Deepwater net cage feeding method based on suction type onboard automatic feeding system

A deep-water net cage and automatic technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of limited use of input costs, damage to plastic delivery pipes, etc., to achieve high feed delivery efficiency, improve efficiency, and improve feed utilization and farming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

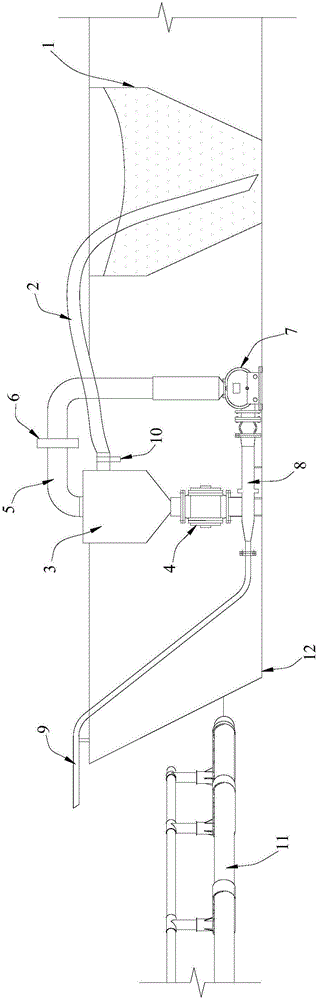

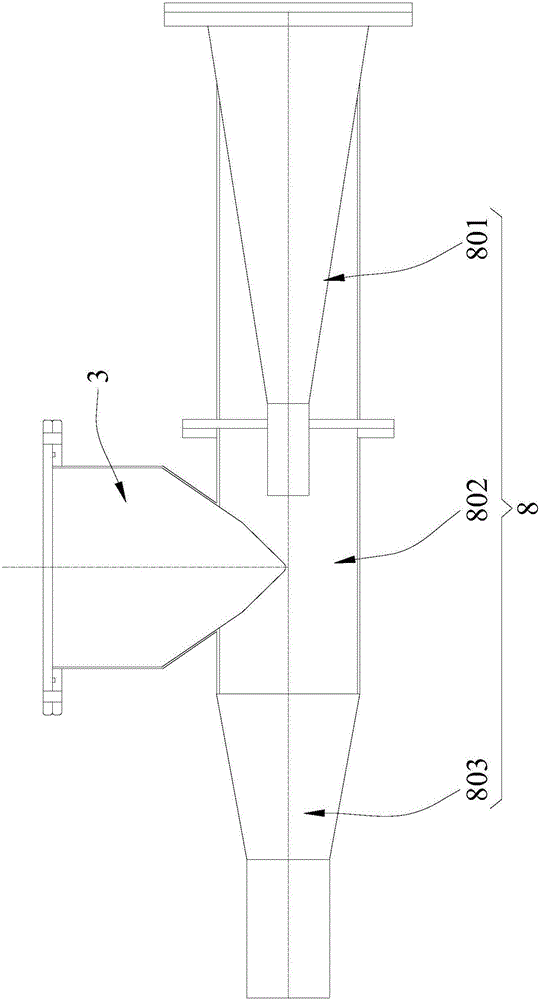

[0032] Such as figure 1 with figure 2 As shown, the deep-water net cage feeding method of the present invention is implemented based on the suction-type ship-borne automatic feeding system, and the suction-type ship-borne automatic feeding system is provided with the feed bin 1, the suction material Pipe 2, sealed chamber 3, shut-off blower 4, air intake pipe 5, Roots blower 7, gas material mixing injection device 8, discharge pipe 9 and power unit. Wherein, the sealed warehouse 3 is composed of a cylindrical warehouse body with a closed top and an open bottom and a conical hopper with a large upper port and a small lower port. The bottom opening of the cylindrical warehouse body is connected to the upper port of the conical hopper; The device is composed of a diesel engine, a generator, etc., and is used to supply power to the motors of the shut-off fan 4 and the Roots blower 7, so as to provide power for the shut-off fan 4 and the Roots blower 7 to work.

[0033] The abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com