Device for demounting bearing

A technology of bearing and supporting shaft, applied in the direction of bearing element, shaft and bearing, bearing unloading, etc., can solve the problems of low bearing disassembly efficiency and easy damage to bearing disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

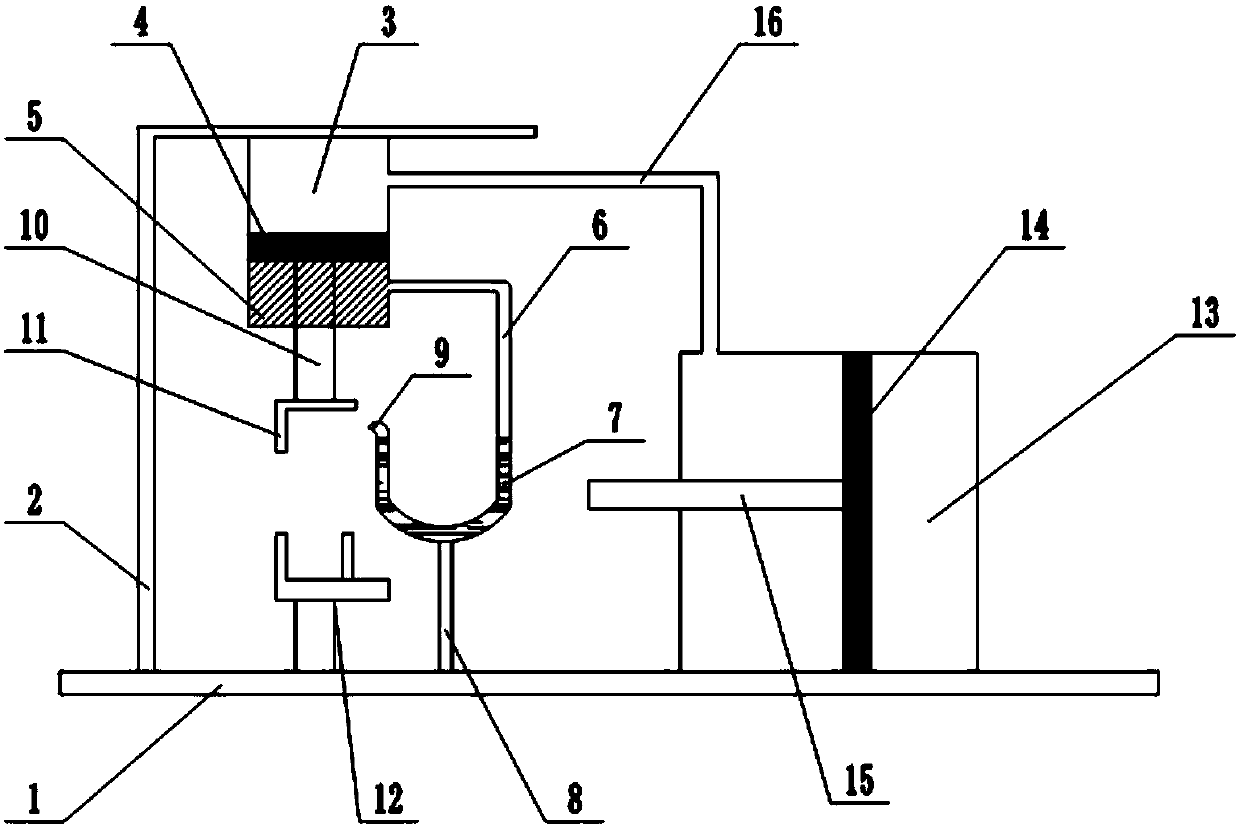

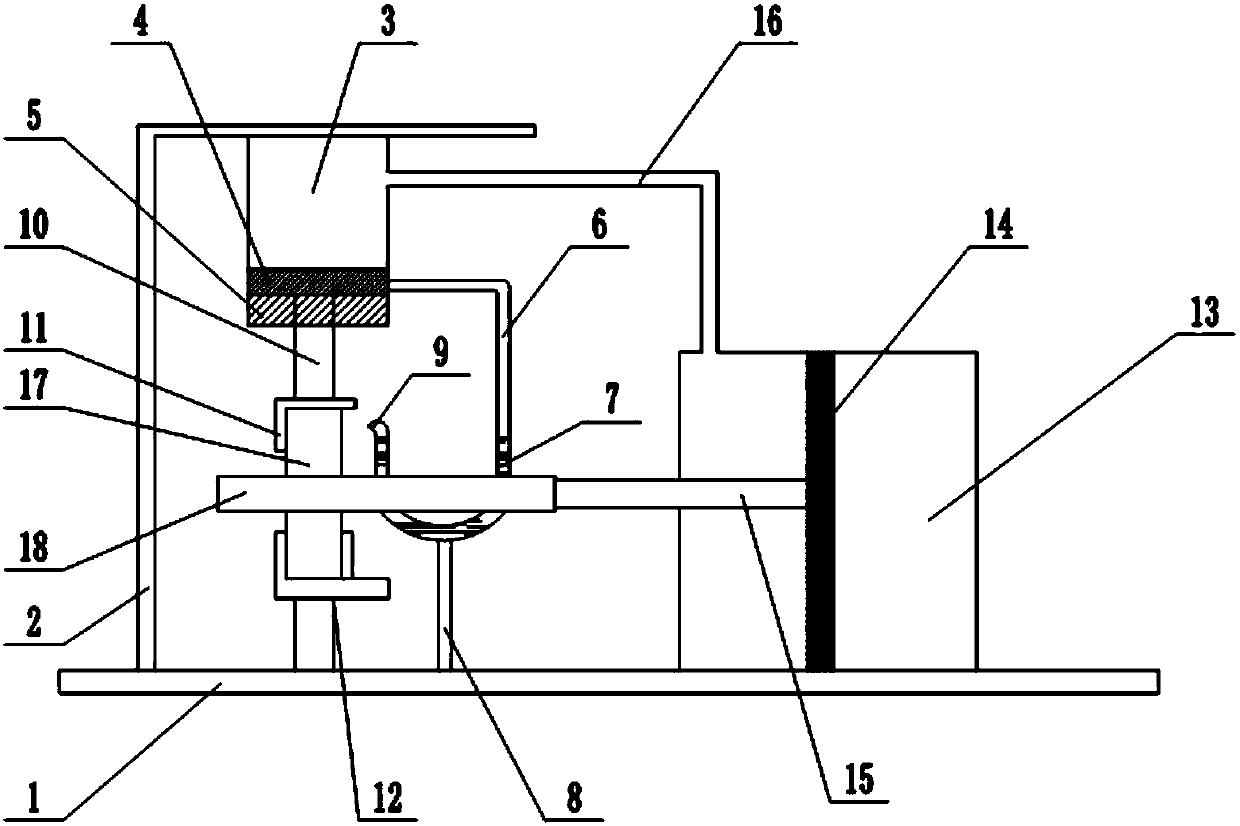

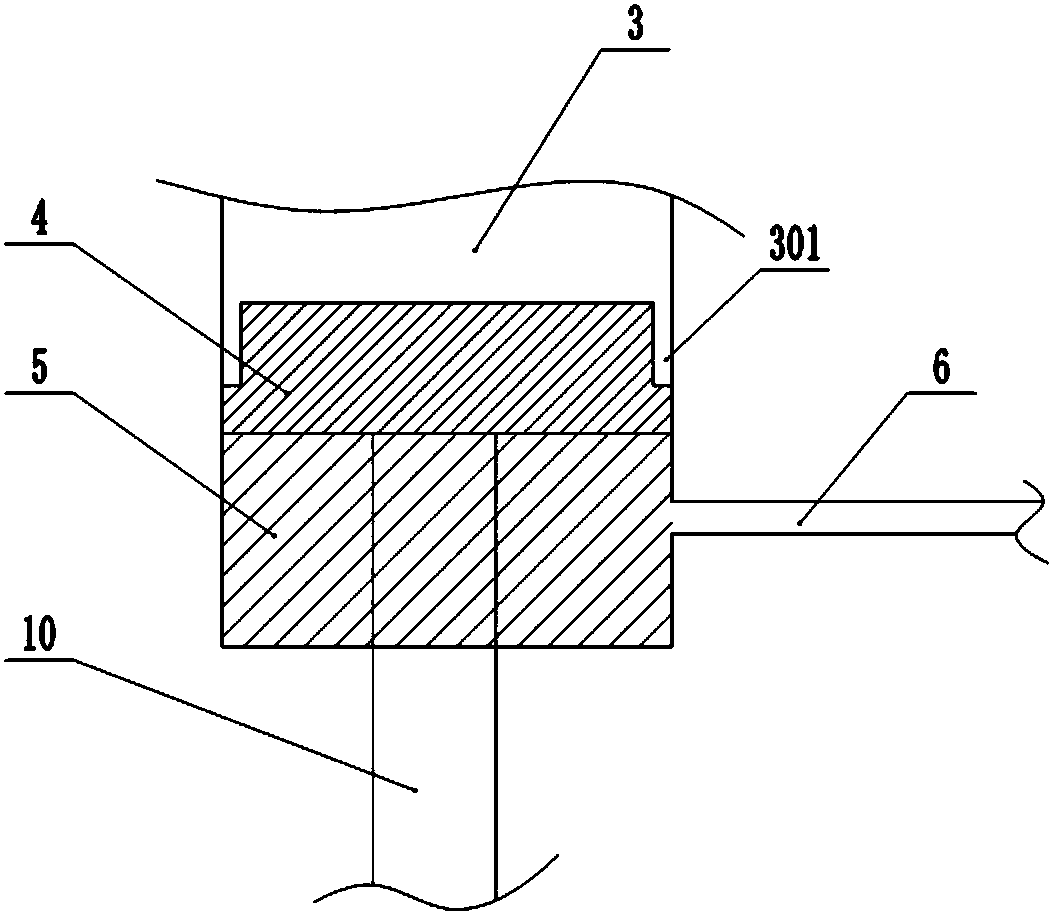

[0020] Such as figure 1 , figure 2 The shown bearing removal device includes a workbench 1 on which a first support shaft 2 , a clamping mechanism 12 , a second support shaft 8 and a cylinder 13 are sequentially arranged from left to right. A cylinder body 3 is welded on the first support shaft 2, and the first piston 4 is fitted in the clearance of the cylinder body 3. There is a gap 301 between the cylinder body 3 and the first piston 4, and the minimum gap between the cylinder body 3 and the first piston 4 is 301 is greater than zero, such as image 3 As shown, the first piston 4 separates the cylinder body 3 from the upper chamber and the lower chamber, the lower chamber is provided with an elastic material layer 5, the elastic material layer 5 is a compressible rubber layer, and the side wall of the lower chamber is connected with an air outlet pipe 6 , the air outlet pipe 6 is sealed and communicated with a "U"-shaped pipe 7 made of glass, the bent part of the "U"-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com