Gantry system of tunnel lining trolley

A technology for lining trolleys and gantry, which is applied in the field of gantry system of tunnel lining trolleys, can solve the problems of difficulty in repairing tunnel trolleys, reducing the accuracy of tunnel lining trolleys, affecting the quality of tunnel lining, etc. Cost and labor intensity, flexible installation and adjustment, and the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

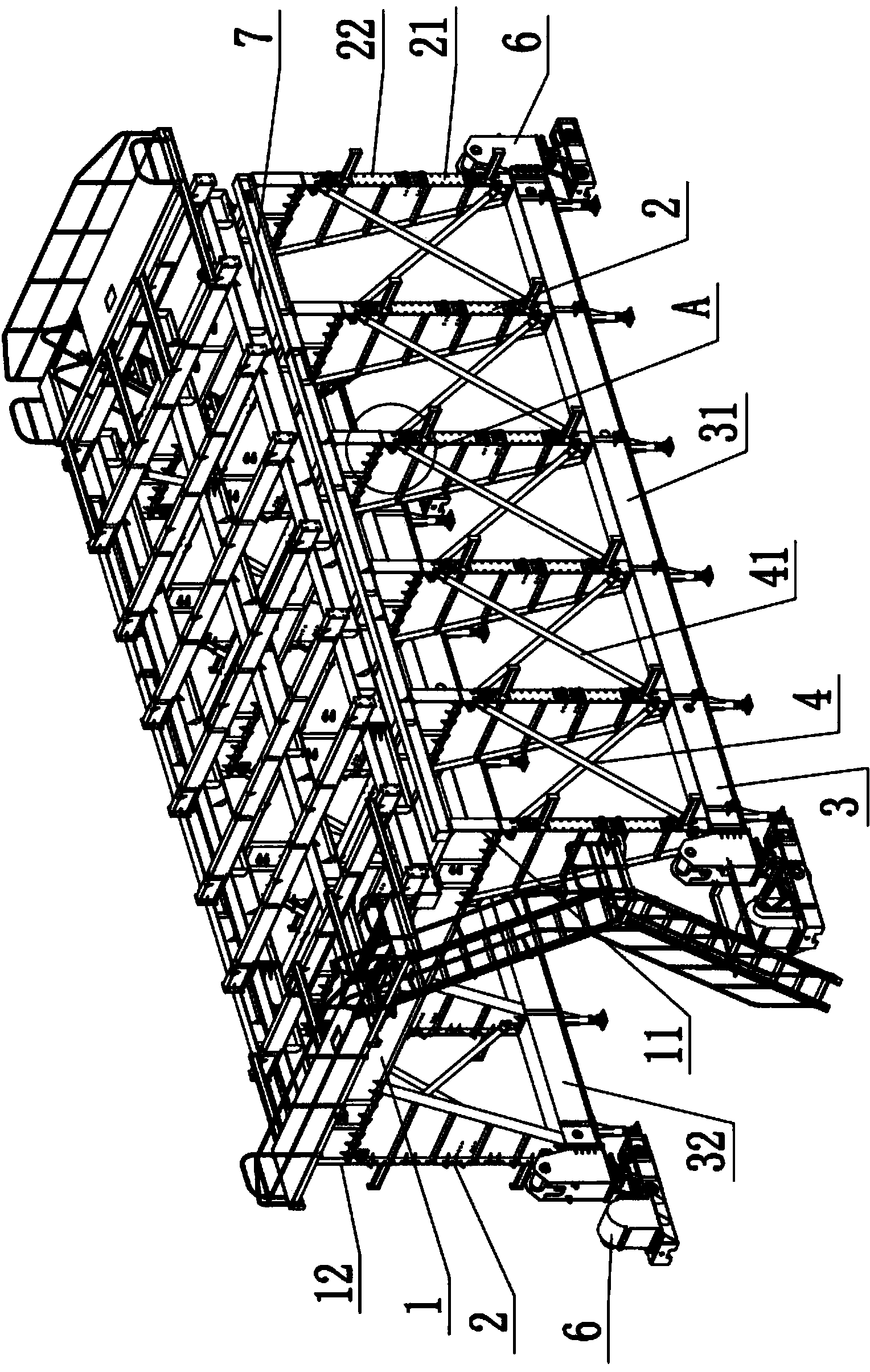

[0037] A portal frame system for a tunnel lining trolley, see figure 1 , specifically including a support frame, a mast longitudinal beam 3, a jacking mechanism 6 and a beam connecting beam 7, and the overall structure is simplified.

[0038] The gantry longitudinal beam 3 includes a first gantry longitudinal beam unit 31 and a second gantry longitudinal beam unit 32 arranged side by side, and the first gantry longitudinal beam unit 31 and the second gantry longitudinal beam unit 31 are arranged side by side. The beam elements 32 are located on the same level.

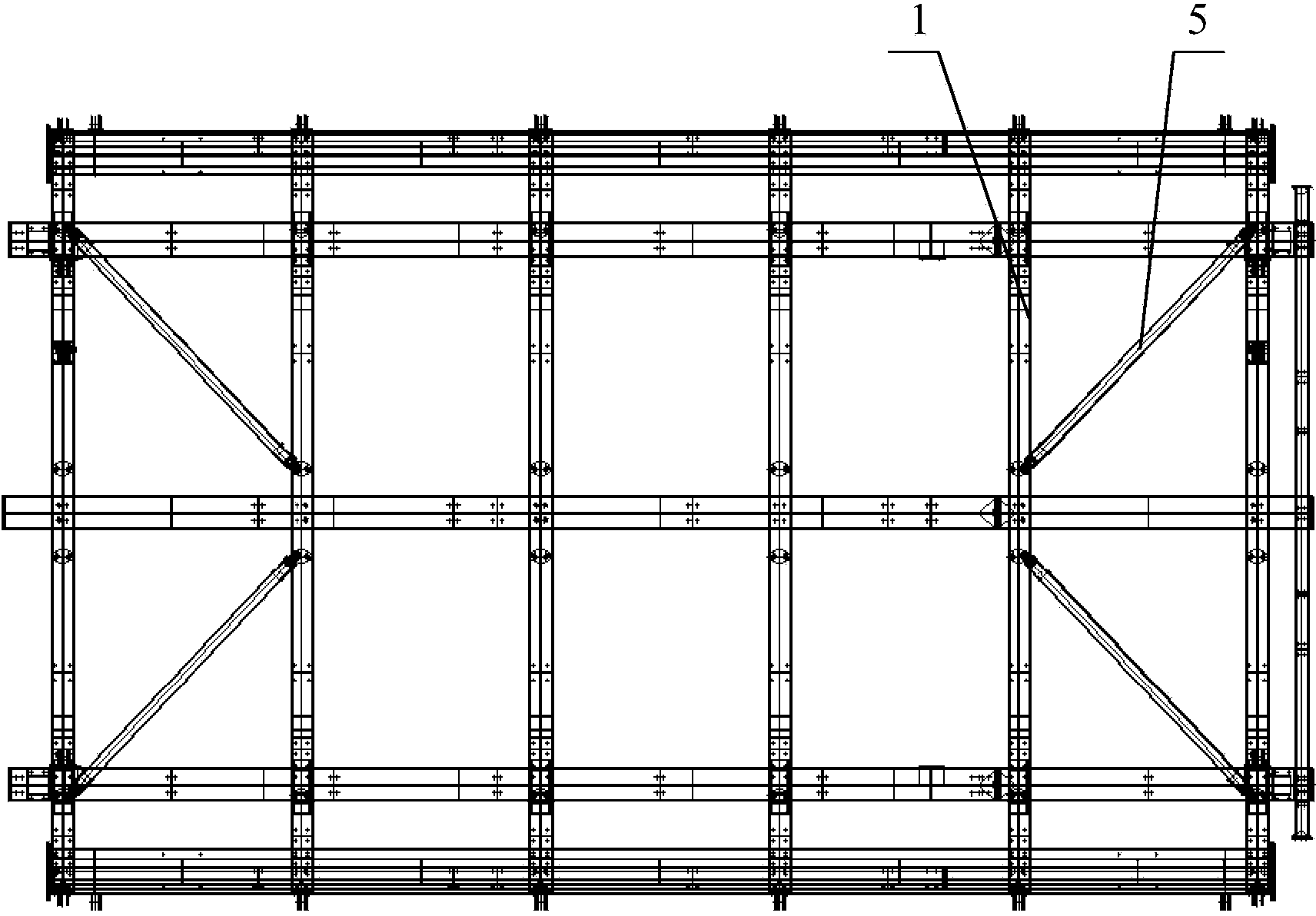

[0039] The support frame includes at least two support frame monomers arranged side by side, the support frame monomer includes a door frame beam 1 and two door frame columns 2 arranged symmetrically, the door frame beam 1 and the door frame longitudinal The beam 3 is arranged vertically and directly above it, and the mast column 2 is vertically arranged between the mast beam 1 and the mast longitudinal beam 3 .

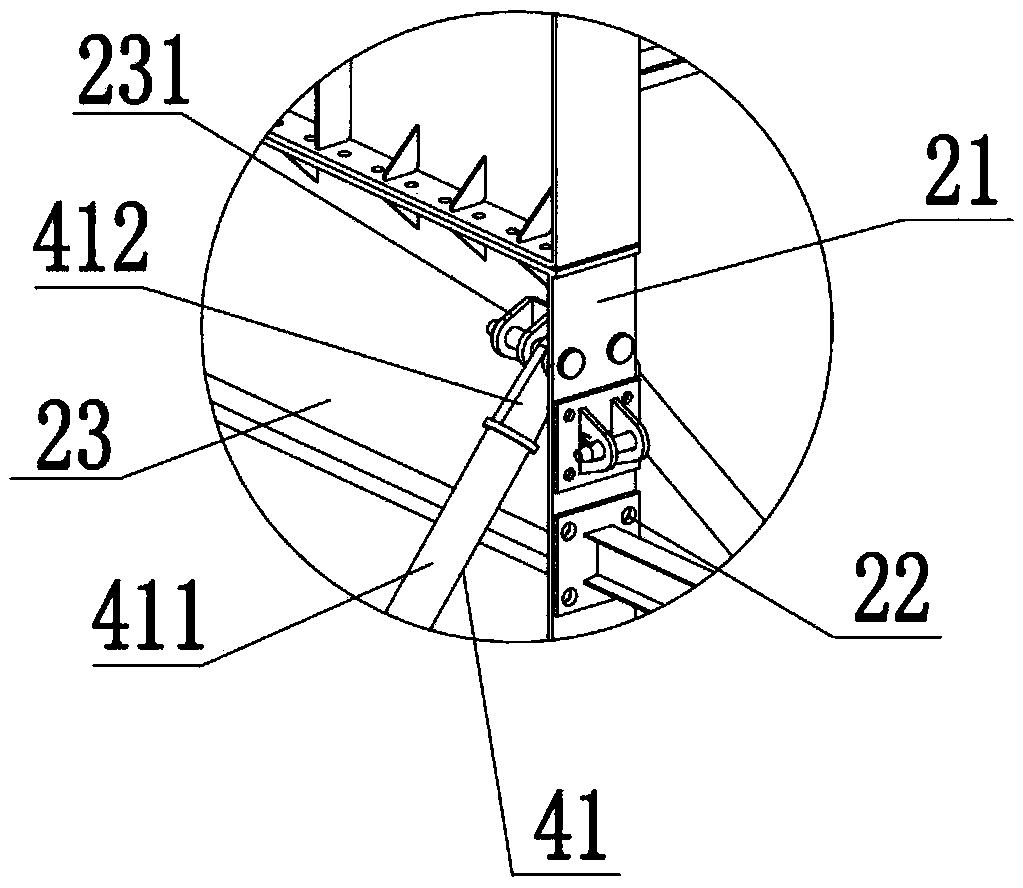

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com