Aluminum ingot fully-automated loading system and method

A fully automated, aluminum ingot technology, applied in loading/unloading, conveyors, conveyor objects, etc., can solve problems such as hidden safety hazards, low work efficiency, high labor intensity, etc., to solve safety problems, comprehensive automation and intelligence , the effect of improving the efficiency of handling and loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

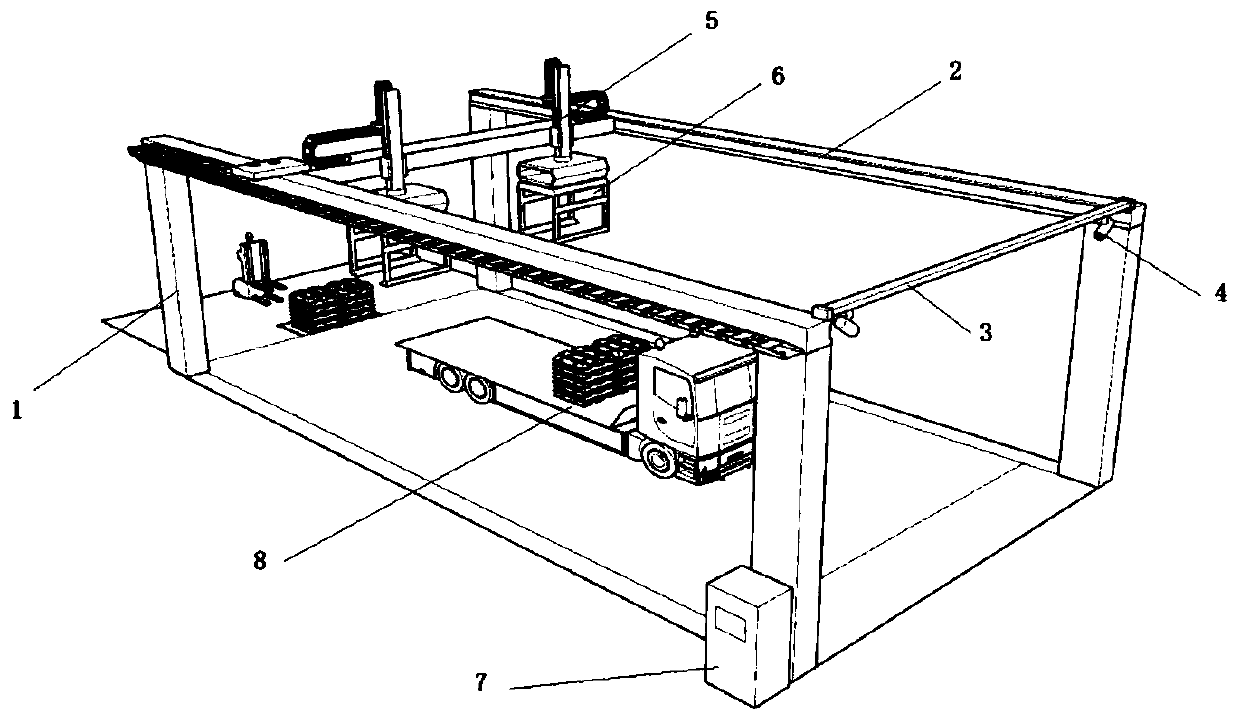

[0047] An embodiment of the present invention is a fully automated loading system for aluminum ingots, refer to figure 1 , the boarding system includes: a support frame 1, two rails 2, a moving part 3, a laser scanning device 4, a three-axis linear slide 5, a fixture 6 and a control center 7.

[0048] The support frame 1 functions as a support rail 2 , a moving part 3 , a laser scanning device 4 , a three-axis linear slide 5 and a fixture 6 . The supporting frame 1 is generally composed of several columns, for example, four columns, and the space between the four columns can be used to park the vehicle 8 .

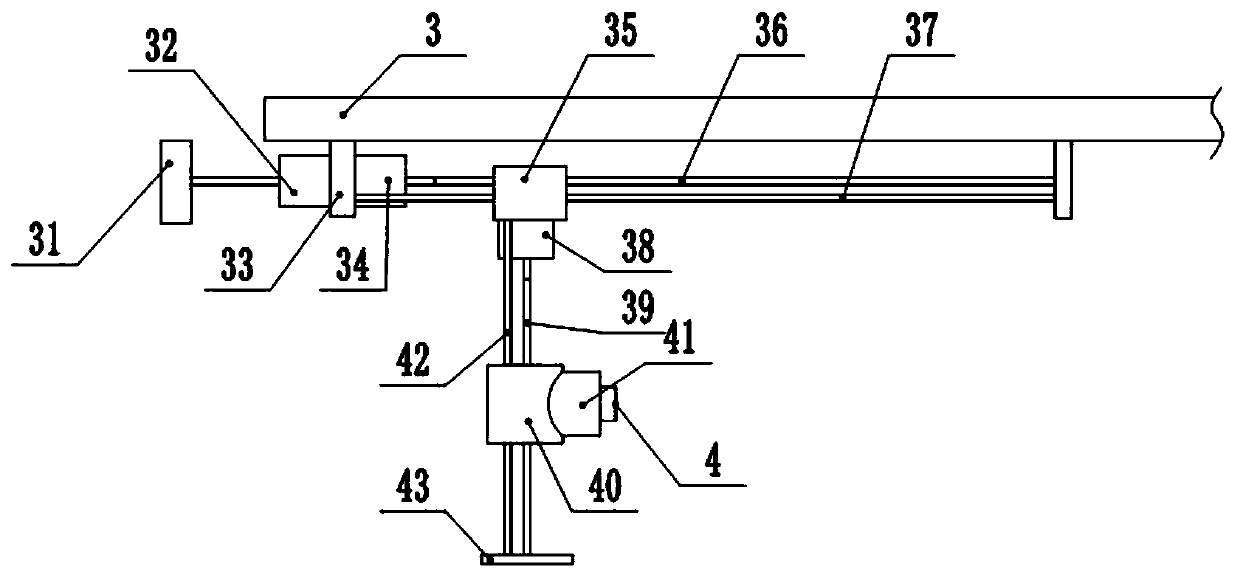

[0049] Two rails 2 are arranged oppositely on the support frame 1, and the rails 2 mainly play the role of supporting the moving part 3 and the three-axis linear sliding table 5, and satisfy the moving requirements of the moving part 3 and the three-axis li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com