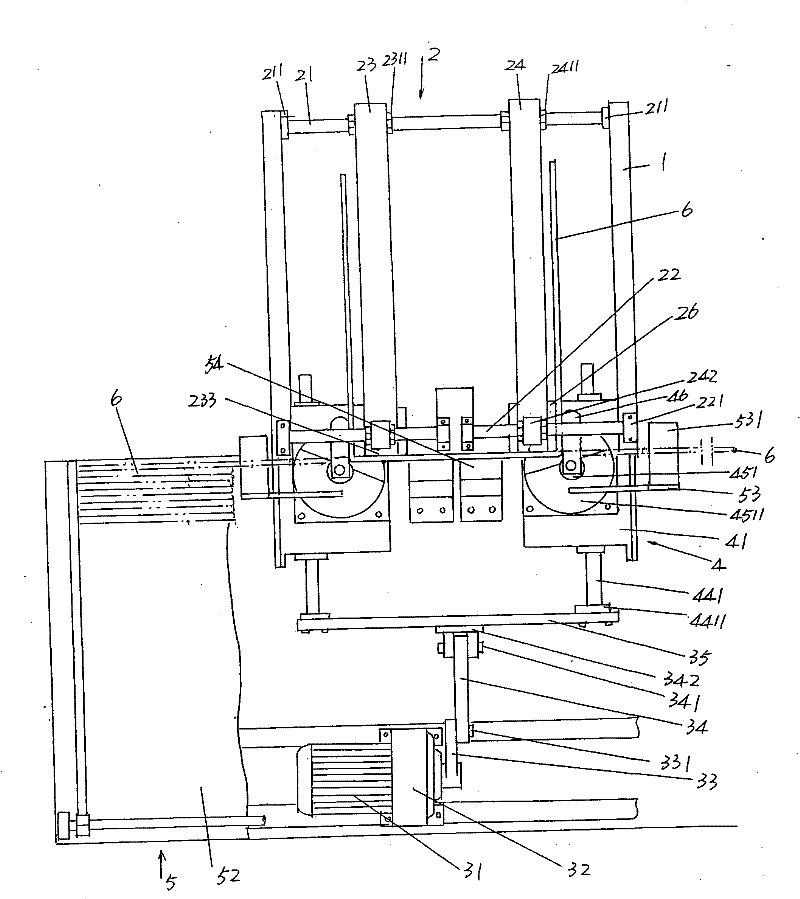

Mesh reinforcement automatic bending and moulding machine

The invention relates to a mesh reinforcement automatic bending and moulding machine, belonging to the technical field of commercial facility processing machinery. The machine comprises a rack, a fixed die mechanism, a power mechanism and a moving die mechanism, wherein the fixed die mechanism is fixed on the rack and is arranged at one side of the rack, the moving die mechanism is arranged on the rack and is arranged between the fixed die mechanism and the power mechanism, one side of the moving die mechanism towards the power mechanism is connected with the power mechanism in a transmissionway, and one side of the moving die mechanism towards the fixed die mechanism is matched with the fixed die mechanism, thus a mesh reinforcement is bent. In the technical scheme, the fixed die mechanism and the moving die mechanism are arranged on the rack, and the moving die mechanism is connected with the power mechanism arranged on the rack, thus the power mechanism drives the moving die mechanism to act and the mesh reinforcement which enters into a gap between the fixed die mechanism and the moving die mechanism can be bent under the coordination of the fixed die mechanism. The machine provided by the invention has the advantages that the bending efficiency is high, the bending quality can be guaranteed, and the labour intensity of an operator can be reduced.

Owner:广州番禺于一金属加工有限公司

Bending mechanism

Owner:CWB AUTOMOTIVE ELECTRONICS

Reshaping device for metal steel processing

ActiveCN111545604ANot easy to moveGuaranteed stabilityMetal-working feeding devicesPositioning devicesElectric machineGear wheel

The invention discloses a reshaping device for metal steel processing. The reshaping device for metal steel processing comprises a workbench. A support is fixedly connected to the workbench. An installation groove is formed in the upper end of the workbench, multiple conveying rollers are connected with the interior of the installation groove in a rotating mode, and a transmission mechanism is arranged among the multiple conveying rollers. A driving motor is installed on the front side of the workbench, a first gear is fixedly connected with the output end of the driving motor, a second gear is installed on the workbench, and the second gear and the first gear mesh with each other. An adjusting mechanism is fixedly connected to the second gear, the adjusting mechanism and the second gear are coaxial, and the adjusting mechanism and the transmission mechanism are connected with each other through a transmission belt. The reshaping device for metal steel processing is reasonable in structure, cutters can be bent into a whole, and therefore the steel plate bending efficiency is greatly improved, the labor workload of a worker is also reduced, steel plates can be subjected to adjustable equal-length cutting operation, the practicability is high, the steel plate bending angle can also be adjusted, and the function is powerful.

Owner:浙江星筑科技有限公司

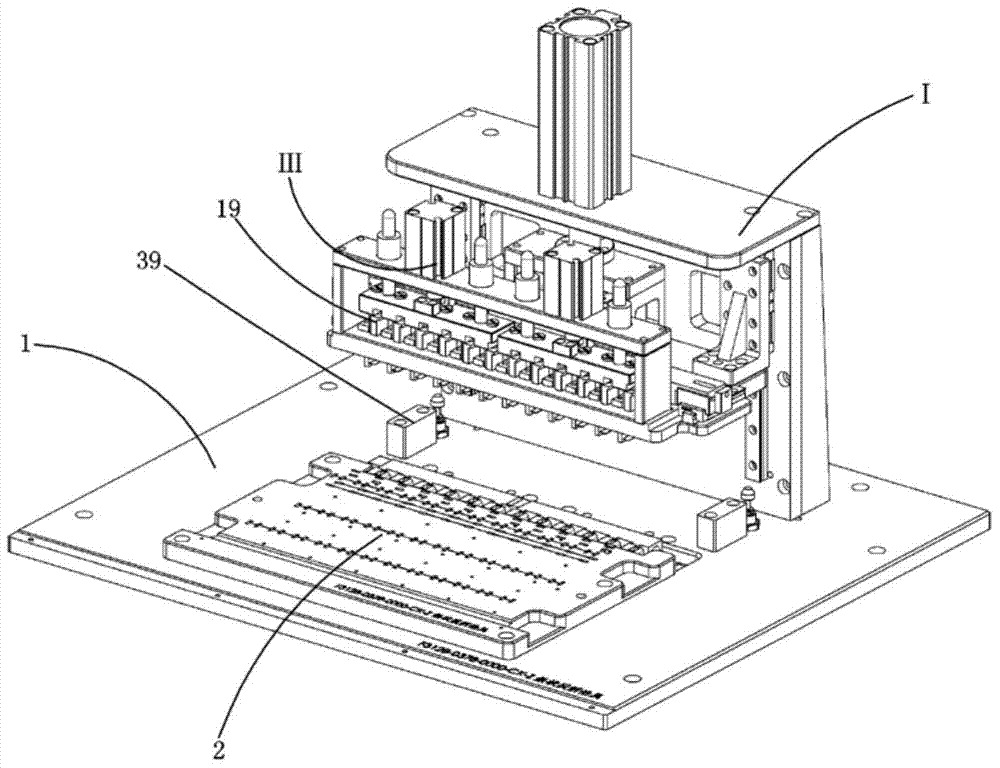

Bending device

ActiveCN102716946AGuaranteed uniformityImprove bending efficiencyMetal-working feeding devicesPositioning devicesEngineeringPress brake

The invention discloses a bending device which comprises a bending machine and a battery clamp, wherein the bending machine comprises a platform, a battery location device which is arranged on the platform, a clamping device and a bending unit; the batter clamp comprises a battery lining plate and a cover plate, the battery lining plate can be separately and fixedly arranged on a clamp platform, a plurality of battery accommodating grooves which are linearly arrayed are arranged on the battery lining plate, and elastic location devices are respectively formed at the side parts and bottoms of the battery accommodating grooves; and the cover plate is separately and fixedly arranged on the battery lining plate. According to the bending device, the battery lining plate adopts a mechanism of precisely locating a plurality of batteries at the same time, and the product quality uniformity can be effectively ensured through utilizing the elastic location devices.

Owner:天津聚元新能源科技有限公司

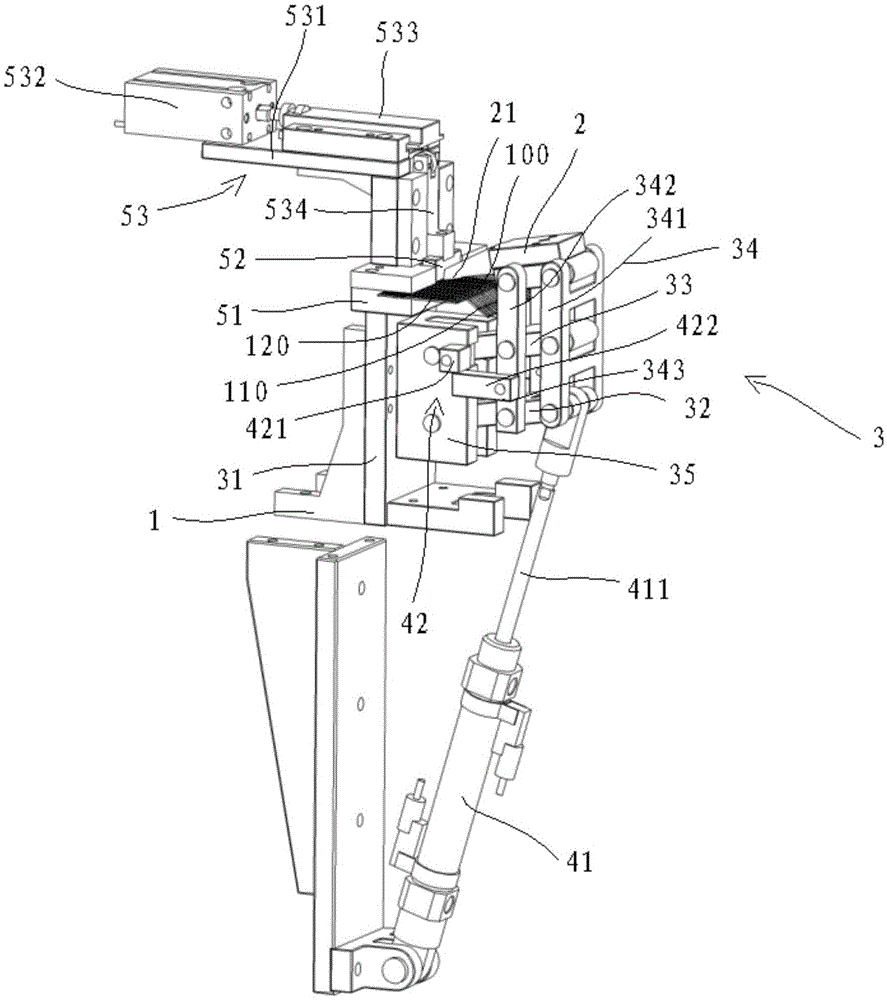

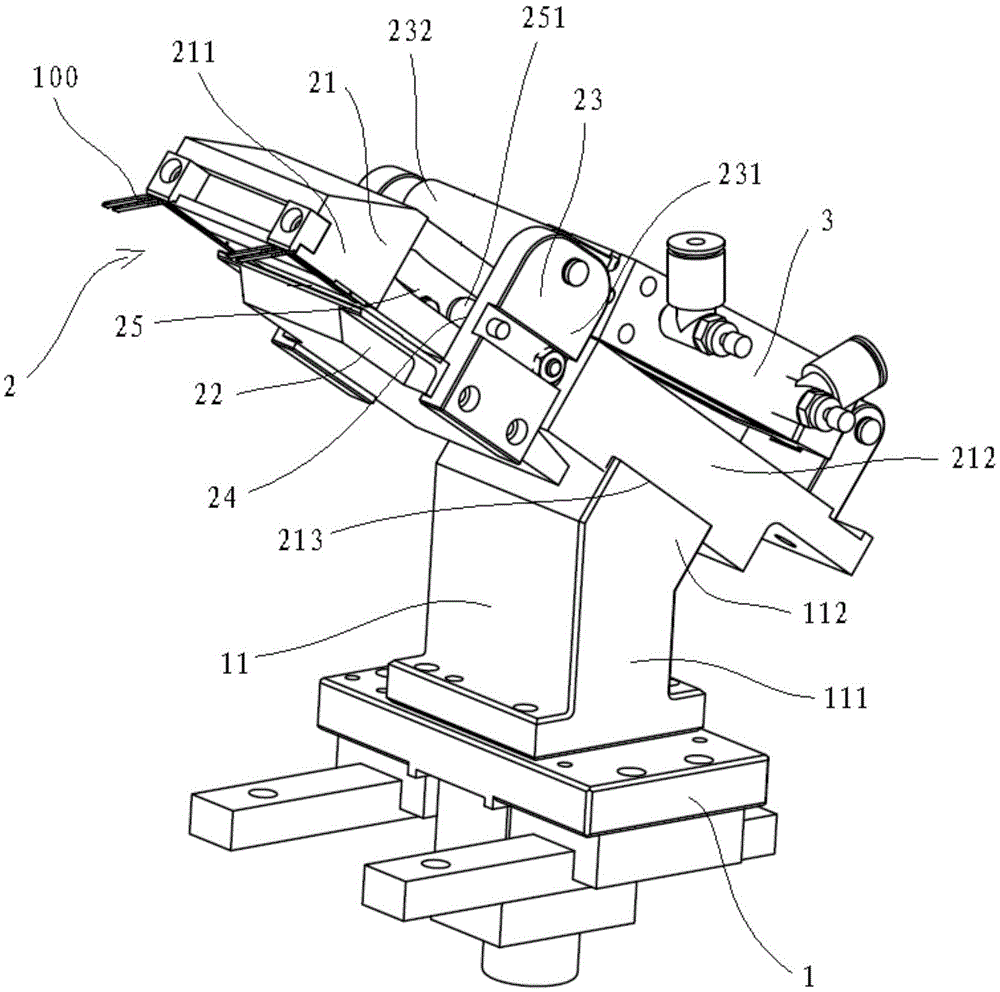

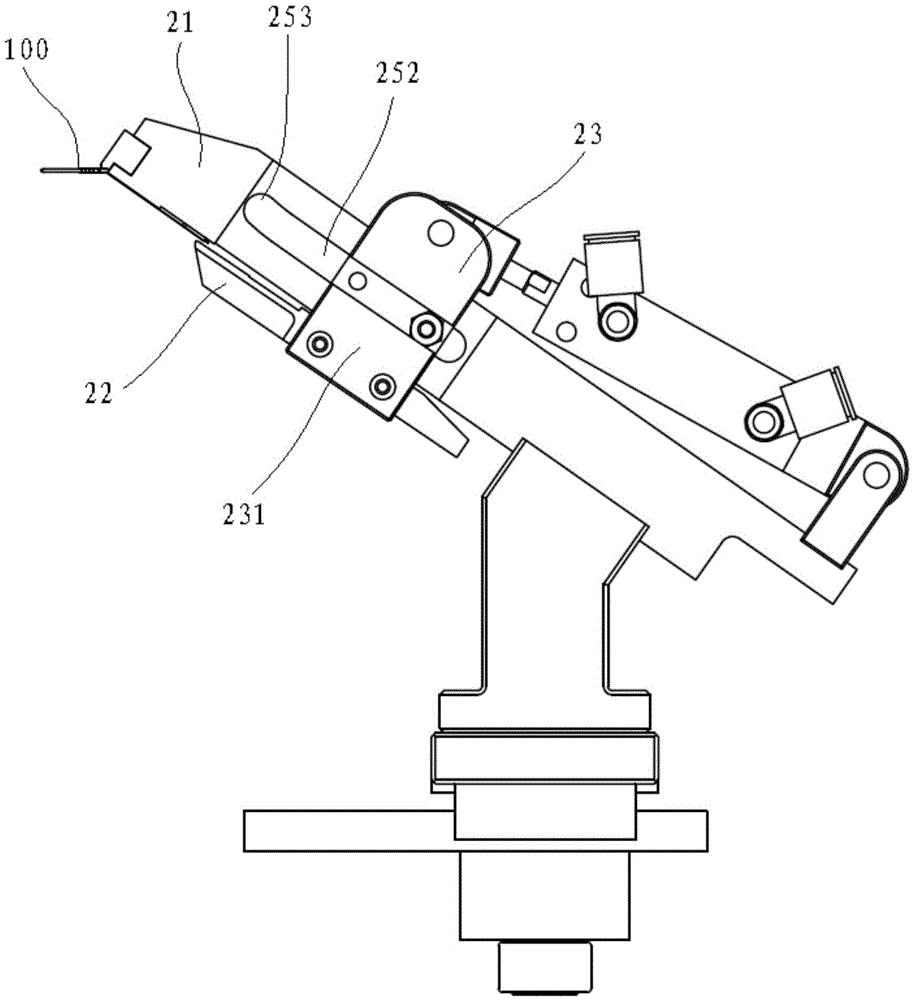

PIN bent plugging and taking device

ActiveCN105576477AReduce production processIncrease productivityContact member manufacturingContact member assembly/disassemblyBiomedical engineering

The invention provides a PIN bent plugging and taking device comprising a bending mechanism which bends a PIN, a cutting mechanism which cuts a PIN material strap into single bent PINs, and a clamping jaw mechanism which clamps the bent PIN from the cutting mechanism and plugs the PIN in a PIN bearer. The clamping jaw mechanism comprises a base which is provided with a supporting structure, a clamping jaw structure and a clamping jaw driving device. The clamping jaw structure comprises a fixed clamping jaw which is obliquely installed on the supporting structure, a flexible clamping jaw and a connecting structure. The clamping surface of the flexible clamping jaw is arranged to be opposite to the clamping surface of the fixed clamping jaw, and the distance between the clamping surface of the flexible clamping jaw and the clamping surface of the fixed clamping jaw is reduced when the clamping surface of the flexible clamping jaw slides towards a first direction along the clamping surface of the fixed clamping jaw; and the distance between the clamping surface of the flexible clamping jaw and the clamping surface of the fixed clamping jaw is increased when the clamping surface of the flexible clamping jaw slides towards a second direction opposite to the first direction along the clamping surface of the fixed clamping jaw. Production process is reduced, production efficiency is enhanced and cost is reduced by the PIN bent plugging and taking device.

Owner:CWB AUTOMOTIVE ELECTRONICS

Reinforcing steel bar bending device for building

The invention discloses a reinforcing steel bar bending device for a building. The reinforcing steel bar bending device comprises a bottom plate, a supporting plate, a supporting device, a cover plate device, a first pushing device, a second pushing device and a positioning device, wherein a first supporting block and a first roller are arranged on the bottom plate; a first supporting rod, a first cross rod and a second roller are arranged on the supporting plate; the supporting device comprises a second supporting rod, a third roller, a third supporting rod, a fourth roller, a fourth supporting rod, a fifth roller, a second cross rod, a first obliquity rod, a third cross rod and a first bent rod; the cover plate device comprises a first bracket, a second bracket, a fourth cross rod, a second vertical rod, a fifth cross rod, a third vertical rod, a fourth vertical rod, a sixth cross rod, a sixth roller and a cover plate; and the first pushing device comprises a first air cylinder, a first pushing rod, an eighth roller, a third bracket, a sixth vertical rod, a fifth supporting rod, a first guide block, a fourth bracket, a second bent rod and a fifth bracket. The reinforcing steel bar bending device can be used for effectively bending a reinforcing steel bar.

Owner:广东筑奥建设集团有限公司

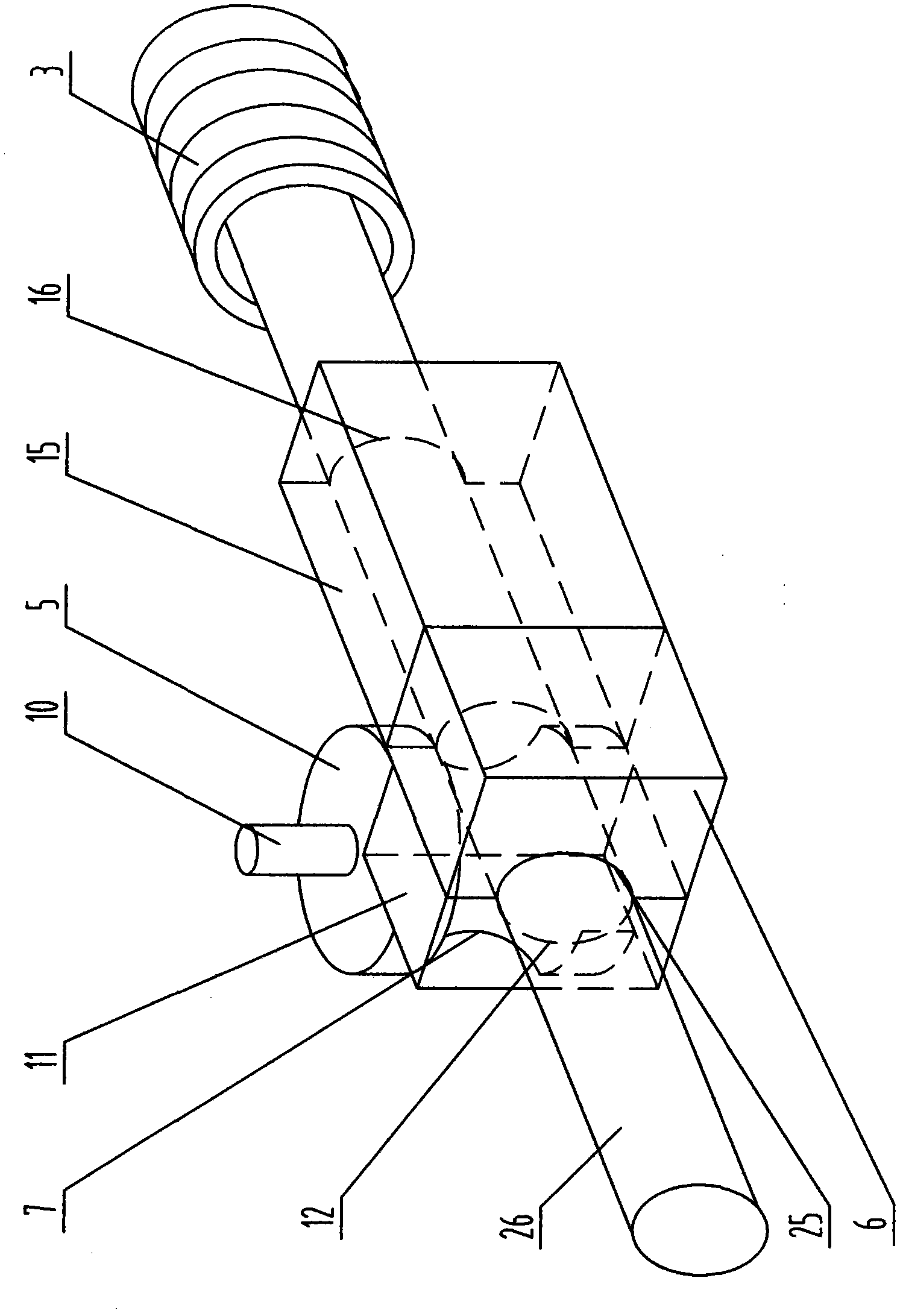

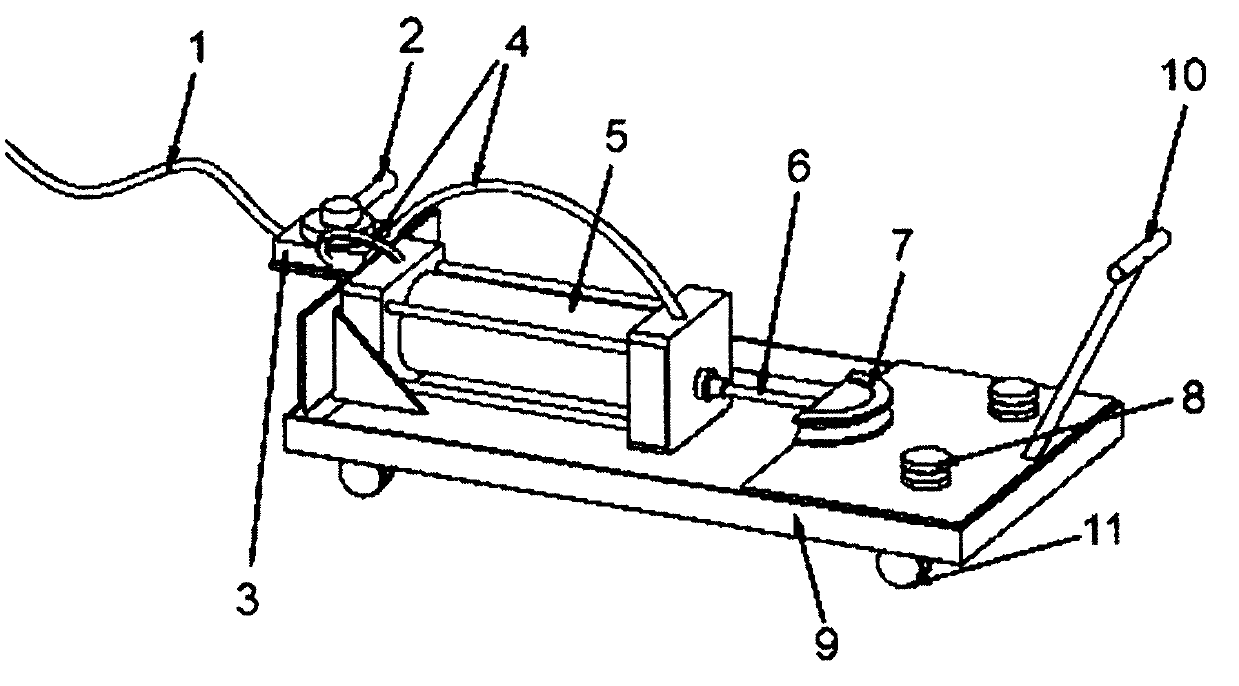

Air pressure pipe bending machine

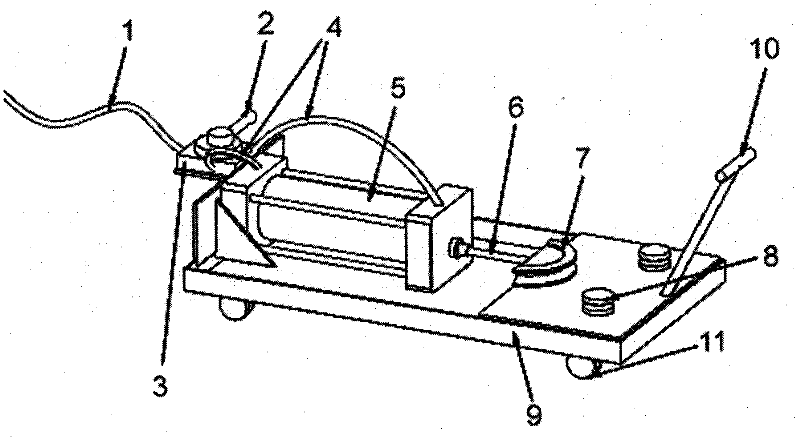

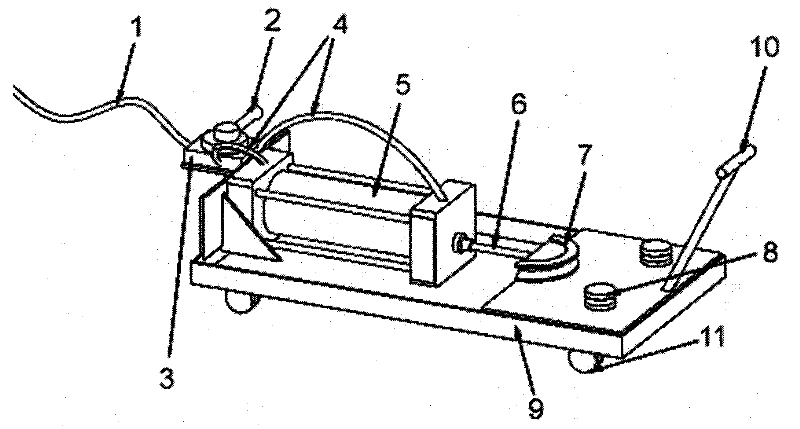

The invention discloses an air pressure pipe bending machine. The machine comprises a worktable, a cylinder (5), a cylinder component, a pipe bending pressure tank (7) and rolling grooves (8), wherein a cylinder piston of the cylinder (5) is connected with the pipe bending pressure tank (7) through a telescopic shaft rod (6); the pipe bending pressure tank (7) is provided with a semi-circular notch of which the diameter is matched with that of a pipe; the worktable is provided with two rolling grooves (8) for positioning the two ends of the pipe and matching with the pipe bending pressure tank (7) to bend the pipe; each rolling groove (8) is provided with a semi-circular notch of which the diameter is matched with that of the pipe; and the cylinder piston moves forwards or backwards to push the telescopic shaft rod (6) and the pipe bending pressure tank (7) to move forwards or backwards along the direction of the worktable. The machine is high in pipe bending quality, ensures consistent and attractive bends, has high work efficiency, is not required to be operated by professional personnel, saves labor cost, is suitable for bending short pipes, can improve the utilization rate of the short pipes in a construction site, and reduces material loss.

Owner:GOLD MANTIS CONSTR DECORATION

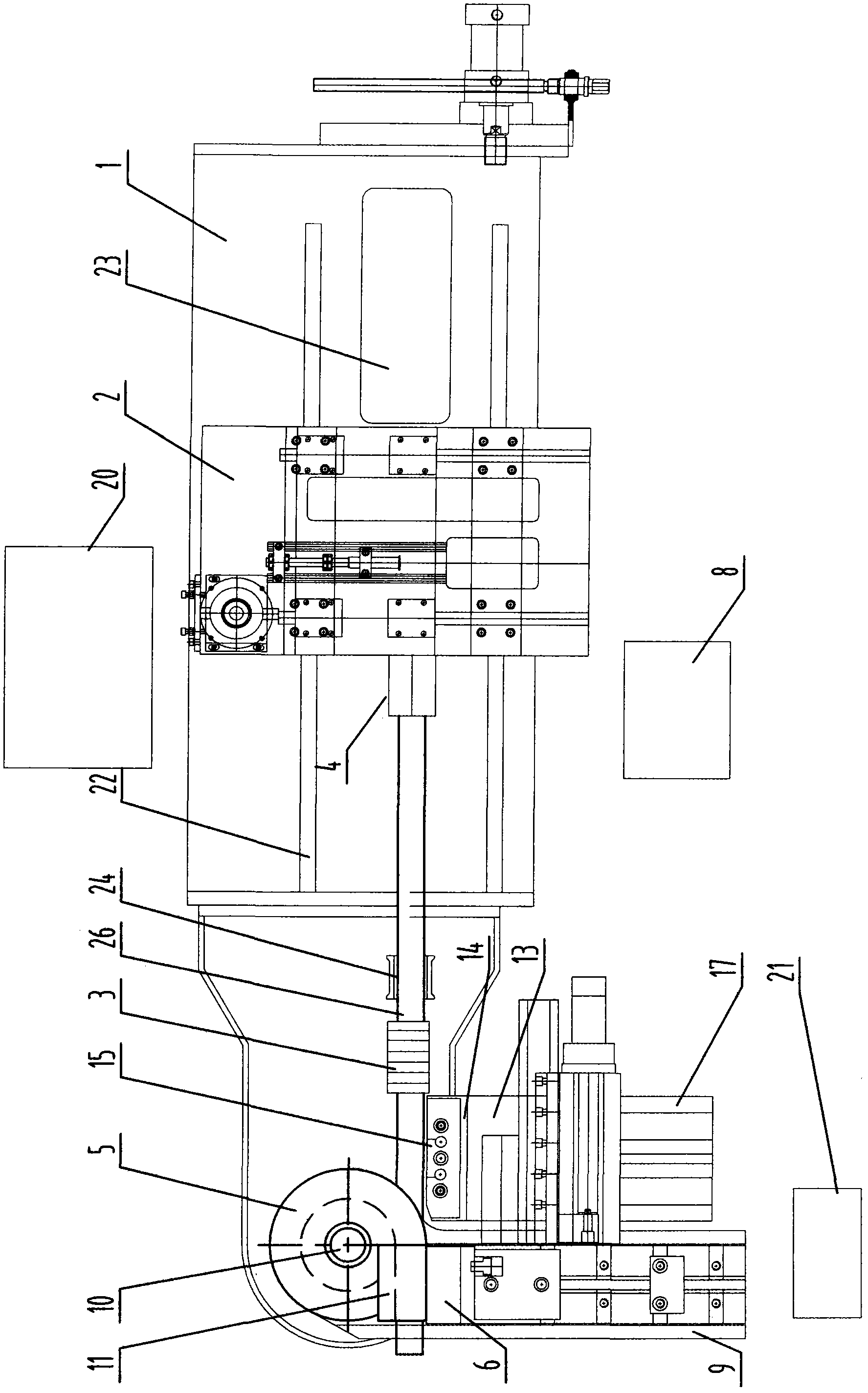

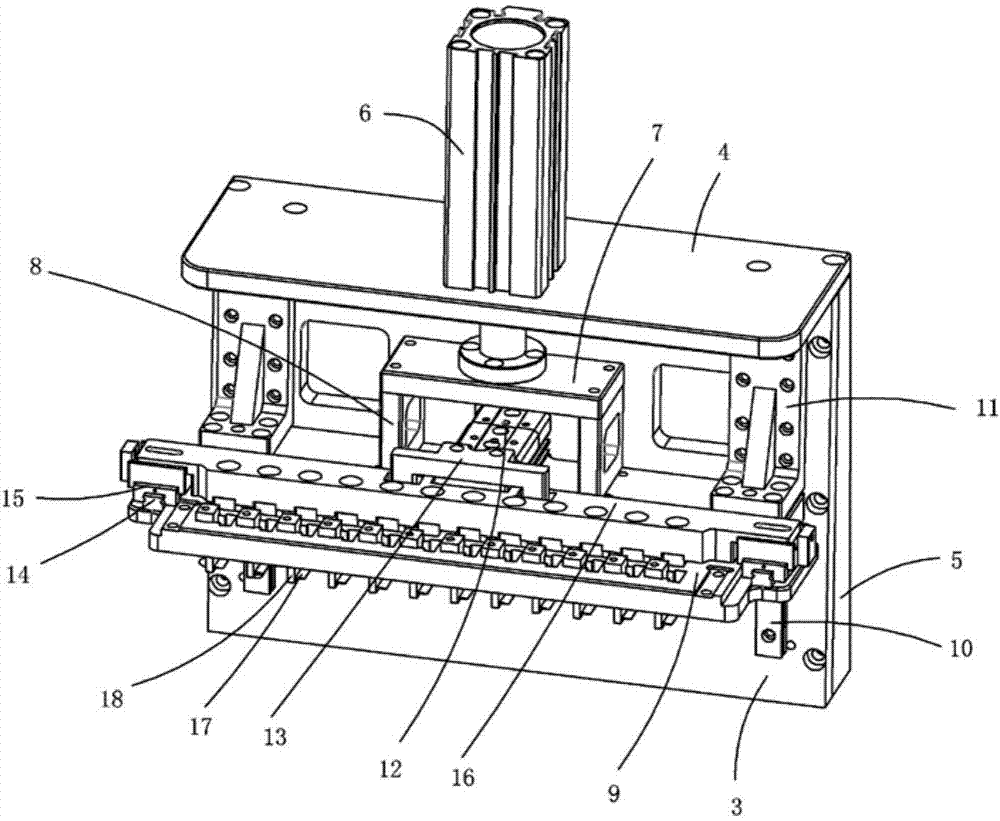

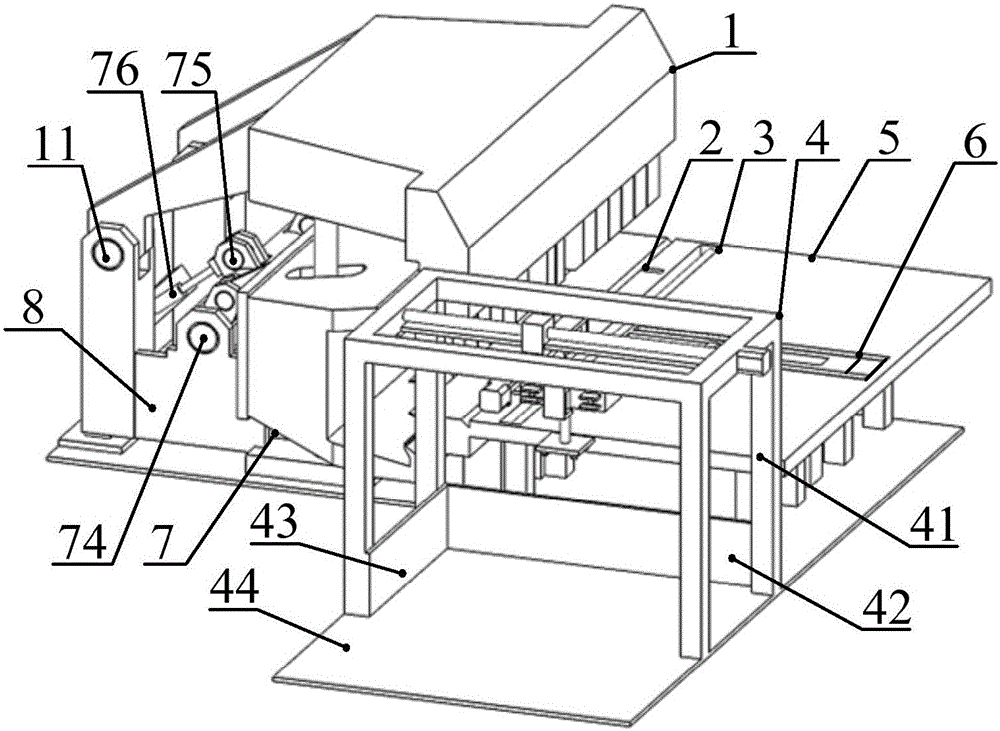

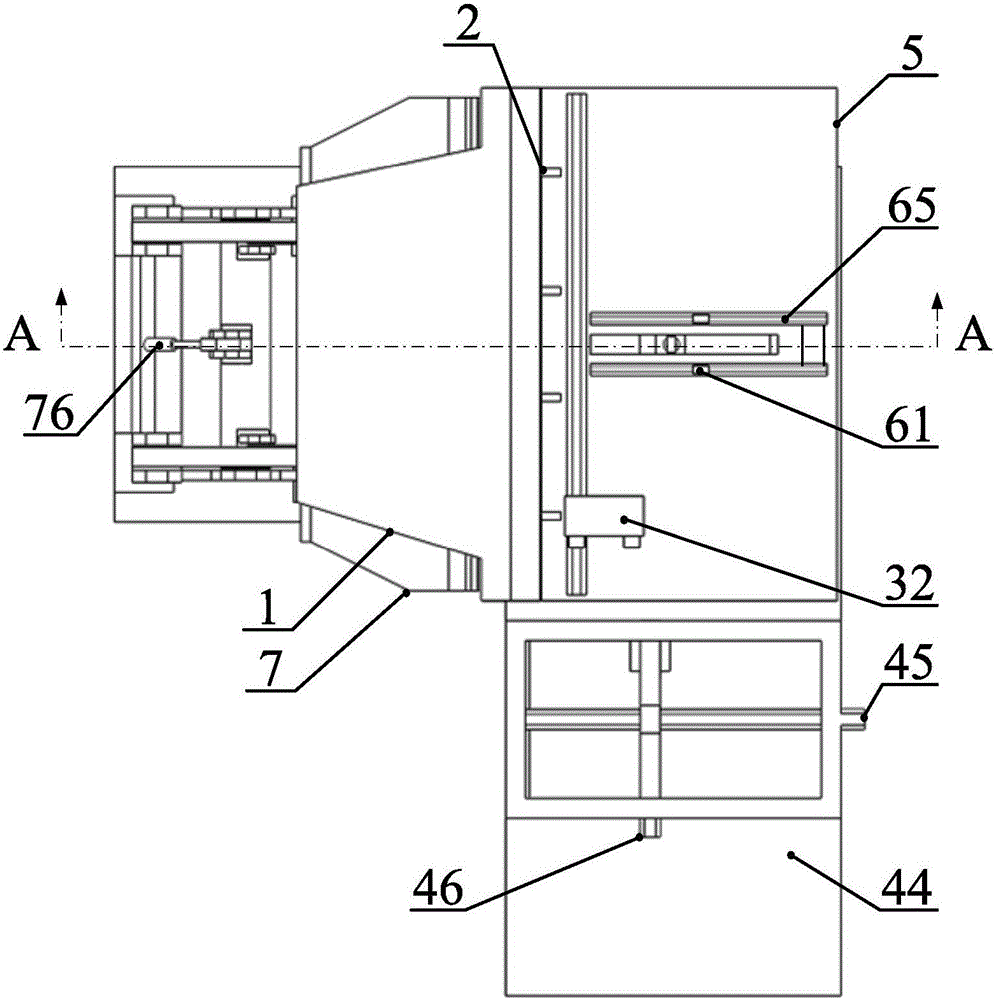

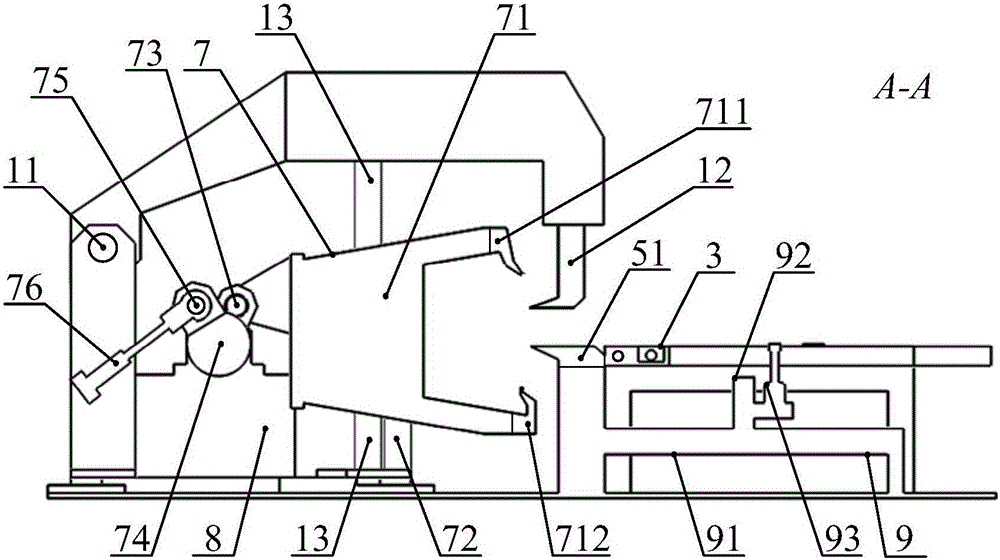

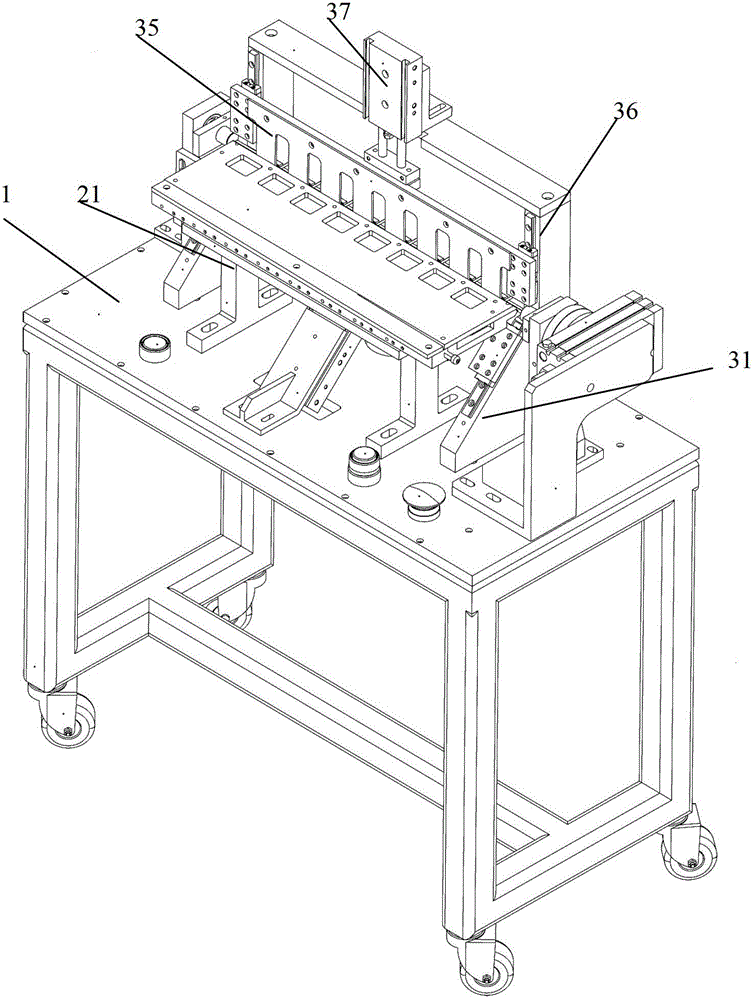

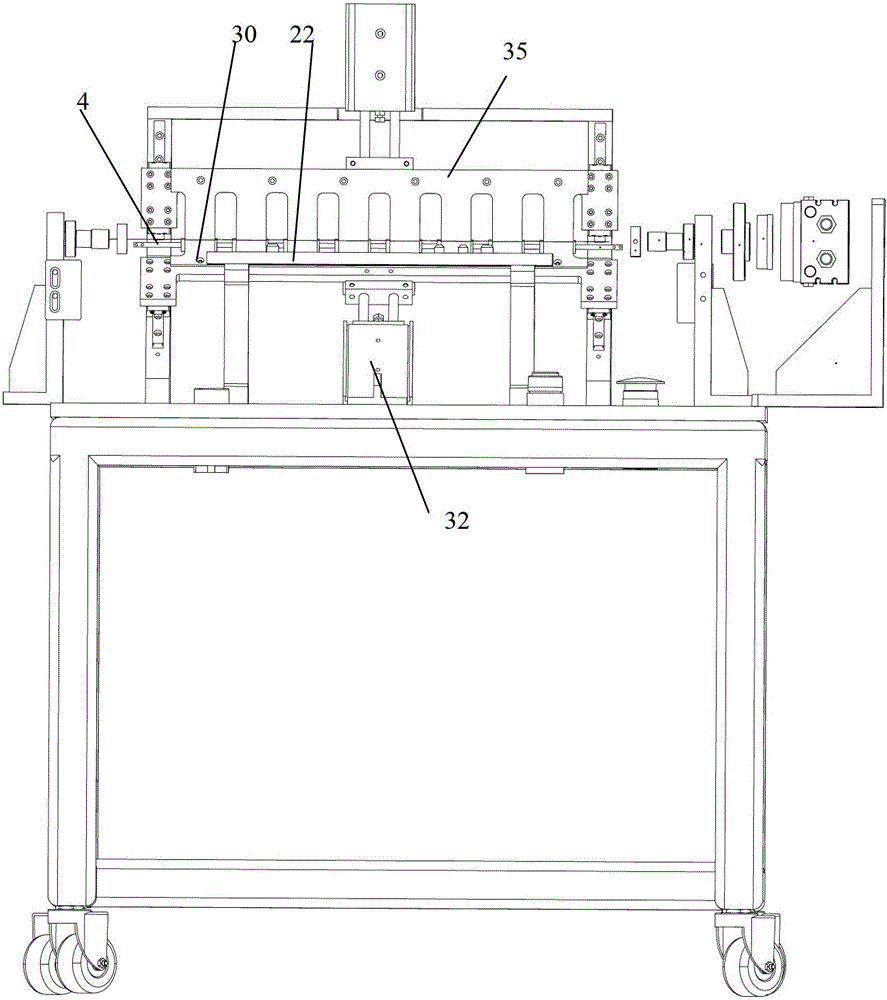

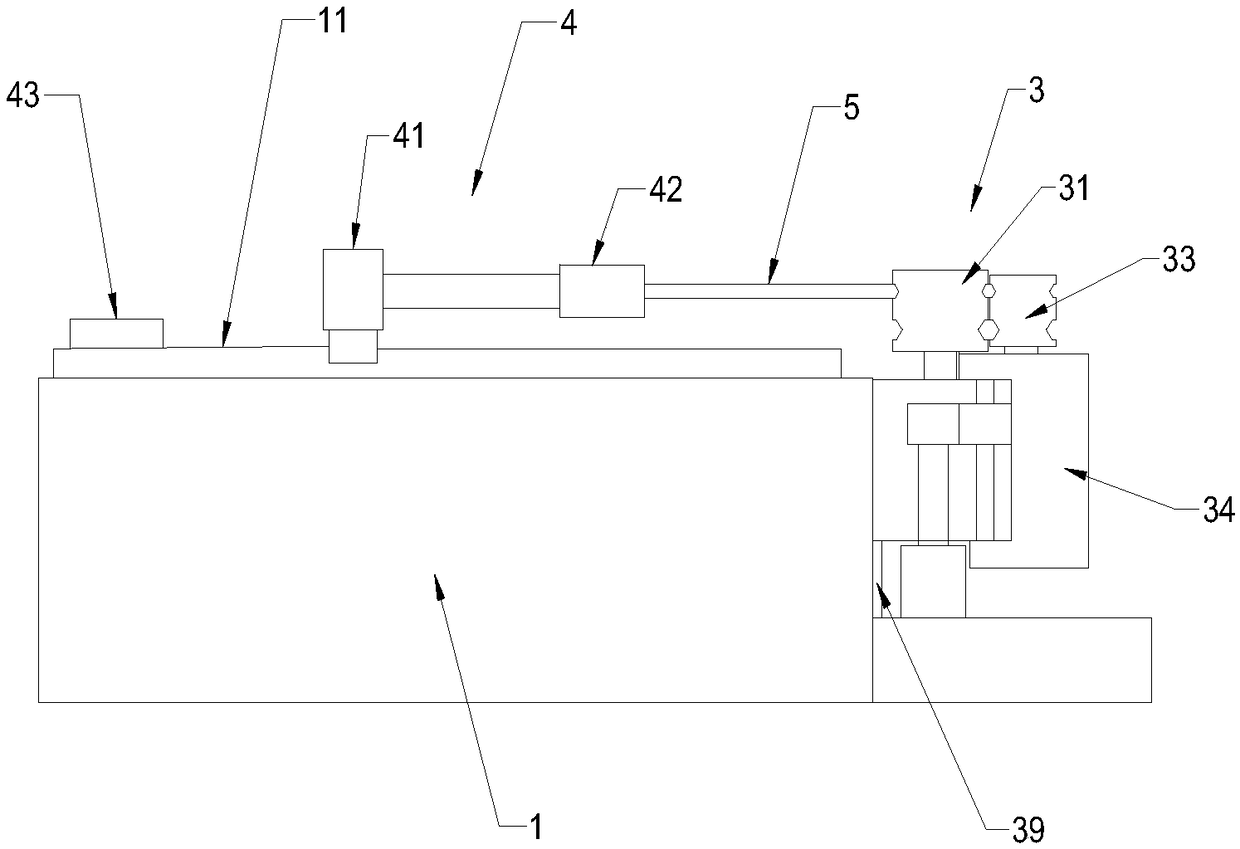

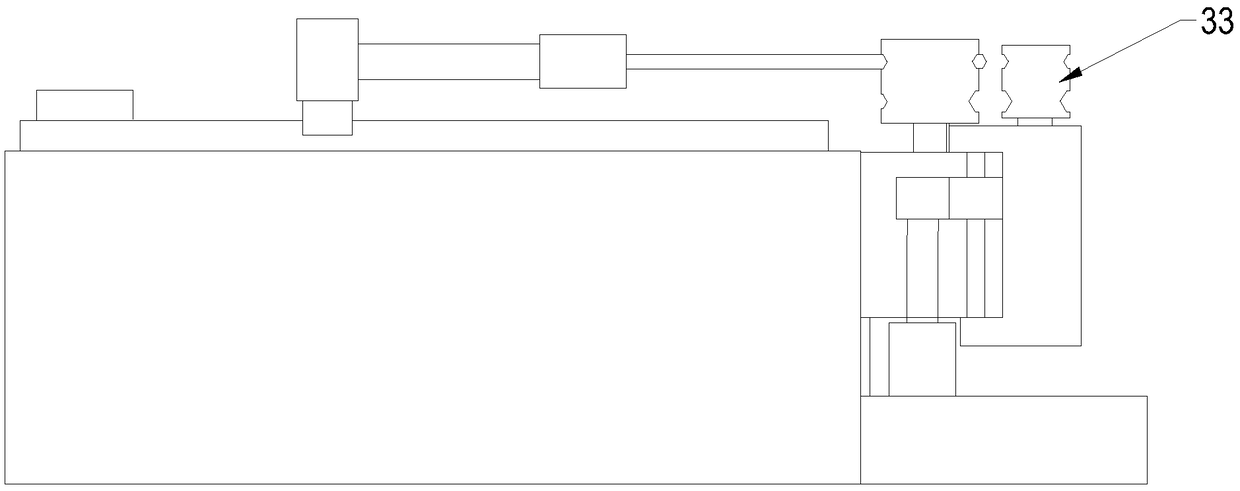

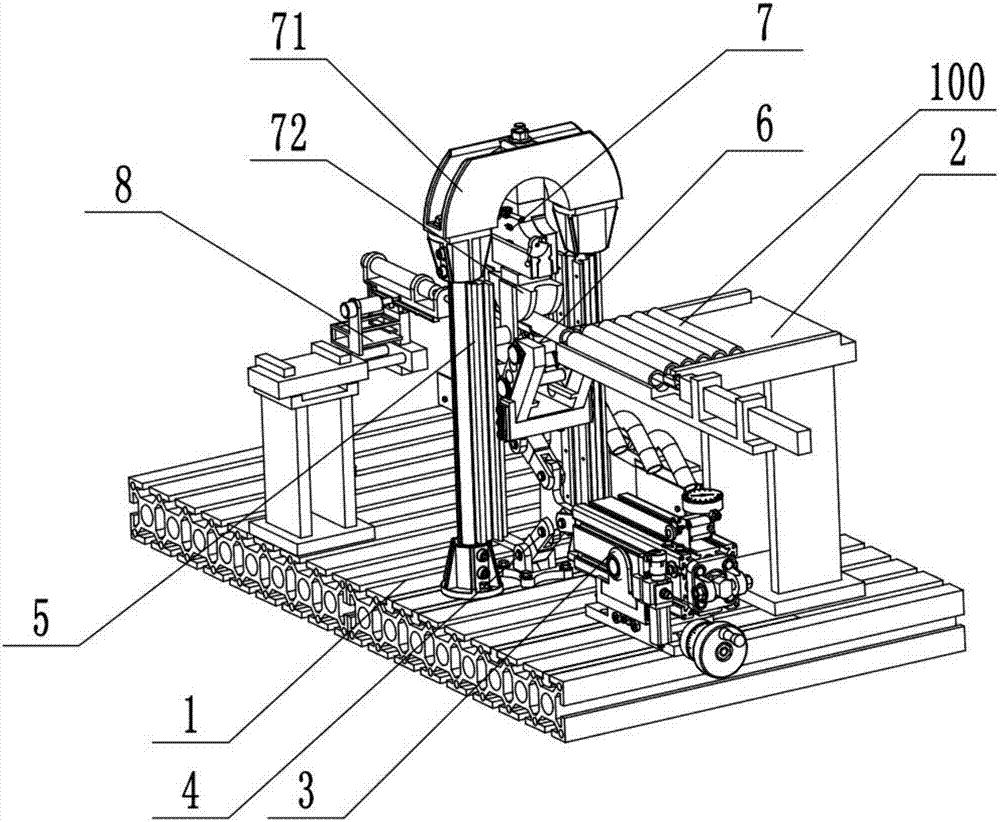

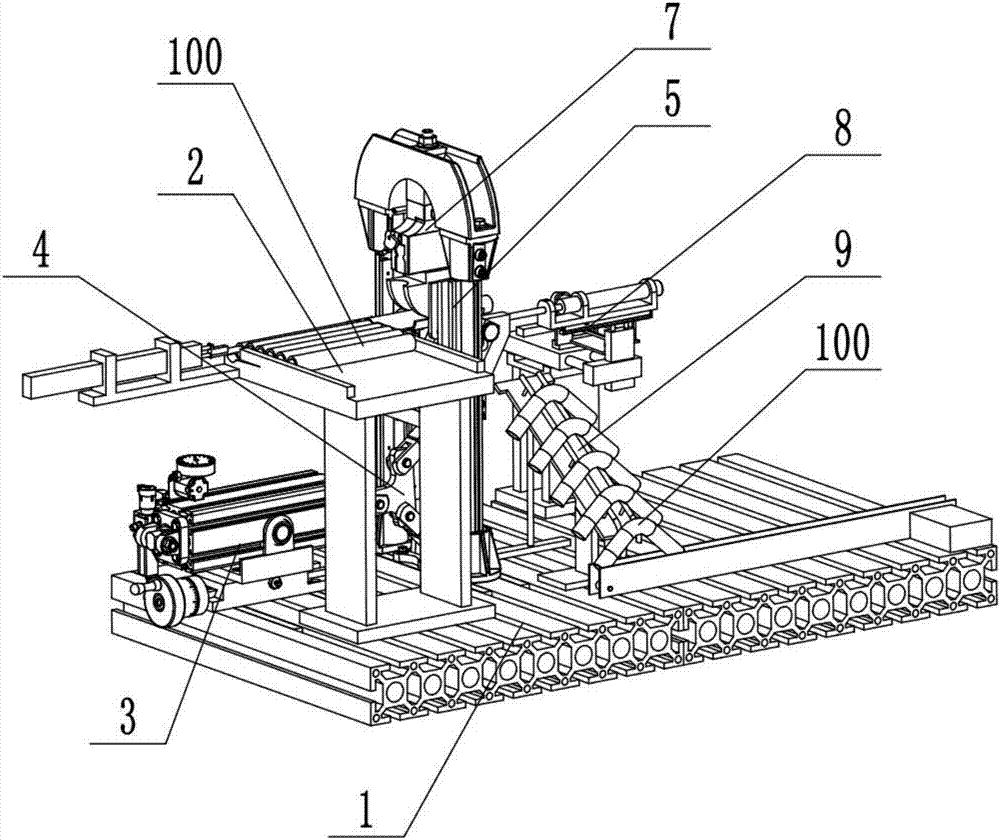

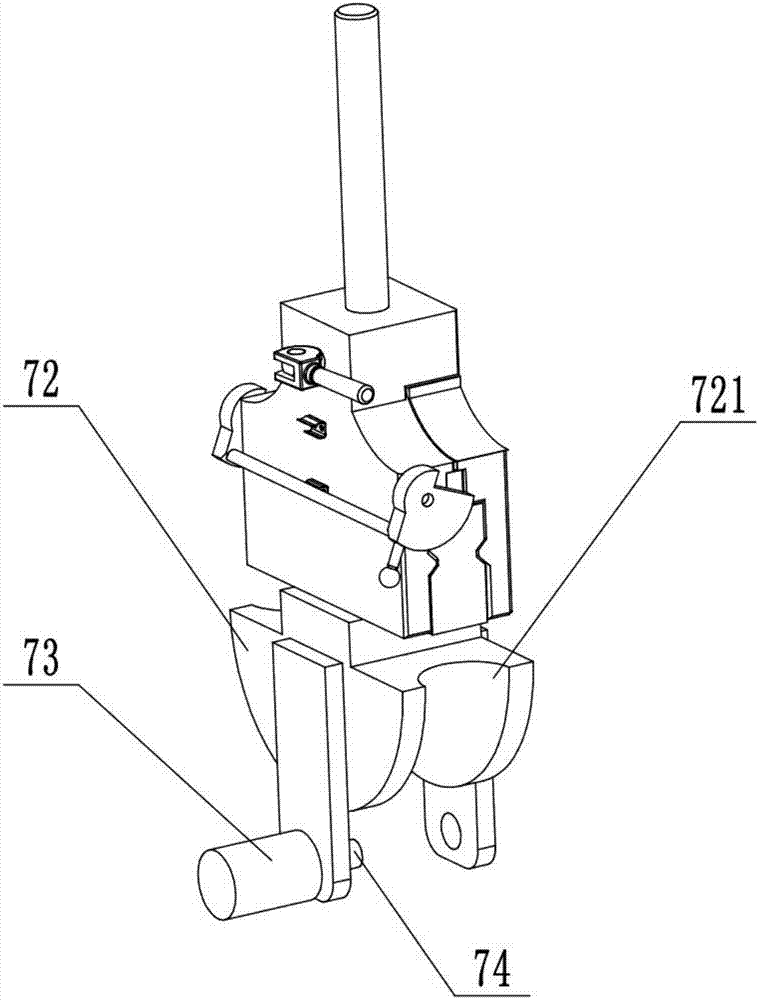

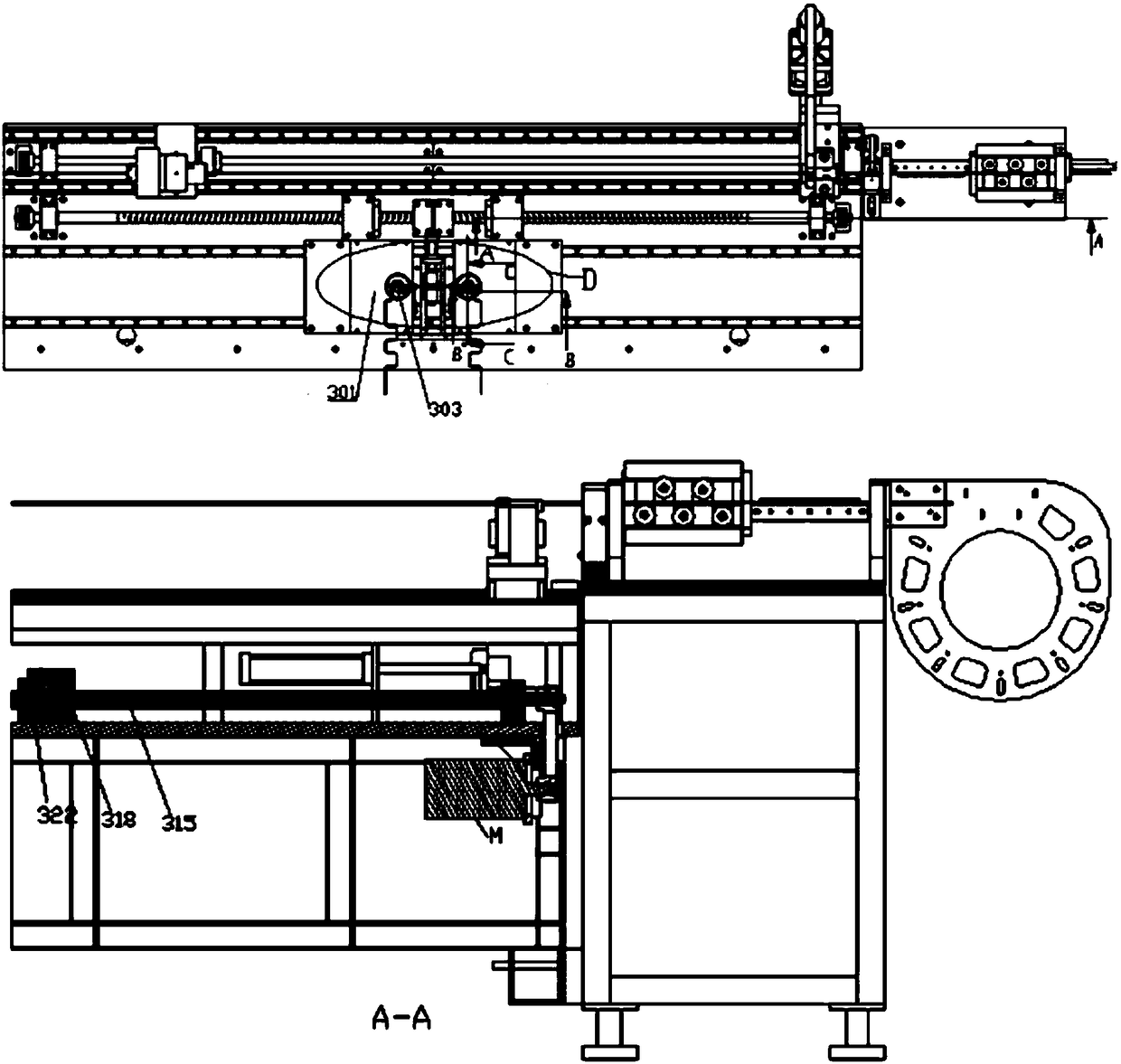

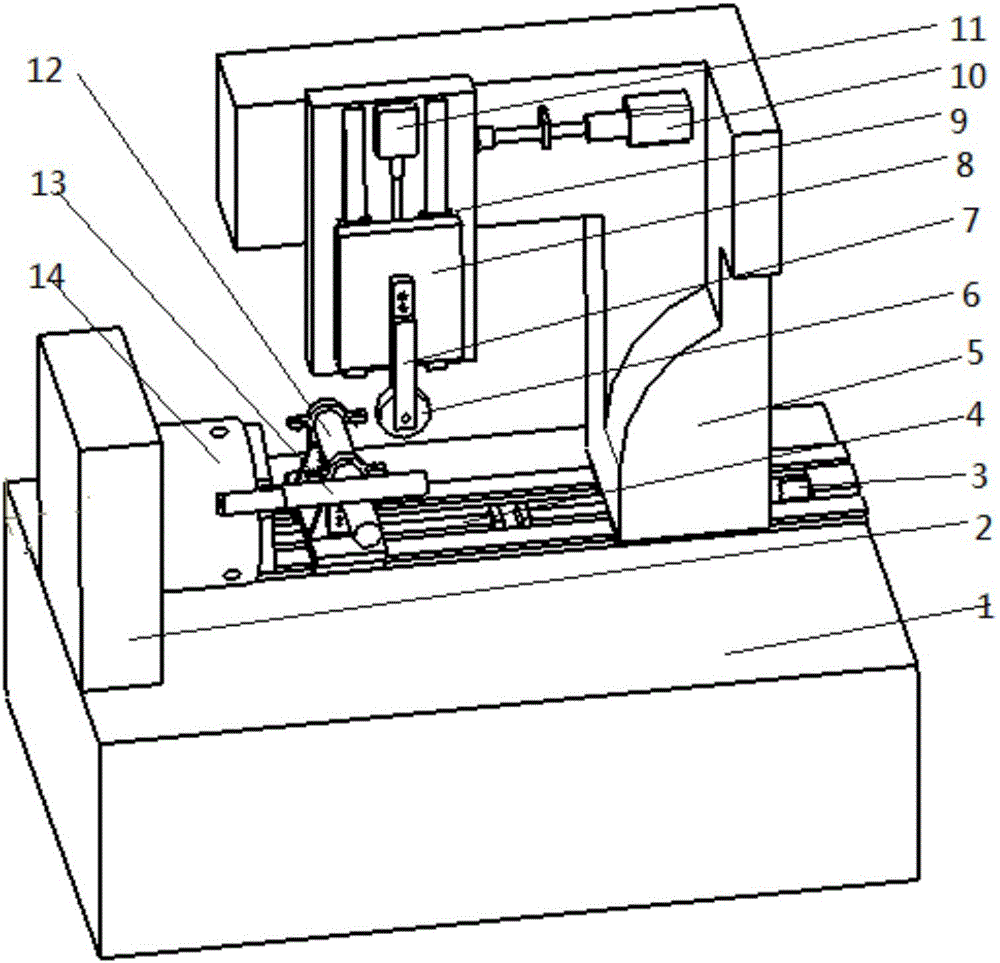

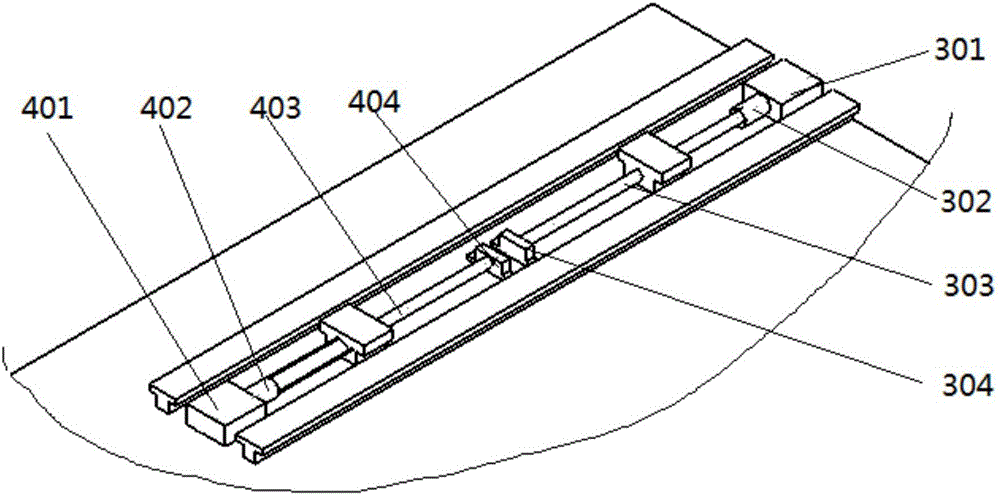

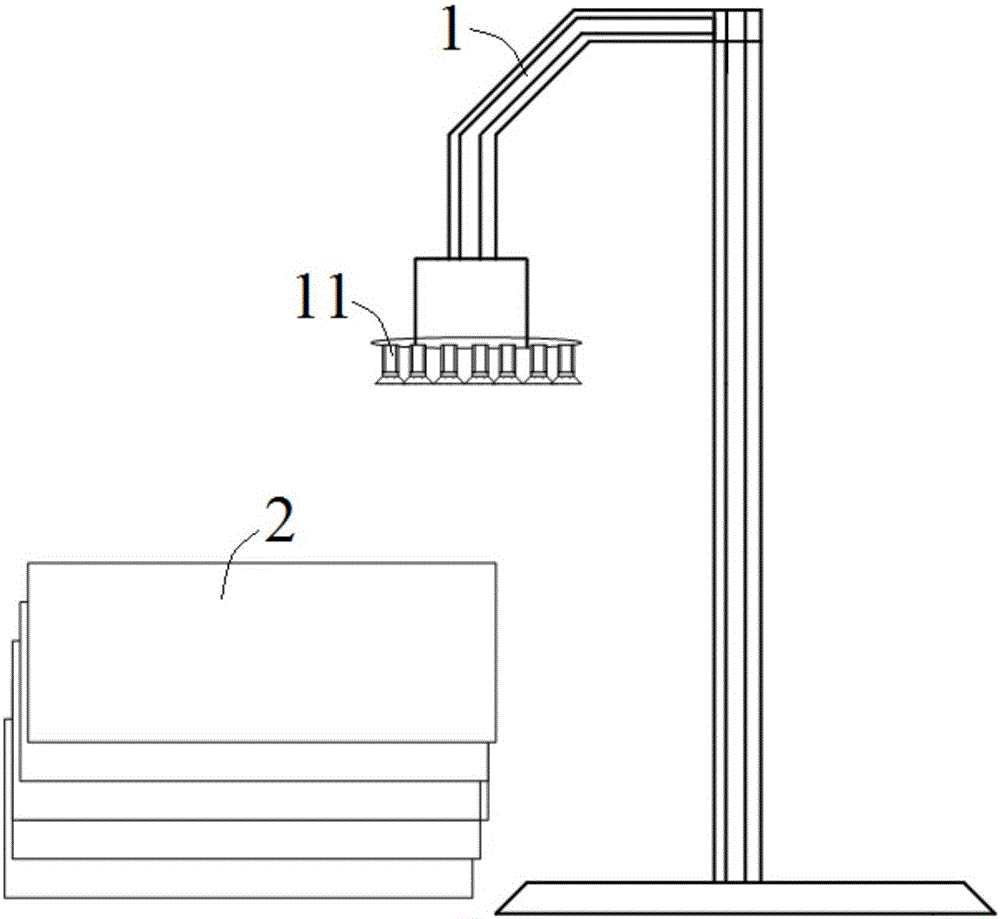

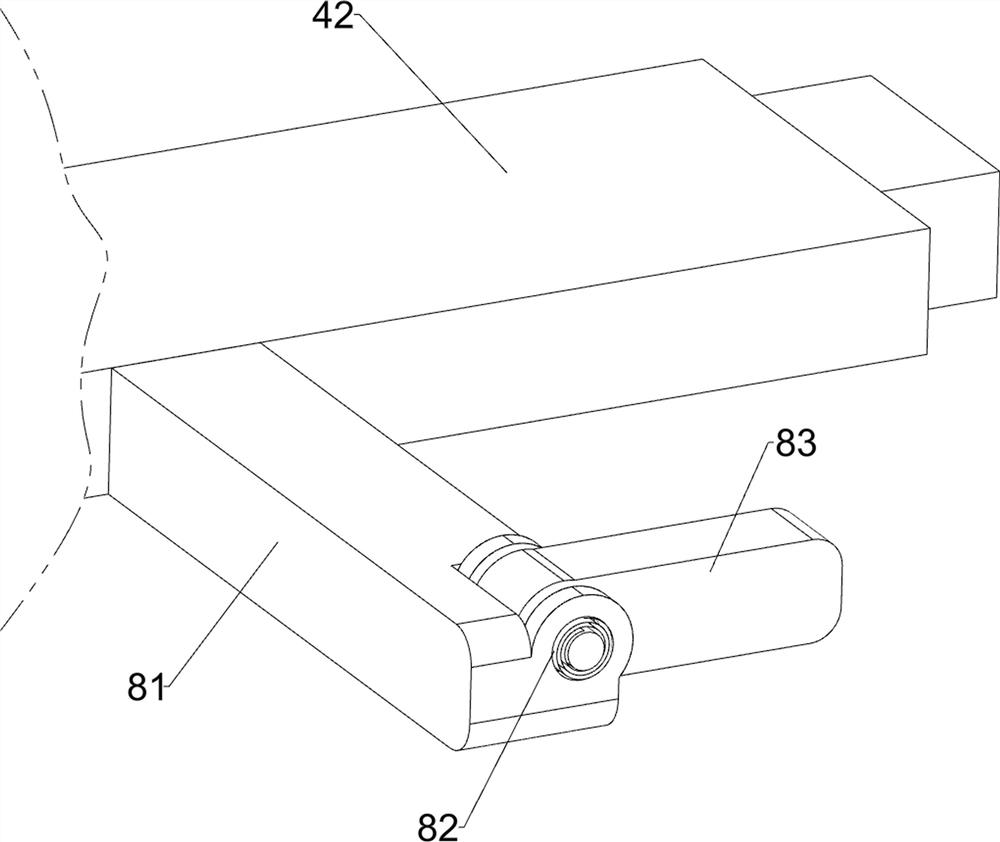

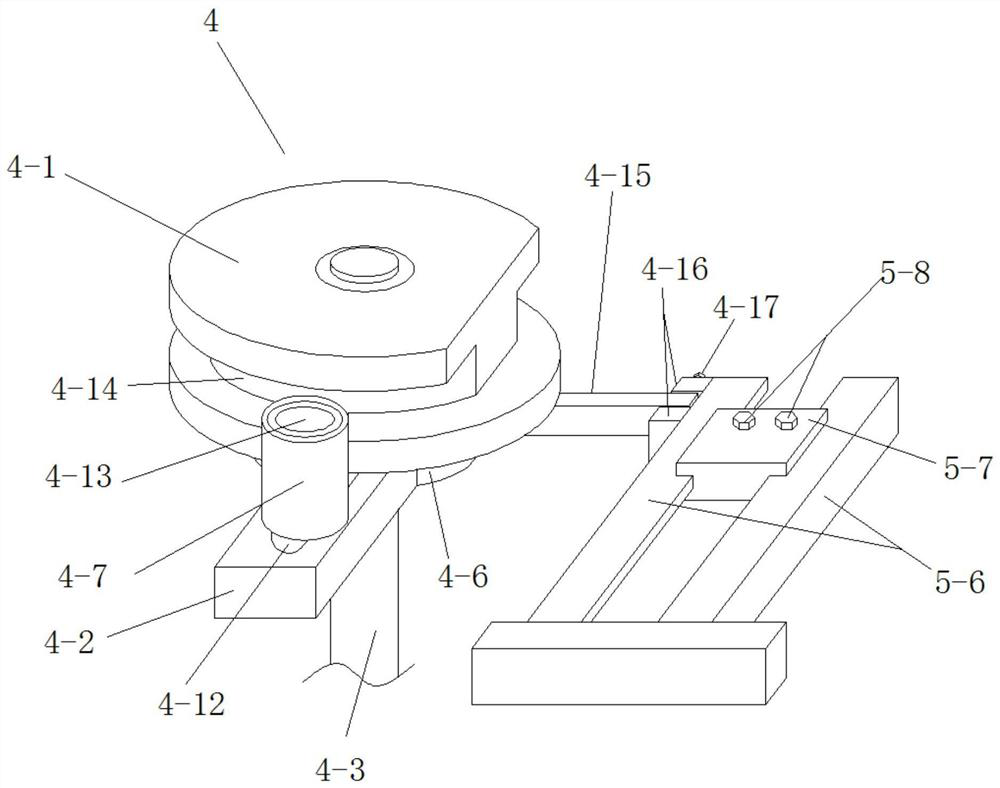

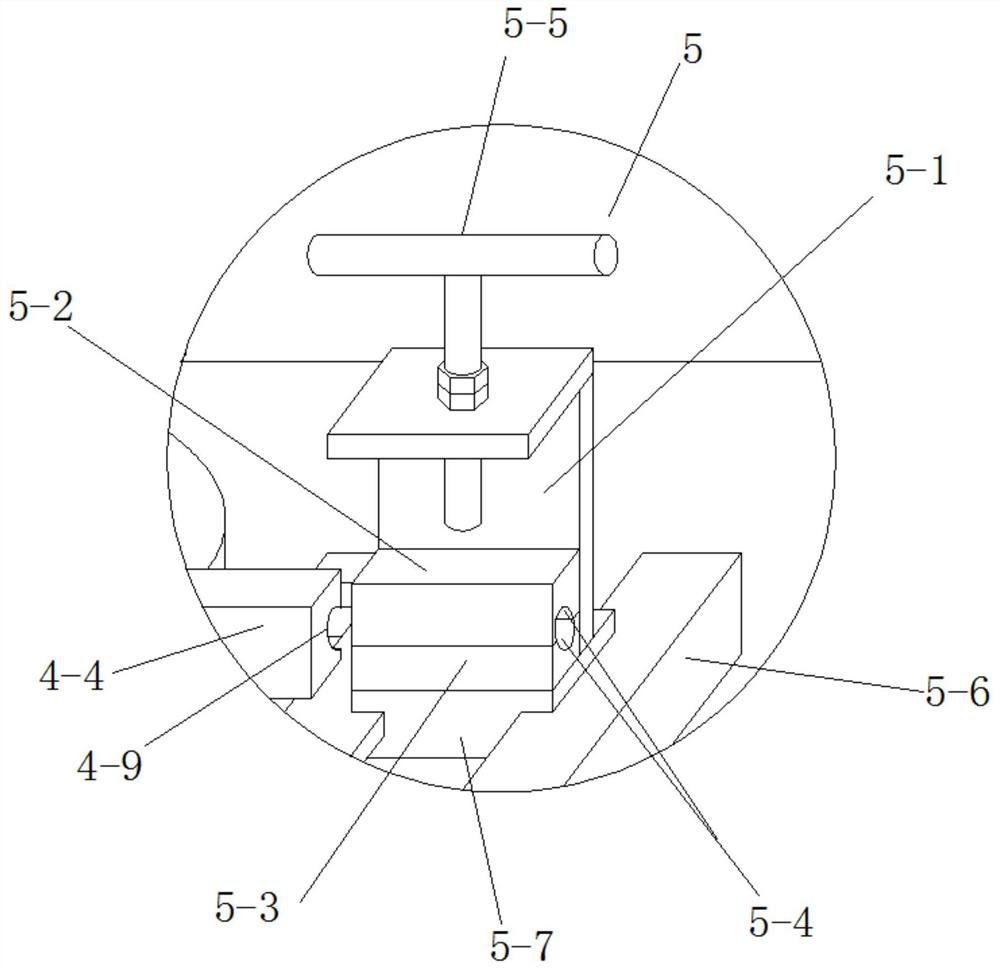

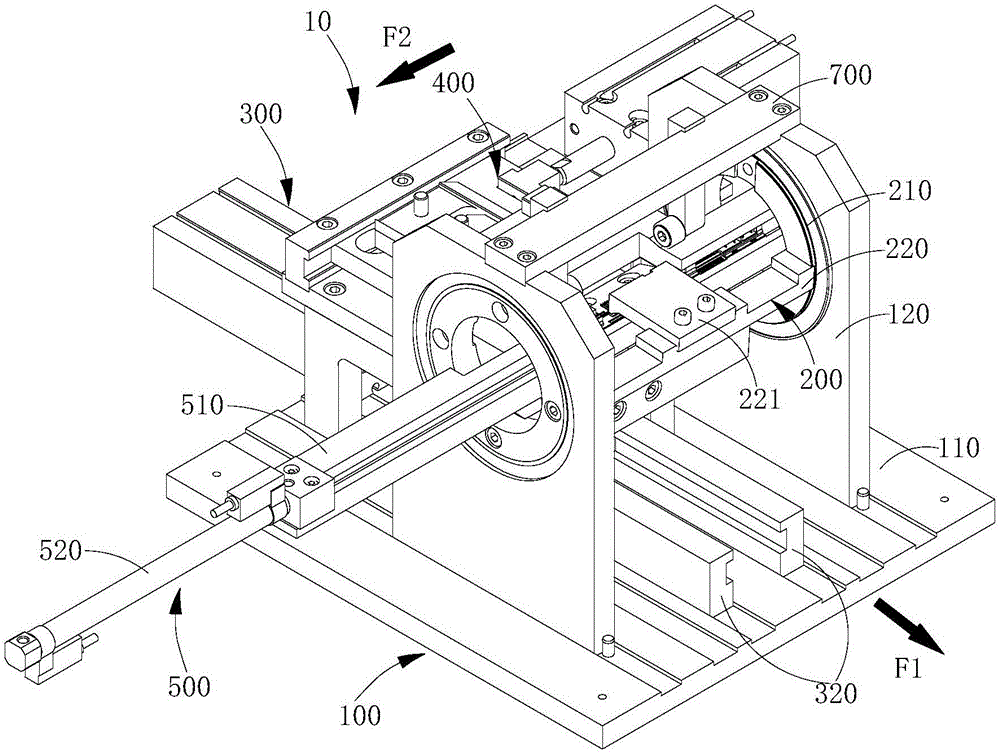

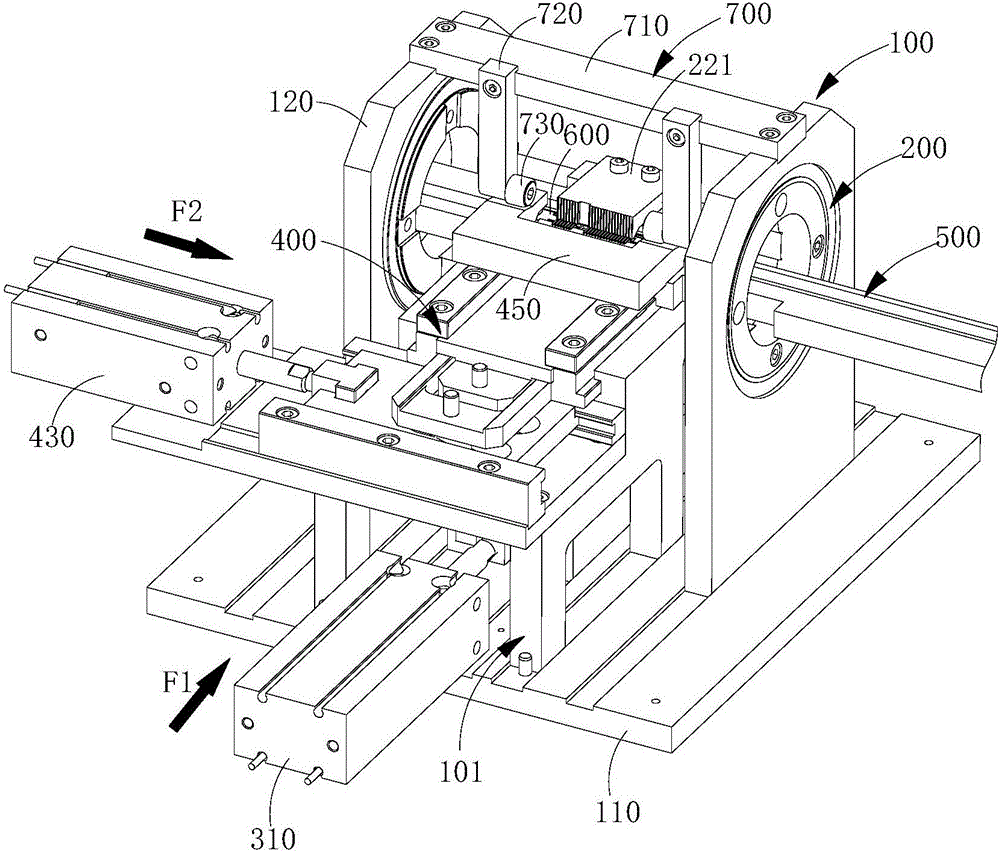

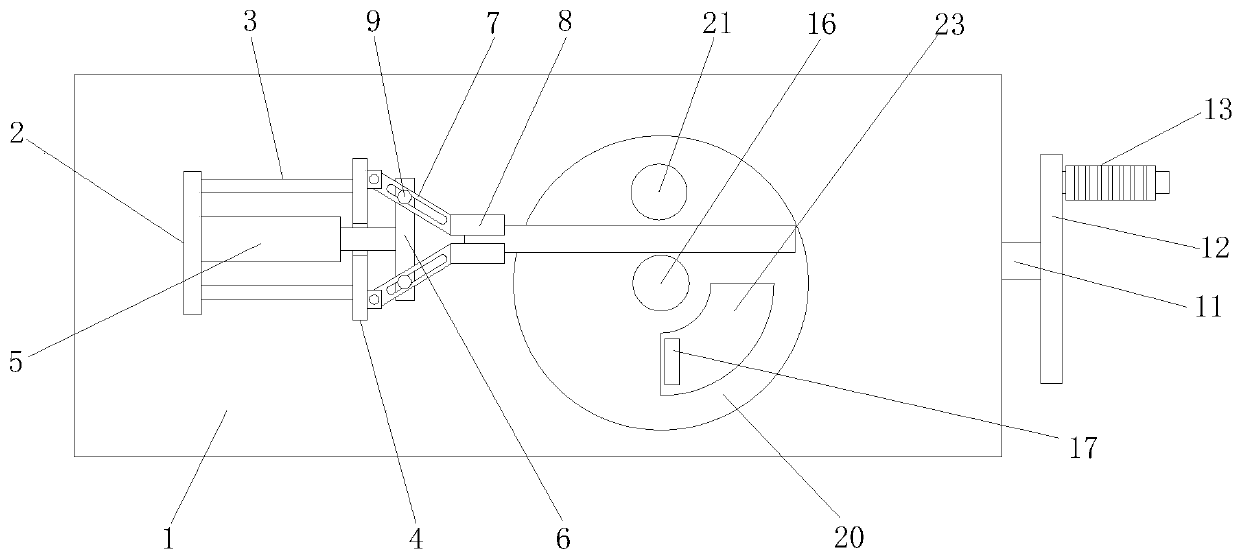

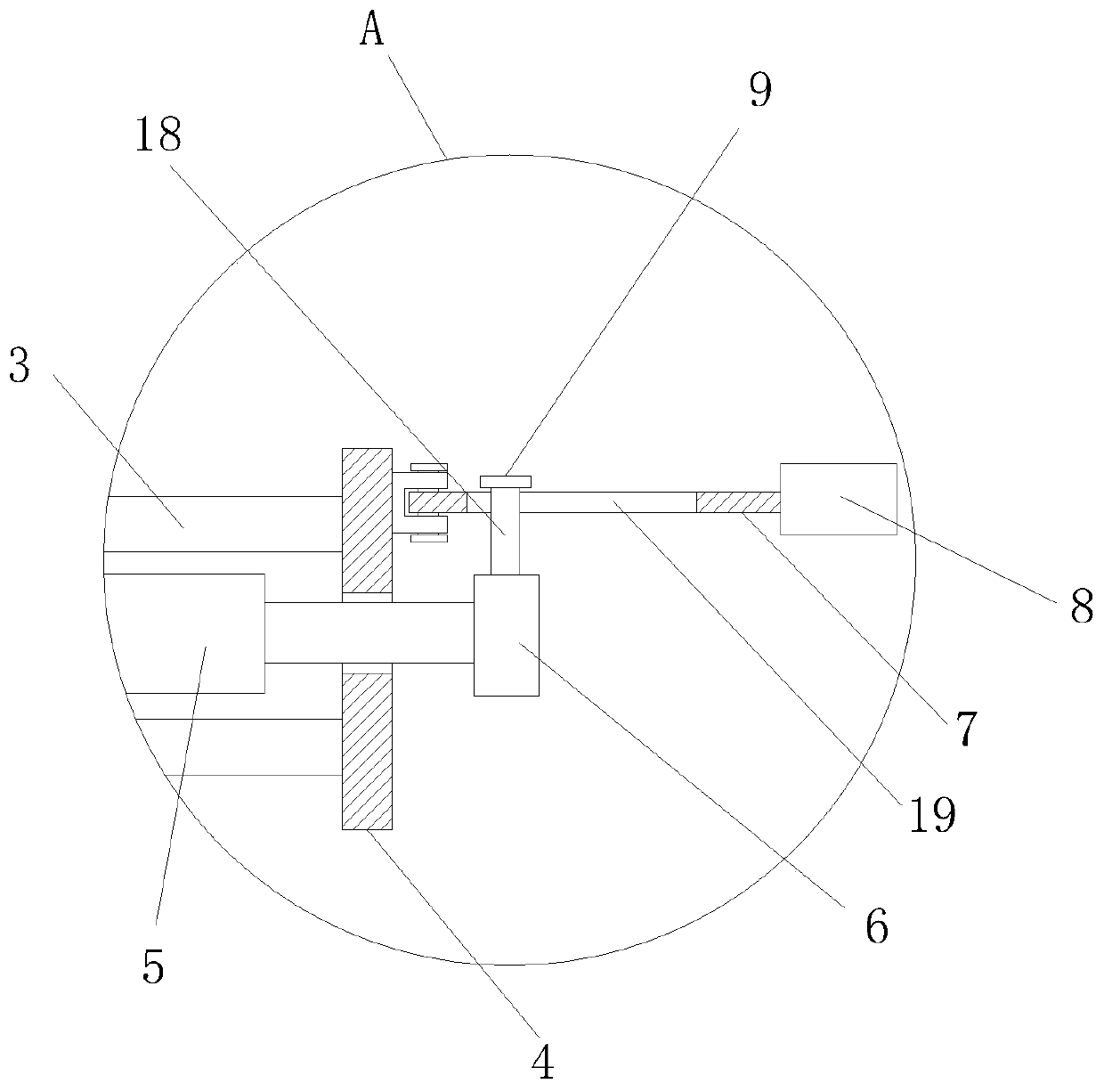

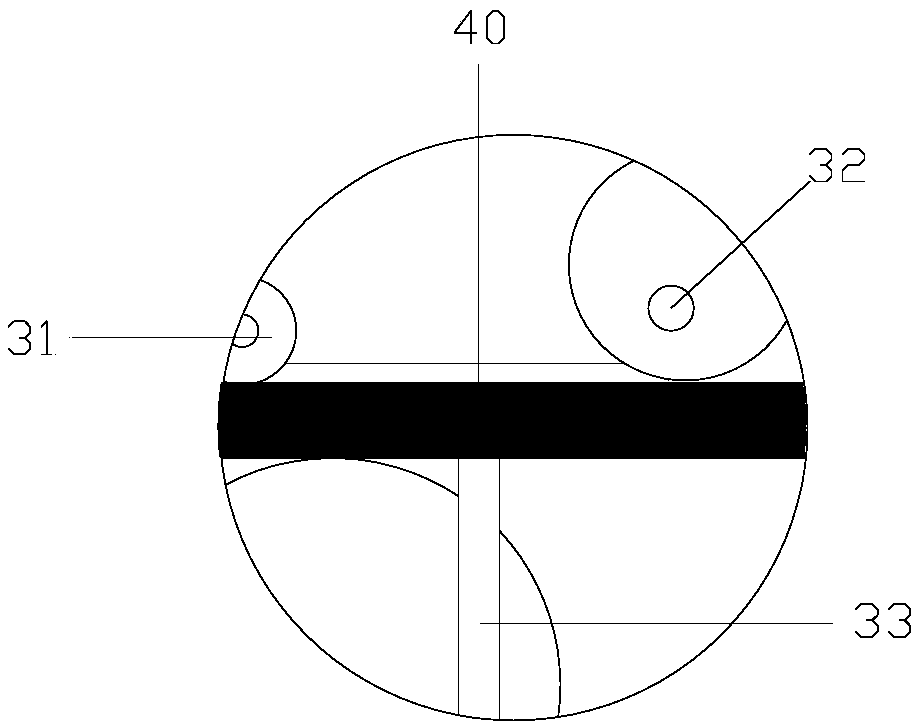

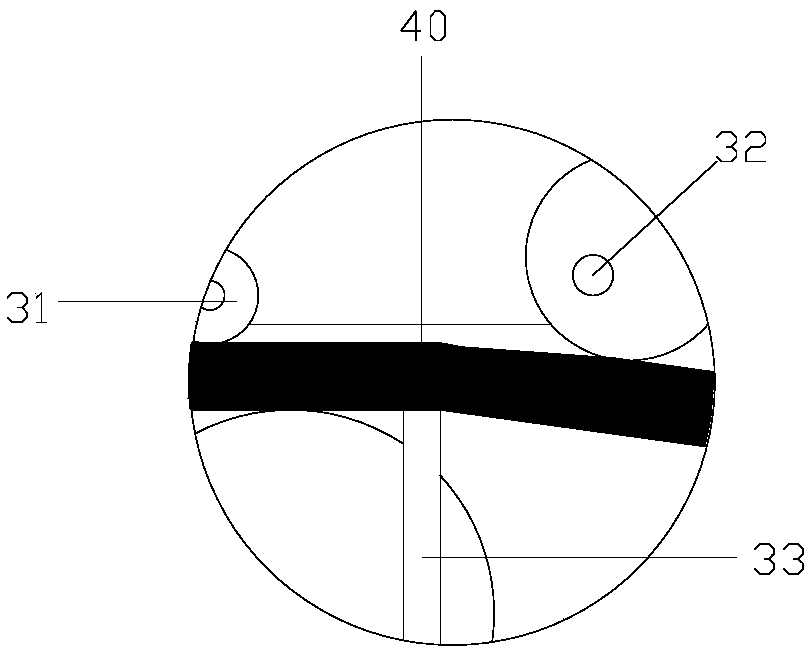

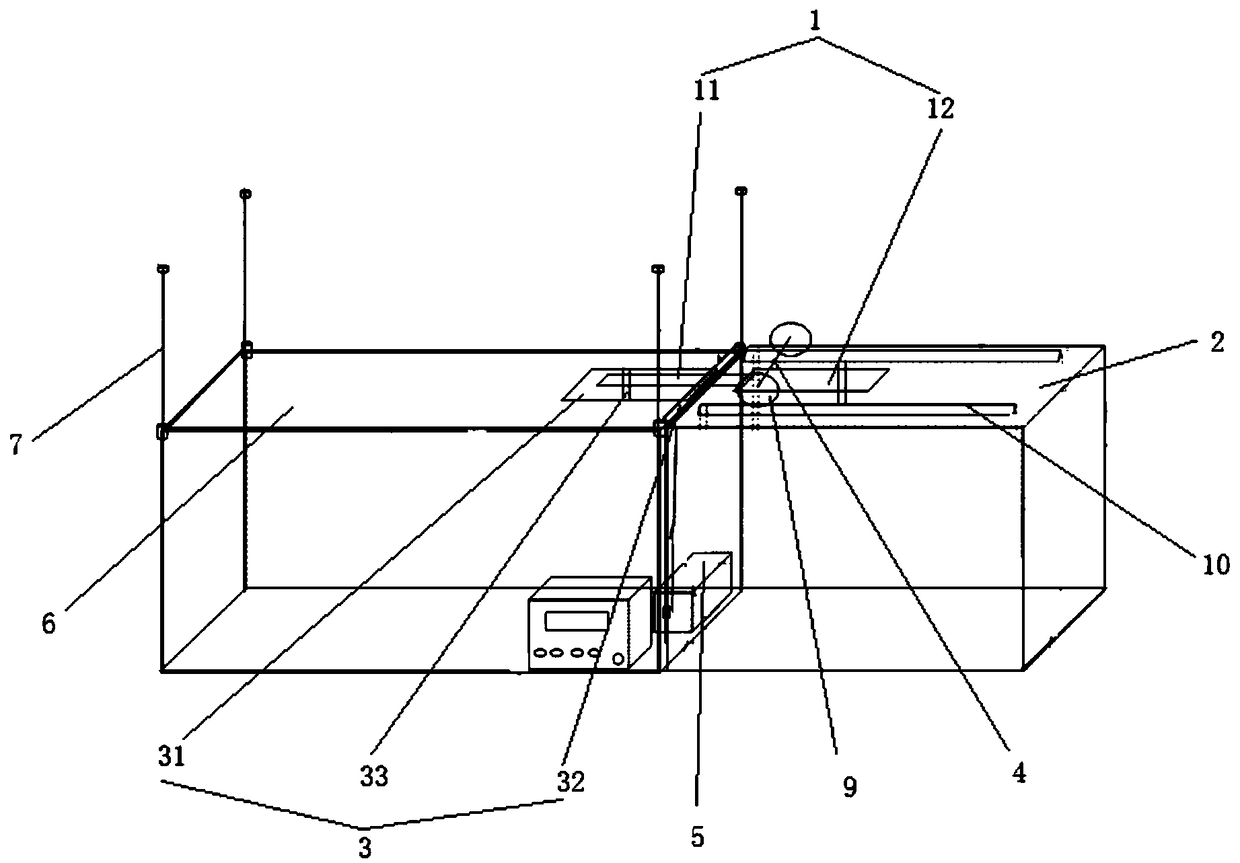

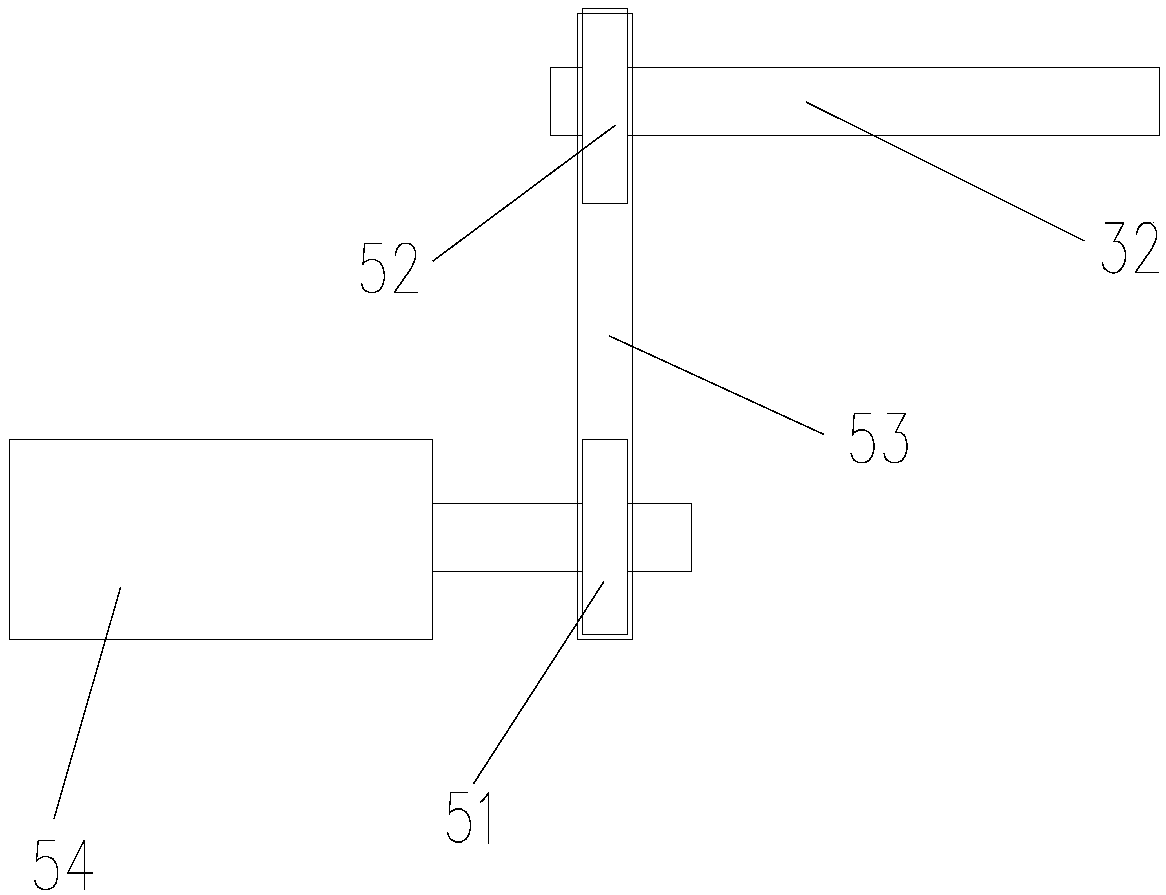

Pipe bending machine

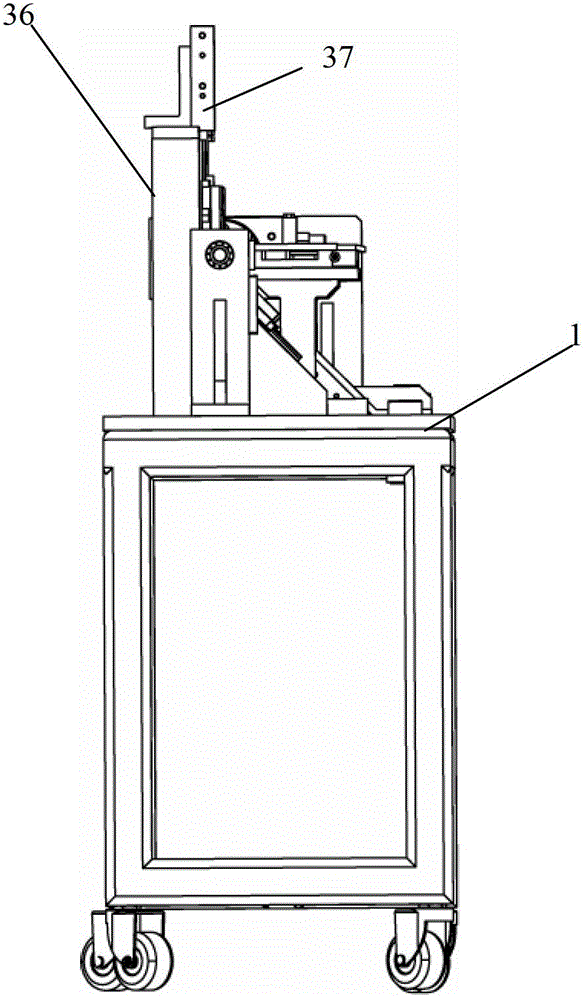

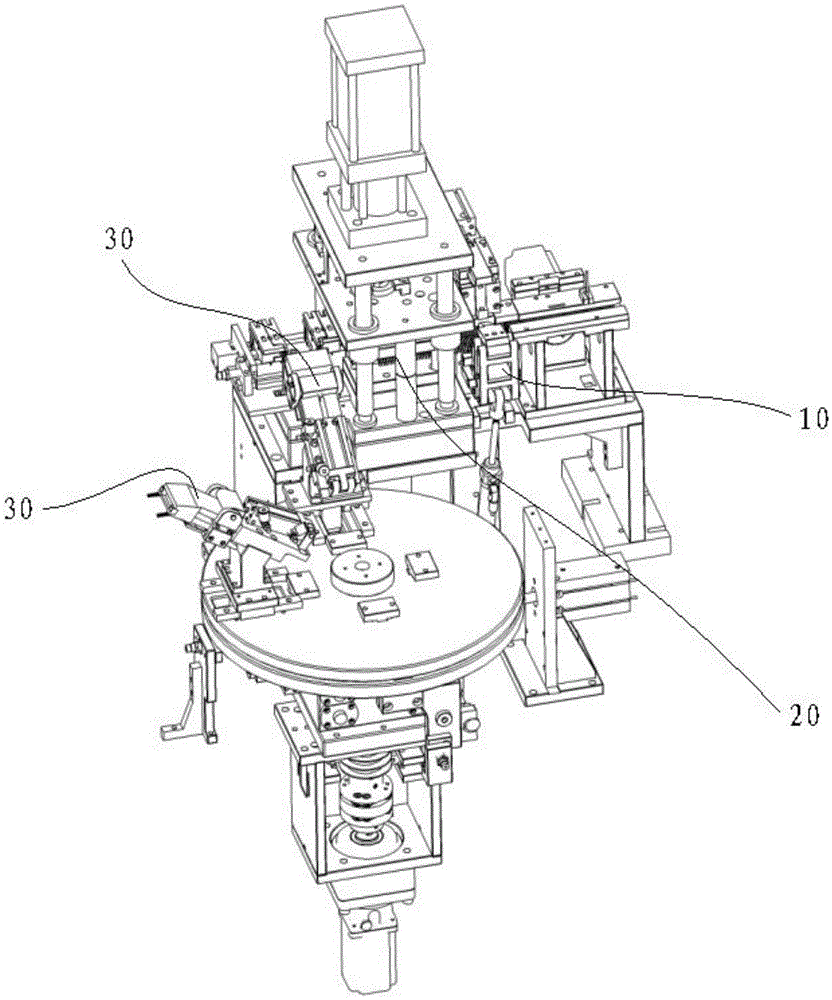

PendingCN108787818AIncrease productivityImprove bending efficiencyMetal-working feeding devicesPositioning devicesIndustrial engineering

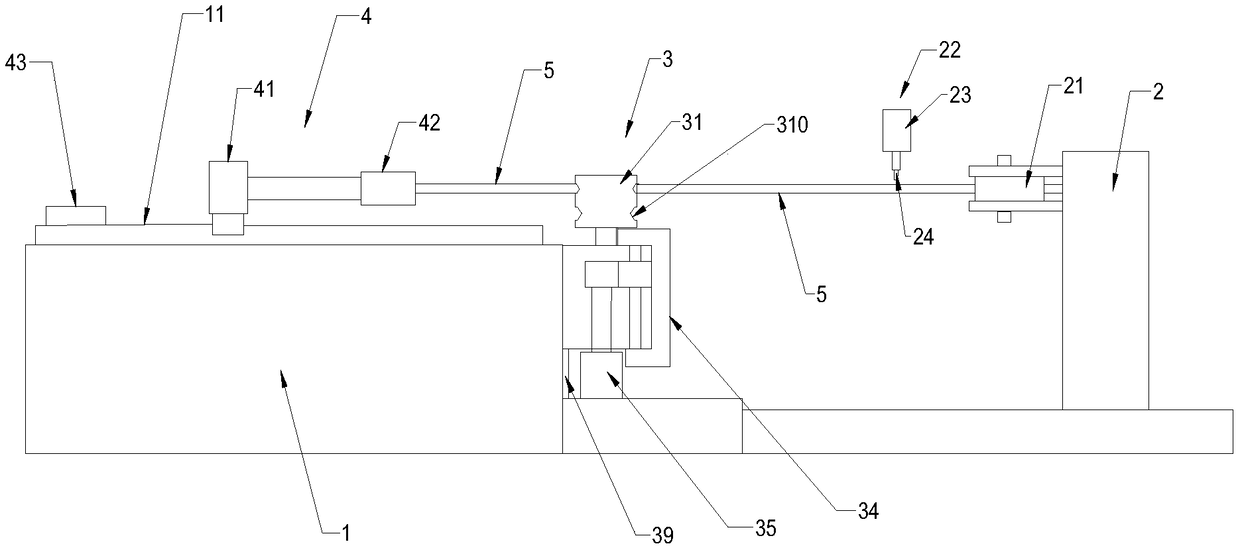

The invention discloses a pipe bending machine which comprises a workbench (1) and a feeder (2). The feeder (2) is arranged on the outer side of one end of the workbench (1), and a first sliding rail(11) is arranged on the upper end face of the workbench (1). A clamping device (4) is slidingly arranged on the first sliding rail (11), and the bottom of the clamping device (4) can slide back and forth in the extending direction of the first sliding rail (11) through cooperation of the clamping lead screw and a clamping motor (43). The clamping device (4) comprises a pipe motor (41), and a clamping pipe (42) arranged at the end of an output shaft of the pipe motor (41). The clamping pipe (42) is in a polygon shape consistent with the shape of a pipe (5) to be bent. A bending device (3) is arranged between the clamping pipe (42) and the feeder (2). According to the pipe bending machine, the polygonal pipe can be continuously bent in multiple planes, and bending efficiency is improved.

Owner:张家港市越泰精密机械有限公司

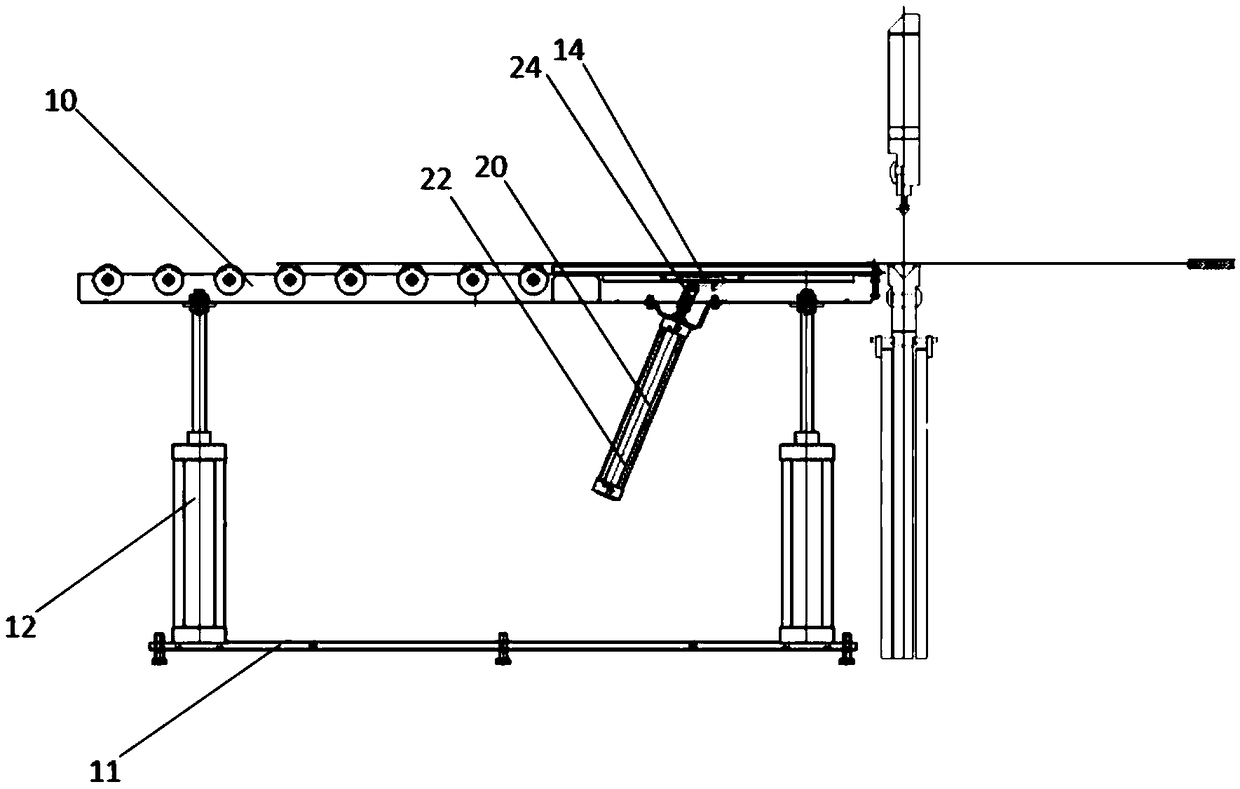

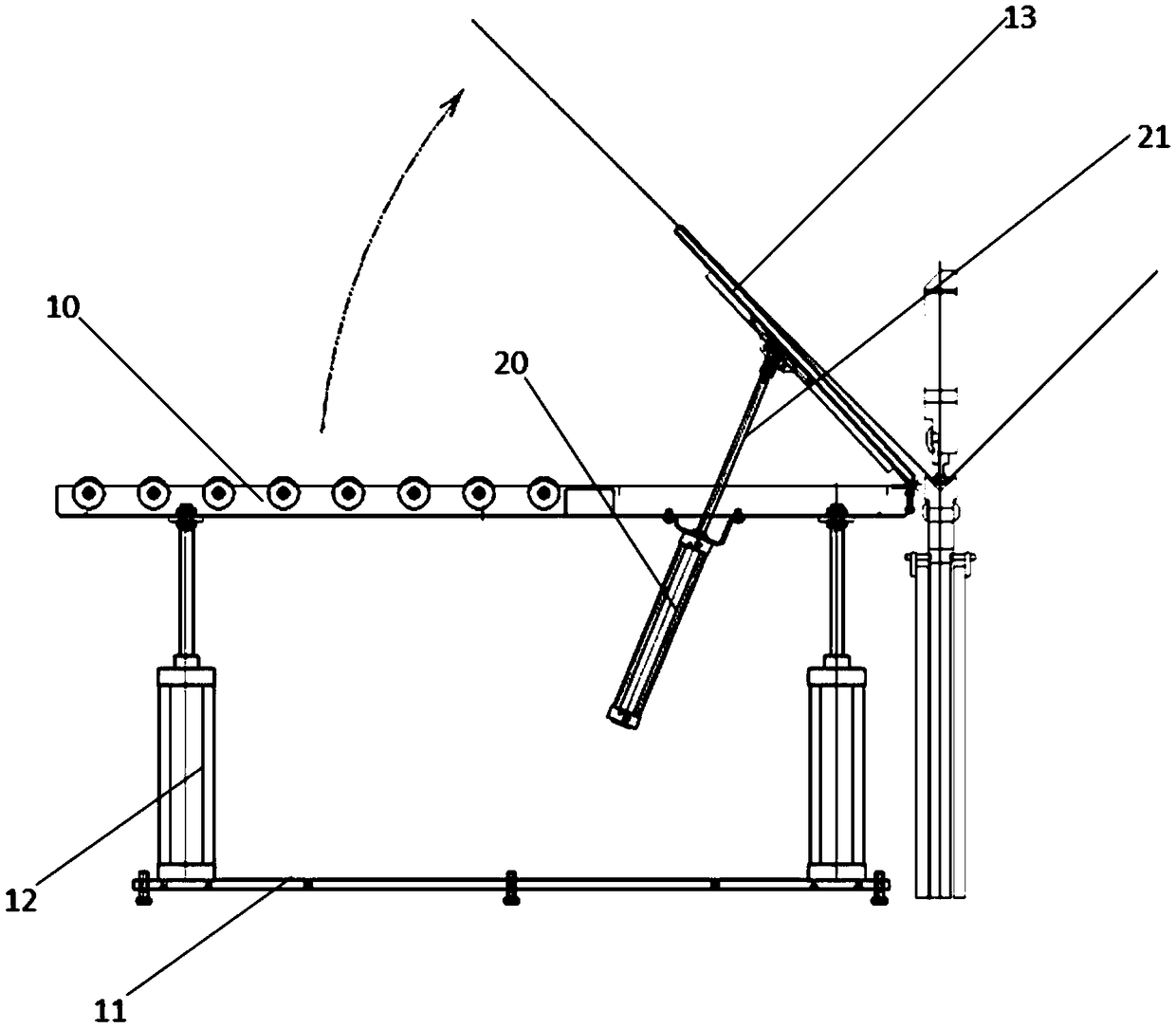

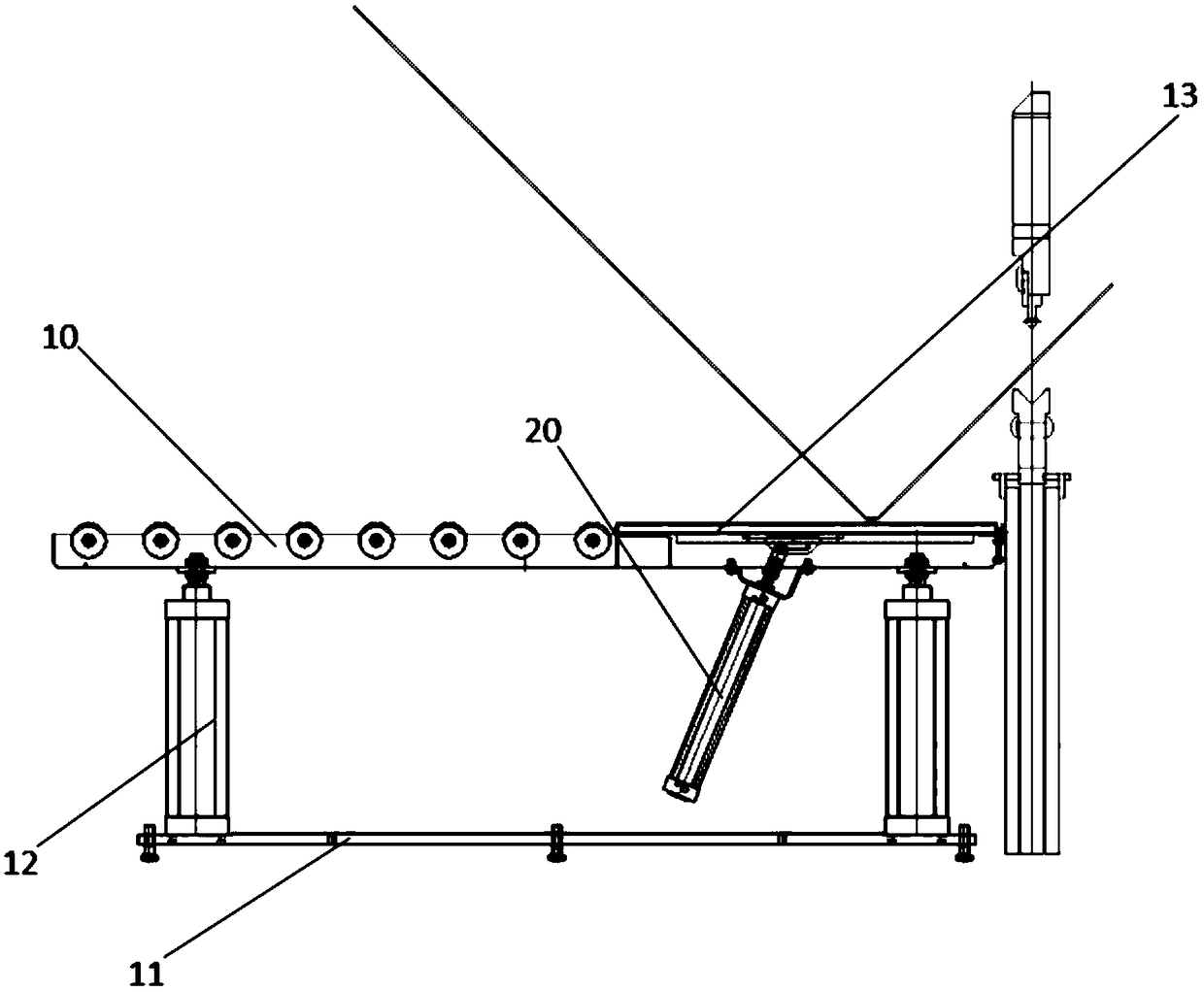

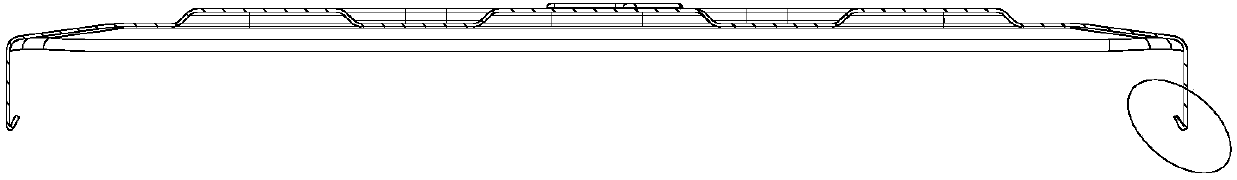

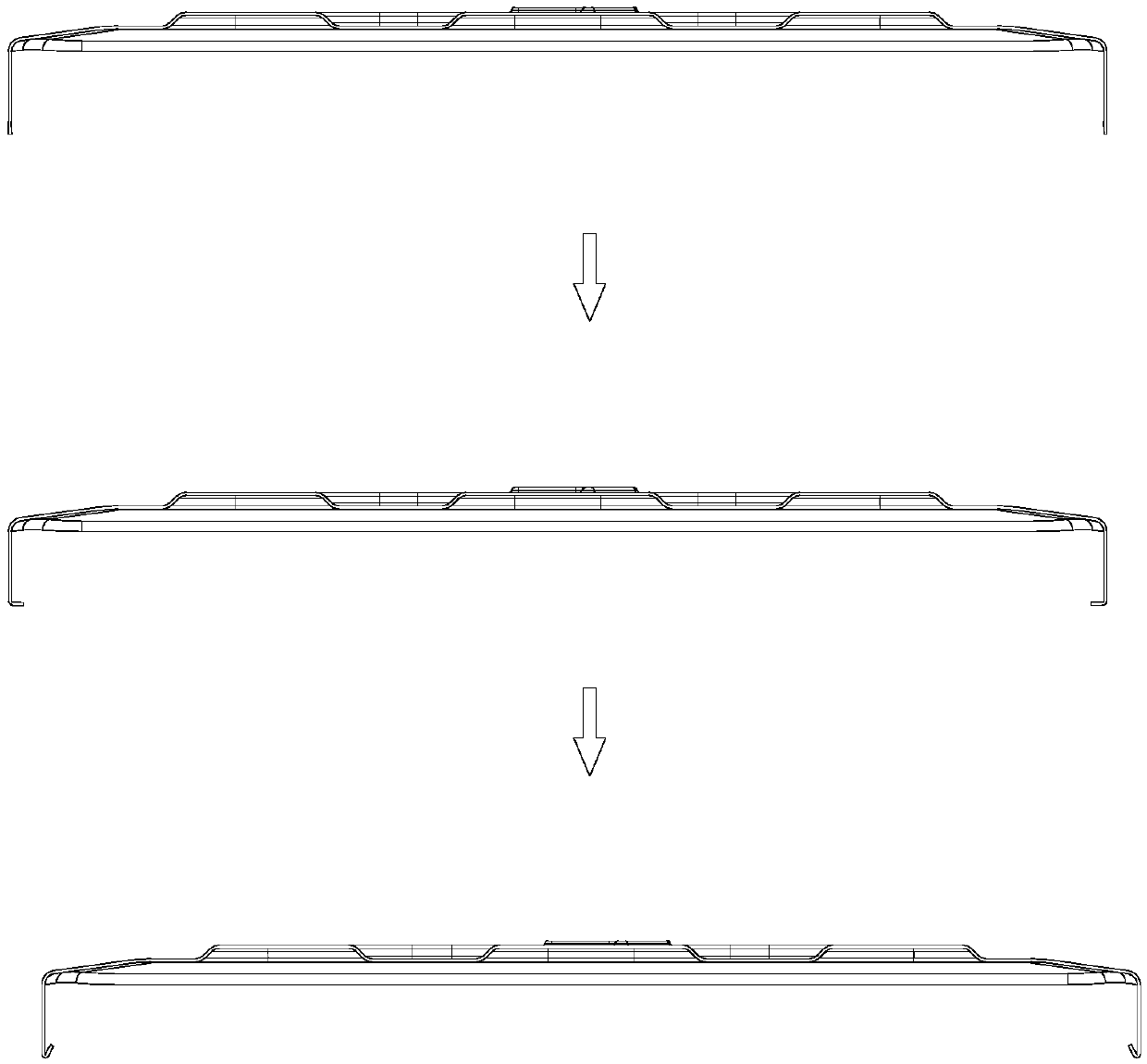

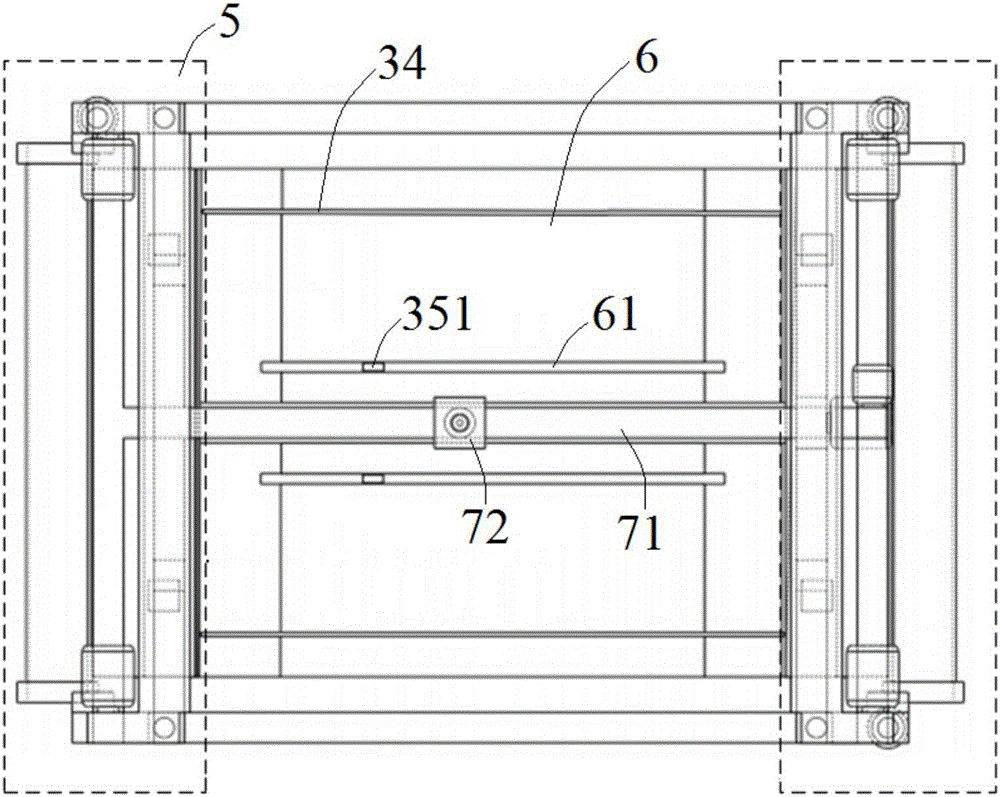

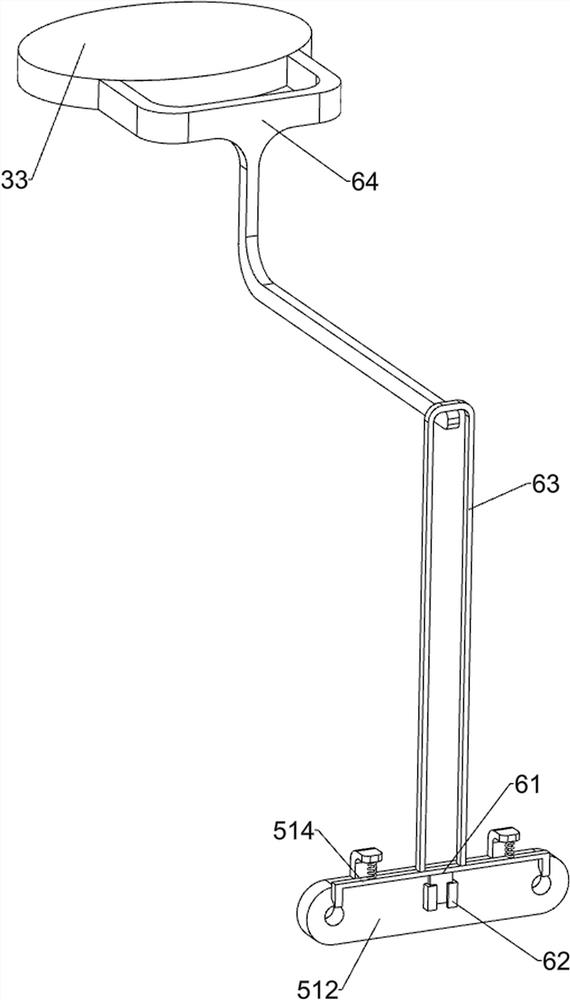

Follow-up supporting device, upward moving type bender and plate bending method

PendingCN108856382AImprove bending efficiencyReduce work intensitySolenoid valveUltimate tensile strength

The invention discloses a follow-up supporting device, an upward moving type bender and a plate bending method. The follow-up supporting device comprises a lifting table, wherein the lifting table isrotatably connected with a lifting flip; the lifting table is fixedly connected with a push rod device; the push rod device is provided with a push rod; the push rod pushes the lifting flip to rotate;and the push rod slides on the side surface, which faces the push rod, of the lifting flip. The upward moving type bender comprises an upper sliding block, a bending upper mold and a bending lower mold, the bending upper mold and the bending lower mold are arranged oppositely, the upper sliding block is fixedly connected with the bending upper mold, a follow-up supporting device is arranged in the feeding direction of the bending upper mold and the bending lower mold, a sensor is arranged on the side surface, which faces away from the push rod, of the lifting flip; the sensor is used for detecting whether a plate begins to be bent or not, the push rod device is provided with a solenoid valve, the solenoid valve drives the push rod to push the lifting flip to rotate when the sensor detectsthat the plate begins to be bent, the work intensity of an operator when a large plate is bent by the bender is relieved, and the plate bending efficiency is improved.

Owner:大连小松雄连机械制造有限公司

Lateral bending device

InactiveCN107737841AGuarantee product qualitySmooth strippingShaping toolsStripping-off devicesEngineeringLateral bending

The lateral bending device of the present invention relates to a bending device, and its purpose is to provide a lateral bending device in which both the bending die and the bending punch can move horizontally, the bending negative angle is large, and the mold can be demolded smoothly. device. It includes an upper mold, a lower mold, and a lateral bending mechanism. The lateral bending mechanism includes an upper mold wedge, a slider and a lateral die; one end of the slider is fixed with a lateral punch, and the other end is fixed with a push block; The slider can slide along the lower mold by connecting with the first elastic reset mechanism; the lateral die can slide along the slider by connecting with the second elastic reset mechanism; one end of the lateral die cooperates with the lateral punch to In bending, the other end and the push block form a gap; in the split state, there is a gap between the lateral punch and the inner surface of the workpiece side; in the closed state, the upper die wedge is inserted into the gap, so that the slider Sliding drives the lateral punch to abut against the side of the workpiece, and makes the lateral die move in the opposite direction of sliding relative to the slider, and cooperates with the lateral punch to bend the side of the workpiece.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

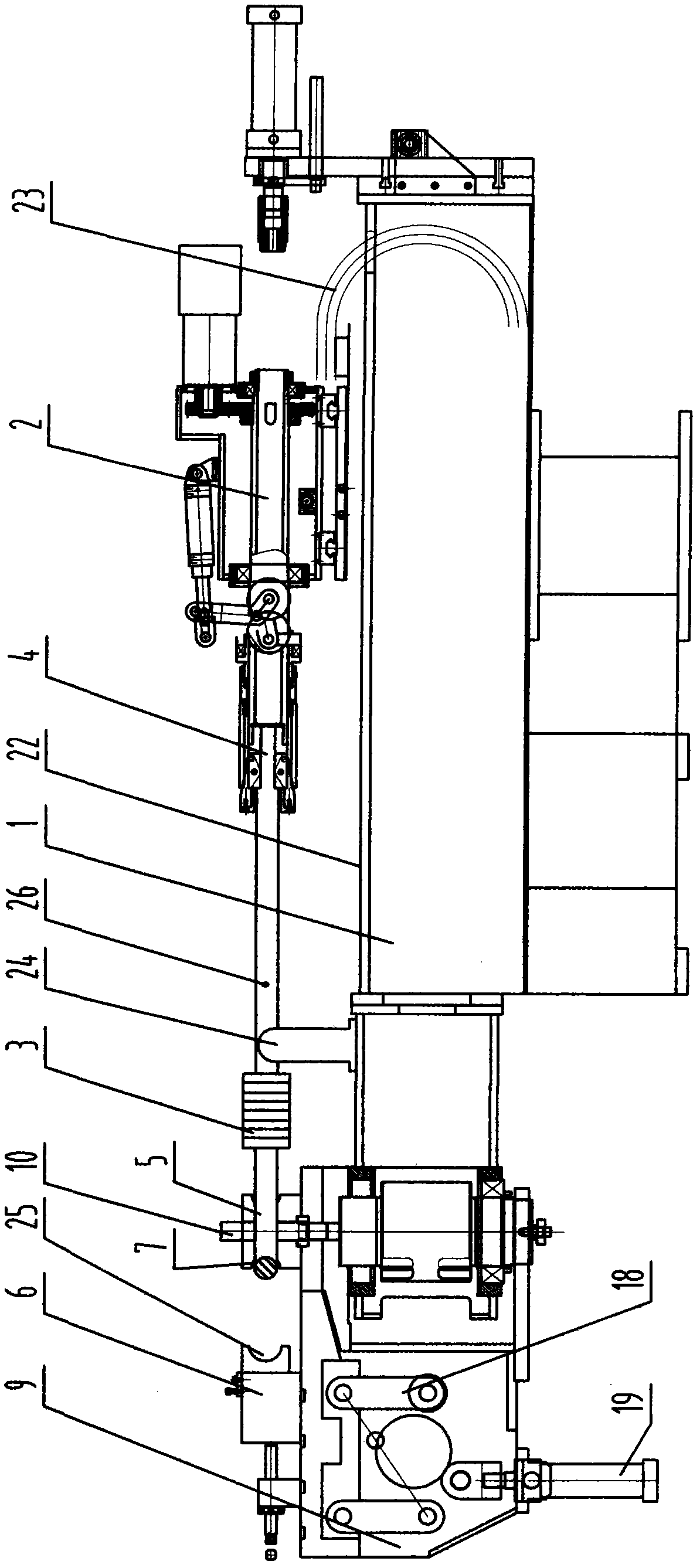

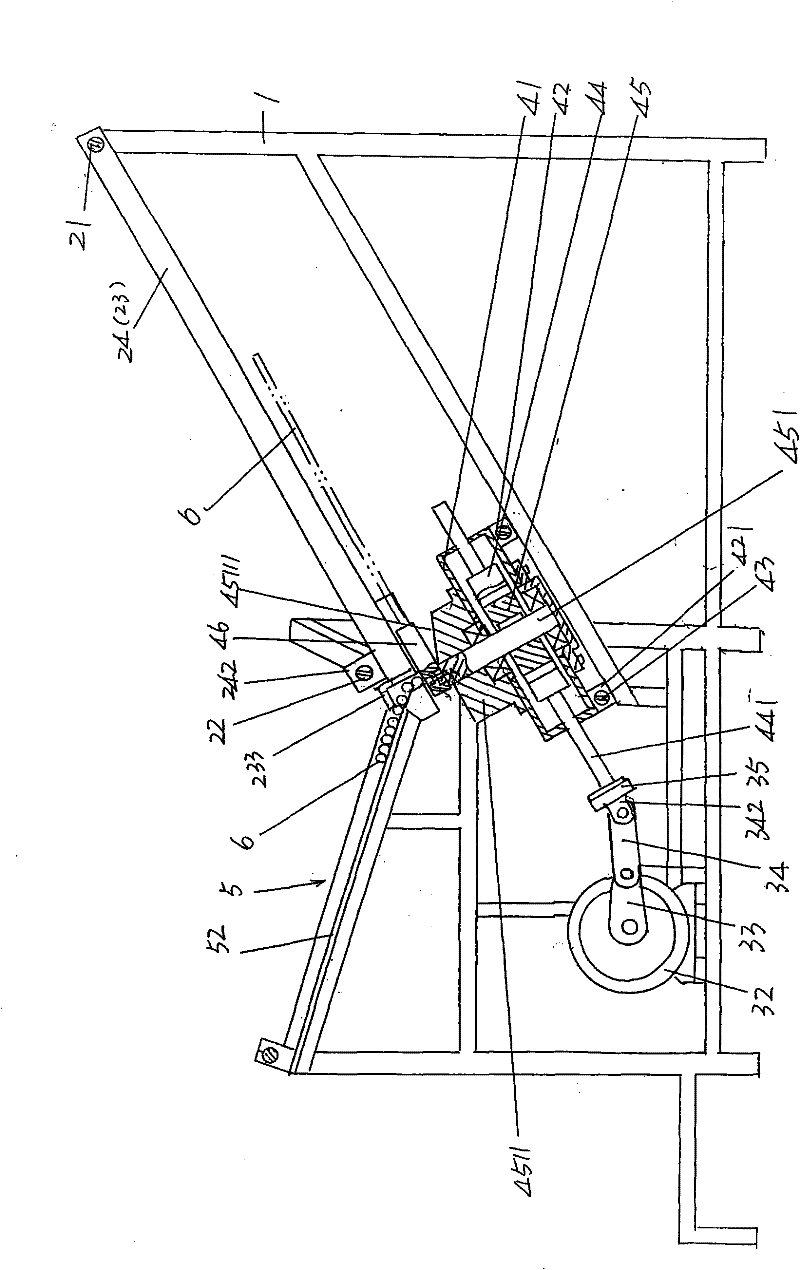

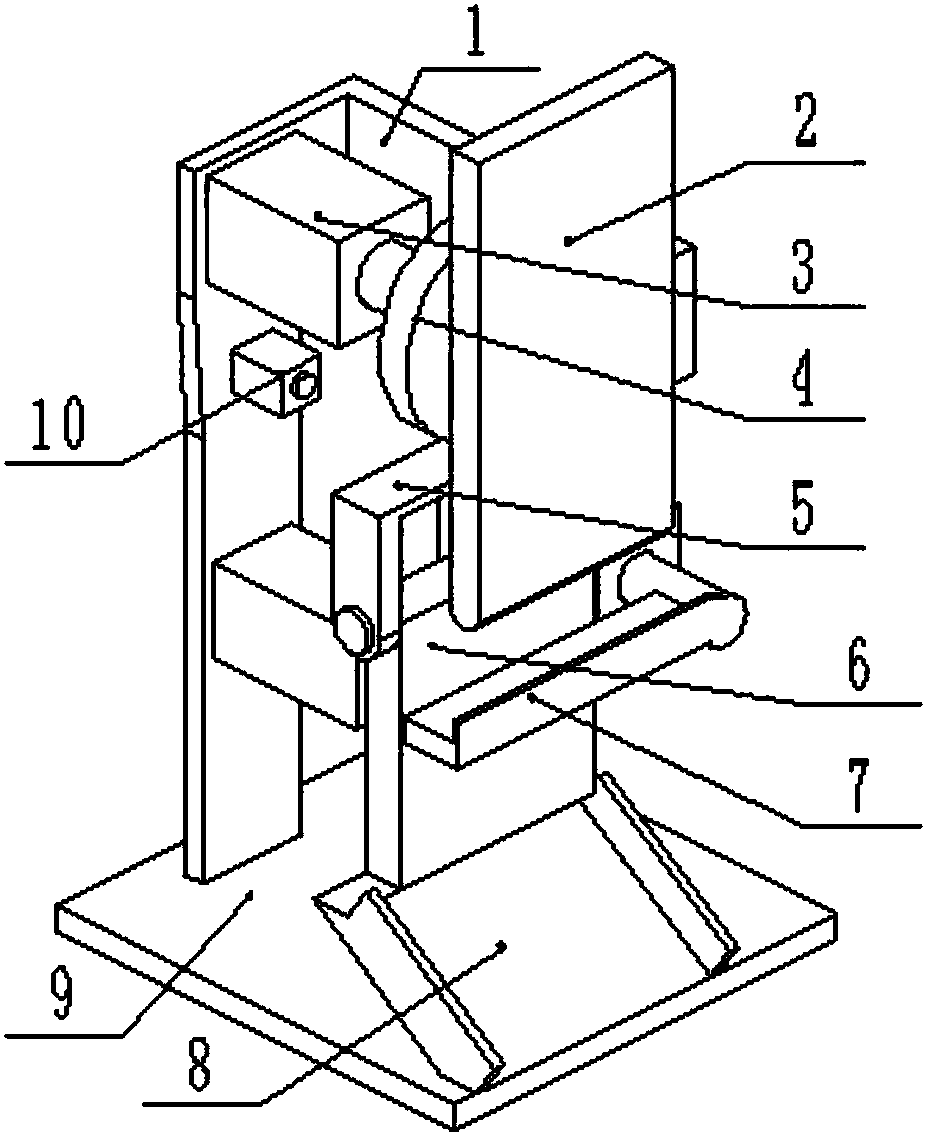

Automatic pipe bender for stainless steel pipes and bending method thereof

InactiveCN107199262AStable and reliable outputIngenious realization of automatic conveyingMetal-working feeding devicesPositioning devicesOutput deviceEngineering

The invention relates to an automatic pipe bender for stainless steel pipes and a bending method thereof. The automatic pipe bender comprises a base, a bending frame, a bending head assembly, a bending seat and a bending driving device, wherein the bending frame is installed on the base, the bending head assembly is fixed to the upper end of the bending frame, the bending seat can vertically slide on the bending frame, the bending driving device is used for driving the bending seat, the bending head assembly comprises a bending head fixed seat which is fixed to the upper end of the bending frame and a bending head which is fixed to the lower part of the bending head fixed seat, and a steel pipe bending groove is formed in the lower end of the bending head; the bending seat comprises a V-shaped bending fixed seat which is installed on the bending frame in a sliding mode through vertical guide wheels on both sides, and a plurality of bending abutting rods are arranged on the V-shaped bending fixed seat; and a steel pipe feeding device, an elbow taking device and an elbow output device are further installed on the base. The automatic pipe bender has the advantages of high bending accuracy, high bending stability, high bending efficiency and low labor intensity.

Owner:HUNAN KUANGCHU TECH CO LTD

Steel plate bending device

ActiveCN108393373AImprove bending efficiencyImprove bending qualityMetal-working feeding devicesPositioning devicesHydraulic cylinderSheet steel

The invention discloses a steel plate bending device and belongs to the field of constructional engineering equipment. A limiting plate is fixed to a supporting frame; a first hydraulic cylinder is perpendicularly fixed to the top of the supporting frame; a bending push plate is arranged below a first bracket; a supporting plate is pressed on a spindle of a stepping motor; a material discharging plate is fixed to a workbench; an ultrasonic sensor is arranged on the supporting frame; a magnet base is fixed to the upper surface of the stepping motor; the stepping motor is connected with the supporting plate; a controller is fixed to the workbench; a pressure sensor is arranged between the first hydraulic cylinder and a push plate; a thrust ball is arranged on a spindle of a second hydrauliccylinder; and the second hydraulic cylinder is fixed to the supporting frame. The first hydraulic cylinder is used for driving the push plate to fix a steel plate, and the second hydraulic cylinder isused for driving the thrust ball to allow the bending push plate to move forwards so as to bend the steel plate, so that the operation that the steel plate is manually bent is replaced, and the working efficiency and the quality are improved.

Owner:贝克曼沃玛金属技术(青岛)有限公司

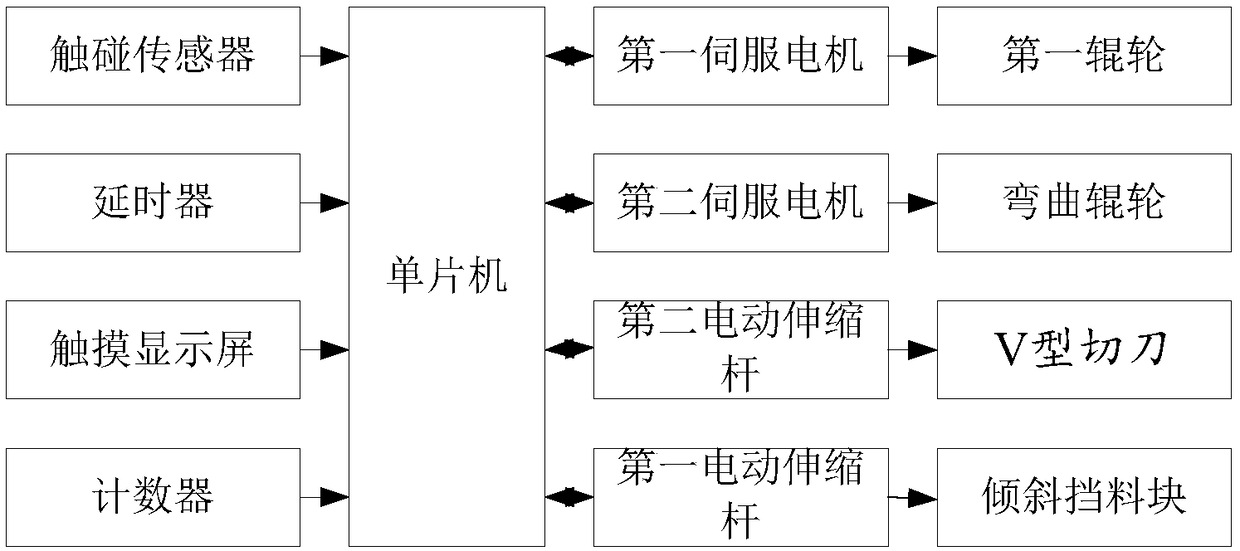

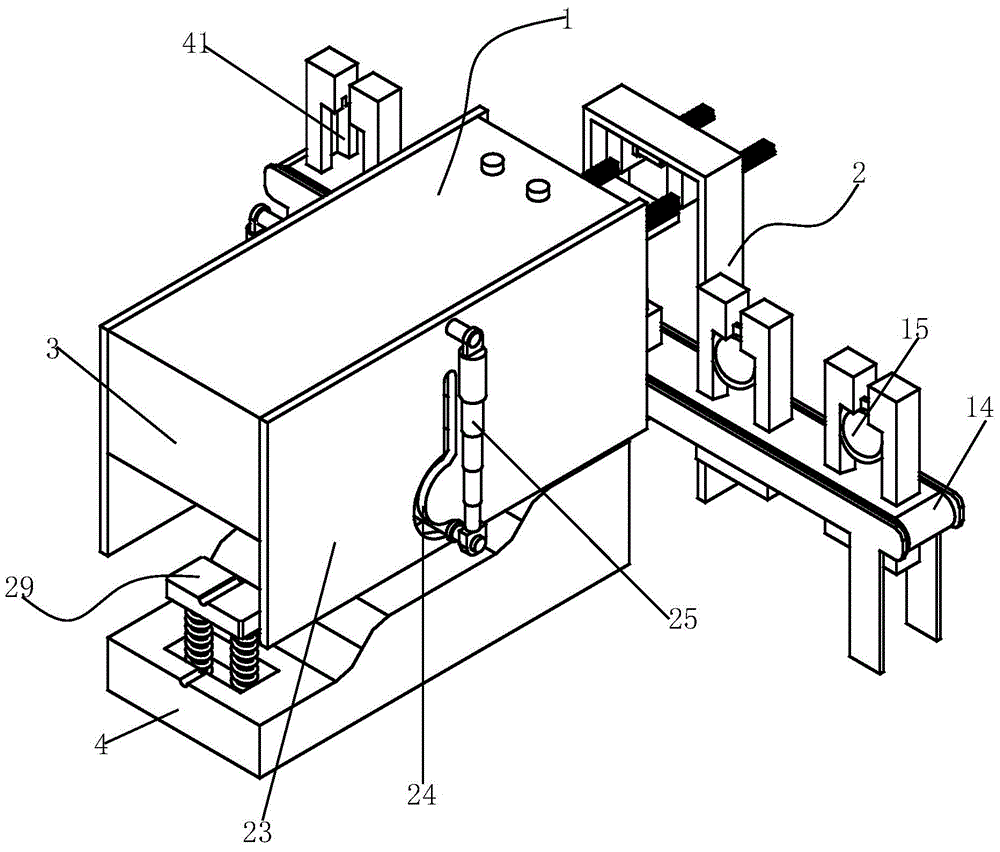

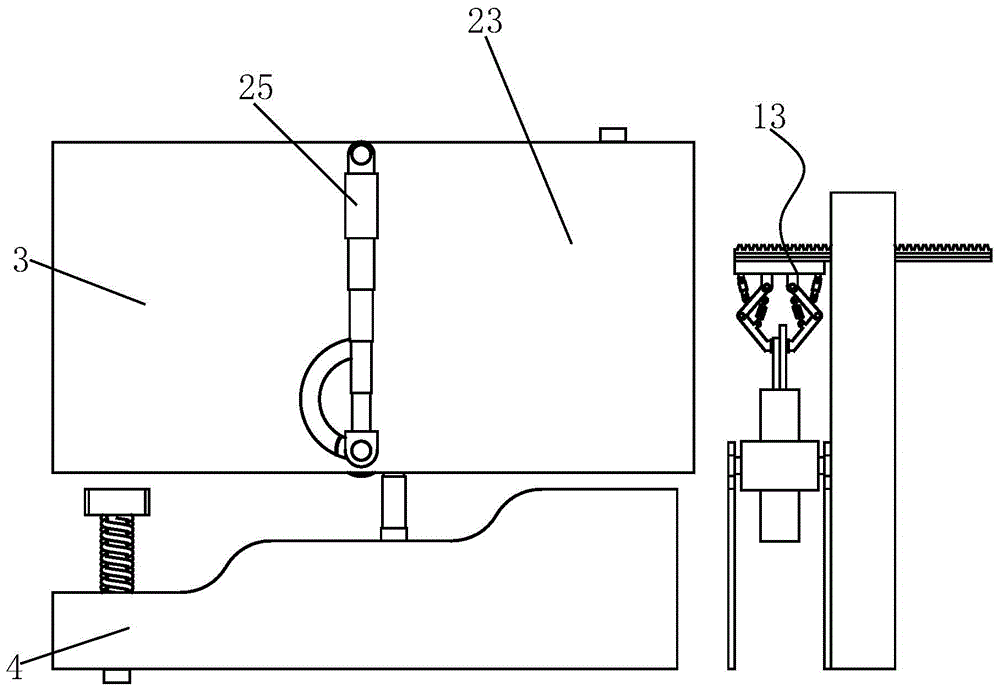

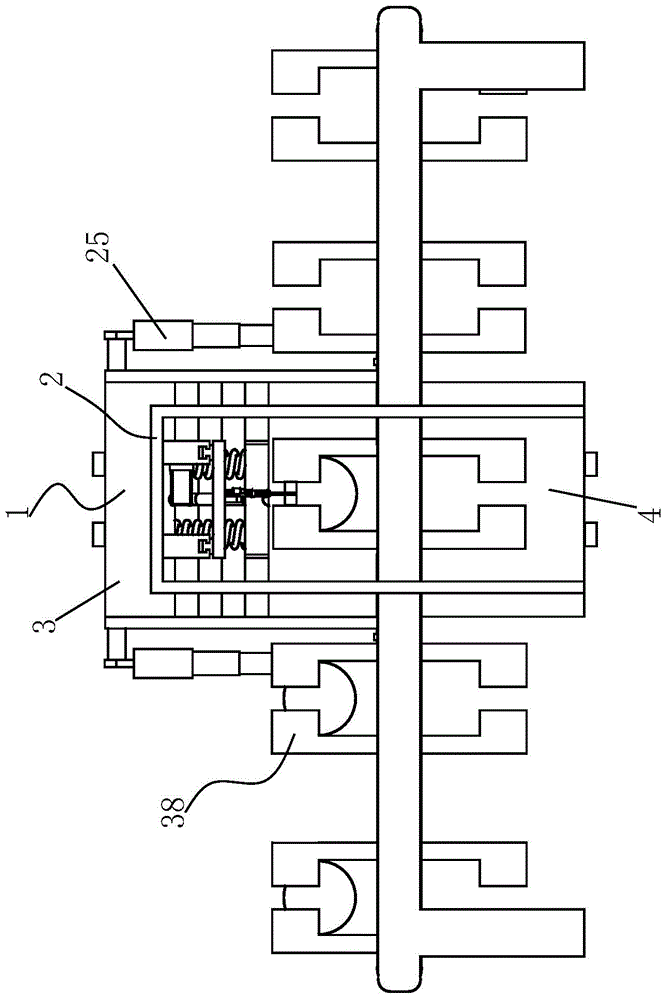

Novel numerical-control steel bar bending machine

The invention relates to the technical field of steel bar bending, and discloses a novel numerical-control steel bar bending machine. The novel numerical-control steel bar bending machine comprises acontrol system and further comprises two straightening devices, two cutting-off devices and two bending devices which are sequentially arranged in the advancing direction of steel bars; the cutting-off devices and the bending devices are connected with the control system; the novel numerical control steel bar bending machine further comprises two guiding devices and two receiving devices; the twostraightening devices, the two cutting-off devices, the two bending devices and the two guiding devices are connected with the control system; each guiding device comprises one or more first electrical telescopic rods and one or more inclined stopping blocks; and telescopic plates serve as baffles. According to the novel numerical-control steel bar bending machine, multiplied improvement of the steel bar bending efficiency is achieved, the production efficiency is improved, and the labor intensity is reduced.

Owner:XUCHANG UNIV +1

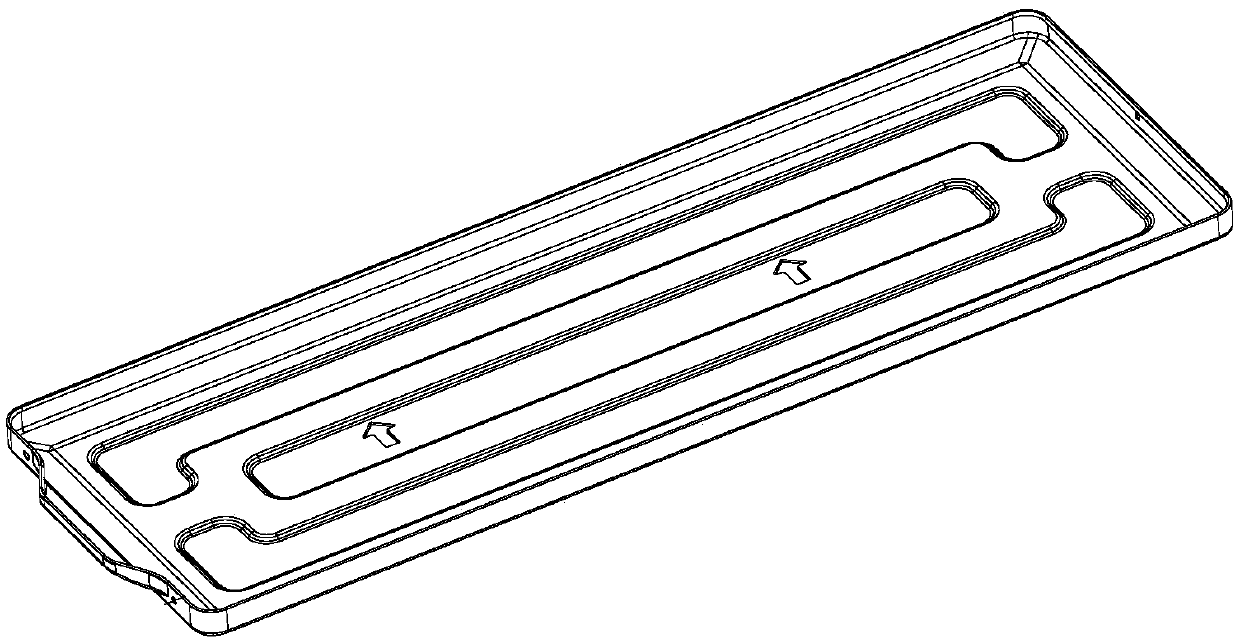

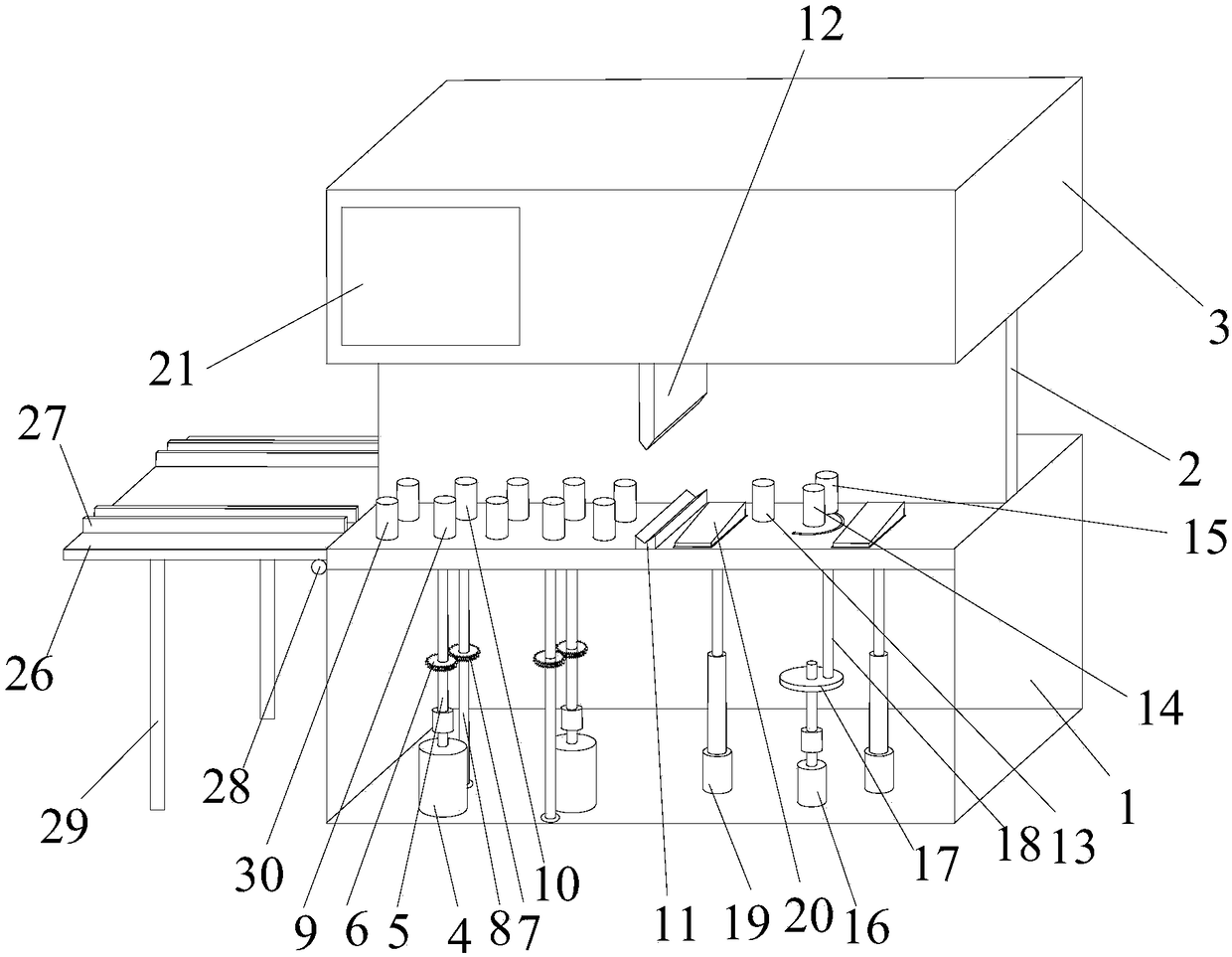

Automatic bending assembly system for electric heating pipe

ActiveCN104551671AImprove bending efficiencyHigh degree of automationShaping toolsWelding/cutting auxillary devicesAssembly lineEngineering

The invention relates to an automatic bending assembly system for an electric heating pipe. The automatic bending assembly system comprises a bending device and a flange assembly device, wherein the bending device comprises an upper mold and a lower mold; the lower end surface of the upper mold is in a ladder-like shape which gradually ascends from right to left; an upper bending groove, which is transversely formed, and of which the section is a semicircular shape, is formed in the middle part of the lower end surface of the upper mold; an upper accommodating groove is formed in the middle part of the lower end surface of the upper mold; a strip accommodating groove, which is vertical to the upper bending groove, is formed in the middle part of the lower end surface of the upper mold; a lower bending grove is formed in the middle part of the upper end surface of the lower mold; a lower accommodating groove is also formed in the middle part of the upper end surface of the lower mold; the flange assembly device comprises clamping assembly mechanical arms and a belt assembly line. According to the automatic bending assembly system, the method for bending and molding the electric heating pipe according to the upper bending groove and the lower bending groove, which are formed in the upper die and the lower die in advance, is achieved by the laminating actions of the upper mold and the lower mold; the automation degree of an electric heating pipe bending device is improved.

Owner:WUHU YINXING AUTO PARTS

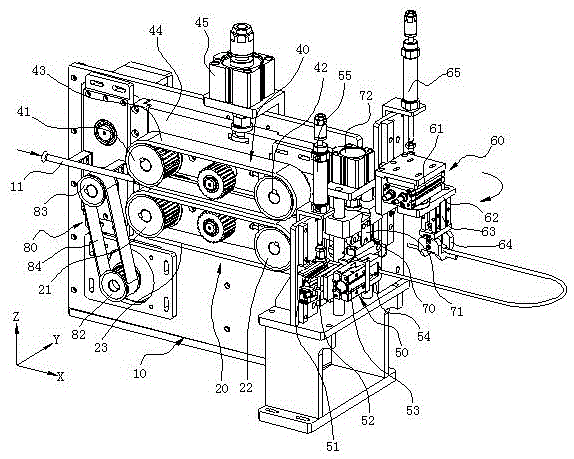

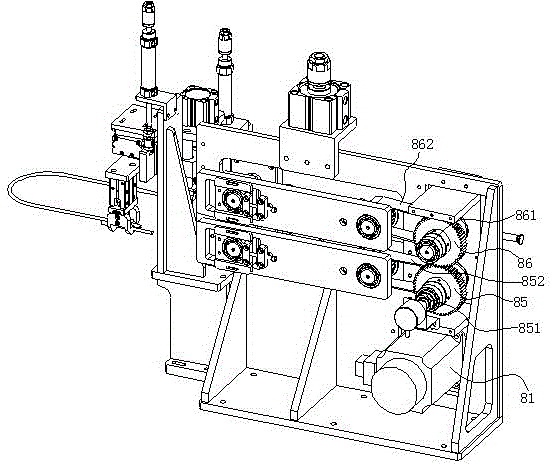

Double-head seven-axis forming machine

The invention discloses a double-head seven-axis forming machine. The double-head seven-axis forming machine comprises a bottom frame and a rack platform arranged on the bottom frame and further comprises a material counting mechanism, a linear mechanism, a cutting-off mechanism, a feeding mechanism, a wire changing mechanism used for adjusting the angle of a wire, a left forming mechanism, a right forming mechanism, and a wire pulling mechanism which are all arranged on the rack platform, wherein the left forming mechanism and the right forming mechanism are used for bending the wire; the left forming mechanism and the right forming mechanism are arranged on the left side and the right side of the wire changing mechanism correspondingly; and the wire changing mechanism is fixed to the rack platform of the double-head seven-axis forming machine. According to the double-head seven-axis forming machine, the structure is integrally designed, the process steps are simplified, the bending forming time is shortened, the structures of front stations and rear stations are compact, cooperation is tight, machining debugging is easy, convenient and easy to operate, and one-time complex linearbending operation can be achieved; the bending efficiency is high, the manufacture process is good in stability, the bending quality is greatly improved, more convenience is realized, the manual handoperation error is reduced, manpower is saved, a computer is utilized to control multiple axes to conduct an action simultaneously, and debugging is easy; and the cost is reduced, the resources are saved, and the production efficiency is improved.

Owner:GUANGZHOU CAIHONG HARDWARE SPRING CO LTD

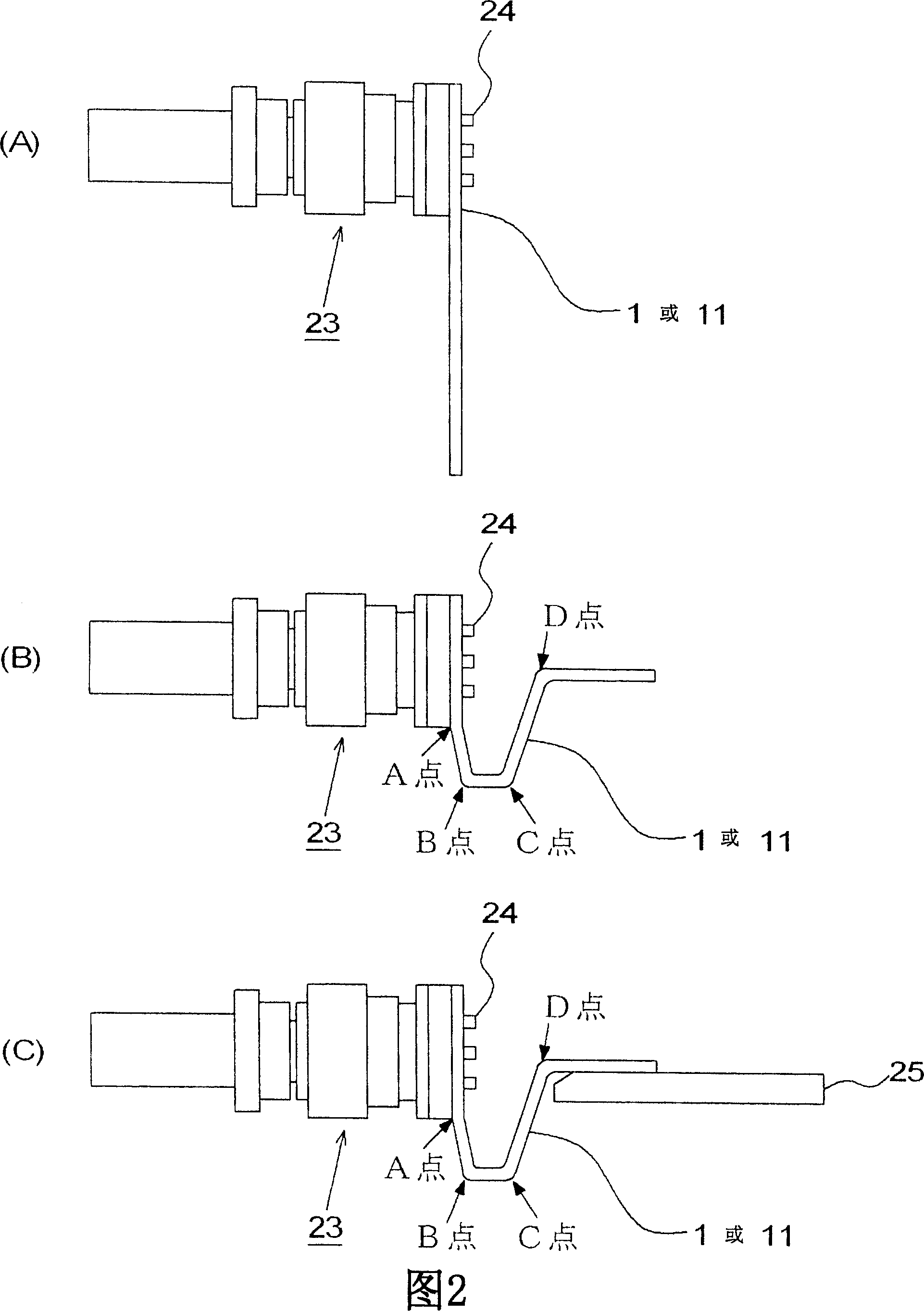

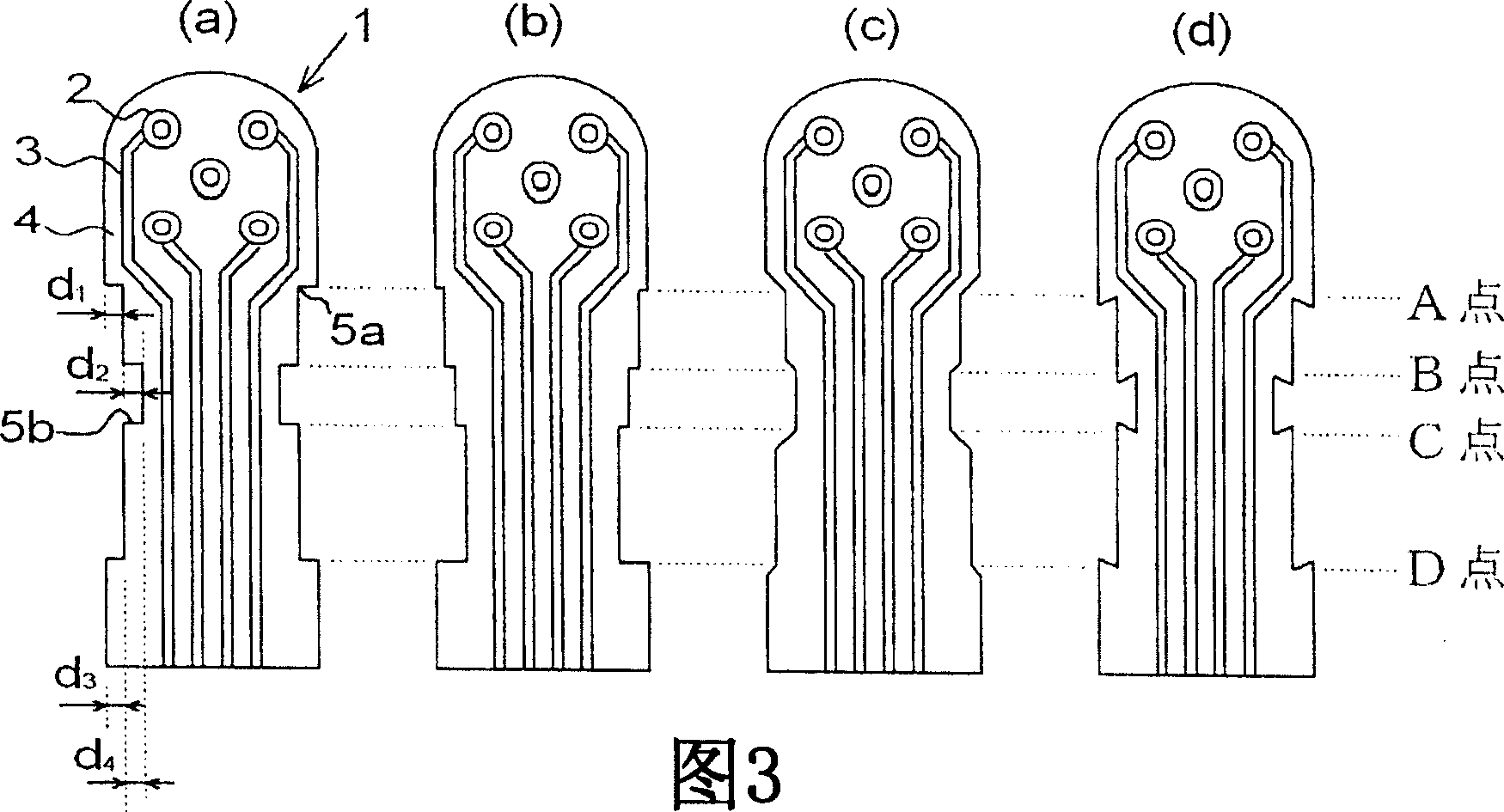

Flexible board

InactiveCN1956619AEasy to adjustWith configurationPrinted circuit aspectsElectrical connection printed elementsElectrical conductorEngineering

A flexible board capable of being bent easily and precisely a plurality of times at desired positions has insulating layer exhibiting flexibility, a conductor layer and recessed angular portions situated in both side edges of the board so as to oppose each other. Three of more of these angular portions are disposed on each side edge of the board. More specifically, the flexible board has at least one constricted portion that reduces the width of the board. The constricted portion is situated on both side edges of the board in such a manner that the constricted portions oppose each other, and has at least one of a step portion having a step-like shape and a cut-out portion having a V- or U-like shape. Three or more step-like portions and cut-out portions are situated together on each side edge the board.

Owner:NEC ELECTRONICS CORP

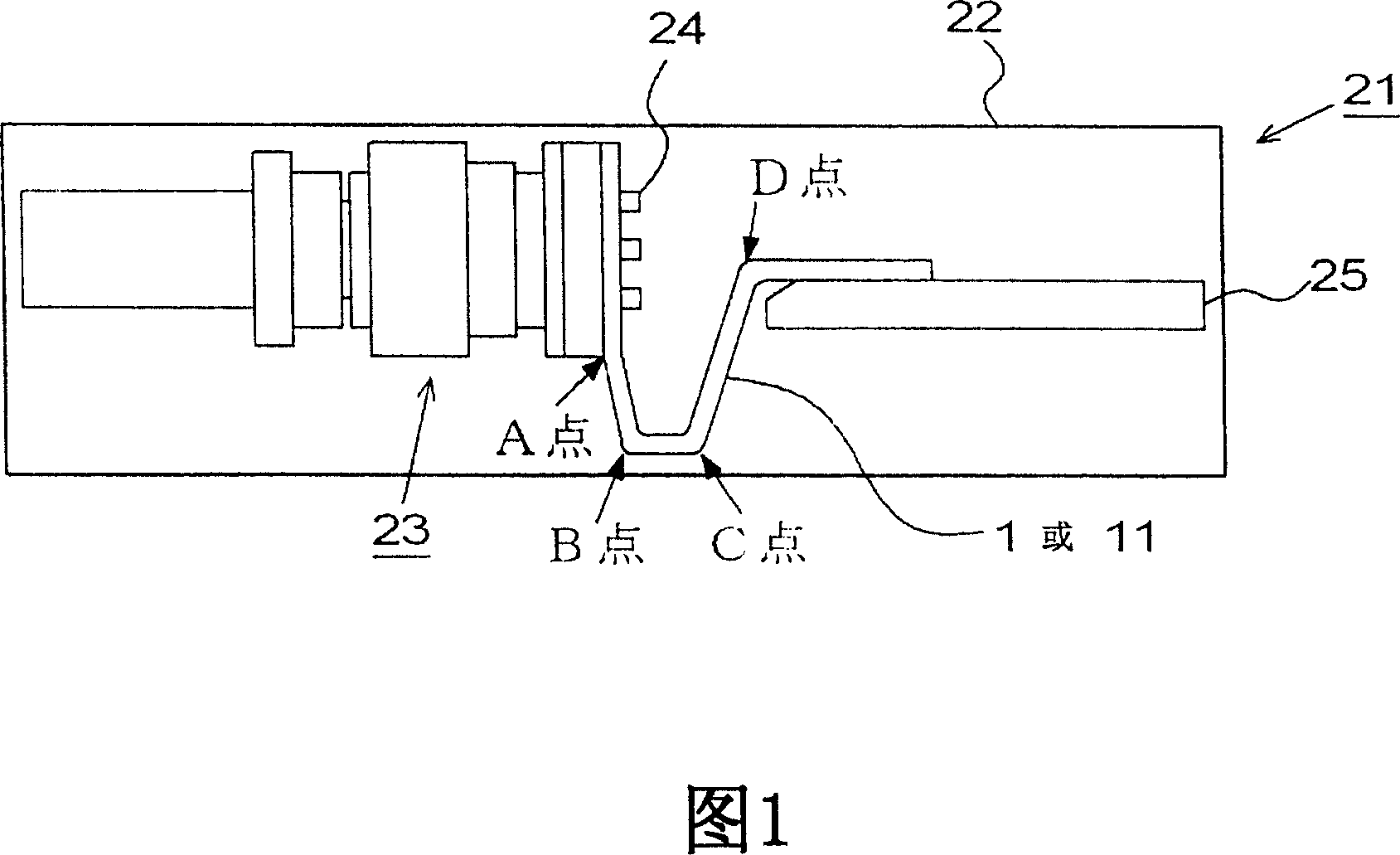

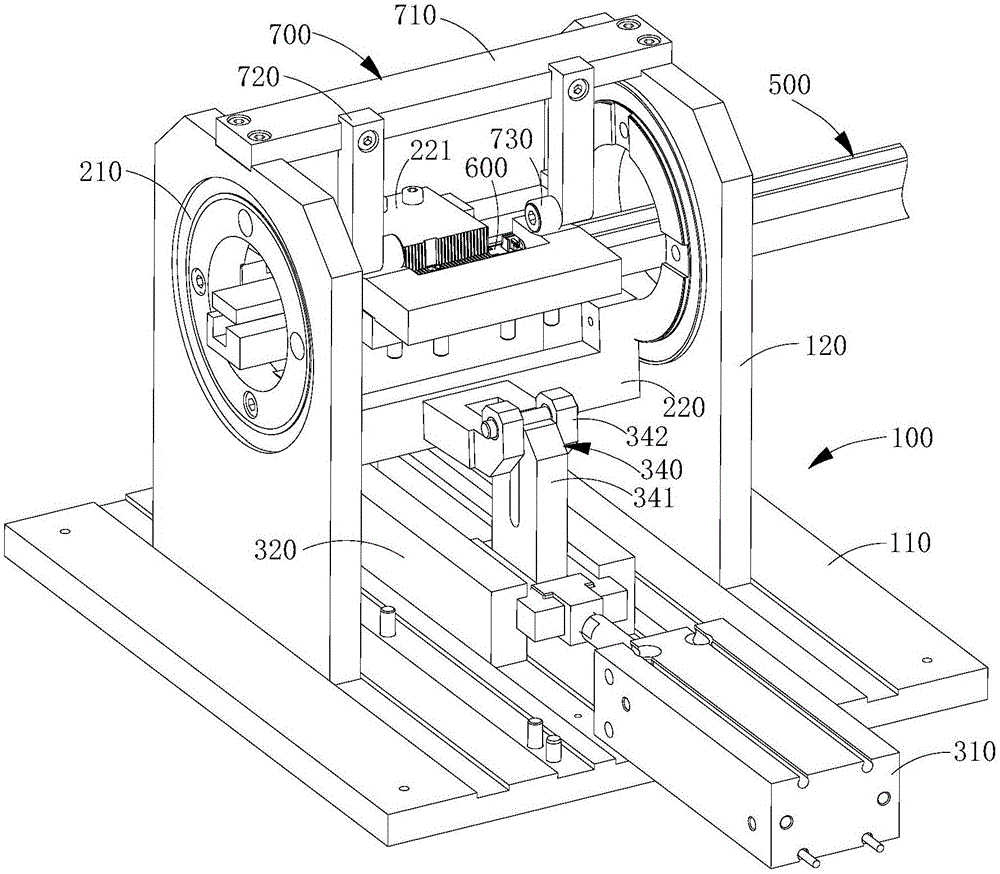

Plastic pipe bending machine

InactiveCN105965864AImprove processing efficiencyReduce processing costsEngineeringElectromagnetic heating

The invention provides a plastic pipe fitting bending machine, which includes a machine body and a three-jaw chuck. A bending die mechanism is slidably connected to the body, and a second X-direction movement mechanism is arranged between the two. The bending die mechanism It includes a bending mold, the body is slidably connected with the body, and a first X-direction movement mechanism is arranged between the two, the side of the body is connected with a first guide plate through a Y-axis rotary movement mechanism, the first guide plate and the second The guide plate is slidingly connected, the second guide plate is fixed with a slide bar, one end of the slide bar is equipped with a bending roller, and the body is also equipped with an electromagnetic heater, the electromagnetic heater includes an electromagnetic heating coil, and the inner ring of the bending roller is close to the bending mold. The inner walls of the pipe parts are all wound with electromagnetic heating coils. The plastic pipe fitting bending machine of the present invention can realize the bending operation of pipe fittings of different specifications on one machine, is suitable for mass production, reduces the scrap rate, saves the operation steps of workers, and reduces the production cost.

Owner:TIANJIN RUILING TECH DEV CO LTD

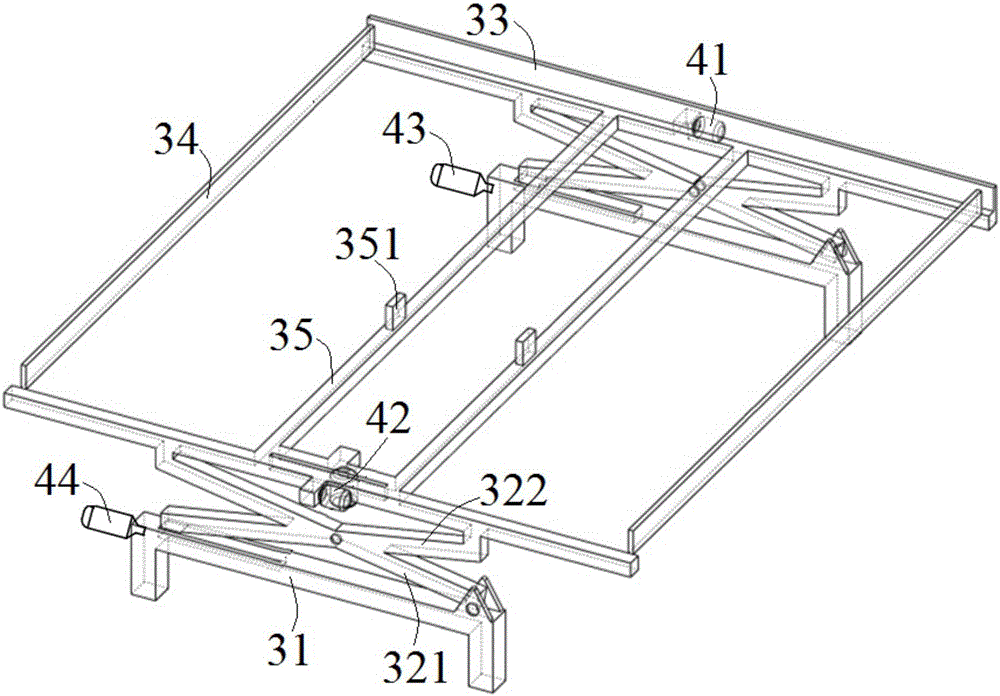

Automatic locating device, bender system employing automatic locating device and plate bending method

ActiveCN105921631APrecise positioningShorten the timeMetal-working feeding devicesPositioning devicesEngineeringSlide plate

The invention discloses an automatic locating device, a bender system employing the automatic locating device and a plate bending method and belongs to the technical field of benders. The automatic locating device comprises an automatic lifting mechanism and a worktable, wherein processing parts are placed on the plane of the worktable; the automatic lifting mechanism moves in the vertical direction and acts on the processing parts to realize locating of the processing parts in the horizontal direction; and the worktable is also provided with grabbing manipulators which realize locating of the processing parts in the vertical direction and rotation of the processing parts in the horizontal direction. The bender system is characterized in that benders are mounted on one side or two sides of the automatic locating device. A loading manipulator is utilized to grab the processing parts and convey the grabbed processing parts to the worktable, then left and right sliding plates and sliders of the automatic lifting mechanism are utilized to accurately locate the processing parts, and finally, the grabbing manipulators are used for realizing automatic rotation and multi-edge bending of the processing parts, so that the production efficiency can be remarkably improved, automation is realized, and the labor force is liberated from tedious work.

Owner:JIANGSU HAIJIAN

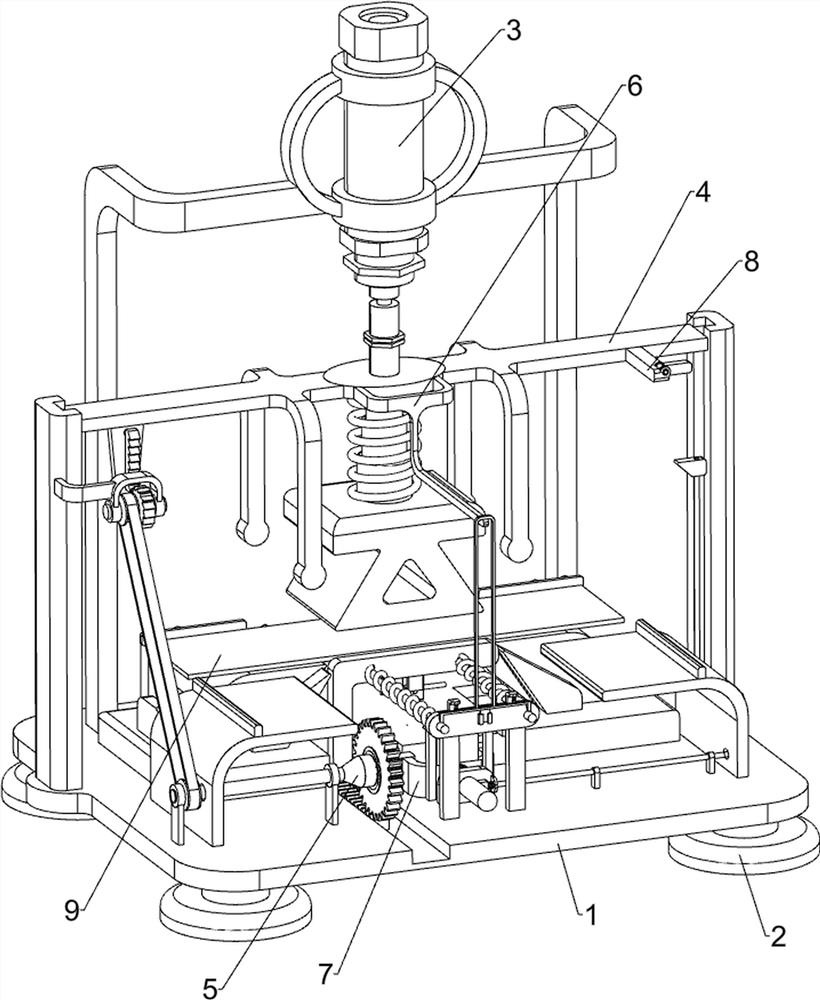

Iron plate bending equipment for machining hardware

PendingCN112845700AImprove bending efficiencyEnsure safetyMetal-working feeding devicesPositioning devicesComputer hardwareStructural engineering

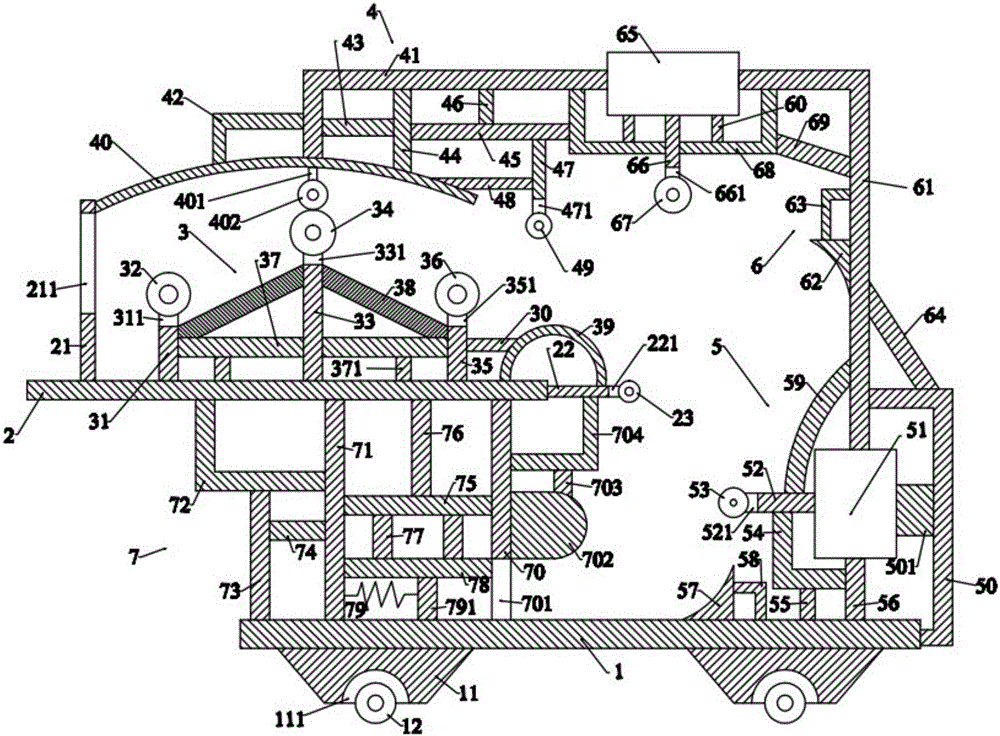

The invention relates to bending equipment and particularly relates to iron plate bending equipment for machining hardware. The technical problem solved by the invention is to provide iron plate bending equipment for machining hardware. The iron plate bending equipment for machining hardware is high in iron plate bending efficiency and low in labor intensity; the materials do not need to be manually placed and taken by people; and the operation safety of operators can be improved. In order to solve the technical problem, the invention provides the iron plate bending equipment for machining hardware. The iron plate bending equipment comprises a bottom plate, a bending mechanism and a side extrusion mechanism, wherein the bottom of the bottom plate is connected with supporting legs; the bending mechanism is mounted on the bottom plate; and the side extrusion mechanism is mounted between the bottom plate and the bending mechanism. According to the iron plate bending equipment for machining hardware, iron plates can be bent and formed through the bending mechanism and the side extrusion mechanism; one-time forming is achieved; and the bending efficiency is high.

Owner:梁康

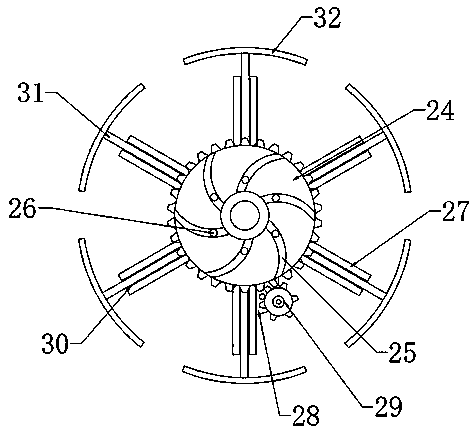

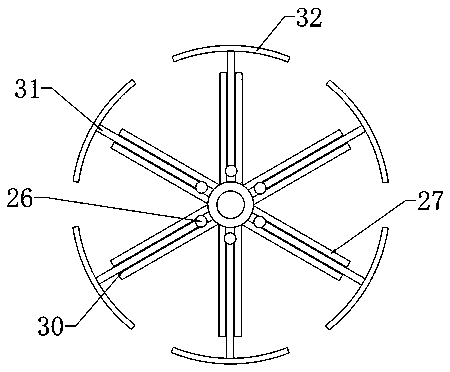

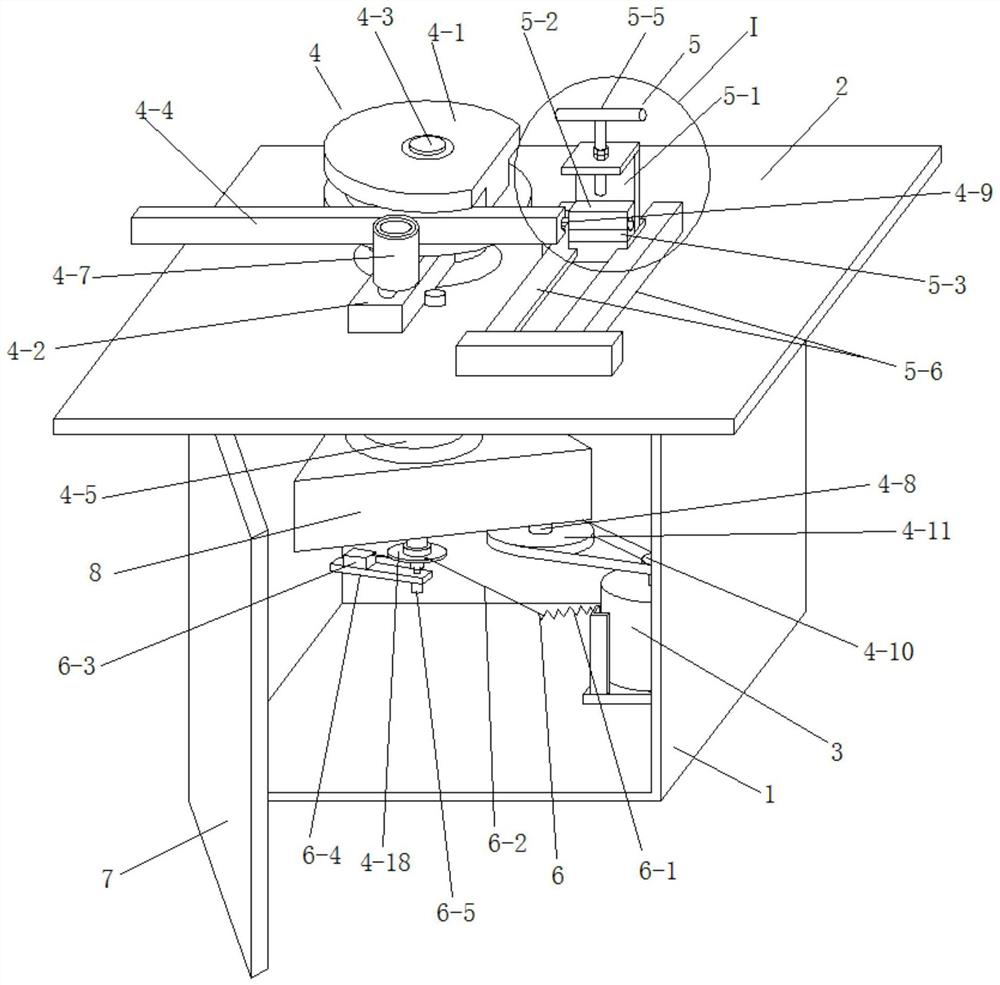

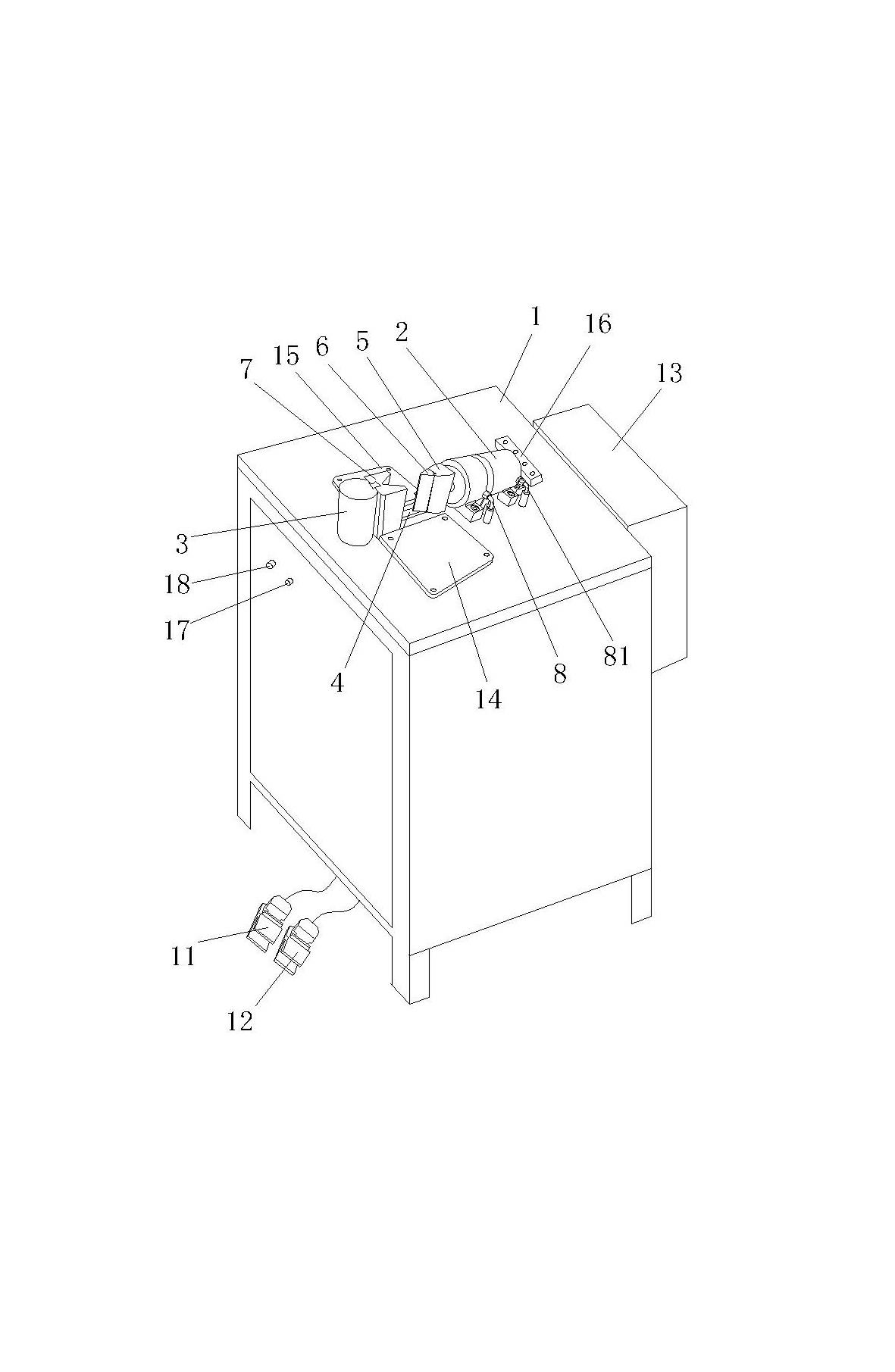

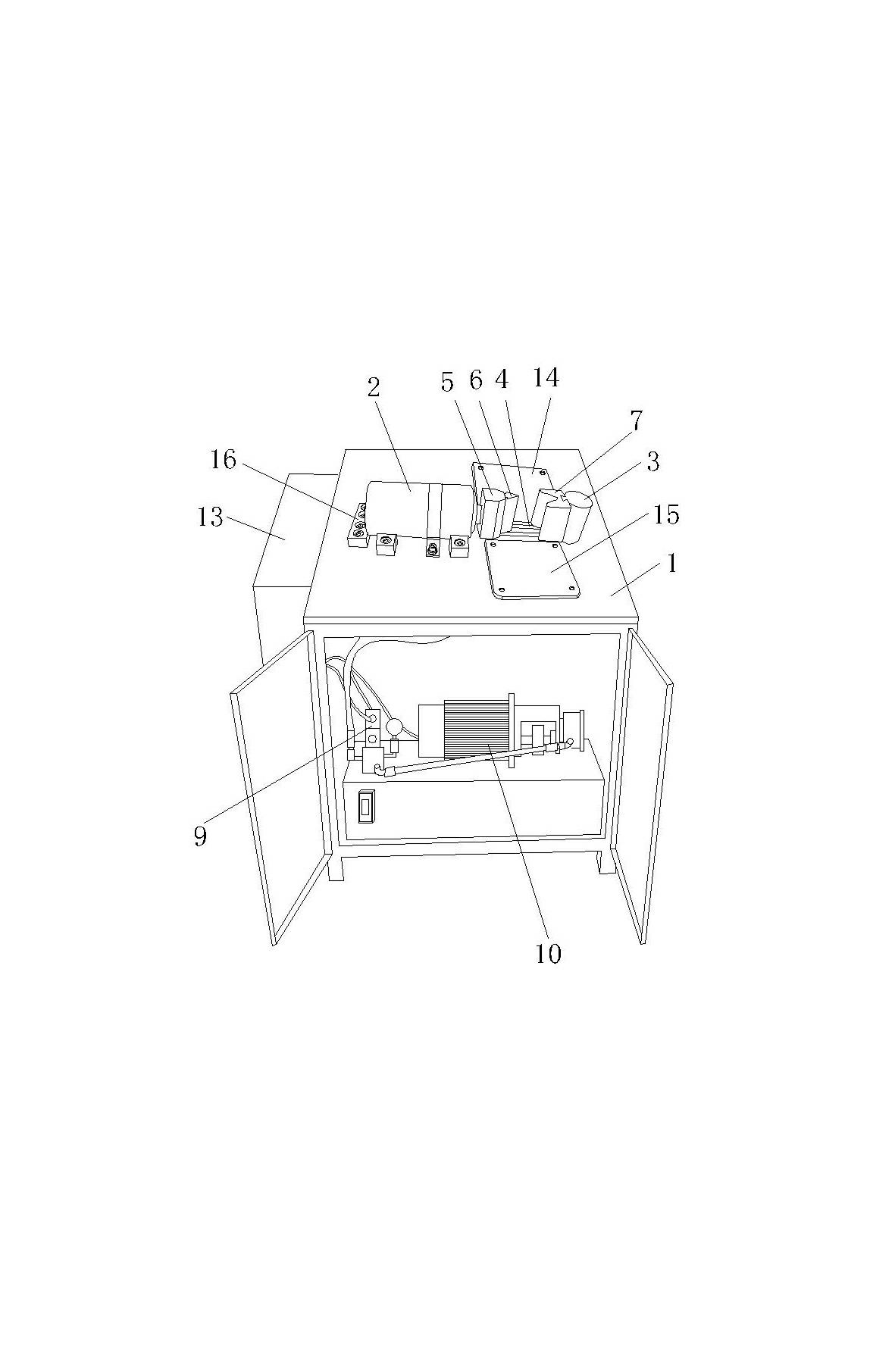

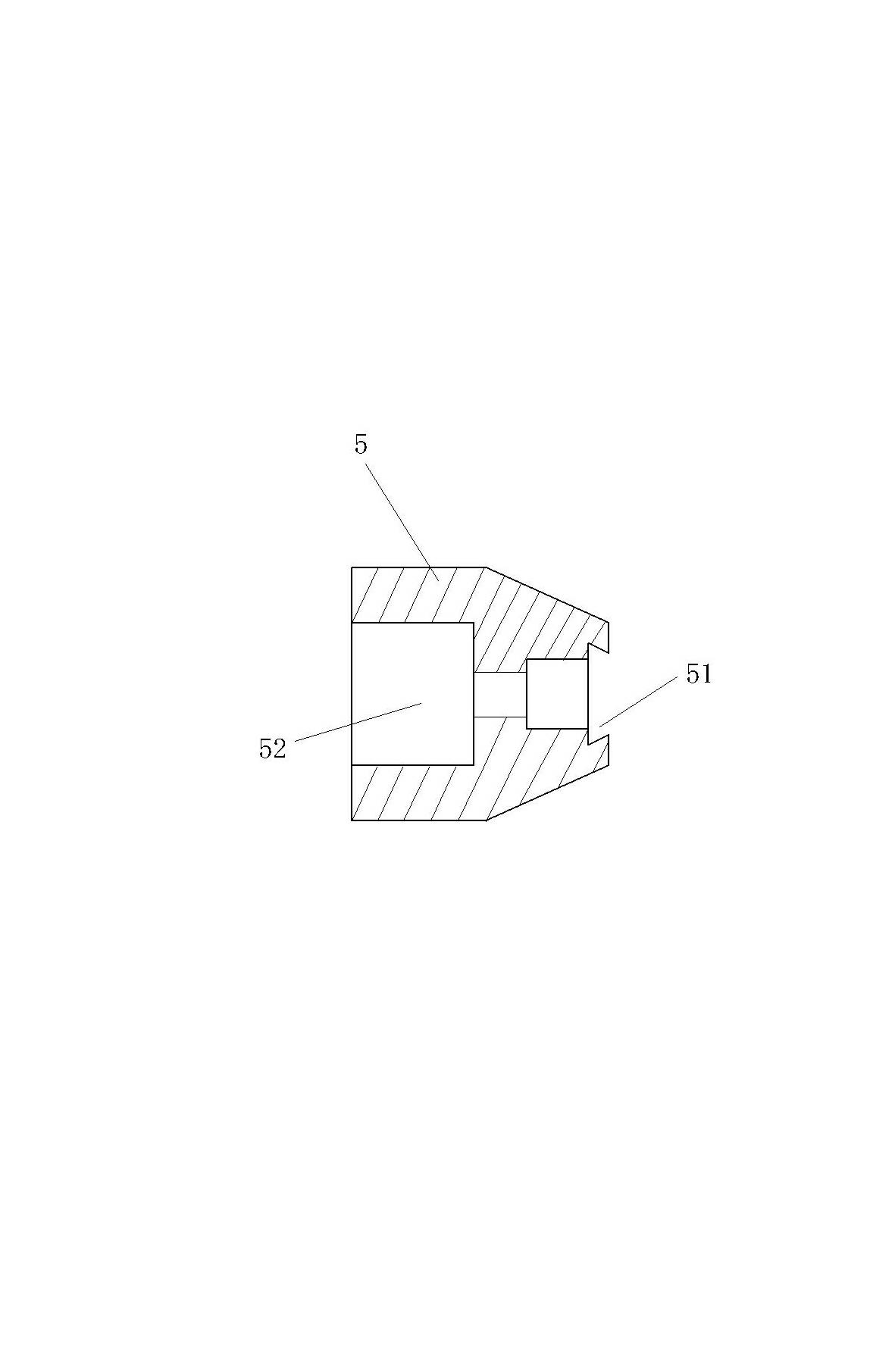

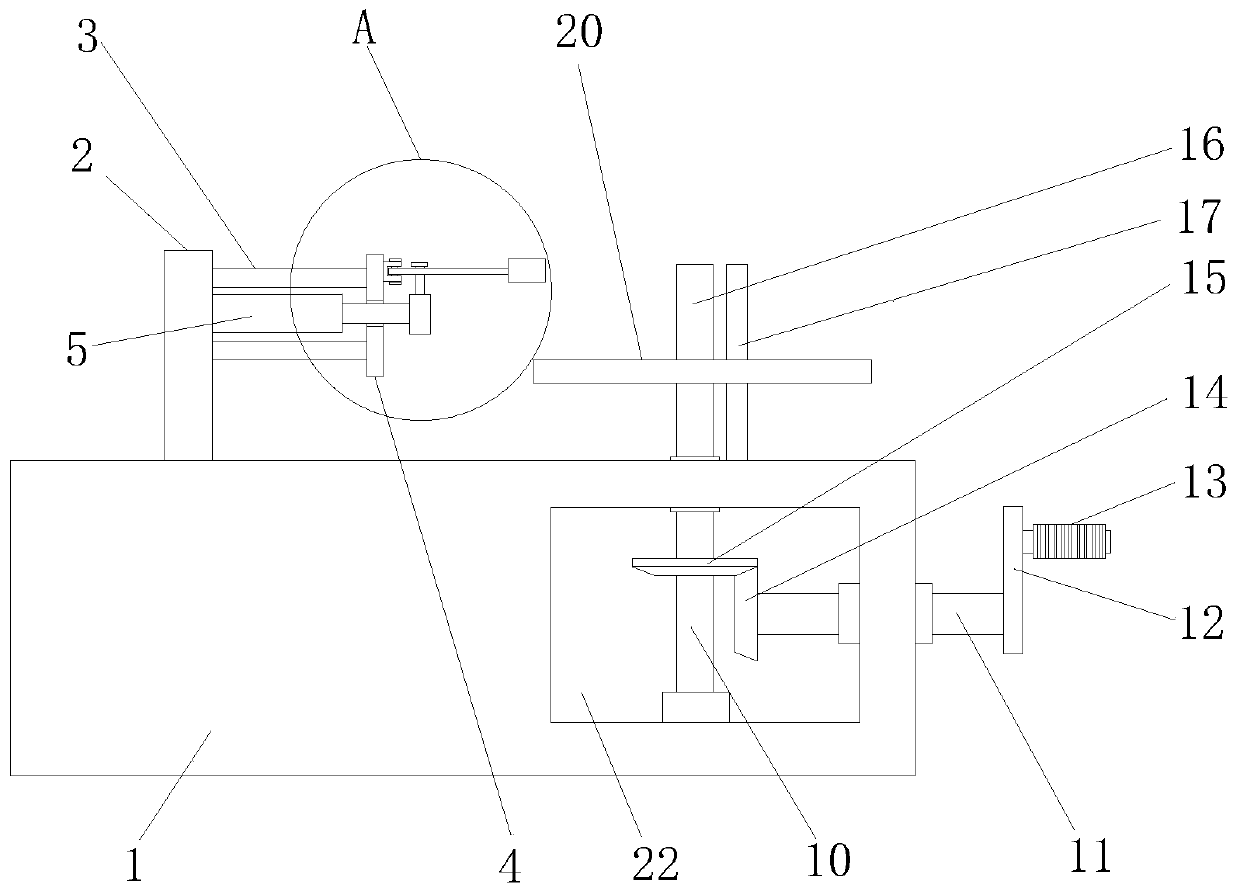

Bending device for thin-walled snake-shaped heat exchange tubes

Provided is a bending device for thin-walled snake-shaped heat exchange tubes. A box body is of an upper-end-open structure defined by a bottom plate, three side plates and a box door hinged to one side plate, and a bending platform is fixed to the upper end opening of the box body; a driving motor is installed in the box body, the driving motor is connected with a bending mechanism through a transmission piece, the lower half part of the bending mechanism is arranged in the box body, the upper half part of the bending mechanism is installed on the bending platform, and a feeding port positioning mechanism arranged on the surface of the bending platform is located on the right side of the bending mechanism; a resetting mechanism connected with the lower end of the bending mechanism is arranged in the box body; and after the driving motor drives the bending mechanism to rotate by a certain angle, bending of a to-be-bent rod piece which penetrates through the feeding port positioning mechanism and is inserted into the bending mechanism is achieved. The bending device overcomes quality defects caused by the deformation of the bending positions of the thin-walled snake-shaped heat exchange tubes, filling is not needed, the bending efficiency is improved, the uniformity of bent finished products is good, the bending process is mechanically completed, the labor intensity of staff isgreatly reduced, and the use value is high.

Owner:宝鸡特钢钛业股份有限公司

Bending device

The invention relates to a bending device. The bending device comprises a rack, a feeding mechanism, an abutting positioning mechanism, a rotary mechanism and a first driving mechanism, wherein the feeding mechanism conveys workpieces to a machining station; the abutting positioning mechanism is arranged on the rack and abuts against one sides of the workpieces in the machining station after moves a certain distance in the first direction, so that the workpieces are fixed relative to the rack, and bent parts of the workpieces abut against the abutting positioning mechanism; the rotary mechanism is rotationally arranged on the rack; the first driving mechanism drives the rotary mechanism to rotate relative to the rack; and the rotary mechanism abuts against the workpieces in the machining station and bends the workpieces when rotates to a preset position. According to the bending device, the first driving mechanism drives the rotary mechanism to rotate, the rotary mechanism abuts against the workpieces after rotates to a certain angle and continues rotating so as to bend the workpieces, the abutting positioning mechanism can fix the workpieces located in the machining station, thus, the workpiece bending machining efficiency is high, the stability is good, and the precision is high.

Owner:GUANGDONG EVERWIN PRECISION TECH

Small horizontal bending machine

The invention discloses a small horizontal bending machine, which comprises a working table and an oil cylinder. A vertical column is longitudinally arranged along one side of the working table, the oil cylinder is fixed on the other side of the working table, and the lower portion of the vertical column penetrates through the working table and is fixed to the working table. A longitudinal rail is fixed on the working table between the vertical column and the oil cylinder, a slider is fixed on a piston rod of the oil cylinder, opposite sides of the slider and the vertical column are respectively provided with a vertical dovetail groove, a male die is mounted on the dovetail groove of the slider, a female die is mounted on the dovetail groove of the vertical column, the lower portion of the slider is provided with a groove matched with the longitudinal rail, and the slider can move front and back along the longitudinal rail. The lateral face of the oil cylinder is connected with a hydraulic station by electromagnetic reversing valves through two oil pipes, two pedal switches are connected with electromagnetic coils of the electromagnetic reversing valves through an electric control box, and the piston rod of the oil cylinder moves ahead or back when the two pedal switches are respectively switched on. The small horizontal bending machine is simple in structure, low in manufacturing cost, convenient in disassembly and assembly and suitable for bending elongated plates.

Owner:SUCTRN TECH

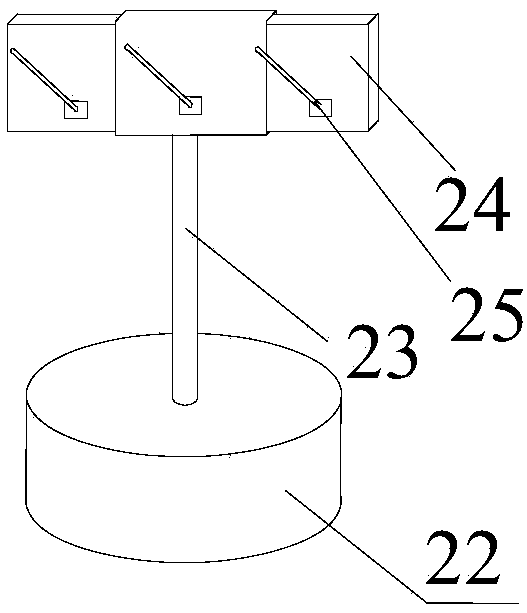

Probe bending device for temperature sensor production

InactiveCN110421034AAchieve the effect of automatically clamping and fixing the probeEasy to operateKnittingNeedlesEngineeringRotating disc

The invention discloses a probe bending device for temperature sensor production. The probe bending device comprises a support seat, wherein a mounting cavity is formed in the support seat; a first rotating rod which is vertically arranged is rotatably mounted on the inner wall of the bottom end of the mounting cavity; a driven bevel gear is fixedly mounted on the outer side of the first rotatingrod; the top end of the first rotating rod extends to the outside of the mounting cavity, and a rotating disc which is horizontally arranged is fixedly mounted; a first bending rod which is verticallyarranged is fixedly mounted on the middle position of the top end of the rotating disc; a second bending rod which is vertically arranged is fixedly mounted at one side, located at the first bendingrod, of the top end of the rotating disc; a mounting hole is formed in one side of the support seat; a second rotating rod which is horizontally arranged is rotatably mounted in the mounting hole; andone end of the second rotating rod extends into the mounting cavity. The probe bending device is ingenious in structure, capable of rapidly bending the probe, simple to operate, small in angle error,high in bending efficiency and labor-saving and convenient to use.

Owner:中电鼎康(天长)科技有限公司

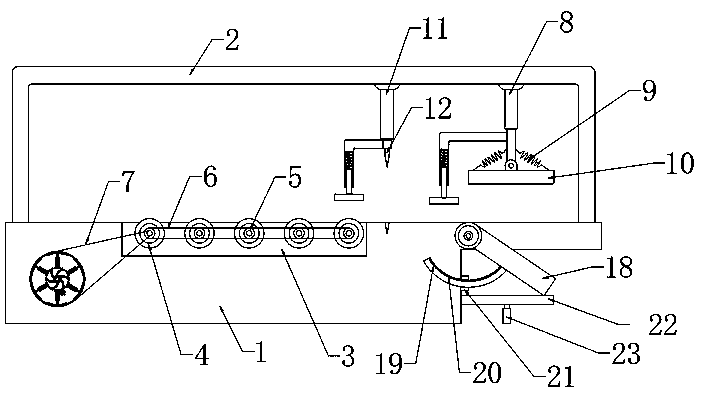

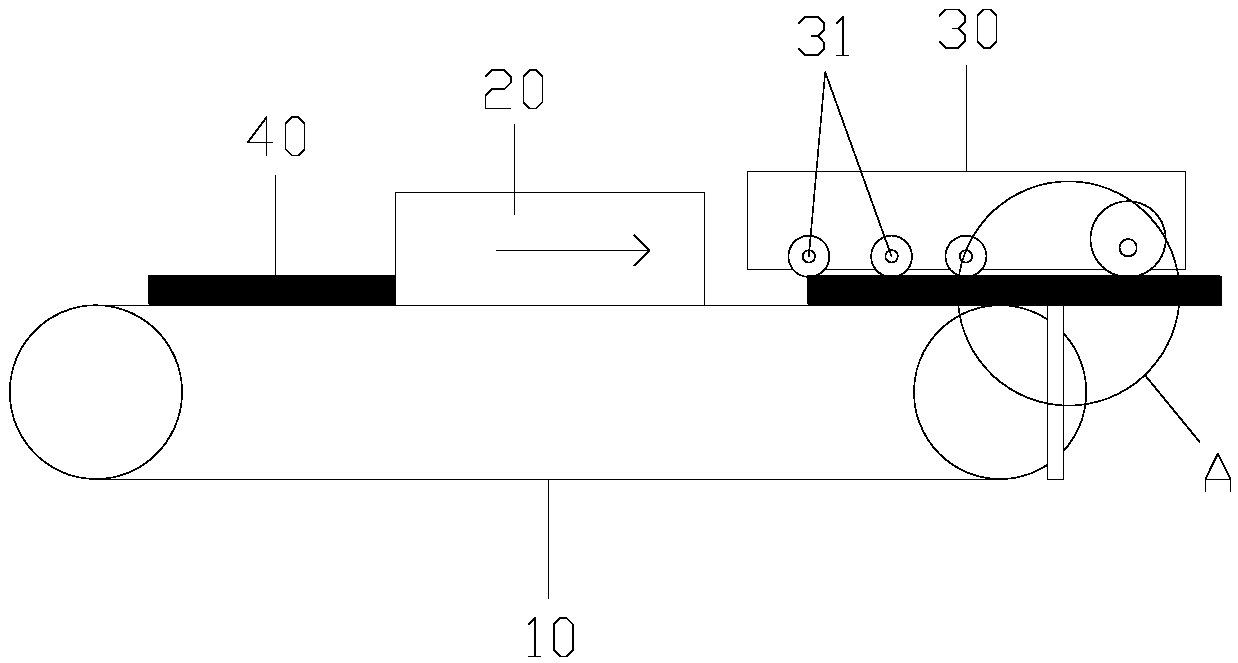

Strip-shaped wood component bending device and method thereof

InactiveCN109719814AImprove bending efficiencyAchieve bendingWood treatment detailsWood stock bendingPulp and paper industryHigh frequency

The invention relates to the technical field of wood component processing equipment, in particular to a strip-shaped wood component bending device and method thereof. The strip-shaped wood component bending device comprises a conveyor device, a high frequency medium heating structure and a bending structure; the conveyor device is used for conveying a strip-shaped wood component to be bent; the high frequency medium heating structure is located on a conveying path of the strip-shaped wood component, and used for heating and softening the strip-shaped wood component; and the bending structure is located behind the high frequency medium heating structure in the conveying direction of the strip-shaped wood component, and used for bending the softened strip-shaped wood component. The inventionaims to provide the strip-shaped wood component bending device and method thereof; and by adopting the technical scheme, the technical problem of low manufacturing efficiency of an existing strip-shaped wood component with a curvature is solved.

Owner:棒天下(惠州)智能科技有限公司

Bending mechanism

InactiveCN108801818AConsistent bending operationGood repeatabilityMaterial strength using repeated/pulsating forcesFlexible circuitsEngineering

The embodiment of the invention relates to mechanical equipment and discloses a bending mechanism. The bending mechanism is used for bending an FPC (Flexible Printed Circuit) board and comprises a test tabletop, an operation panel, a hold-down part, a driving device and a master control unit, wherein the operation panel is opposite to the test tabletop and is used for crossing over the test tabletop and the operation panel; the test tabletop and the operation panel jointly bear the FPC; the PFC comprises a first part extending towards the direction of the operation panel and a second part extending towards the direction of the test tabletop; the first driving device drives the operation panel to turn over around a preset axis; the operation panel bends the first part of the FPC round the hold-down part during turnover; the master control unit controls the first driving device to drive the operation panel to be turned over to a preset angle. Compared with the prior art, bending operation of the FPC is kept consistent and the repeatability efficiency is higher; the positions of the FPC are unified in the bending process, so that a test result is more reliable, labor force is reducedand the test cost is reduced.

Owner:SHANGHAI YUDE COMM TECH

Air pressure pipe bending machine

Owner:GOLD MANTIS CONSTR DECORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com