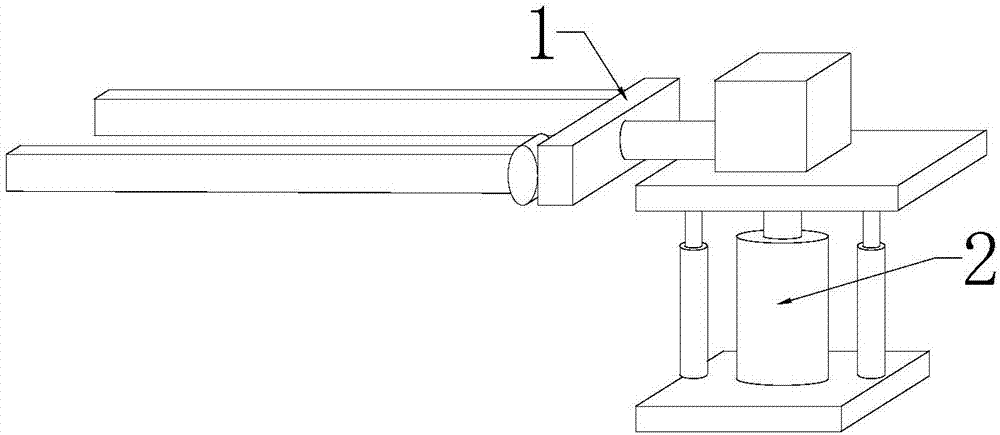

Auxiliary tool for brick overturning

A technology of auxiliary tools and bricks, applied in the direction of lifting device, load hanging element, hoisting device, etc., can solve the problems of increasing economic investment, high labor intensity, unable to control the clamping force well, etc. The effect of large economic investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

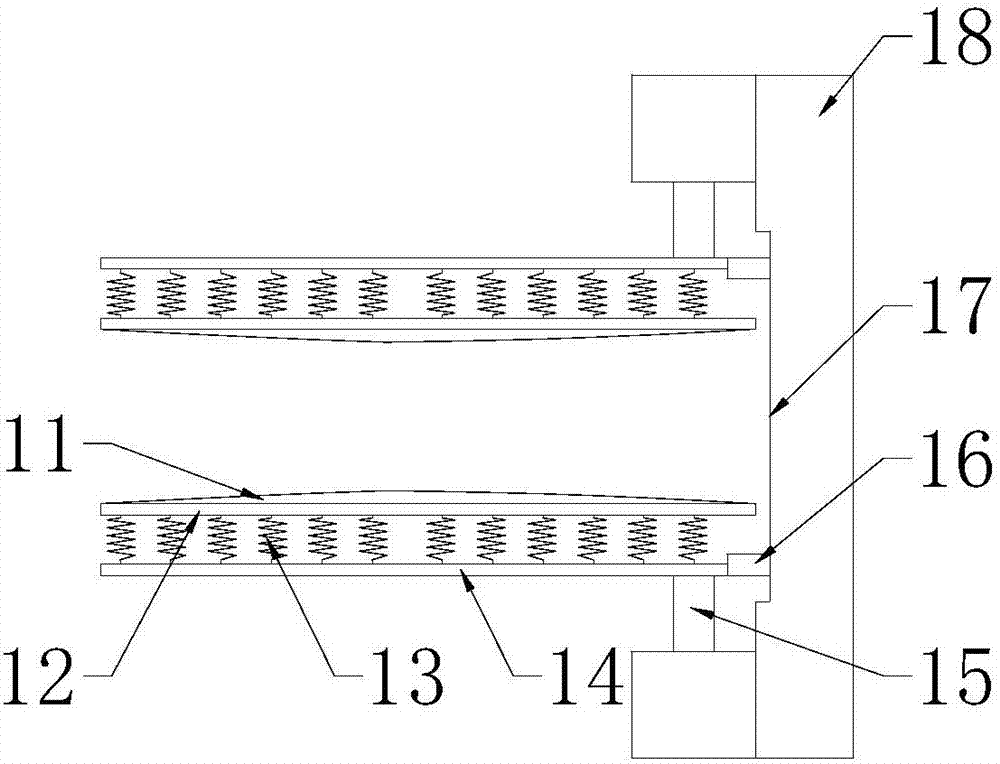

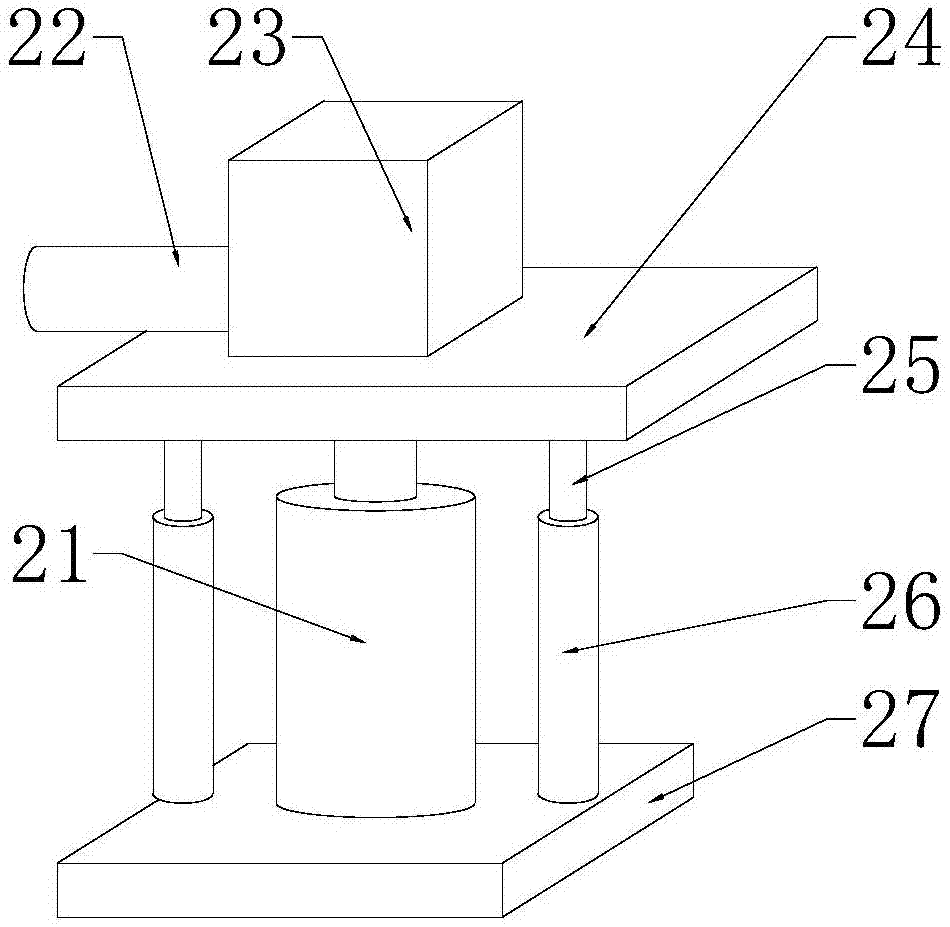

specific Embodiment approach

[0024] Specific implementation method: before using the present invention to carry out hollow brick adobe turning work, the staff first arranges the hollow brick adobes side by side in a row and places them on the placement surface, and then the staff pushes the support plate 24 to the left to make the support plate 24 Moving to the left, the support plate 24 moves to the left to drive the clamping mechanism 1 to move to the left. When the clamping mechanism 1 moves to the top of a row of hollow bricks, the staff starts the electric lifter 21, and the electric lifter 21 works to drive the support The plate 24 moves downward, and the downward movement of the support plate 24 drives the motor 23 to move downward. The downward movement of the motor 23 drives the rotating shaft 22 to move downward, and then drives the clamping mechanism 1 to move downward. When the height of the upper end surface of the billet is consistent, the staff closes the electric elevator 21, and then the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com