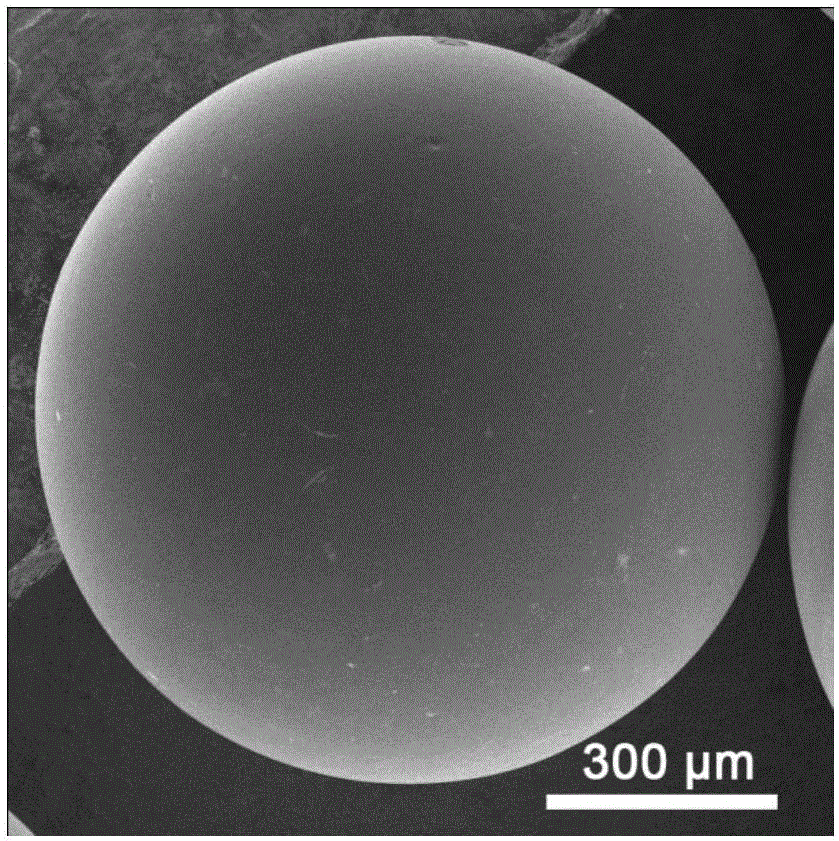

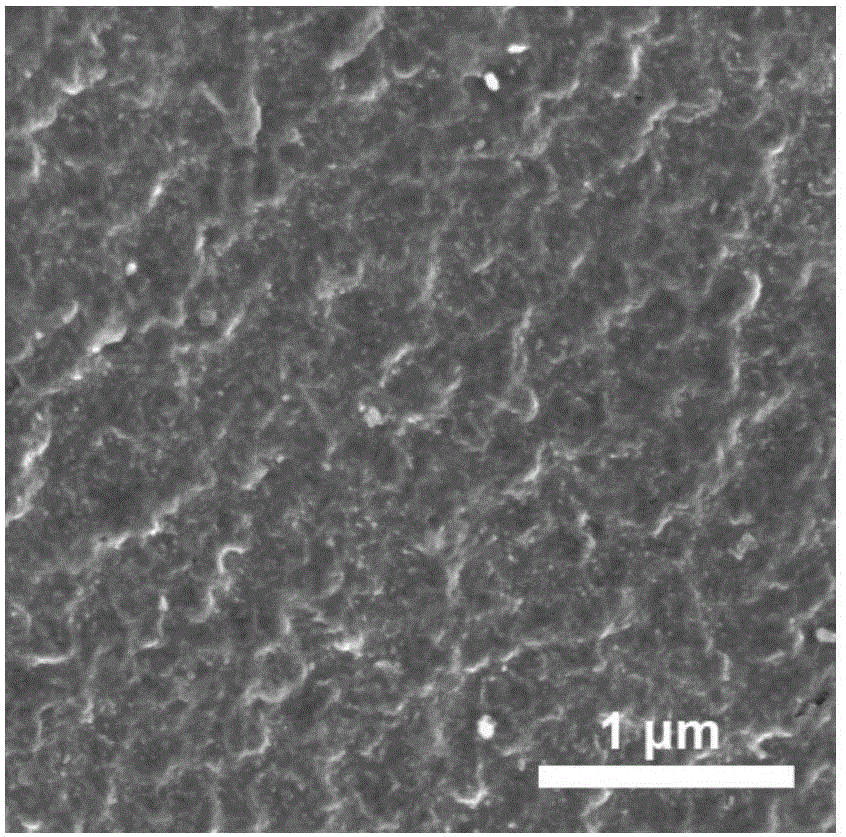

Preparation method of spherical mesoporous carbon for blood purification

A blood purification and spherical technology, applied in chemical instruments and methods, other chemical processes, dialysis systems, etc., can solve problems such as unsuitable adsorbents for blood purification, clogging blood vessels, affecting cardiovascular system functions, etc., to achieve good blood phase Capacitance, good sphericity, and good blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First, dilute the commercially available water glass to 3%, and pass it through a cation exchange resin column to obtain an active silicic acid solution, add sodium hydroxide solution to adjust the pH to 9.5, hydrolyze at a constant temperature of 40°C for 4 hours, and reach the silica sol with the required particle size, concentrate to 30% Alkaline SiO 2 Sol. Then resorcinol, formaldehyde and SiO 2 Mix at a molar ratio of 1:2:3, add a certain amount of deionized water so that the total concentration of organic matter in the reactant is 20g / 100mL, polymerize at 40°C for 70min to form an organic-inorganic sol, pour it into paraffin oil, and stir to form spheres, and further aged at 85 °C to obtain spherical composite hydrogels. Separated and washed, and then dried under normal pressure. Under the protection of nitrogen, carbonization and cracking at 900°C for 2 hours resulted in spherical carbon-silicon composite airgel. Then the spherical carbon-silicon composite ai...

Embodiment 2

[0031] First, dilute the commercially available water glass to 8%, pass it through a cation exchange resin column to obtain an active silicic acid solution, add sodium hydroxide solution to adjust the pH to 9, hydrolyze at a constant temperature of 50°C for 0h, and concentrate to a concentration of 30% alkaline SiO 2 Sol. Then resorcinol, formaldehyde and SiO 2 Mix evenly at a molar ratio of 1:2:3, add a certain amount of deionized water so that the total concentration of organic matter in the reactant is 20g / 100mL, polymerize at 50°C for 60min to form an organic-inorganic sol, pour it into silicone oil, and stir to form spheres, and further aged at 80 °C to obtain spherical composite hydrogels. Separated and washed, and then dried under normal pressure. Under the protection of nitrogen, carbonization and cracking at 850°C for 2.5 hours was carried out to obtain spherical carbon-silicon composite airgel. Then soak the spherical carbon-silicon composite airgel in 15% sodium ...

Embodiment 3

[0033] First, dilute the commercially available water glass to 10%, pass it through a cation exchange resin column to obtain an active silicic acid solution, add sodium hydroxide solution to adjust the pH to 9.5, hydrolyze at a constant temperature of 60°C for 2 hours, and reach the silica sol with the required particle size, and then concentrate to 30% Alkaline SiO 2 Sol. Then resorcinol, formaldehyde and SiO 2 Mix evenly at a molar ratio of 1:2:4, add a certain amount of deionized water so that the total concentration of organic matter in the reactant is 15g / 100mL, polymerize at 60°C for 35min to form an organic-inorganic sol, pour it into paraffin oil, and stir Balls were formed and further aged at 75 °C to obtain spherical composite hydrogels. Separated and washed, and then dried under normal pressure. Under the protection of nitrogen, carbonization and cracking at 800°C for 3 hours resulted in spherical carbon-silicon composite airgel. Then soak the spherical carbon-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com