Patents

Literature

36results about How to "Reduced clamping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

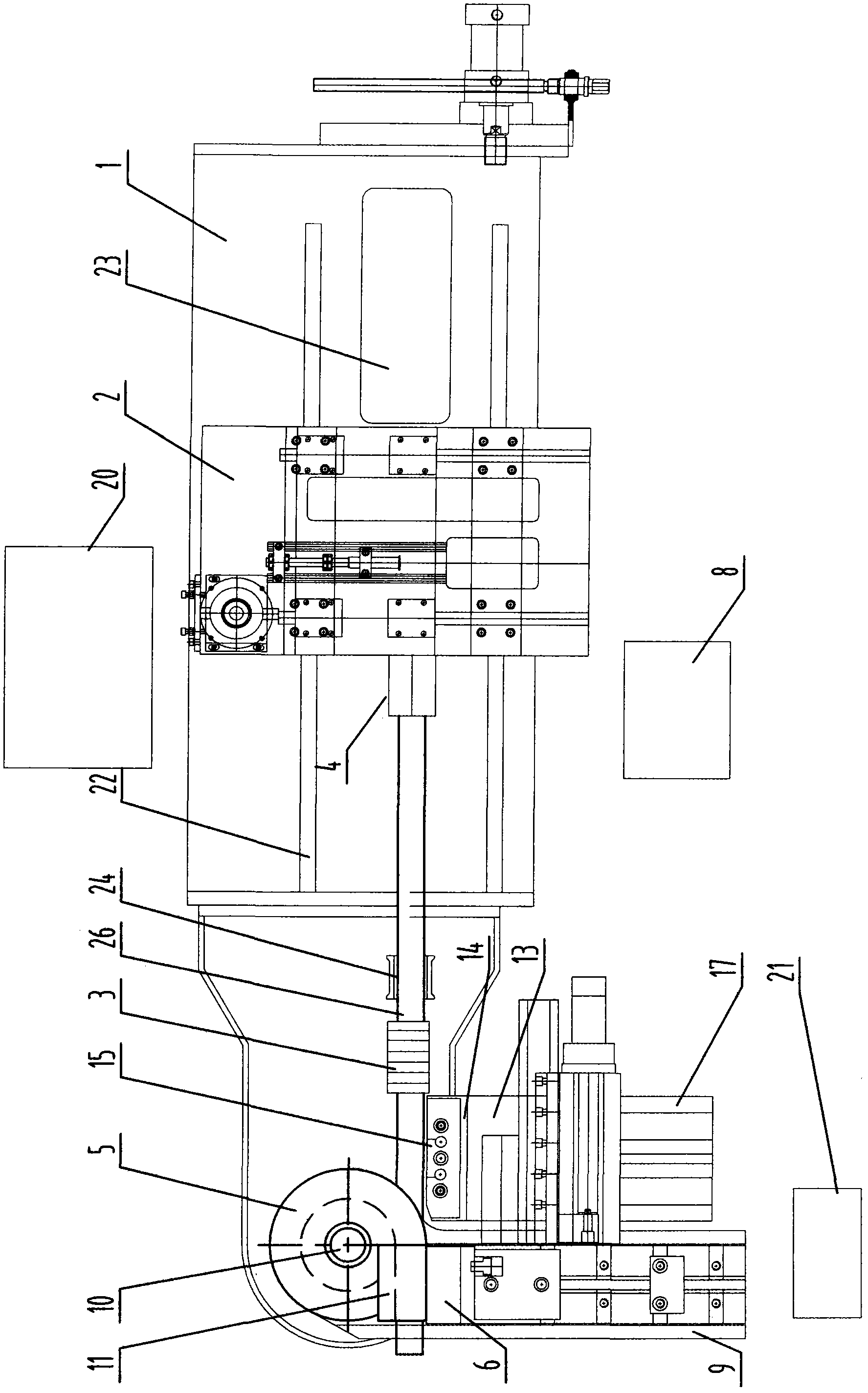

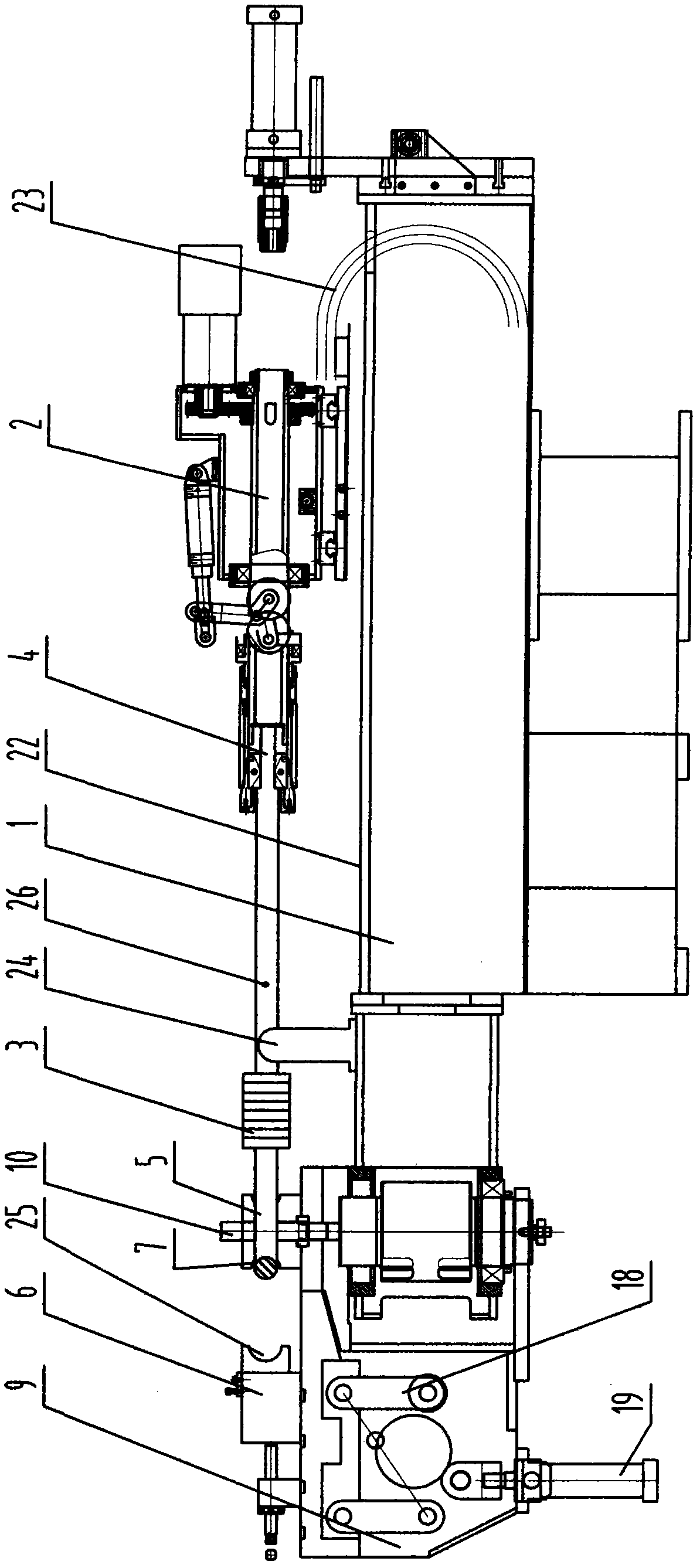

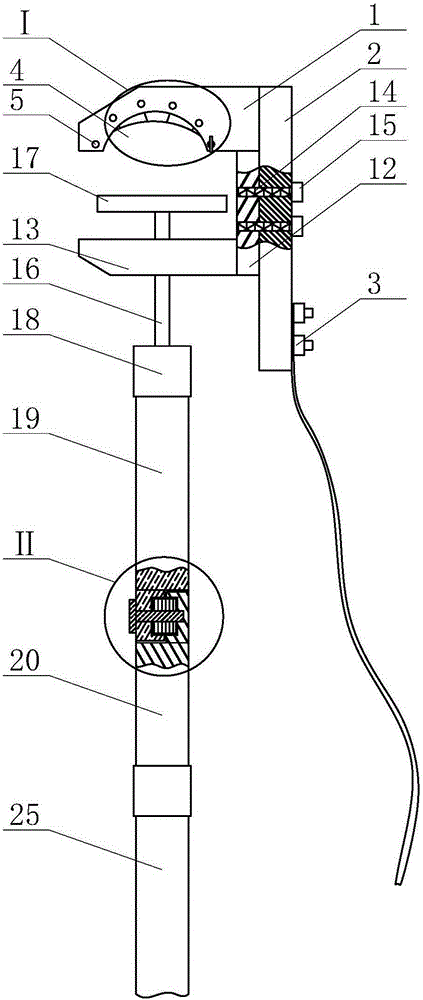

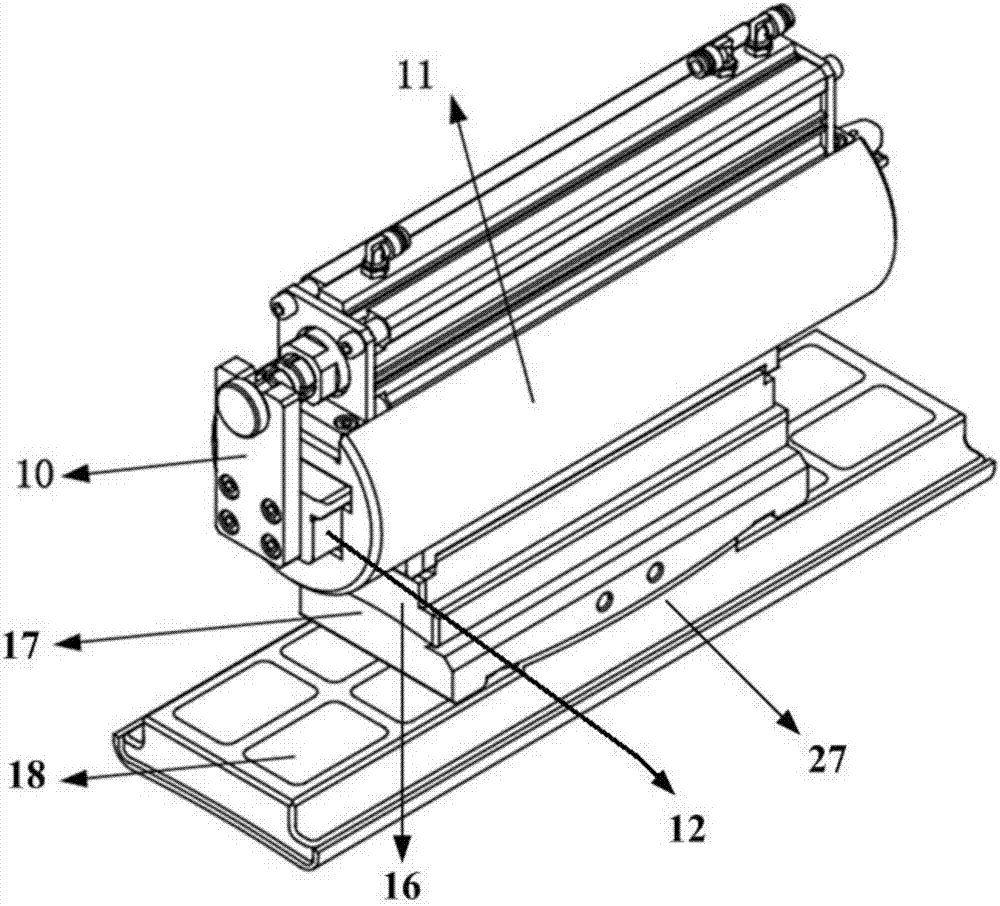

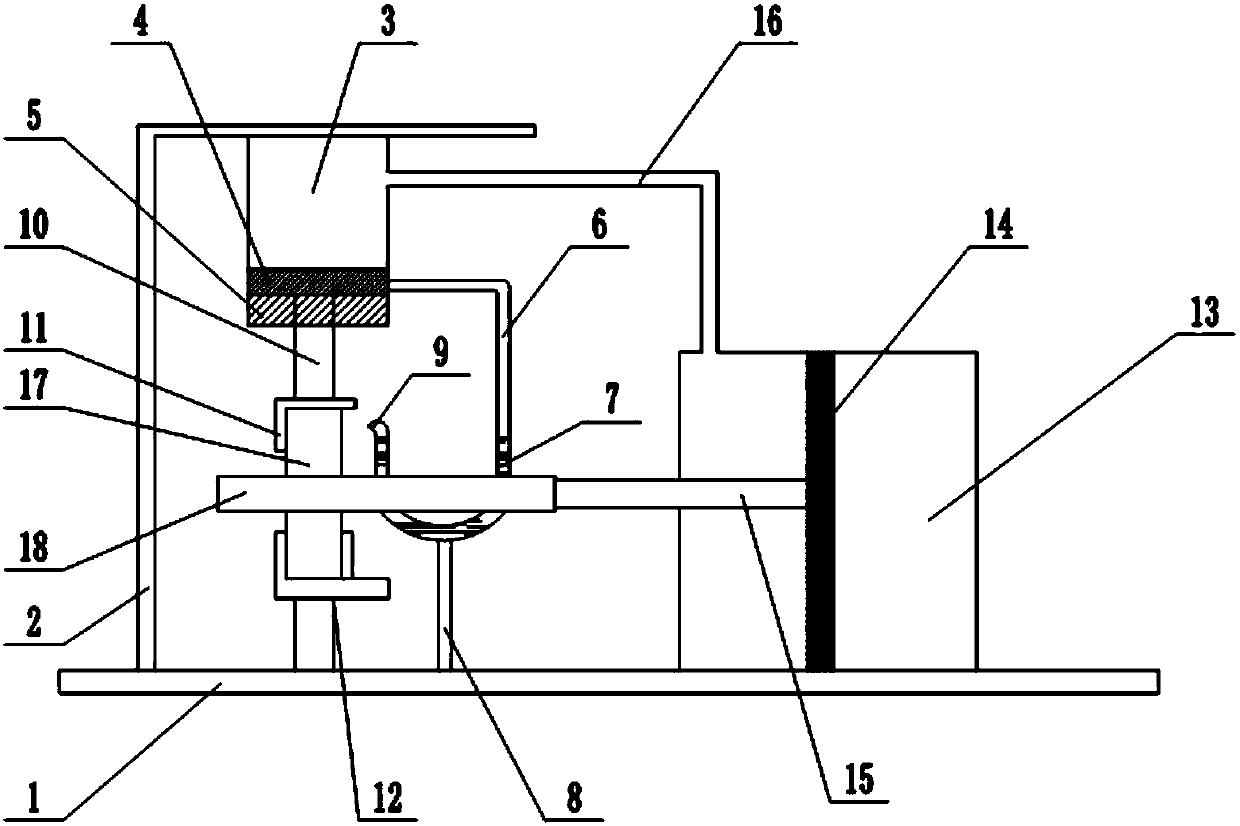

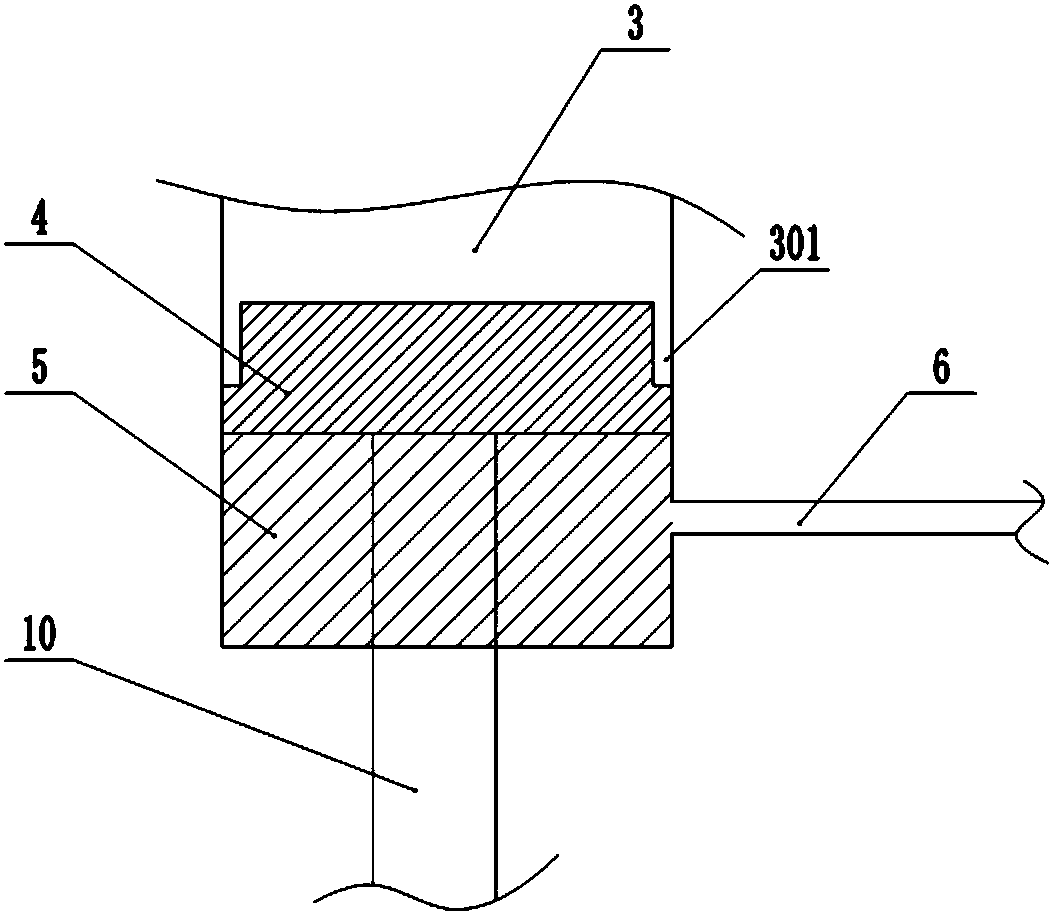

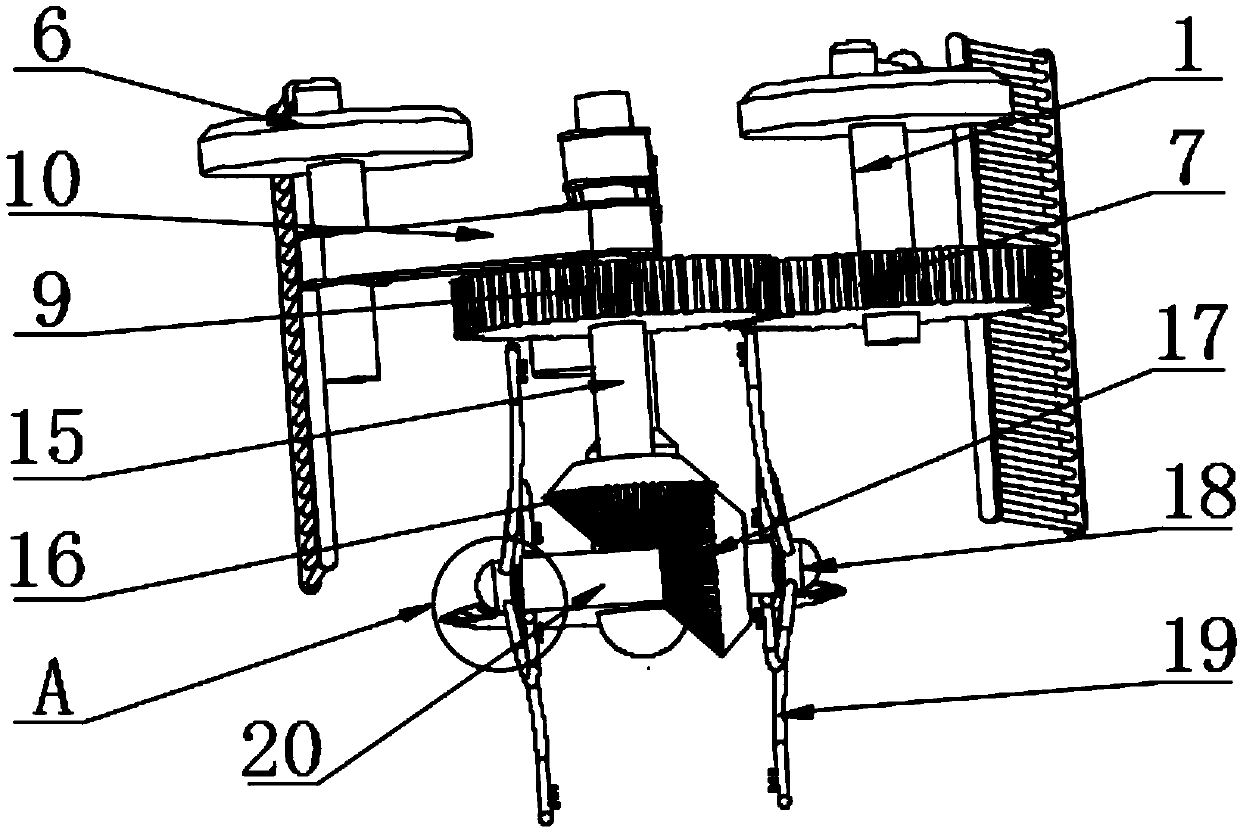

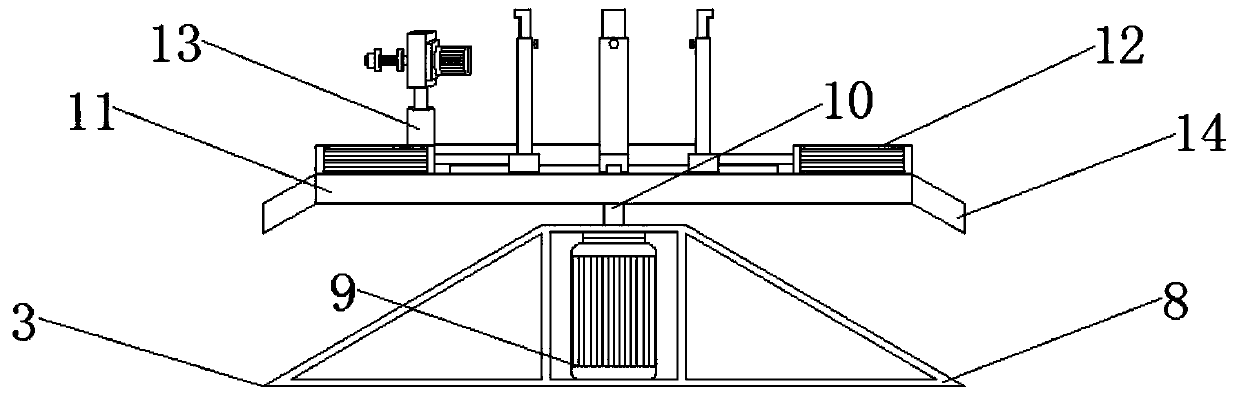

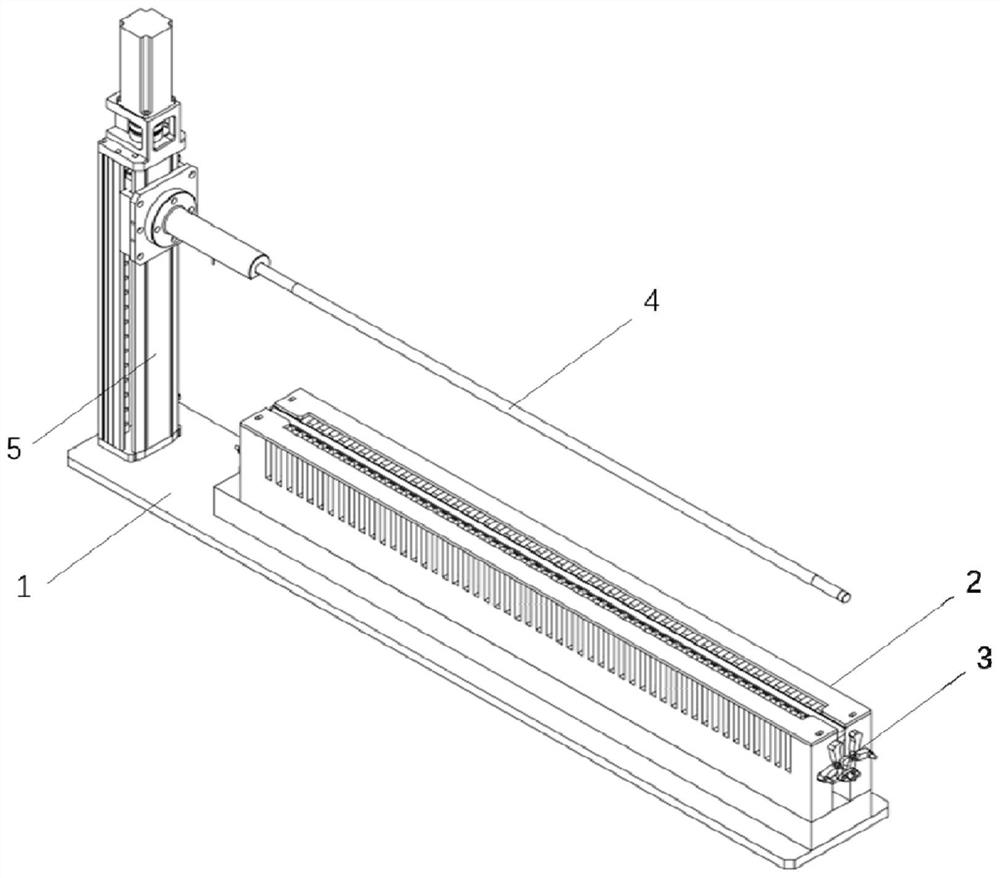

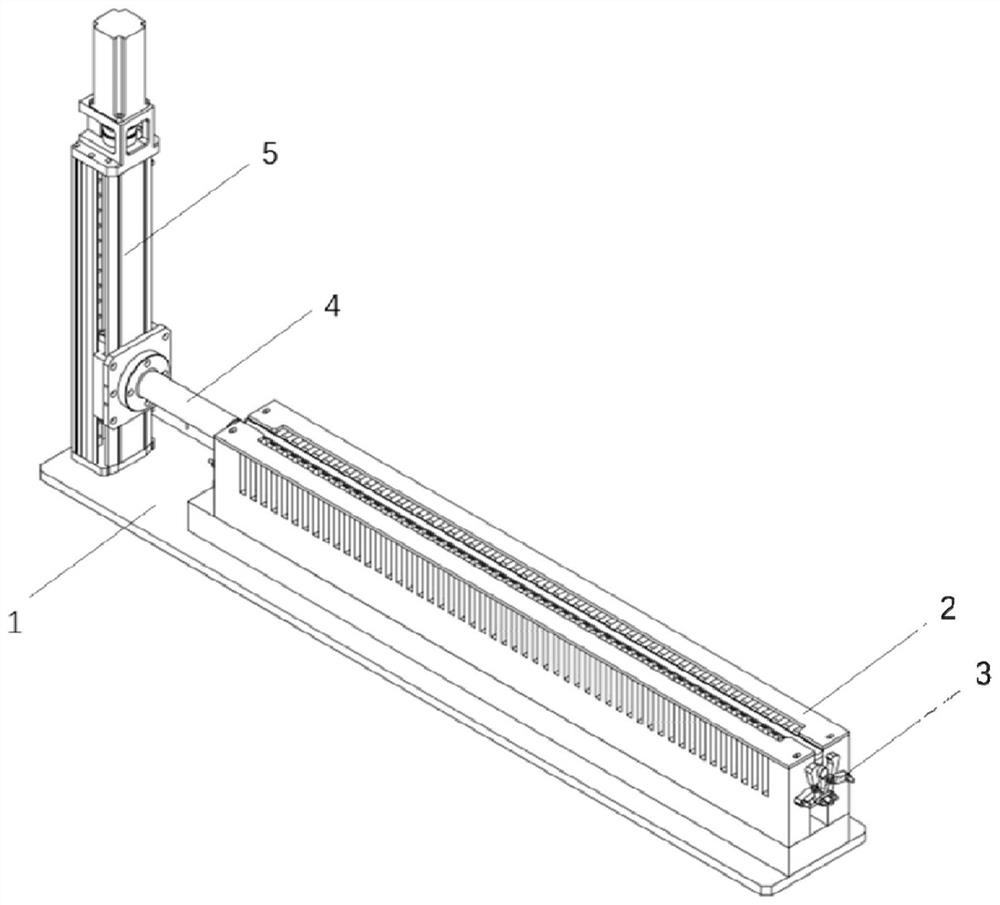

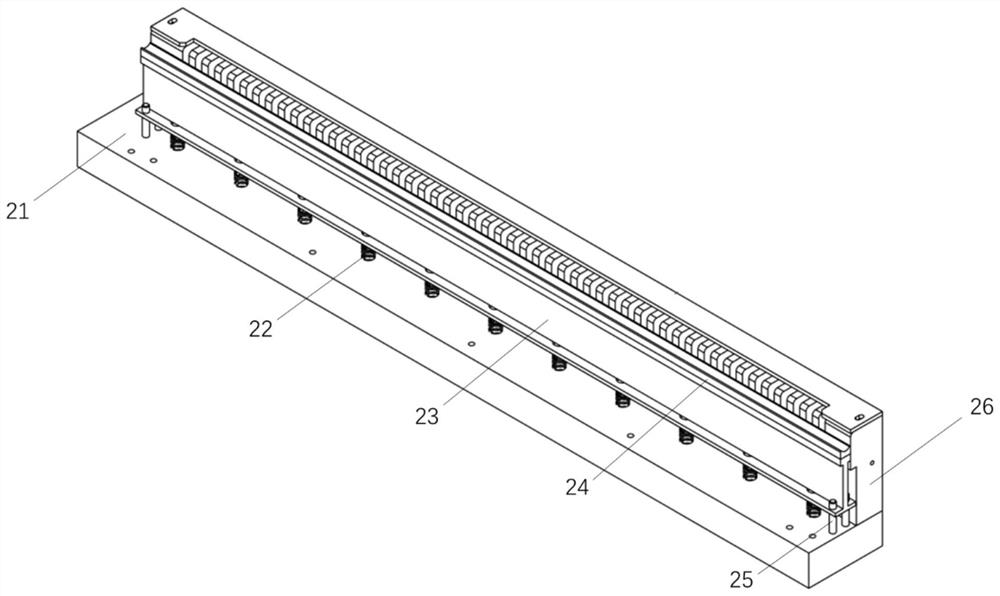

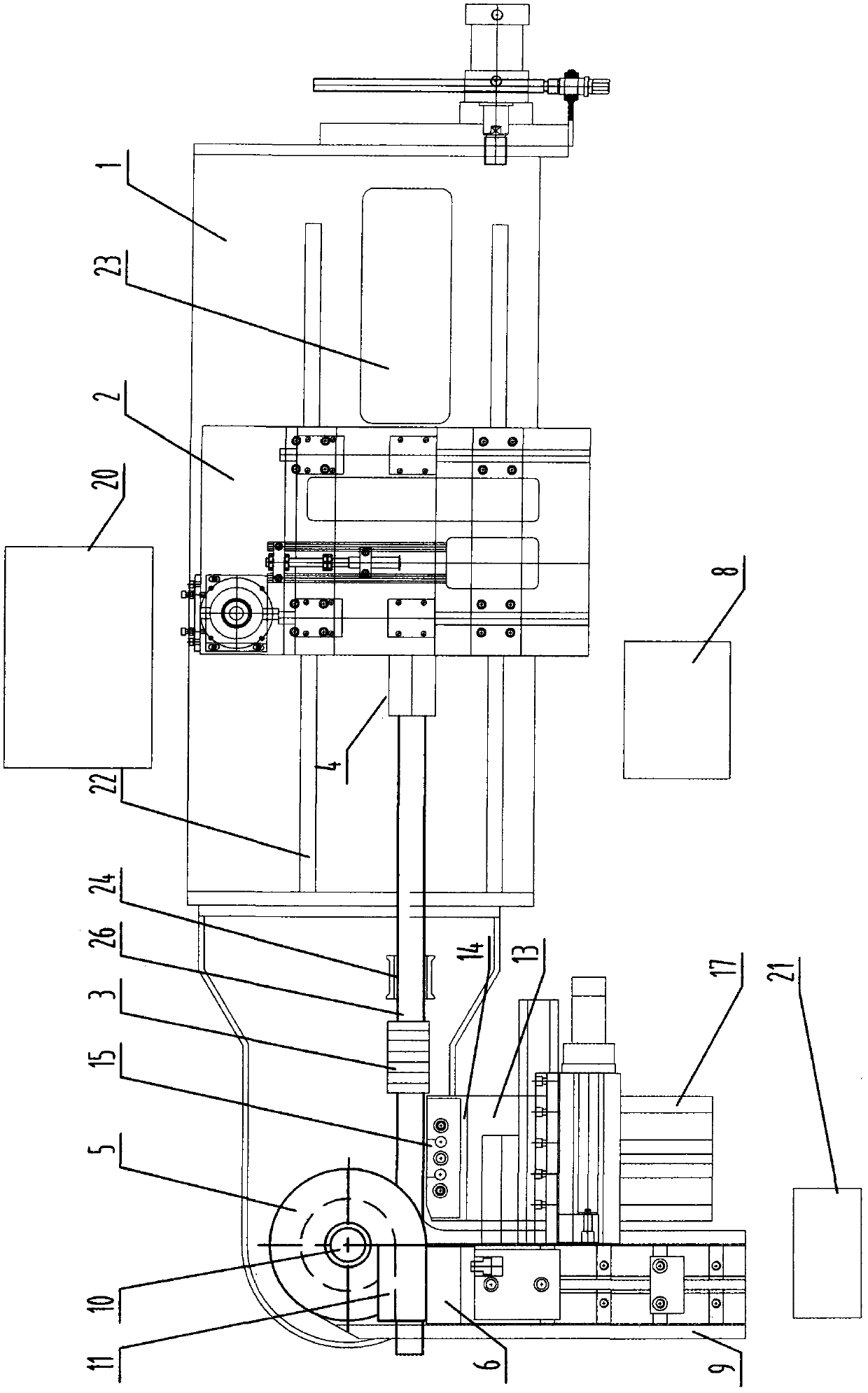

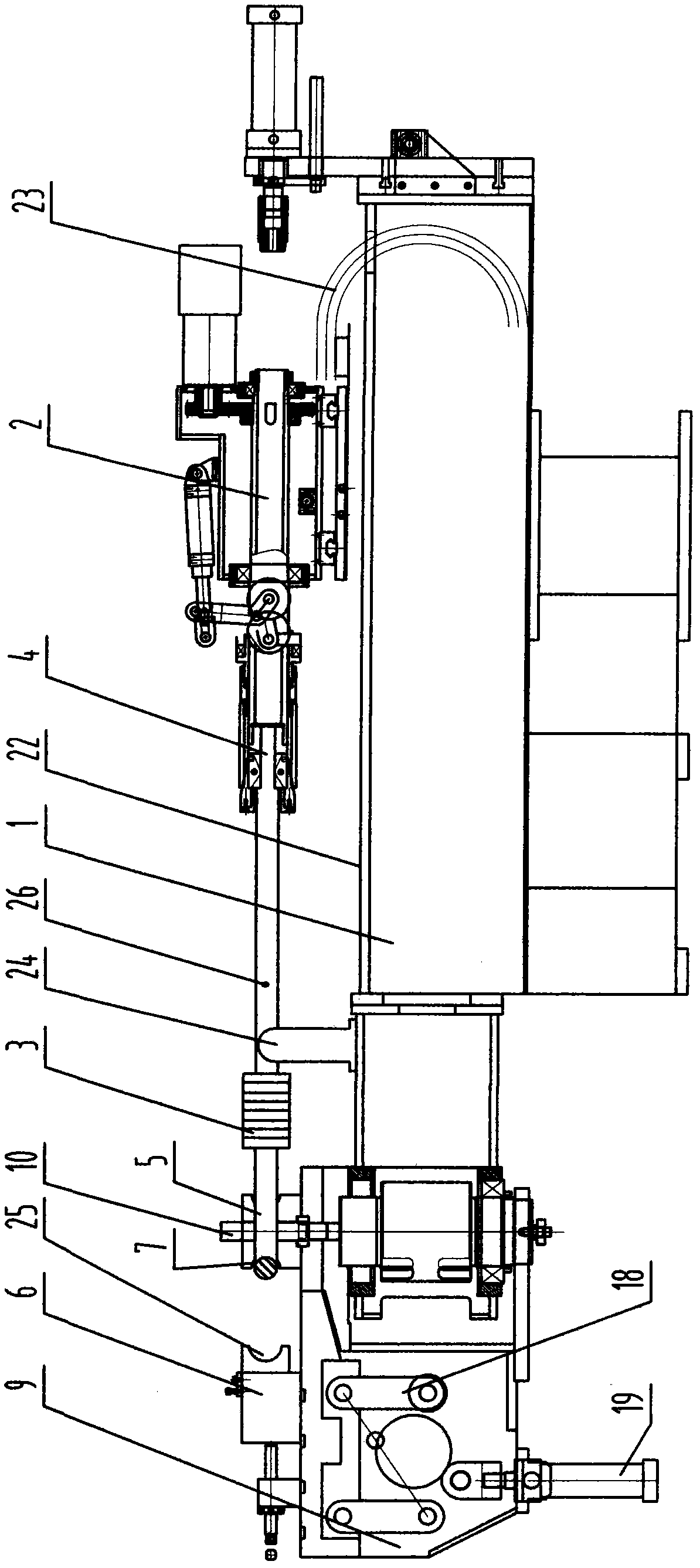

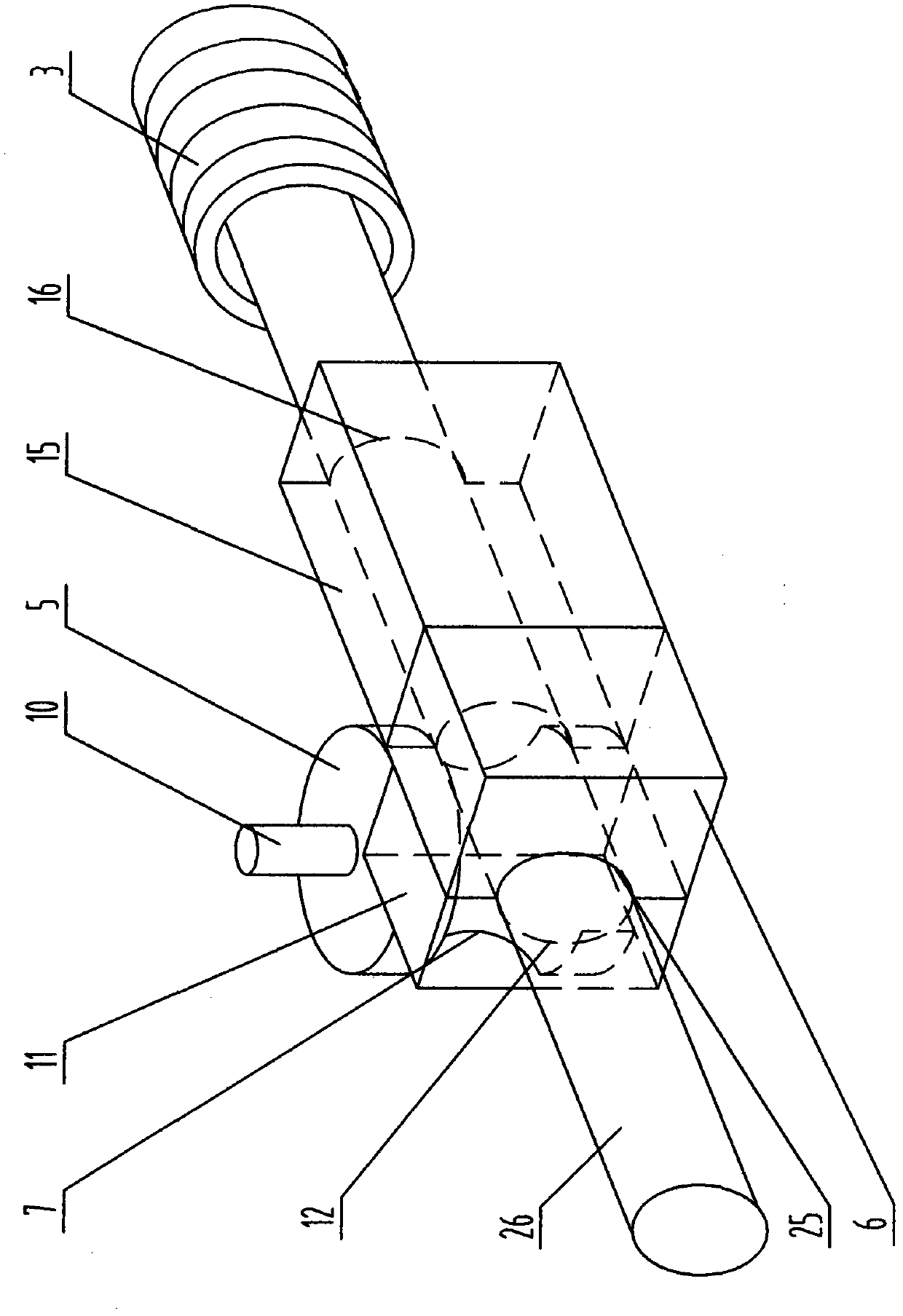

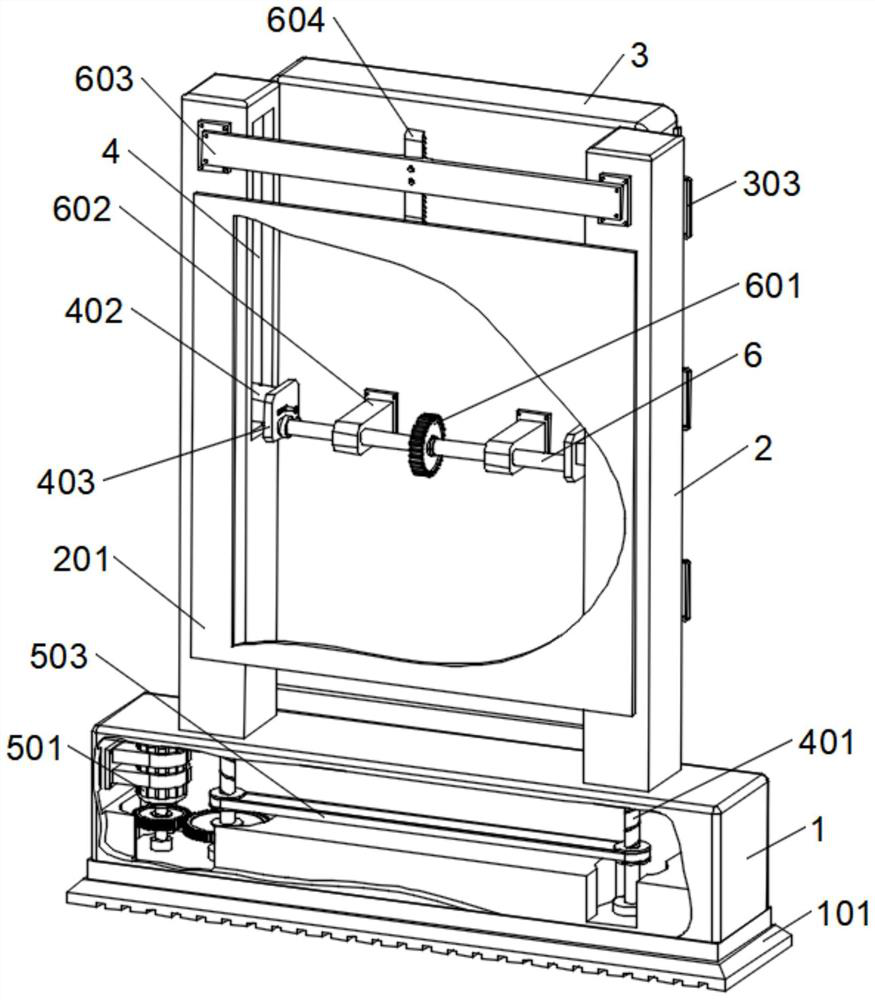

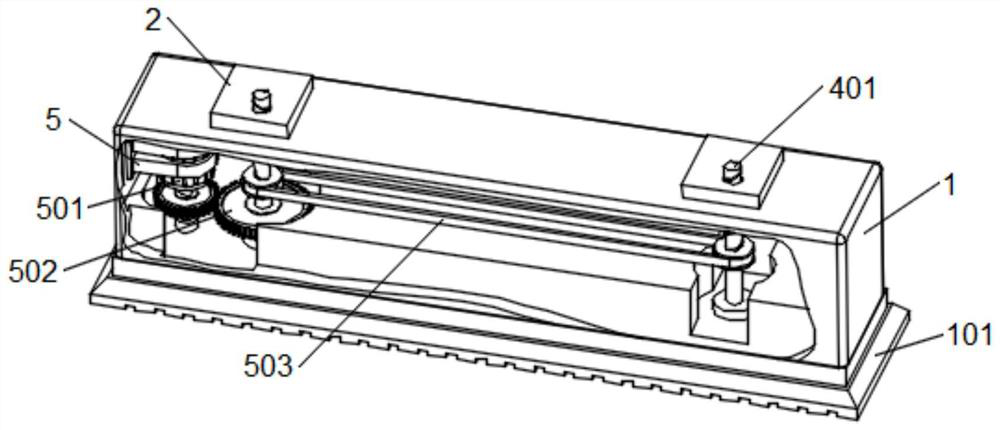

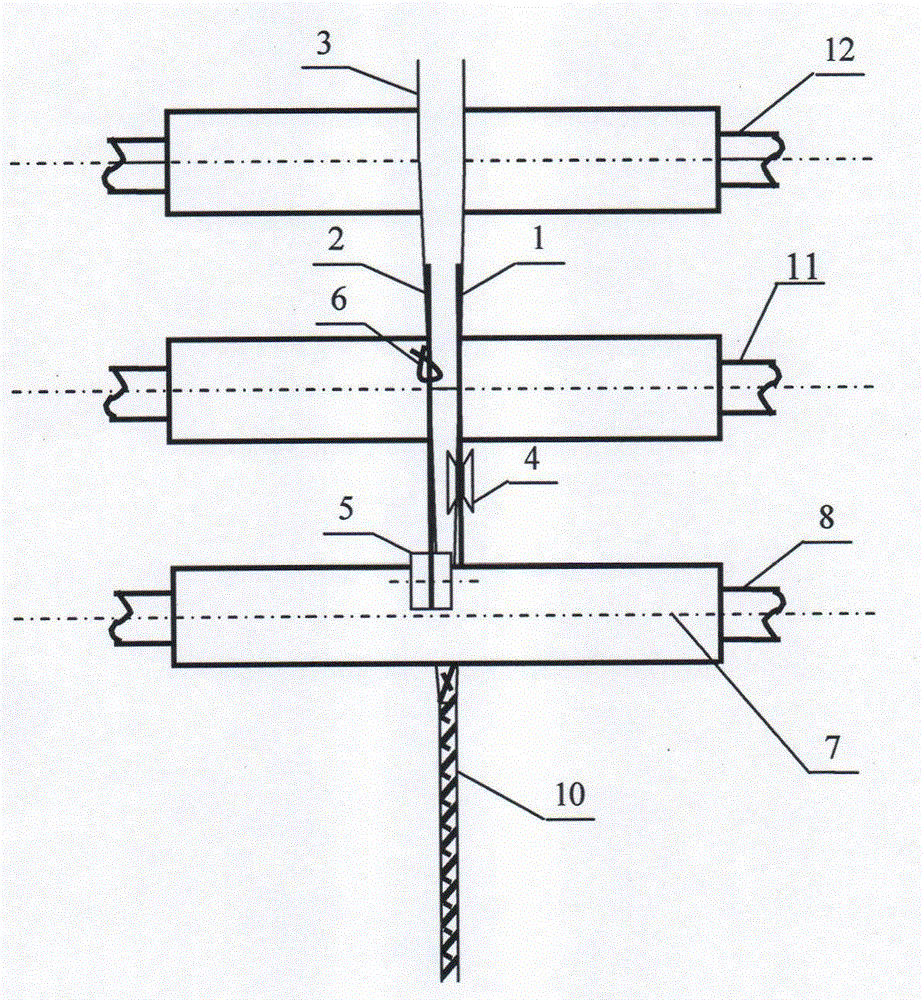

Automatic pipe bending device and pipe bending process thereof

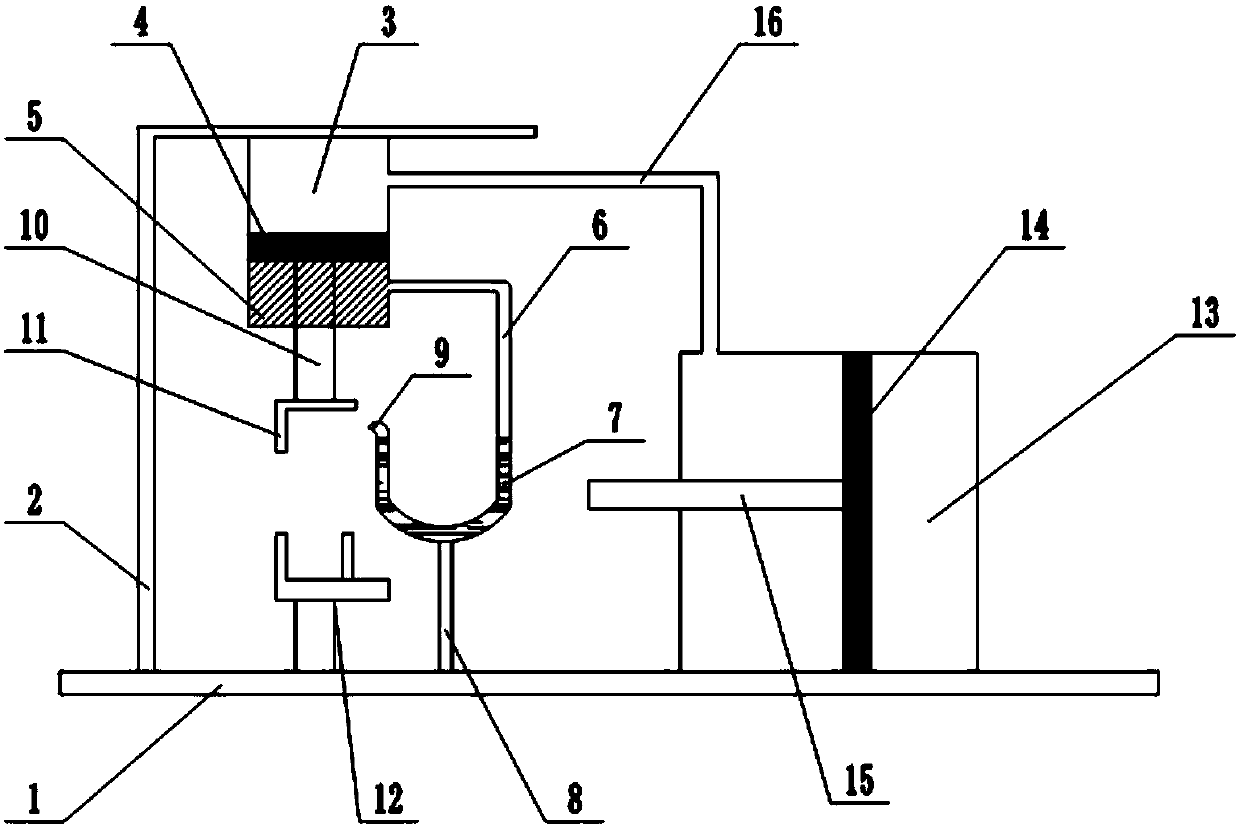

The invention discloses an automatic pipe bending device and a pipe bending process thereof, belonging to the technical field of mechanical processing and manufacturing. The technical scheme adopted by the invention is as follows: under the automatic control of an automatic control platform, a loading claw of a pipe loading machine firstly shifts a single pipe into a rotating fixture of a pinch device, the pinch device drives the pipe to move forward through a heater, the heater heats a bent part of the pipe to 1200-1350 DEG C, the bent part is moved to a bending mold, a follower plate and a movable jaw clamp the pipe, the movable jaw and the bending mold rotate to a bending angle around a rotating shaft, the follower plate and the movable jaw are reset after the pipe is released, the above process is repeated until the bending of the whole pipe is finished, and an unloading manipulator carries out unloading operation, thus finishing the bending process. The system can automatically finish pipe operations such as loading, feeding, heating, rotating, bending, unloading and the like, so that the pipe can be automatically bent and molded, the molding process is more accurate, and theyield is high; and the number of times for transporting the pipe in the processing process is reduced, and the productivity is improved.

Owner:西安德卡汽车系统有限公司

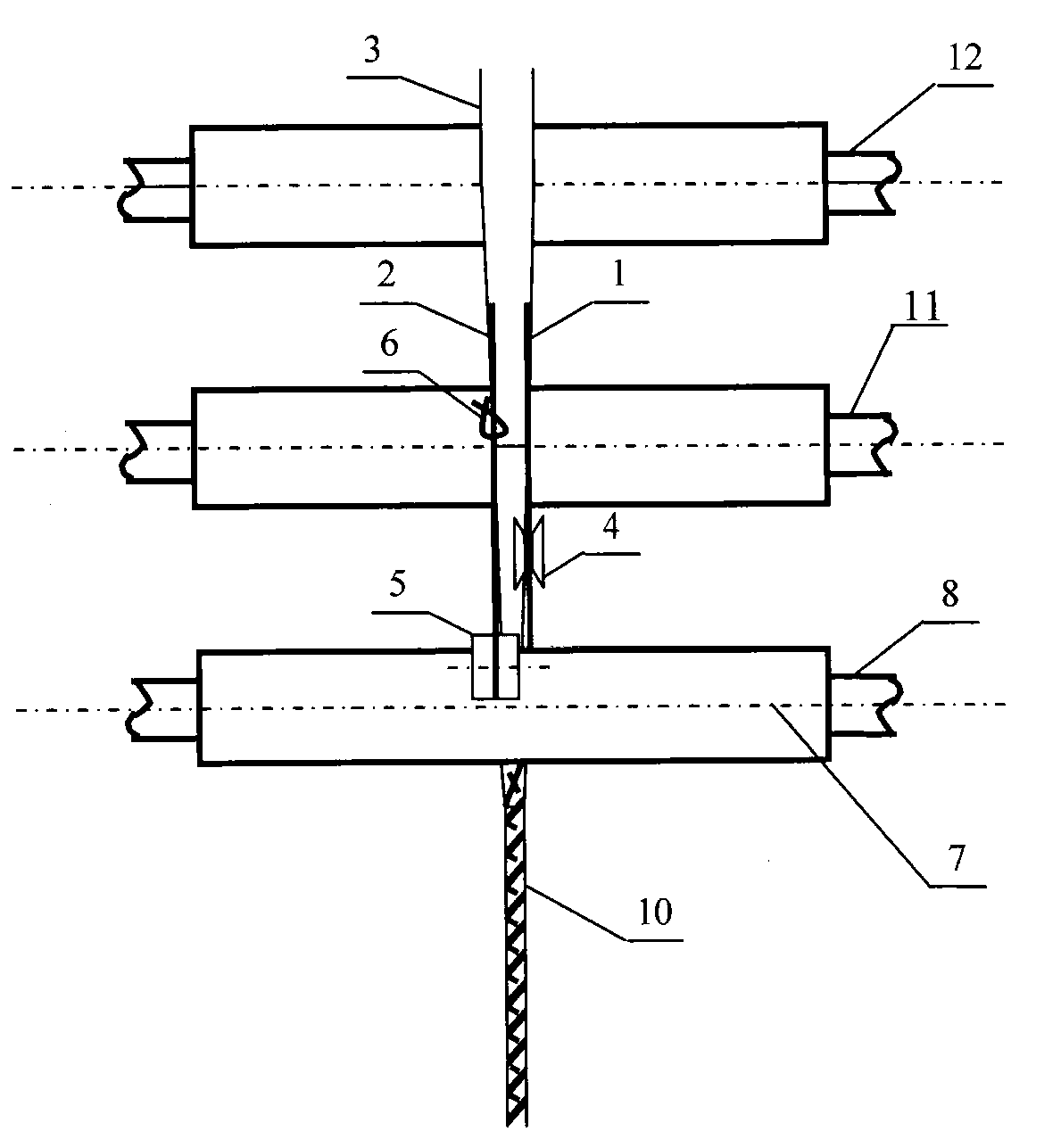

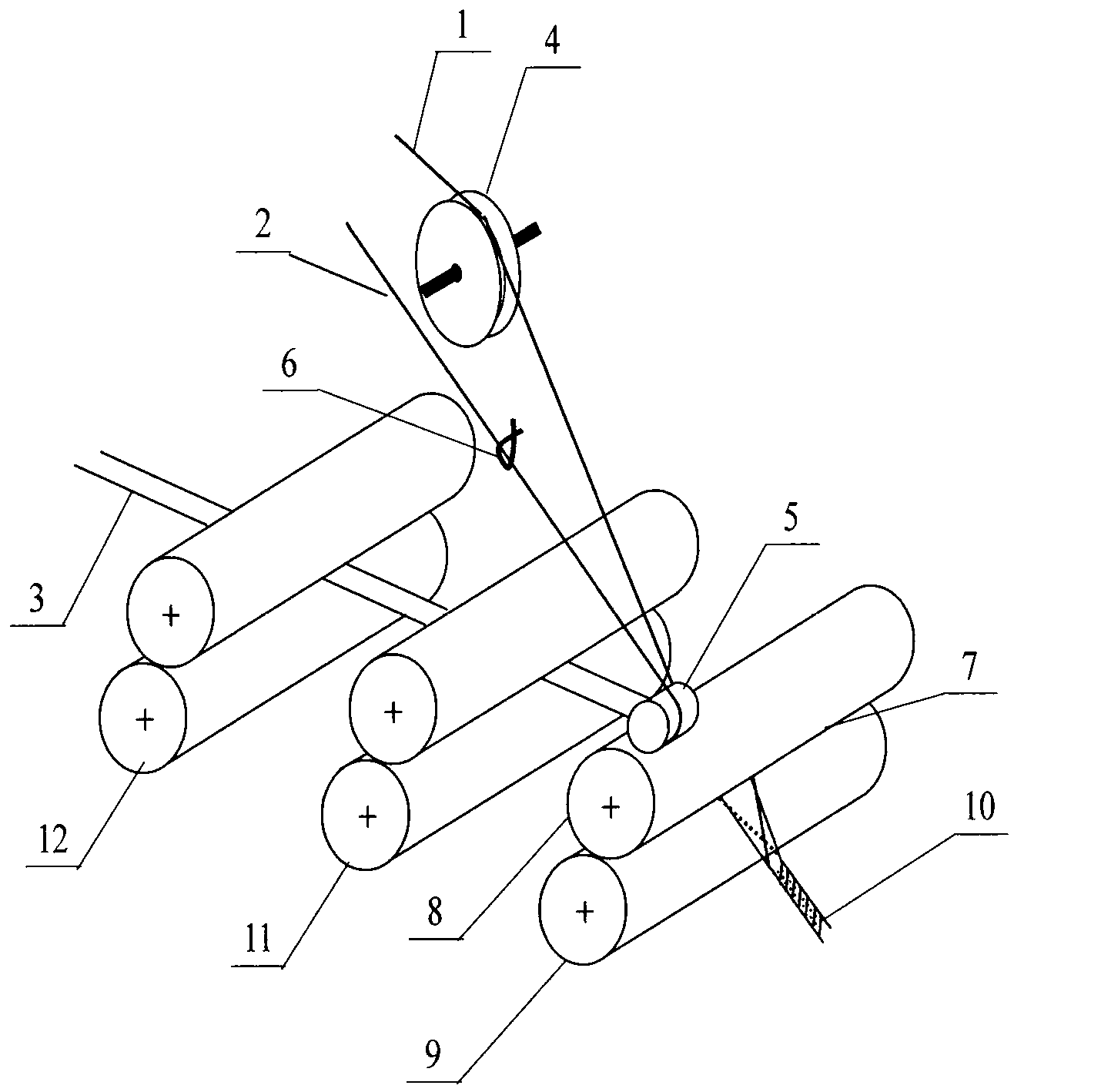

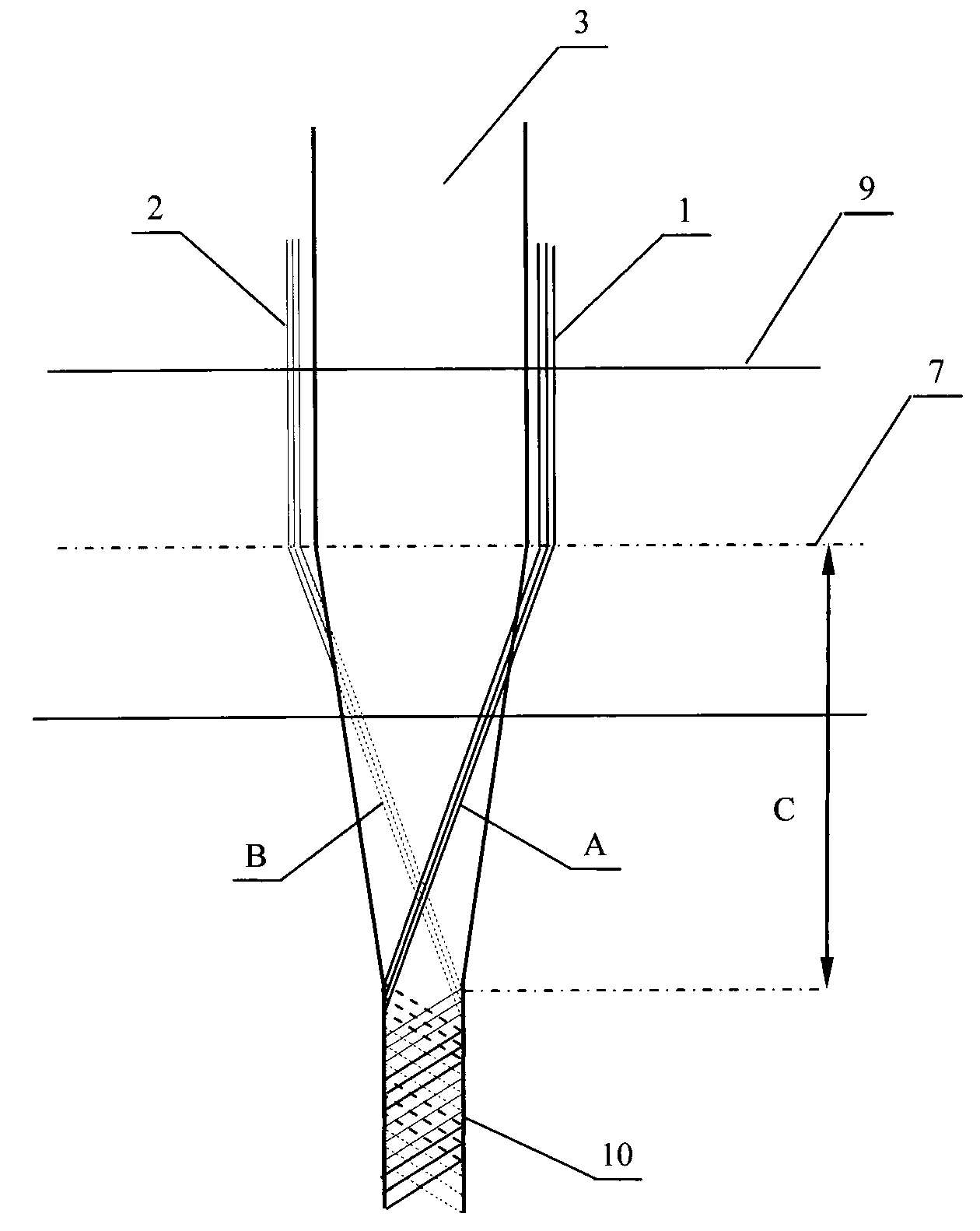

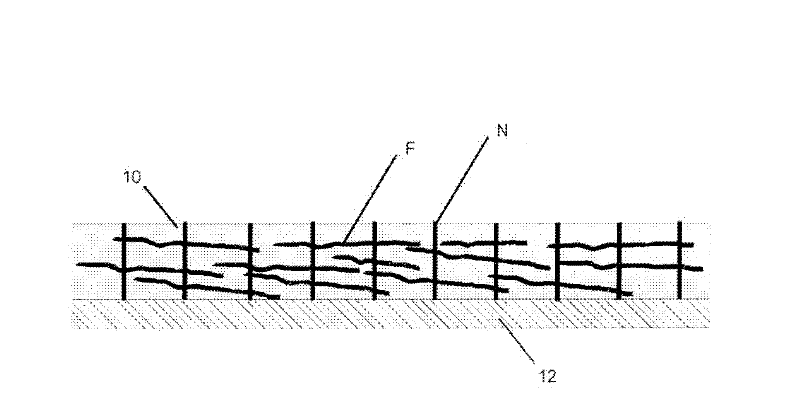

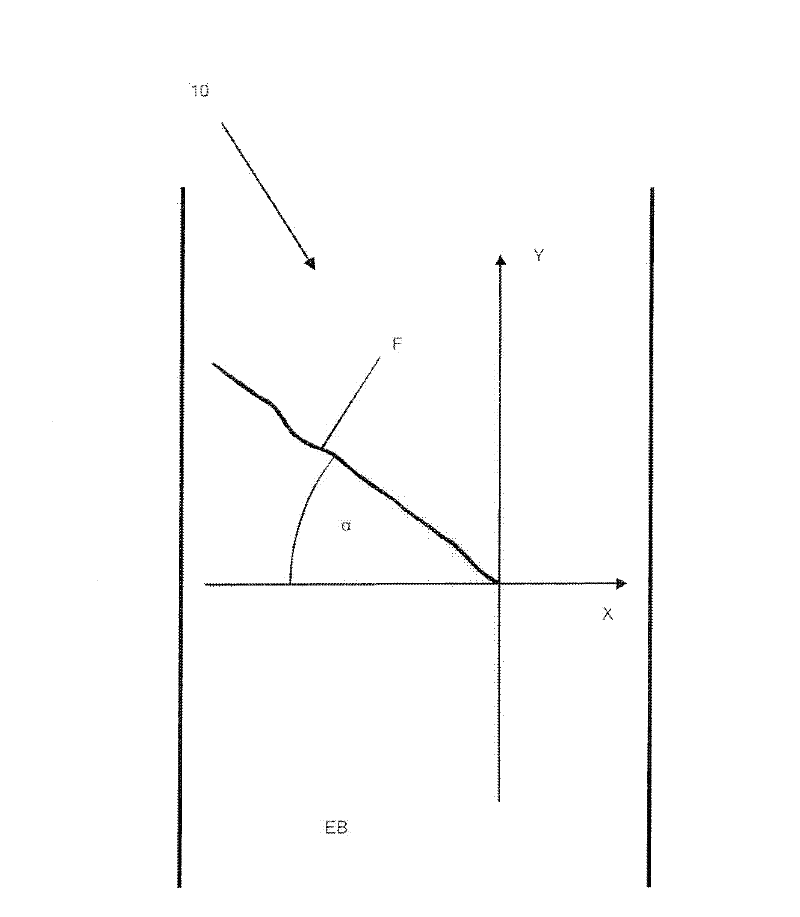

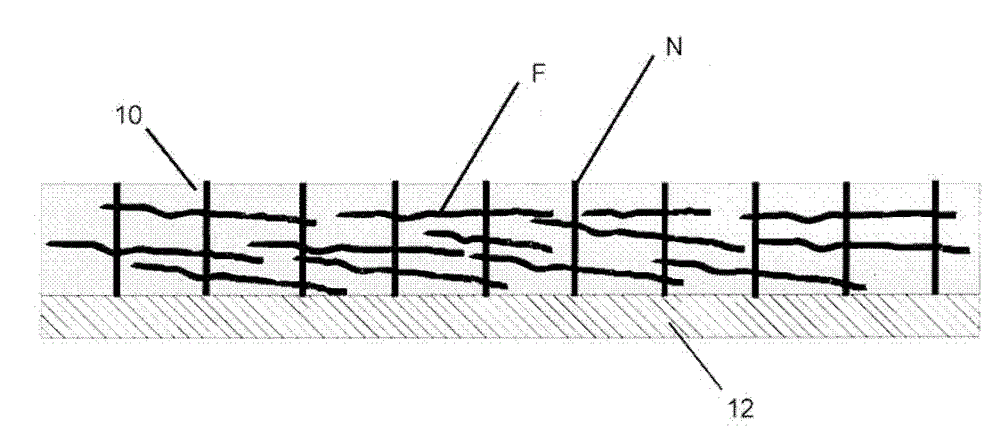

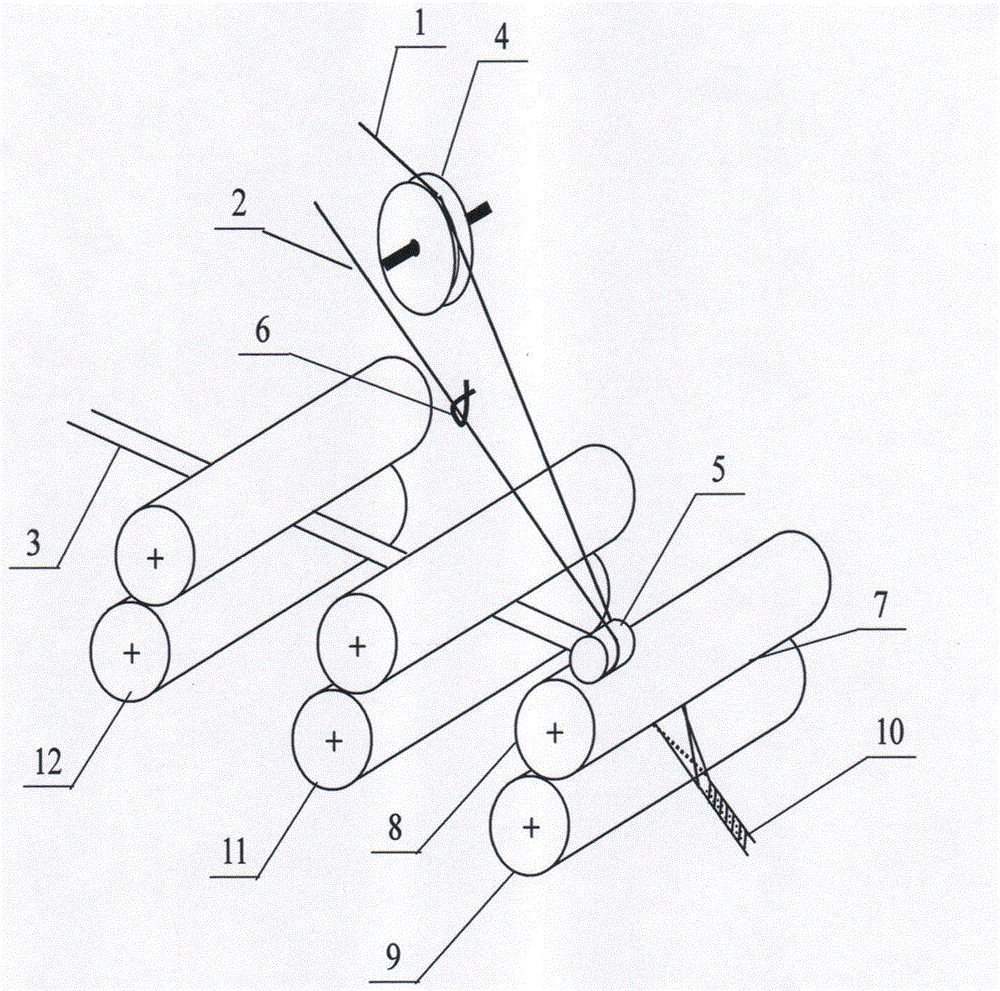

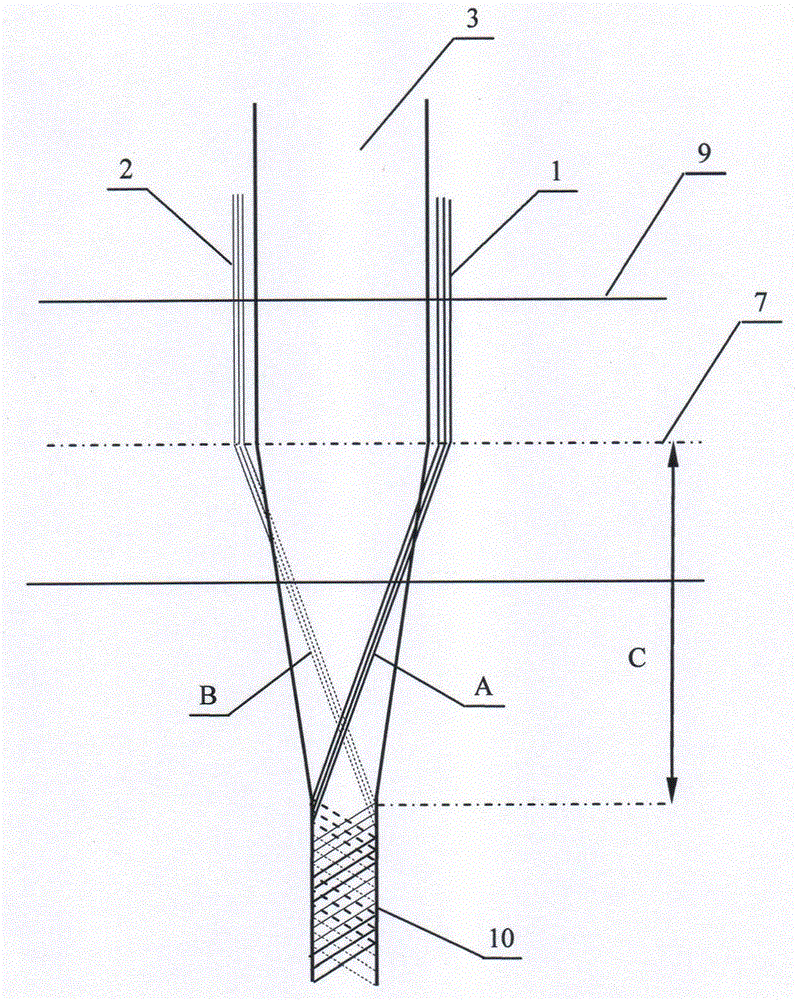

Smooth composite spinning mechanism and method of short fiber whisker strip clamped by double filaments via unequal tension

The invention relates to a smooth composite spinning mechanism, method and application of a short fiber whisker strip clamped by double filaments via unequal tension. The mechanism is composed of a tension disk used for locating a tension filament and controlling tension thereof, a yarn guide hook used for locating a low-tension filament and a holding roller used for keeping the tension. The composite spinning method comprises the steps of: synchronously feeding the tension filament, the low-tension filament as well as the short fiber whisker strip into a front roller to enable the short fiber whisker strip to be wrapped by the two filaments in a traction zone; and forming a three-shafting spinning yarn with the short fiber whisker strip covered by the tension filament from the upside and support by the low-tension filament from the downside, wherein the composite yarn is a smooth composite yarn which is formed by spirally twisting the tension filament and the short fiber whisker strip and externally coating the low-tension filament. The mechanism is light, practical, convenient to install, controllable and adjustable, can produce yarns with steady structure and is suitable for composite spinning of high-count smooth yarns and superfine yarns of short fibers.

Owner:DONGHUA UNIV

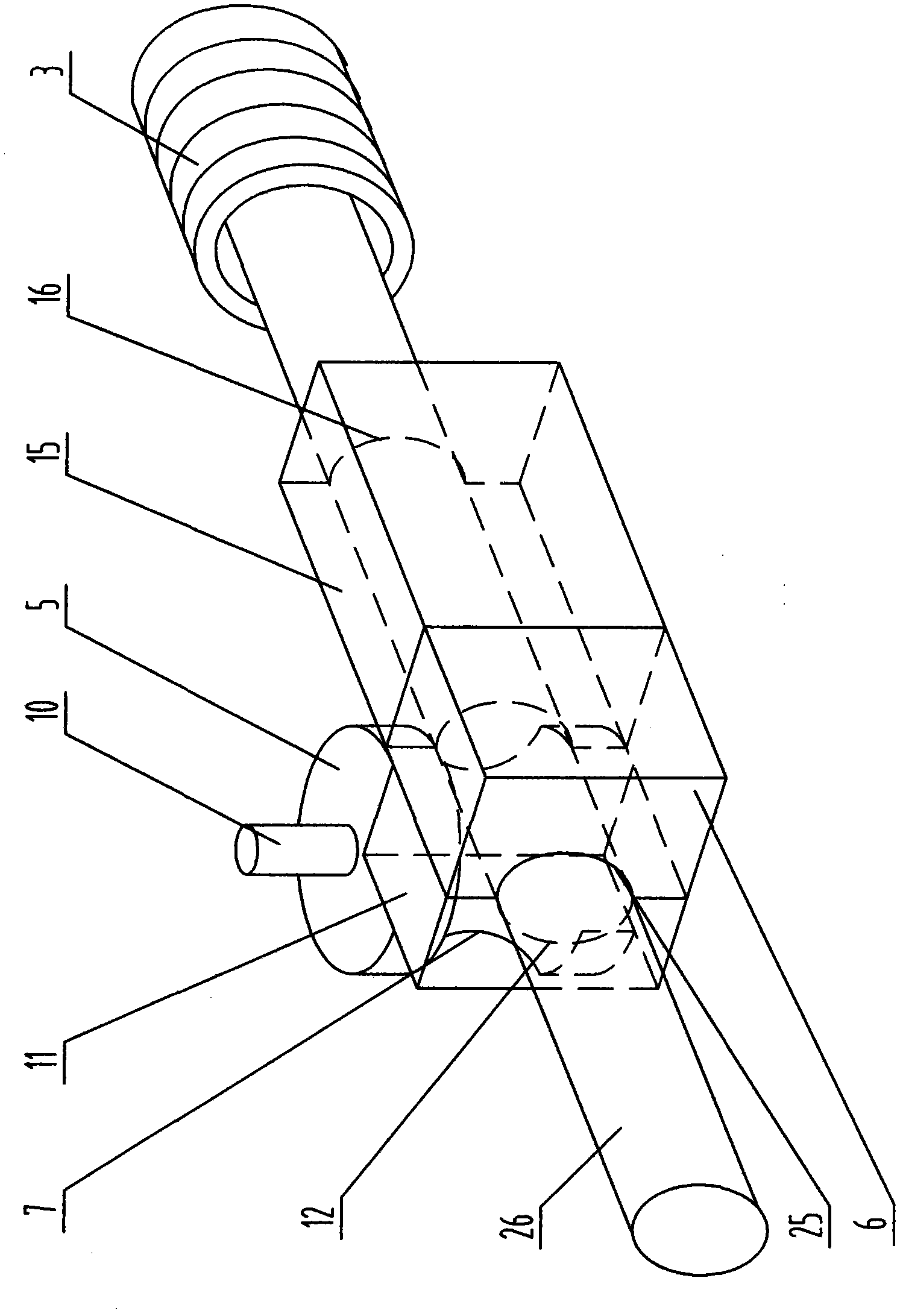

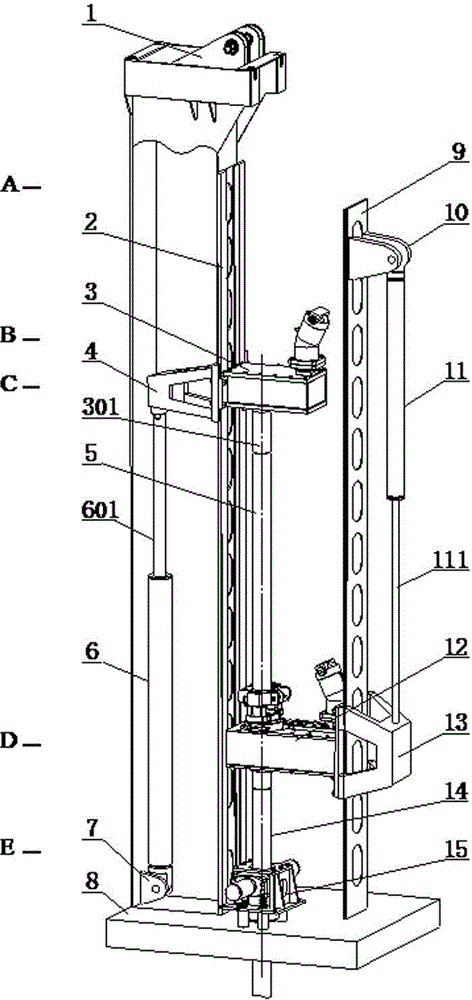

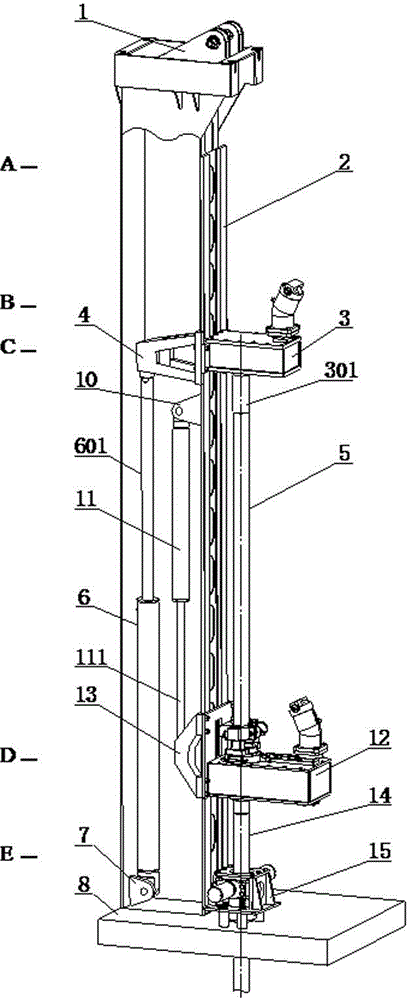

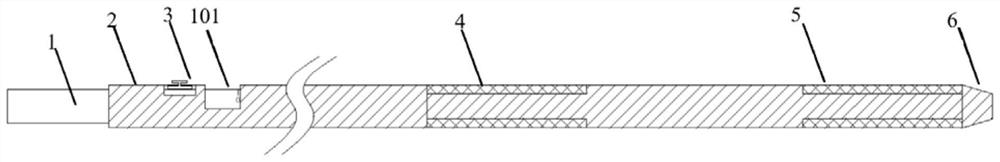

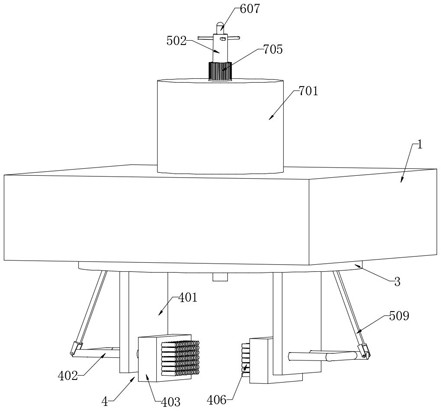

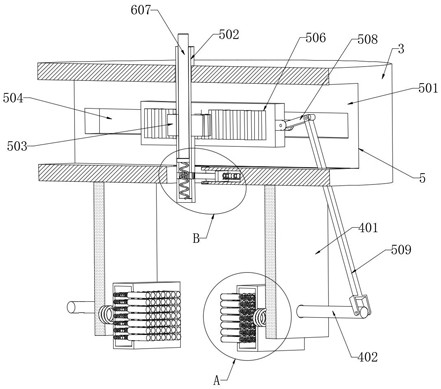

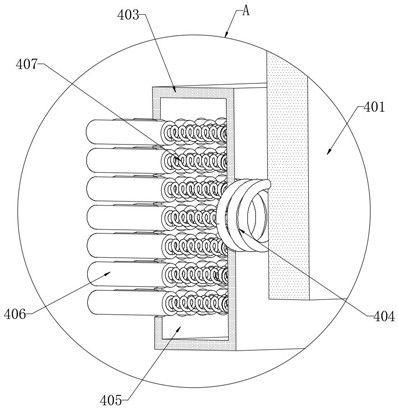

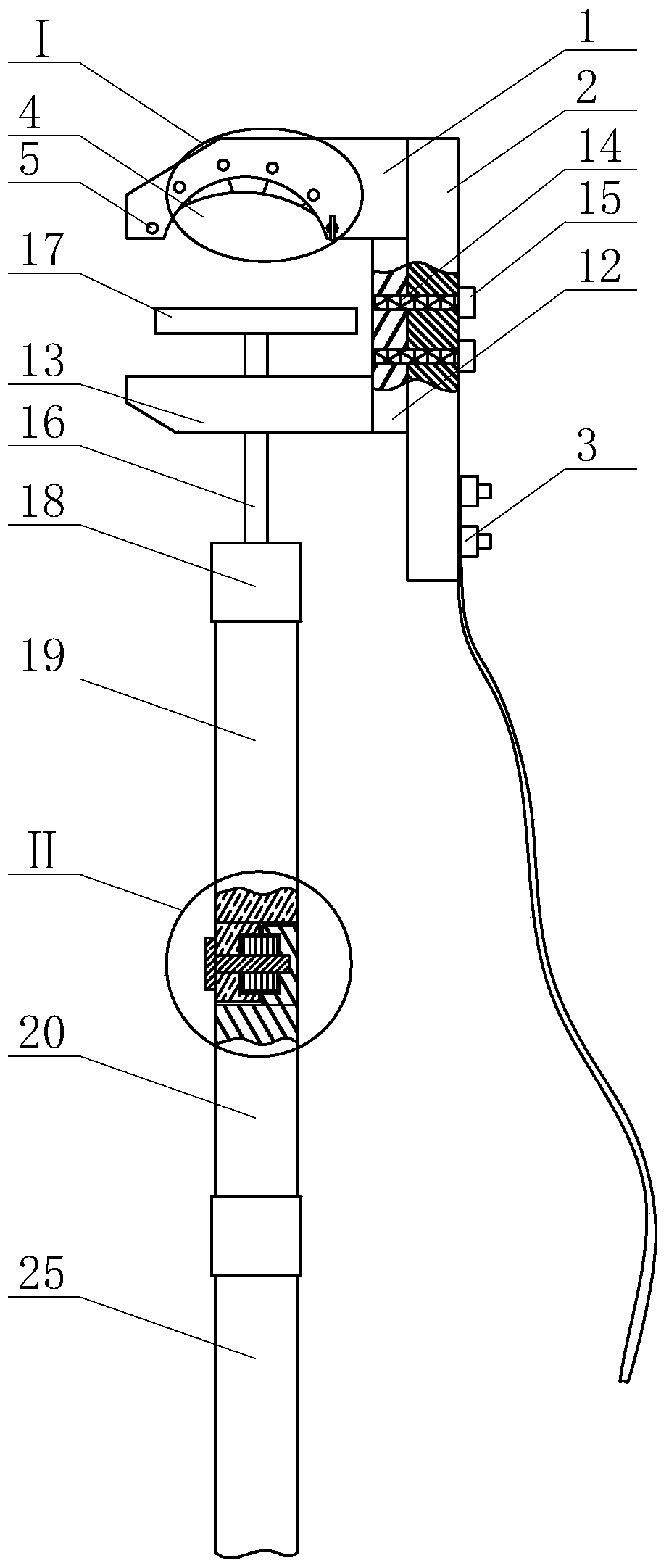

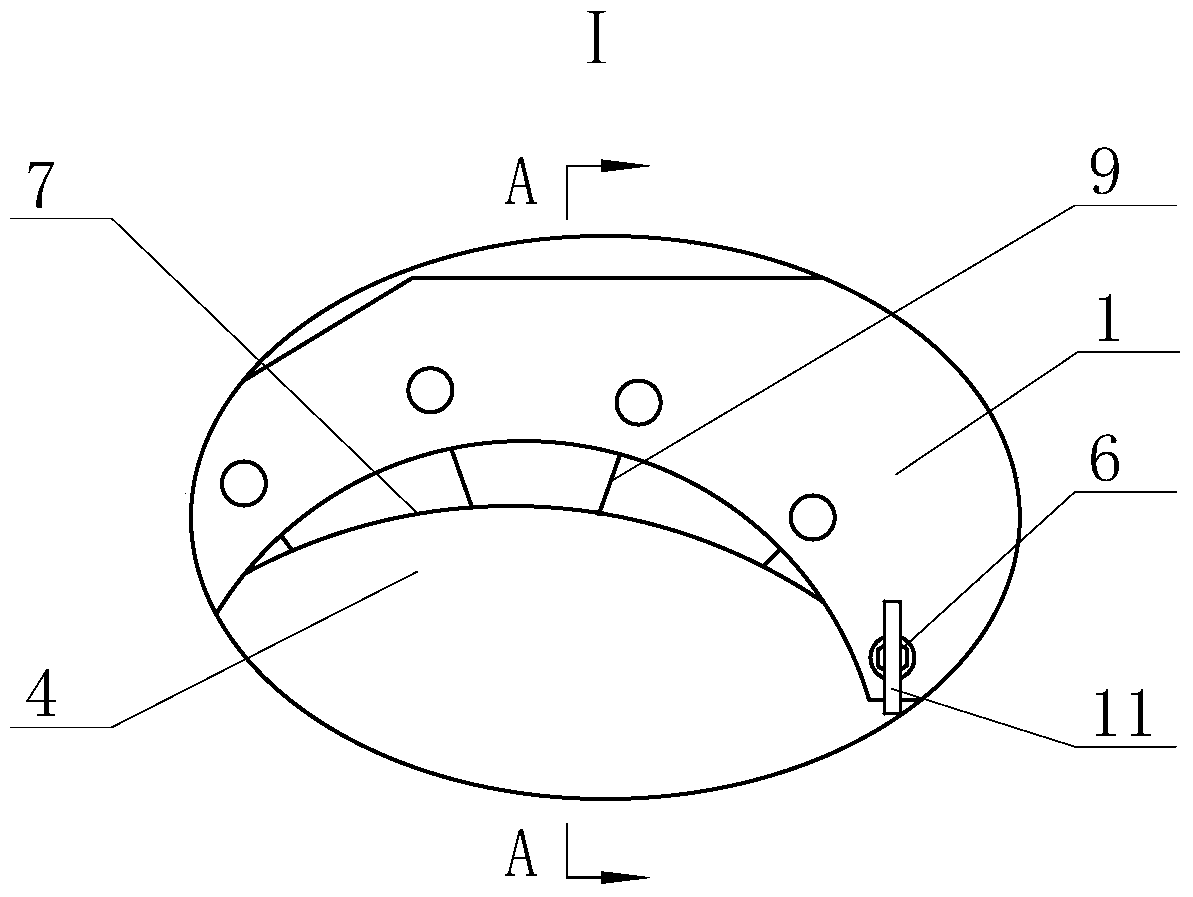

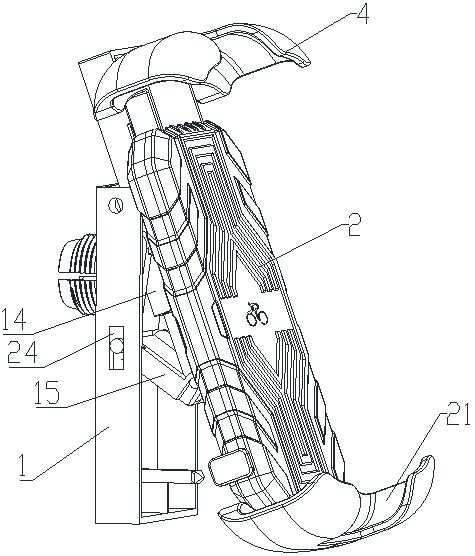

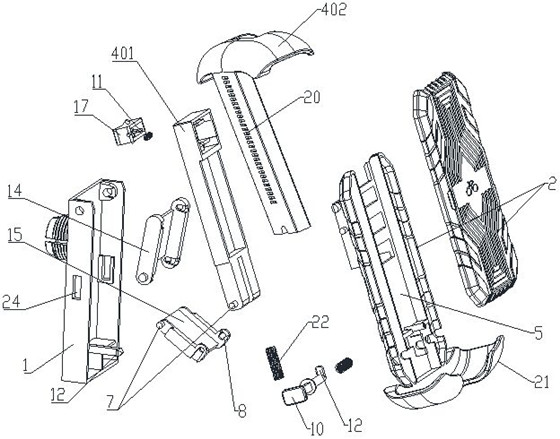

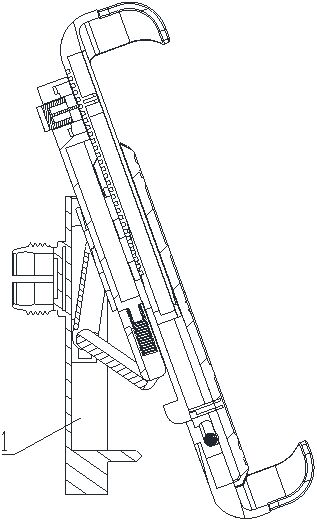

Drill rod unloading device suitable for submarine drilling rig

InactiveCN105239940AReduced clamping effectReduced stiffness requirementsDrilling rodsDrilling casingsScrew threadSubmarine

The invention discloses a drill rod unloading device suitable for a submarine drilling rig; a power chuck for drill rod clamping and screw thread unloading on a traditional submarine drilling rig is formed to a whole component having a slide support piece; an installation mode thereof on the submarine drilling rig guarantees the axis of a center through hole thereof to be always coaxial with the axis of a driving drill rod on a drilling power head of the submarine drilling rig; meanwhile, the submarine drilling rig is additionally provided with a lifting hydraulic oil cylinder and a slide rail frame having an installation direction parallel to a slide way of the drilling power head of the submarine drilling rig; and the whole component of the power chuck can be driven by the lifting hydraulic oil cylinder to vertically move along the slide rail frame. The drill rod unloading device uses the advantage of capability of shifting the position of the power chuck, so that the power chuck can be used for unscrewing upper and lower screw threads of a drill rod, and when the upper and lower screw threads of the drill rod are not totally unscrewed, the drill rod is always kept in a center hole of the power chuck and prevented from tilting; and meanwhile, when the upper and lower screw threads of the drill rod are both unscrewed, and the drill rod needs to displace in parallel, the drill rod can be disconnected for providing a space.

Owner:HUNAN UNIV OF SCI & TECH

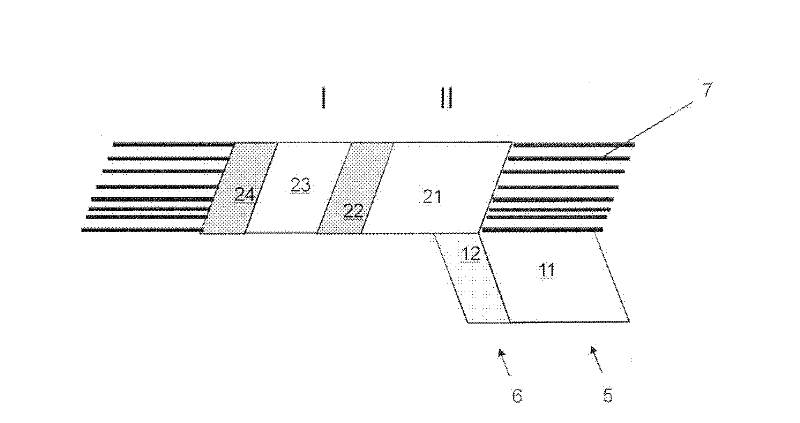

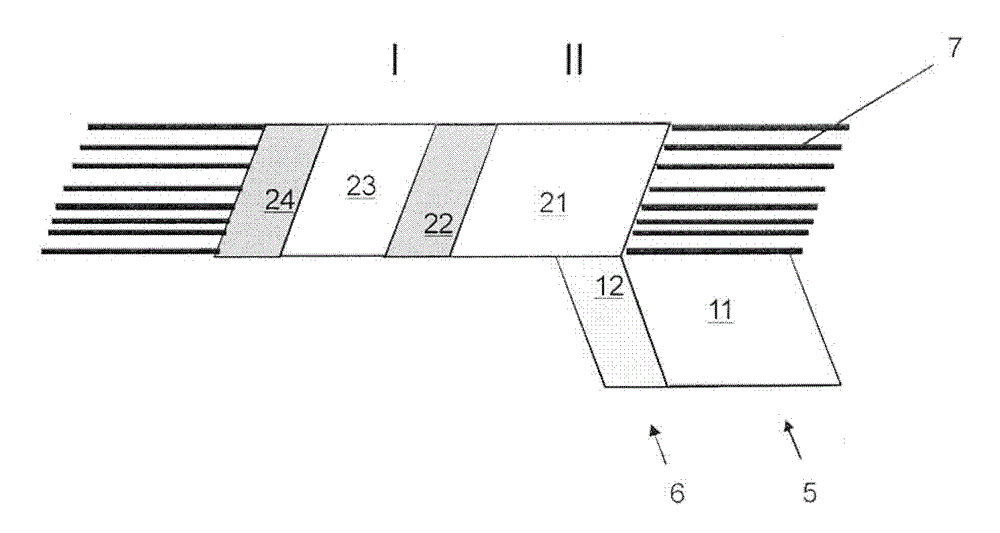

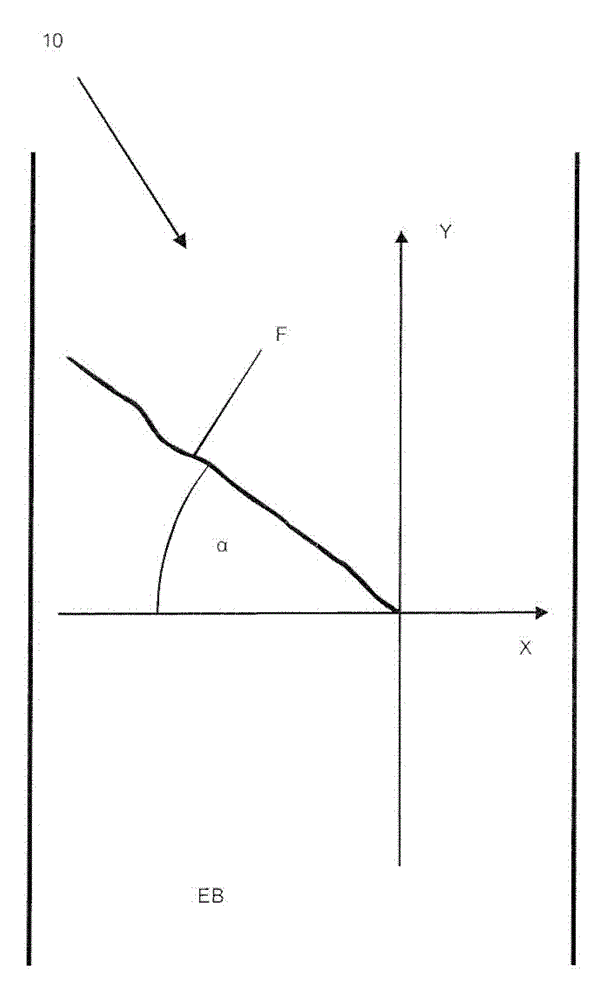

Adhesive tape with textile carrier for cable bandaging

ActiveCN102676076AReduced clamping effectEffective tearabilityFilm/foil adhesivesWoven fabricsAdhesive beltEngineering

The invention relates to an adhesive tape. An adhesive tape having a carrier and an adhesive layer applied to at least one side of the carrier, wherein the carrier is a thread-stitched web nonwoven carrier produced from a preconsolidated base web of staple fibres. Mutually parallel threads are stitched into the base web to form the final thread-stitched web nonwoven carrier, wherein the ultimate tensile strength of the preconsolidated but not as yet overstitched base web is less than 2 N / cm. In embodiments, the ultimate tensile strength of the preconsolidated but not as yet overstitched base web is below 1 N / cm or below 0.5 N / cm.

Owner:TESA SE

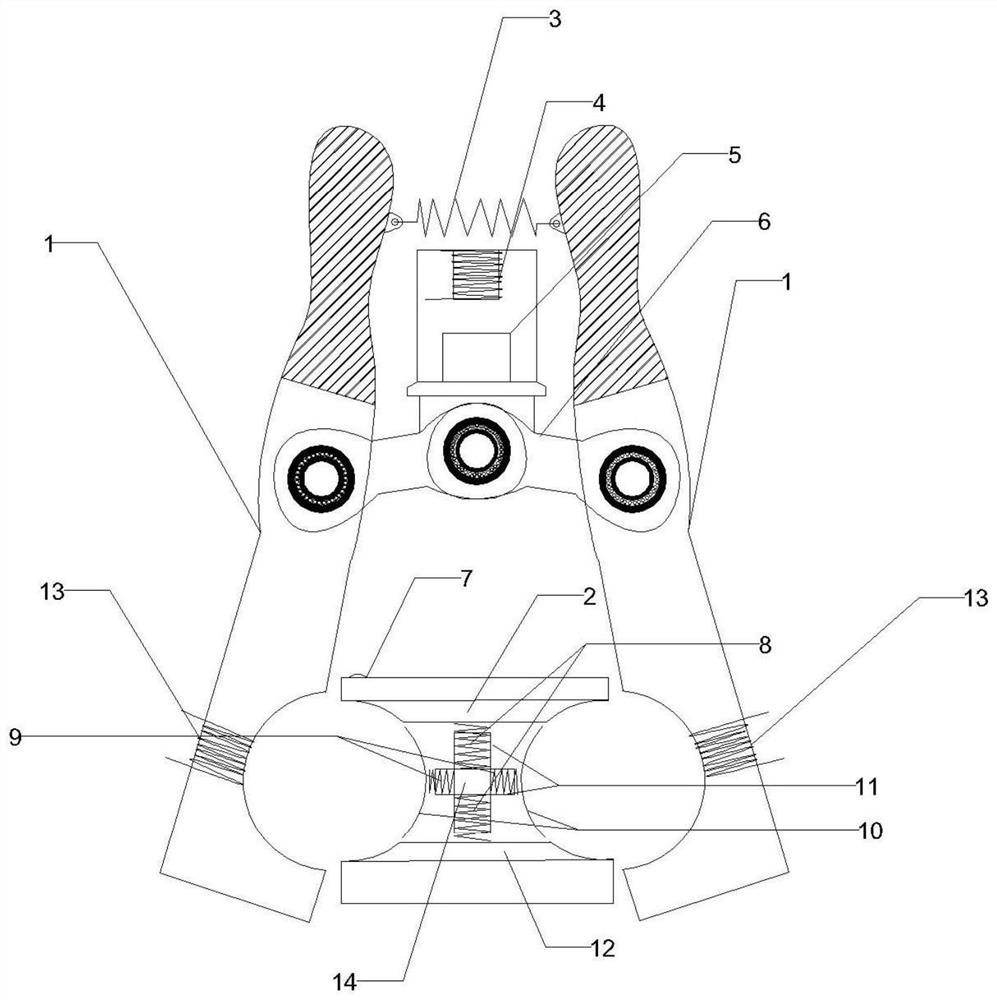

Multifunctional ground wire insulating rod

InactiveCN105226412AEasy to adjust and useEasy to adjust arcElectric connection structural associationsCopper wireGround line

The invention discloses a multifunctional ground wire insulating rod, which comprises a ground wire clamp and an insulating rod, wherein the ground wire clamp comprises a fixed part and a movable part; the fixed part comprises an upper clamping plate; the upper clamping plate is a cavity body with an opening in the bottom surface; an arc-shaped recess is formed in the middle part of the cavity body; a longitudinal support rod and a movable rod are arranged in the cavity body; an elastic electric conductor is arranged between the support rod and the movable rod; the middle part of the elastic electric conductor is arranged in the arc-shaped recess; three fixing rings at least sleeve the elastic electric conductor along the arc length at equal intervals; the upper side of each fixing ring is connected with the lower end of a stretched spring; the upper end of the stretched spring is fixed with the upper clamping plate along the radial direction of the arc-shaped recess; the elastic electric conductor comprises a plurality of conductive copper wires which are arranged in parallel; one end of each conductive copper wire is fixed with the support rod; and the other end of each conductive copper wire is fixed with the movable rod and then can wind the periphery of the movable rod in a contracting and releasing manner. The multifunctional ground wire insulating rod has the advantages of being relatively wide in application range, convenient to use and firm to contact; meanwhile, the ground wire clamp has relatively good clamping force on a charged body; and the safety of using staff is ensured.

Owner:国网山东郓城县供电公司 +1

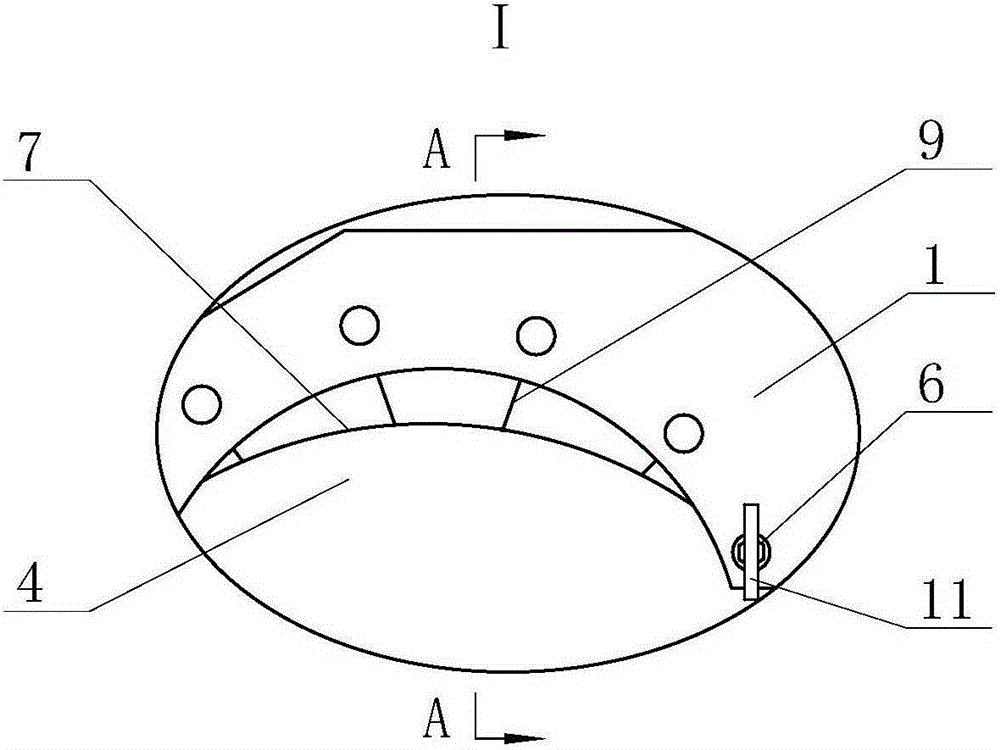

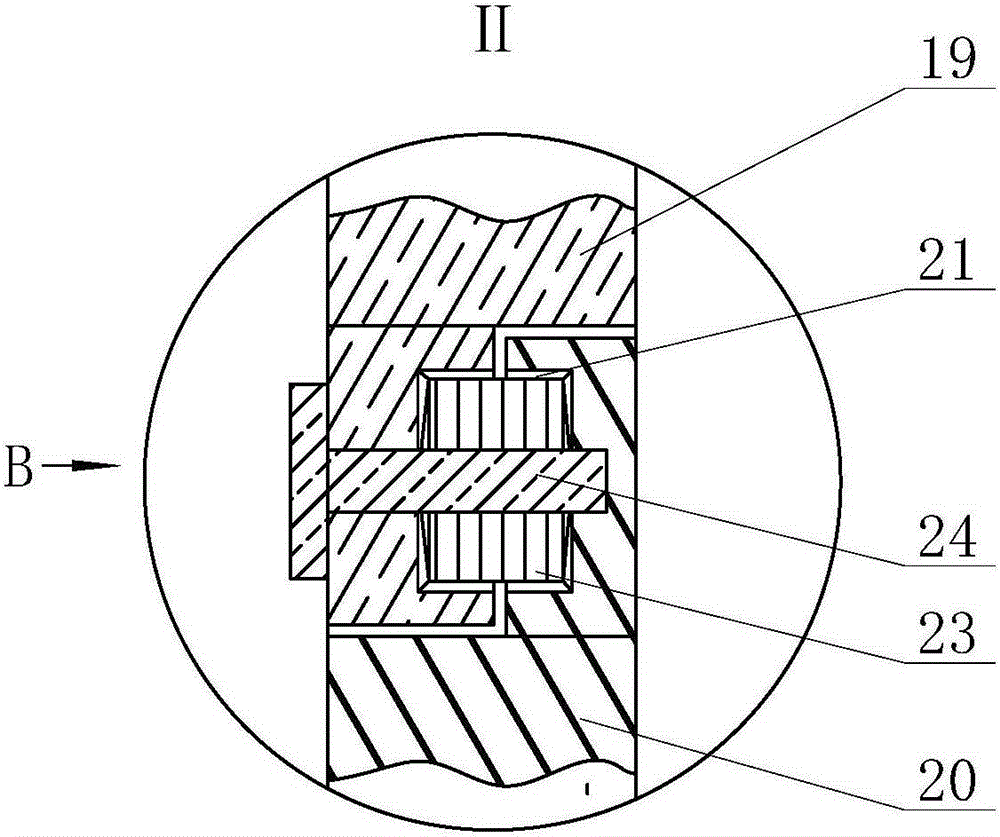

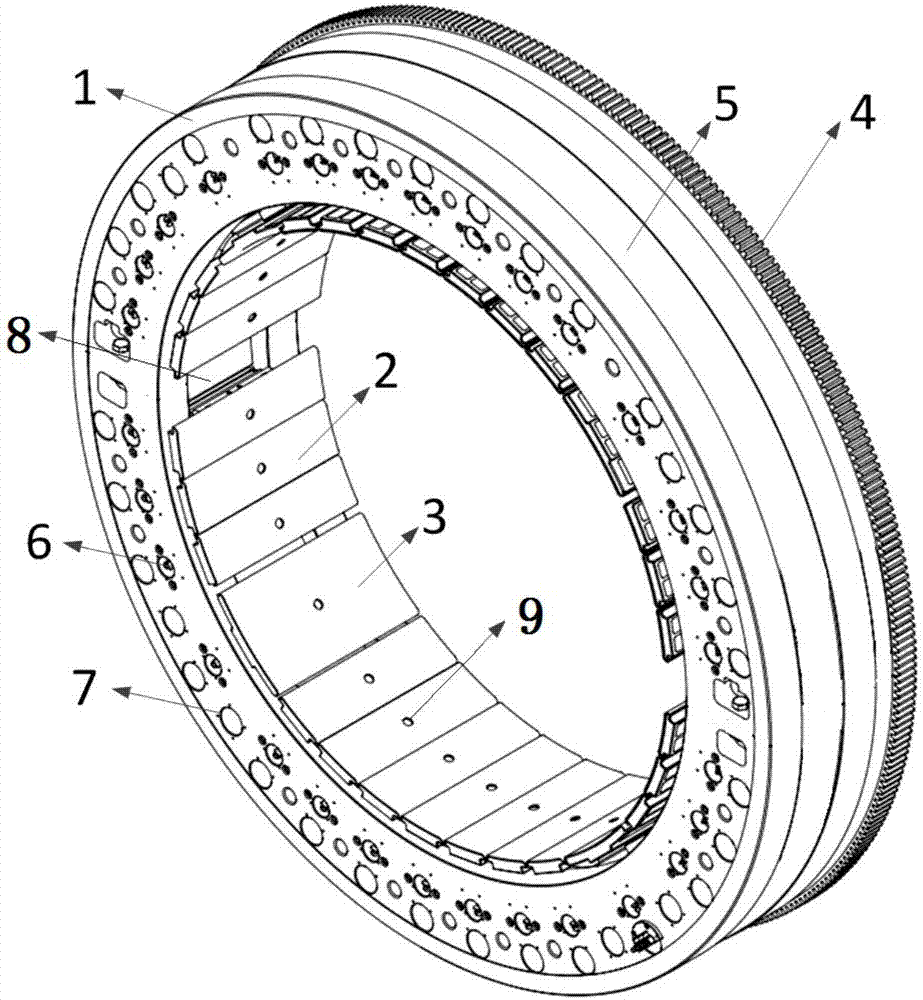

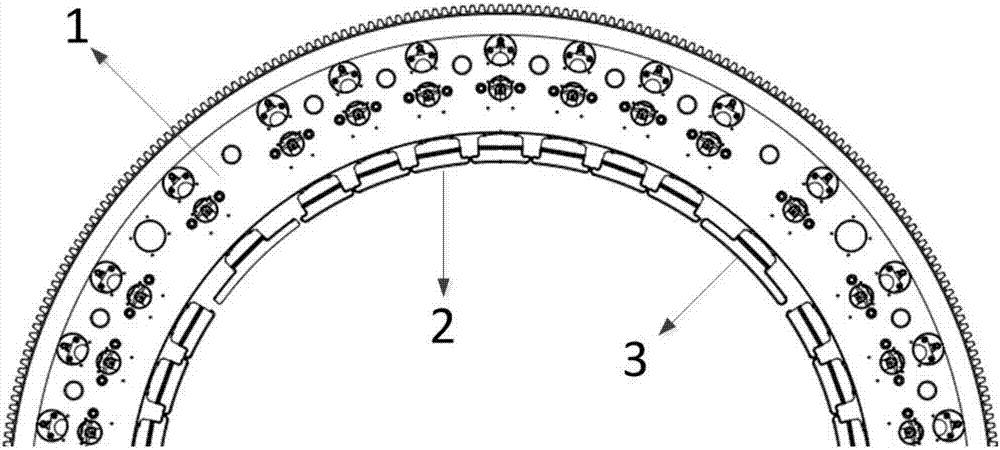

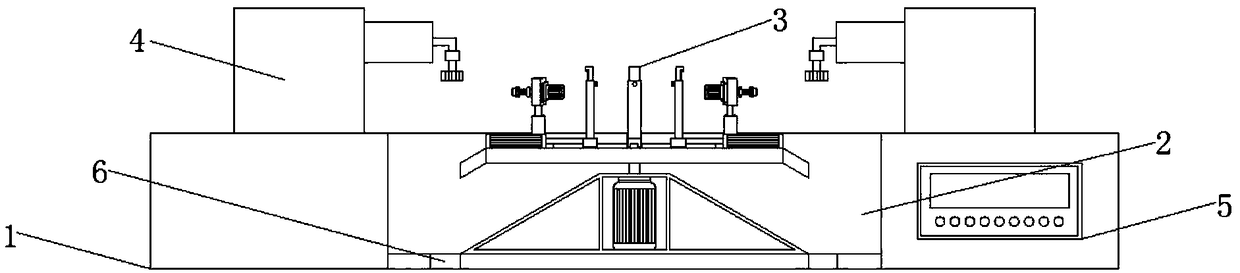

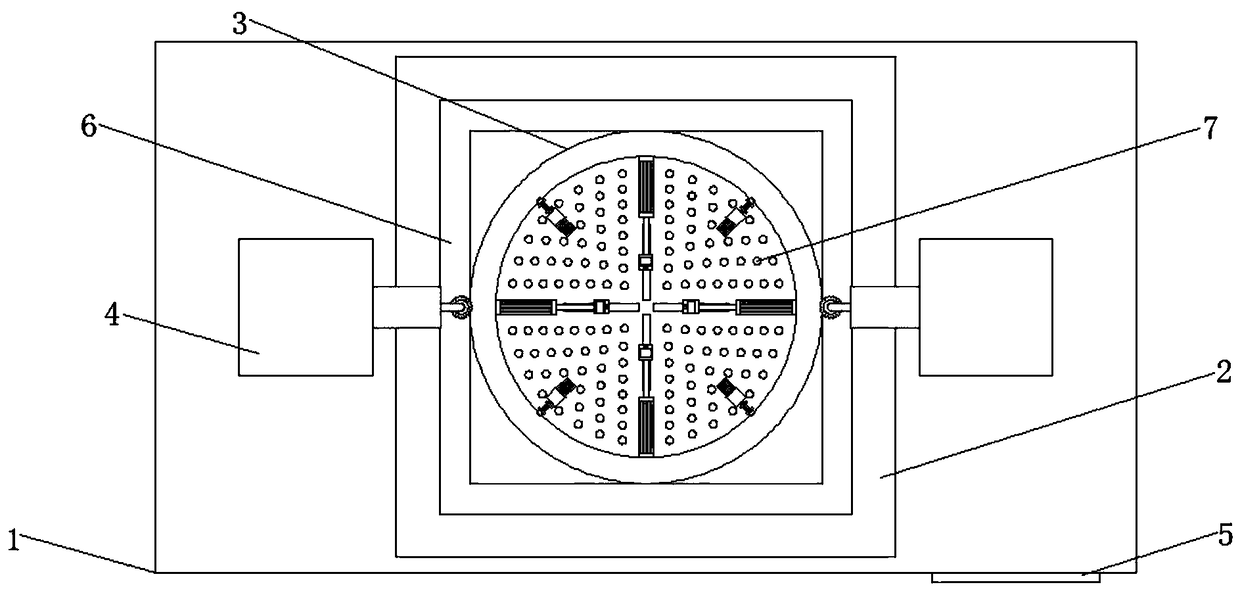

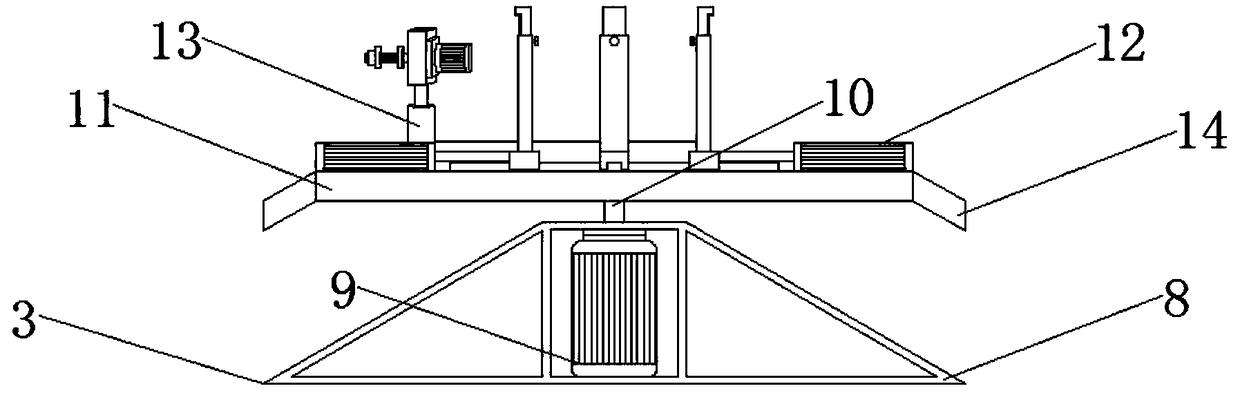

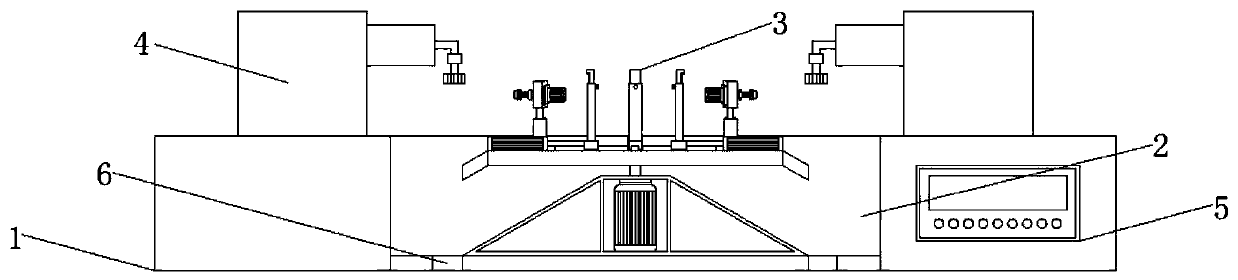

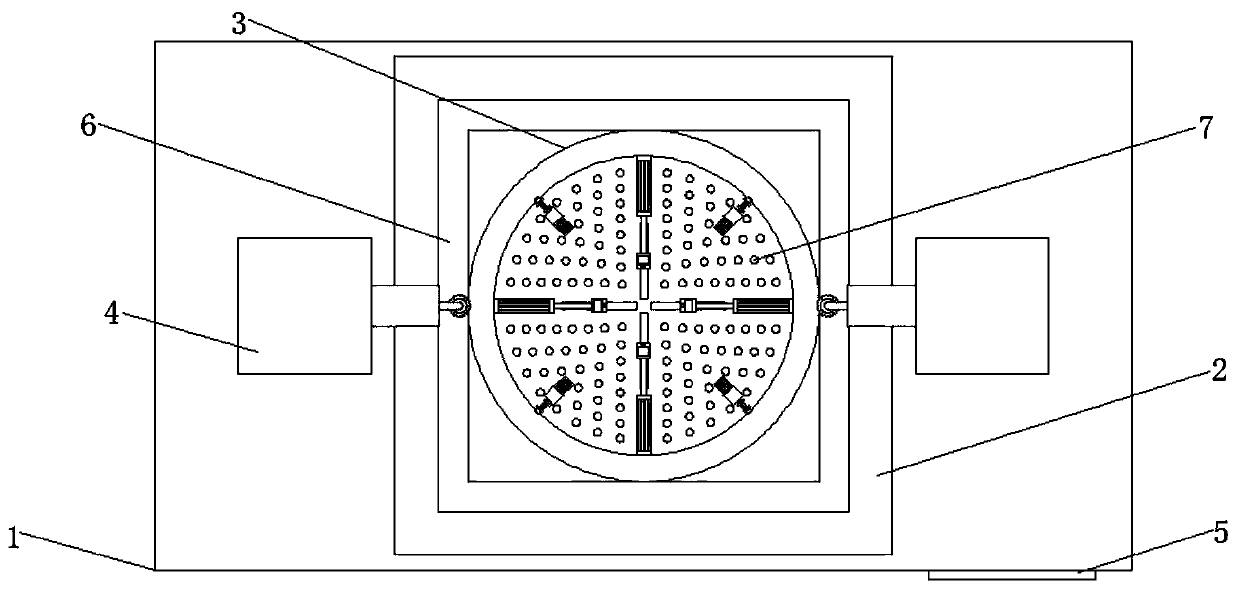

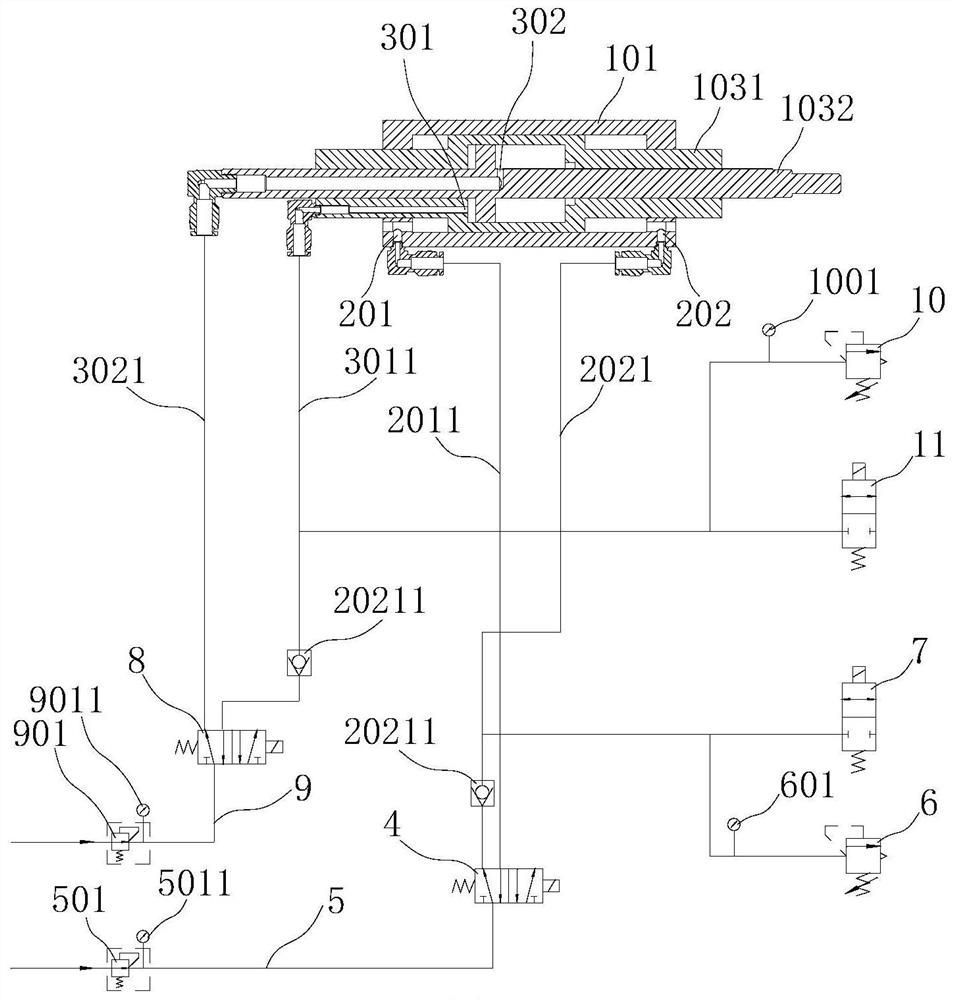

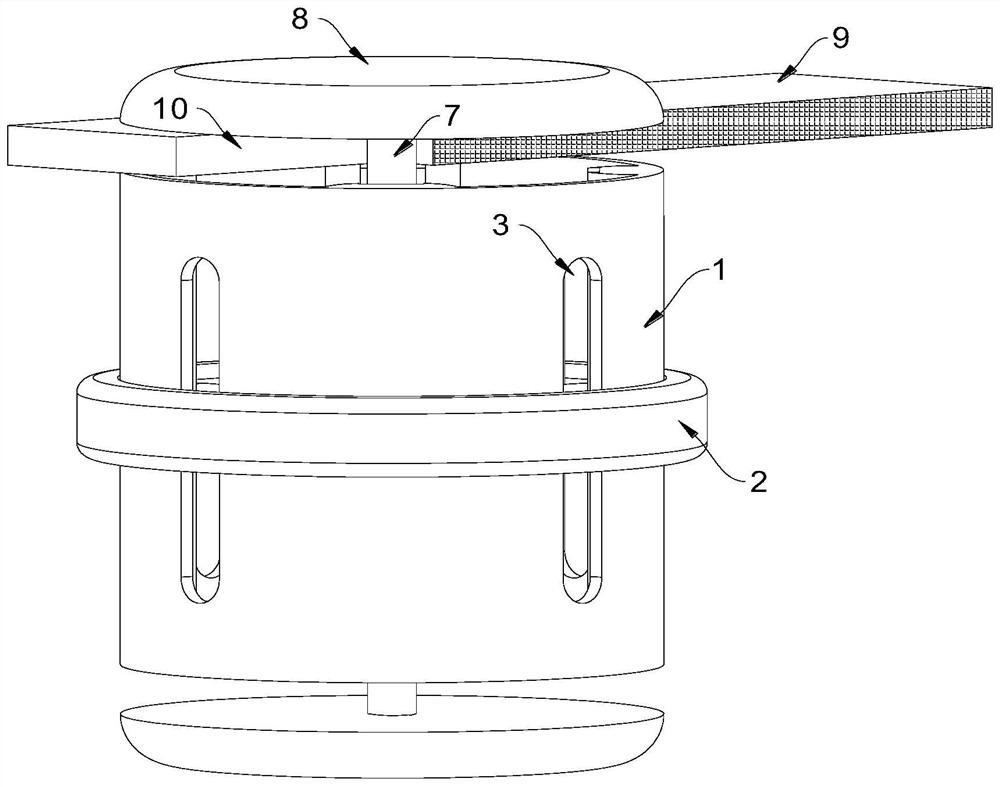

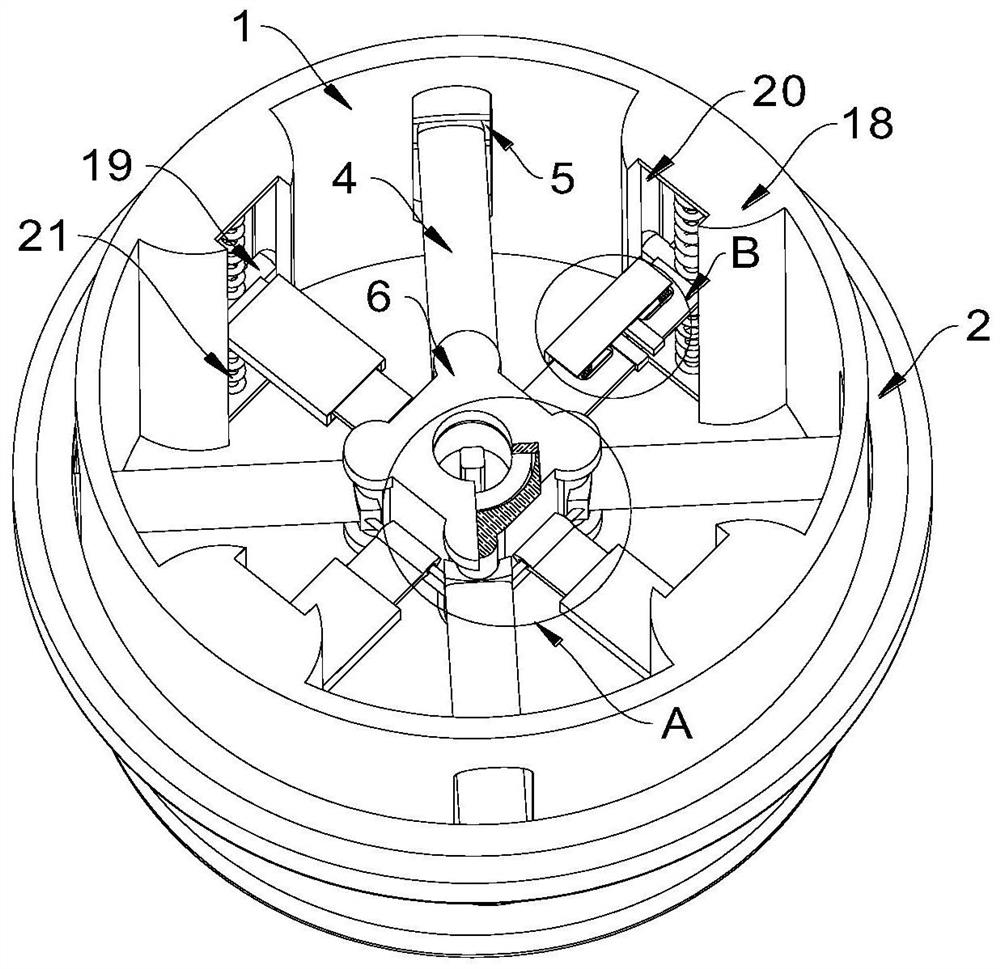

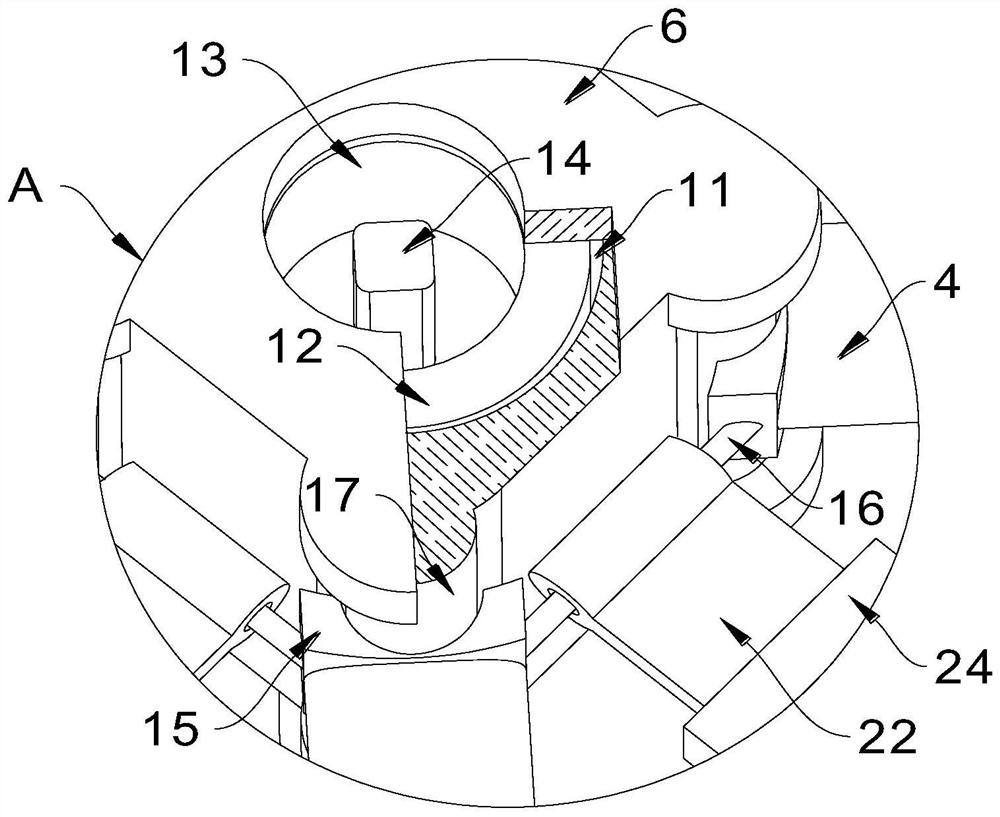

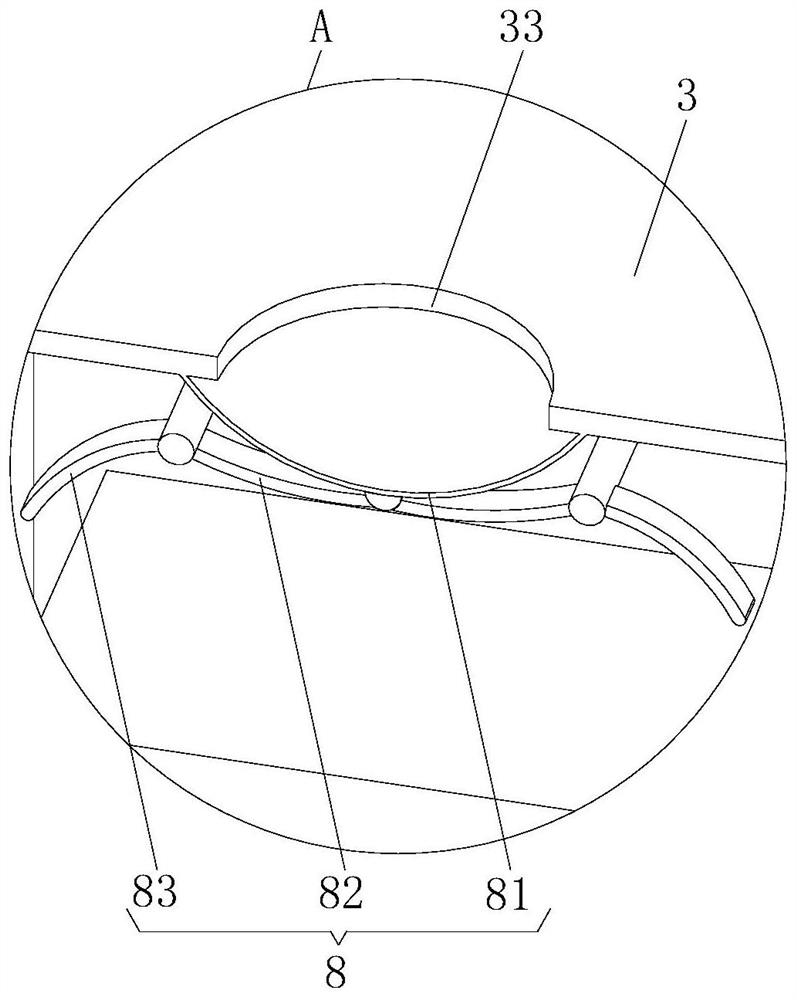

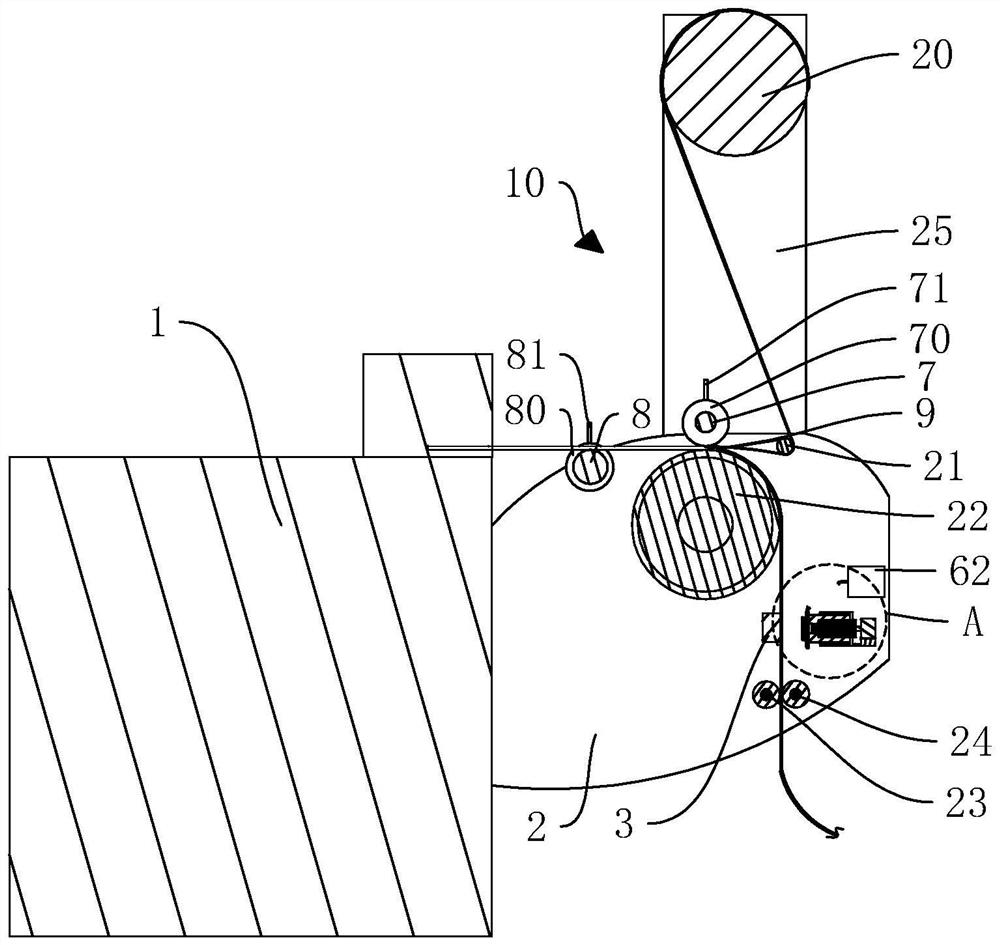

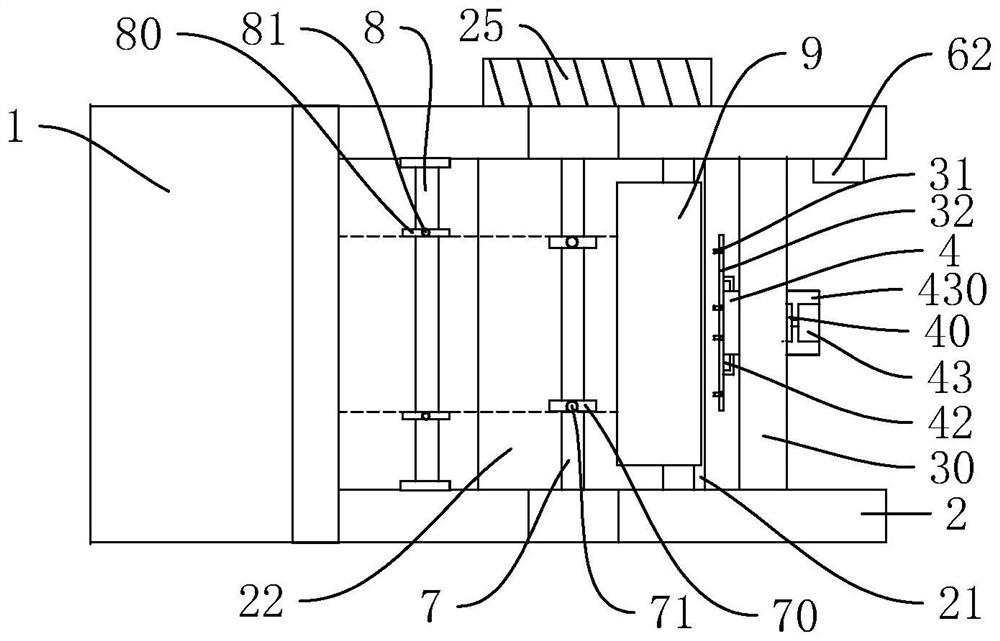

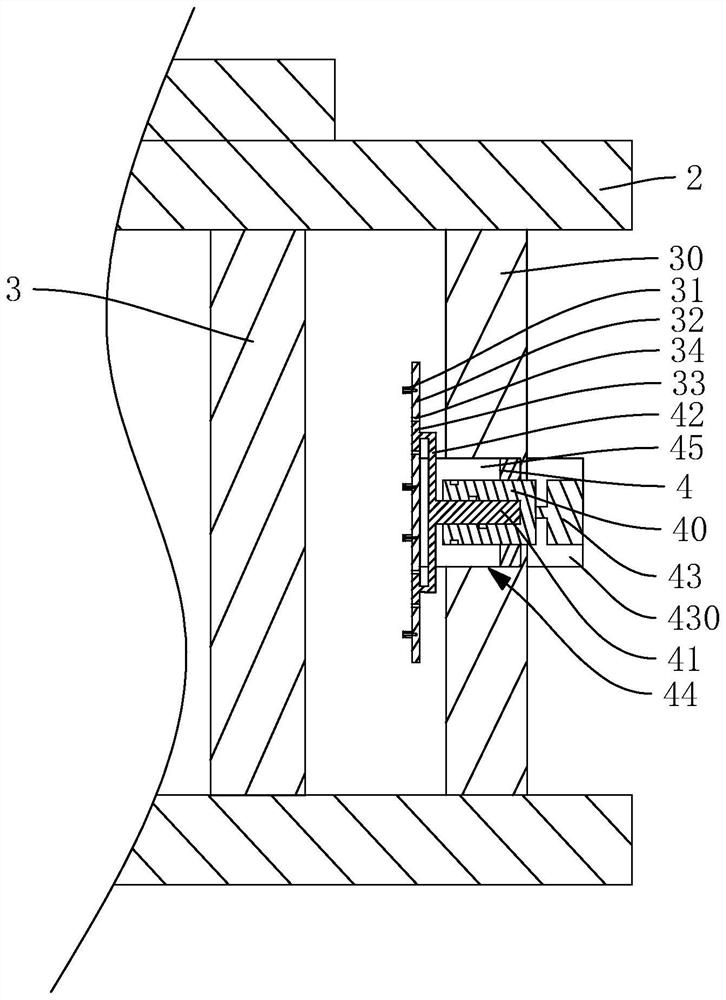

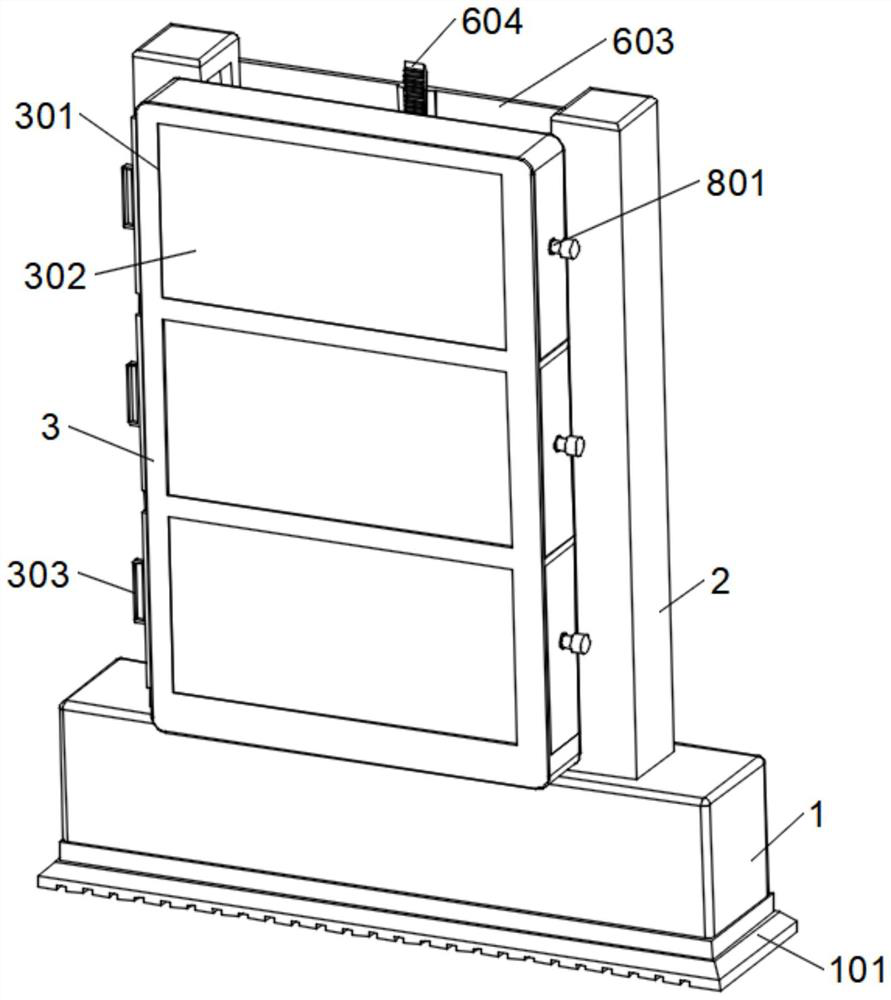

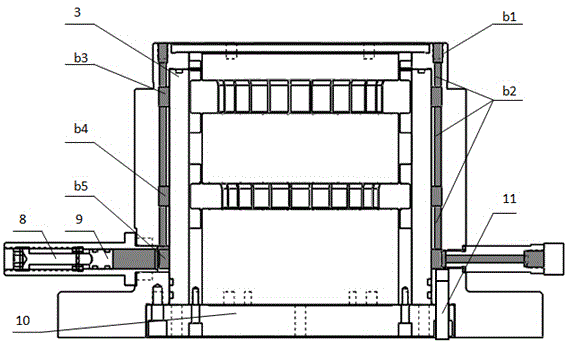

Large workpiece clamping device and clamping system

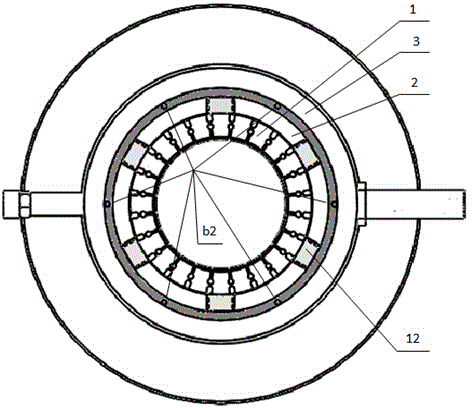

ActiveCN107309686AIncrease the effective contact areaClamping state effectPositioning apparatusMetal-working holdersRadial motionEngineering

The invention provides a large workpiece clamping device. The large workpiece clamping device comprises a circular clamp body. A mounting groove is formed in the inner ring of the clamp body so that multiple detachable clamping units can be mounted. Each clamping unit comprises a clamping execution device and a clamping drive device. Each clamping drive device is connected with the corresponding clamping execution device and used for driving the corresponding clamping execution device to move in the axial direction and / or the radial direction of a ring of the clamp body. The clamping execution devices are circumferentially distributed along the inner ring of the clamp body. Each clamping drive device comprises a drive device connecting portion fixedly connected with the clamp body. The invention further provides a large workpiece clamping system which comprises the large workpiece clamping device and a bearing platform. Supporting bases are arranged on the bearing platform in parallel. The supporting bases are provided with rolling bearing grooves matched with the outer edge of the clamp body. The large workpiece clamping device and the large workpiece clamping system have the beneficial effects that floating clamping is achieved; the center position of a workpiece does not need to be adjusted repeatedly when the workpiece is clamped; an extra auxiliary supporting structure is not needed; and the clamping efficiency is improved.

Owner:重庆真测科技股份有限公司 +2

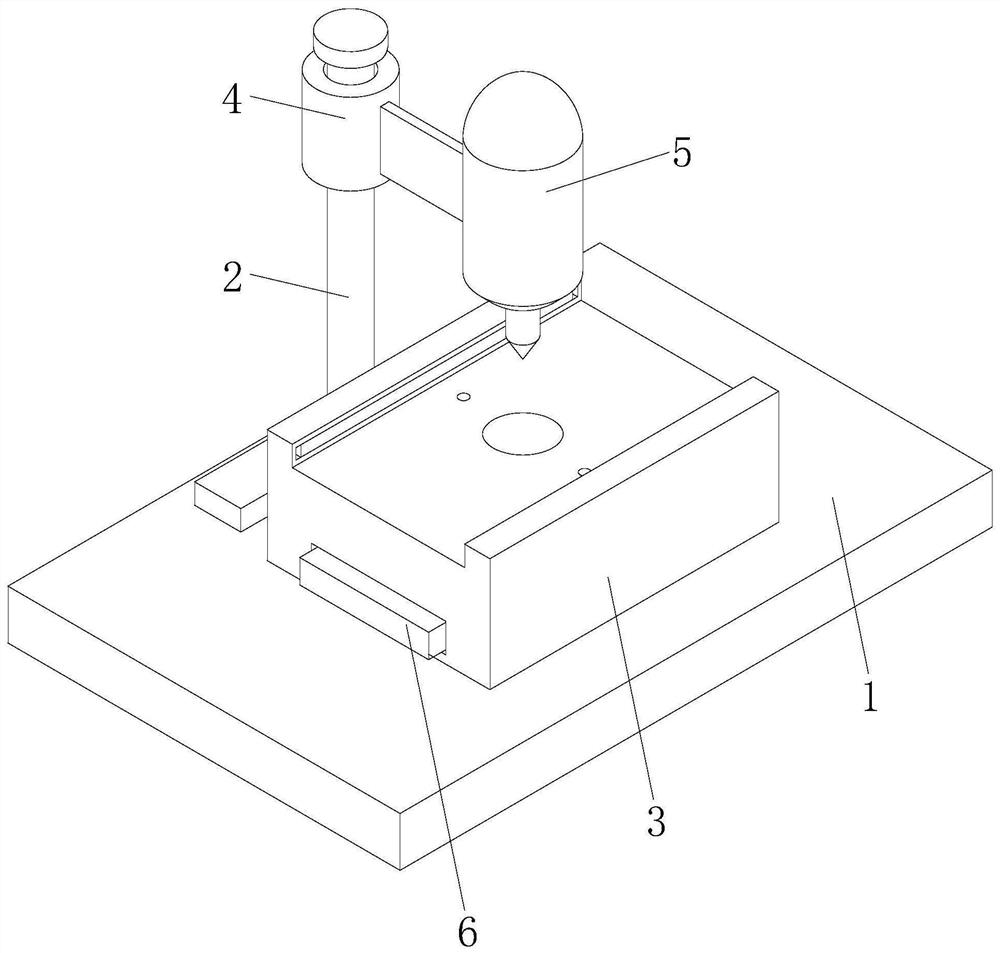

Precision gear machining machine tool base fixing part

ActiveCN108971662AImprove practicalityAchieve fixationPositioning apparatusGear-cutting machinesMachine toolMachining

The invention discloses a precision gear machining machine tool base fixing part. A control panel is mounted on the right side of the front face of a base, the middle of the base is provided with a rove, a fixing part body is mounted in the middle of the groove, a Y355 motor is mounted in a protective cover which is mounted at the bottom end of the fixing part, and a rotating disc is mounted at the top of a rotating shaft which is fixedly connected to the top end of the Y355 motor. First clamping parts are mounted around the top of the rotating disc, an electric cylinder is mounted at one endof each first clamping part, a slider is mounted at one end of each electric cylinder, a fixing plate is mounted at the top of each slider, a retractable plate is fixedly connected to the top of eachfixing plate, a second clamping part is mounted on one side of each first clamping part, and machining tools are mounted on two sides of the top of the base. Top ends of the retractable plates are provided with flanging edges, grooves formed between the flanging edges and the fixing plates play a role in gear limiting and fixing to avoid gear sliding and shedding, and accordingly clamping effectsof the first clamping parts are improved, and gear machining precision is improved.

Owner:江苏爱雷德塑机有限公司

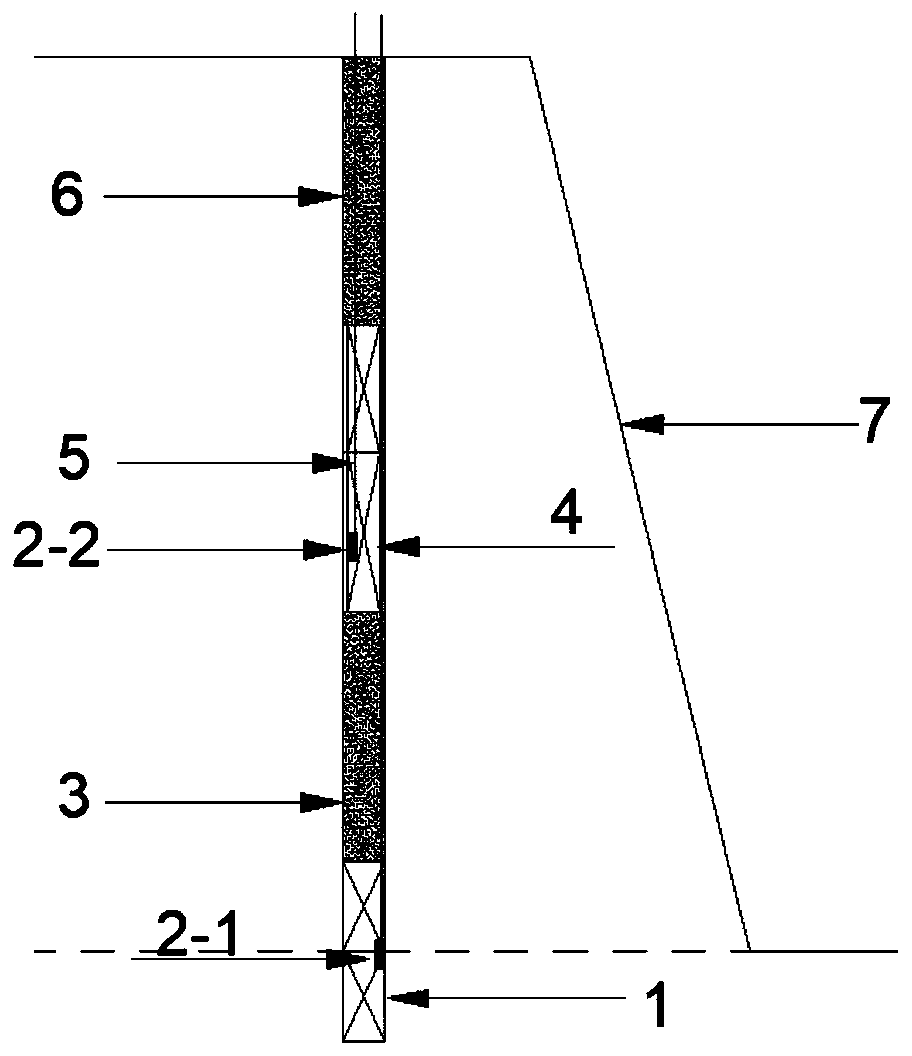

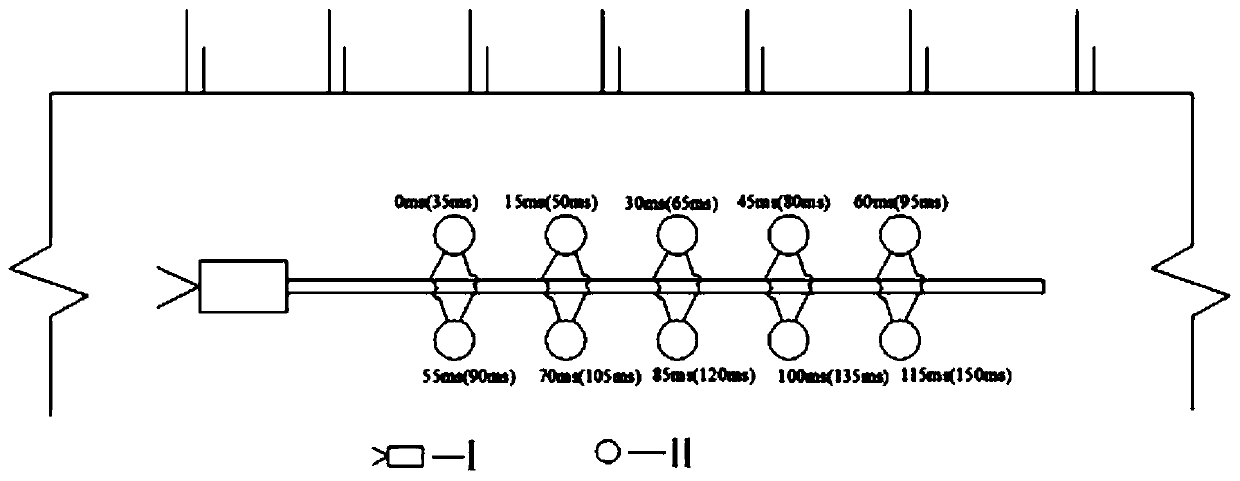

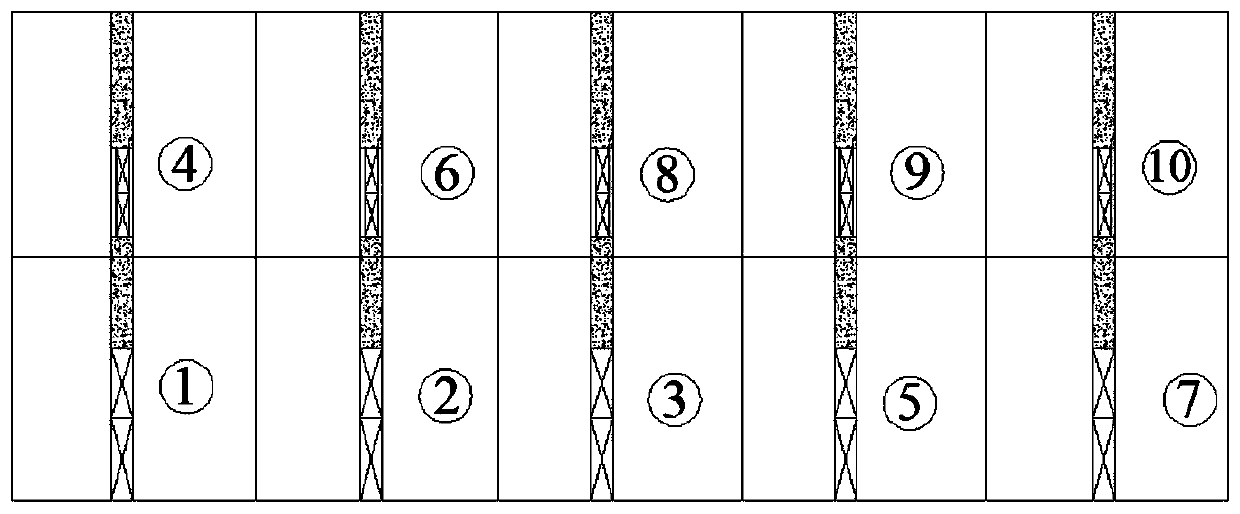

Deep hole blasting charging and detonating method for lowering foundation based on digital detonators

The invention discloses a deep hole blasting charging and detonating method for lowering the foundation based on digital detonators. The method comprises steps of drilling; in-hole section division, including a lower charging section, a lower blocking section, an upper charging section and an orifice blocking section; charging in the sections; networking detonation and the like. During detonation,the detonation sequence and the time interval are strictly set through digital detonators. The method is advantaged in that in-hole segmented blasting is carried out, the blasting sequence and the time interval are strictly set through the digital detonators, rockfill generates relative dislocation in space after a front-row lower charging section is blasted, a free face is created for the bottomof a rear-row hole step, the clamping effect of front-row rock on the bottom of the step is reduced, and constraint conditions are changed; moreover, due to the blocking effect of the bottom blockingsection, explosion gas can be prevented from escaping too early, the action time of the explosion gas at the bottom of the hole is prolonged, explosion energy is fully utilized, the stress strength of a chassis resistance line part is improved, rock mass at the chassis part is fully crushed, generation of explosion roots is greatly reduced, and flatness of a bottom plate is improved.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

Device for demounting bearing

ActiveCN108035979AImprove clamping stabilityReduce cleaning workloadCleaning using liquidsBearing load reliefEngineeringMachining

The invention relates to the technical field of car accessory machining device, and particularly discloses a device for demounting a bearing. The device comprises a working table, the working table isprovided with a first supporting shaft, a clamping mechanism, a second supporting shaft and an air cylinder. The first supporting shaft is fixedly connected with a cylinder body, a first piston is arranged in the cylinder body, an elastic material layer and an air outlet pipe are arranged in the cylinder body, the air outlet pipe is in sealed connection with a U-shaped pipe, and an oil contamination washing agent is contained in the U-shaped pipe; a first piston rod is connected to the first piston, and a stopping block is fixedly connected to the first piston rod; the clamping mechanism comprises a strut, a clamping body, a first clamping piece and a second clamping piece; a second piston is arranged in the air cylinder, and the air cylinder is communicated with the cylinder body throughan air pipe; and a second piston rod is connected to the second piston. By means of the device, the bearing can be stably clamped, bearing stress is even in the bearing demounting process, and bearing damage is avoided.

Owner:宁波江北清锐汽车零部件有限公司

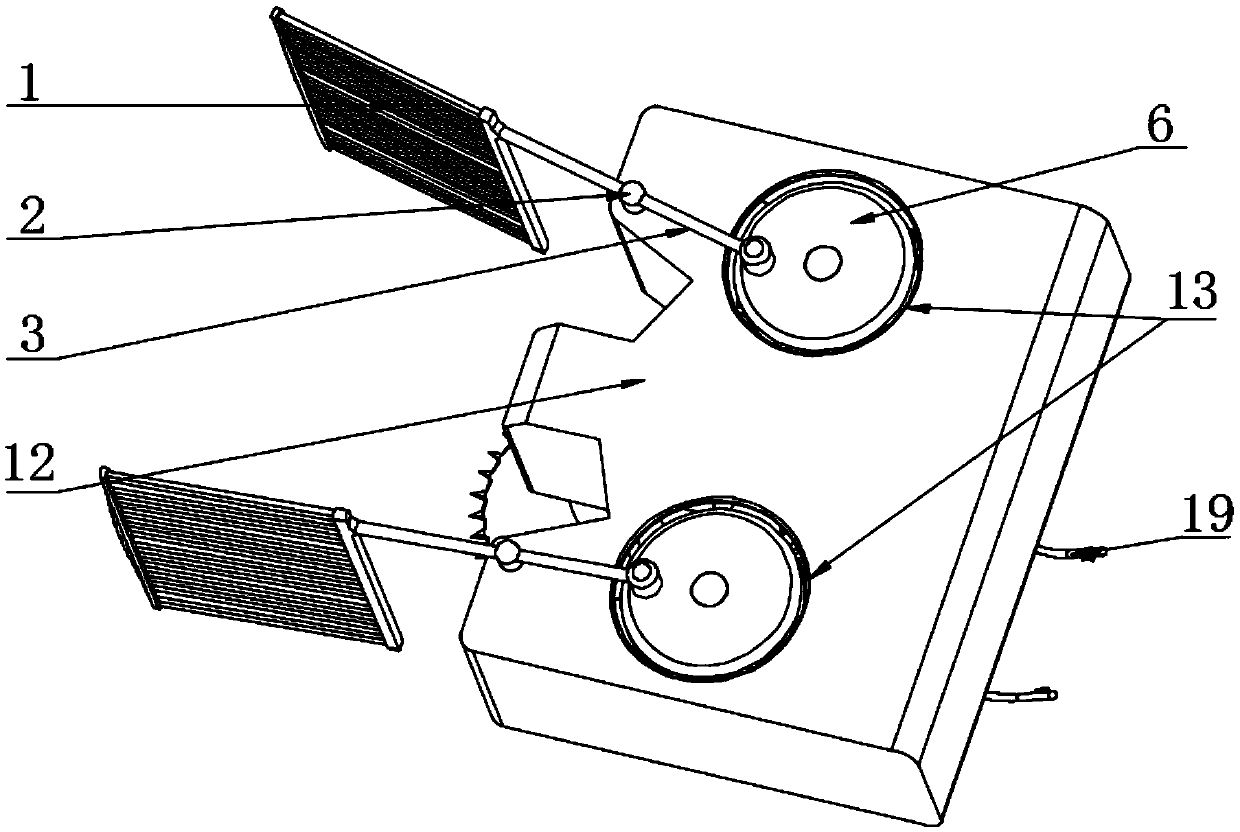

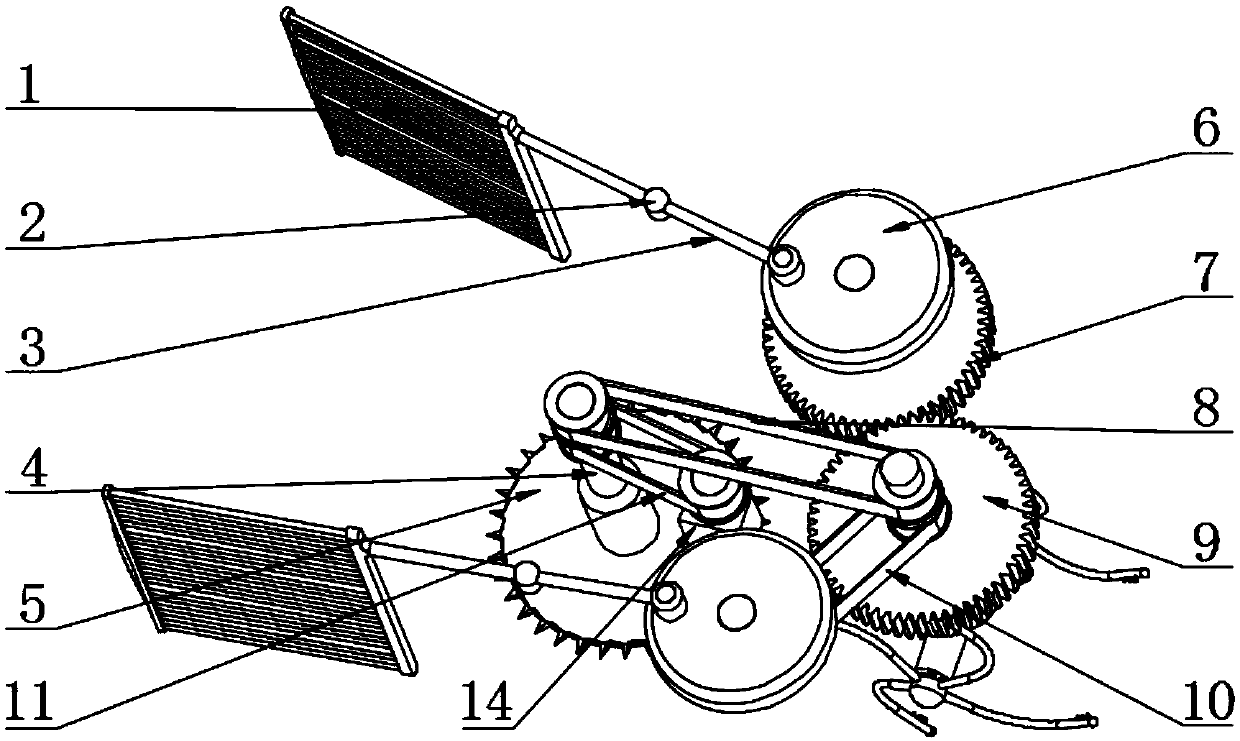

Taro harvesting device

The invention discloses a taro harvesting device, which comprises a drive plate, a fixed point, a swing rod, a fixed rod, a cutting head, an eccentric wheel, a first cylindrical gear, a first synchronous belt, a second cylindrical gear, a second synchronous belt, a third synchronous belt, a first shell, a through hole, a motor, a first transmission shaft, a first bevel wheel, a second bevel wheel,an irregular rod head, an irregular rod body, a second transmission shaft, a spring column, a dial head, and a second shell. The motor is vertically and fixedly mounted on one side of the bottom of the first shell. The structure of the taro harvesting device is compact, and thus the taro harvesting device can be conveniently installed on a taro harvesting functional machine. Cut-off stems and leaves can be pushed to two sides. The irregular rod body with a bionic pulling effect is used to pull and cut off residual stems. The dial head can enhance the force. During the rotation process of theirregular rod body, the stems are clamped by the lower end of the irregular rod body and pulled out; when the irregular rod body rotates to the front end and contacts with the first shell, the irregular rod body is expanded by the spring column, the clamping force is reduced therefore, and the taro harvesting device is convenient to use.

Owner:CHANGSHA NINGHU MACHINERY CO LTD

A precision gear processing machine tool

ActiveCN108971662BImprove practicalityAchieve fixationPositioning apparatusGear-cutting machinesGear wheelMachine tool

The invention discloses a precision gear machining machine tool base fixing part. A control panel is mounted on the right side of the front face of a base, the middle of the base is provided with a rove, a fixing part body is mounted in the middle of the groove, a Y355 motor is mounted in a protective cover which is mounted at the bottom end of the fixing part, and a rotating disc is mounted at the top of a rotating shaft which is fixedly connected to the top end of the Y355 motor. First clamping parts are mounted around the top of the rotating disc, an electric cylinder is mounted at one endof each first clamping part, a slider is mounted at one end of each electric cylinder, a fixing plate is mounted at the top of each slider, a retractable plate is fixedly connected to the top of eachfixing plate, a second clamping part is mounted on one side of each first clamping part, and machining tools are mounted on two sides of the top of the base. Top ends of the retractable plates are provided with flanging edges, grooves formed between the flanging edges and the fixing plates play a role in gear limiting and fixing to avoid gear sliding and shedding, and accordingly clamping effectsof the first clamping parts are improved, and gear machining precision is improved.

Owner:江苏爱雷德塑机有限公司

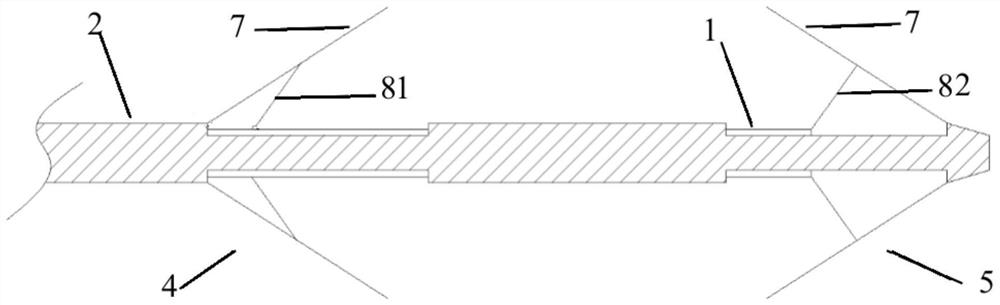

Silicon carbide rod clamping device and using method thereof

ActiveCN113752189AEfficient replacementReduced clamping effectWork holdersEngineeringMechanical engineering

The invention belongs to the technical field of clamping devices, and particularly relates to a silicon carbide rod clamping device and a using method thereof. The silicon carbide rod clamping device comprises clamping arms, second electromagnetic coils, a second power supply, a supporting seat, an elastic part, clamping seats, and movable clamping parts, wherein the clamping arms comprise a left clamping arm and a right clamping arm which are symmetrically arranged; clamping grooves are formed in the inner side faces of the lower ends of the left clamping arm and the right clamping arm correspondingly; the second electromagnetic coils are mounted on the clamping grooves; the second power supply is electrically connected with the second electromagnetic coils; the supporting seat is located in the middle of the two clamping grooves; the elastic part is connected onto the supporting seat and can independently apply elastic force in the upper direction, the lower direction, the left direction and the right direction of the supporting seat; the two clamping seats are located above and below the elastic part respectively and connected with the elastic part, and pre-clamping parts are arranged on the left bottom face and the right bottom face of each clamping seat respectively; and the two movable clamping parts are symmetrically connected to the left side and the right side of the elastic part. The silicon carbide rod clamping device provided by the invention is small in size, compact in structure, rapid in clamping, high in replacement efficiency and capable of adapting to silicon carbide rods with different sizes.

Owner:SGIS SONGSHAN CO LTD

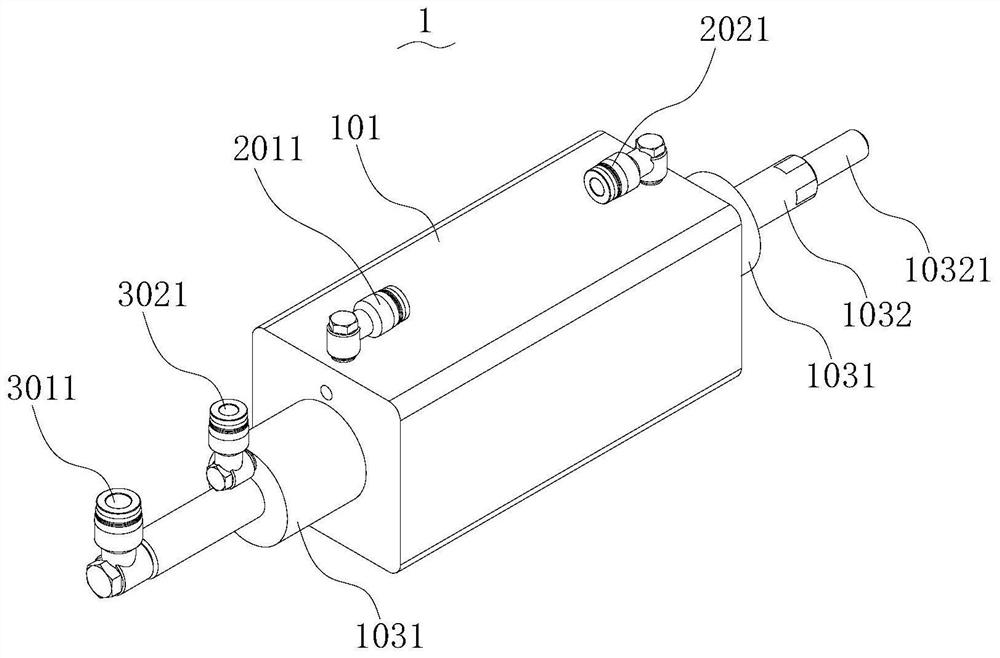

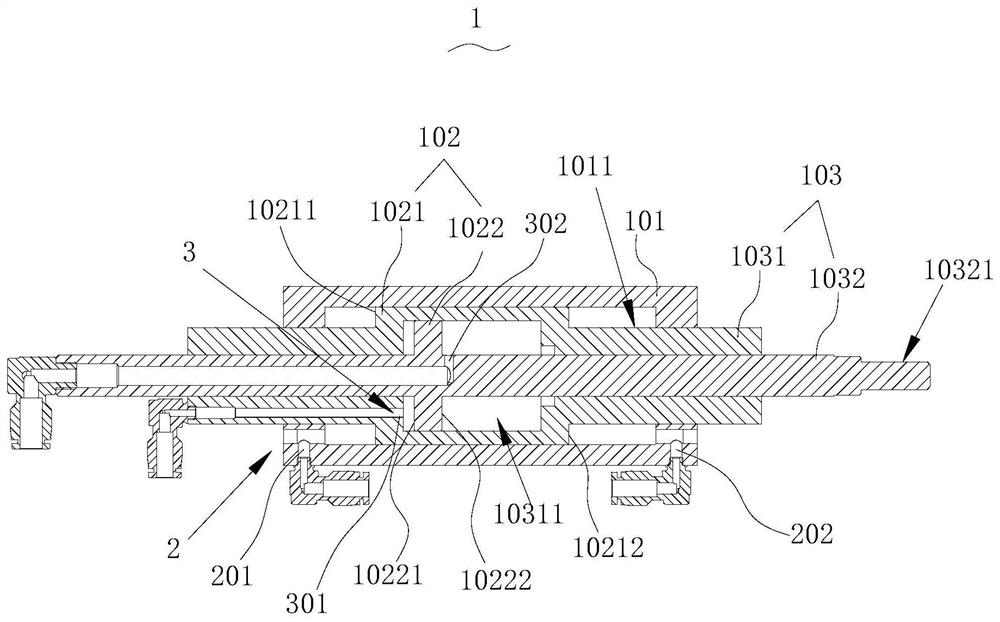

Differential pressure type pneumatic clamp

The invention discloses a differential pressure type pneumatic clamp, and relates to the field of pneumatic clamps. According to the scheme, the differential pressure type pneumatic clamp comprises aclamp body, a first clamping jaw, a second clamping jaw and a gear and rack transmission assembly, and the gear and rack transmission assembly drives the first clamping jaw and the second clamping jawto move towards each other or away from each other; and the differential pressure type pneumatic clamp further comprises a differential pressure type pneumatic telescopic cylinder, a cylinder body ofthe differential pressure type pneumatic telescopic cylinder is fixed to the clamp body, an output end is connected with the first clamping jaw or the second clamping jaw, and the moving direction ofthe output end is parallel to the moving direction of the first clamping jaw or the second clamping jaw. The differential pressure type pneumatic telescopic cylinder can output forces of different magnitudes, so that the pneumatic clamp can output clamping forces of different magnitudes, different clamping forces can be used for clamping to-be-clamped parts of different rigidities, the situationthat the to-be-clamped parts are clamped to be flat due to the fact that the clamping force is too large or cannot be clamped due to the fact that the clamping force is too small is reduced, the clamping stability and reliability are improved, and the applicability is high.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

Intelligent adjustable precise self-locking type clamping device for furniture plate body

ActiveCN114776674AReduced clamping effectEasy to holdFriction grip releasable fasteningsStructural engineeringRubber sheet

The embodiment of the invention discloses an intelligent adjustable precise self-locking type clamping device for a furniture plate body. The clamping device comprises an outer frame, and a lantern ring is arranged on the outer side face of the outer frame. The inner side end of an inner pulling plate is driven by a clamping frame through a connecting rod to move downwards, and due to the fact that the outer side end of a stretching frame is limited by a spring, the inner pulling plate slides on the surface of a protruding rod at the end of a limiting sleeve through a through groove till the whole stretching frame extends to the maximum distance; the clamping frame continues to move downwards, at the moment, a sliding rod at the outer side end of the stretching frame moves downwards on the inner side of a sliding groove, the sliding rod extrudes a spring at the bottom, the sliding rod stretches a spring at the top till the clamping frame makes contact with a flange at the bottom of the adjusting block, and at the moment, the elastic force of the spring acts on the bottom of the adjusting block through the stretching frame; and when the clamping effect on the plate is reduced due to rotation of the pressing plate or aging of the rubber sheet, the clamping effect of the top pressing plate on the plate can be improved by the adjusting block through the elastic force of the spring, and the plate is prevented from falling or moving in the clamping process.

Owner:广东朗哥家具实业有限公司

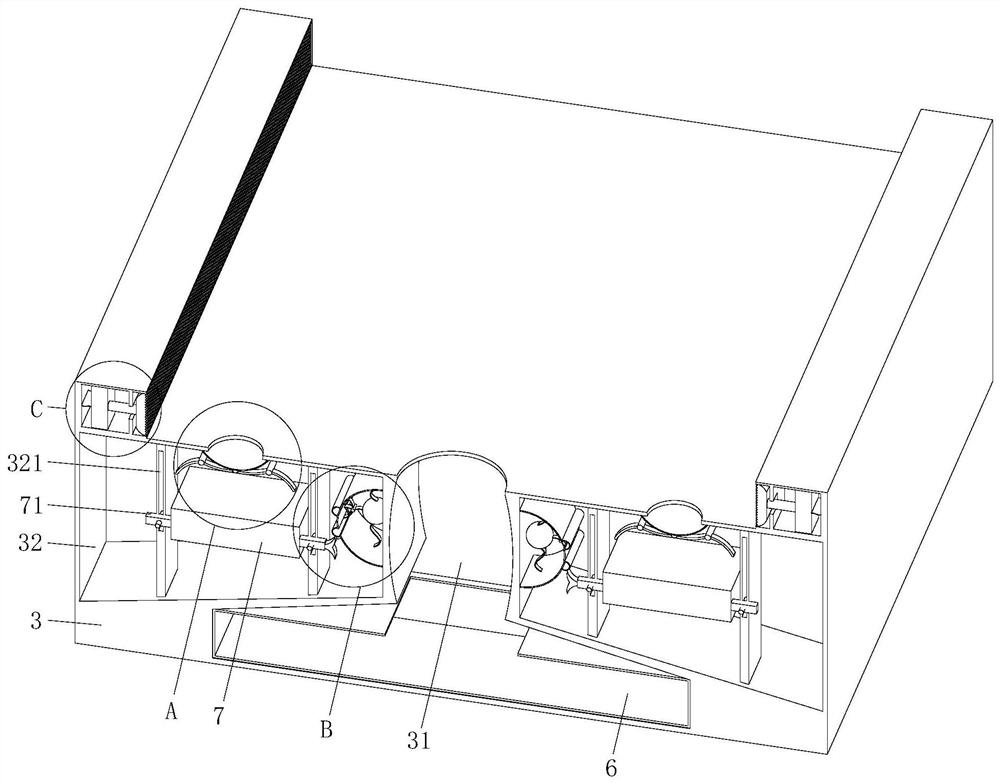

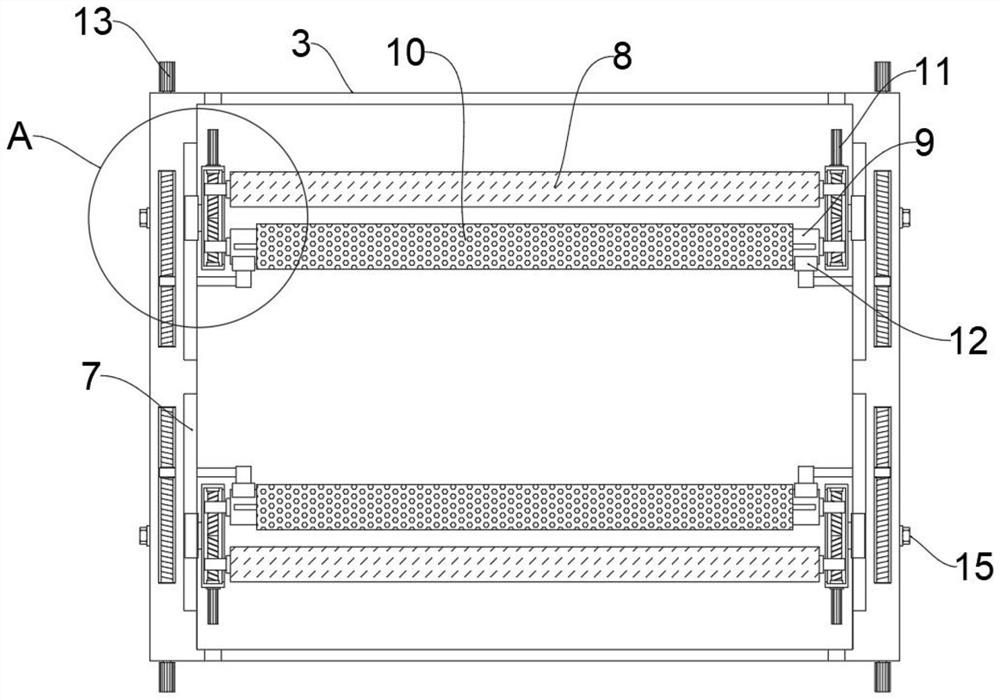

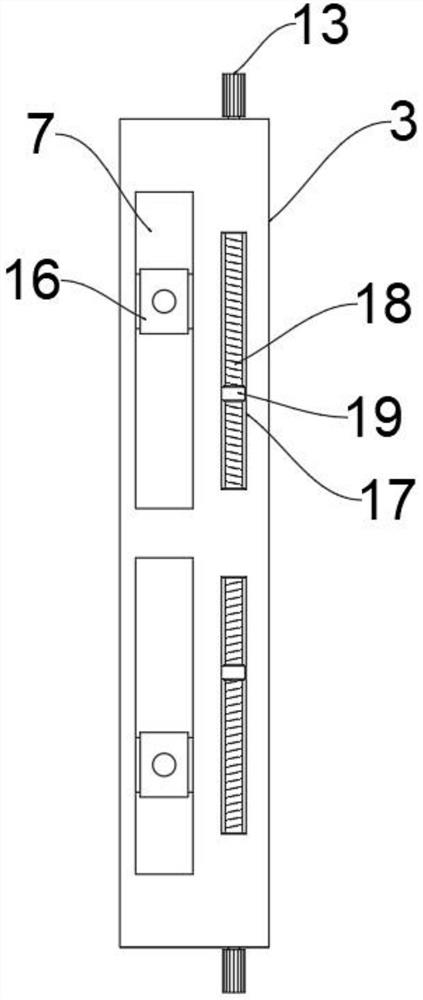

Automatic clamping device for stainless steel wire mesh pipe fitting spot welding

ActiveCN112247446AImprove conductivityImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingStructural engineering

The invention discloses an automatic clamping device for stainless steel wire mesh pipe fitting spot welding. The automatic clamping device comprises a mounting bottom plate, a forming device and a vertical movement device, wherein the forming device and the vertical movement device are arranged on the mounting bottom plate, a clamping device body is arranged in the forming device, and a welding mandrel device is arranged on the vertical movement device. Wire mesh blank is accurately positioned and formed through the forming device, so that the material forming precision is favorably improved;the clamping device composed of a plurality of clamping modules is adopted, so that the clamping force is distributed evenly, then the workpiece taking and placing efficiency can be improved, the clamping and welding auxiliary time is shortened, and the production efficiency is improved; and structurally speaking, the technical scheme has the advantages that the structure is simple and compact, the action is concise, the manufacturing is convenient, and the cost is low.

Owner:CHENGDU AERONAUTIC POLYTECHNIC +1

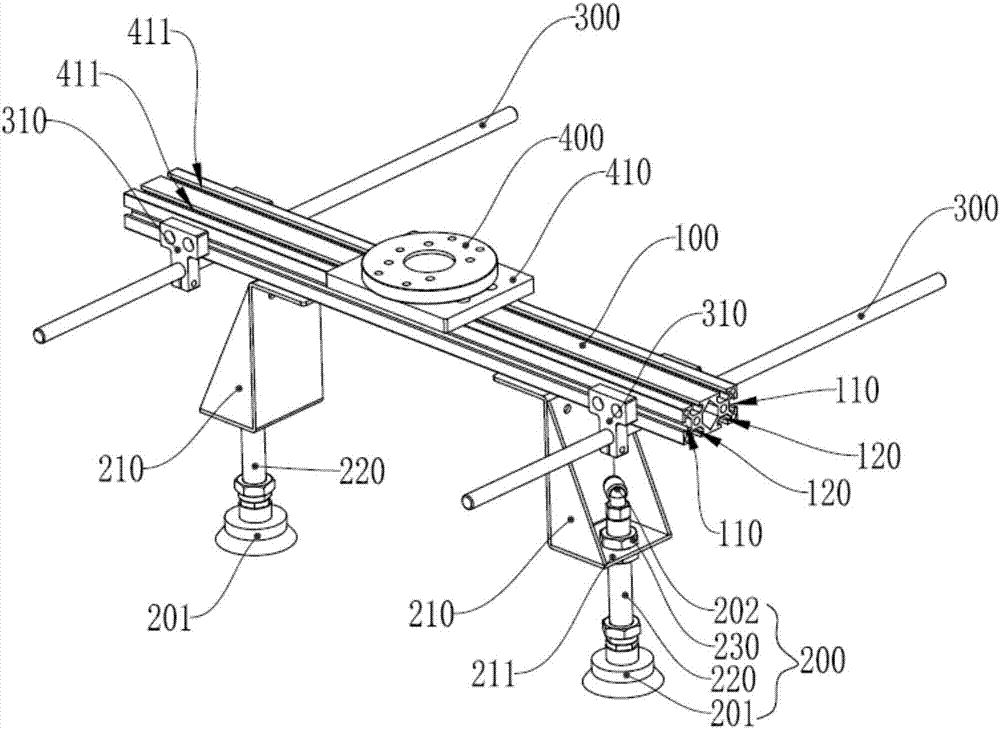

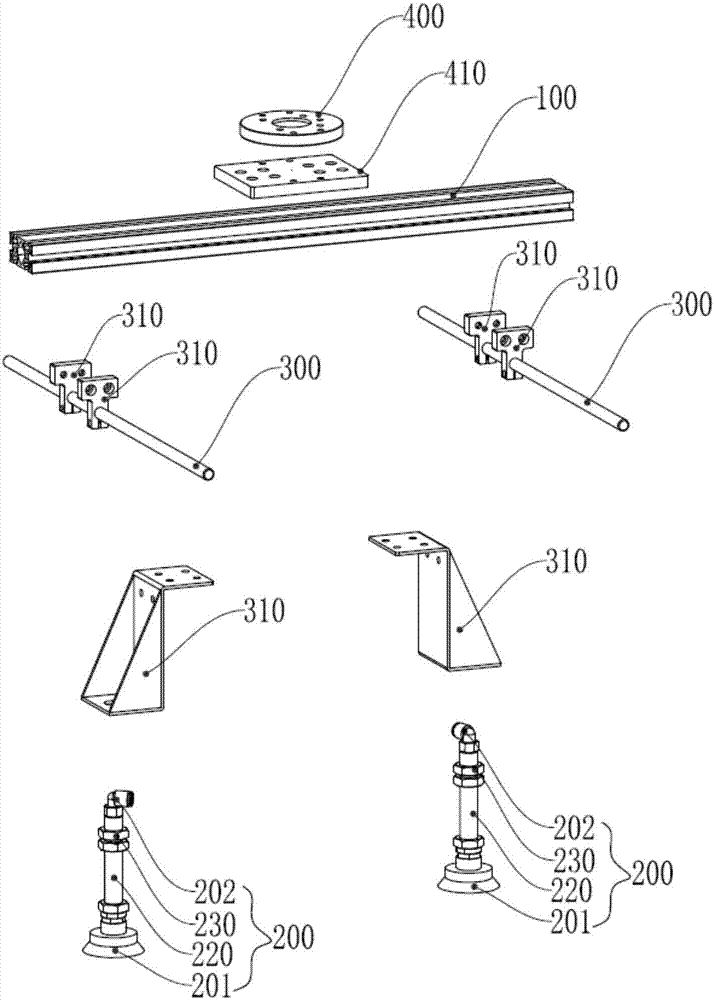

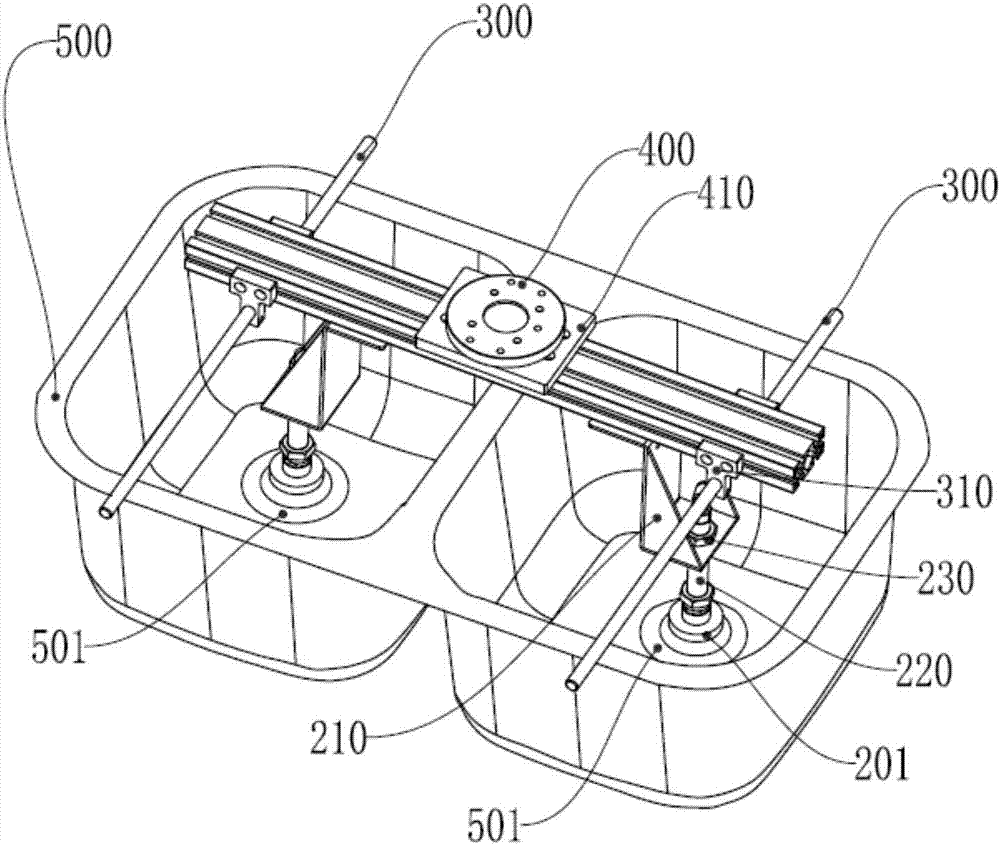

Water tank feeding and discharging clamp and method for machining water tank with same

ActiveCN107363725AWon't shakeEnsure balanceGrinding feedersGrinding work supportsEngineeringMechanics

The invention relates to the field of machining, in particular to a water tank feeding and discharging clamp and a method for machining a water tank with the same. The water tank feeding and discharging clamp comprises a body cross beam, adsorption devices and balance correction rods. The adsorption devices are arranged at the two ends of the body cross beam correspondingly. Adsorption ends arranged at the lower ends of the adsorption devices are located below the body cross beam and are further vertically arranged downwards. The balance correction rods penetrate through the two ends of the body cross beam. When the adsorption ends of the adsorption devices are adsorbed onto the inner bottom face of the water tank, the balance correction rods can be tightly attached to the edges of the two sides of the upper end face of the water tank. The water tank feeding and discharging clamp is simple in structure, ingenious in design, easy and convenient to operate and meanwhile stable in clamping. By the adoption of the mode that feeding and discharging of the water tank is completed through the clamp, bumping and scratching caused in the feeding and discharging processes of the water tank can be avoided completely. Meanwhile, the clamping and adjusting frequency of a mechanical arm can be decreased, and the efficiency and precision in feeding and discharging of the water tank are greatly improved.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Drilling machine for steel plate machining

PendingCN113021043AImprove the fixed effectImprove processing effectPositioning apparatusMaintainance and safety accessoriesSteel platesSmooth surface

The invention discloses a drilling machine for steel plate machining, and relates to the technical field of drilling machines. The drilling machine for steel plate machining comprises a base, a positioning shaft and a containing clamping table are fixedly installed at the top of the base, a stabilizing sleeve sleeves the top of the positioning shaft, the outer wall of the stabilizing sleeve is fixed to a drill bit, the bottom of the drill bit is arranged at the top of the center of the containing clamping table, and a drilling auxiliary channel is formed in the top of the containing clamping table. According to the drilling machine for steel plate machining, a steel plate at the top of the containing clamping table can be magnetically attracted by arranging reinforcing magnetic blocks, so that the steel plate is automatically fixed to the top of the containing clamping table, under the limiting effect of the two sides of the top of the containing clamping table, the steel plate cannot move in the drilling process, deviation in the steel plate drilling process is prevented; and meanwhile, a clamping enhancing mechanism is arranged, so that the smooth surface of the bottom of the steel plate is subjected to a negative pressure adsorption effect by utilizing ascending of the reinforcing magnetic blocks, and the steel plate fixing effect of the containing clamping table is further improved.

Owner:曹卫国

Efficient label printing equipment

PendingCN114348731AReduced clamping effectReduce the situationRotary pressesArticle deliveryWinding machinePaper tape

The invention relates to efficient label printing equipment which comprises a glue cutting device and a glue tearing device, the glue tearing device comprises two mounting plates, and a winding machine, an abutting rod, a conveying roller, a driving clamping roller and a driven clamping roller are horizontally arranged between the two mounting plates from top to bottom. A gap between the driving clamping roller and the driven clamping roller is located under the side, away from the rubber cutting device, of the conveying roller, plane rods and mounting rods are horizontally arranged at the positions, between the driving clamping roller and the conveying roller, of the two mounting plates, and abutting pieces used for abutting against the plane rods are arranged on the sides, facing the plane rods, of the mounting rods. A driving assembly used for driving the abutting part to horizontally move towards the plane rod is arranged in the mounting rod. The production quality and the production efficiency of the printing body paper tape are improved.

Owner:上海兢鸿包装制品有限公司

Automatic pipe bending device and pipe bending process thereof

Owner:西安德卡汽车系统有限公司

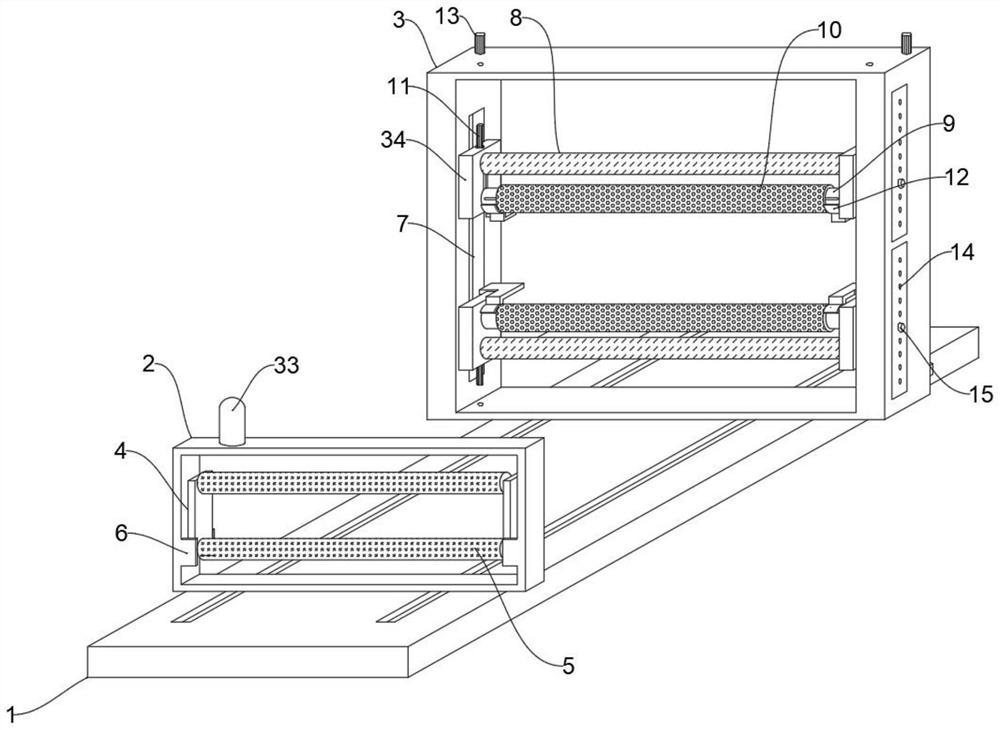

Foam tension adjusting mechanism for irradiation cross-linked polyethylene foam slicing

InactiveCN113184597AReduced clamping effectAchieve extrusionArticle deliveryWebs handlingPolymer scienceEngineering

The invention discloses a foam tension adjusting mechanism for irradiation cross-linked polyethylene foam slicing, relates to the technical field of irradiation cross-linked polyethylene foam processing, and aims to solve the problem that tension is loose or tight during conveying due to the fact that existing foam is affected by self and external factors. A tension protection device is mounted in front of the upper end of an adjusting base and is in sliding connection with the adjusting base, rotating mounting plates are symmetrically arranged at the two sides of the interior of the tension protection device, and the rotating mounting plates are rotationally connected with the tension protection device through rotating shafts; and a tension testing roller is mounted between the rotating mounting plates, a tension adjusting device is mounted behind the upper end of the adjusting base, space adjusting devices are mounted at the upper end and the lower end in the tension adjusting device, a pressing roller and a mounting roller are mounted between the space adjusting devices, and a tension roller is mounted outside the mounting roller.

Owner:湖北天泰辐照股份有限公司

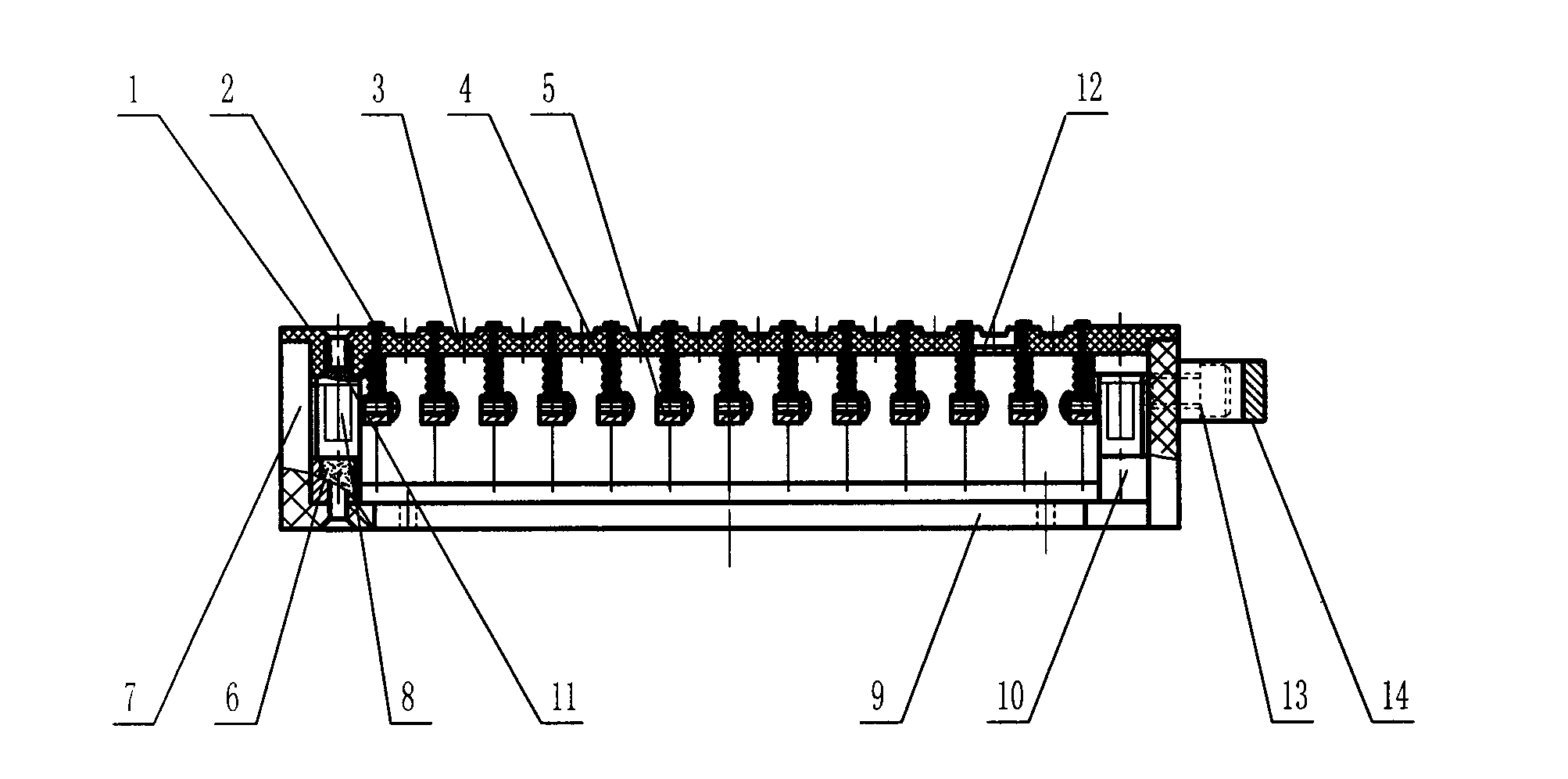

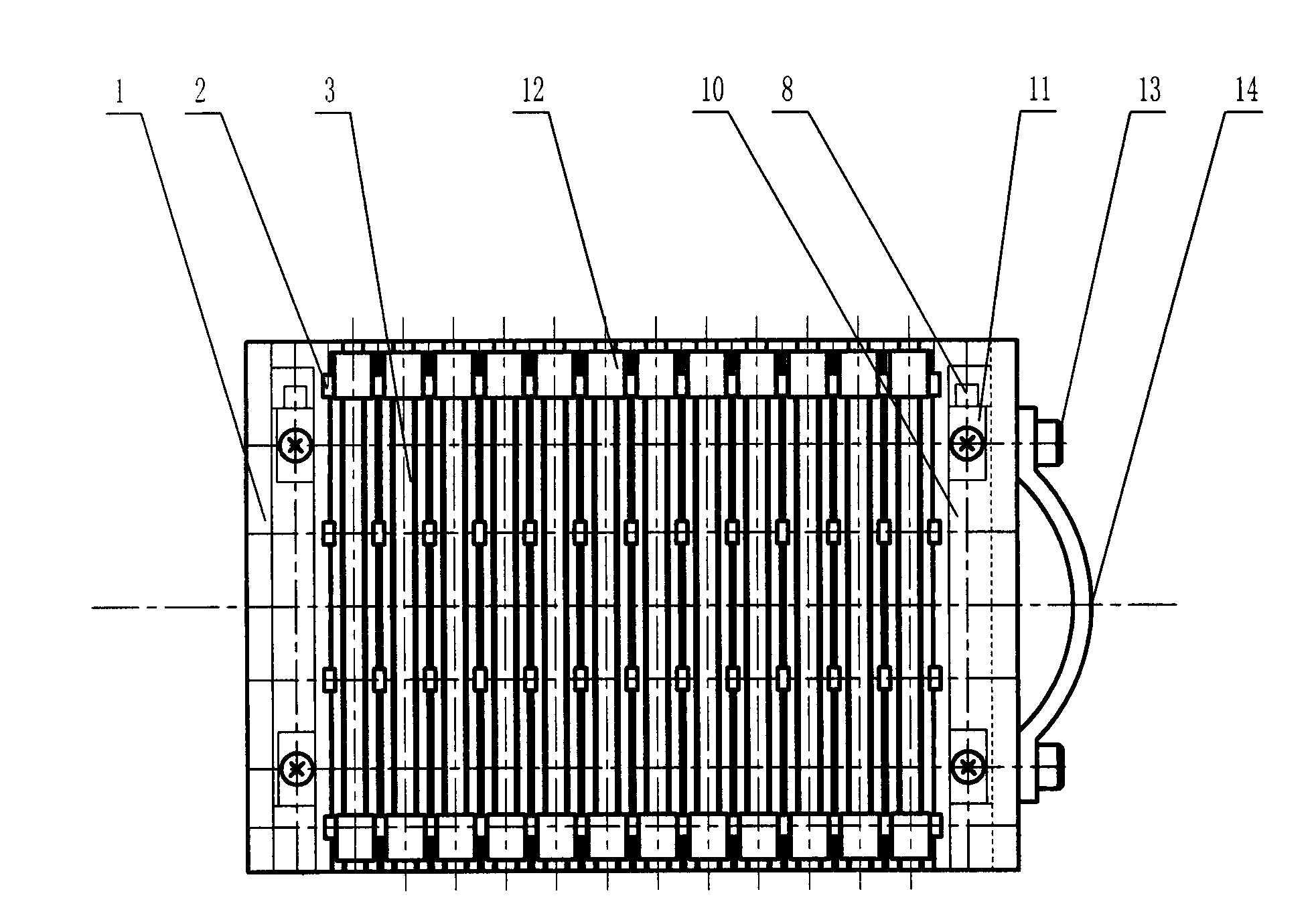

Composite pressing clamp of panel-type electrode bracket for COMMB-LED (chip on mirror metal board-light emitting diode)

InactiveCN102709459AReduced clamping effectLower requirementSemiconductor devicesEngineering plasticEngineering

The invention discloses a composite pressing clamp of a panel-type electrode bracket for a COMMB-LED (chip on mirror metal board-light emitting diode), wherein the connection of the bearing platform of the clamp and a clamp body made of engineering plastics by injection molding is actuation of a magnetic vertical direction (Z direction) and actuation of a transverse direction (X direction), and the composite pressing clamp can achieve online transverse thrust and is convenient to dismantle. The clamp body is attached to the limiting block clamp of the bearing platform and the bottom plate flange of the clamp without clearance due to magnetic force, so higher position precision is achieved. Each single body integrated by adopting the panel-type electrode bracket for the COMMB-LED respectively and independently finishes single-body self-lock pressing arrangement in a height direction by a mechanical spring, and the composite pressing clamp is processed by insulated interlayers of electrodes outwards led at two sides of the panel-type electrode bracket for the COMMB-LED and achieved on the bearing platform of the panel-type electrode bracket for the COMMB-LED by a glue injecting mode, so the manufacture and use efficiencies of the clamp are greatly improved.

Owner:彭雯

Adhesive tape with fabric carrier for cable wrapping

ActiveCN102676076BReduced clamping effectEffective tearabilityFilm/foil adhesivesWoven fabricsFiberEngineering

Adhesive tape comprises a substrate, and an adhesive layer applied on at least one side of the substrate. The substrate is a fleece bonding machine substrate that is made of a pre-consolidated pre-fleece of staple fibers. The pre-fleece are sewn in parallel running threads such that the complete fleece bonding machine substrate is produced. The maximum tensile strength of the pre-hardened and not non-sewn pre-fleece is less than 2 N / cm, preferably less than 0.5 N / cm. An independent claim is also included for the fleece bonding machine substrate.

Owner:TESA SE

Magnetic resonance coil support

ActiveCN113990598AReduce labor intensityHigh degree of automationWater resource assessmentContainers to prevent mechanical damageGear wheelControl theory

The invention discloses a magnetic resonance coil support, and relates to the technical field of coil supports, the magnetic resonance coil support comprises a base, fixing columns and a rotary storage box, the base is internally provided with an inner cavity, the inner cavity of the base is provided with a driving assembly, and the upper surface of the base is symmetrically and fixedly provided with two groups of fixing columns; a rear protection plate is fixedly installed on the rear sides of the two sets of fixing columns, and a rotating assembly is arranged between the two sets of fixing columns. When a rotating shaft is about to move to the upper end of a fixing column, a driving gear is meshed with the lower end of a driving rack, along with continuous upward movement of the rotating shaft, the driving rack drives the driving gear and drives the rotating shaft to rotate, and finally the rotating storage box can be driven to swing by 90 degrees through the connection effect of a fixing end block; the front face of the rotating storage box faces upwards, a manual pulling mode adopted in the prior art is replaced, the labor intensity of an operator is reduced to a certain degree, the overall automation degree of the device is improved, operation is easy, and time and labor are saved.

Owner:PEKING UNIV SHENZHEN HOSPITAL

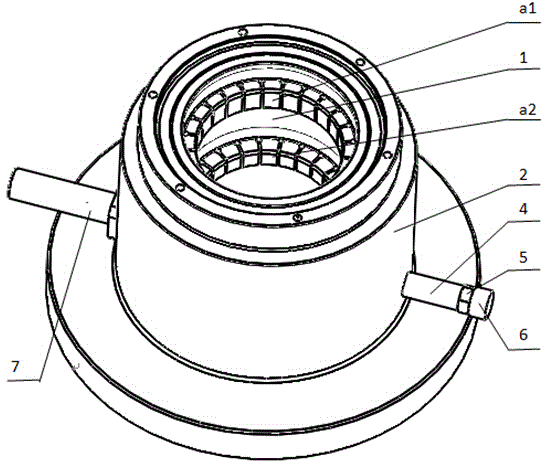

Aeroengine rotor-stator clamping device combined with hydraulic drive and double working belt

The invention discloses a hydraulic drive and double-working-tape compounded aero-engine rotor and stator clamping device, which belongs to the technical field of precise clamping. The device is characterized in that a sealing cavity is surrounded by an inner sleeve, a middle sleeve, an outer sleeve, an extension pipe, a connecting piece, a pressure detector, a pressurizer, a bottom plate, a sealing nozzle and a piston; hydraulic oil is injected through an oil injection hole and is pressurized in the cavity by the pressurizer; pressure is transmitted to an upper-layer annular oil duct, a middle-layer annular oil duct and a lower-layer annular duct via a communication path; the piston is pushed to drive an upper-layer annular working tape and a lower-layer annular working tape to synchronously retract to clamp a tested piece, and clamping force is monitored in real time and precisely controlled. The invention establishes the precise clamping device which combines high precision and high stability.

Owner:哈尔滨超精密装备工程技术中心有限公司

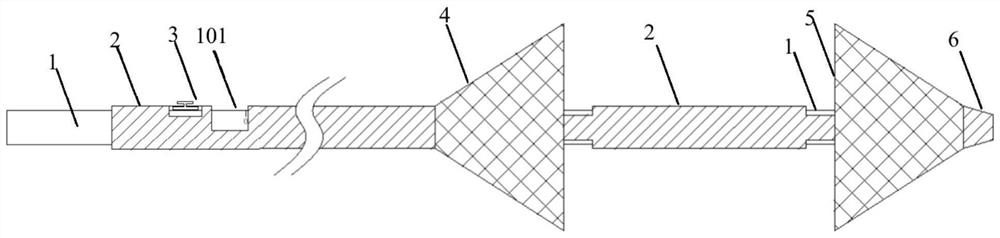

A dual-umbrella adjustable thrombus retrieval device

The invention discloses a double-umbrella-type adjustable thrombus taking device and relates to cardiovascular and cerebrovascular thrombus taking devices. The device comprises an inner pipe, an outerpipe, a near-end catching umbrella and a far-end catching umbrella; the inner pipe is positioned in the outer pipe, and the inner pipe can slide relative to the outer pipe; a slot is arranged on theside surface of the outer pipe; in the slot, the near-end catching umbrella is configured to slide relative to the outer pipe along with the inner pipe, and the umbrella surface of the near-end catching umbrella can be supported and closed relative to the outer pipe; and the far-end catching umbrella is configured to slide relative to the outer pipe along with the inner pipe, and the umbrella surface of the far-end catching umbrella can be supported and closed relative to the outer pipe. According to the thrombus taking device disclosed by the invention, the thrombus can be caught on both sides, the clamping force is improved, and the falling or broken thrombus is prevented from escaping along with blood flow.

Owner:SHANGHAI HEARTCARE MEDICAL TECH CORP LTD

A clamping manipulator for capacitor production and processing

ActiveCN113666103BAvoid crashing and fallingPracticalCapacitor manufactureConveyor partsClamp capacitorCircular disc

The invention discloses a clamping manipulator used for producing and processing capacitors, which comprises a fixing plate, a circular groove is opened at the lower end of the fixing plate, a disk is slidably connected to the inner wall of the circular groove, and a pair of capacitors is arranged on the disk. A clamping mechanism for clamping, the clamping mechanism includes two vertical plates fixedly connected to the lower end of the disc, the side walls of the vertical plates are slidably connected to a driving rod, and one end of the driving rod is fixedly connected to a splint, the The side wall of the splint is elastically connected with the side wall of the riser through the first spring. The multiple clamping rods of the present invention can be extruded to form a shape that fits with the capacitor, and then can clamp capacitors of different shapes, and the unextruded clamping rods can also protect the capacitor from colliding during transportation Compared with the prior art, it can hold capacitors of different shapes, and no matter what position the capacitor is in, it can hold it stably by itself, without excessive operation, and has strong practicability.

Owner:南通海美电子有限公司

Smooth composite spinning mechanism and method of short fiber whisker strip clamped by double filaments via unequal tension

The invention relates to a smooth composite spinning mechanism, method and application of a short fiber whisker strip clamped by double filaments via unequal tension. The mechanism is composed of a tension disk used for locating a tension filament and controlling tension thereof, a yarn guide hook used for locating a low-tension filament and a holding roller used for keeping the tension. The composite spinning method comprises the steps of: synchronously feeding the tension filament, the low-tension filament as well as the short fiber whisker strip into a front roller to enable the short fiber whisker strip to be wrapped by the two filaments in a traction zone; and forming a three-shafting spinning yarn with the short fiber whisker strip covered by the tension filament from the upside and support by the low-tension filament from the downside, wherein the composite yarn is a smooth composite yarn which is formed by spirally twisting the tension filament and the short fiber whisker strip and externally coating the low-tension filament. The mechanism is light, practical, convenient to install, controllable and adjustable, can produce yarns with steady structure and is suitable for composite spinning of high-count smooth yarns and superfine yarns of short fibers.

Owner:DONGHUA UNIV

Multifunctional ground wire insulation rod

InactiveCN105226412BChange the curvatureEasy to adjustElectric connection structural associationsCopper wireMechanical engineering

The multi-functional grounding wire insulating rod includes a grounding wire clamp and an insulating rod. The grounding wire clamp includes a fixed part and a movable part. The fixed part includes an upper splint. A vertical support rod and a movable rod are installed in the cavity, and an elastic conductor is arranged between the support rod and the movable rod. The fixed ring, the upper side of the fixed ring is connected with the lower end of the tension spring, and the upper end of the tension spring is fixed with the upper splint along the radial direction of the arc-shaped notch; the elastic conductor is composed of multiple conductive copper wires arranged in parallel, and the conductive copper wire One end of the utility model is fixed to the support rod, and the other end is fixed to the movable rod and can be retracted and wound around the outer periphery of the movable rod. The invention has a wide application range and is convenient to use. At the same time, the grounding wire clamp has a good clamping force on the charged body, and the contact is firm, ensuring the safety of users.

Owner:国网山东郓城县供电公司 +1

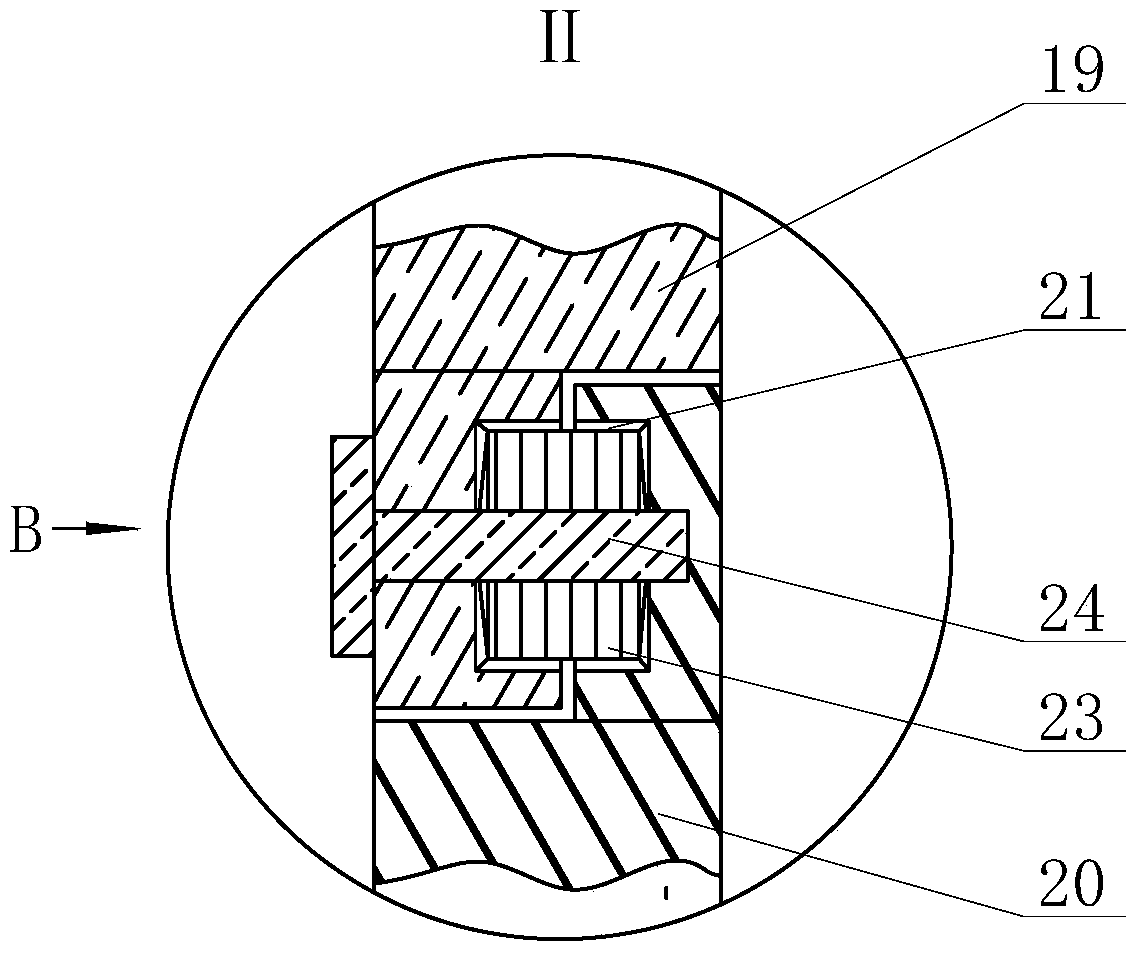

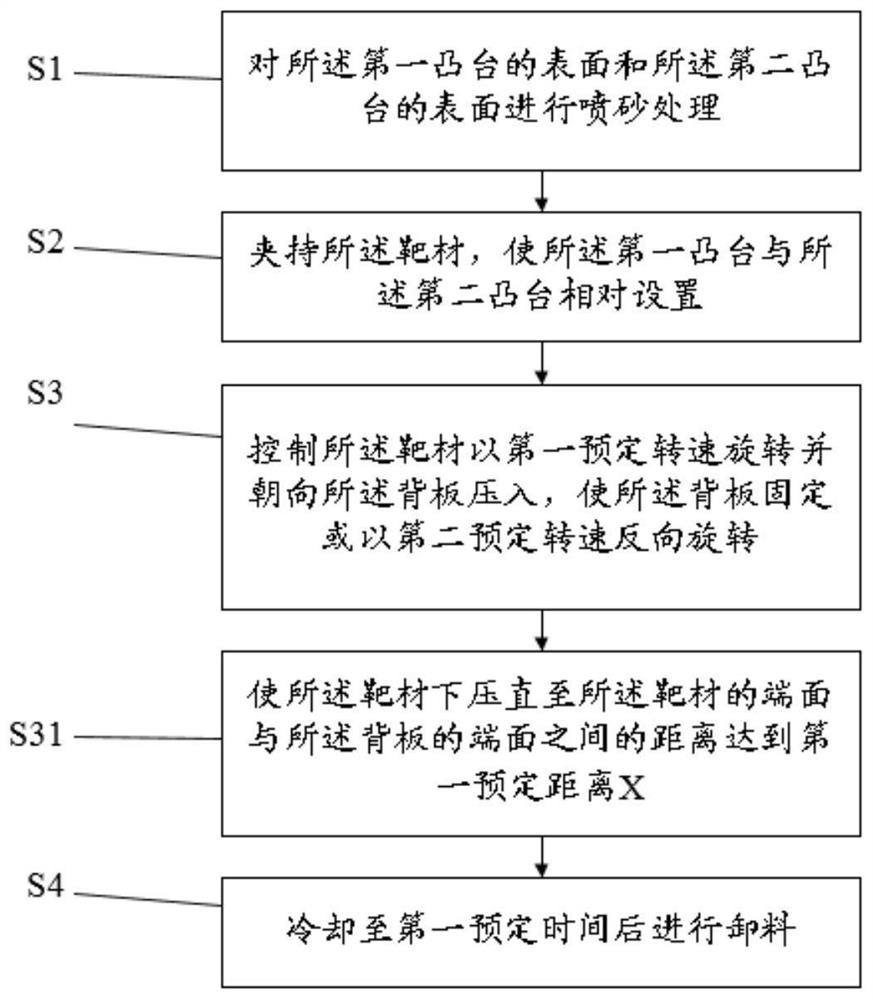

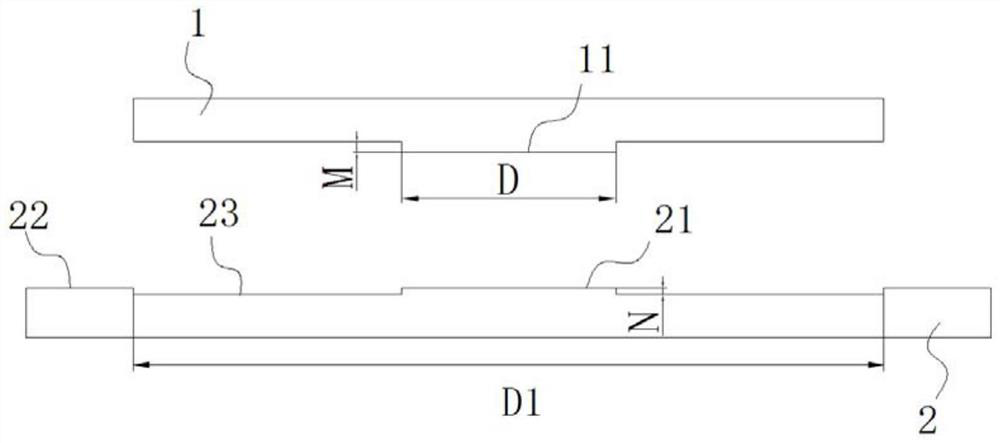

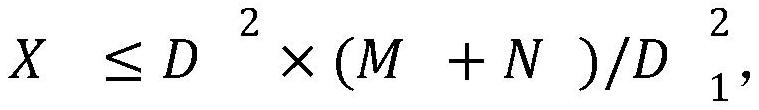

Friction welding method for target material assembly

ActiveCN114273771AHigh strengthShort timeNuclear energy generationNon-electric welding apparatusIndiumWeld seam

The invention relates to the technical field of welding, and discloses a friction welding method of a target material assembly, according to the friction welding method, heat generated by friction between a target material rotating at a high speed and a back plate is used for locally melting a first boss and a second boss, and a compact solid-phase welding seam is formed under extrusion of a welding tool. According to the friction welding method, the welding bonding layer is formed through melting, the bonding strength is higher than that of brazing indium, the high-temperature resistance is better, and desoldering is not prone to occurring; compared with electron beam welding, the welding area of the first boss and the second boss is larger, namely, the metallurgical bonding area is larger, and the overall strength is higher; compared with diffusion welding, the friction welding method is shorter in consumed time, inert gas or other working conditions do not need to be adopted for protection, and the cost is low; and secondly, the friction welding method is small in friction force, low in equipment requirement, low in energy consumption and short in welding time consumption, and small-area contact friction is not prone to causing overall deformation of the target material or the back plate.

Owner:先导薄膜材料(安徽)有限公司

Clamping support with double driving rods

PendingCN114838252AQuick pick and placeReduced clamping effectStands/trestlesVehicle componentsStructural engineeringMechanical engineering

The invention relates to a double-driving-rod clamping support which comprises a base and a support shell and further comprises at least one movable clamping arm, a first driving rod and a second driving rod, a sliding rail is arranged on the support shell, the movable clamping arm slides in the sliding rail, one end of the first driving rod is rotationally connected with the support shell, and the other end of the first driving rod is rotationally connected with the support shell. The other end of the first driving rod is rotationally connected with the second driving rod, the other end of the second driving rod drives the movable clamping arm to move, the rotationally-connected ends of the first driving rod and the second driving rod abut against the base when being pressed, and one end of the base is rotationally connected with one end of the support shell. And a space for the driving rod to swing is reserved between the other end of the base and the other end of the bracket shell. According to the invention, by using the use habits of placing and taking the mobile phone, pressing down, lifting and taking the mobile phone, the electronic equipment is easy to clamp and take out, the electronic equipment can be conveniently and quickly taken and placed, and the previous repeated clamping, clamping unlocking and locking unlocking operations are reduced.

Owner:SHENZHEN CHEANDA ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com