Glasses plate and cutting ring for concrete delivery pump

A technology for concrete conveying pumps and cutting rings, which is applied to pumps, pump components, variable capacity pump components, etc. It can solve the problems of increased processing volume, low processing accuracy, and difficulty in ensuring tight extrusion, so as to improve the connection strength, The overall wear resistance is good, and the effect of avoiding direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

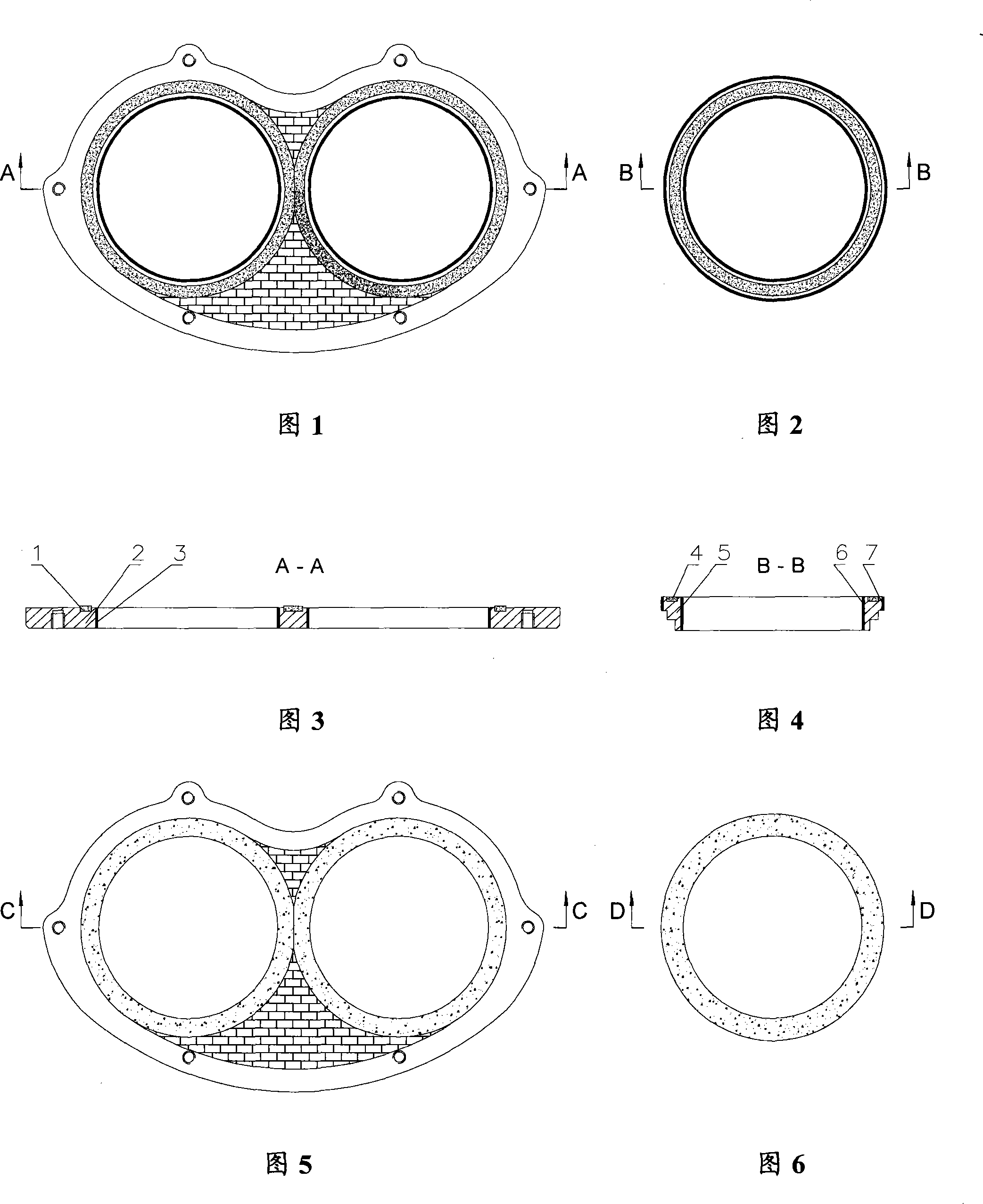

[0043] Embodiment 1 Spectacle plate

[0044] As shown in Fig. 9 and Fig. 11, be the structural representation of cemented carbide spectacle plate of the present invention, comprise spectacle plate substrate 14 and be embedded in the cemented carbide ring that forms substrate wear-resistant plane at substrate cutting surface place, by Fig. 9 can It can be seen that the cemented carbide ring in this embodiment is composed of six cemented carbide blocks 12 in the ring direction.

[0045] As shown in Figure 11, the inner edge of each hard alloy block 12 is turned 90 degrees along the hole wall at the feeding hole of the spectacle plate substrate 14 and extends into the feeding hole to form a hard alloy covering the inner wall of the feeding hole. The ring constitutes the wear-resistant layer on the inner wall of the delivery hole, which improves the wear resistance of the delivery hole and reduces the erosion and wear of the concrete. This kind of cemented carbide block 12 whose ...

Embodiment 2

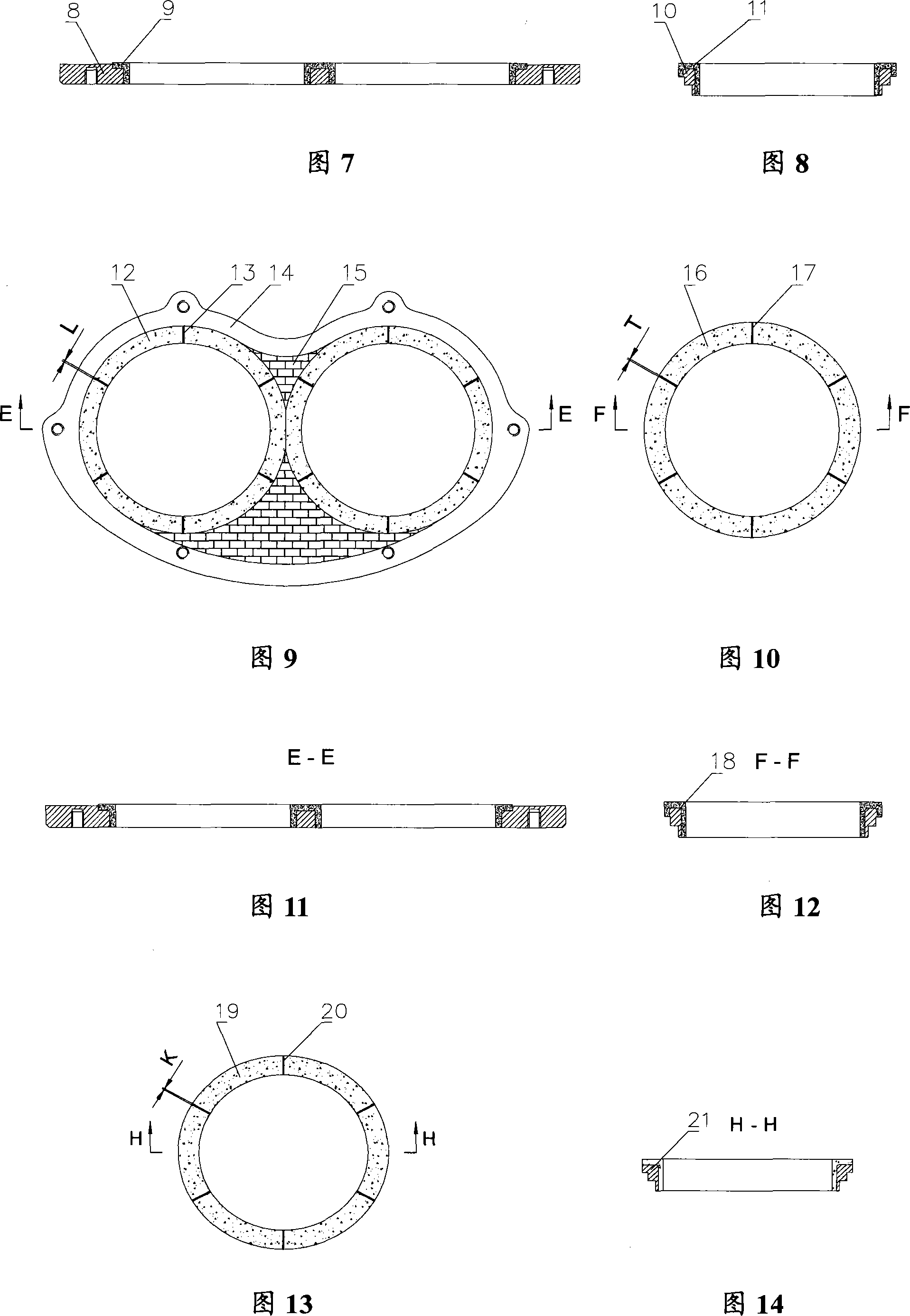

[0052] Example 2 cutting ring

[0053] As shown in Fig. 13 and Fig. 14, it is a cutting ring with an L-shaped cross-sectional carbide ring structure. It includes a cutting ring base body 21 and a hard alloy ring forming a wear-resistant plane of the base body at the cutting surface of the base body. The hard alloy ring is composed of six hard alloy blocks 19 in the ring direction. As shown in FIG. Extending in the feed hole makes the cross section of the cemented carbide block 19 become L-shaped, wherein the arc part is assembled into a cemented carbide ring pasted in the feed hole to form the wear-resistant surface of the feed hole. At the cutting surface and in the feeding hole, a linear gap 20 is formed between adjacent hard alloy blocks, and the entire adjacent surface of the hard alloy block 19 and the cutting ring base 21 is welded together, that is, not only the upper, The lower edge is welded, and the gap 20 formed between the adjacent hard alloy blocks is also fille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com