Intelligent suspension system and suspension distribution control method

A hanging and intelligent technology, applied in conveyor control devices, conveyor objects, conveyors, etc., can solve problems such as the inability of the system to intelligently schedule production, waste of resources, etc., to avoid errors, reduce enterprise costs, and quickly and accurately search. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Intelligent hanging system, including hanging system and control system.

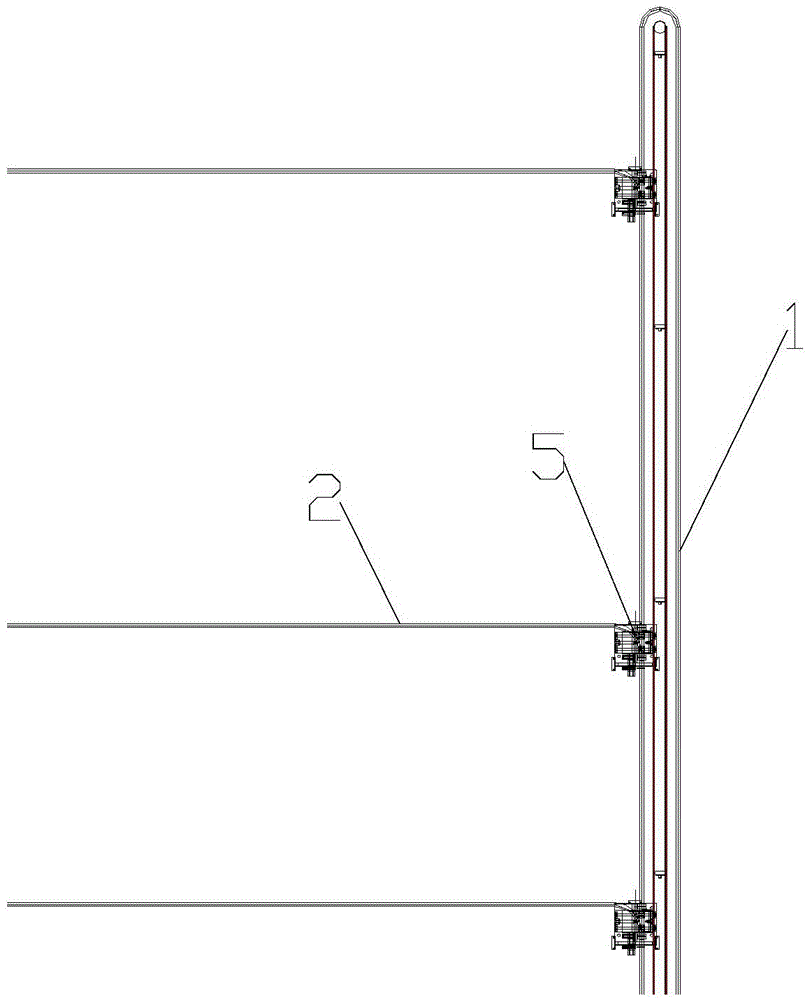

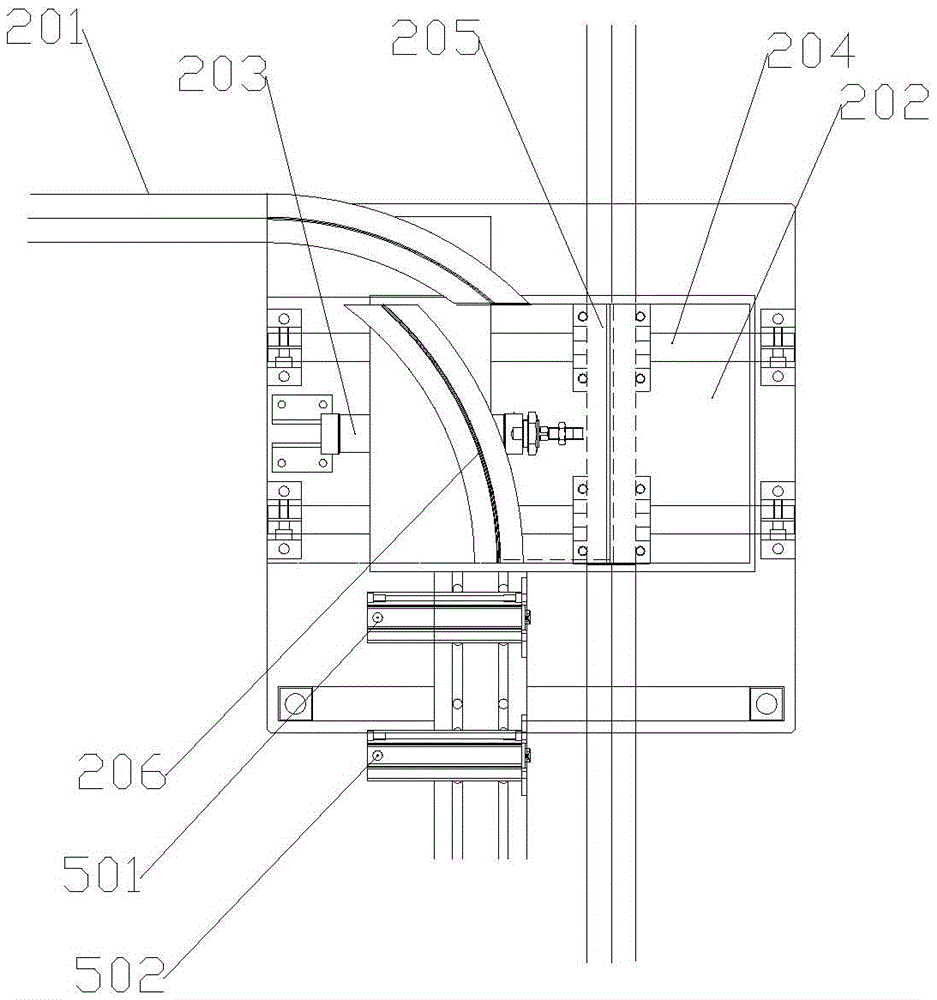

[0039] Such as figure 1 As shown, the hanging system is used for transportation and hanging, and the materials to be processed are hoisted on the hanging; the transportation channel includes a main transport circulation channel 1 and a plurality of branch channels 2 . A plurality of branch passages 2 lead to different workshops respectively.

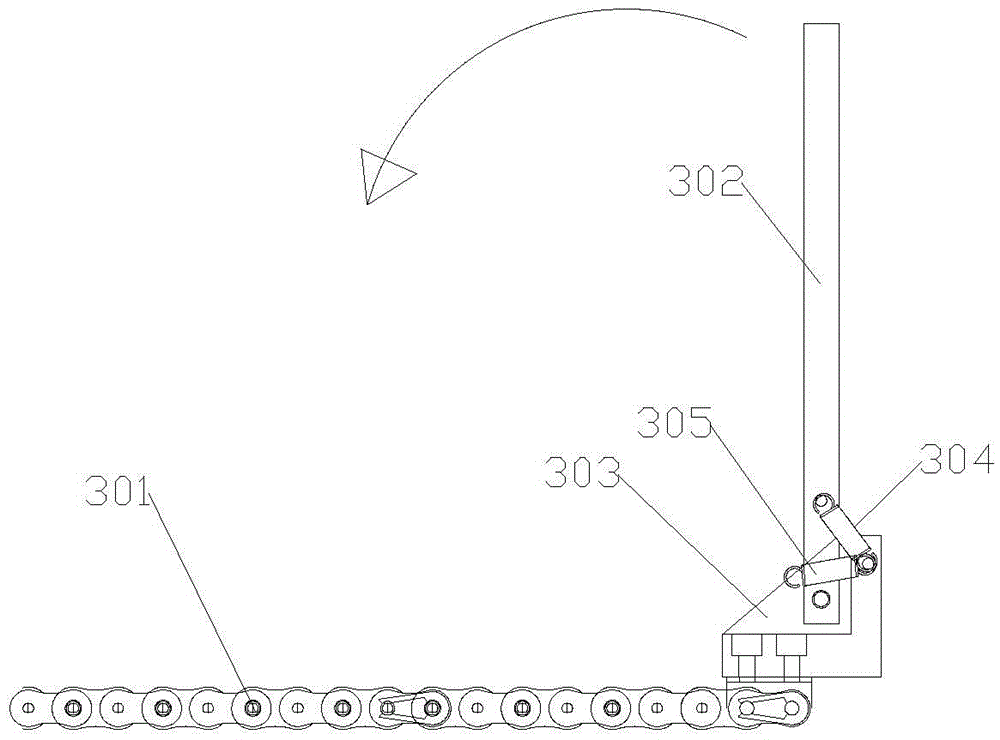

[0040] The main transport circulation channel 1 is ring-shaped, including the transmission chain track on the inside and the suspension main track on the outside. The two ends of the transmission chain track are transmission shafts, and a transmission chain 301 is arranged around the transmission shaft at both ends, such as figure 2 As shown, the transmission chain 301 is provided with suspension driving rods 302 at intervals. The suspension lever 302 is installed on the transmission chain 301 through the base 303 , the end of the suspension lever 302 is...

Embodiment 2

[0061] This embodiment provides a more compact structure of the main transportation channel.

[0062] Such as Figure 5 shown. The main transport channel includes two mutually perpendicular main transport channel I6 and the main transport circulation channel II7, which are connected by a transition channel 8; multiple branch channels 2 are connected to the main transport channel II7.

[0063] In this embodiment, the function of the main transportation channel II7 is equivalent to that of the main transportation circulation channel 1 in the first embodiment.

[0064] Such as Image 6 As shown, the transition channel 8 includes a section of hanging walking rail 801 and an annular transmission chain track 802, and the transmission chain of the transmission chain track 802 is provided with a suspension lever 302 at intervals, and its installation method is the same as that of the suspension lever 302 on the main transportation channel 1. The installation method is the same.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com