Buried type garbage compressor

A garbage compressor, buried technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of wear and tear of the lifting connection part of the collision box, increase the floor height of the transfer station building, and increase the time of one cycle of the equipment, and achieve daily life. Easy to maintain, convenient for daily maintenance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

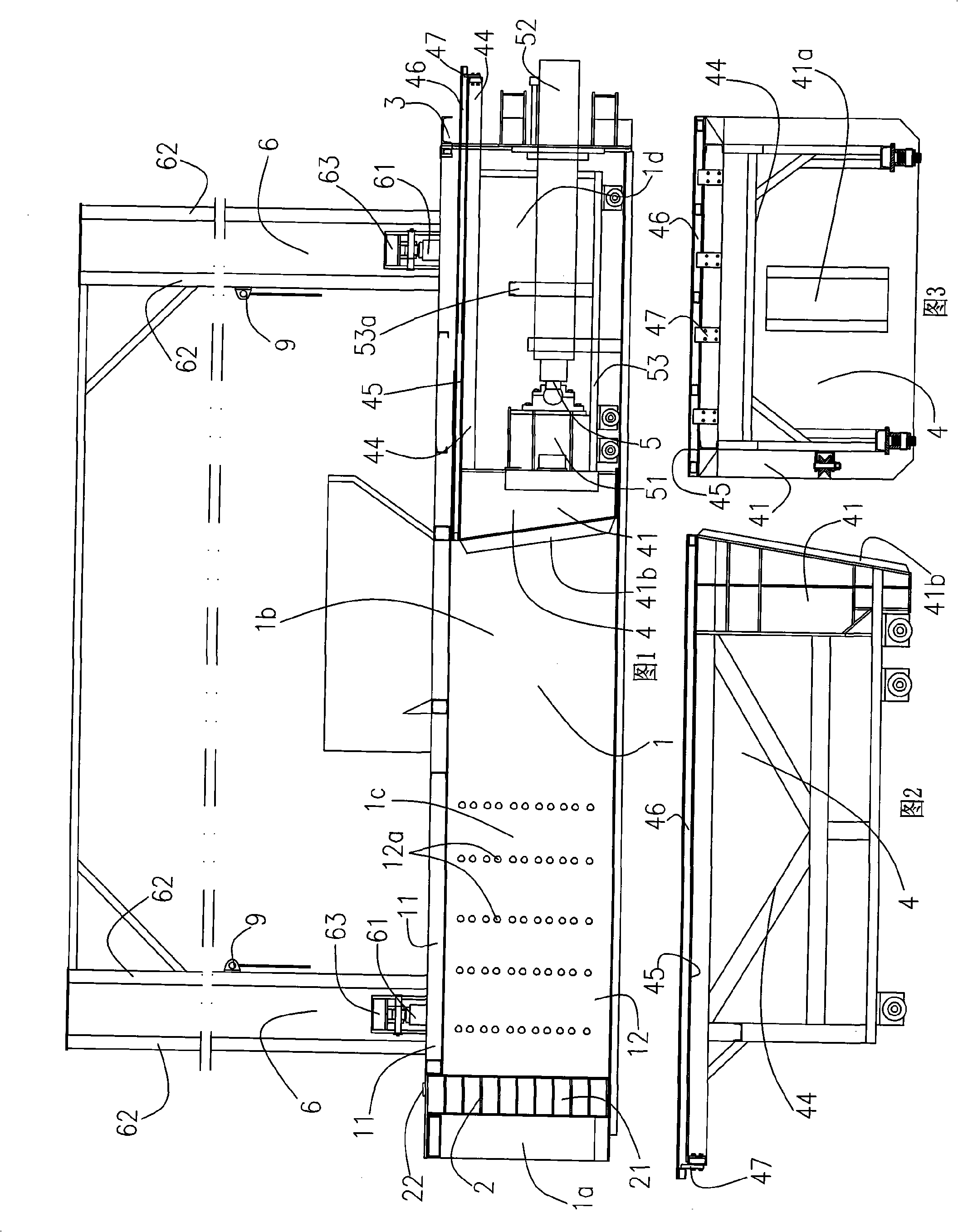

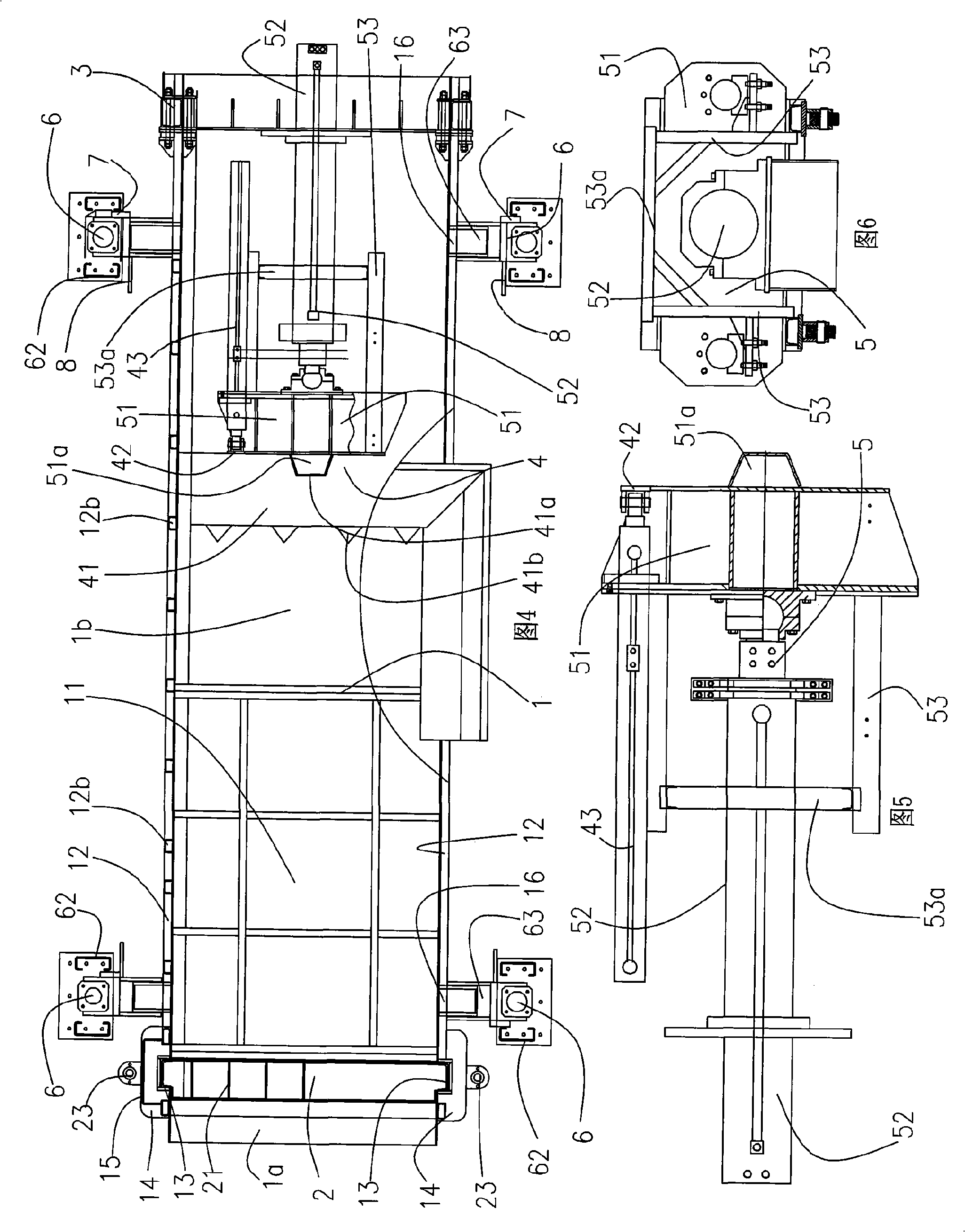

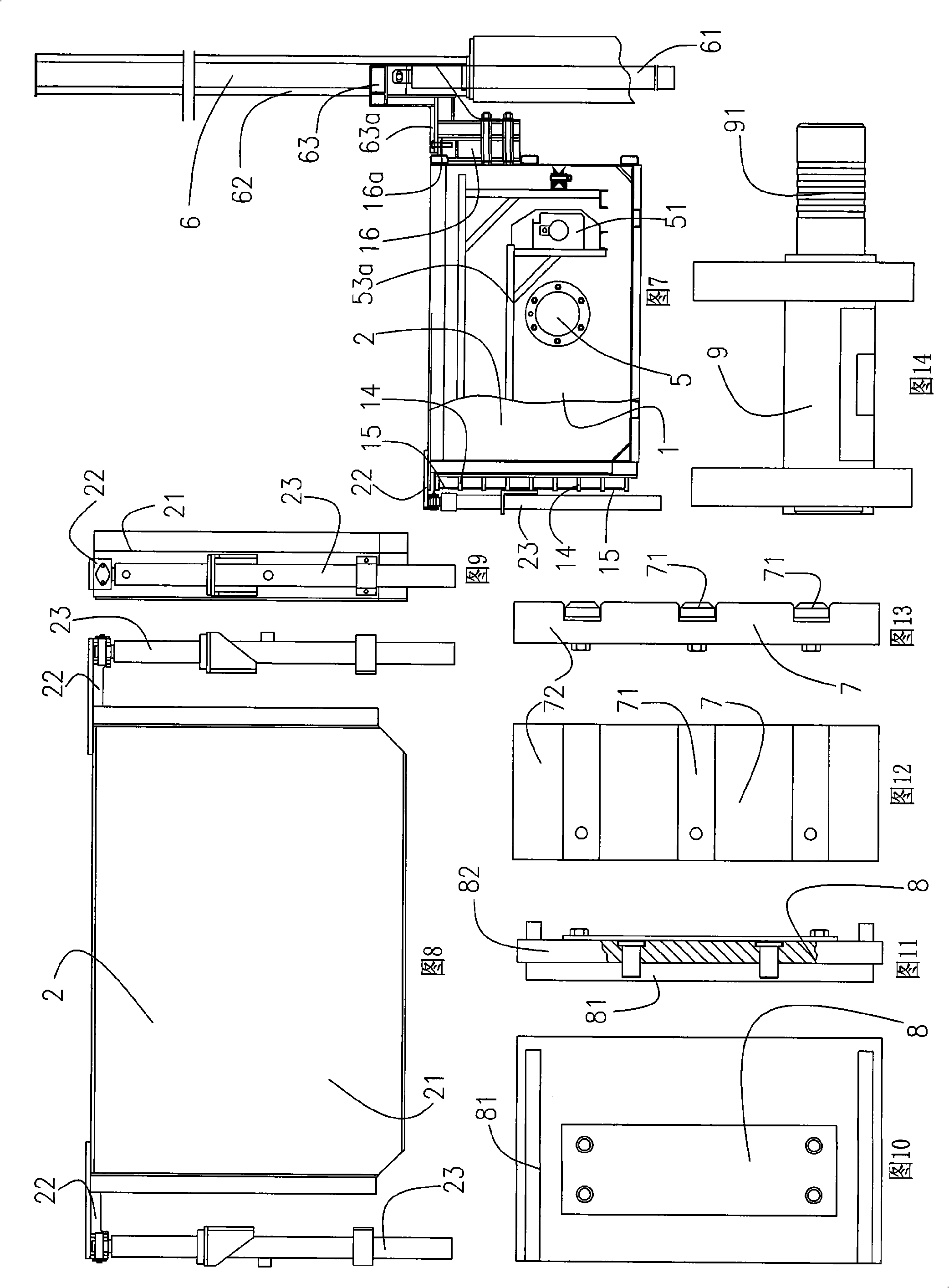

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] The structure of the present invention is shown in Fig. 1 to Fig. 14 . Explanation of icon numbers: garbage bin 1, discharge port 1a, feeding bin 1b, storage bin 1c, pushing bin 1d, surface layer body 11, side vertical plate 12, sewage hole 12a, reinforcing rib 12b, U-shaped groove body 13 , Buckle fixed plate 14, reinforcement plate 15, box lifting seat 16, top edge 16a, gate mechanism 2, gate 21, lifting lug 22, gate cylinder 23, rear top seat 3, push-out mechanism 4, push platform 41, the first A positioning body 41a, a rubbish block 41b, a push-out seat 42, a push-out cylinder 43, a push frame body 44, a rubbish-stop fixing plate 45, a rubbish-stop slide plate 46, a limit block 47, a compression mechanism 5, a compression seat 51, and a second positioning Body 51a, compression cylinder 52, mobile frame 53, bridge body 53a, lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com