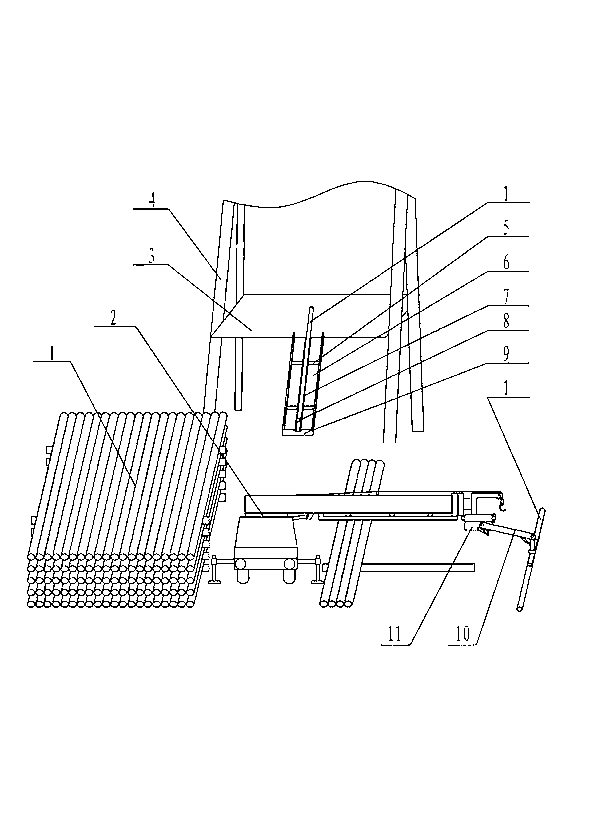

Drill rod automatic stacking and conveying device

A technology for conveying devices and drill pipes, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problem of high cost of catwalk machines, and achieve the effect of reducing labor intensity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

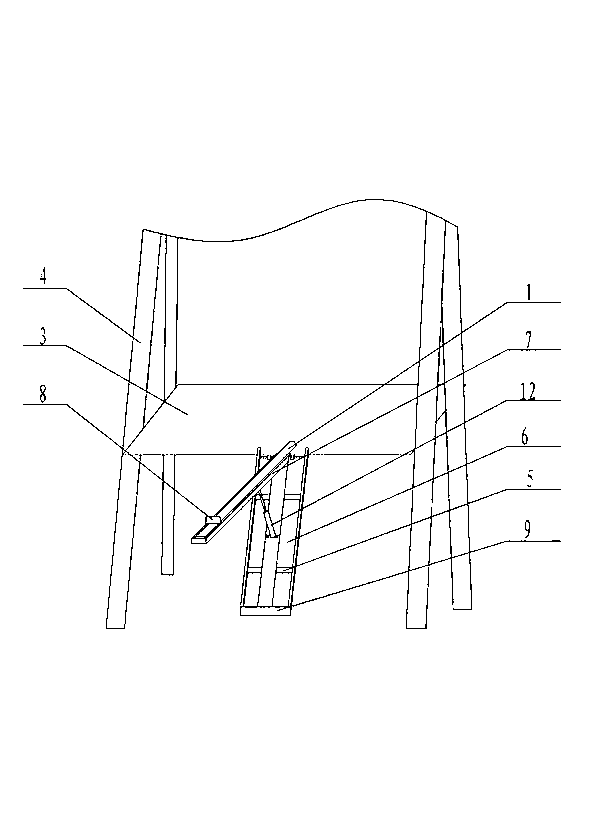

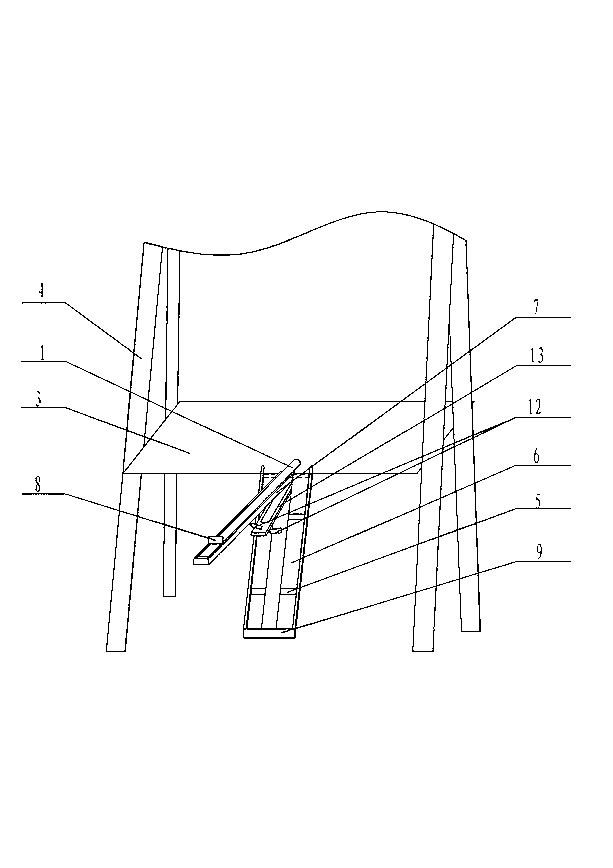

[0033] The truck crane drives into the well site and stops at an appropriate position in front of the ramp in front of the drill floor, and stretches out its outriggers. The axis of rotation of the boom of the truck crane is the center point. 1. Stack drill pipes. The drill pipes are transported into the well site, and the crane is stacked separately according to the area designated by the well site, according to the specifications and models of the drill pipes and steel pipes, and the first piece of each pile is discharged on the bottom layer by the workers. pipe on. The operator inputs: the number of the drill pipe stack, how many layers of drill pipes are placed in the drill pipe stack, the number of drill pipes in each layer, the diameter of the backing pipe, and the diameter of the drill pipe (based on the thickest section of the drill pipe), can be automatically pressed by the crane figure 1 The pile of drill pipes on the left in the middle is well arranged. Every ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com