Steel strand finished product storage and distribution system and method

A technology for producing finished products and steel strands, which is applied in the field of warehousing and distribution systems for finished products of steel strands, and can solve the problems of difficulty in realizing product first-in, first-out, large labor, and difficulty in meeting the needs of product delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

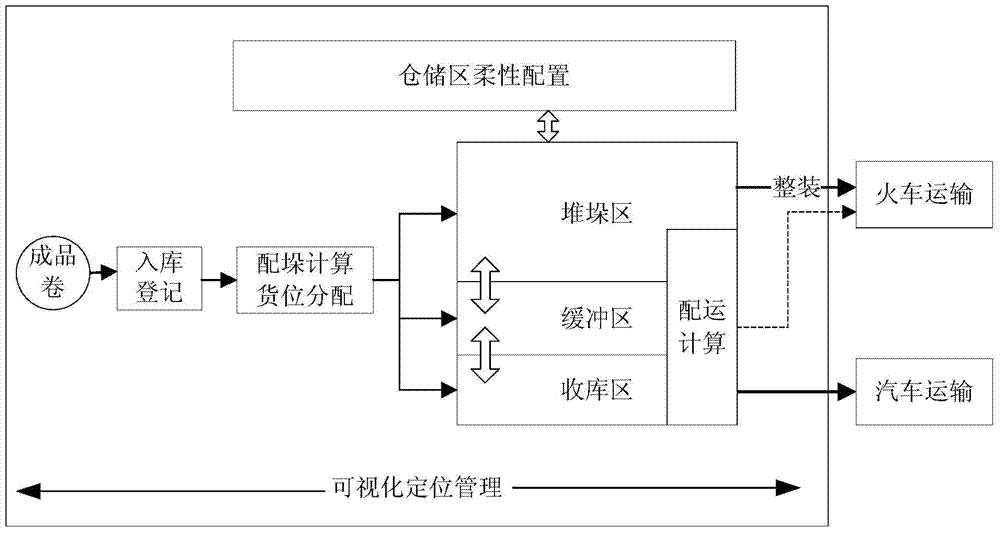

[0079] The steel strand finished product storage and distribution system in this embodiment, such as figure 2 As shown in , it is used to allocate storage locations for steel strand finished products in the storage area for positioning and storage, and to distribute and transport the finished steel strand products in the storage area. The storage area is as follows Figure 4 shown.

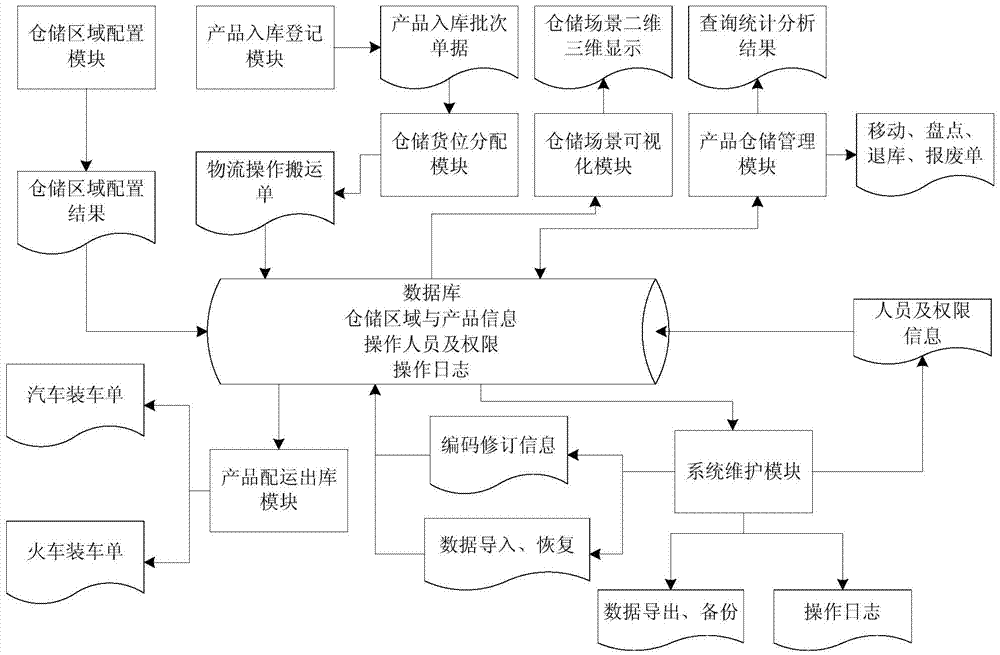

[0080] Such as image 3 As shown, the system includes: storage area configuration module, product storage registration module, storage location allocation module, product distribution and delivery module, product storage management module and storage scene visualization module;

[0081] The storage area configuration module is used to configure the storage area according to the type and quantity of the steel strand finished products to be stored. The storage ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com