Heat management and energy recycling system and method for battery module group of electric vehicle

A battery module and energy recovery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of no energy recovery, difficult control, low reliability, etc., to increase usage, increase coverage area, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

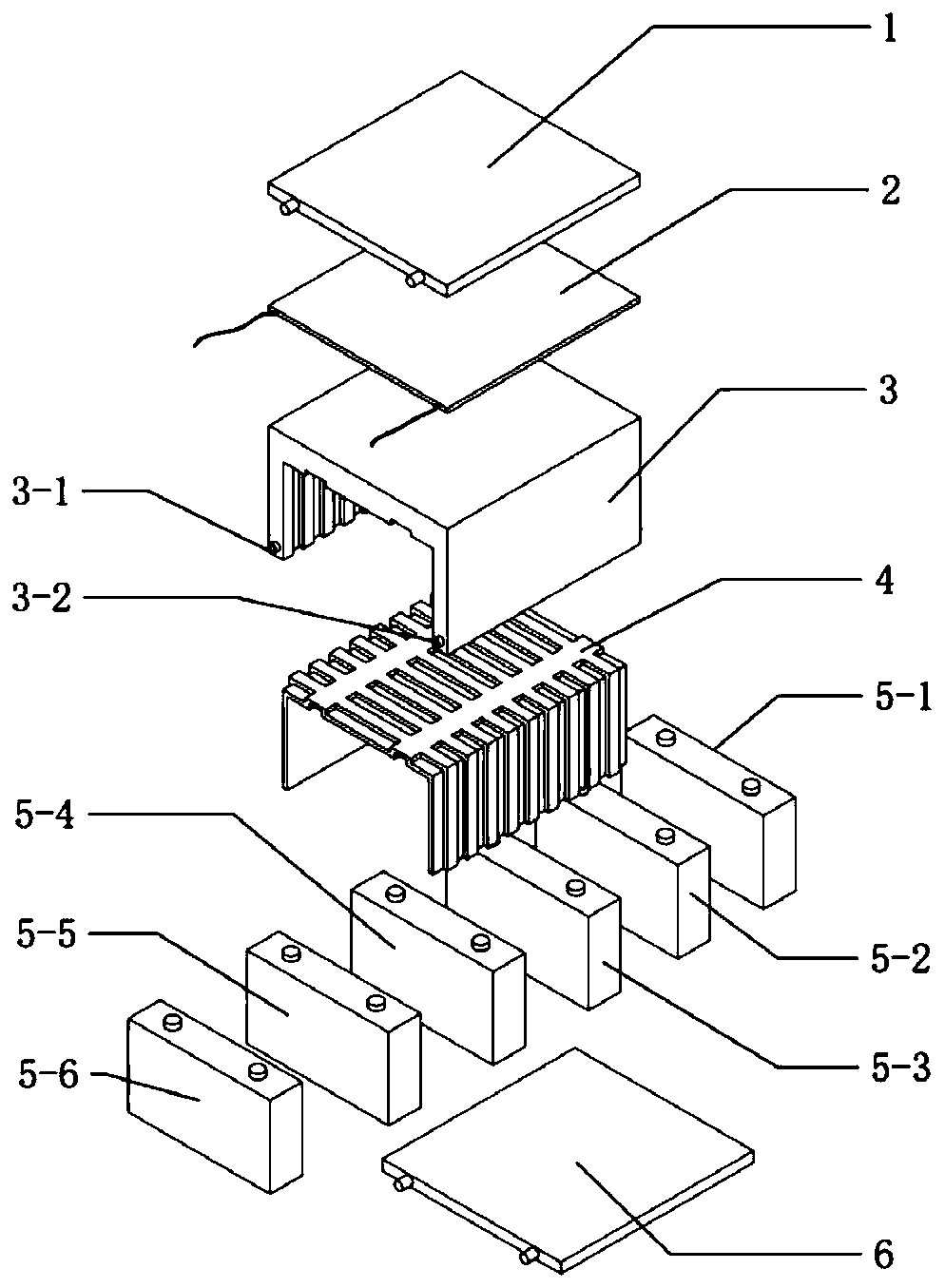

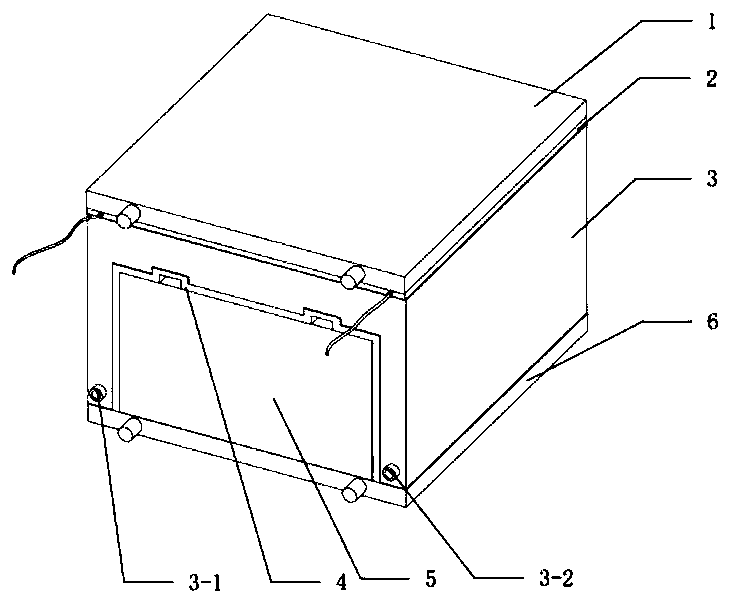

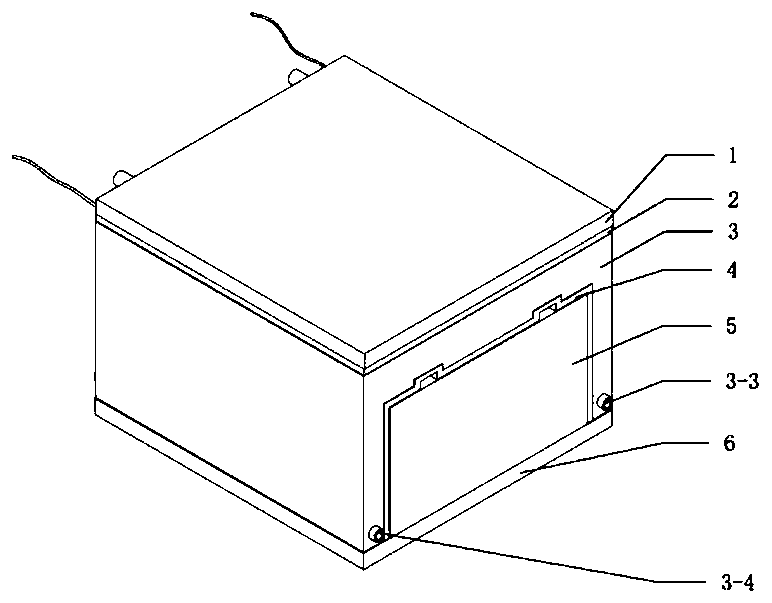

[0054] Such as Figure 1-13 As described above, the present disclosure provides a thermal management and energy recovery system for an electric vehicle battery module;

[0055] Such as figure 1 , figure 2 , image 3 , Figure 12 with Figure 13 As shown, the present disclosure is installed together with the battery module 5 of the electric vehicle and connected with the electronic control unit ECU10 of the electric vehicle, and its technical solution includes a thermoelectric power generation module, a cooling and heating module and an electronic control module.

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, the thermoelectric power generation module includes a first liquid cold plate 1 , a thermoelectric power generation sheet 2 , a phase change material box 3 , a battery module case 4 and a second liquid cold plate 6 .

[0057] Such as figure 1 , Figure 5 , Figure 10 , Fi...

Embodiment 2

[0080] Such as Figure 14 As shown, Embodiment 2 of the present disclosure provides a method for thermal management and energy recovery of an electric vehicle battery module, and the steps are as follows:

[0081] Set the first temperature threshold T according to the phase change melting point of the phase change material 1 , the temperature T of the phase change material is collected in real time and compared with the first temperature threshold T 1 comparing;

[0082] When the temperature of the phase change material rises to the first temperature threshold T 1 When , the phase change material begins to change phase, absorbs the heat of the battery module and stores the heat, and maintains the temperature of the battery module at the first temperature threshold T 1 nearby;

[0083] When the phase change material in the phase change material box is completely melted, the temperature of the battery module and the phase change material starts to rise further, which is grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com