Automatic pipe bending device and pipe bending process thereof

A pipe bending device and automatic technology, applied in the field of mechanical processing and manufacturing, can solve the problems of non-compliance with production standards, product quality impact, inner pipe wall wrinkling, etc., and achieve long service life, high qualification rate, and uniform pipe wall thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

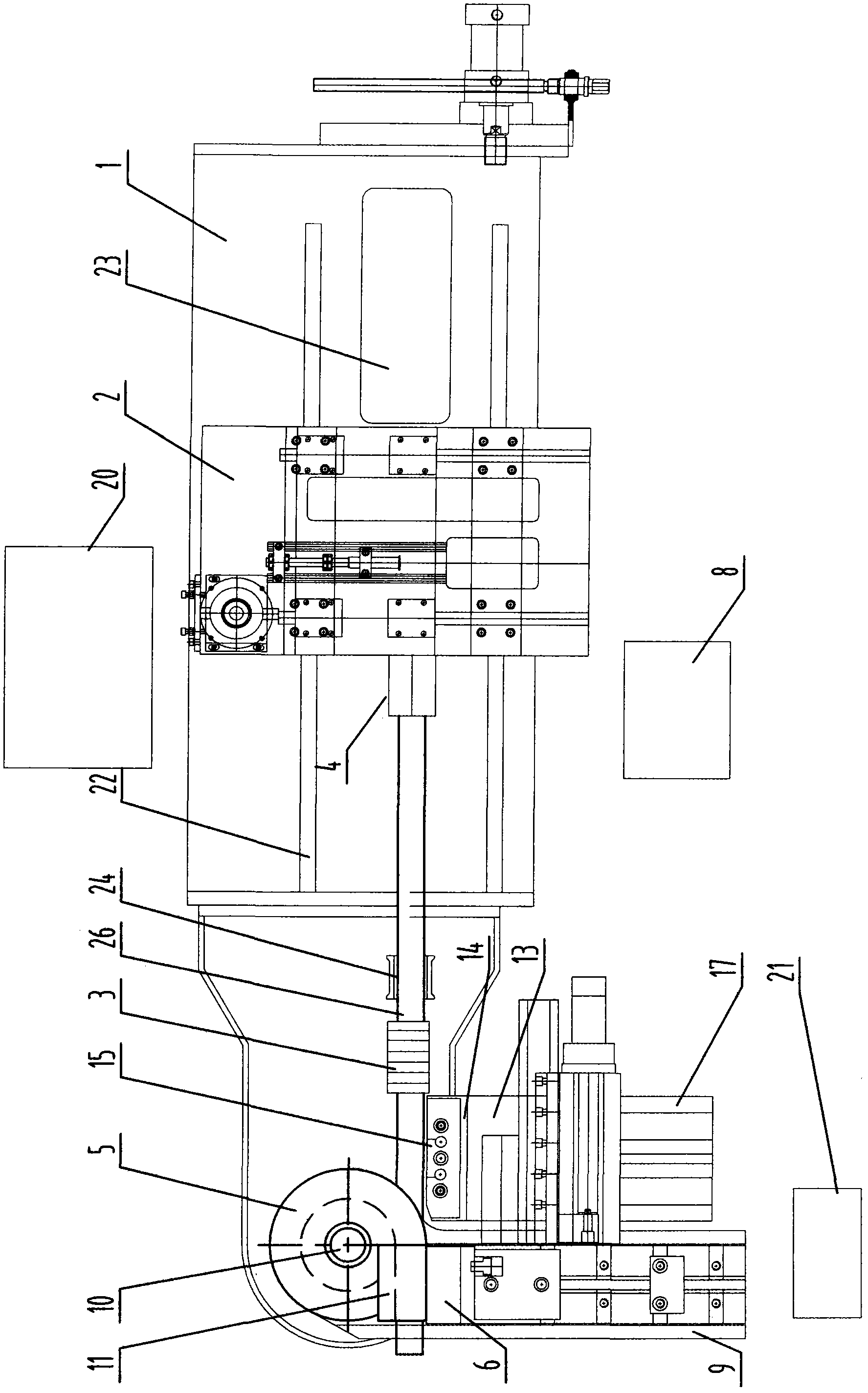

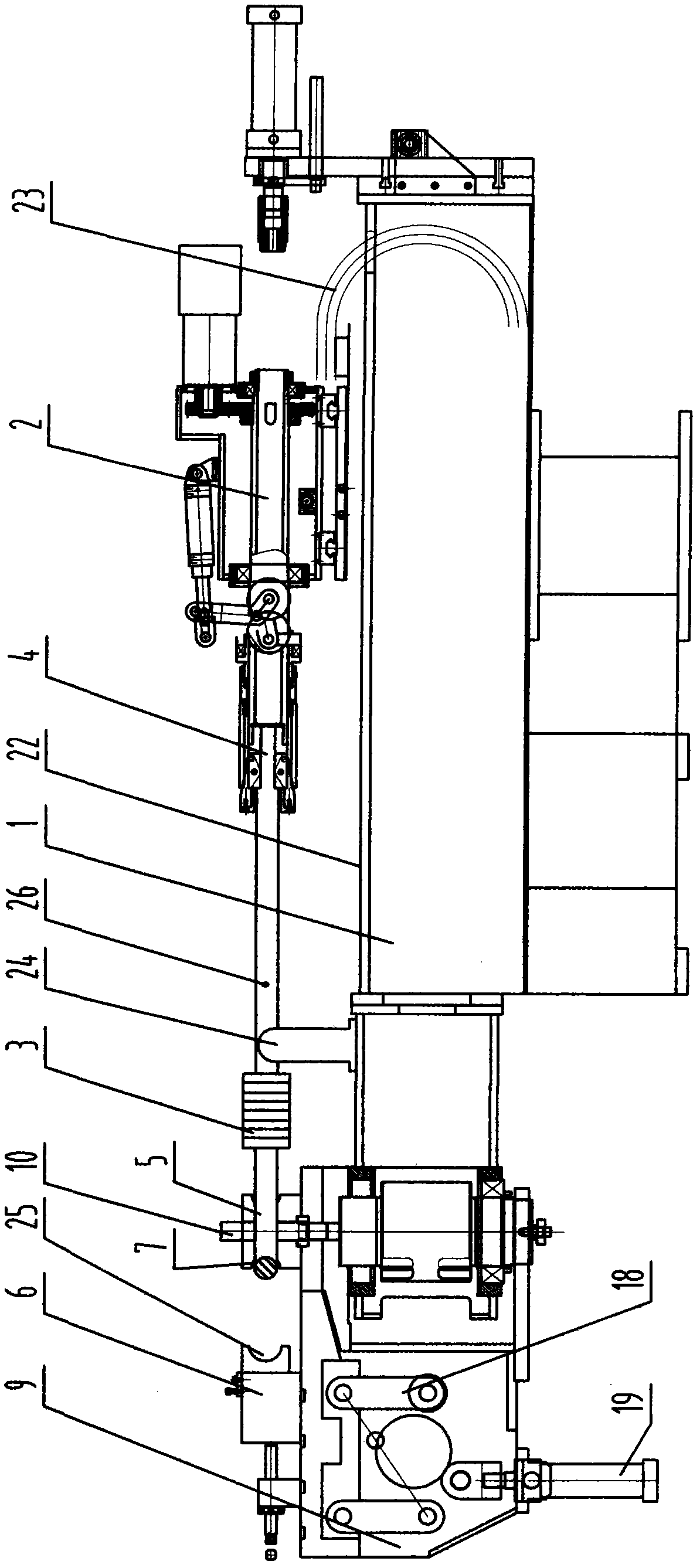

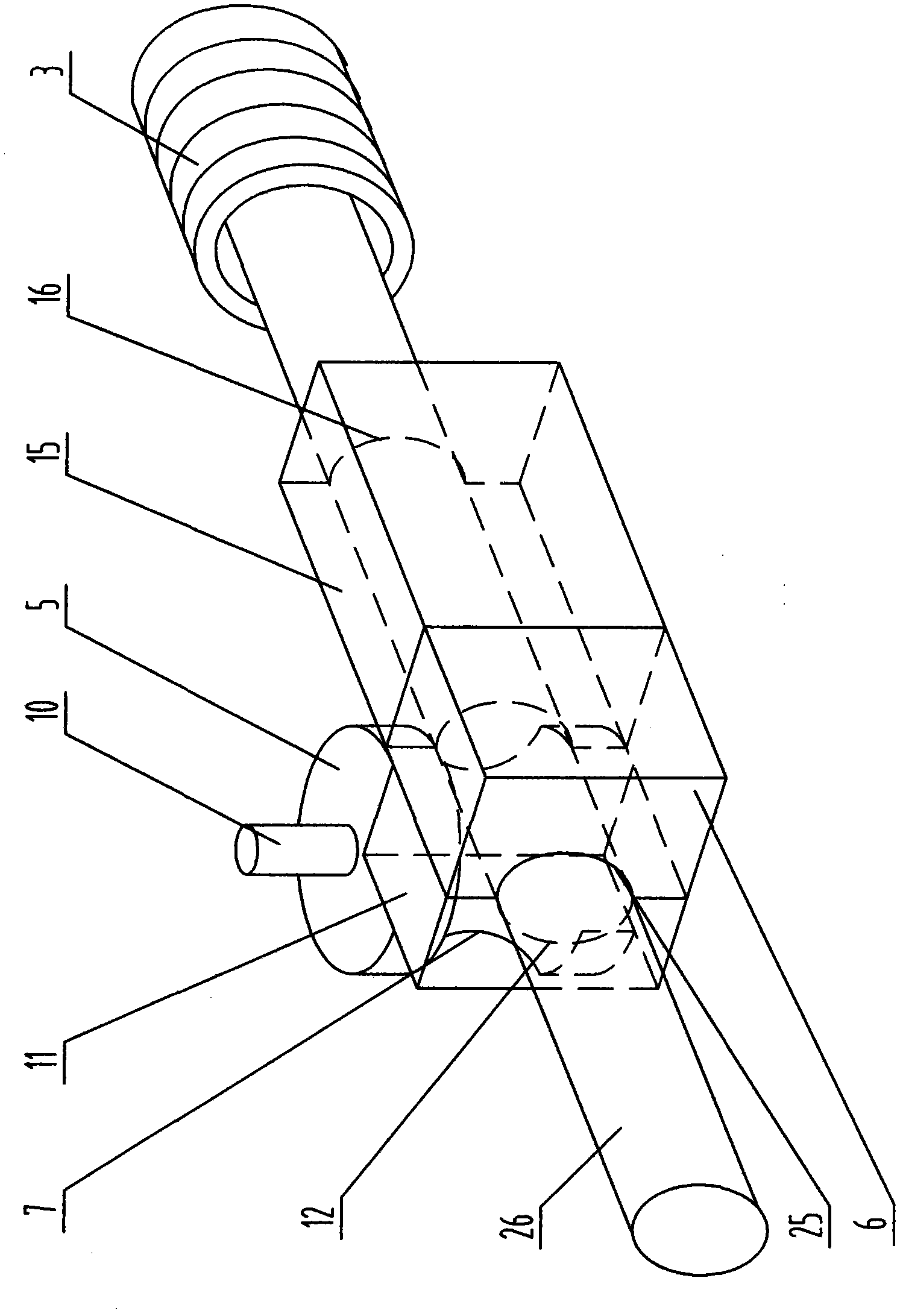

Embodiment 1

[0039] As shown in the figure, in the automatic pipe bending device of the present invention, a pipe bending mold, a heater 3 and a pinch device 2 are sequentially installed on the machine base 1, and an automatic control console 8 is installed on one side of the machine base 1 for automatic control. Taiwan 8 is equipped with numerical control program. A guide rail 22 is installed on the support 1, and a pinch device 2 is installed on the guide rail 22, and the pinch device 2 can move longitudinally on the guide rail 22. The pincer 2 is provided with a rotating fixture 4, which can hold the pipe 26 in the pincer 2 and drive it to rotate. The rear end of the clamper 2 is equipped with a row chain 23, and the other end of the row chain 23 is installed with a power source, which can be a cylinder or a motor. Both the power source and the clamper 2 are connected to the self-control console 8, and the console 8 controls the clamper to automatically advance or retreat. The heater ...

Embodiment 2

[0046] For medium carbon steel pipe fittings, it needs to be heated to 1100-1200°C when bending. The actuator 18 can be an air cylinder or an oil cylinder, and the telescopic shaft of the air cylinder or the oil cylinder drives the movable jaw 6 to fasten the pipe fitting 26. All the other are with embodiment 1.

Embodiment 3

[0048] For medium carbon steel pipe fittings, when bending, it needs to be heated to 1250-1350°C, up to 1400°C. The actuator 18 can be a rack and pinion transmission mechanism. A motor is installed in the actuator 18. The motor drives the gear to rotate, and the gear drives the rack to move. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com