Mobile lubricating oil filling automobile

A technology of lubricating oil and oil trucks, which is applied in the field of mobile lubricating oil filling vehicles, which can solve the problems of poor thermal insulation of transported oil products, less oil products, and large volume of conveying equipment, so as to ensure thermal insulation, high safety, and improve conveying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

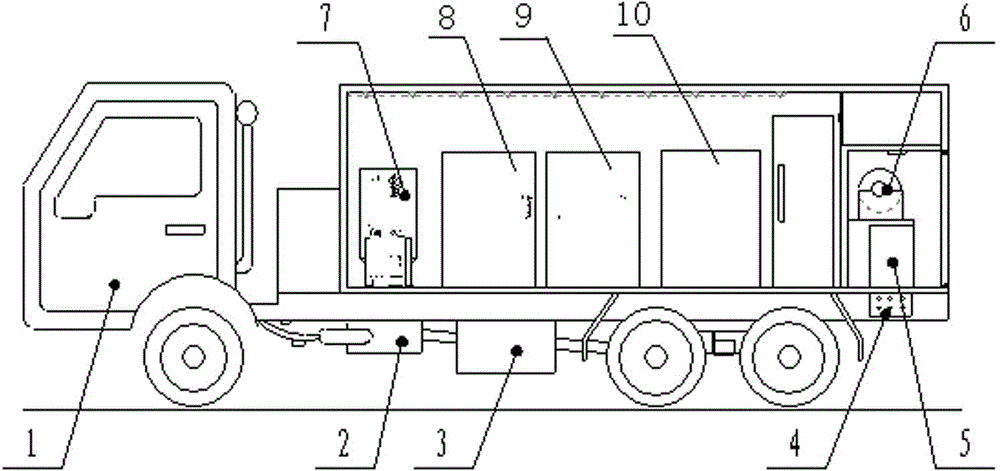

[0024] like figure 1 As shown, a mobile lubricating oil filling vehicle includes the following seven parts: automobile body 1, hydraulic oil supply power system 2, heating and heat preservation system 3, oil replenishment system 4, electrical control system 5, oil output device 6, Grease delivery device 7.

[0025] The car body 1 adopts a heavy truck chassis, the upper part is a box structure, the box body frame structure is high-strength structural steel, the box body cover is glass fiber reinforced plastic, and the box body adopts a polyurethane thermal insulation layer.

[0026] A grease conveying device 7 , a hydraulic oil tank 8 , an oil oil tank 9 , a gear oil tank 10 and an oil filling device are arranged in the car body.

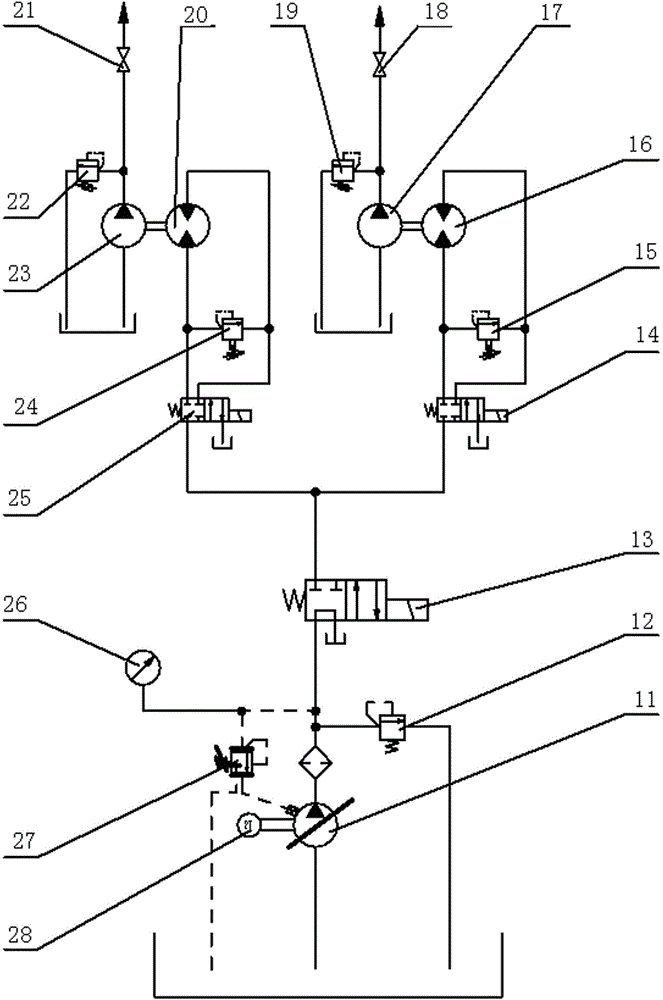

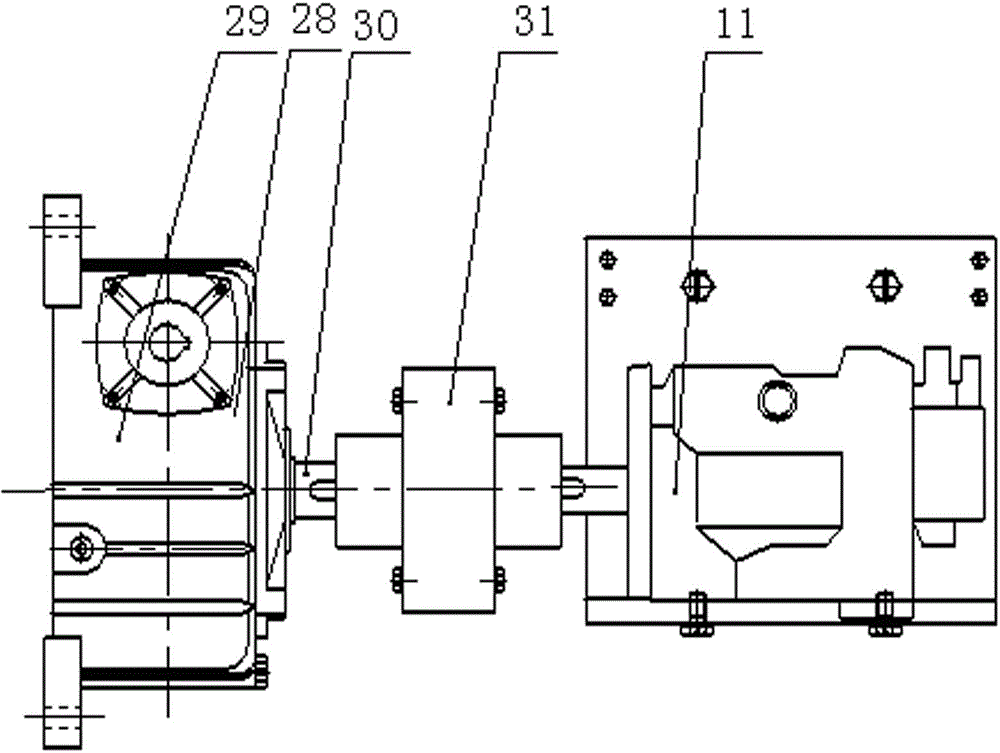

[0027] like figure 2As shown, the hydraulic oil supply power system 2 includes: a variable pump 11, a reversing valve one 13, a reversing valve two 14, a reversing valve three 25, a motor one 16, a motor two 20, an oil pump 17, an oil pump two 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com