Split guide beam type tunnel-passing bridge girder erecting machine

A bridge erecting machine and tunnel passing technology, which is applied in the field of structural improvement, can solve the problems of unable to complete the opening of the opening beam, high stability of the guide beam, and large cross-section of the rear outrigger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

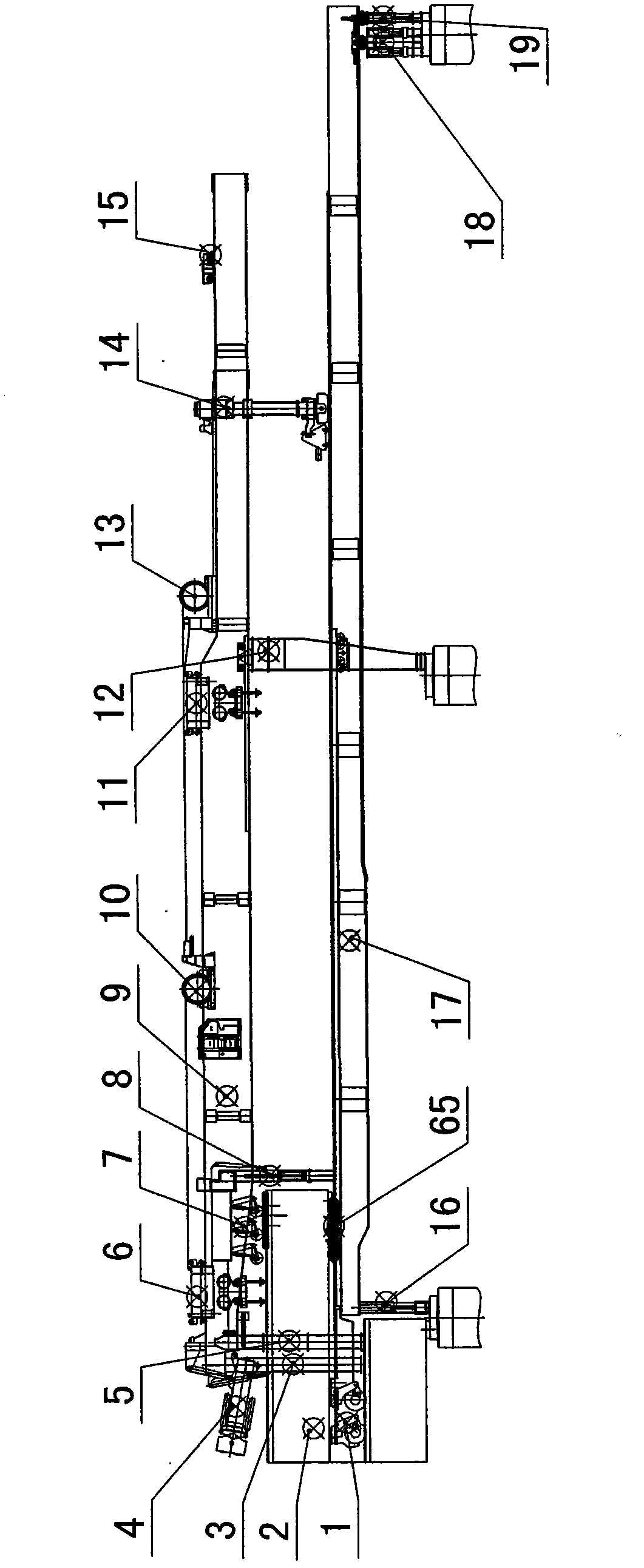

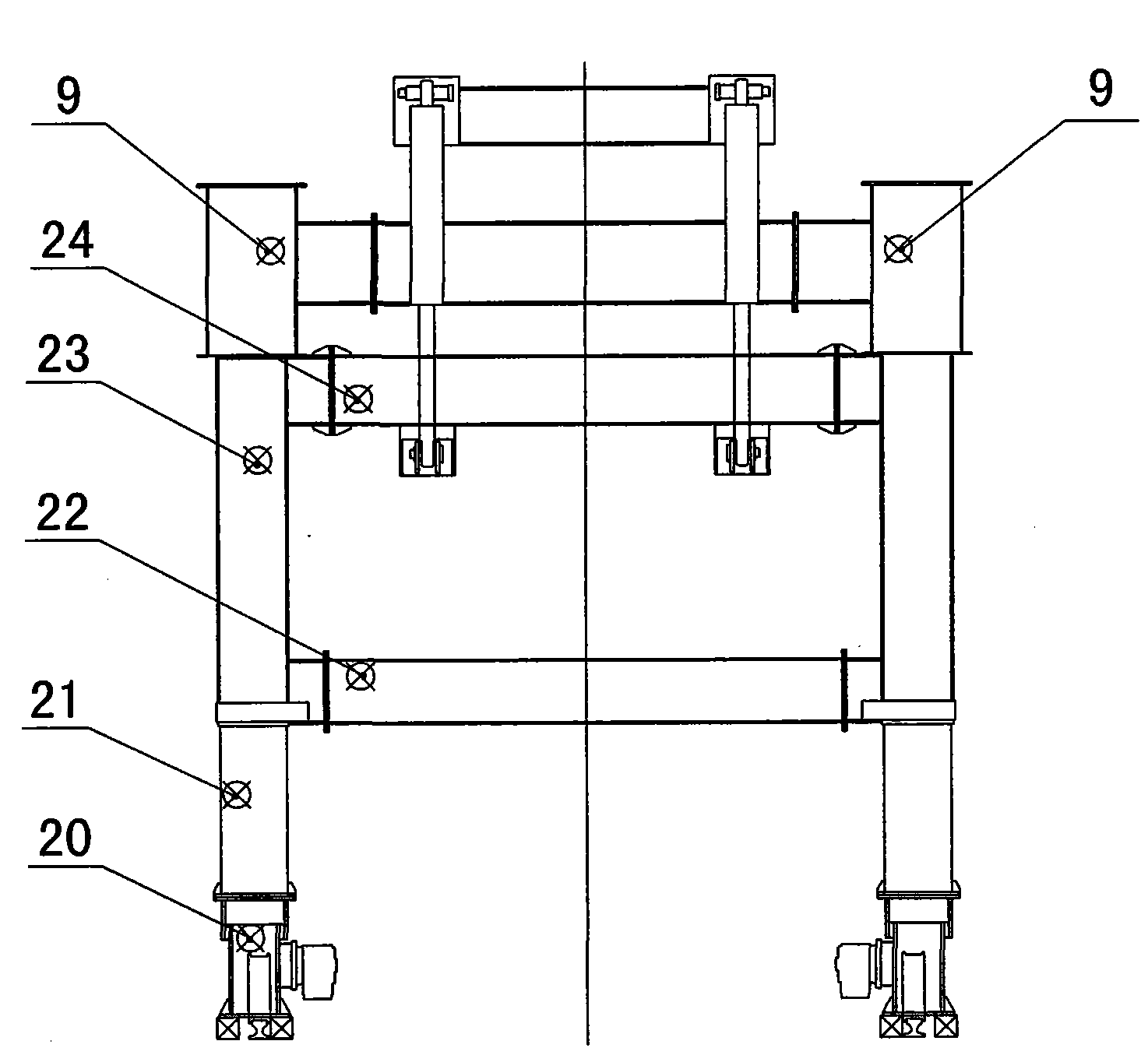

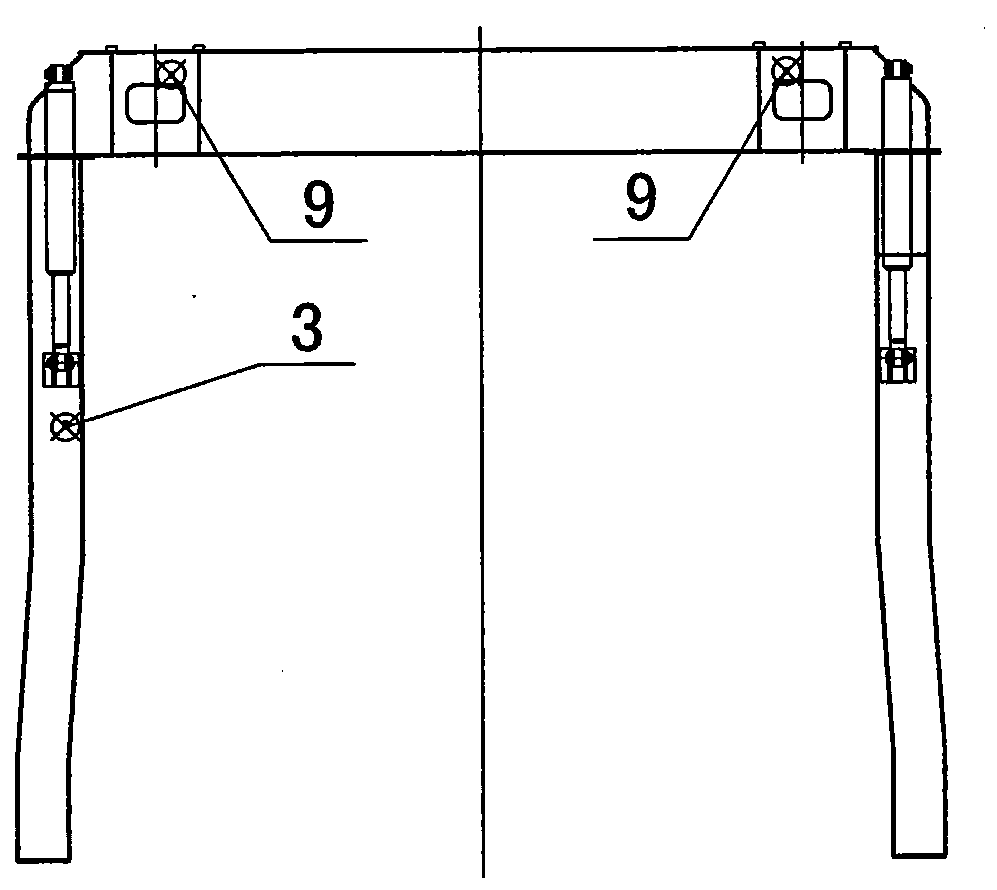

[0045] The split guide beam type tunnel bridge erecting machine includes a main beam and a lower guide beam arranged below the main beam. The lower guide beam is sequentially provided with front legs, middle legs and rear legs for supporting the lower guide beam. Outriggers; the main beam is sequentially provided with traction devices for pulling the front outriggers and middle outriggers to turn over, front support devices for supporting the main beam, and front lifting devices for lifting the box girder to be erected And the rear lifting device, the middle supporting device for supporting the main girder, the C-shaped outrigger for supporting the main girder and enabling the box girder to be erected to pass therethrough, and the rear supporting device for supporting the main girder. The C-shaped legs can pass through the tunnel by folding themselves. The main girder of the lower guide beam is a fish belly type, the rear end is a single main girder, and the front end is a dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com