Metal plate intelligent separating and merging machine

A sheet metal and sheet metal technology, applied in the field of sheet metal intelligent splitters, can solve few problems such as integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

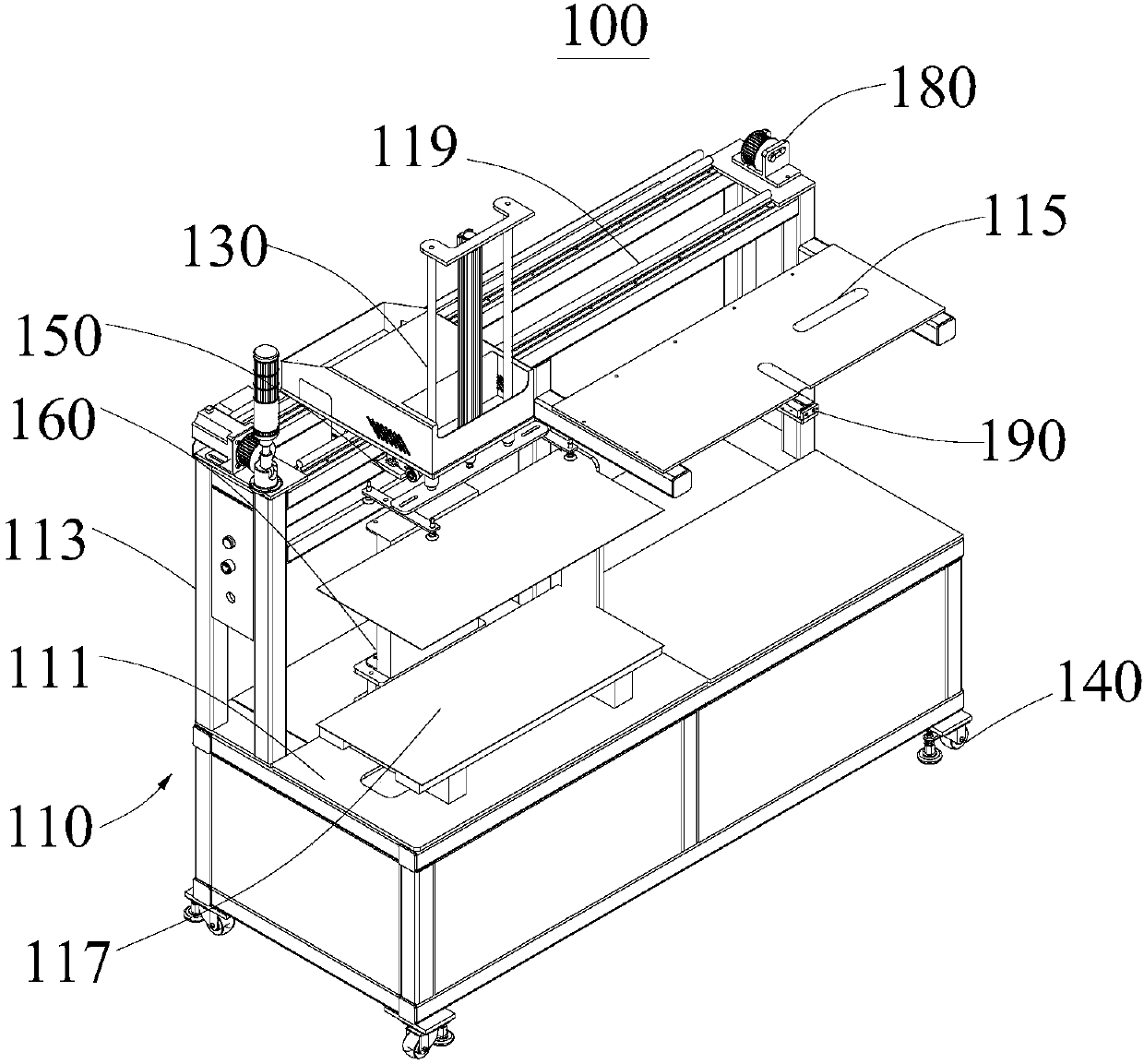

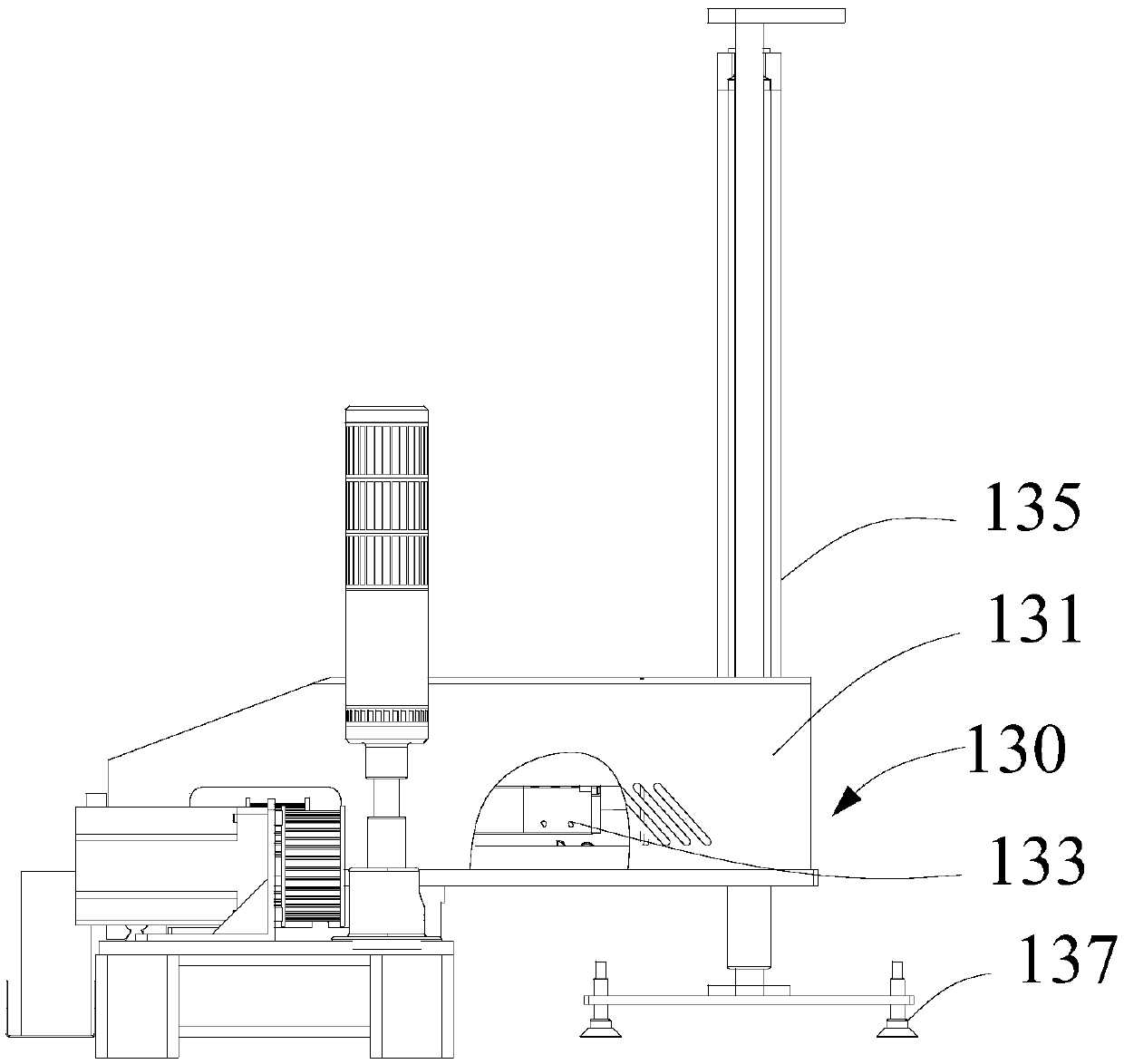

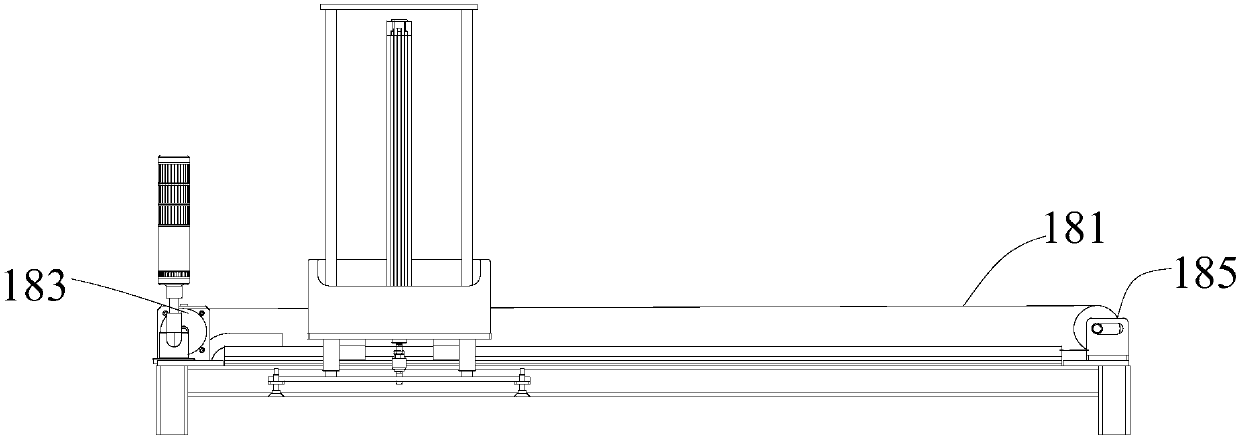

[0033] see figure 1, the present embodiment provides a sheet metal intelligent splitting machine 100, including a frame 110, a handling manipulator 130, a thickness detection mechanism 150, an electromagnetic separator 160, a sheet positioning mechanism 170, a driving mechanism 180 and a weighing mechanism 190, The handling manipulator 130 is slidably connected to the top of the frame 110 , the thickness monitoring mechanism, the battery separator and the sheet positioning mechanism 170 are all connected to the frame 110 , and the driving mechanism 180 is connected to the top of the frame 110 . The weighing mechanism 190 is fixedly connected to the frame 110 .

[0034] The frame 110 includes a loading platform 111, a sliding frame 113, a sheet material frame 115 and a stacking frame 117. The sliding frame 113 is fixedly connected to one side edge of the loading platform 111, and the top of the sliding frame 113 is provided with a slide rail 119, and the sheet material The fra...

no. 2 example

[0047] This embodiment provides a sheet metal intelligent splitter 100. Its basic structure, principle and technical effects are the same as those of the first embodiment. For a brief description, for the parts not mentioned in this embodiment, please refer to the first Corresponding content in an embodiment.

[0048] The sheet metal intelligent splitter 100 includes a frame 110, a transport manipulator 130, a thickness detection mechanism 150, an electromagnetic separator 160, a sheet positioning mechanism 170, and a control mechanism. The frame 110 includes a loading platform 111, a sliding frame 113, a sheet material frame 115 and a stacking frame 117. The sliding frame 113 is fixedly connected to one side edge of the loading platform 111, and the top of the sliding frame 113 is provided with a slide rail 119, and the sheet material The frame 115 is arranged on the carrying platform 111 and has a sheet material seating area for accommodating the sheet material.

[0049] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com