Patents

Literature

453results about How to "Reduce disassembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

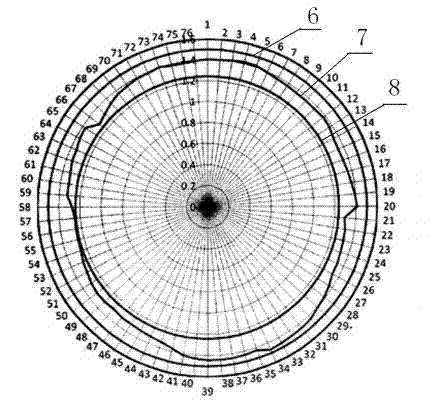

Non-contact measuring method for leaf apex radial clearance of engine rotor

InactiveCN102175135AImprove assembly qualityReduce disassemblyEngine testingUsing electrical meansCapacitanceFailure rate

The invention relates to a non-contact measuring method for a leaf apex radial clearance of an engine rotor, and the method comprises the following steps: 1) assembling a measuring system, calibrating a sensor and determining the relation between the radial clearance and voltage of a leaf apex; 2) preparing before measuring; and 3) measuring the leaf apex radial clearance of the engine rotor. In the measuring method provided by the invention, a measurement technique based on a capacitance method is adopted; the measuring course and the assembling are synchronously carried out; the once cartridge disassembly and assembly is reduced; the measuring time is shortened; the production efficiency is improved; and the measuring accuracy is improved, thereby improving the assembly quality of an engine and reducing the failure rate of the engine. The non-contact measuring method provided by the invention is mainly used for measuring the leaf apex radial clearance of the rotors of parts such as an engine, a high-pressure compressor, a low-pressure compressor, a high-pressure turbine, a low-pressure turbine and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

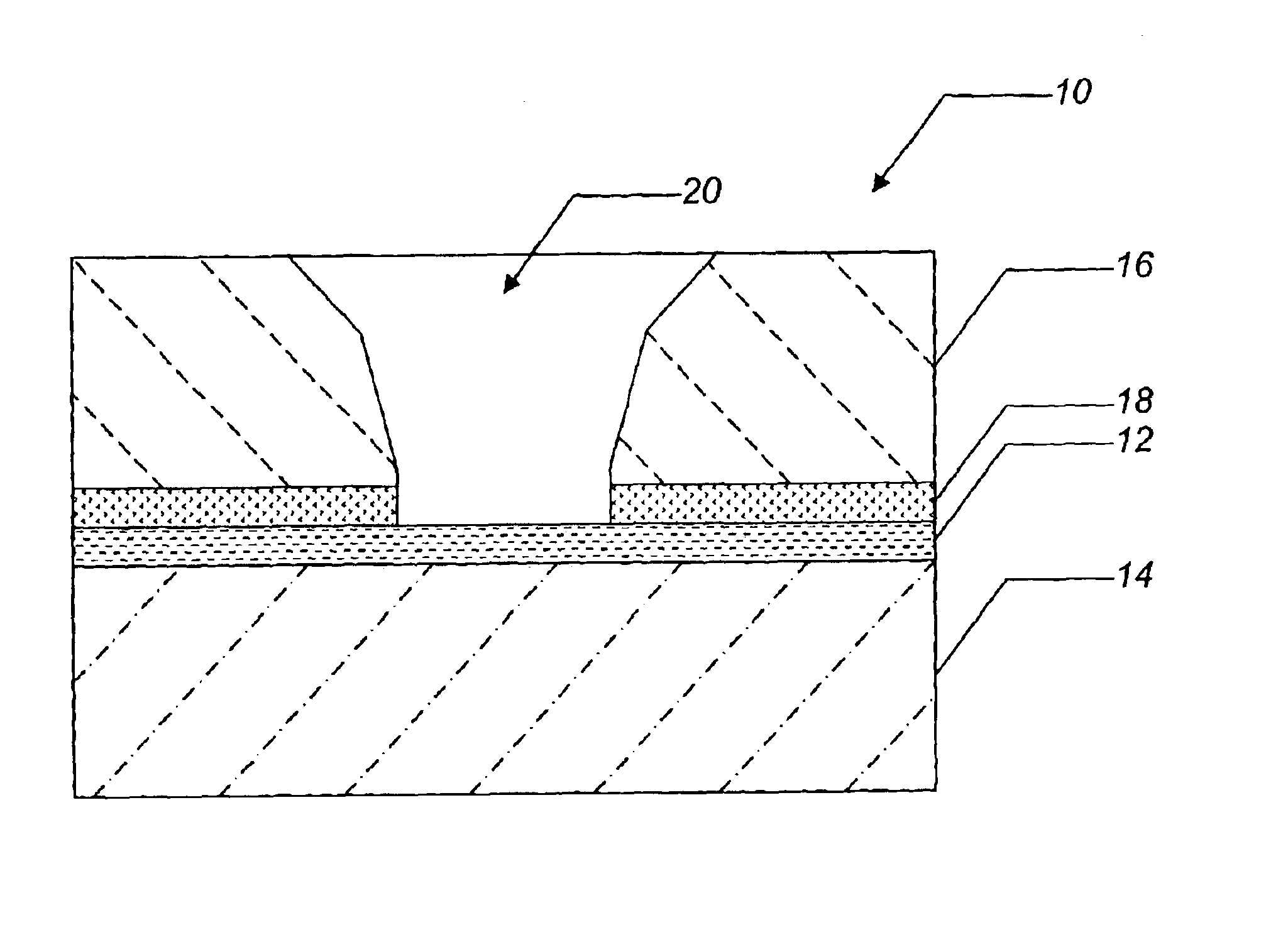

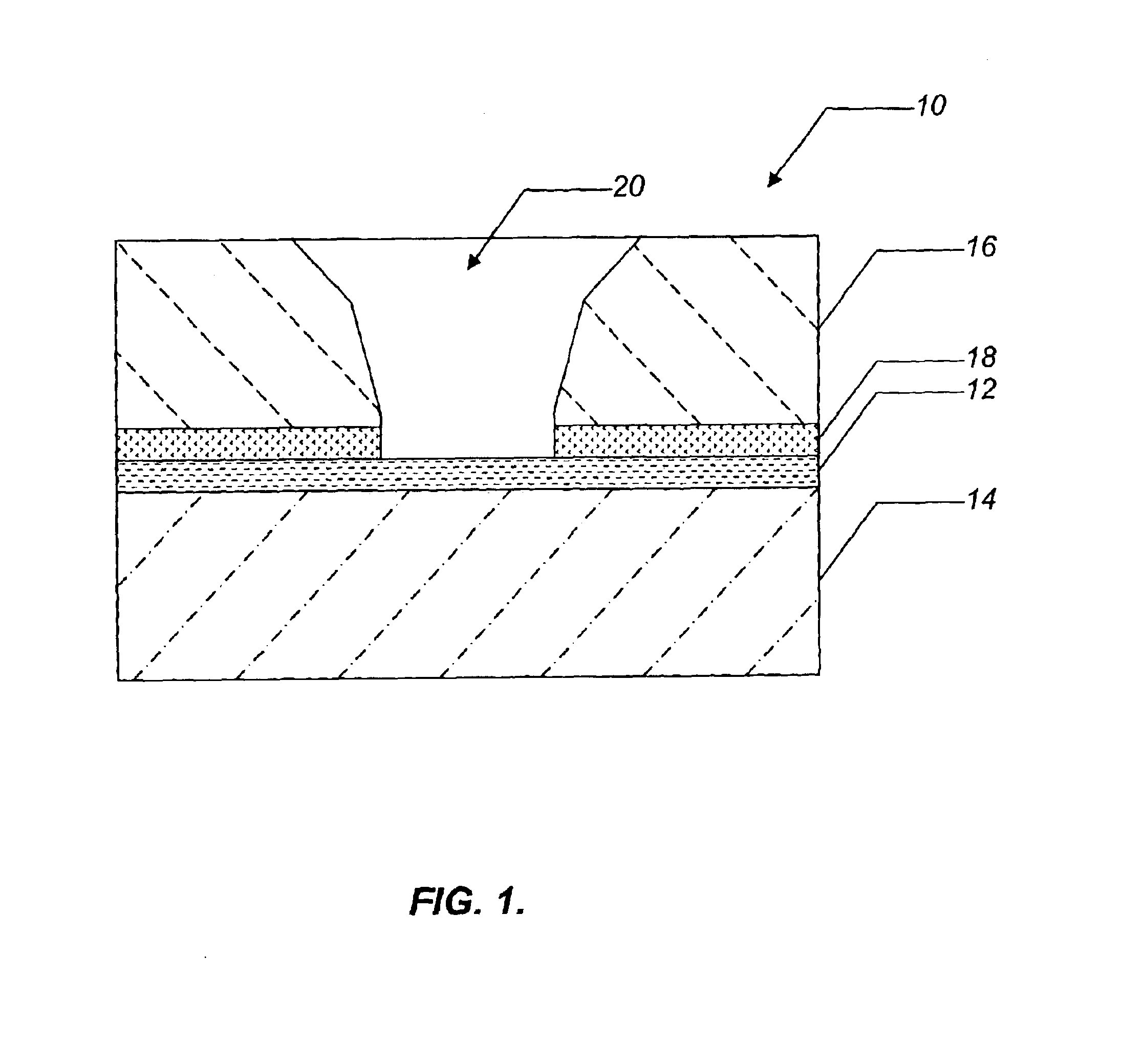

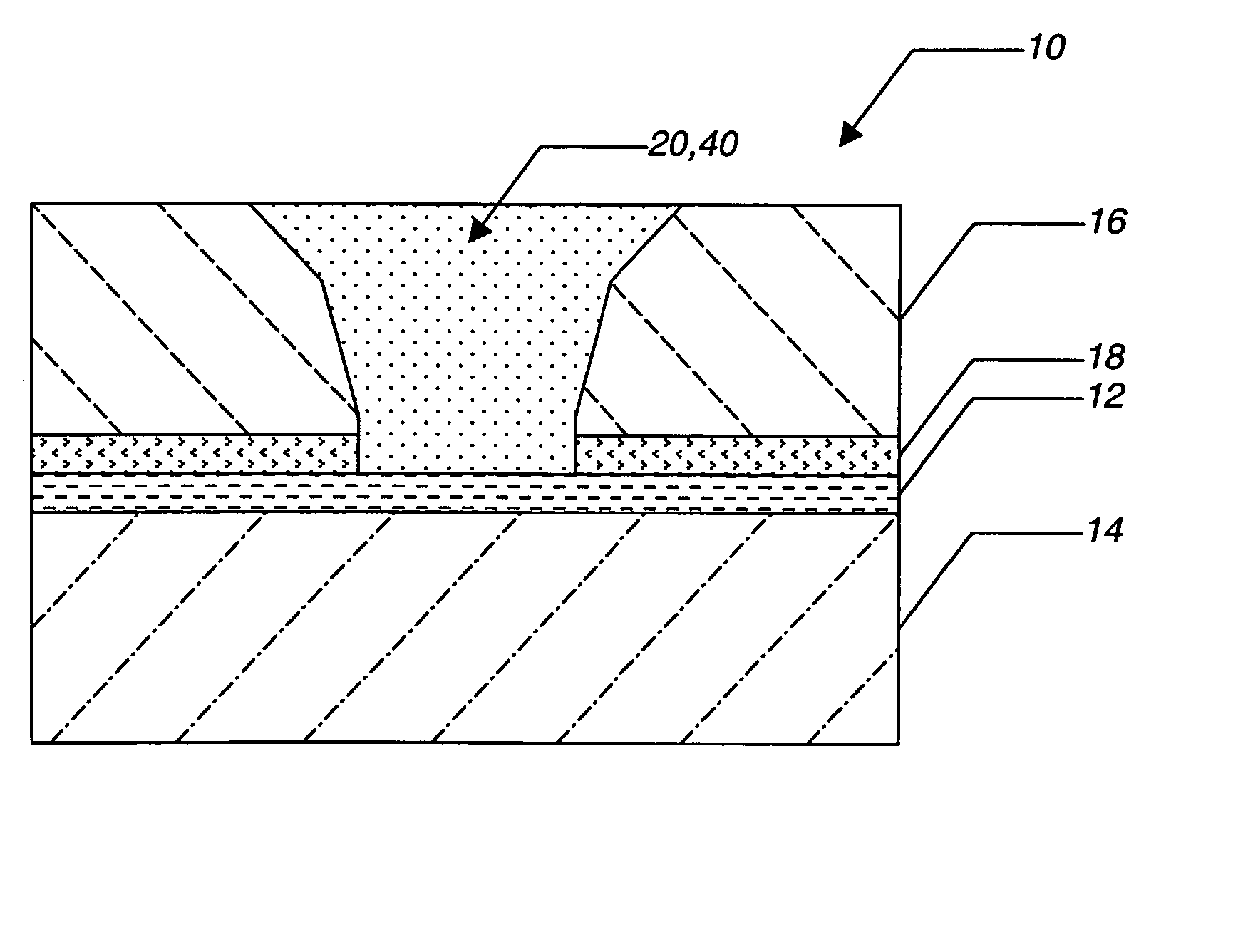

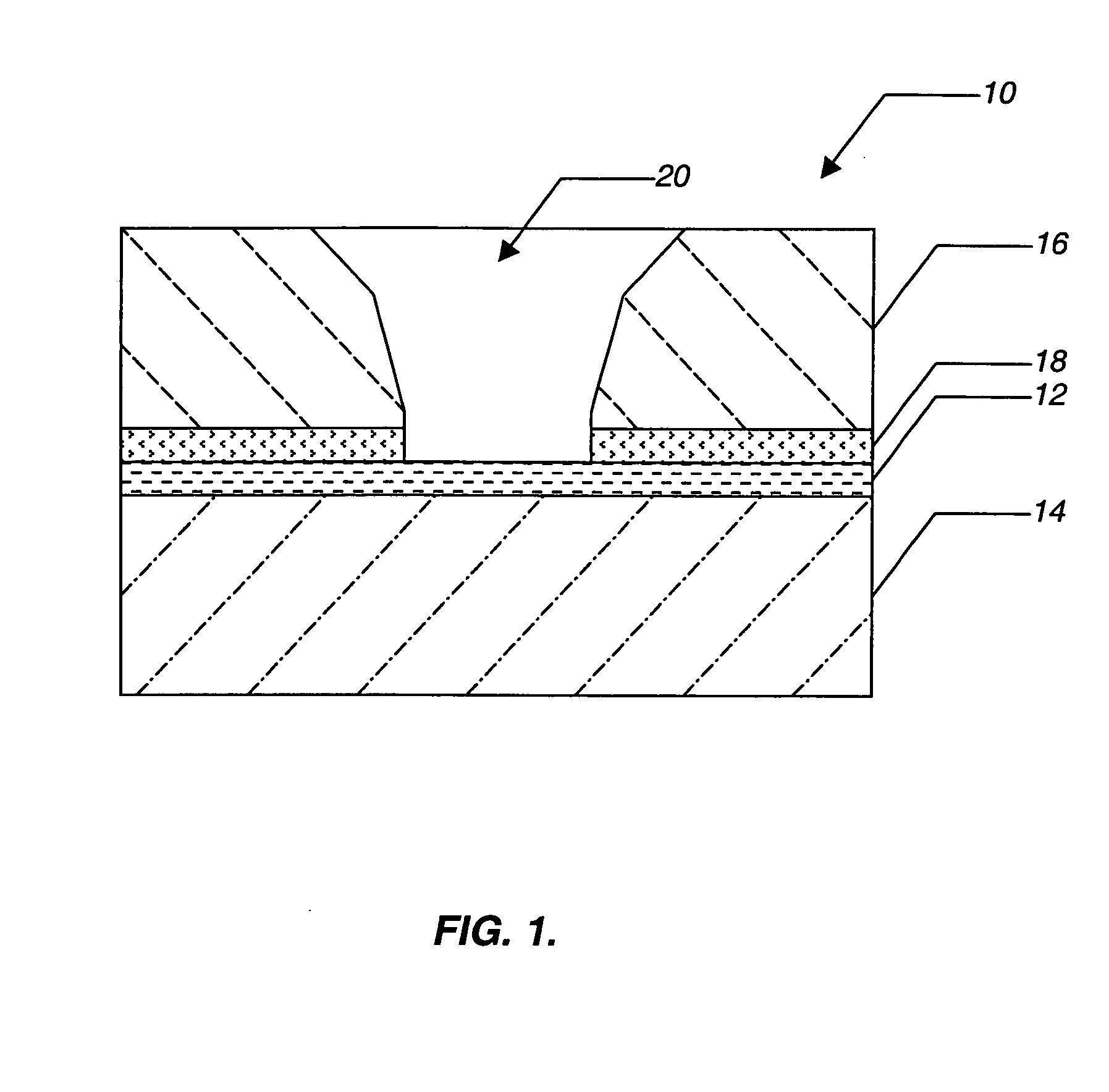

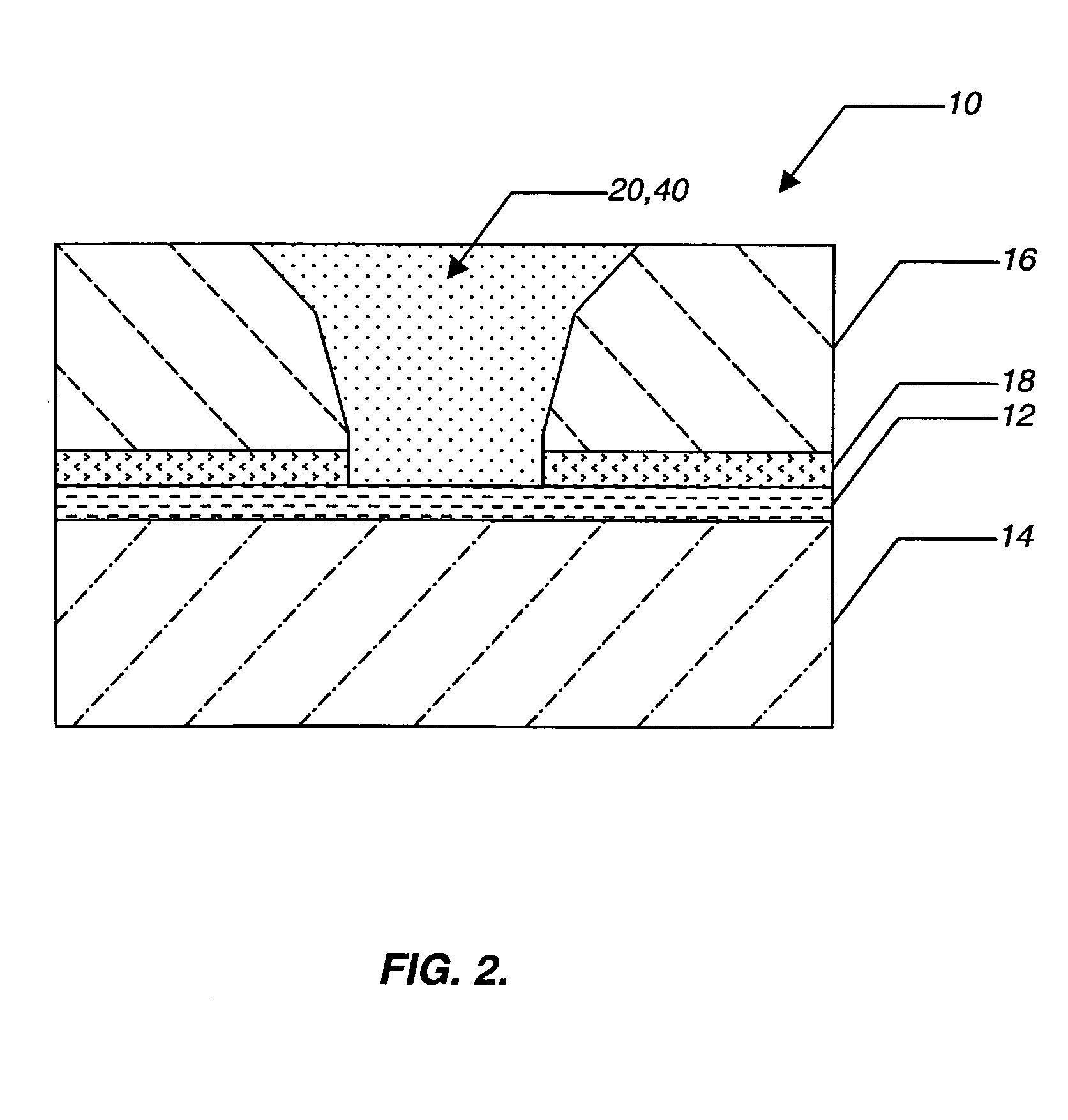

In-situ method and composition for repairing a thermal barrier coating

InactiveUS6875464B2Reduce disassemblyMolten spray coatingEngine manufactureMetallurgyThermal barrier coating

An in-situ method for repairing a thermal barrier coating deposited on a component that has suffered localized spallation including depositing a ceramic paste on a surface area of the component exposed by the localized spallation, the ceramic paste including a ceramic material in a binder material, the ceramic material including solid zirconia particles, the binder material including a silicone compound. The method also including heating the binder material to yield a repair coating that covers the surface area of the component, the silicone compound promoting the bonding of the solid zirconia particles.

Owner:GENERAL ELECTRIC CO

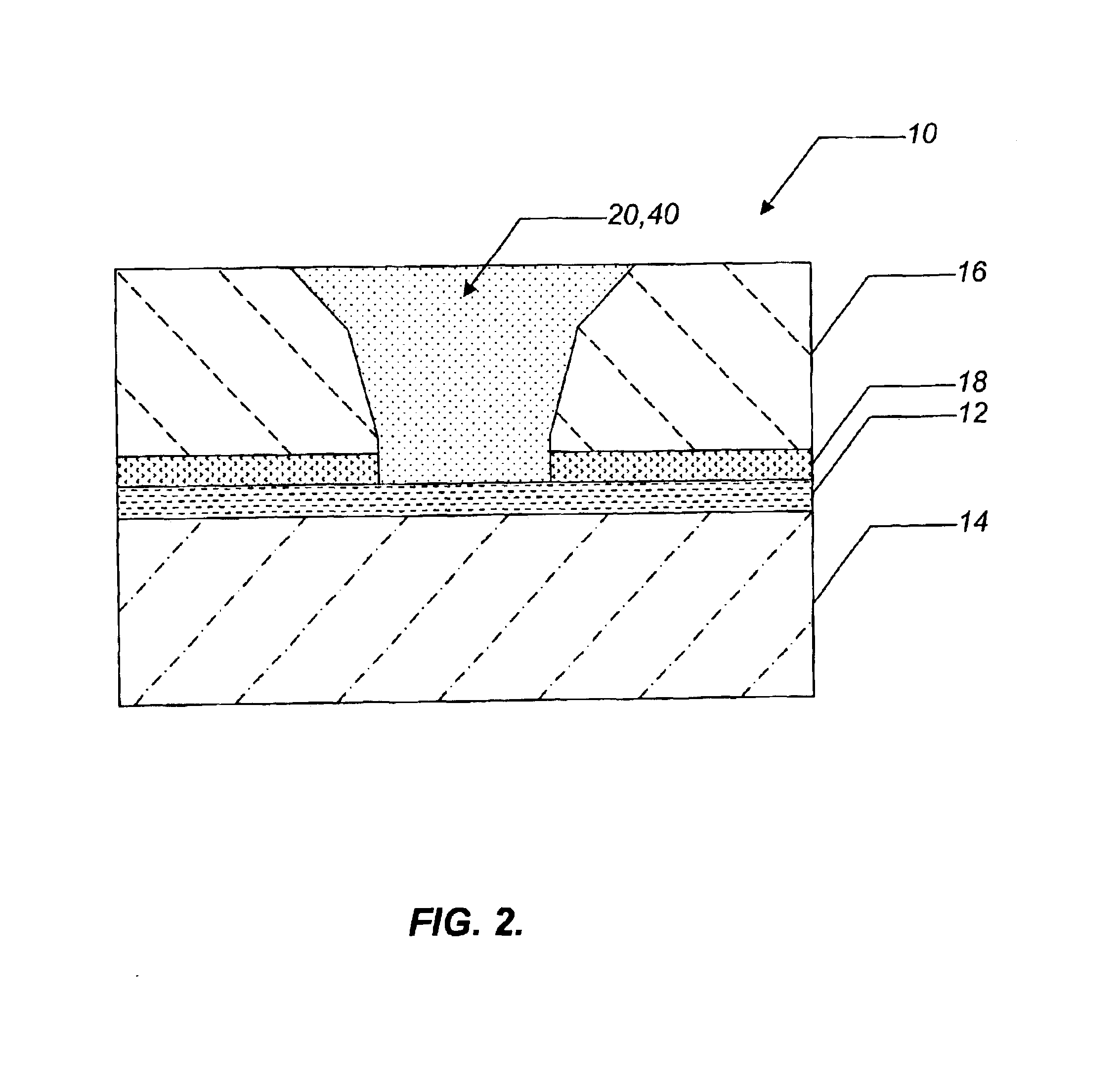

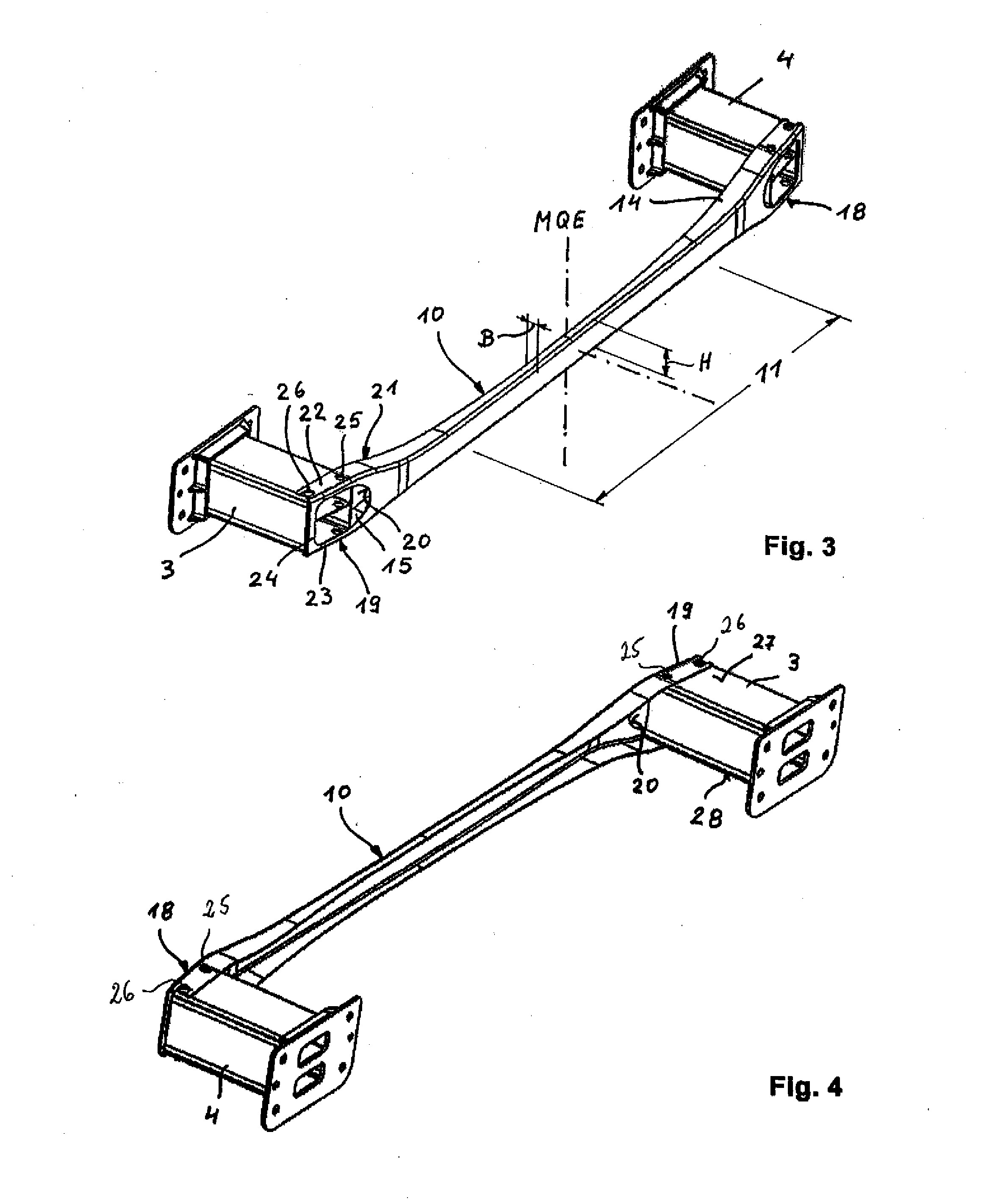

Bumper for a motor vehicle

A bumper for a motor vehicle includes a cross member which is disposed transversely to side rails of a motor vehicle frame and connected to the side rails via crash boxes. The cross member has a C-shaped cross section and includes an outer shell member and an inner shell member. The inner shell member is constructed as tension link which is made of a material having a tensile strength that is greater than the tensile strength of a material of the outer shell member.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

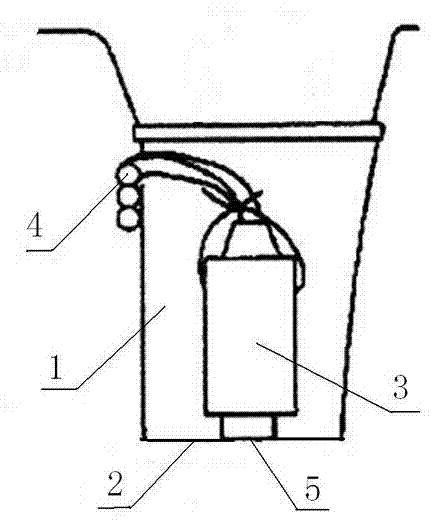

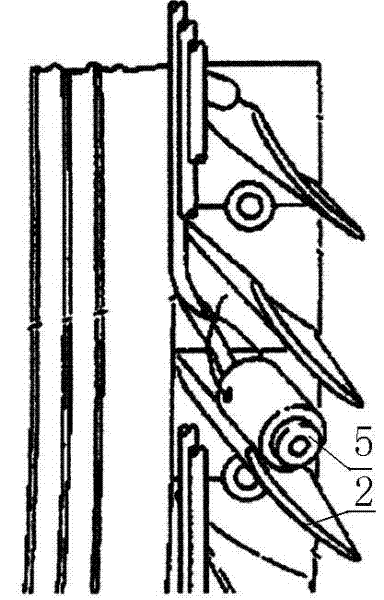

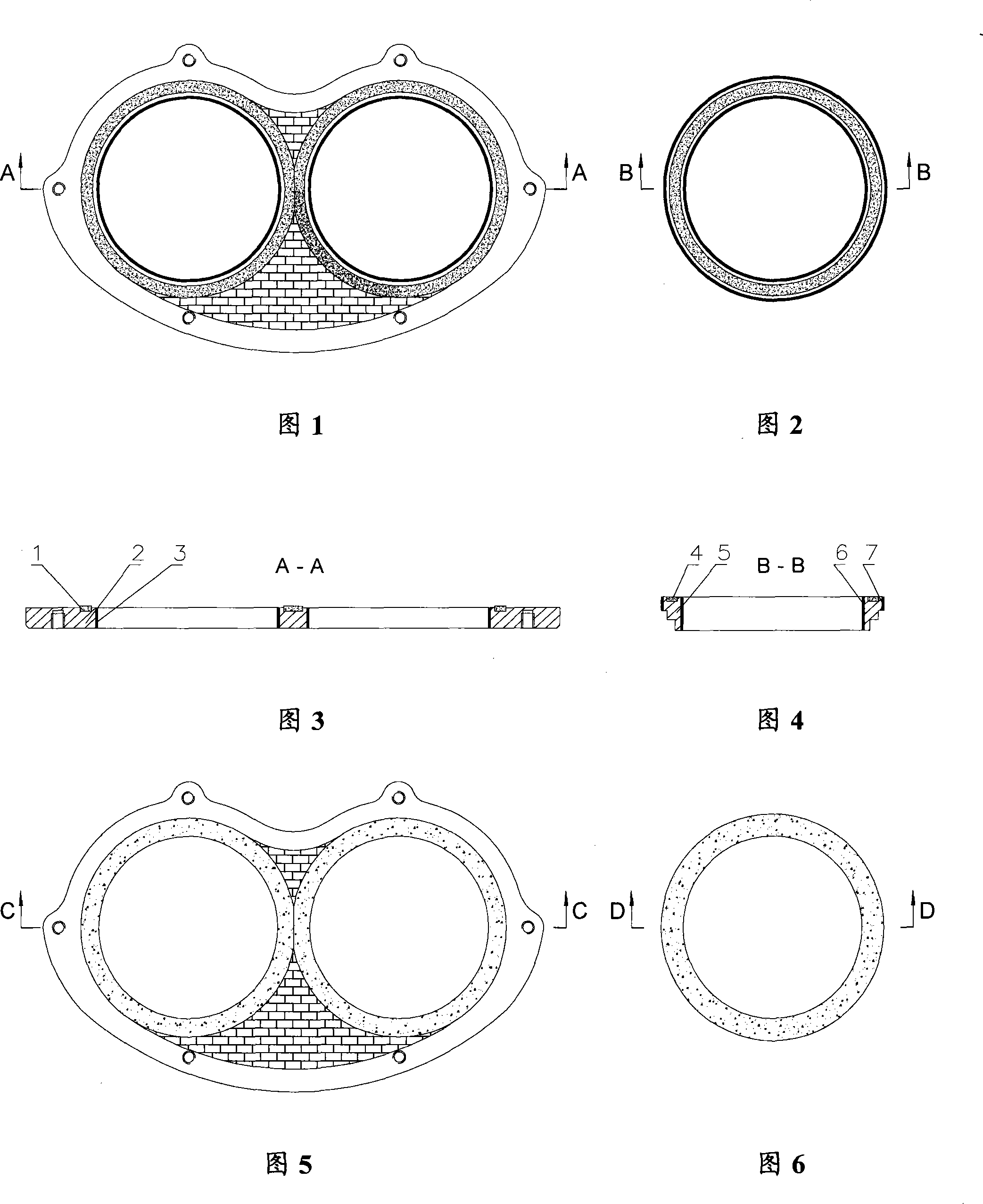

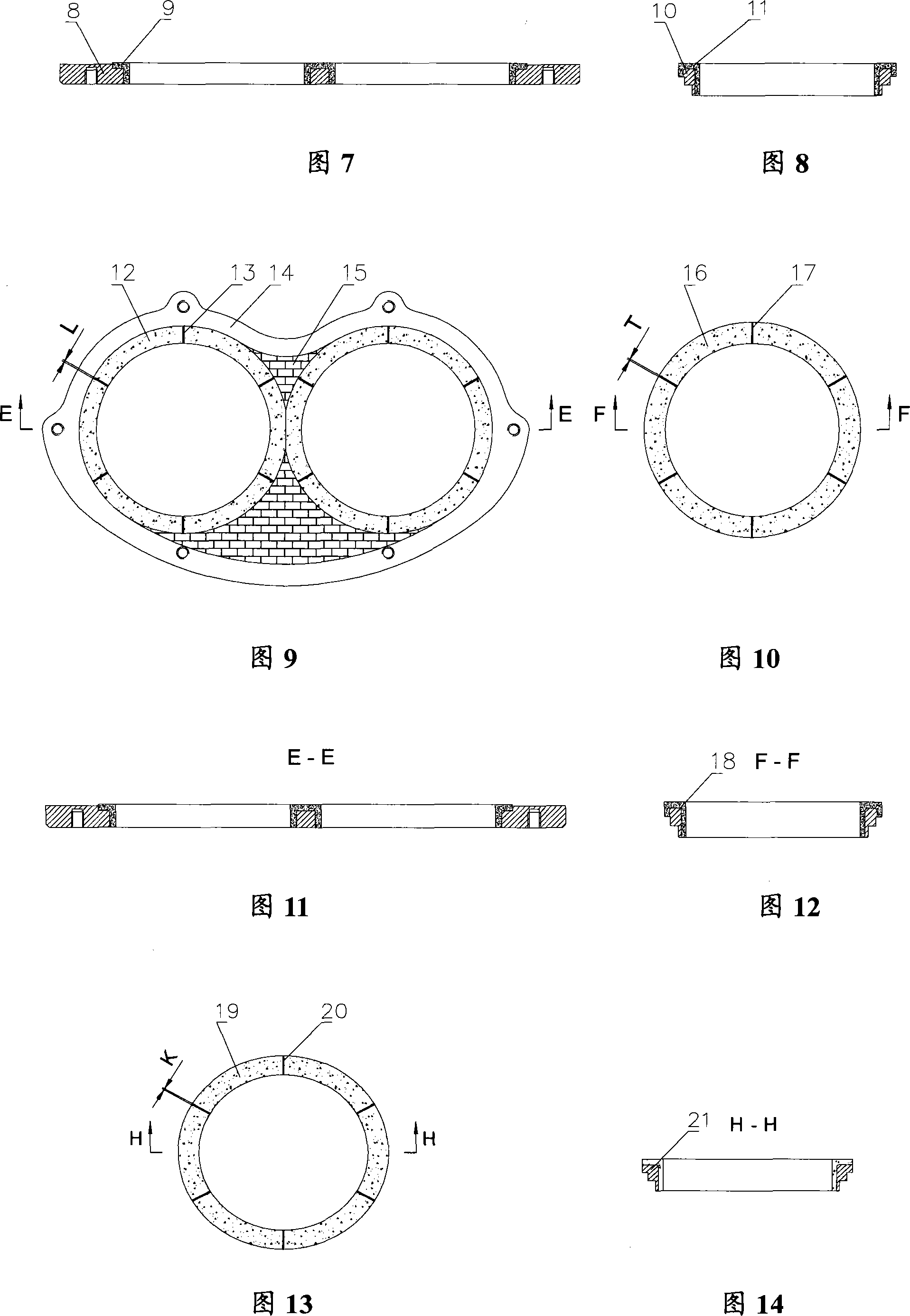

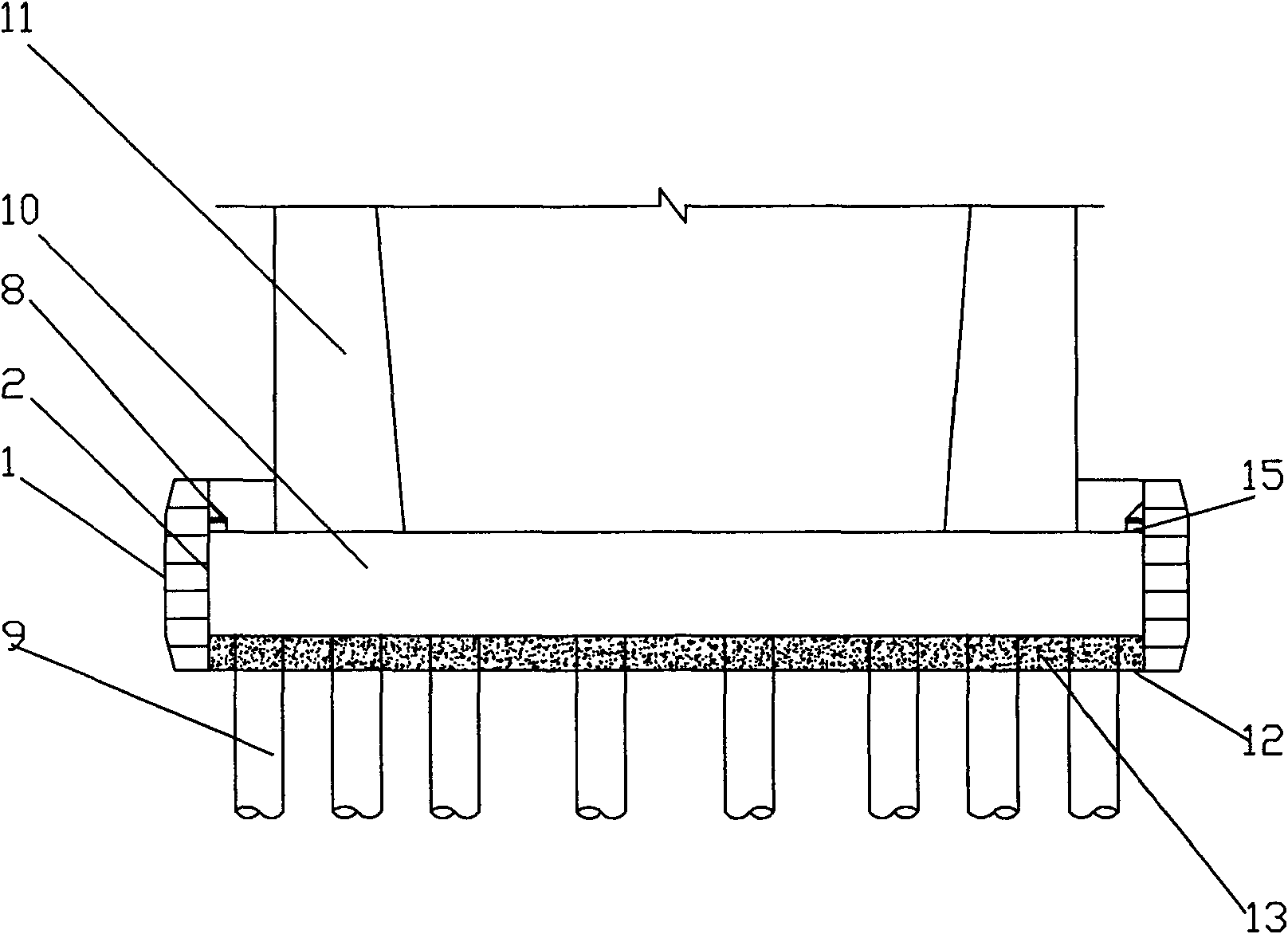

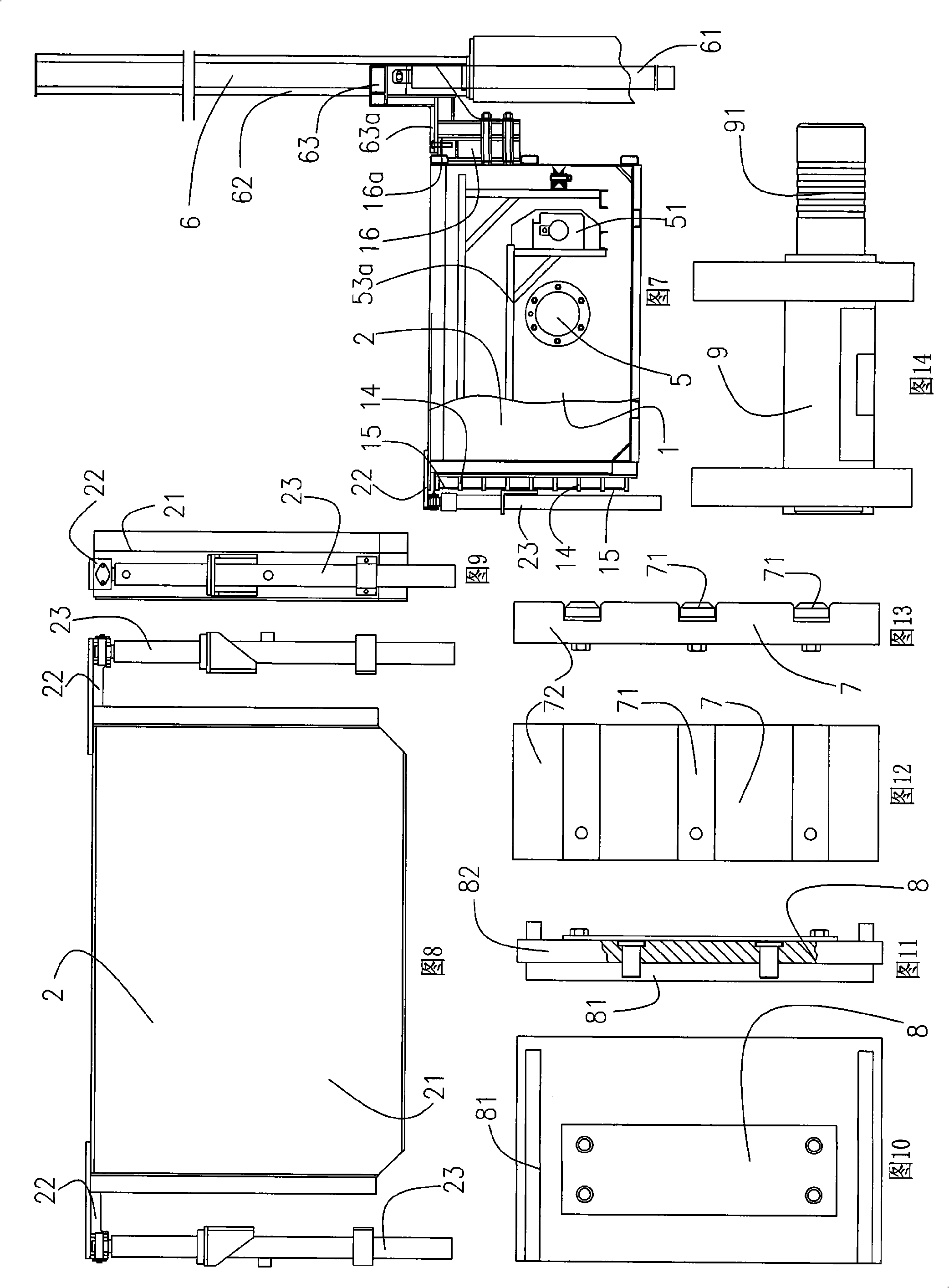

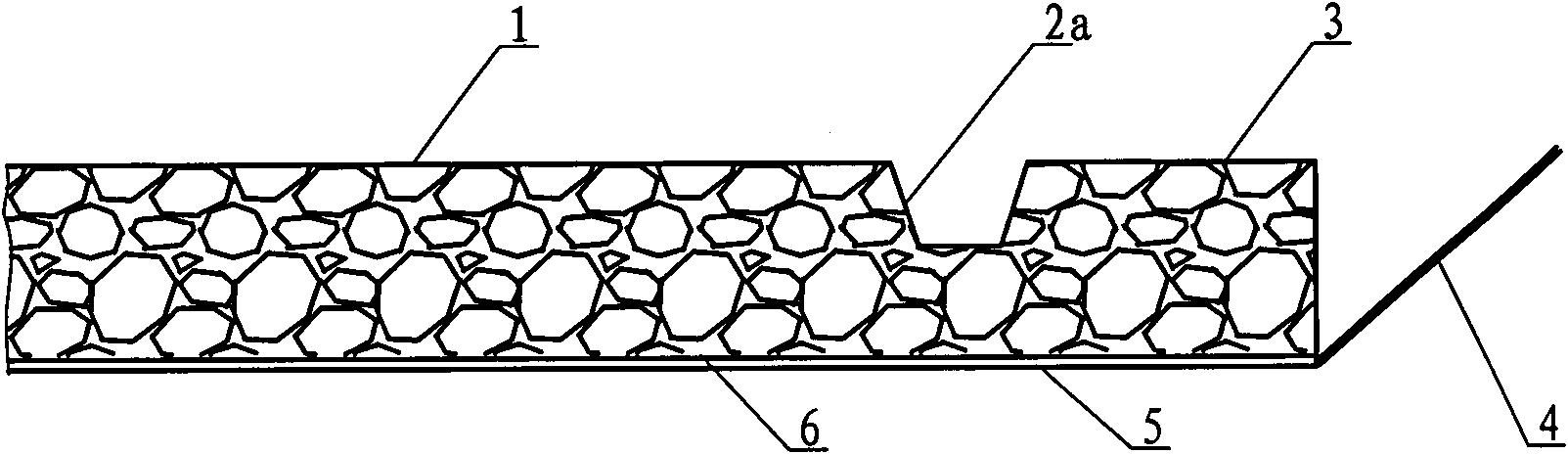

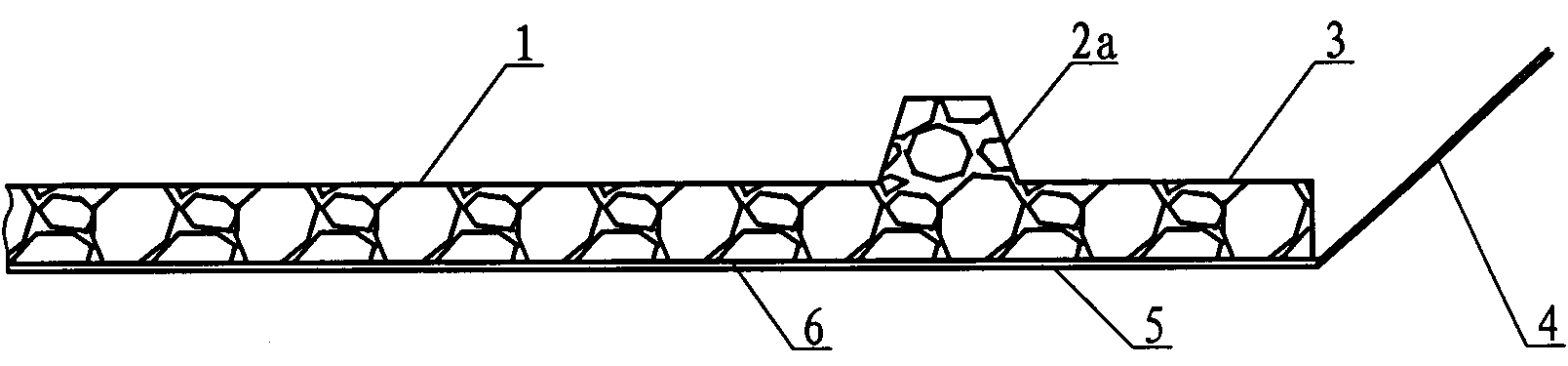

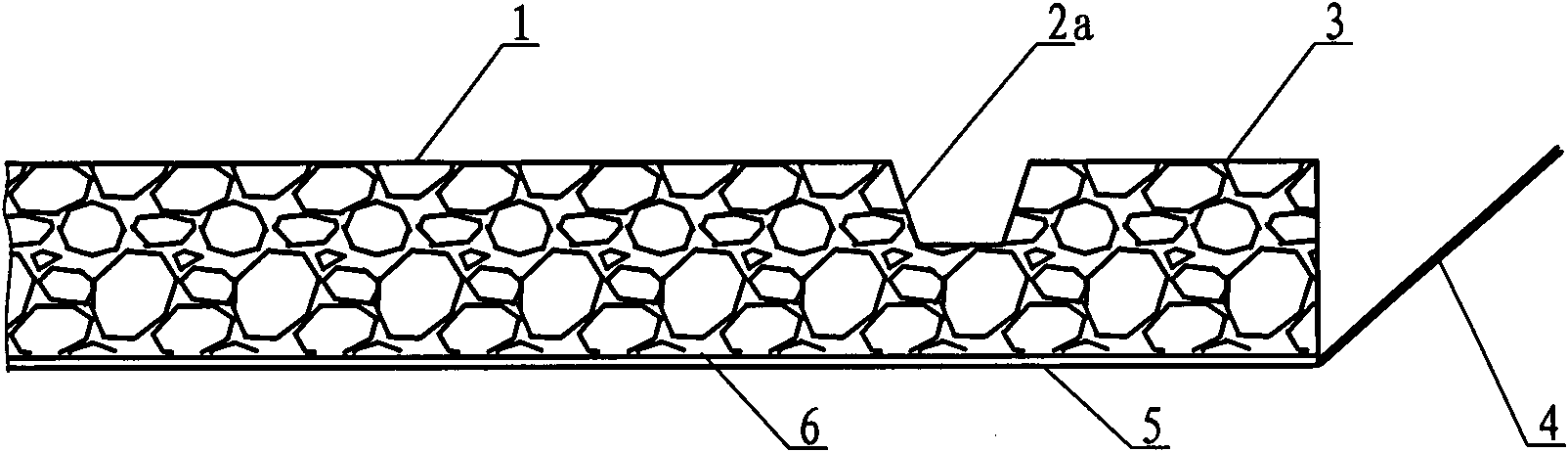

Glasses plate and cutting ring for concrete delivery pump

InactiveCN101158347ALarge coverage areaAvoid crackingPositive displacement pump componentsPumpsAlloyWear resistance

The invention discloses glasses plate and a cutting ring used for a concrete delivery pump, comprising a base and a hard alloy ring arranged on the cutting surface of the base; the hard alloy ring radially consists of a plurality of hard alloy blocked; the internal edge of the hard alloy block is folded and extends into a material delivery hole along the internal wall of the material delivery hole which is arranged on the base; a hard alloy cirque attached to the internal wall of the material delivery hole is assembled in the material delivery hole of the base; a linear spacing is reserved between adjacent hard alloy blocks in the material delivery hole at the cutting surface; the hard alloy blocks and the adjacent surfaces of the base are welded together; the linear spacing between adjacent hard alloy blocks are filled with welding flux. The glasses plate and cutting ring has good anti-wear and anti-shock performance and long service life.

Owner:SANY HEAVY IND CO LTD (CN)

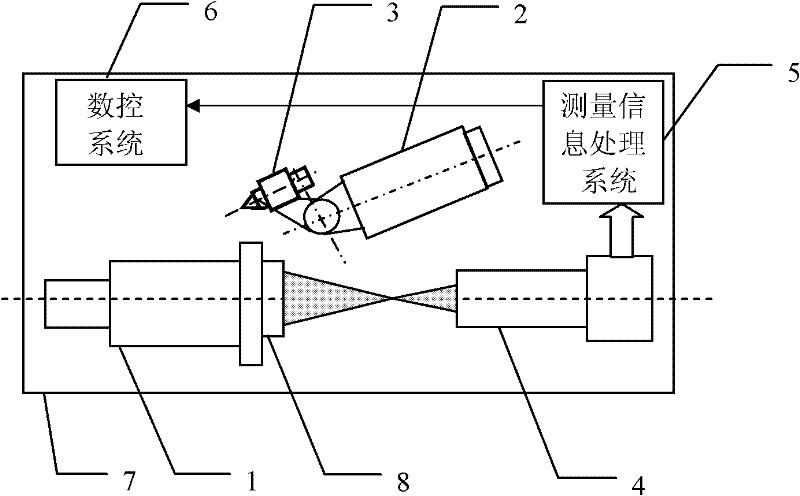

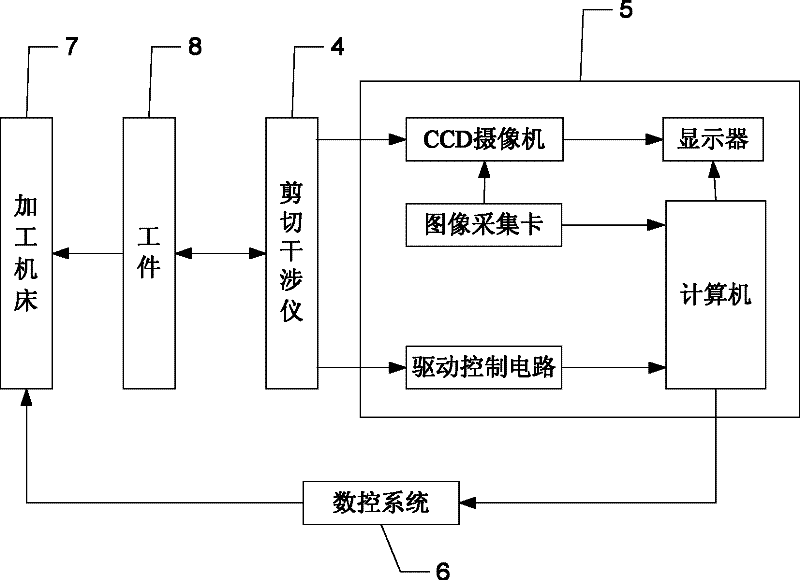

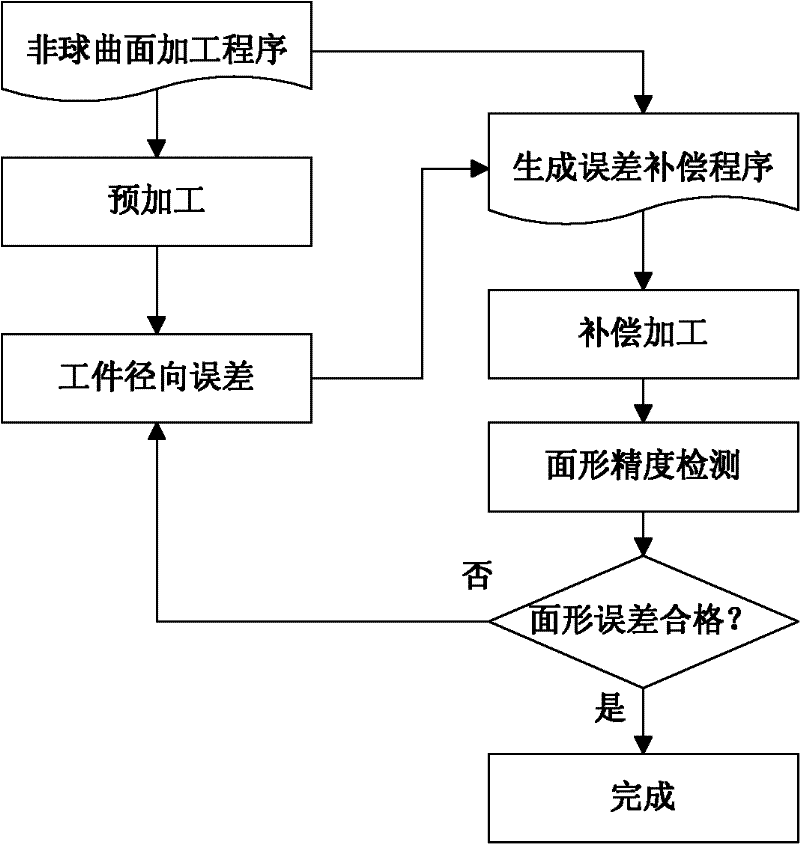

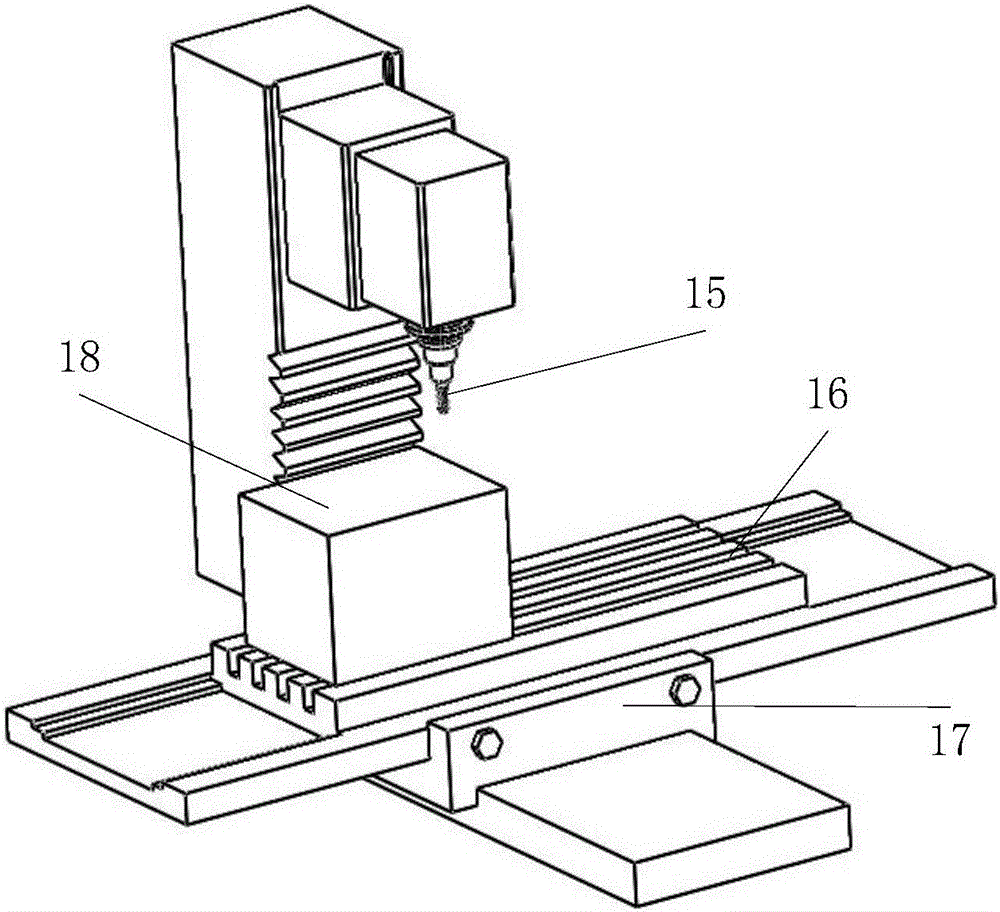

Device and method for integrally machining and measuring optical parts

ActiveCN102303224AReduce intermediate linksRealize feedback compensation machiningMeasurement/indication equipmentsNumerical controlInformation processingOptical axis

The invention relates to a device and method for integrally machining and measuring optical parts, belonging to the field of optical part machining. The invention aims at solving the problems that: an off-line measuring manner is mostly adopted in the traditional optical part machining, thus the machining efficiency is low; and the traditional optical part machining equipment cannot satisfy with the requirement of online measuring. According to the invention, a workpiece main shaft, a cutting tool main shaft and a shearing interferometer are mounted on a worktable surface of a machining machine; a workpiece is mounted on the workpiece main shaft; a cutting tool is mounted on the cutting tool main shaft through an oscillating arm and a tool carrier; a numerical control system is used for driving the cutting tool main shaft to rotate and driving the cutting tool to machine the workpiece; the optical axis of a measuring light beam which is emitted by the shearing interferometer and the central line of the workpiece main shaft are the same straight line; the shearing interferometer is used for emitting the measuring light beam to the workpiece; the shearing interferometer is used for acquiring image information which is returned by the measuring light beam and is used for sending the image information to a measured information processing system; the measured information processingsystem is used for acquiring surface error information of the surface of the workpiece according to the image information and is used for sending the information to the numerical control system; and the numerical control system is used for carrying out compensation machining on the workpiece.

Owner:HARBIN INST OF TECH

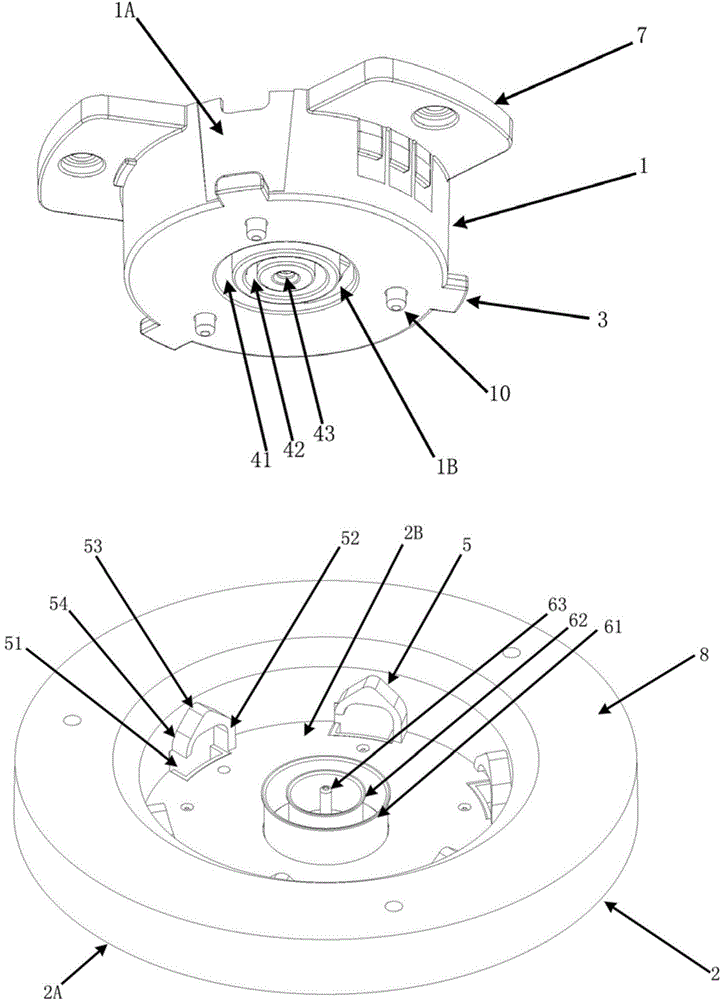

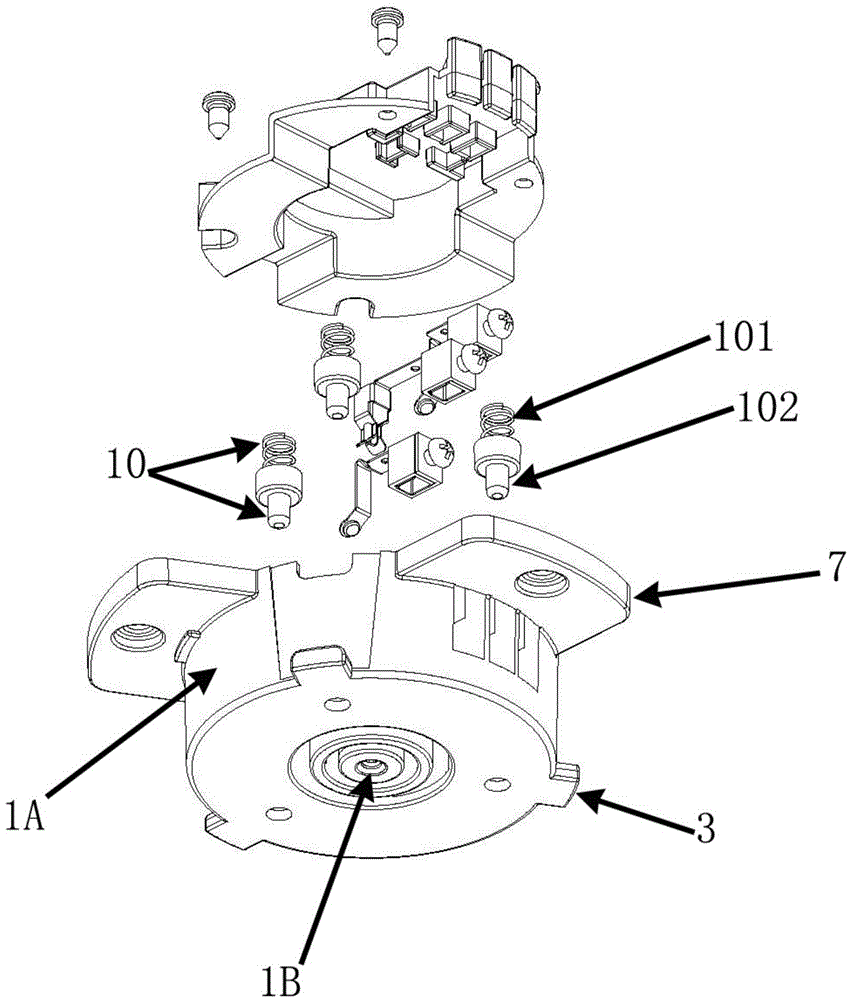

Lamp fixing base, lamp connecting base and lamp fixing device

ActiveCN104456446AQuick installationEasy to installLighting support devicesElectric circuit arrangementsElastic componentDevice form

The invention provided a lamp fixing base. The lamp fixing base is provided with a first body part, wherein a first combining part is arranged on the outer side of the bottom end face of the first body part, an inwards-concave first containing cavity is formed in the middle of the bottom end face of the first body part, and a first electrical connecting part is arranged in the first containing cavity; the fixing base is further provided with an elastic component. The invention further provides a lamp connecting base. The lamp connecting base is provided with a second body part, a second containing cavity used for containing the first body part of the fixing base is formed in the second body part, a second combining part is arranged on the inner wall of the second containing cavity, and a second electrical connecting part is arranged in the middle of the second containing cavity. The invention further provides a lamp fixing device formed by the lamp fixing base and the lamp connecting base. Due to the lamp fixing base, the lamp connecting base and the lamp fixing device, a lamp can be fast installed and detached by an operator, use is easy, and maintenance is convenient.

Owner:OPPLE LIGHTING

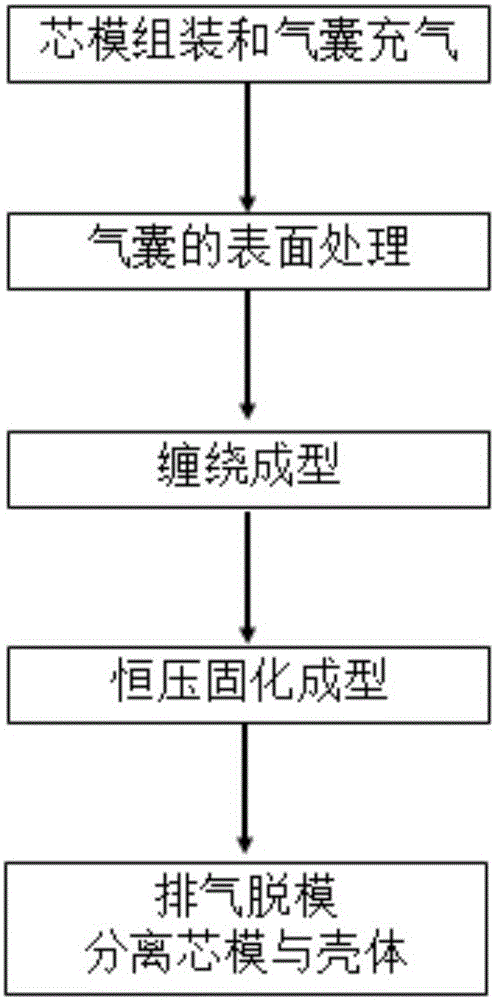

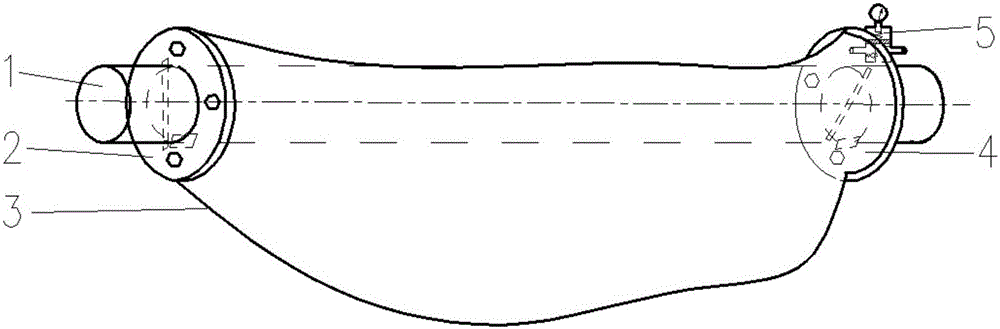

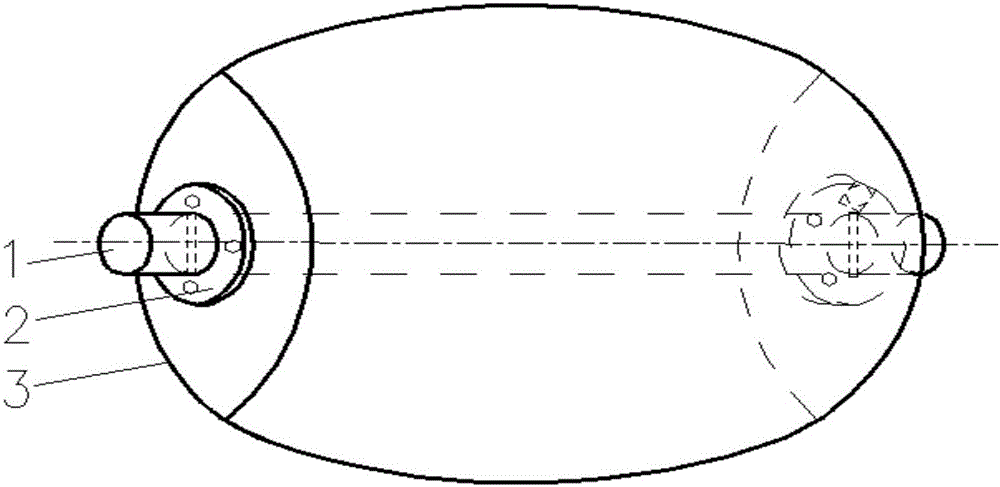

Winding molding method of all-composite material shells

The invention discloses a winding molding method of all-composite material shells, belongs to the technical field of molding process, and relates to the winding molding method of the all-composite material shells. The winding molding method comprises the steps: firstly, assembling a core mold, and filling a gas bag with light gas; next, carrying out surface treatment of the gas bag; then adopting the winding molding control program to control a winding machine to wind the outer surface of the gas bag with fiber bundles or cloth belts according to the program, and curing and molding according to temperature and time requirements required for molding; and finally, obtaining the composite material shells through a demolding process. The winding molding method has wide applicability, and can be used for manufacturing the composite material shells with different shapes and sizes and meeting a requirement of asymmetric front and back sealing surfaces. The process has good stability, equipment is simple and convenient, low in weight and strong in controllability, and the method is simple, practical, and easy to operate and popularize. Workers are prevented from entering the interior of the core mold for operation, the complex assembly and disassembly processes in a traditional winding process are greatly reduced, the difficulty of production operation is reduced, and the production efficiency is improved.

Owner:DALIAN UNIV OF TECH

Technology for constructing anti-collision bridge pier by steel cofferdam

InactiveCN101649621AGood energy absorptionSimplify the construction processBridge structural detailsFoundation engineeringWater blockEnergy absorption

The invention discloses a technology for constructing an anti-collision bridge pier by a steel cofferdam. The upper part of a pile steel protection cylinder is provided with a horizontal fixed bottomplate; a prefabricated anti-collision steel cofferdam is erected on the bottom plate, and the top of the anti-collision steel cofferdam is higher than the water surface; sealed foundation concrete ispoured on the bottom plate, water in the anti-collision steel cofferdam is pumped, the anti-collision steel cofferdam has double functions and integrates the water blocking function of a conventionalsteel cofferdam and the anti-collision function of a bridge pier permanent, and an inner layer is used as a template for pouring a support platform on the sealed foundation concrete; a bridge pier ora pylon is poured on the support platform; and the invention adopts an anti-collision steel cofferdam structure with a sandwich structure and has better energy absorption effect, the support platformand an internal plate of a sleeve box are directly poured into a whole after pouring is completed, the anti-collision steel cofferdam acts as an anti-collision function after construction, and the processes of disassembling and assembling the template are omitted, thereby the construction process can be simplified, the construction efficiency is enhanced, the construction period of a main body isnot occupied, the bonding strength with the bridge pier is higher, the bridge pier can not be damaged during construction and the construction quality is ensured.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

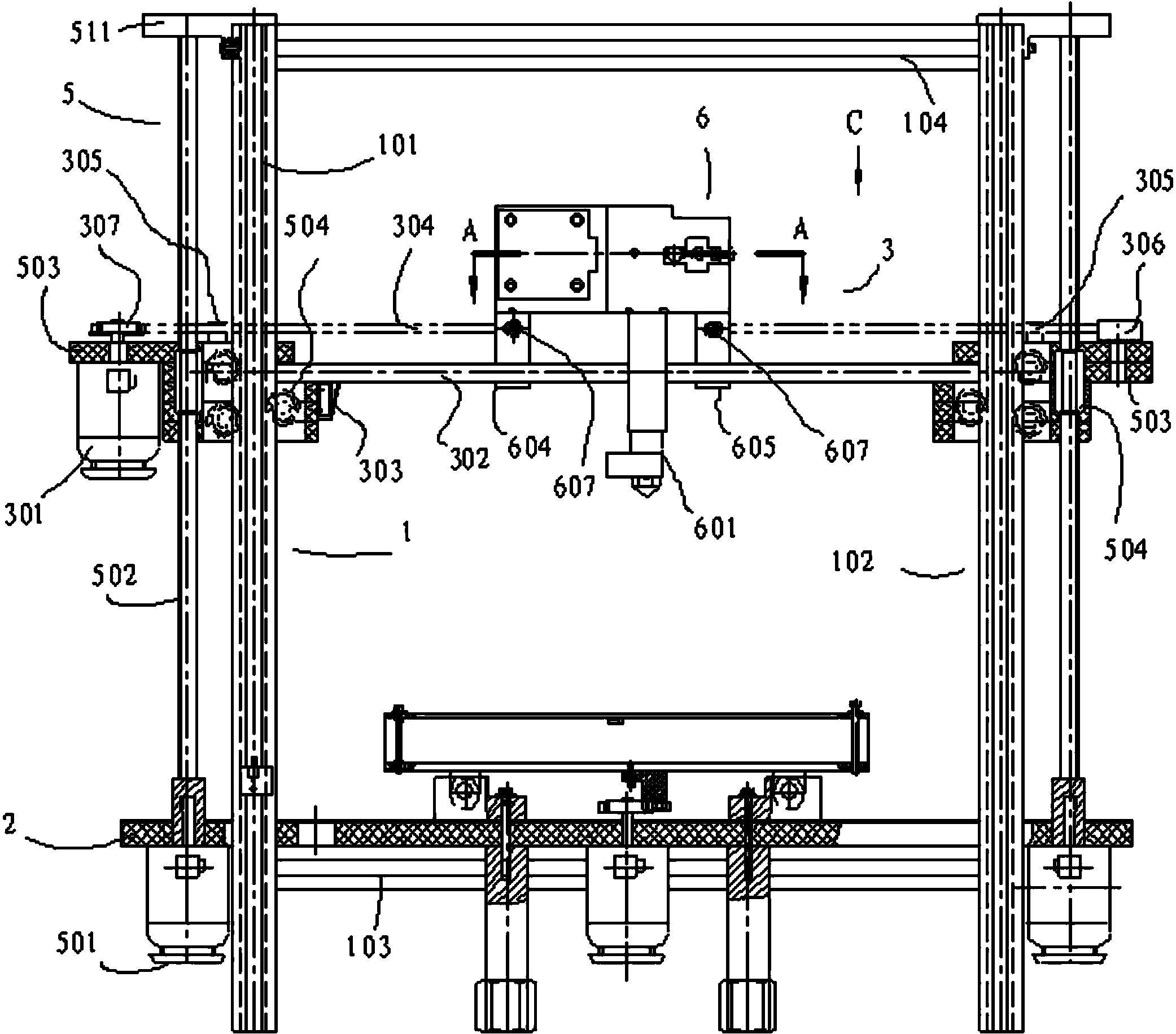

FDM (frequency-division multiplexing) 3D (three dimensional) printer

The invention discloses an FDM (frequency-division multiplexing) 3D (three dimensional) printer. The 3D printer comprises a rack and an X-axis moving system, wherein a controller is connected with the X-axis moving system and a printing device; the X-axis moving system comprises a first numerical control motor and a horizontal X-axis moving guide rail, the horizontal X-axis moving guide rail is connected with a left-side support arm and a right-side support arm, the first numerical control motor is connected with a first synchronous toothed belt, the first synchronous toothed belt is a long-strip belt, one end of the long-strip belt is connected with the left-side support arm, the other end of the long-strip belt is connected with the right-side support arm, a first groove is formed in the left-side support arm, a second groove is formed in the right-side support arm, the left end of the first synchronous toothed belt is meshed and locked with the first groove, the right end of the first synchronous toothed belt is bent inwards, tooth grooves on two sides of a bent part of the first synchronous toothed belt are correspondingly matched with a tooth top to form a gear belt overlap region, and the gear belt overlap region is matched and locked with the second groove. The FDM 3D printer is simple in structure and small in volume and low in cost.

Owner:UNIV OF JINAN

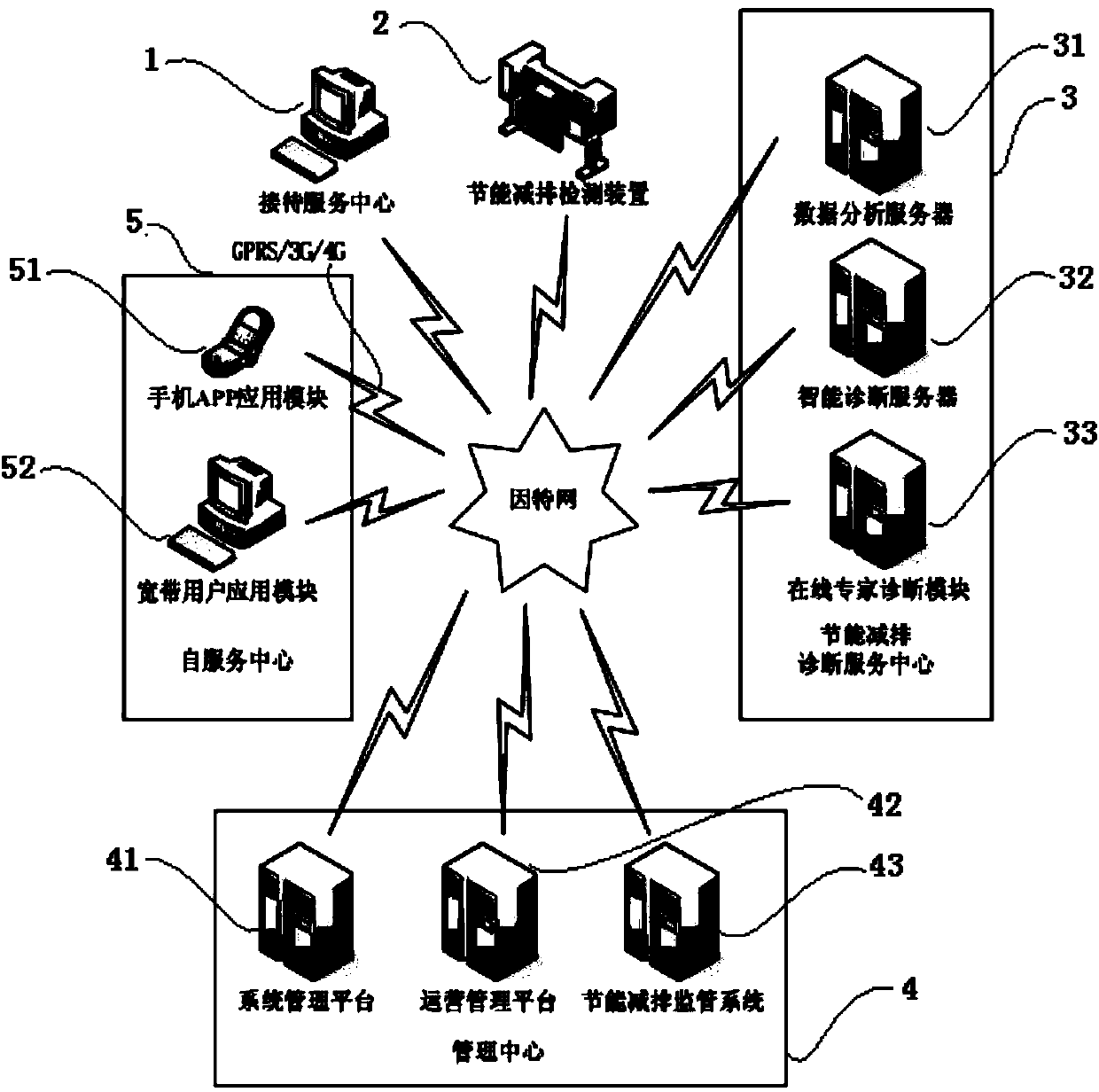

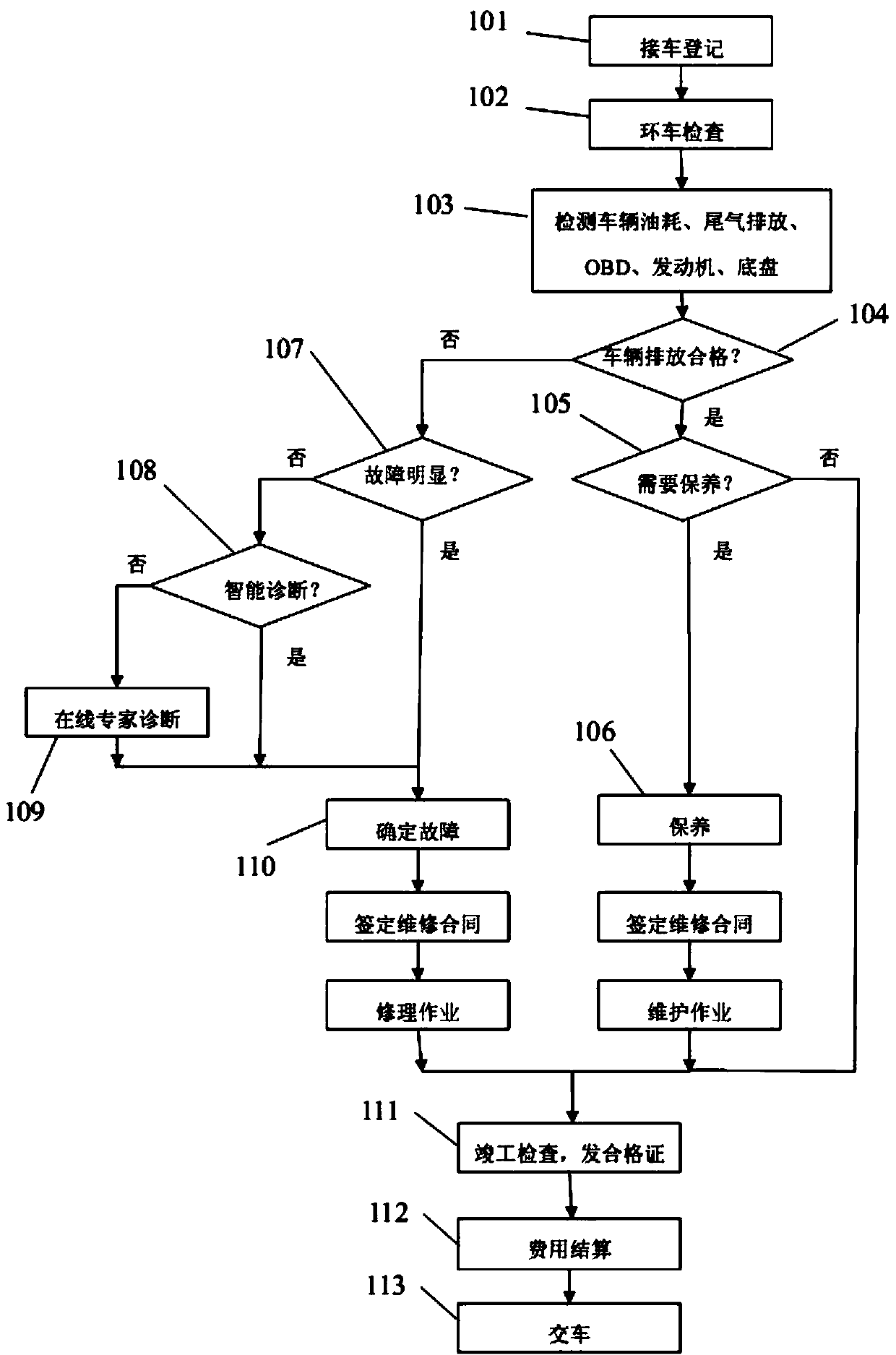

Automatic diagnosing system for energy conservation, emission reduction and repair of automobile

ActiveCN104199436APromote energy-saving technologiesReduce disassemblyElectric testing/monitoringIntelligent NetworkDiagnostic system

The invention provides an automatic diagnosing system for energy conservation, emission reduction and repair of an automobile. The system comprises an energy conservation and emission reduction detecting device, and an energy conservation and emission reduction diagnosing service center, wherein the energy conservation and emission reduction detecting device comprises an oil consumption detecting module, a tail gas emission detecting module, an OBD detecting module, an engine detecting module and a basis system detecting module, and is used for detecting energy conservation and emission reduction data comprising the oil consumption and the tail gas emission of the automobile so as to generate the detected data to be transferred to the energy conservation and emission reduction diagnosing service center to be processed; and the energy conservation and emission reduction diagnosing service center comprises a data analysis server, an intelligent diagnosis server, an on-line expert diagnosing module and an assisting server. The system can be applied to the comprehensive detection for the superscalar positions of the automobile and the intelligent network bug diagnosis, so that maintenance technicians can accurately repair and maintain in time, the unnecessary dismounting for the automobile is reduced, the energy-saving technology of the automobile is promoted, the consumption of the fuel and the discharge amount of the pollutants for the automobile are reduced, and the purposes of energy conservation and emission reduction are realized.

Owner:广西三原高新科技有限公司

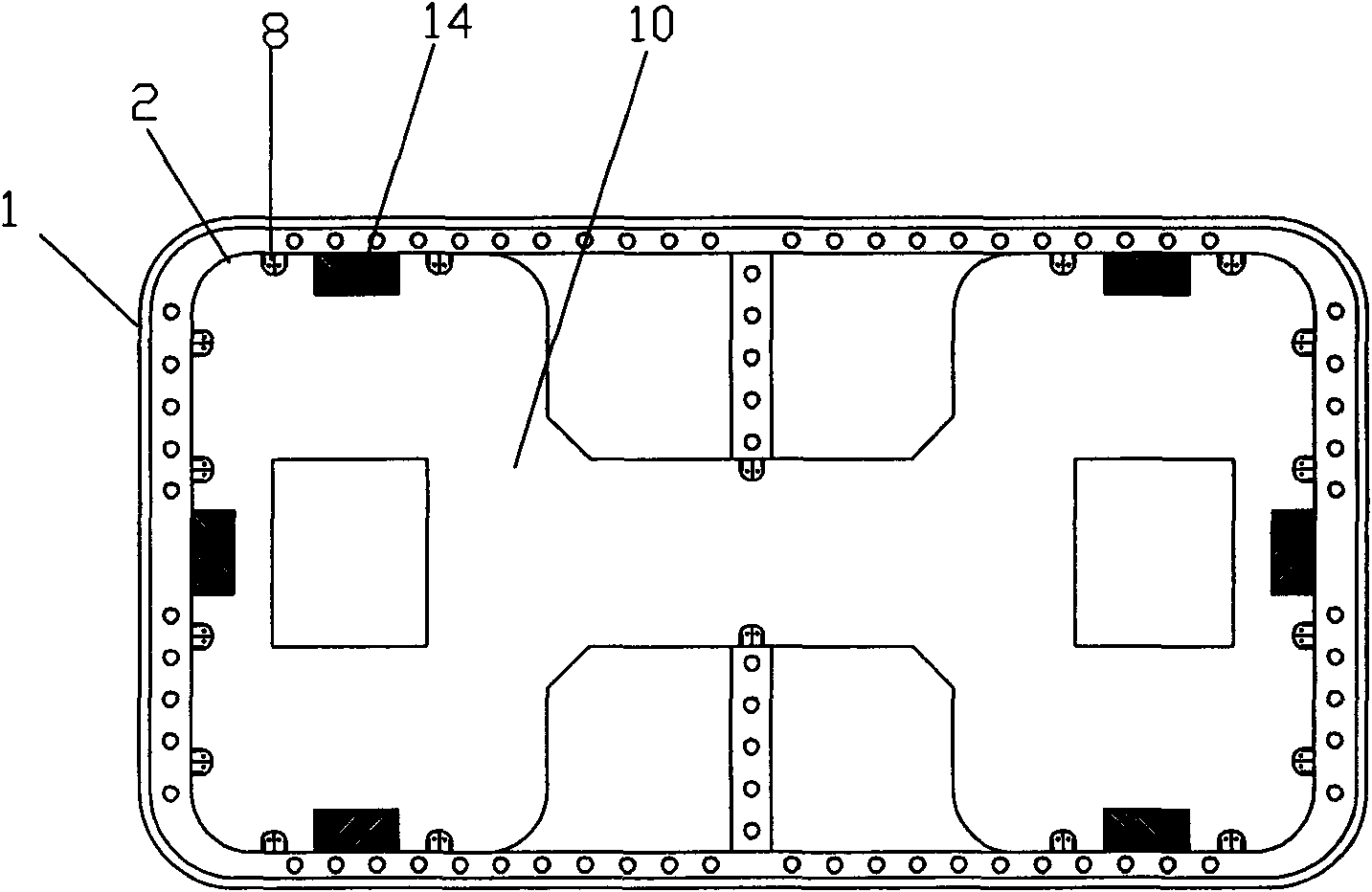

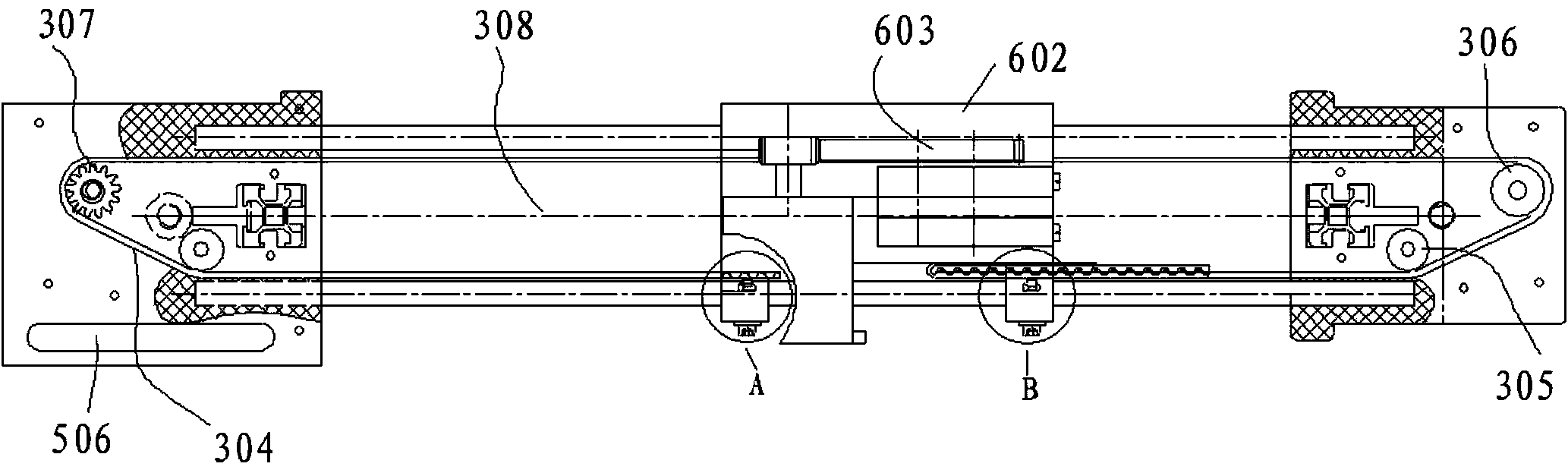

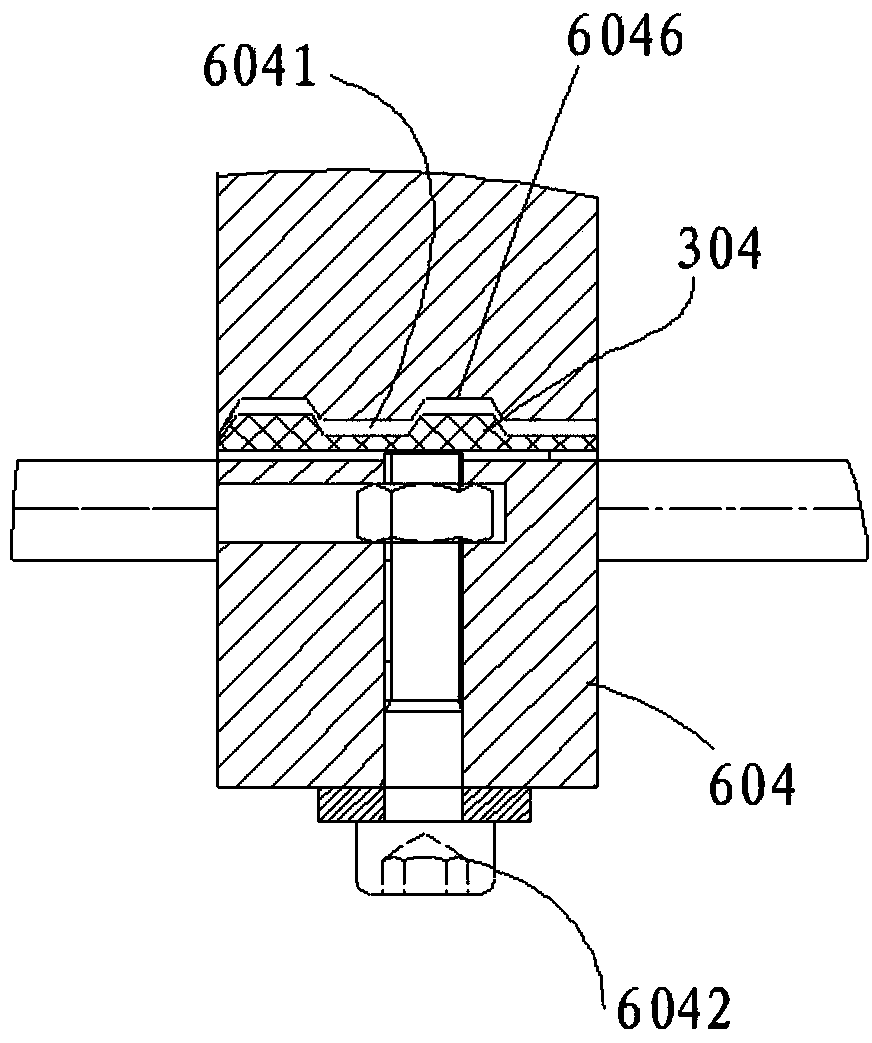

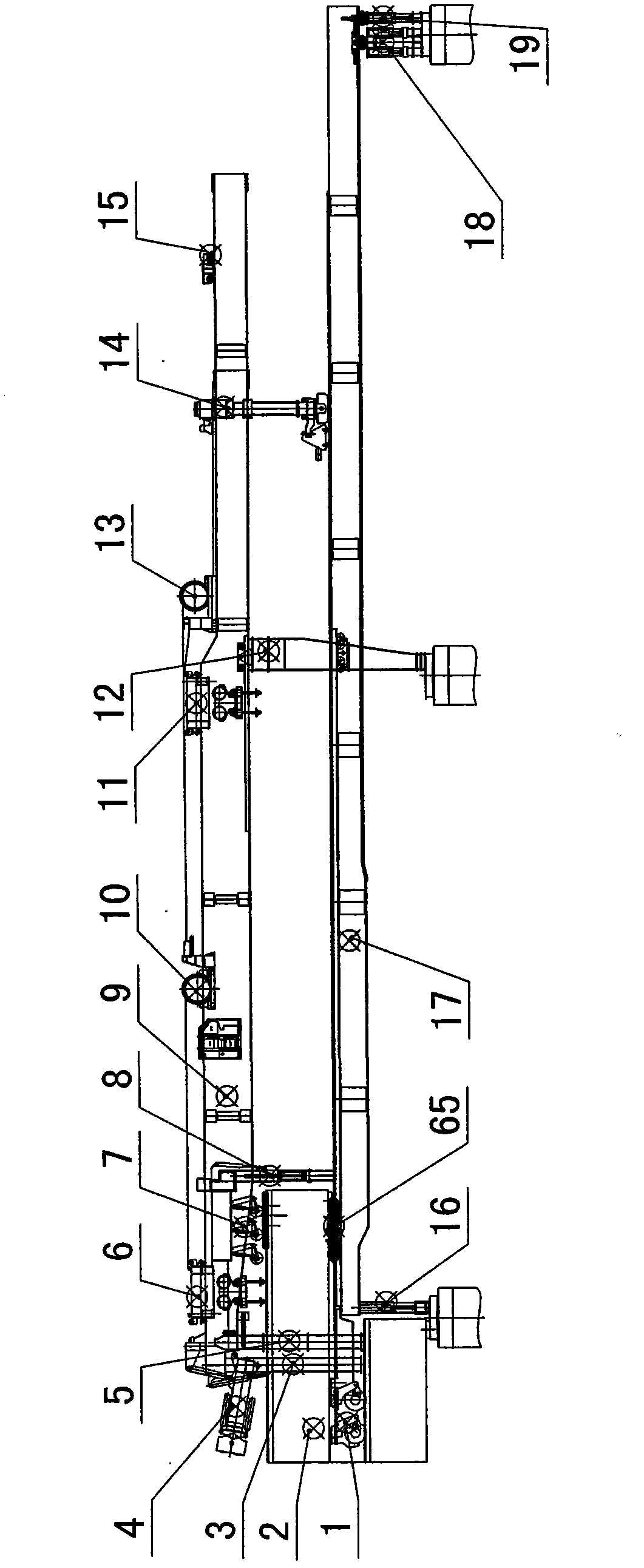

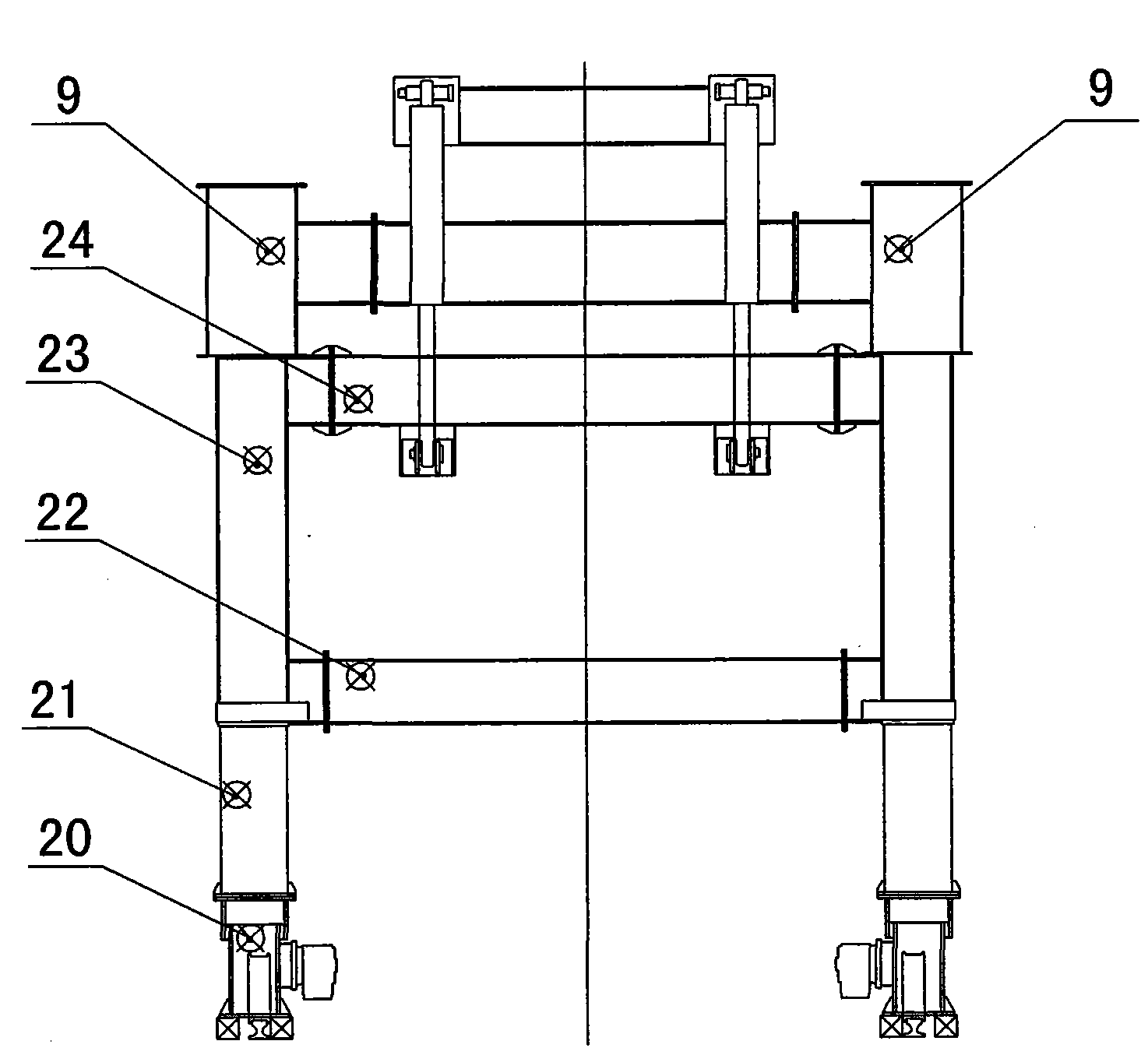

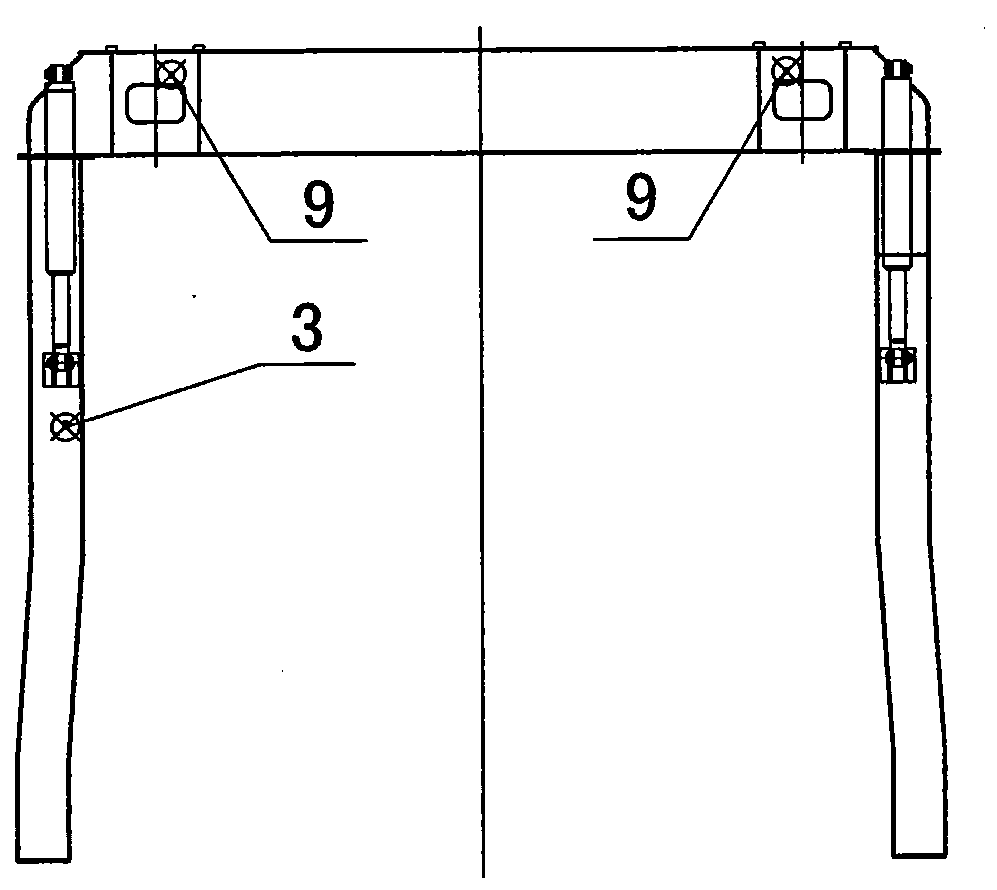

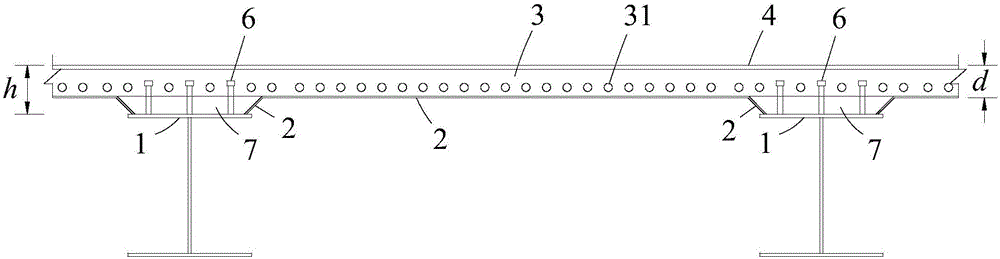

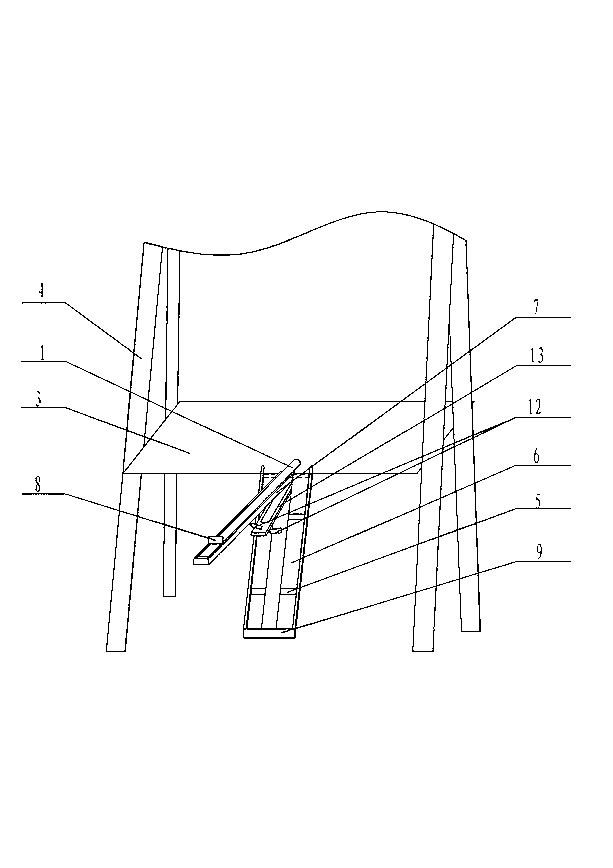

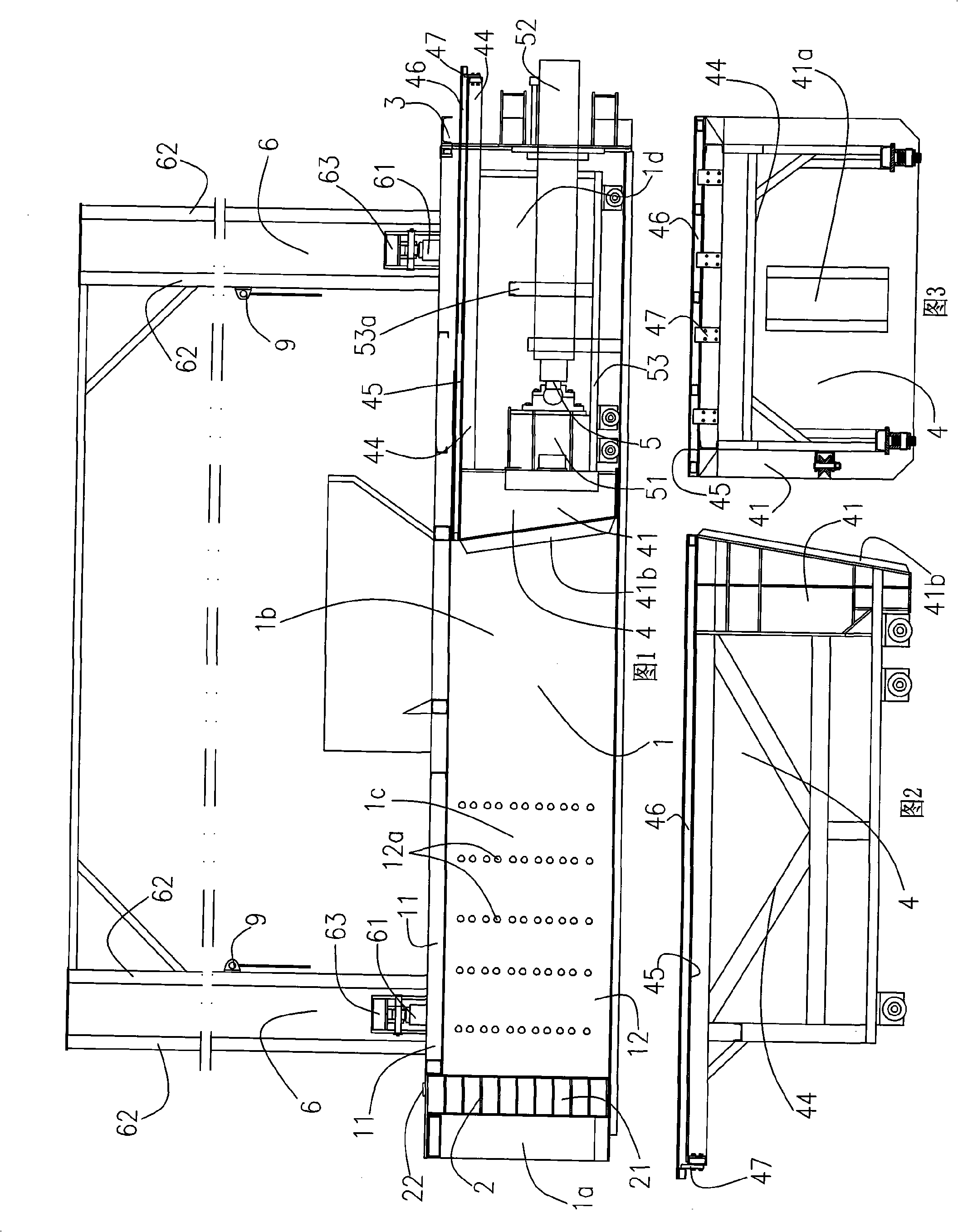

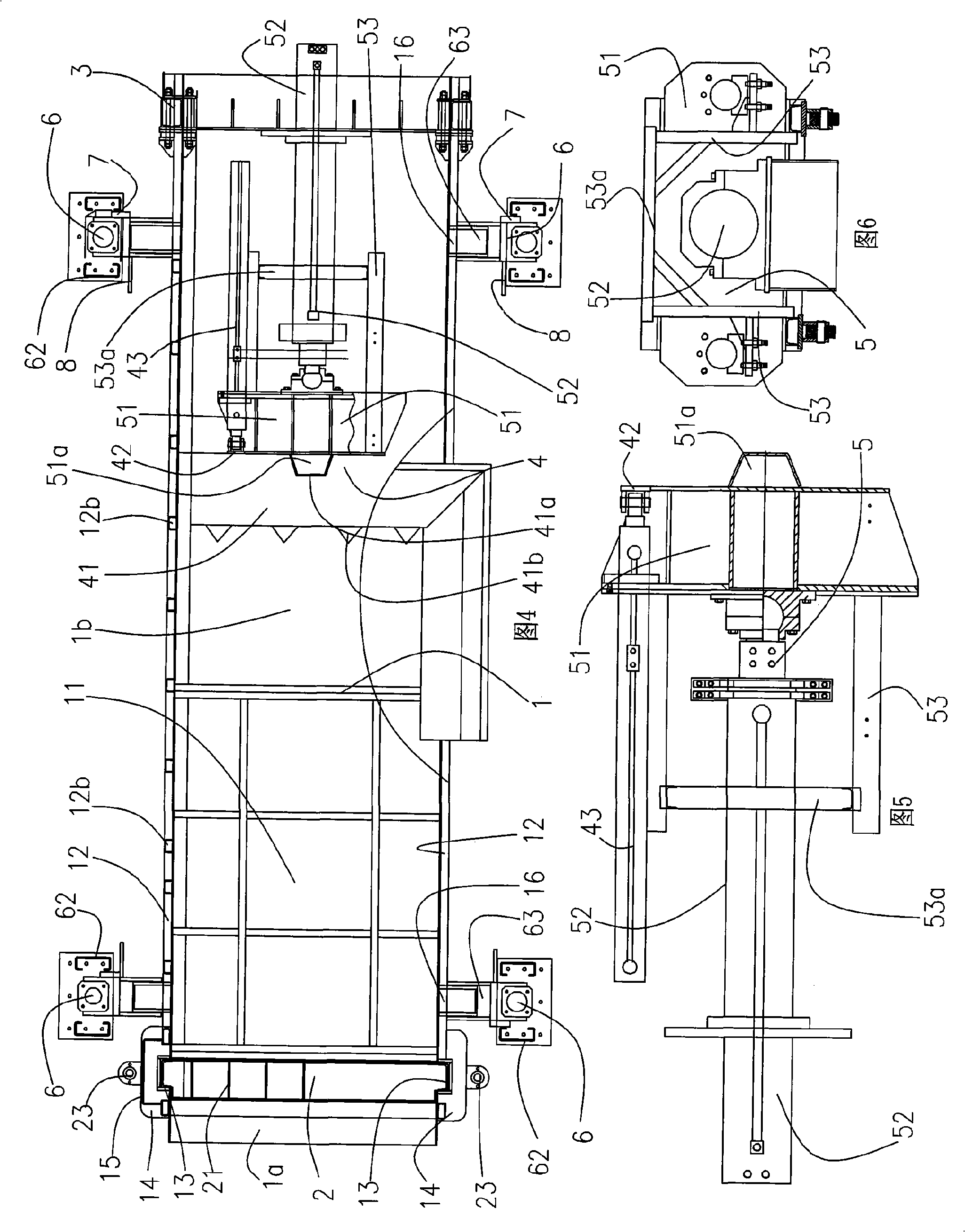

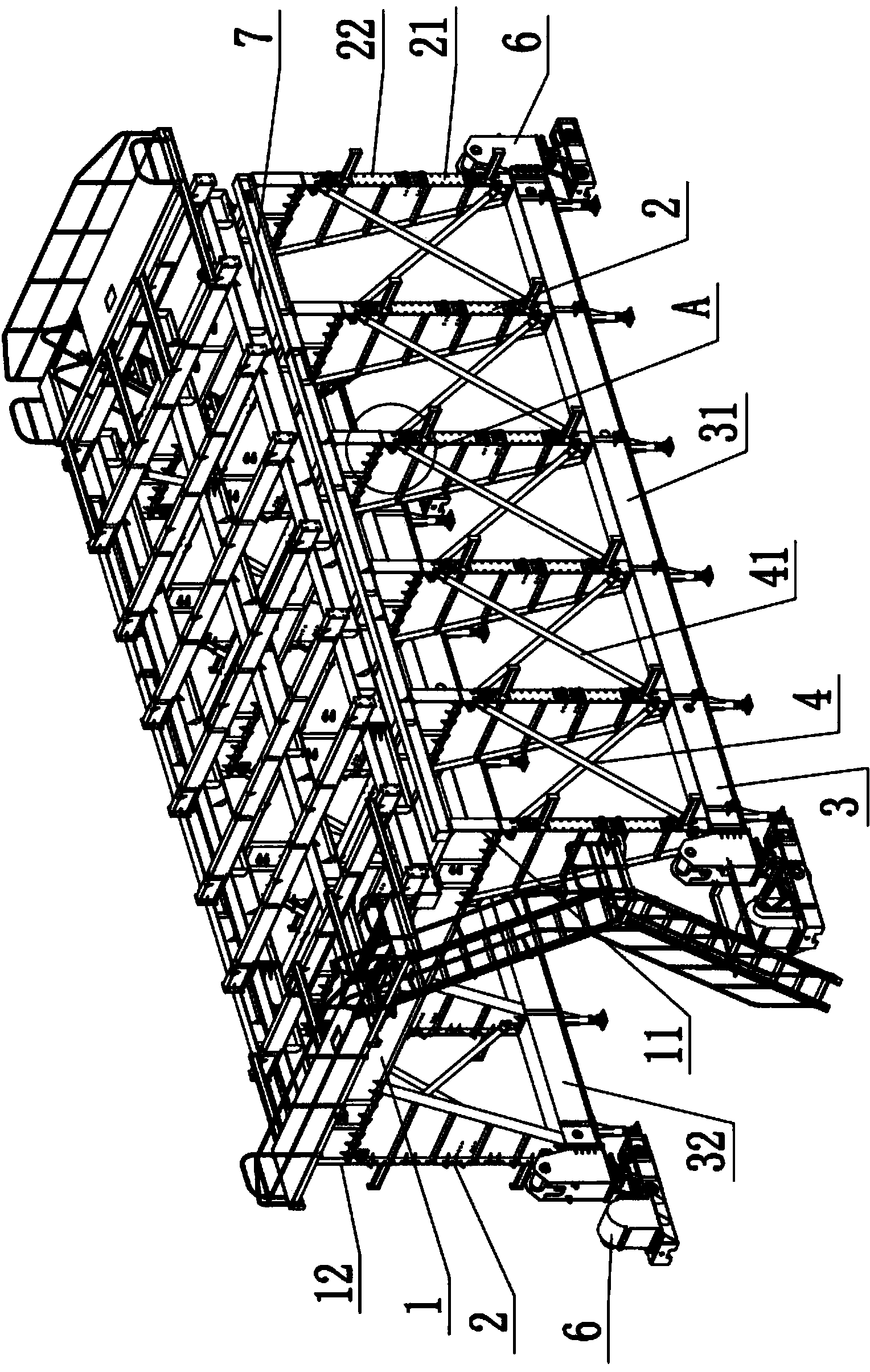

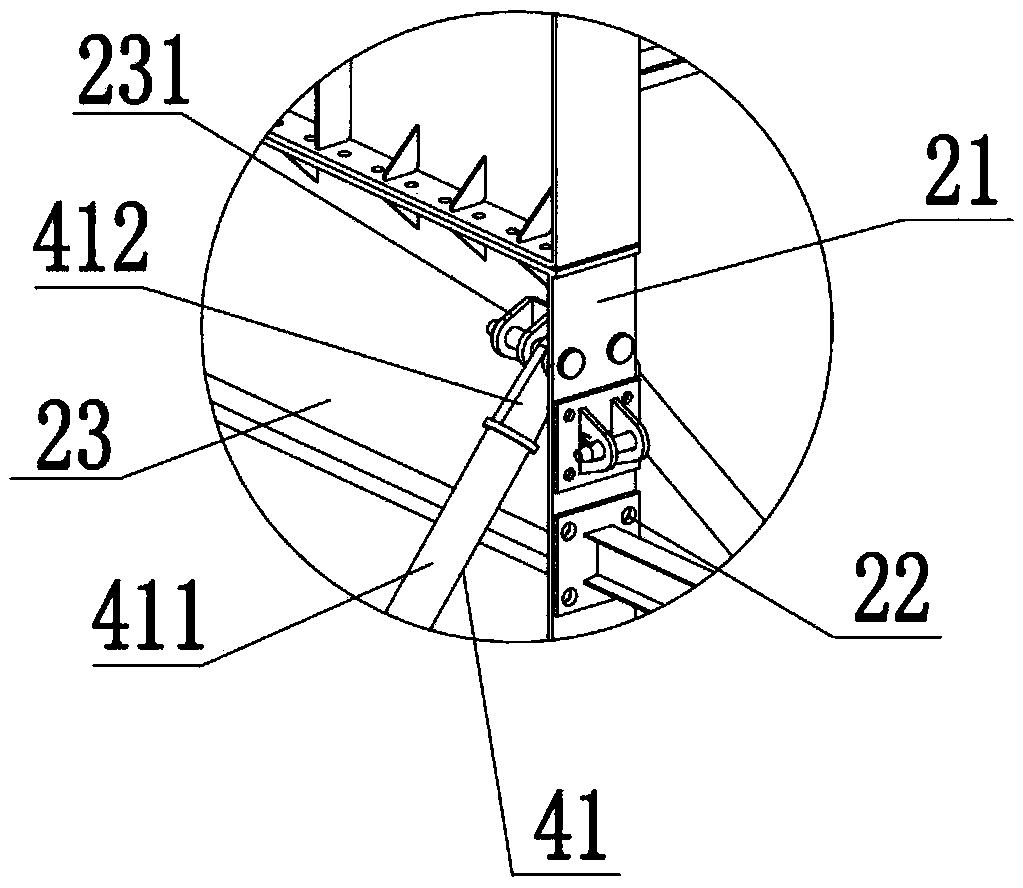

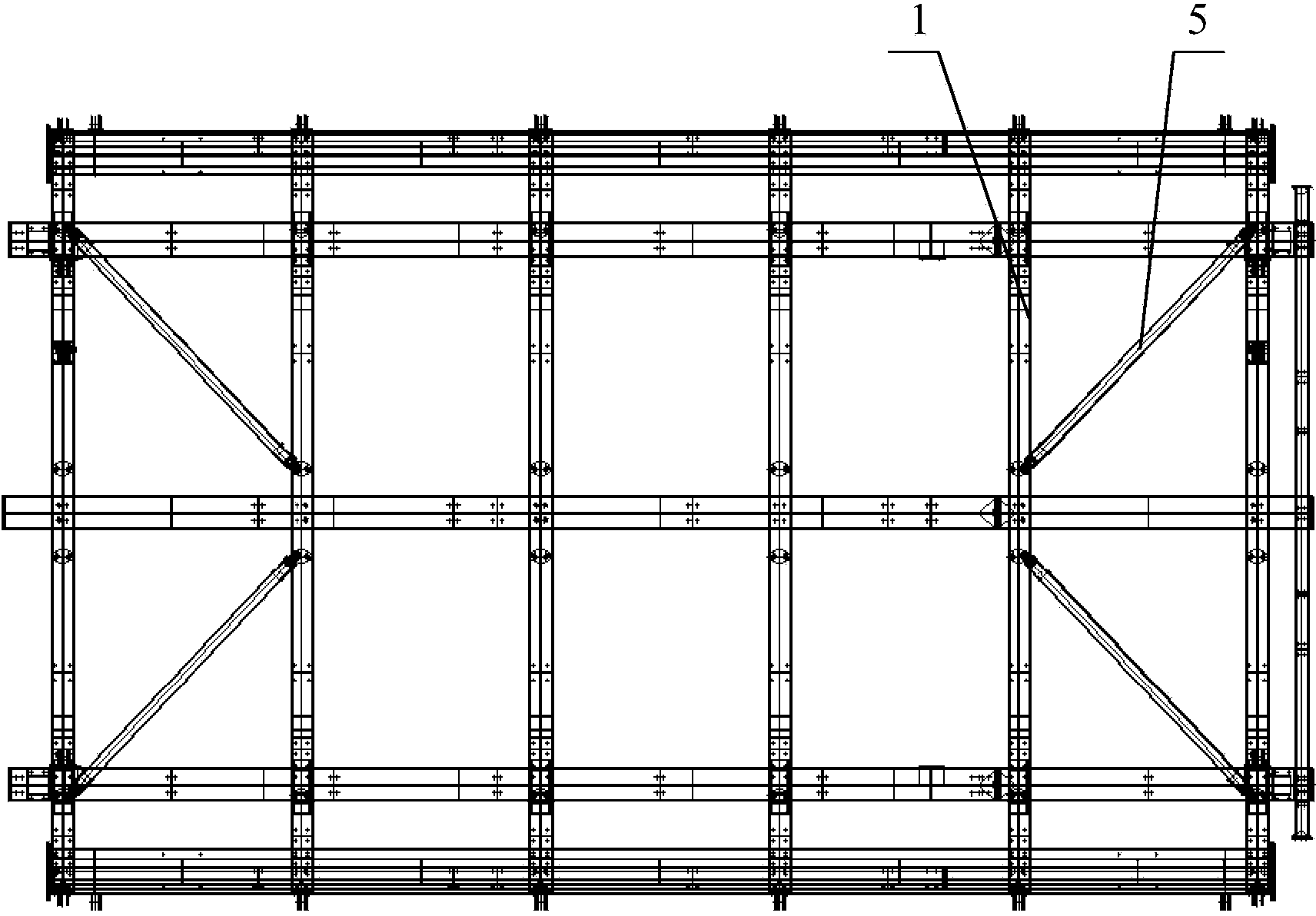

Split guide beam type tunnel-passing bridge girder erecting machine

ActiveCN102425120ARealize zero distanceReduce disassemblyBridge erection/assemblyEngineeringMechanical engineering

The invention relates to a bridge girder erecting machine, in particular to structural improvement on a split guide beam type tunnel-passing bridge girder erecting machine. The split guide beam type tunnel-passing bridge girder erecting machine comprises a girder and a lower guide beam, wherein the lower guide beam is arranged below the girder, a front leg, an intermediate leg and a rear leg which are used for supporting the lower guide beam are sequentially arranged on the lower guide beam, a traction device, a front support device, a front lifting device, a rear lifting device, an intermediate support device, a C-shaped leg and a rear support device are sequentially arranged on the girder, the traction device is used for drawing the front leg and the intermediate leg to turn over, the front support device is used for supporting the girder, the front lifting device and the rear lifting device are used for hoisting a box beam to be erected, the intermediate support device is used for supporting the girder, the C-shaped leg is used for supporting the girder and making the box beam to be erected pass through the girder, and the rear support device is used for supporting the girder. The split guide beam type tunnel-passing bridge girder erecting machine has the following advantages that zero-distance or minus-distance beam erecting at a tunnel portal or in a tunnel can be realized when the bridge girder erecting machine is used with a low-level beam transportation vehicle in a matching way, tunnel passing can be realized in a slight disassembly and assembly manner, and the legs of the guide beams at an initial hole and an end hole can be disassembled and assembled through a mechanism of the bridge erecting machine per se.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

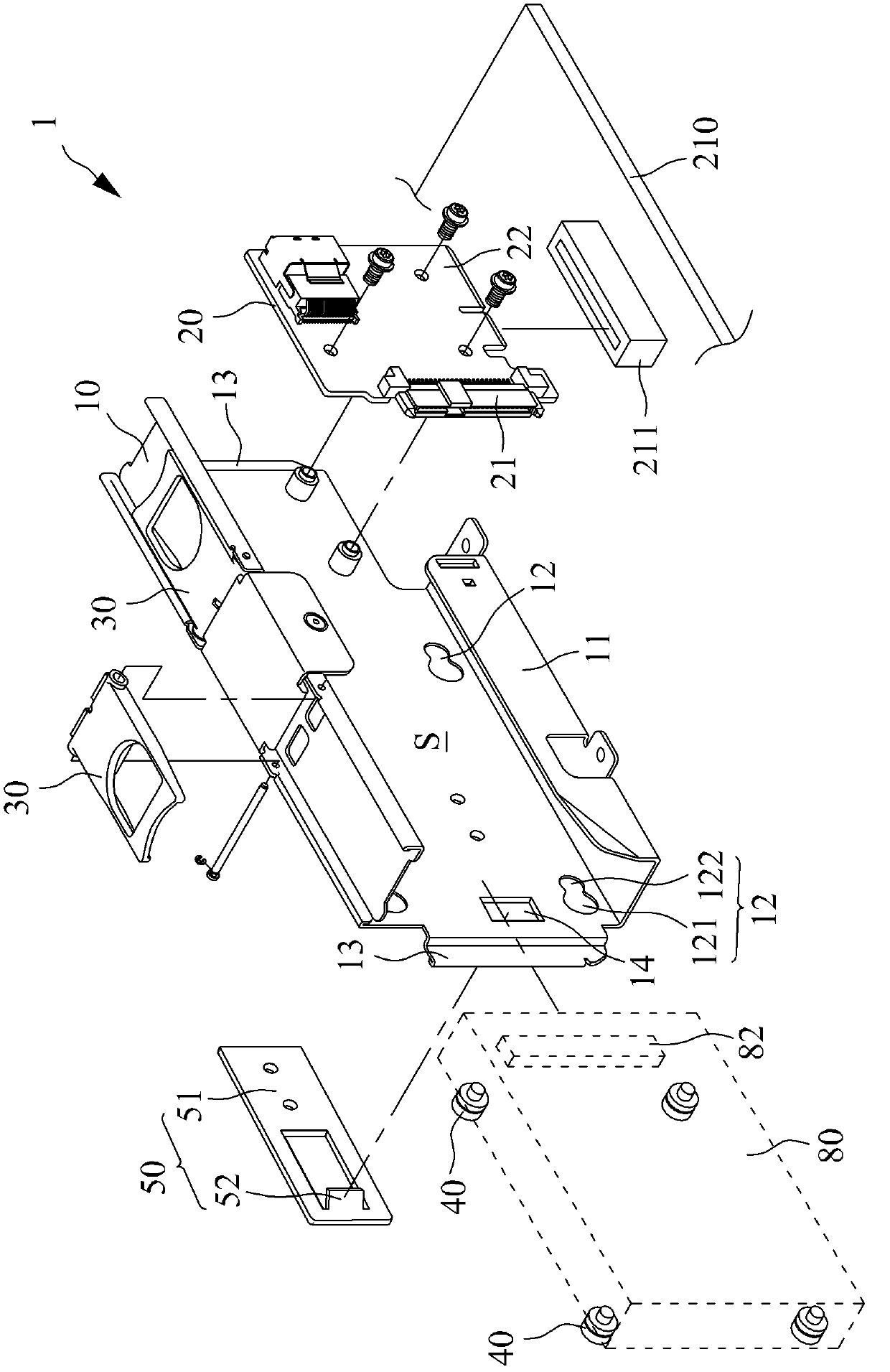

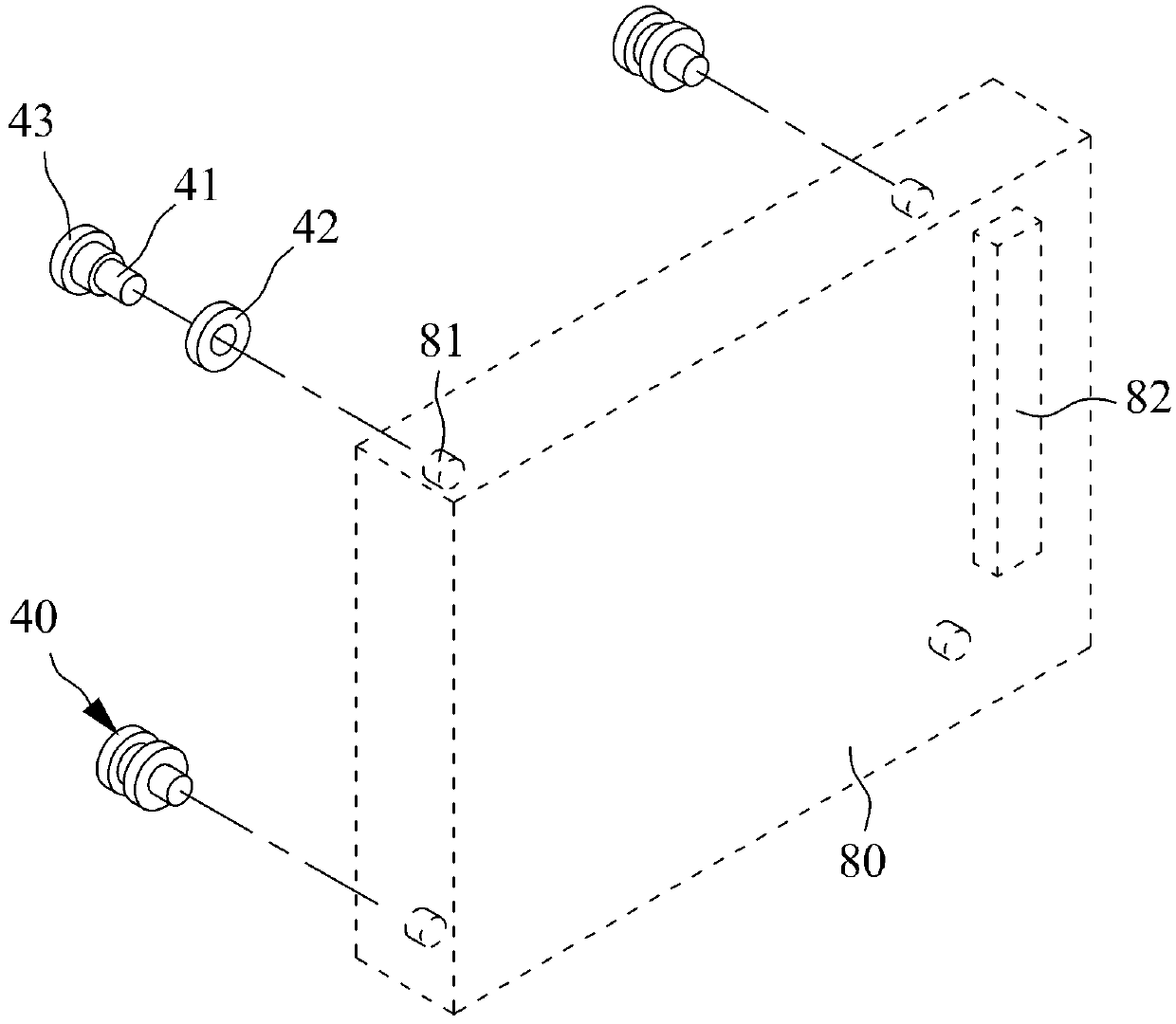

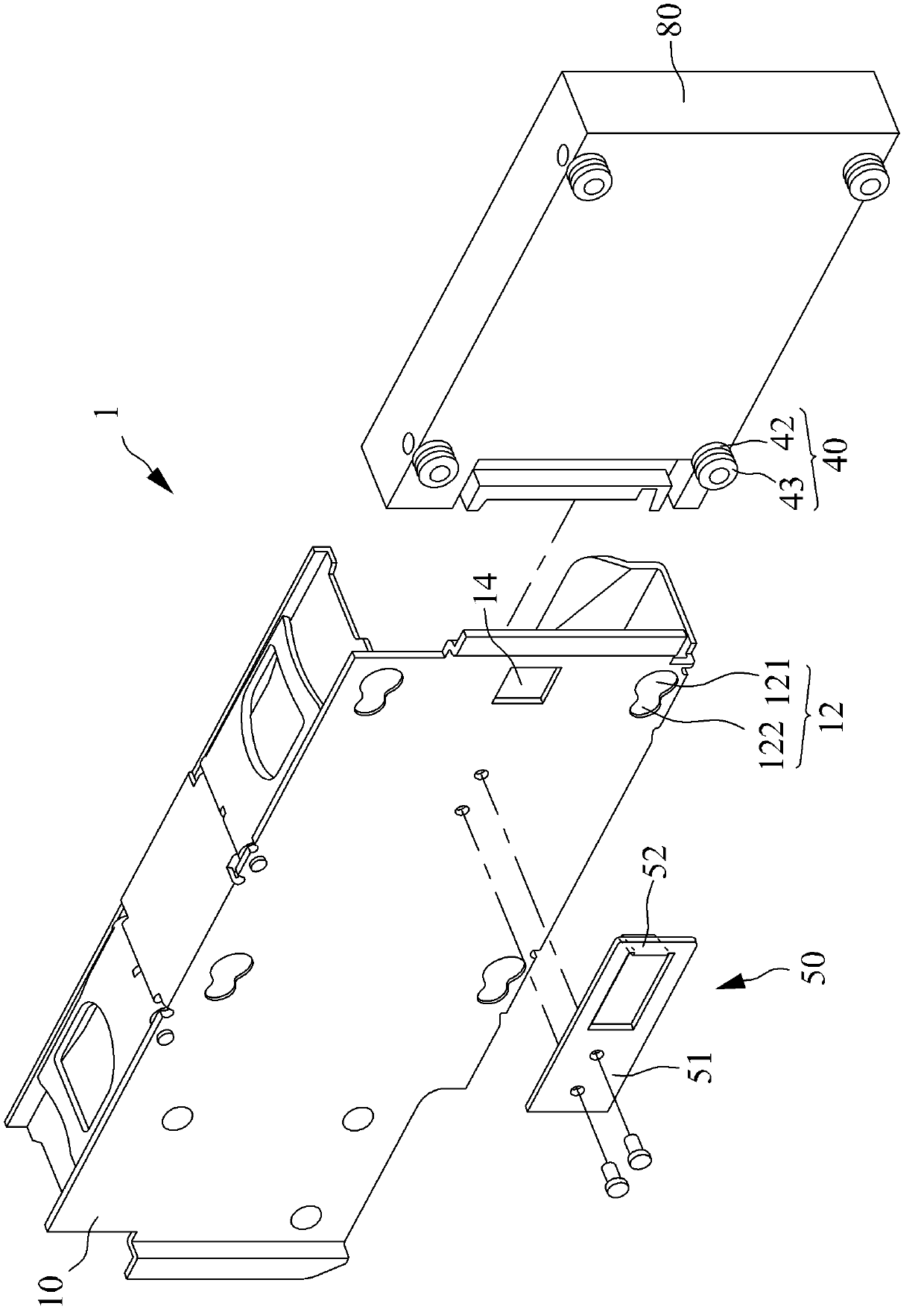

Storage device assembly module and electronic device

ActiveCN103376824AEasy to disassembleReduce disassemblyDigital processing power distributionWire rodEngineering

Owner:WISTRON CORP

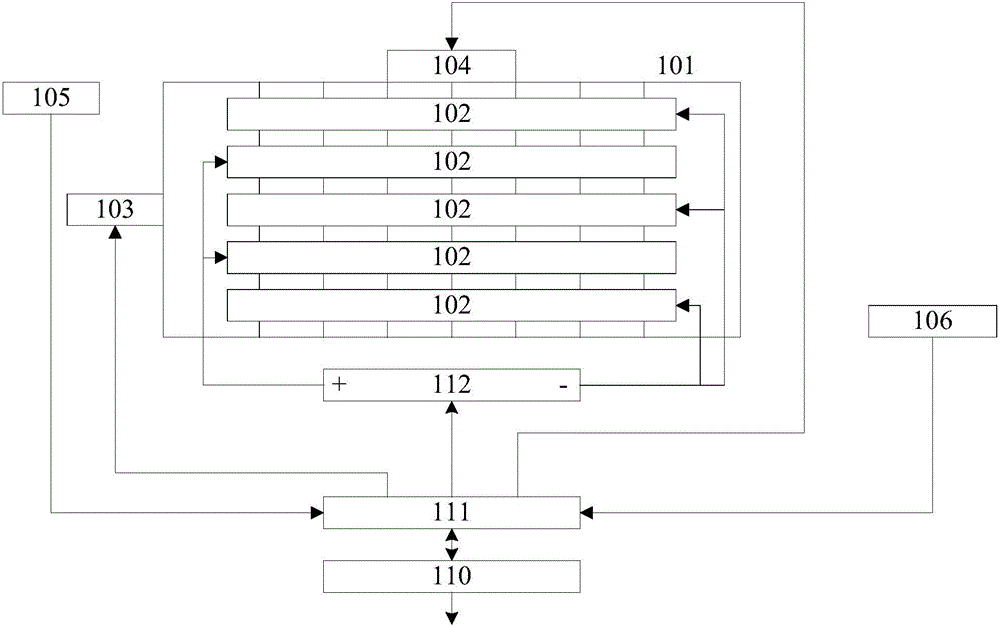

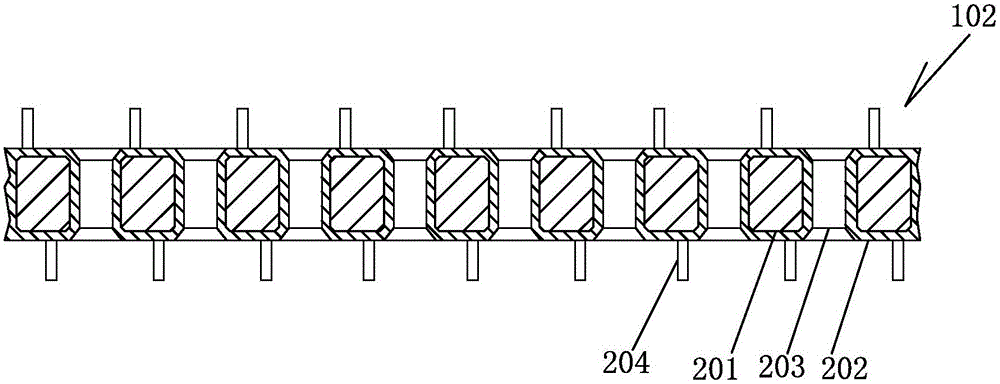

Intelligent self-cleaning composite microporous electrostatic adherence air purifying device and control method

InactiveCN105091147AAvoid high voltage dischargeKeep dryMechanical apparatusSpace heating and ventilation safety systemsVoltage converterWater source

An intelligent self-cleaning composite microporous electrostatic adherence air purifying device comprises a voltage converter; electrode plates which are fixed and stacked at intervals through a supporting frame form column module groups; an electrostatic filtering channel is formed by arranging the column module groups; the air inlet end face of each column module group is provided with a ventilating and spraying clean device used for covering the corresponding air inlet end face; a control signal is received through a built-in control loop, the air inlet end faces are opened and closed, and therefore a channel and spray nozzles of a spray water source are provided; a multi-angle balance device is fixed to the top end of each column module group, the multi-angle balance device is coaxial with a supporting rotating shaft at the bottom of the column module group and is used for controlling the built-in control loop to receive the control signal, and each column module group is driven to swing slightly in the direction perpendicular to the air inlet or air outlet direction. According to the intelligent self-cleaning composite microporous electrostatic adherence air purifying device, the air quality can be monitored in real time, the purification efficiency can be fed back and adjusted in time, and the device is convenient to clean. Meanwhile, by means of an automatic washing function, the tedious manual dismantling and washing process can be omitted, the later-stage maintenance cost can be saved, and the service life of a product can be prolonged. The device has the functions of publishing the quality of purified air in real time and receiving authoritative data for forming a control command. The invention further discloses a control method.

Owner:上海迪安诺环境技术有限公司

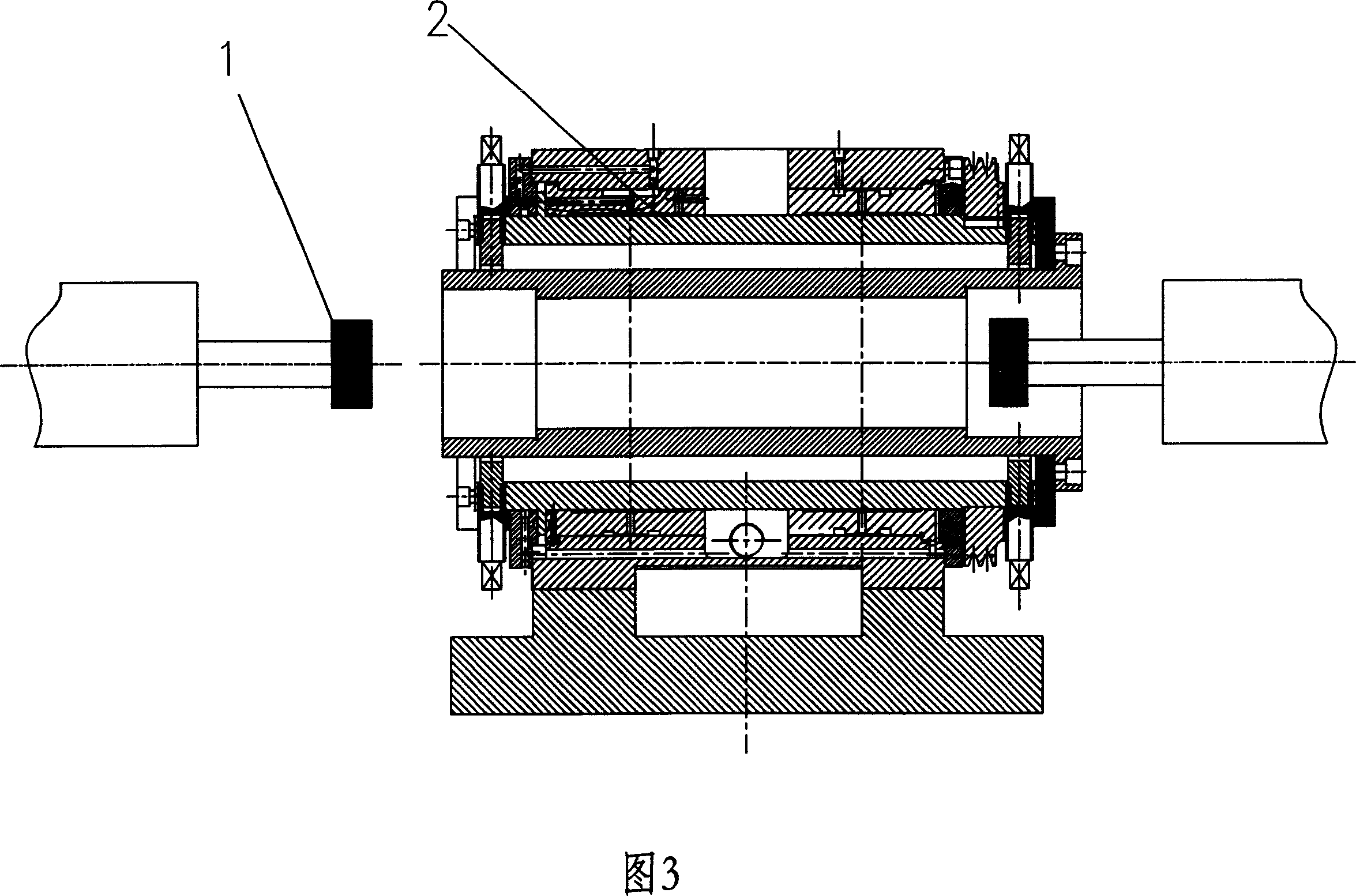

Movable random boring lathe

InactiveCN101829795AReduce disassemblyEasy to transportBoring/drilling machinesControl signalCost savings

The invention provides a movable random boring lathe for solving the problems of great difficulty of each link, such as disassembly and assembly, transportation, processing, installation, and the like during boring maintenance by various kinds of large or middle-sized mechanical parts, long downtime during maintenance, and high maintenance cost and great difficulty bringing to enterprises. The invention is characterized in that split body installation comprises a power and control device and a processing machine head and is connected by transmission lines; and the power and control device provides power and control signals to the processing machine head. The invention has the advantages of capability of maintenance on large equipment in processing sites, large amount of maintenance cost saving, and processing precision improvement due to the split body installation and no shock transference to the processing machine head from the power and control device.

Owner:沈阳三义兴业自动控制设备有限公司

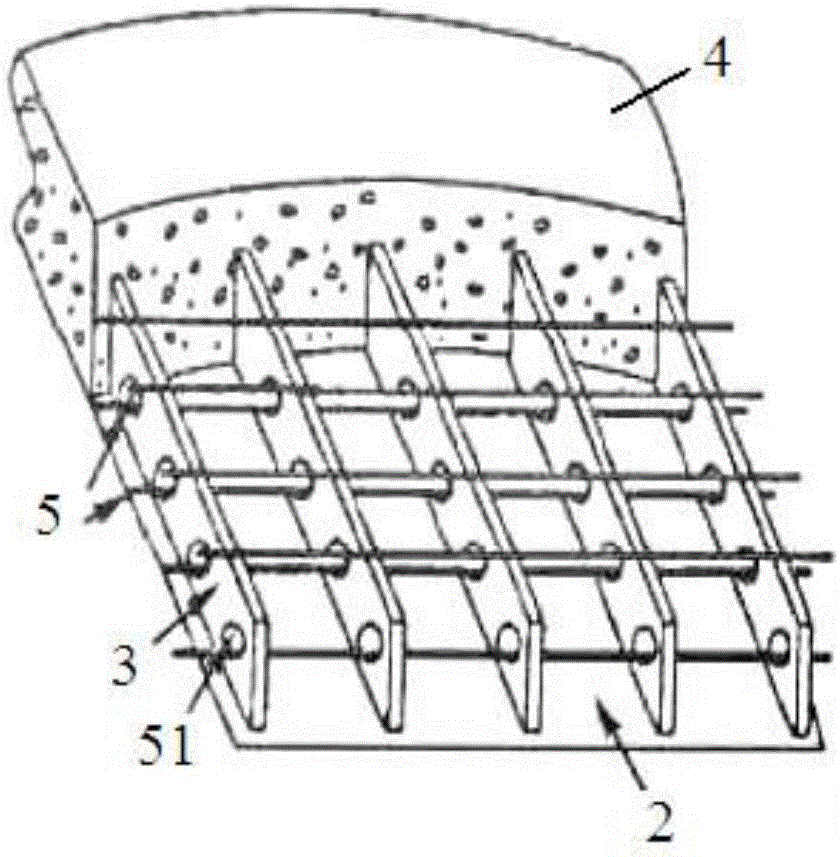

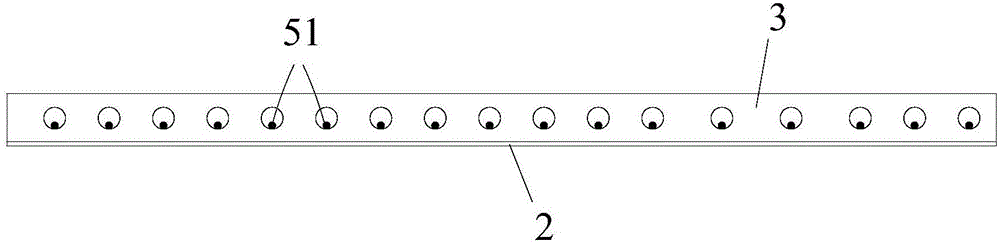

Steel-concrete combination deck plate and construction method thereof

ActiveCN106638302APrevent concrete layer from crackingGuarantee the construction qualityBridge structural detailsBridge erection/assemblySteel platesRebar

The invention relates to a steel-concrete combination deck plate and a construction method thereof, wherein the steel-concrete combination deck plate comprises: bottom steel plates arranged on steel girders, wherein the bottom steel plates in the bearing regions of the steel girders are bent in shape, and the bottom steel plates are 8-10 mm in thickness; a plurality of shear plates vertically connected to the bottom steel plates; a concrete tier including reinforcement fabric penetrating through the shear plates, wherein the concrete tier is cast to the bottom steel plates, and the combination deck plate is 10-15 cm in thickness. The steel-concrete combination deck plate uses the bottom steel plates as stress-bearing parts as well as a formwork for a cast-in-place desk concrete tier, and steps of mounting and releasing concrete formwork are omitted; the shear plates serve as stiffeners for the bottom steel plates, good combination of the bottom steel plates with the concrete tier can be guaranteed, and cracking of the concrete tier is prevented; the deck thickness is controlled to 10-15 cm and is reduced, the weight is 25% and above lower than that of a composite beam deck system, dead load is reduced, crossing ability, structural strength and durability of the main structure are improved, construction input is reduced, and the efficiency of a construction method is high.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

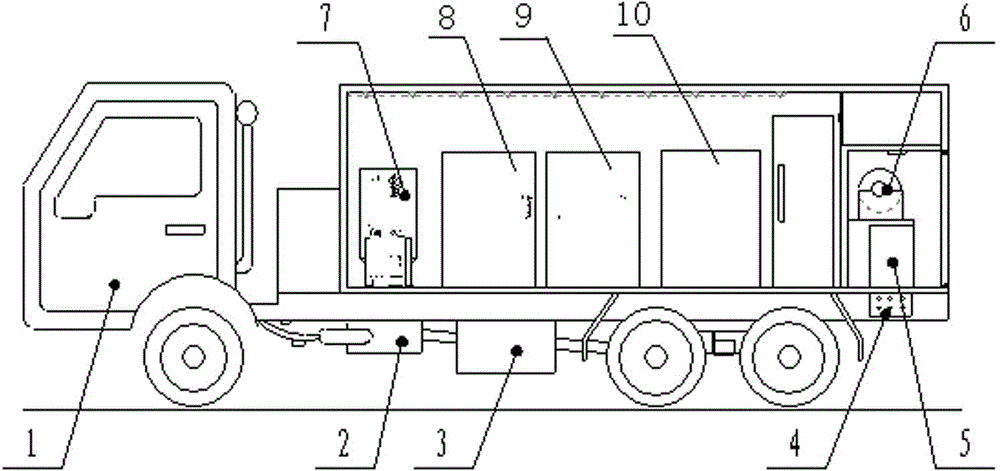

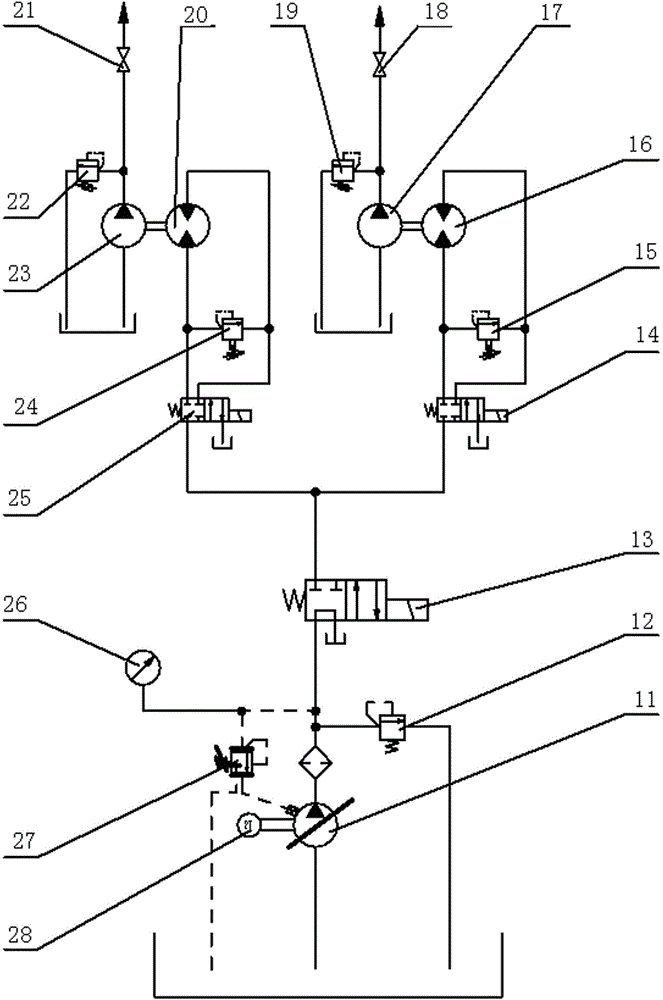

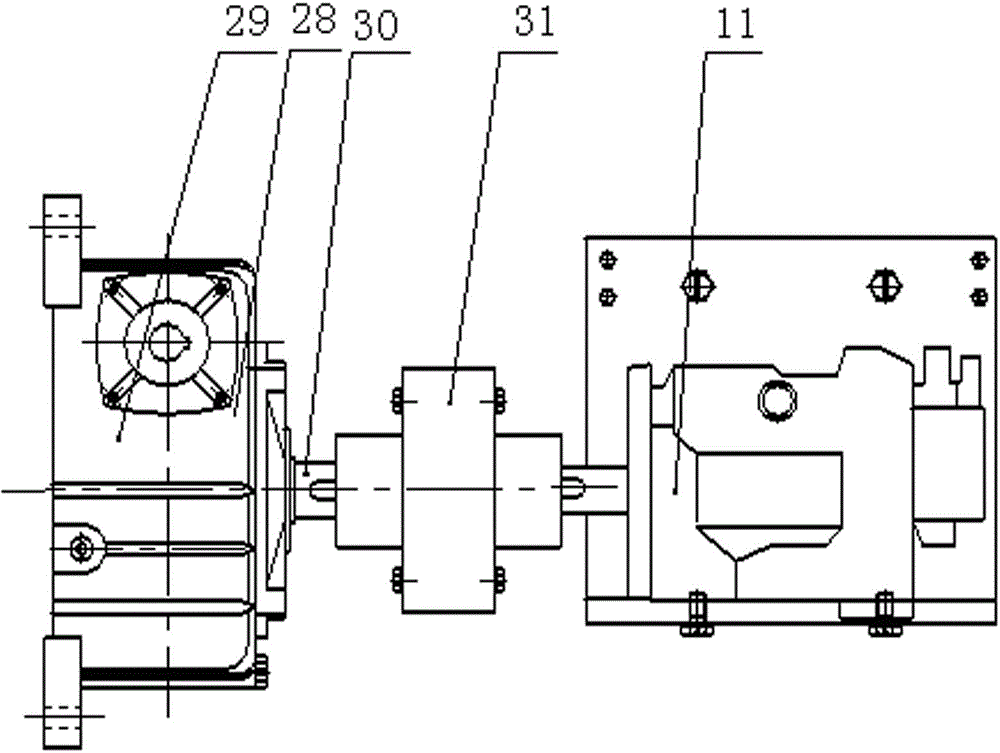

Mobile lubricating oil filling automobile

ActiveCN104528625AExtended replacement timeImprove delivery efficiencyLiquid transferring devicesOil and greaseElectrical control

The invention relates to an oil filling vehicle, specifically relates to a mobile lubricating oil filling automobile, and aims at solving the problems of potential risk of firing of the currently provided diesel compressor type mobile oil filling automobile, as well as solving the problem that a conveying device is large in size and can convey little oil and the heat preserving performance is poor for the oil products under conveying. The mobile lubricating oil filling device comprises the following seven major parts: an automobile body, a hydraulic oil supply power system, a heating and heat preserving system, an oil supplementing system, an electrical control system, an oil product output device and a grease conveying device. The mobile oil filling automobile is high in automation degree, convenient to operate, safe and reliable.

Owner:太原市磊焱科技有限公司

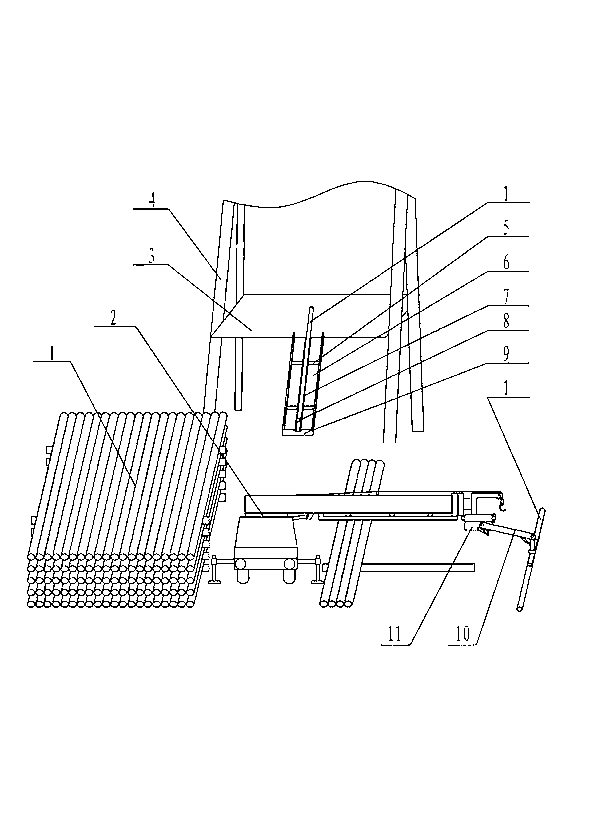

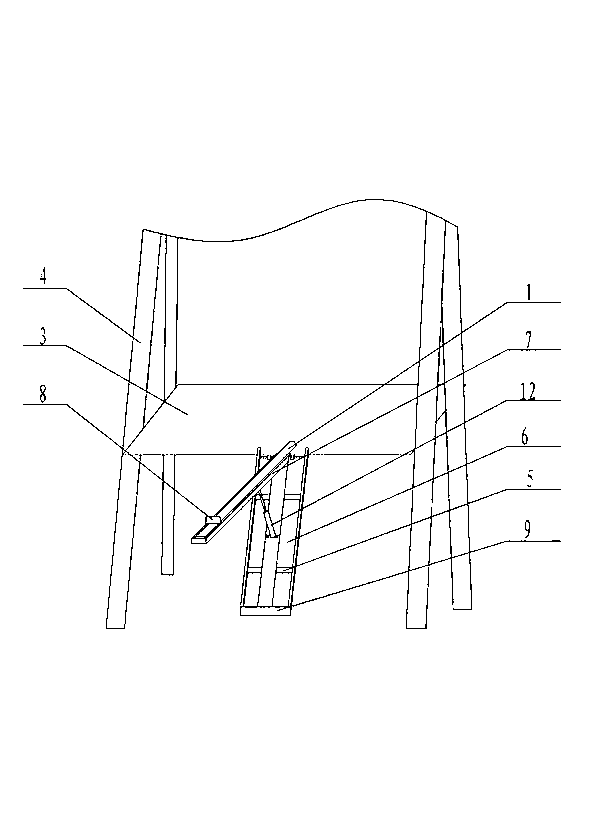

Drill rod automatic stacking and conveying device

InactiveCN103306617ARealize stackingReduce labor intensityDrilling rodsDrilling casingsTraveling blockDrill floor

The invention discloses a drill rod automatic stacking and conveying device, which is mainly composed of a ramp part, a specific crane and a clamping arm and clamping jaw mechanism, wherein a slideway and a trolley are arranged below a suspension arm of the automotive crane; the trolley is provided with the clamping arm and clamping jaw mechanism which can be used for directly grabbing drill rods; a catwalk body provided with a groove is directly fixed on an inclined plane of the ramp; arranged pipe blocks (namely groove entering mechanisms) are arranged at two sides of the catwalk body; when the drill rods are conveyed to a drill floor, one drill rod is suspended to be placed on the arranged pipe blocks on the ramp by the crane, the drill rod rolls into the groove through the arranged pipe blocks, and is pushed to the drill floor through a pulley; when the drill rod is put down by the drill floor, the process is opposite to the above process; the drill rod which glides into the groove and is jacked and pushed onto the arranged tube blocks is automatically suspended onto the ground to be put in order by the crane; the catwalk body is in a fixed type and in a rotary type; the upper end of the rotary-type catwalk body is connected with the upper end of the ramp through a hinge; the lower side of the rotary-type catwalk body can be rotated upwards around a hinge under hydraulic control, and the rear end of the rotary-type catwalk body is lifted up. With the adoption of the drill rod automatic stacking and conveying device, a catwalk machine is leaved out, the arranging and conveying complete automation of the underground drill rods is realized, so that unmanned operation is realized.

Owner:邹永平 +1

In-situ method and composition for repairing a thermal barrier coating

InactiveUS20050118331A1Reduce disassemblyMolten spray coatingEngine manufactureMetallurgyThermal barrier coating

An in-situ method for repairing a thermal barrier coating deposited on a component that has suffered localized spallation including depositing a ceramic paste on a surface area of the component exposed by the localized spallation, the ceramic paste including a ceramic material in a binder material, the ceramic material including solid zirconia particles, the binder material including a silicone compound. The method also including heating the binder material to yield a repair coating that covers the surface area of the component, the silicone compound promoting the bonding of the solid zirconia particles.

Owner:GENERAL ELECTRIC CO

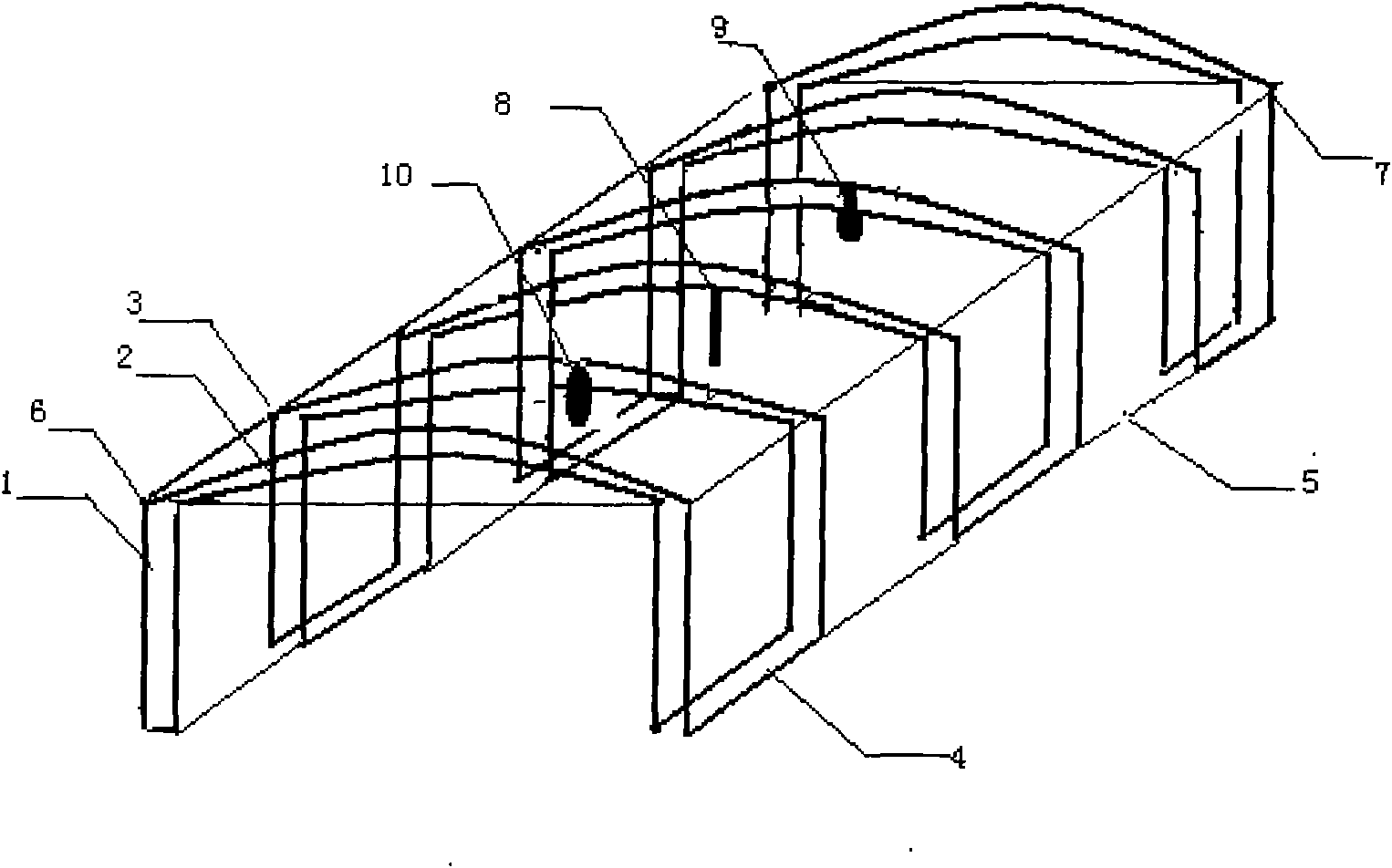

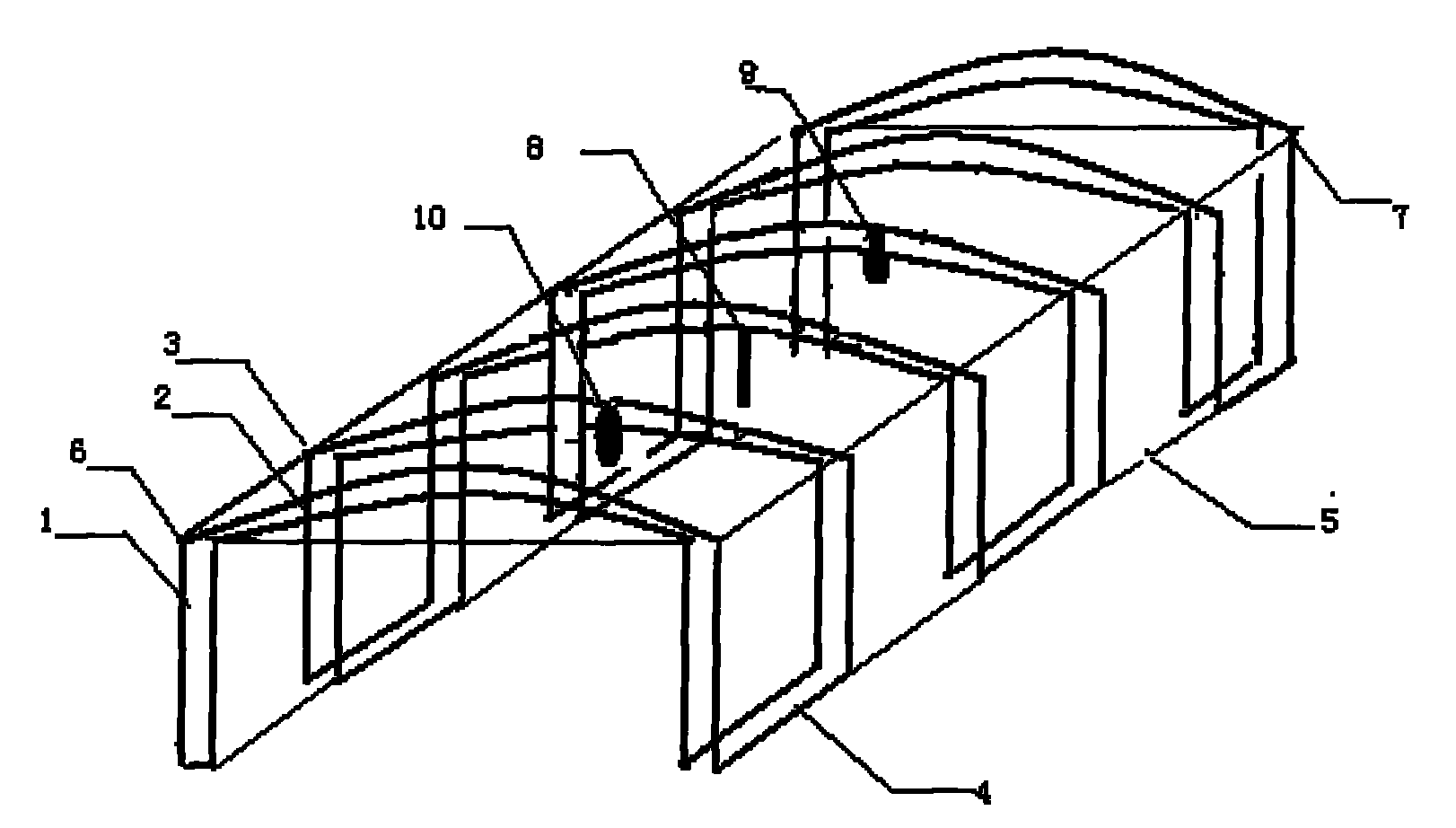

Glasshouse movable type animal feeding stall

InactiveCN101874474ASuitable room temperature for all seasonsPromote growthAgricultural buildingsAnimal housingGreenhouseKeel

Owner:叶传林

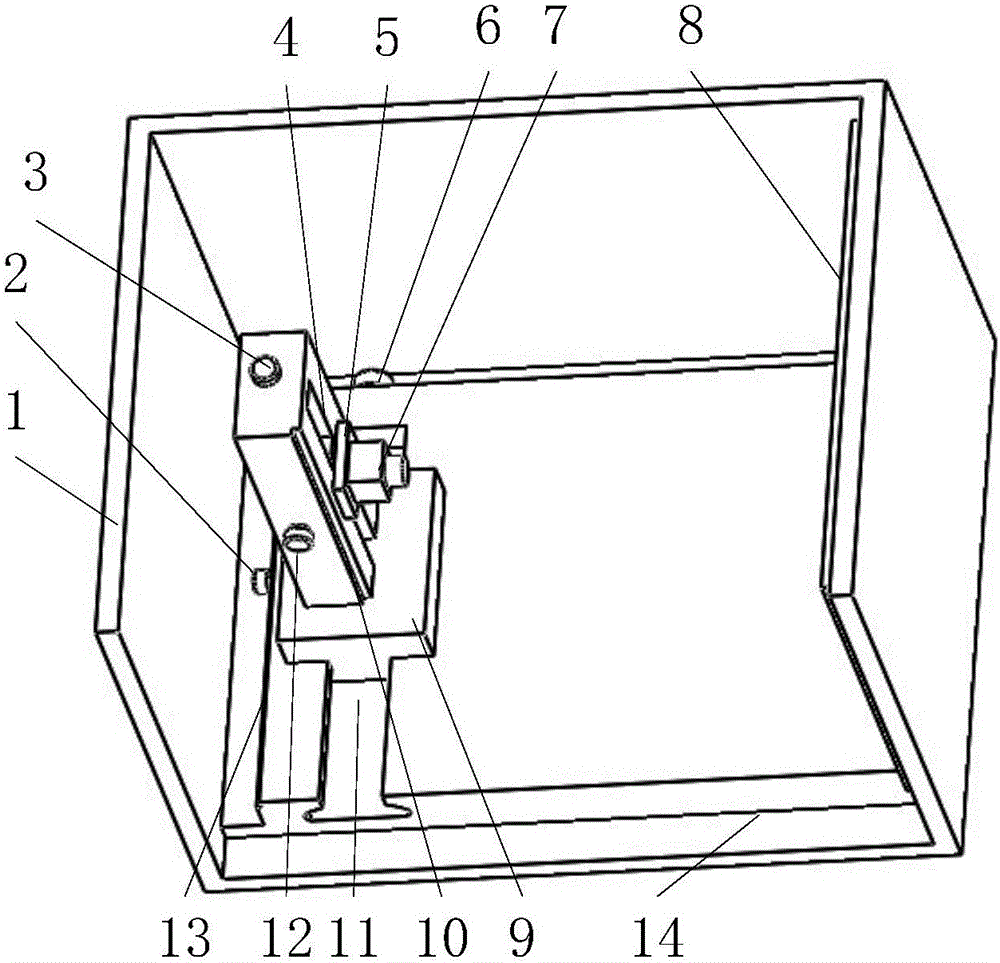

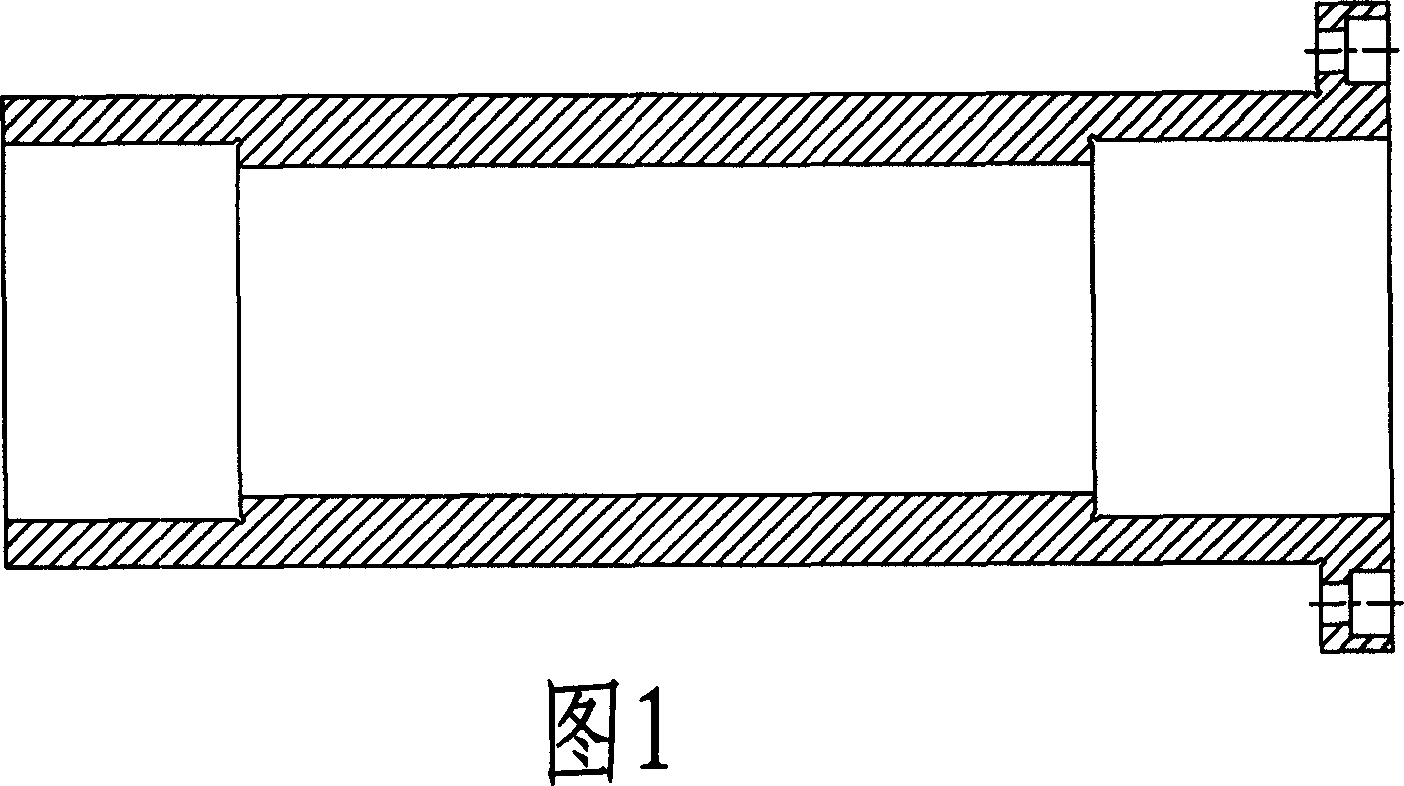

Tool parameter measurement device based on CCD and measurement method of device

ActiveCN105666246AReduce disassemblyHigh precisionMeasurement/indication equipmentsMeasurement deviceNon contact measurement

The invention relates to a tool parameter measurement device based on a CCD and a measurement method of the device.The tool parameter measurement device comprises a collection box, a CCD industrial camera, an industrial personal computer and a display, and the CCD industrial camera, the industrial personal computer and the display are sequentially connected; a camera transverse moving mechanism is arranged on a base of the collection box, a camera longitudinal moving mechanism is arranged on the camera transverse moving mechanism, and the CCD industrial camera is installed on the camera longitudinal moving mechanism.When measurement is conducted, a machine tool main shaft does not rotate, and static collecting is conducted; the main shaft collects an image whenever the main shaft rotates by one angle, and peripheral morphology of a tool is collected and stored in the specific location; data processing is conducted on a collected gray image.According to the tool parameter measurement device based on the CCD and the measurement method of the device, the tool parameters are directly measured on a machine tool, tool disassembly is omitted, the precision and efficiency are improved, non-contact measurement is conducted on a digital image based on the CCD, static measurement is conducted on the tool parameters, and the cost is reduced compared with that of a camera needing automatic focusing under rotation; the parameters such as slack length, radius, fillet and form and location tolerance of the tool can be measured.

Owner:SHANDONG UNIV

Inner circle machining method and internal grinder therefor

InactiveCN1974126ANo concentricity errorConcentricity error will not produceRevolution surface grinding machinesHeadstockMachining

The present invention discloses one kind of inner circle machining method and the internal grinder therefor. The present invention has the typical application of machining high precision sleeve type spindle unit. By means of setting two grinding head spindle units separately on two sides of the headstock spindle unit to clamp the workpiece, the two sides of the workpiece may be machined after once clamping and this can raise the coaxiality of the machined end holes of the sleeve.

Owner:钟洪

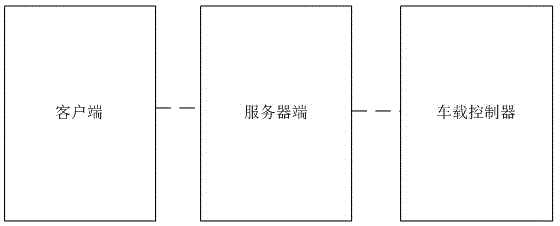

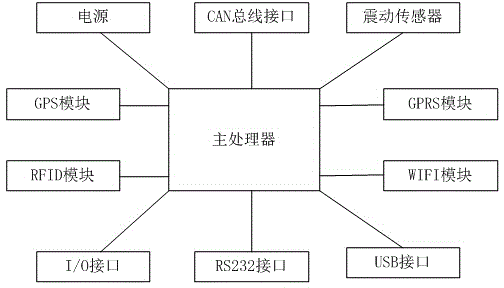

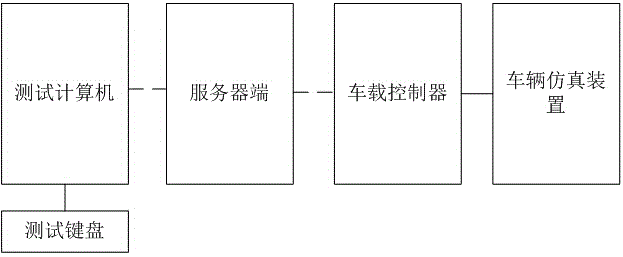

Test method and system for testing vehicle-mounted controller by means of vehicle simulation device

InactiveCN105589453AReduce assemblyReduce disassemblyElectric testing/monitoringIn vehicleSimulation

The invention discloses a test method and a system for testing a vehicle-mounted controller by means of a vehicle simulation device. The test method comprises the steps of connecting a vehicle simulation device with a power supply; connecting a vehicle-mounted controller with the power supply; conducting the wireless communication connection of the vehicle-mounted controller with a server; connecting a test keyboard for specially testing the vehicle-mounted controller with a test computer, wherein the test keyboard is used for simulating a client to send a control instruction to the server; pressing down the test key of the test keyboard one by one; receiving the corresponding instruction information by the test computer; sending the corresponding instruction information to the server so as to send the corresponding instruction information to the vehicle-mounted controller via the server; judging whether the vehicle-mounted controller successively controls a corresponding electronic part in the vehicle simulation device to conduct the corresponding treatment or not; on the condition that the vehicle-mounted controller successively controls the vehicle simulation device to conduct the corresponding treatment, deeming the function of the vehicle-mounted controller to be normal.

Owner:重庆联导金宏电子有限公司

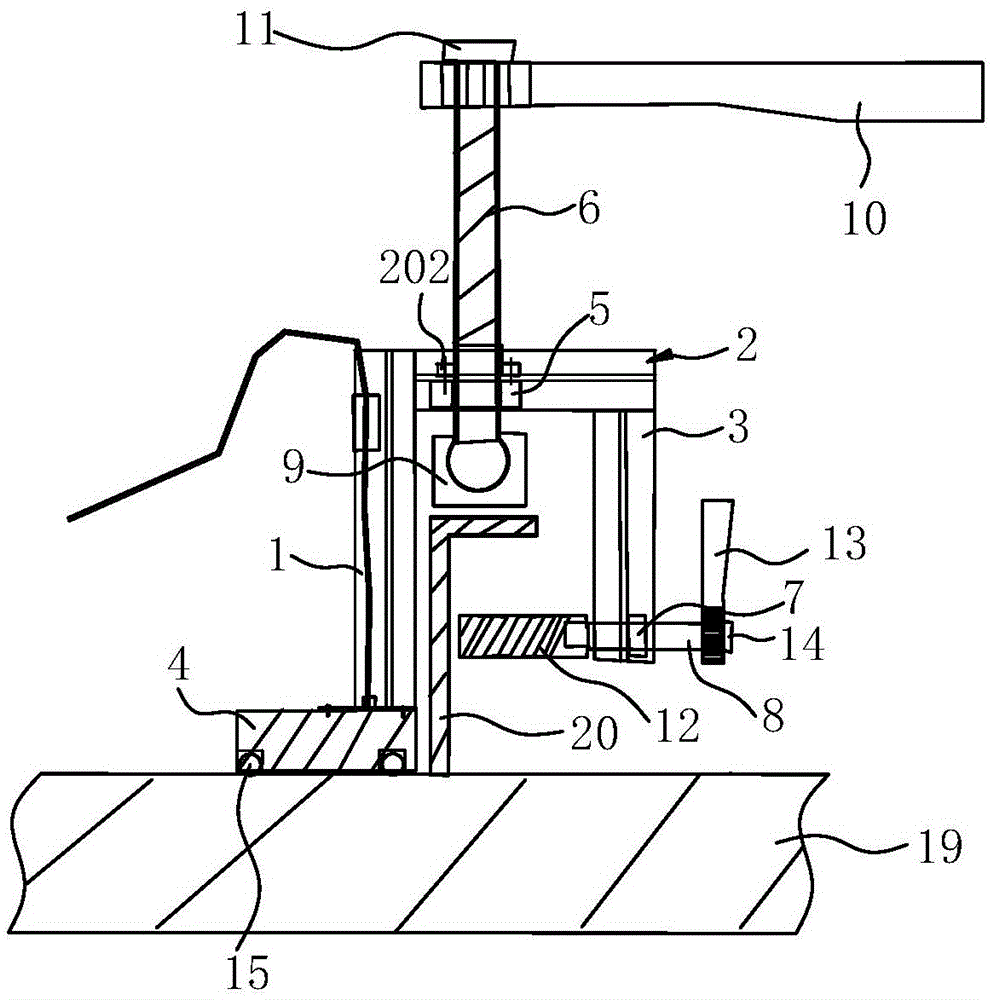

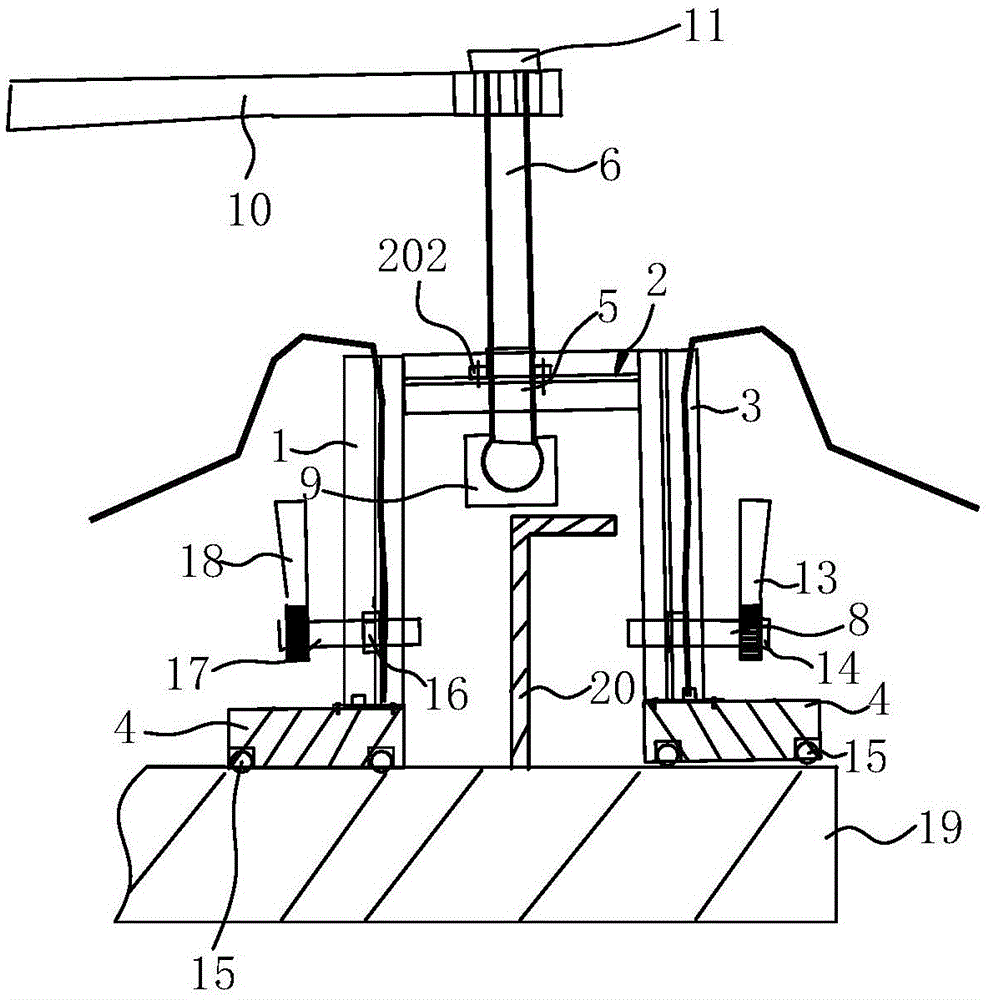

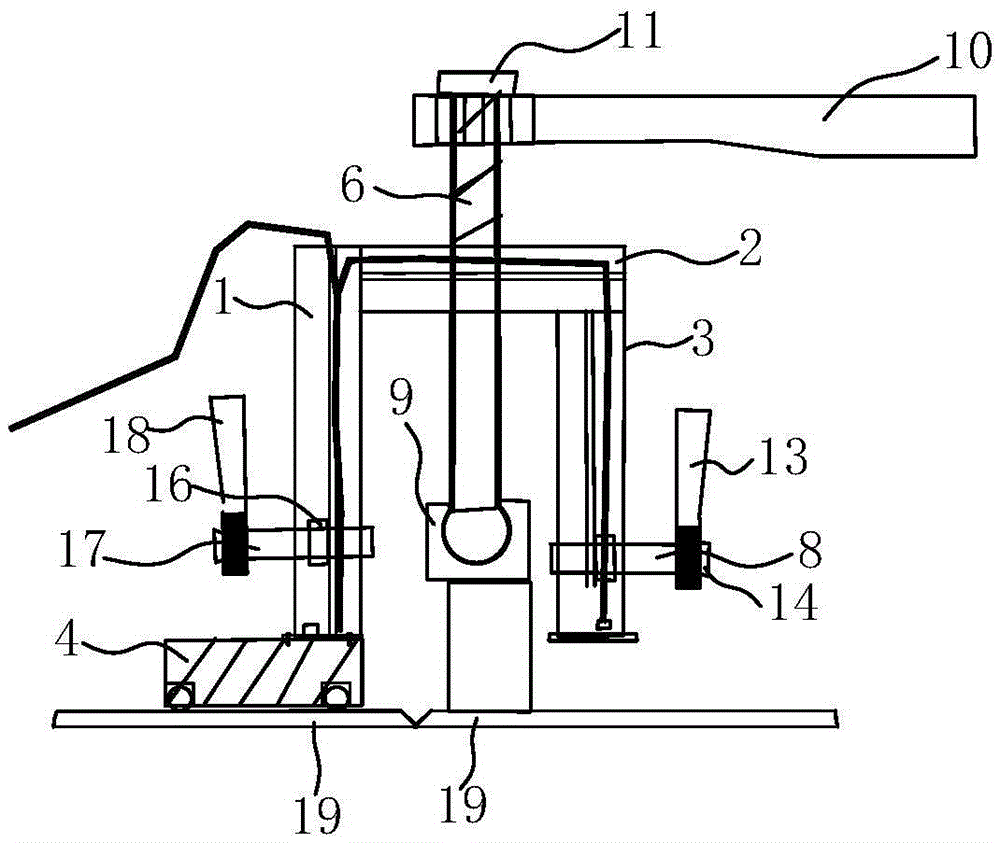

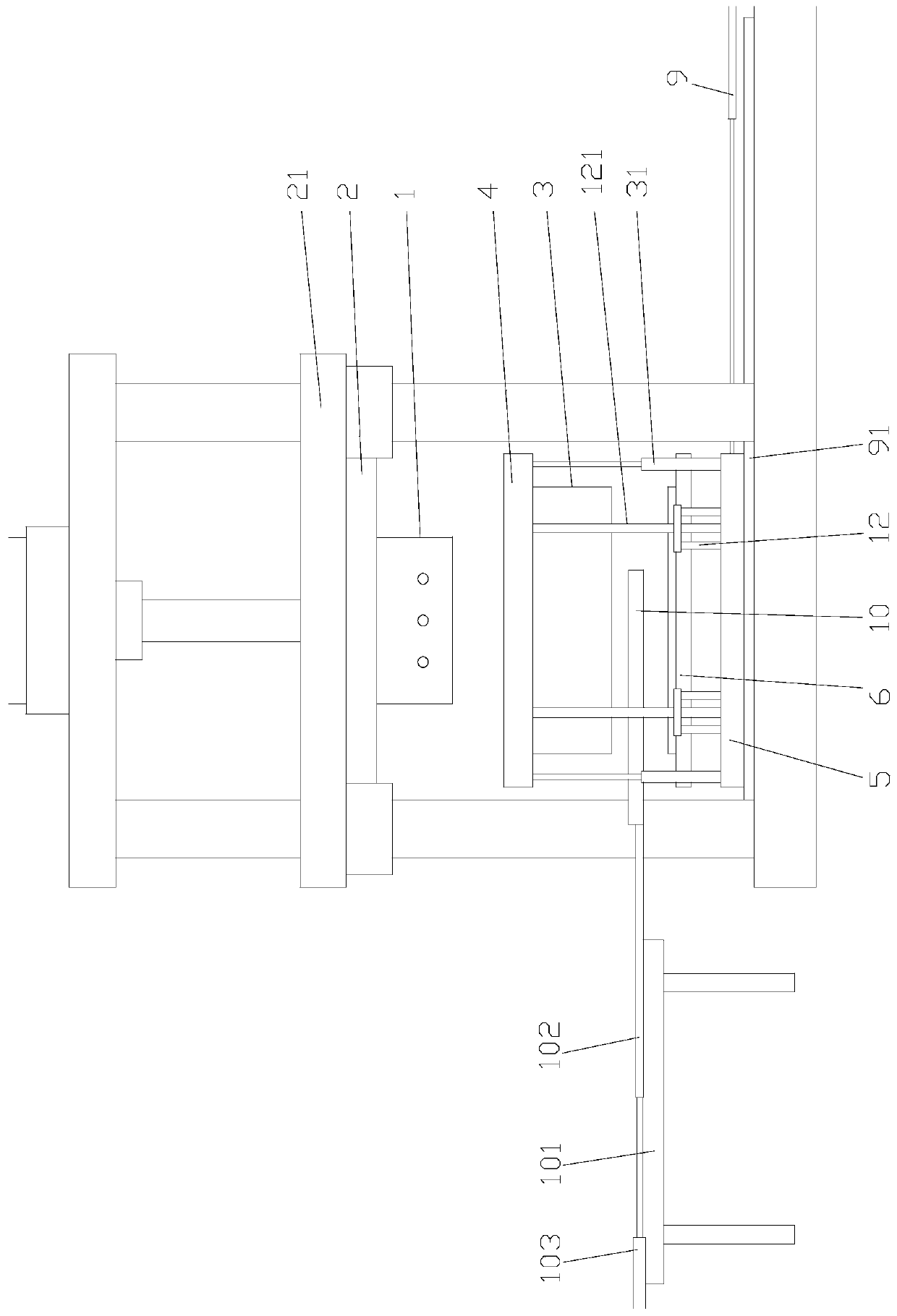

Assembling fixture without corner bracket

ActiveCN105479085ASimple structureImprove versatilityWelding/cutting auxillary devicesAuxillary welding devicesSheet steelEngineering

The invention discloses an assembling fixture without a corner bracket. The assembling fixture without the corner bracket comprises a first vertical support, a transverse support and a second vertical support. The two vertical supports are perpendicularly arranged at the two ends of the transverse support respectively and located on the same side of the transverse support. An electric sucker is arranged at the end, away from the transverse support, of the first vertical support, a first screw rod sleeve seat is arranged on the transverse support, and a first screw rod is screwed on the first screw rod sleeve seat through a thread, moves in the vertical direction and comprises a first abutting end and a first screwing end. The second vertical support is provided with a second screw rod sleeve seat, a second screw rod is screwed on the second screw rod sleeve seat through a thread, moves in the horizontal direction and comprises a second abutting end and a second screwing end, and the first abutting end and the second abutting end are both located between the first vertical support and the second vertical support. Compared with the prior art, the assembling fixture without the corner bracket is simple in structure and high in universality, it can be avoided that craters are left on the surface of a steel plate or profile steel, the disassembling and polishing procedures in a later stage are omitted, the production efficiency is improved, and the manufacturing cost is reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Cement-based stone-like curb stone as well as preparation method and molding equipment thereof

InactiveCN109986678AFast removalHigh removal rateDischarging arrangementMouldsVacuum pumpingWork in process

The invention relates to the technical field of artificial stones, in particular to a cement-based stone-like curb stone as well as a preparation method and molding equipment thereof. The cement-basedstone-like curb stone comprises the following components of, in percentage by weight, 14-16% of cement, 26-28% of yellow sand, 45-55% of gypsum and 6-8% of water. The preparation method comprises thefollowing steps of a) fully mixing, in percentage by weight, 14-16% of cement, 26-28% of yellow sand, 45-55% of gypsum and 6-8% of water to obtain a concrete mixed wet material; (b) placing the concrete mixed wet material into the molding equipment, closing a mold, wherein the closing pressure is 100-160 MPa, and performing negative pressure vacuum pumping on a cavity, wherein the vacuum degree value of the vacuum pumping is 0.8-1.0 MPa, the closing and pressure maintaining time and the vacuum pumping time are less than or equal to 5 minutes, and the concrete mixed wet material quickly loses90% of moisture and is initially solidified and formed into a curb stone semi-finished product; and (c) carrying out mold opening and demolding by the molding equipment, transferring the semi-finishedcurb stone product out of the mold for stacking to obtain a finished cement-based stone-like curb stone product. The molding equipment is adopted, the manufacturing efficiency is high, the strength of the curb stone is high, the production efficiency is high, and the production cost is reduced.

Owner:CHANGZHOU INST OF LIGHT IND TECH

Buried type garbage compressor

The invention provides a buried garbage compressor, comprising a garbage bin which is arranged in a pit; the front end of the garbage bin is provided with a material outlet; the middle position of the garbage bin is provided with a material pouring bin; the front end of the garbage box is provided with a gate mechanism which is provided with a gate arranged at the internal side of the material outlet; a material storage bin is formed between the gate and the material pouring bin; the top of the material storage bin is provided with a surface layer body; the rear end of the garbage bin is provided with a rear top base; a push pressing bin is formed between the rear top base and the material pouring bin; the push pressing bin is internally provided with a push-out mechanism and a compression mechanism which are connected with each other in a moving way; the compression mechanism is provided with a compression base; the rear end surface of the compression base is provided with a compression cylinder; furthermore, the compression cylinder is fixed on the rear top base; the prepositive gate with insertion structure is adopted; the garbage bin smartly moves up and down; a dual mechanism for compression and push-out is arranged; the whole machine has long service life; the design of a convex top block has high operation efficiency; the upper garbage baffle which slides by dual layers has good cleaning at the rear part of the garbage bin; an insurance mechanism is configured, thus the operation is safe.

Owner:阮志华

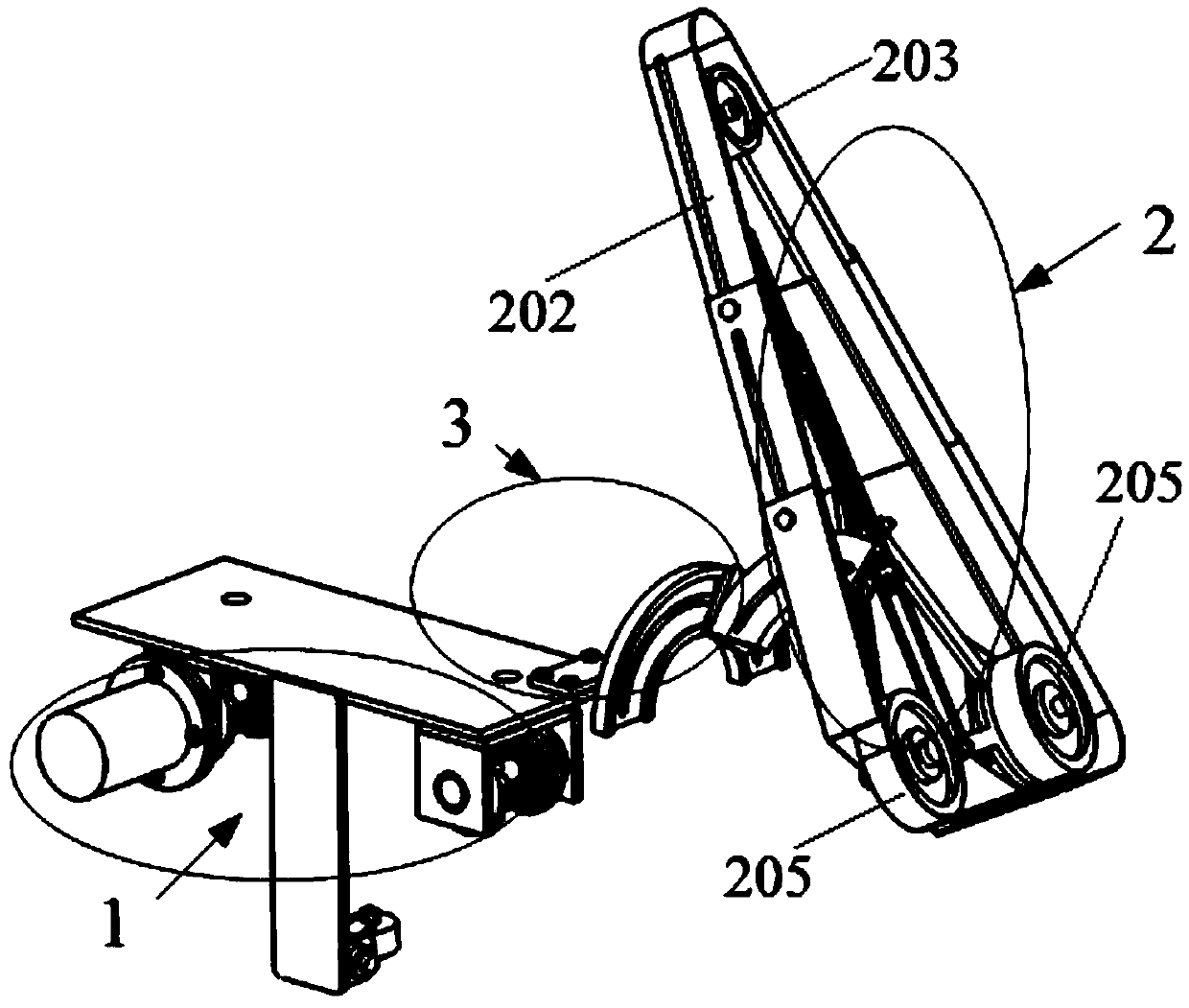

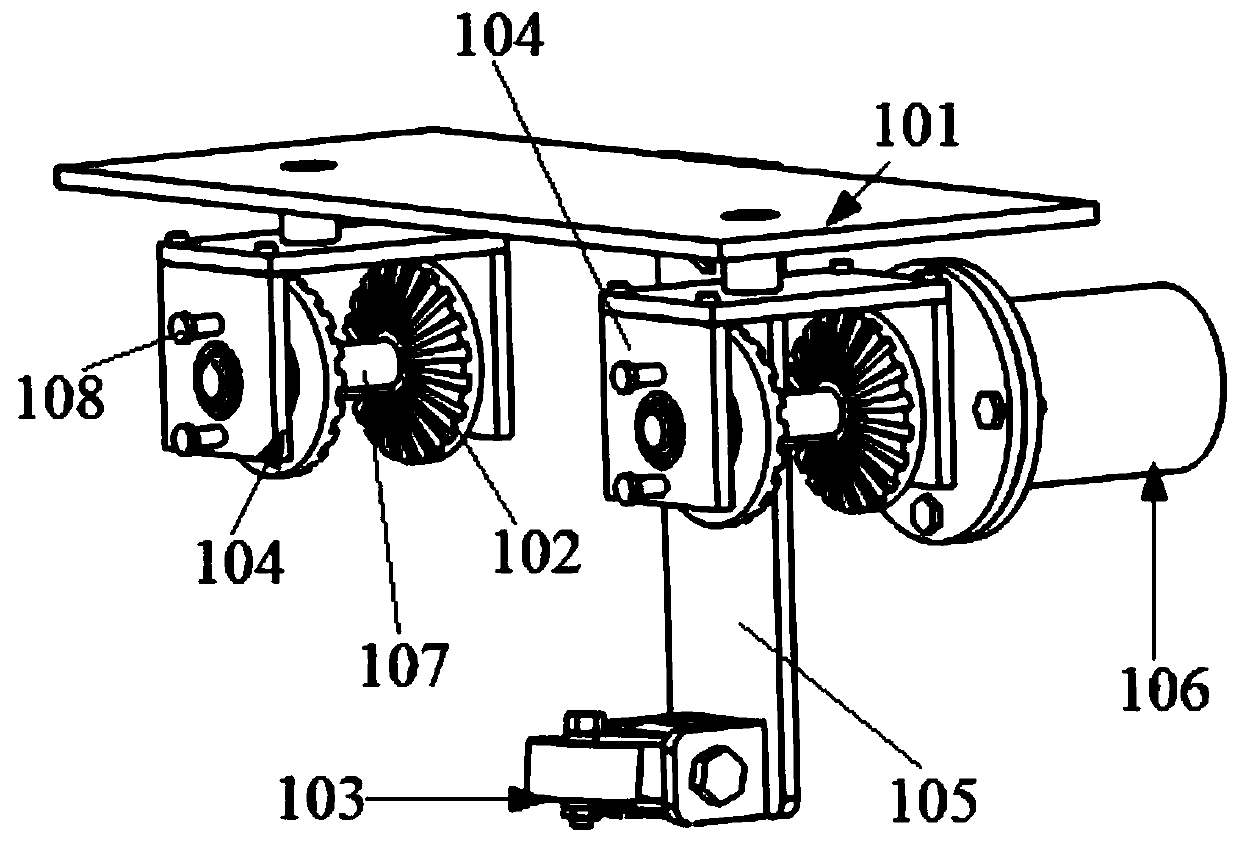

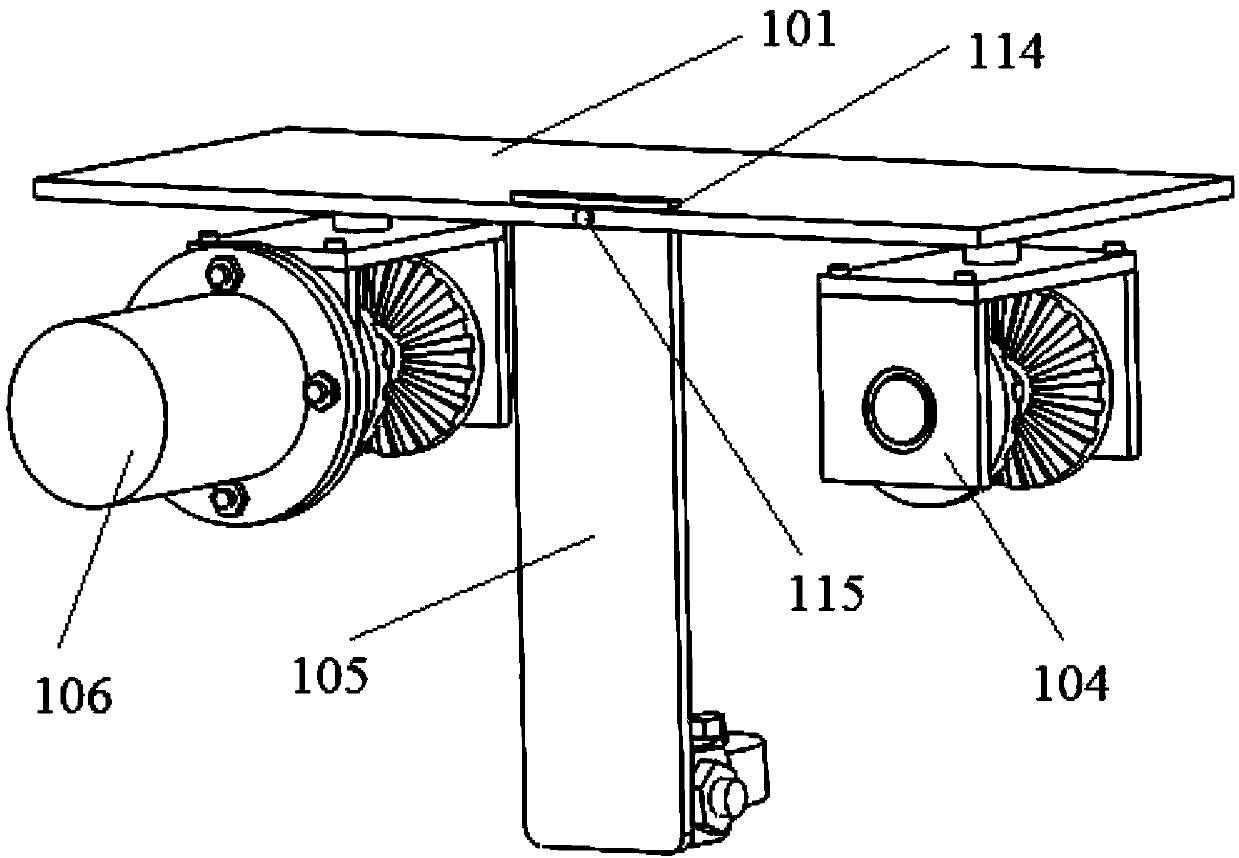

Portable belt grinding machine for sealing head

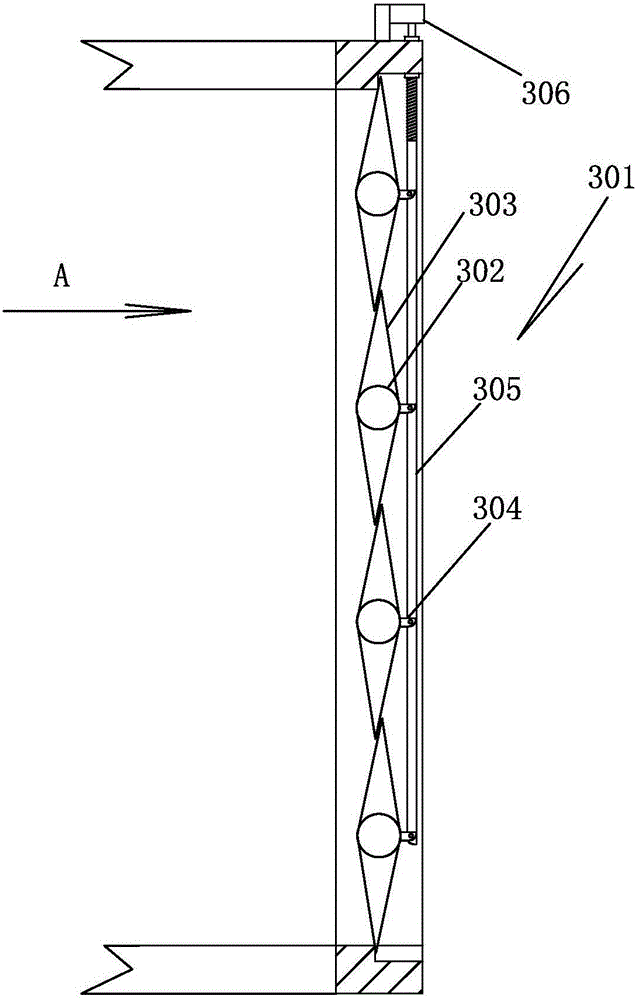

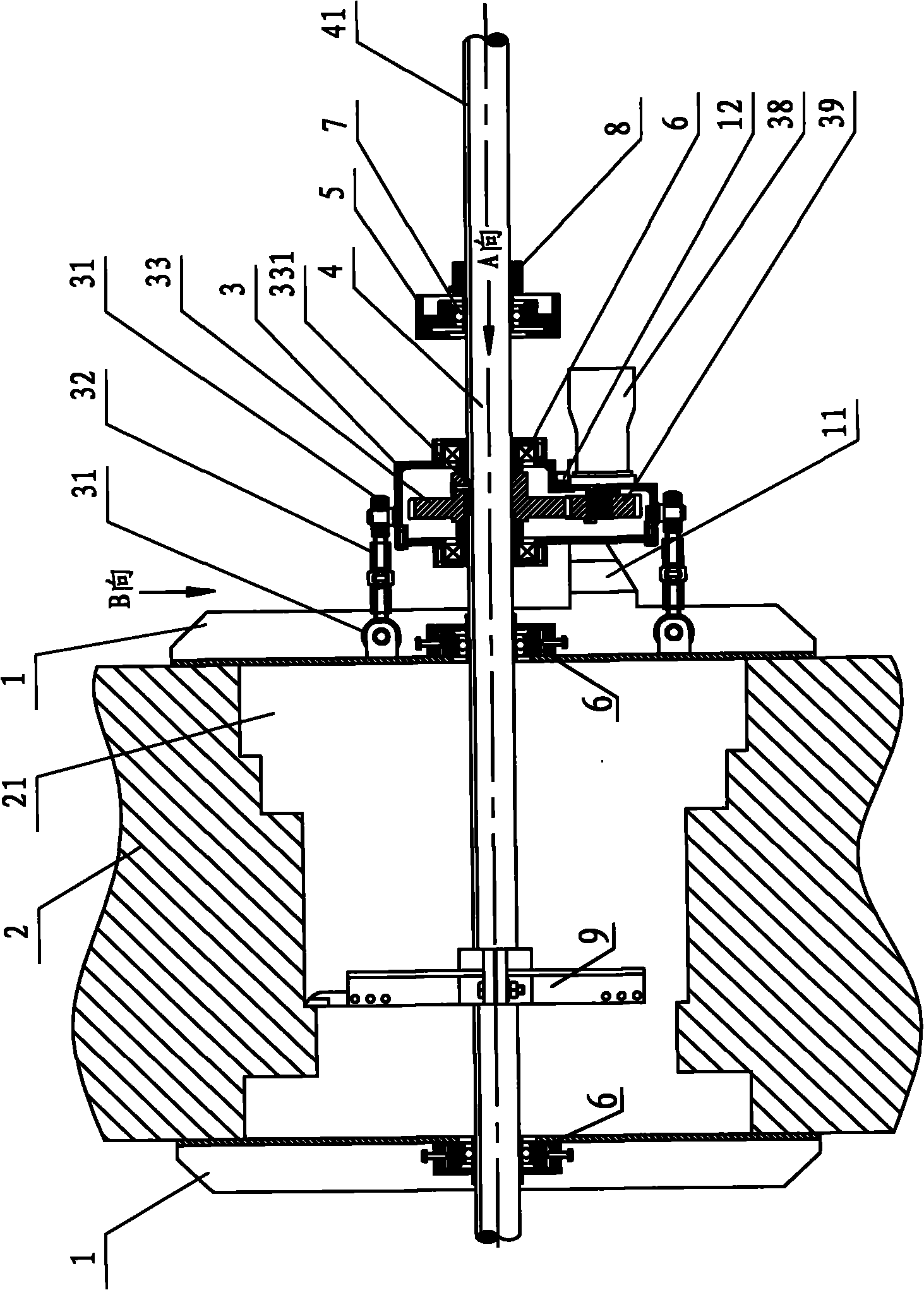

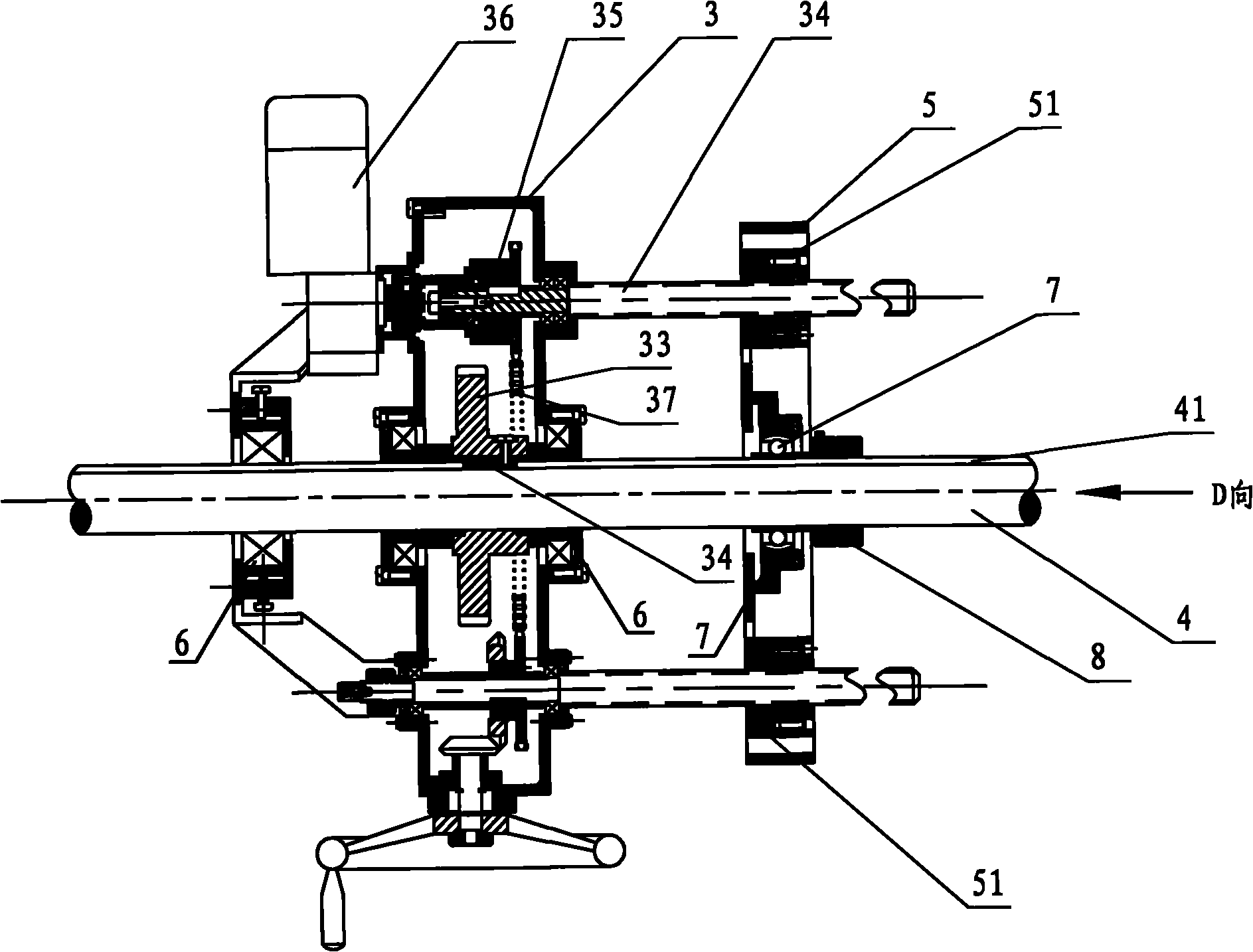

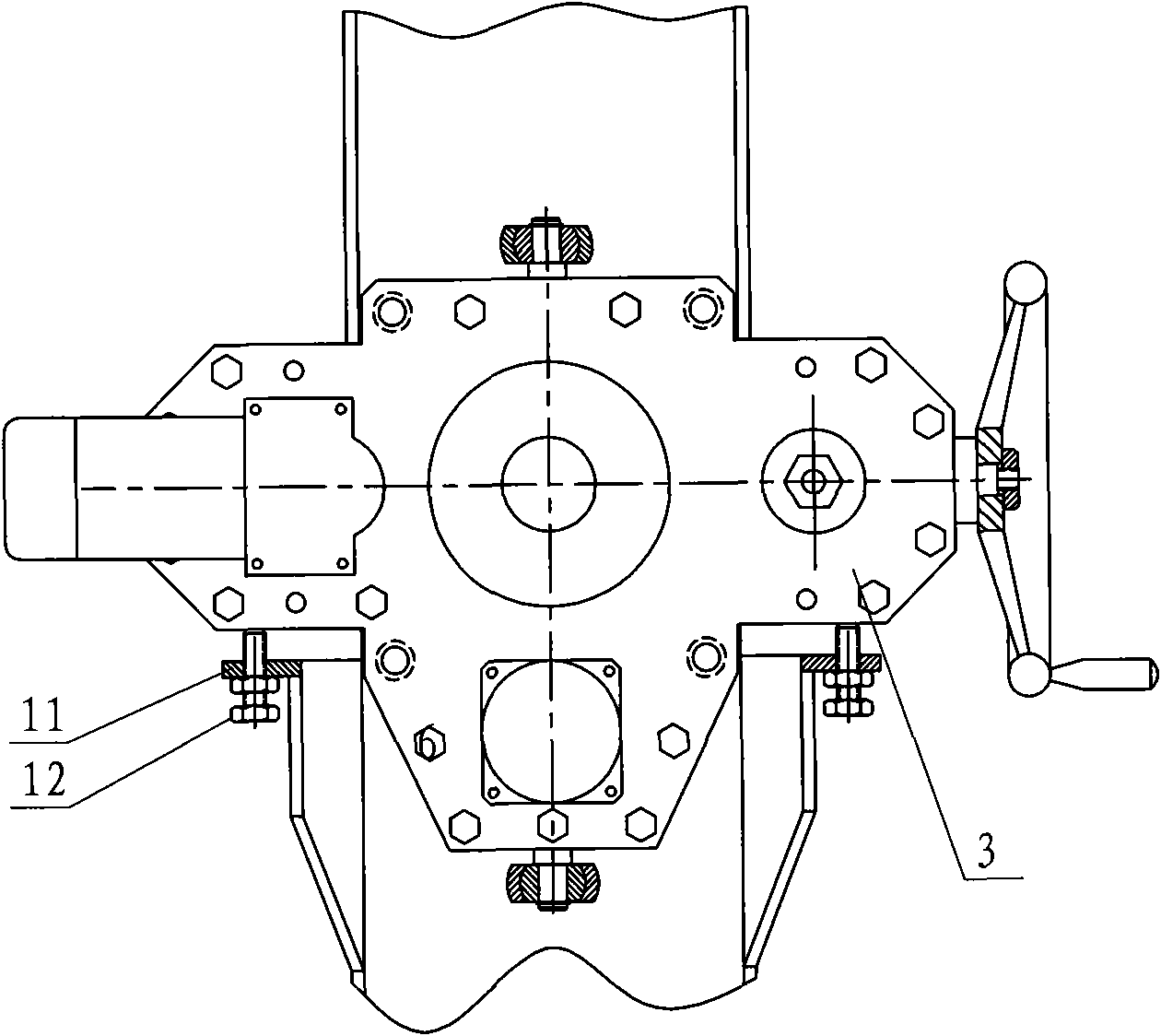

PendingCN108673307AReduce your weightReduce complexityGrinding machine componentsBelt grinding machinesEngineeringMechanical engineering

The invention discloses a portable belt grinding machine for a sealing head. The portable belt grinding machine comprises a grinding mechanism, a moving mechanism and a posture adjusting mechanism, wherein the moving mechanism comprises a flat plate, moving wheel sets, a supporting wheel, moving wheel seats and an auxiliary wheel seat, wherein the moving wheel sets, the supporting wheels, the moving wheel seats and the auxiliary wheel seats are mounted below the flat plate; two moving wheel seats are correspondingly mounted at the bottom parts of the two ends of the flat plate through rotatingshafts; each moving wheel seat is equipped with one moving wheel set, and each moving wheel set comprises two moving wheels which are correspondingly clamped at the inner side and the outer side of the sealing head; a moving motor is arranged on at least one moving wheel seat and is used for driving the moving wheels on the moving wheel seat to rotate; the supporting wheel is mounted at the sidepart of the flat plate between the two moving wheel seats through the supporting wheel seat; the two moving wheel sets and the supporting wheel are integrally clamped at the inner side and the outer side of the sealing head, and thus the flat plate can stably move at an edge opening of the sealing head; and the grinding mechanism for grinding the inner wall of the sealing head is mounted on the flat plate through the posture adjusting mechanism. The machine is suitable for the sealing heads with different size and thickness, and has the advantages of being small in size, light in weight, and portable.

Owner:WUHAN UNIV OF SCI & TECH

Disposable building formwork

InactiveCN101892739AAvoid destructionTake advantage ofForming/stuttering elementsReinforced concreteSurface layer

The invention discloses a disposable building formwork and belongs to the technical field of building construction. The disposable building formwork is characterized by comprising a base layer formed by rolling filler aggregate and a surface layer and a bottom layer of a building decorative surface matched on an upper surface and a lower surface of the base layer; the filler aggregate comprises industrial wastes and various matched additives, wherein the additives comprise water reducing agents and gelatinization materials; the surface layer is provided with uneven patterns. The disposable building formwork is made from the industrial wastes, effectively treats electronic wastes and saves a large number of resources; amoreover, the cast disposable building formwork is integrated with reinforced concrete, does not need dismantling, saves separant painting, formwork cleaning, dismantling and secondary conveying required in a common technology, reduces the casting volume of the concrete and greatly saves both labor and financial resources.

Owner:陈校兴

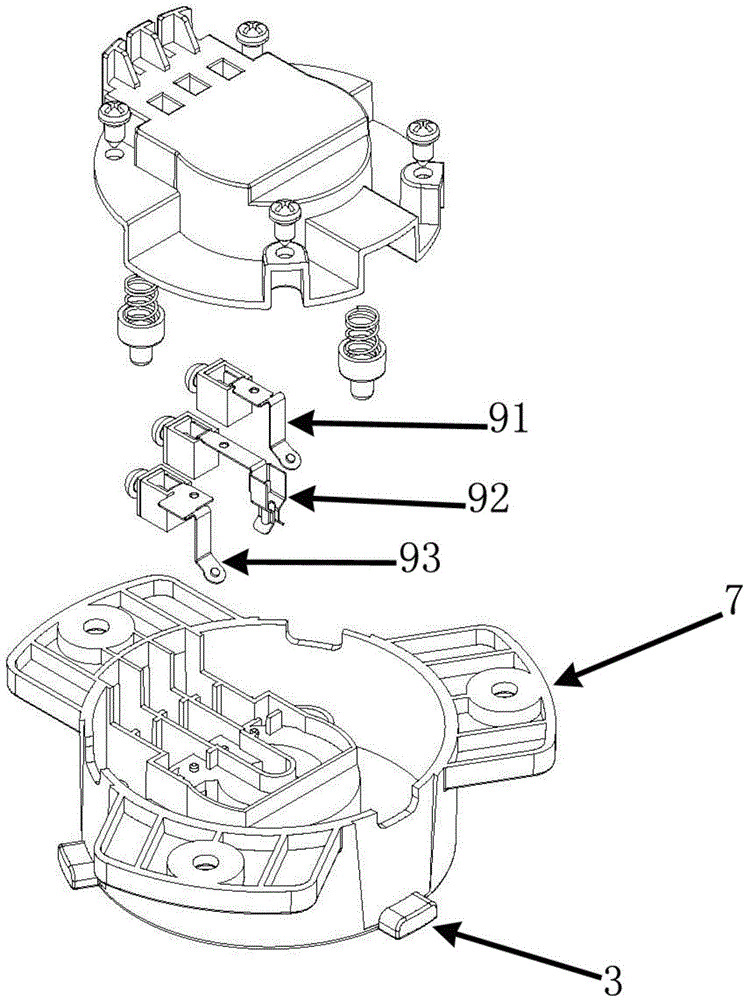

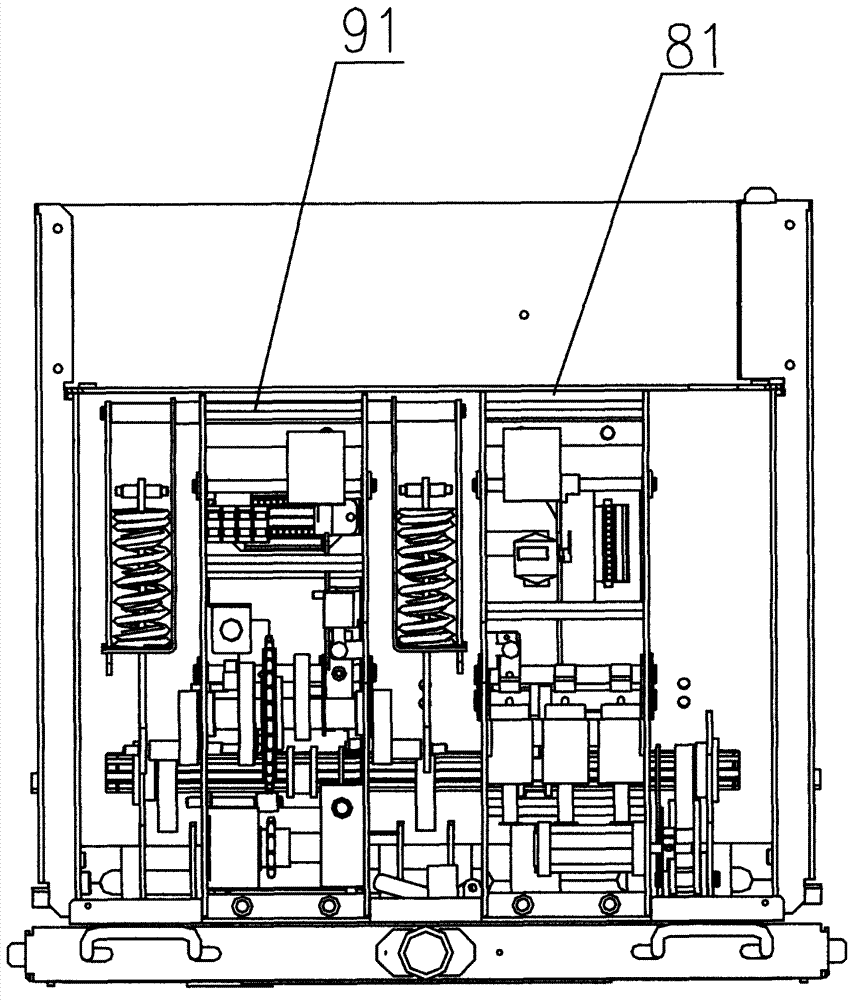

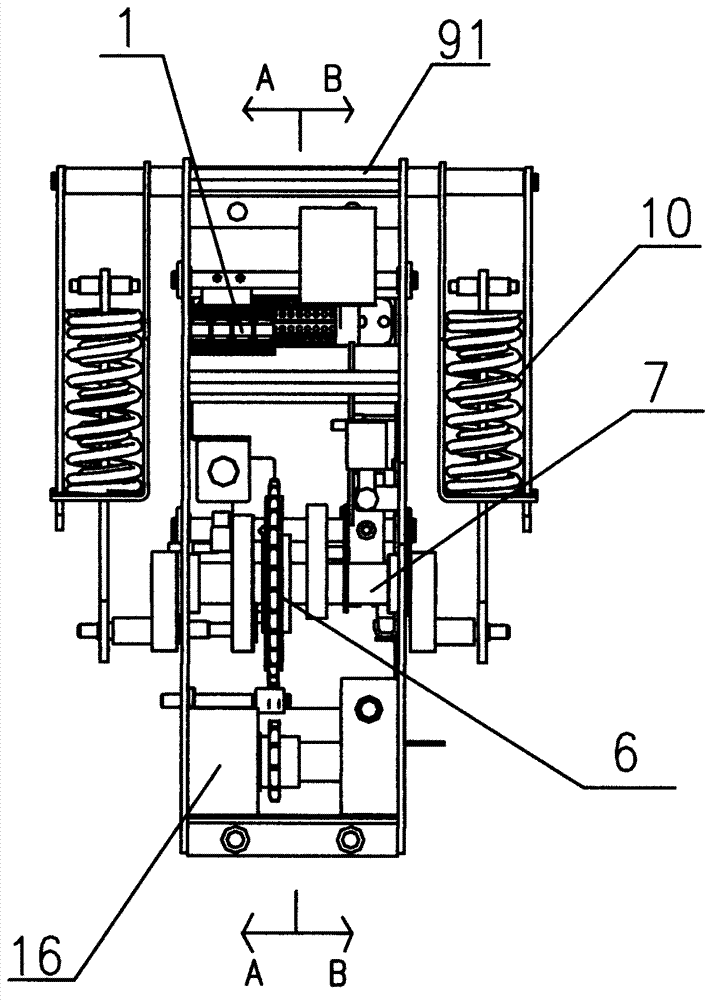

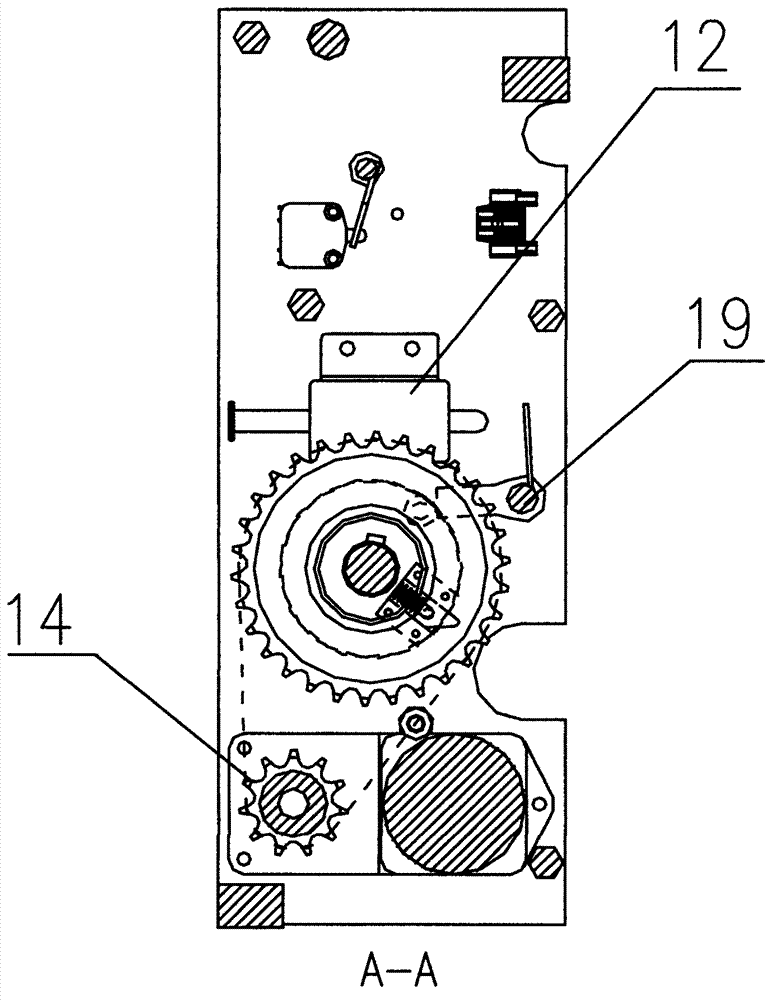

Operating mechanism for circuit breaker

InactiveCN104766768AIncrease varietyOptimize quantitySwitching device condition indicationProtective switch operating/release mechanismsComputer moduleCam

The invention discloses an operating mechanism for a circuit breaker. The operating mechanism for the circuit breaker comprises a switching-on module unit and a switching-off module unit. The switching-on module unit is composed of a left side board, a right side board, an energy storage motor, an energy storage compression spring, a crank arm, an energy storage shaft, a cam, a chain wheel, a tripping shaft, a trigger, a microswitch, a switching-on electromagnet and an energy storage sign board. The switching-off module unit is composed of a left side board, a right side board, one or more tripping electromagnets, a switching-off half shaft, a pinch plate, a trigger and a switching on / off sign board. The operating mechanism for the circuit breaker has the advantages that the operating mechanism is practical and low in production cost, and the spring operating mechanism of the circuit breaker is combined into a modularized unit, is independent from the circuit breaker, and is integrally assembled and disassembled conveniently; a switching on module and a switching off module in the modularized operating mechanism can be independently assembled in advance and are each of one specification, and therefore the variety and the number of spare parts and stored parts are both greatly reduced, and the production efficiency of products is improved.

Owner:黄国强

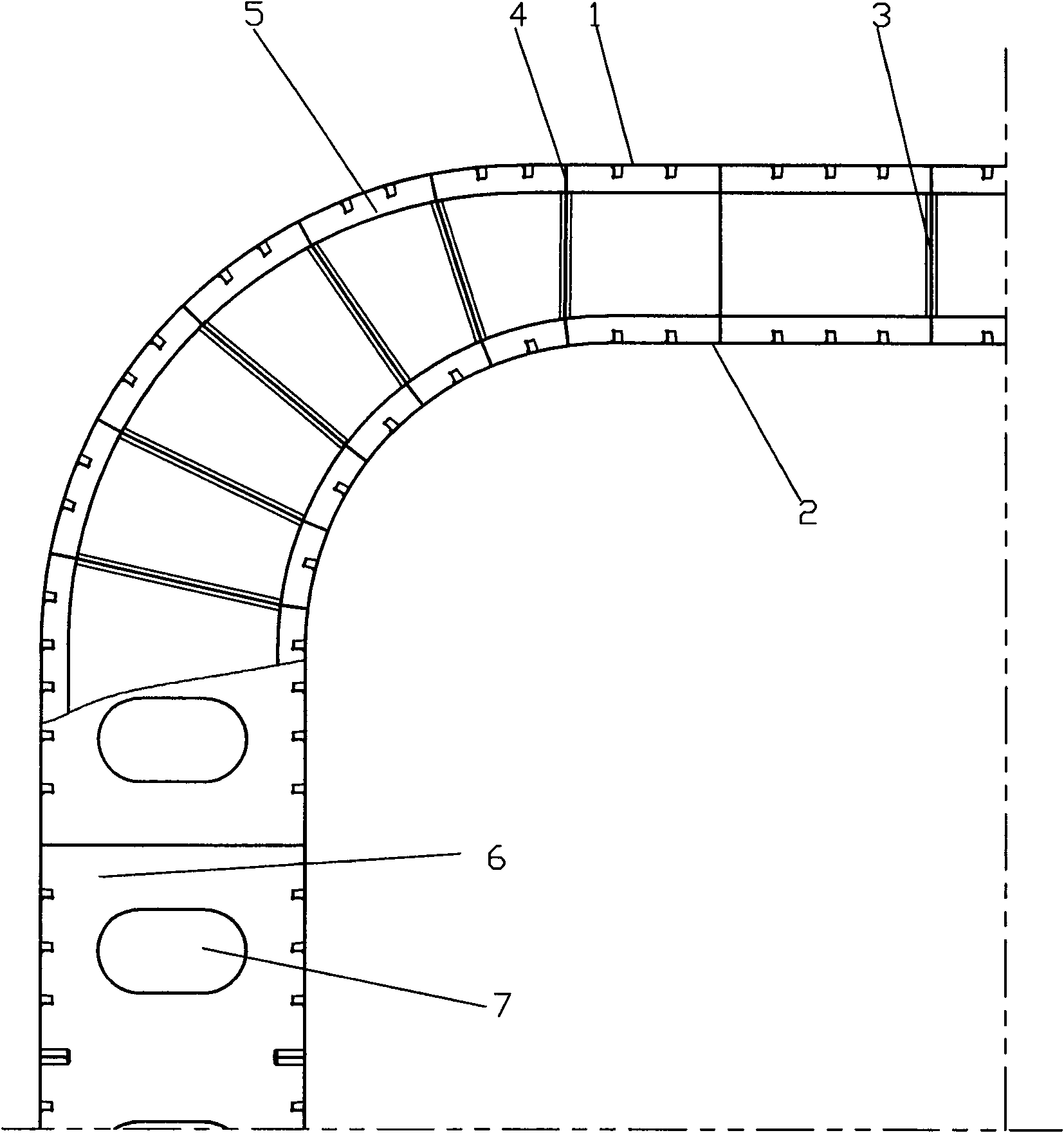

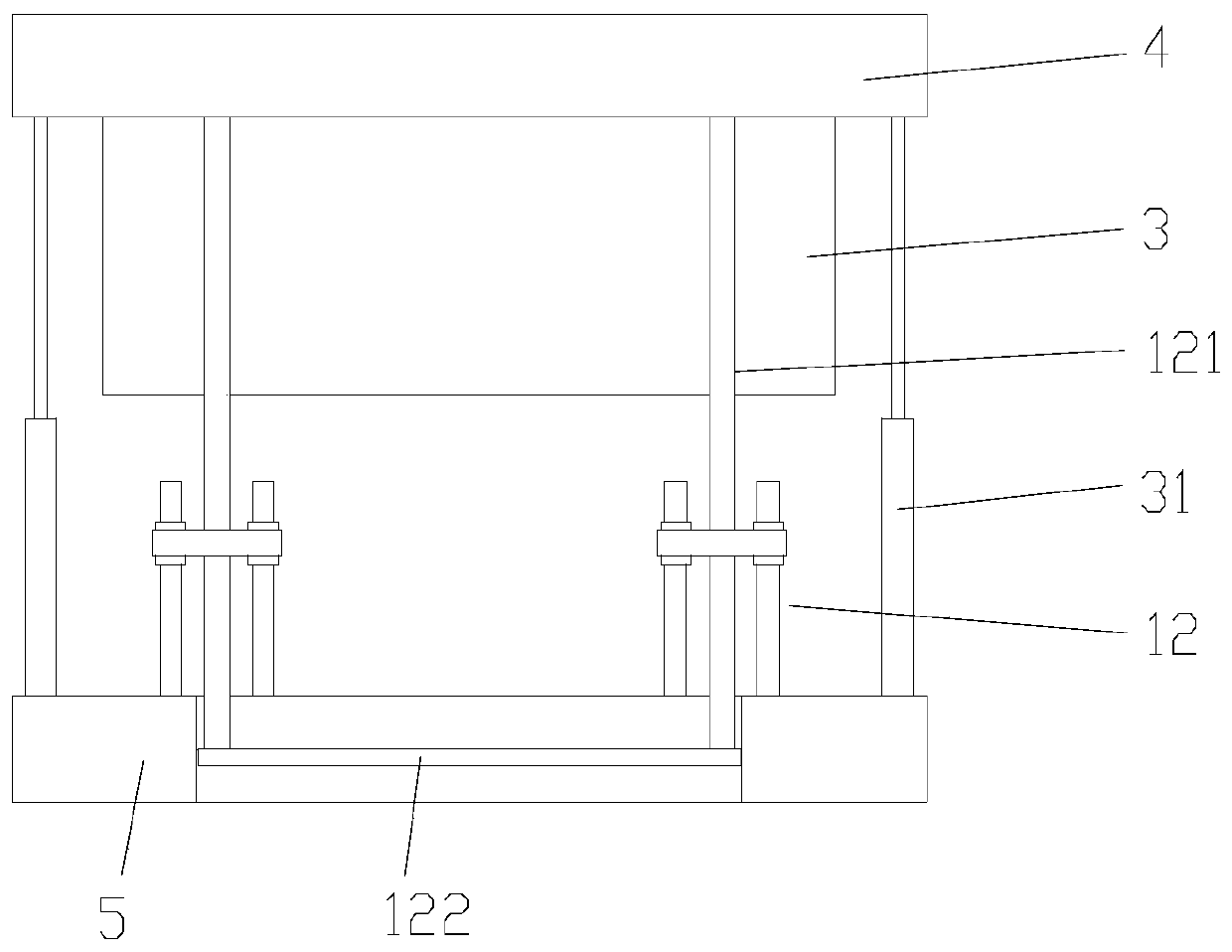

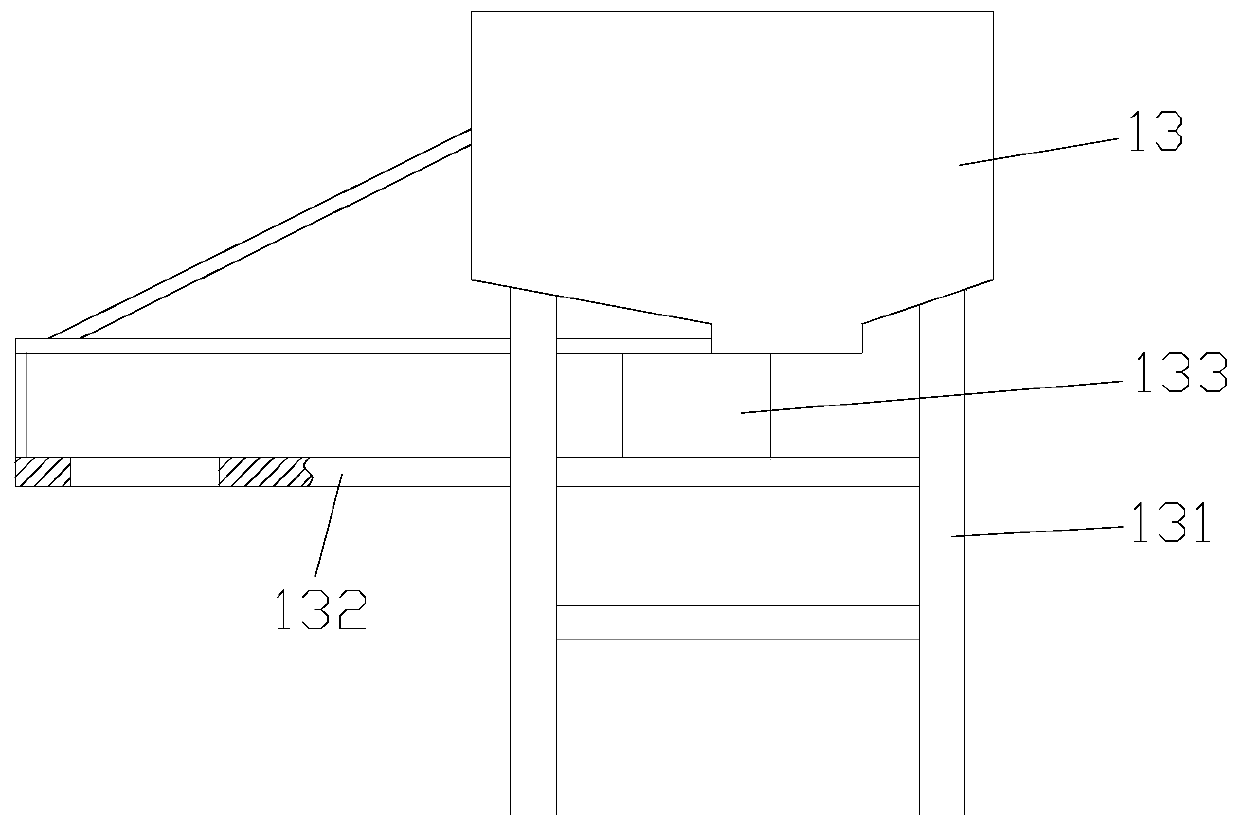

Gantry system of tunnel lining trolley

ActiveCN104033166AReduce in quantityReduce typesUnderground chambersTunnel liningSingle supportFlange

The invention provides a gantry system of a tunnel lining trolley. The gantry system comprises a support frame, a gantry longitudinal beam, jacking mechanisms and transverse beam connecting beams. The support frame comprises a plurality of single support frame bodies, each single support frame body comprises a gantry transverse beam and two gantry upright columns, the two gantry upright columns of each single support frame body are symmetrically arranged, the gantry transverse beams are perpendicular to the gantry longitudinal beam and are positioned right above the gantry longitudinal beam, and the gantry upright columns are vertically arranged among the gantry transverse beams and the gantry longitudinal beam; the transverse beam connecting beams are parallel to the gantry longitudinal beam and are arranged on the gantry transverse beams; flange plates are arranged on the side surfaces of the gantry upright columns, and two groups of through holes which are used for mounting supporting jack seats and supporting cylinder seats are equidistantly formed in each flange plate; the jacking mechanisms are arranged at two ends of the gantry longitudinal beam. The gantry system has the advantages that the gantry system is simple in integral structure; the supporting jack seats and the supporting cylinder seats can be conveniently vertically adjusted owing to the through holes, so that requirements of different working conditions can be met, and the gantry system is high in practicality; supporting jacks and supporting cylinders can be flexibly mounted and adjusted, accordingly, the construction cost can be greatly lowered, and the labor intensity can be greatly relieved.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

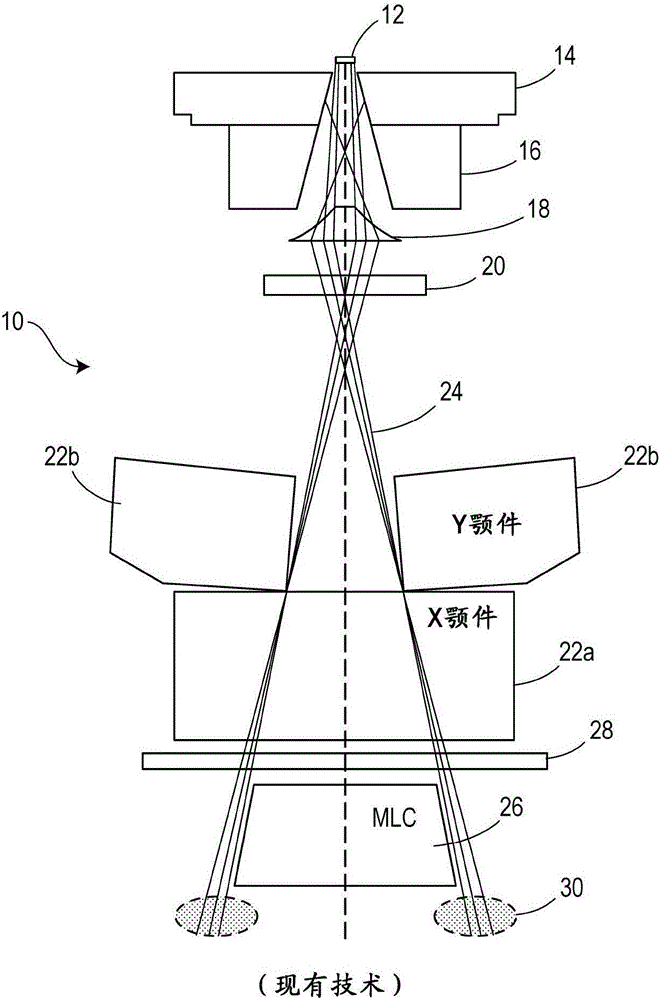

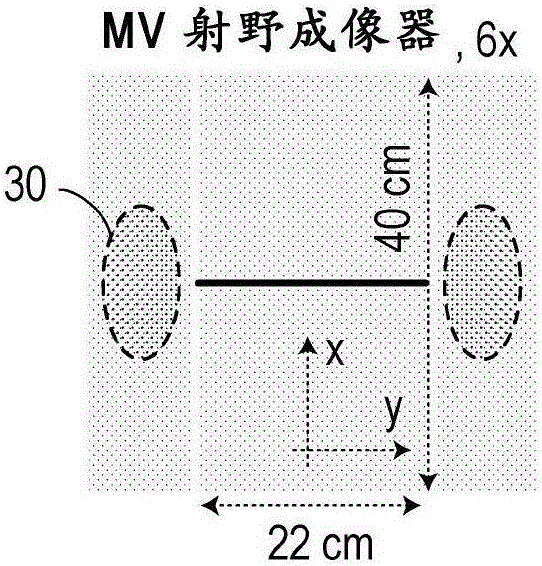

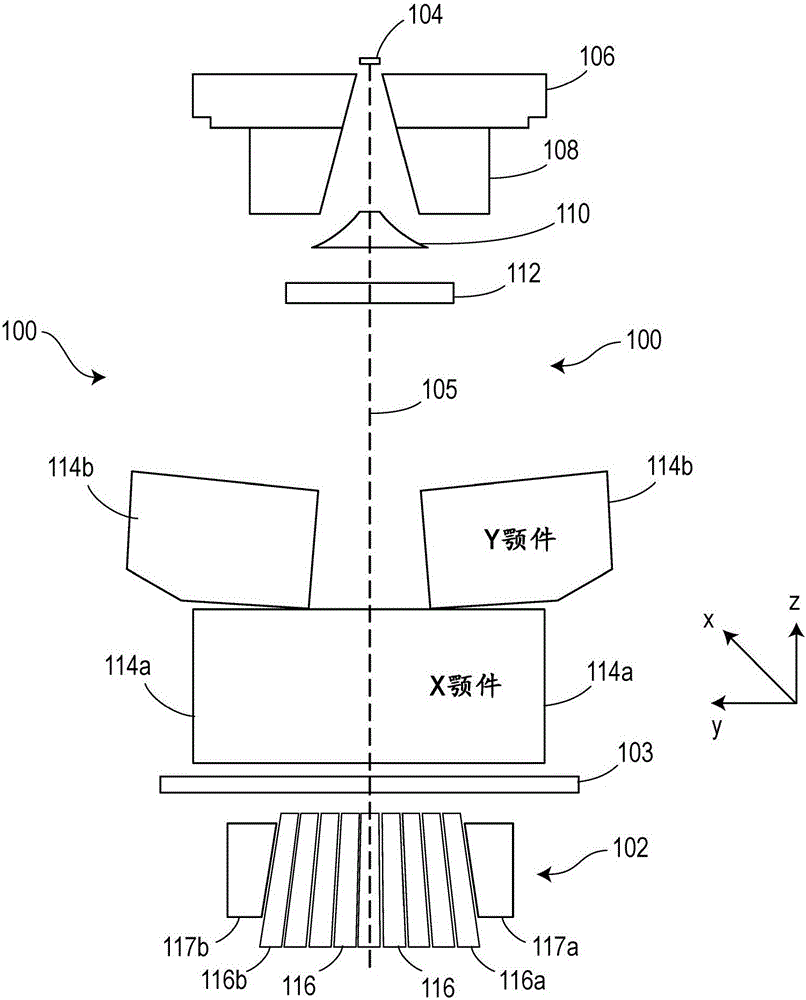

Multileaf collimator assembly with reduced extra-focal leakage

ActiveCN106540380ALow costSimplify the rough shapeRadiation/particle handlingX-ray/gamma-ray/particle-irradiation therapyMultileaf collimatorMedical physics

A multileaf collimator assembly employs one or more static blocks to significantly reduce extra focal leakage or out of field dose. The multileaf collimator assembly includes a plurality of pairs of beam shaping leaves. The leaves of each pair are movable relative to each other in a longitudinal direction. The one or more static blocks are disposed adjacent to the outermost pair of beam shaping leaves and unmovable in the longitudinal direction. The material composition and geometric characteristics of the static blocks may be chosen based on the pre-determined leakage specification for a particular radiation apparatus in the patient plane.

Owner:VARIAN MEDICAL SYSTEMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com