Novel sawing machine blade connection structure and manufacturing method thereof

A technology of connecting structure and saw blade, which is applied in the direction of tool manufacturing, manufacturing tools, metal sawing equipment, etc. of sawing machine devices, can solve the problems of increased production cost, increased vibration of sawing machine, consumption of spare parts, etc., and achieves easy installation and disassembly. , The effect of reducing the chance of turbulence and saving replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

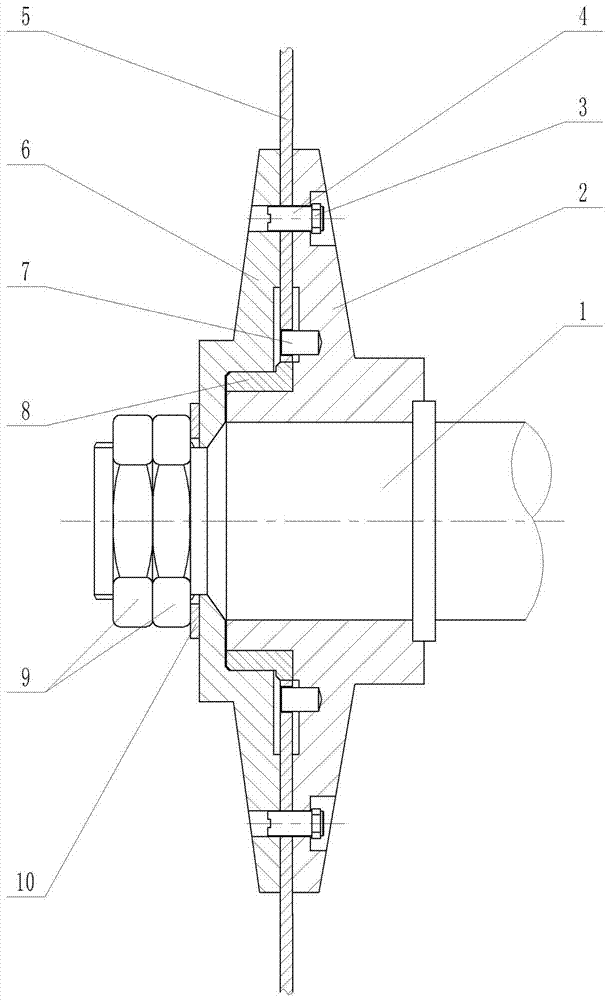

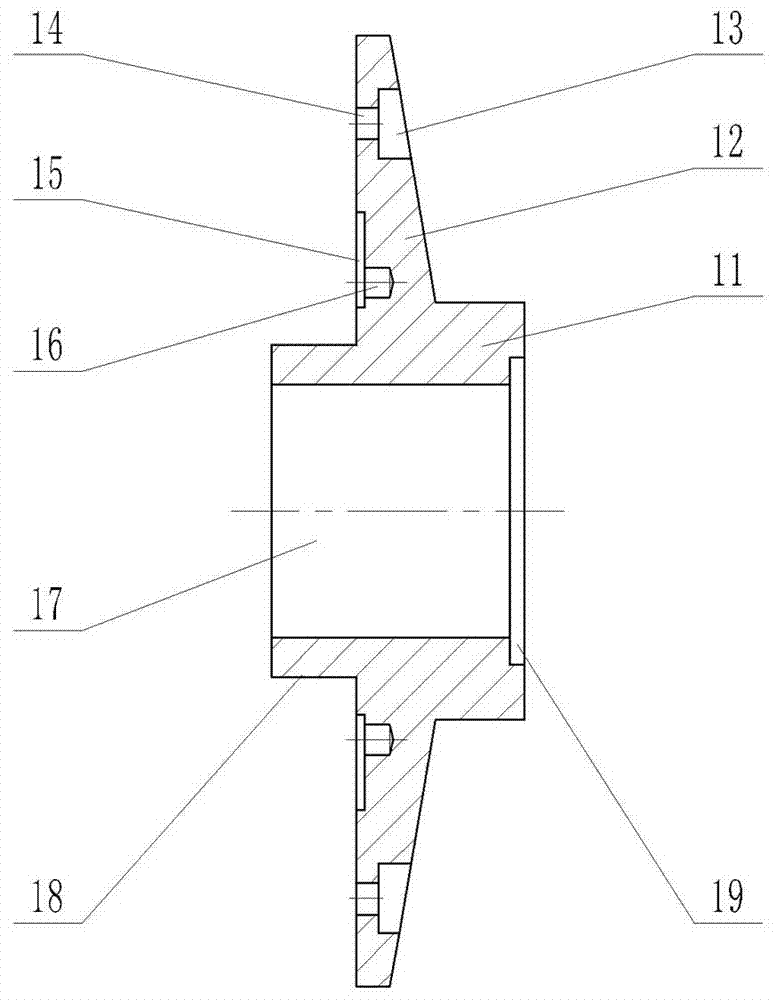

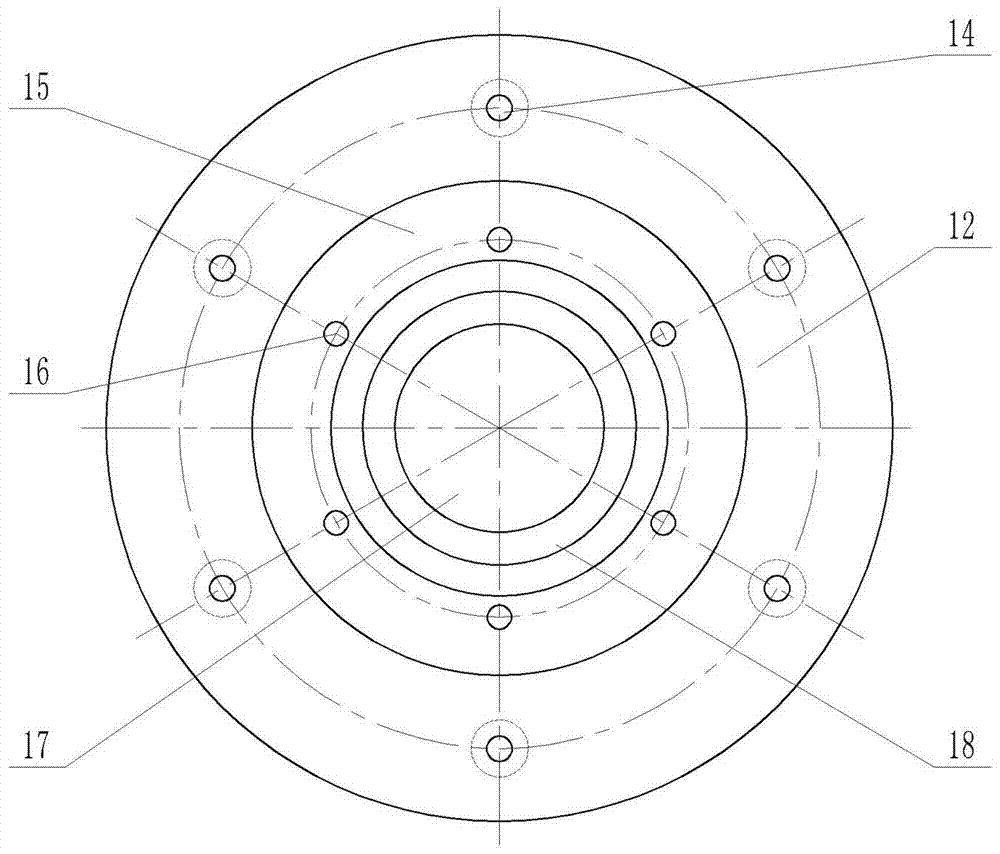

[0026] according to Figure 1-7The specific structure of the present invention will be described in detail. This novel saw blade connecting structure includes a saw disc arranged on the main shaft 1 of the saw machine for connecting the saw blade 5 of the fixed saw machine, wherein the saw disc consists of the main saw disc 2 fixed on the main shaft 1 of the saw machine and the The dismantled auxiliary saw disc 6 constitutes. The main saw disc 2 is composed of a cylindrical main disc body 11, and the middle part of the main disc body 11 is provided with a main shaft connecting through hole 17 arranged along the axis; There is a saw disc journal 18 for mounting the journal bushing 8 . On the outer wall of the main saw disc 2 main disc body 11, a disc-shaped main fixed disc 12 for fastening the saw blade 5 of the saw machine is also provided; the main fixed disc 12 is provided with six bolts arranged at equal intervals along the same circumference Through hole 14. Moreover, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com