Portable belt grinding machine for sealing head

A portable, belt machine technology, applied in belt grinders, grinding machine parts, grinding machines, etc., can solve the problems of limiting the head grinding location, unable to supplement grinding, unfavorable carrying, etc., to reduce its own weight and complexity. , Quickly and accurately grind the head, and promote the effect of economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings.

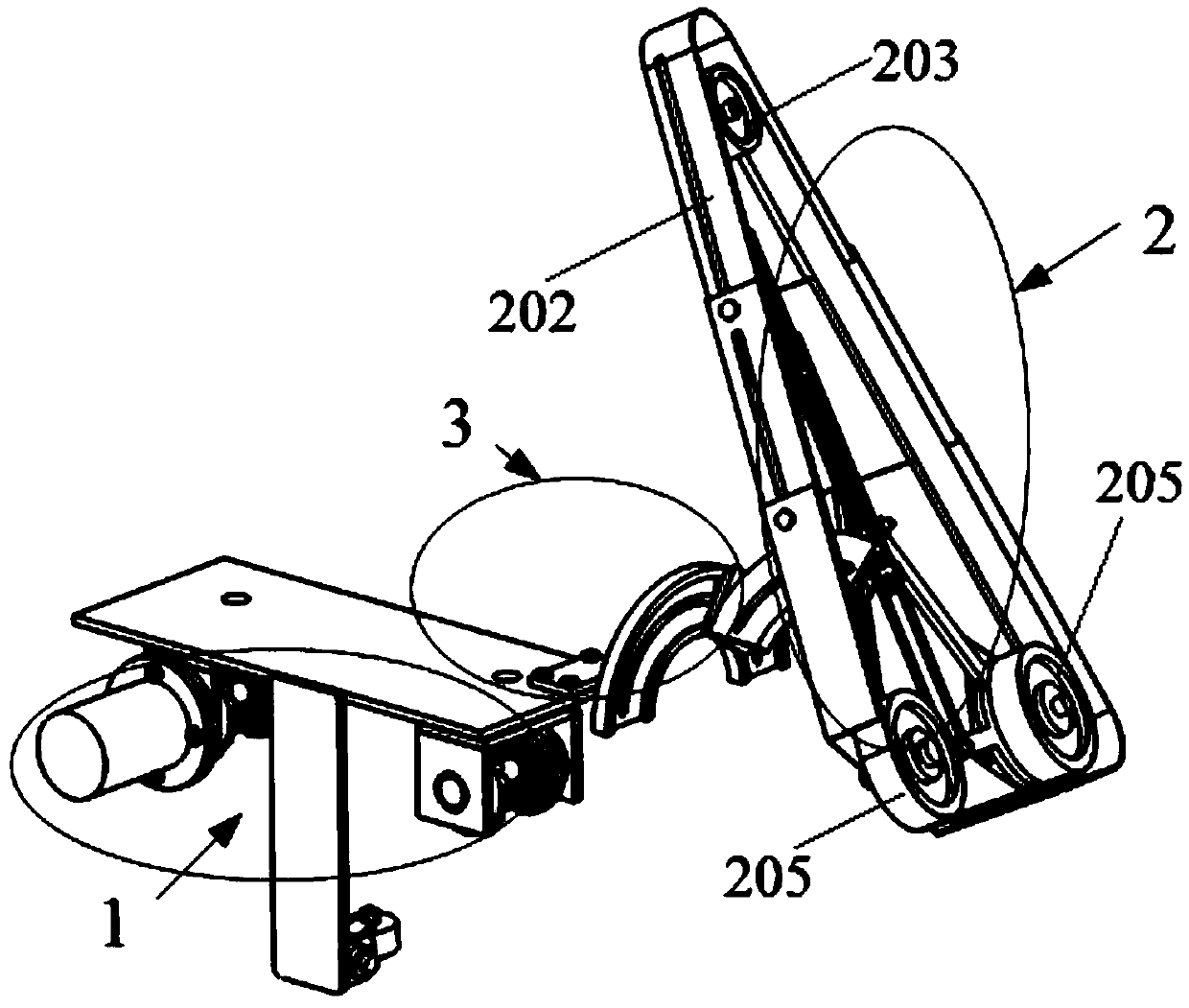

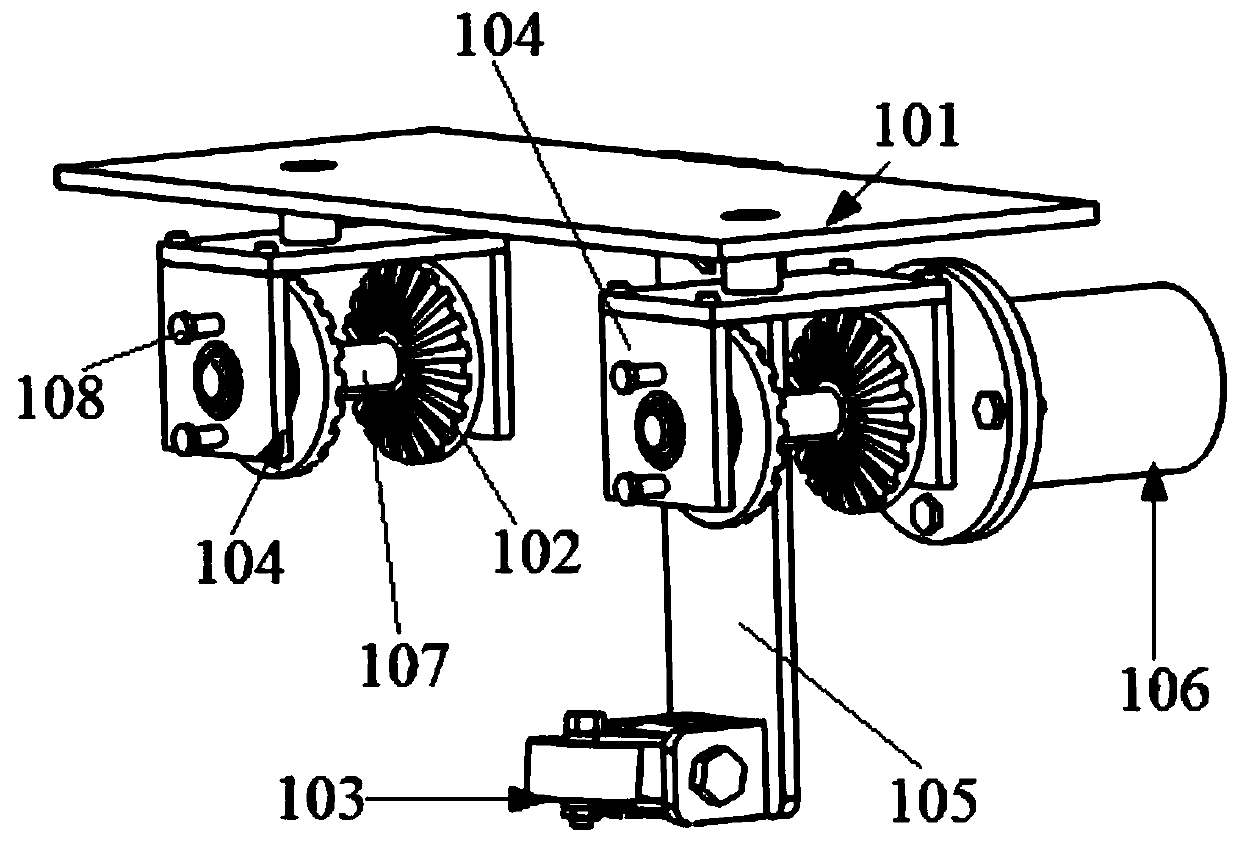

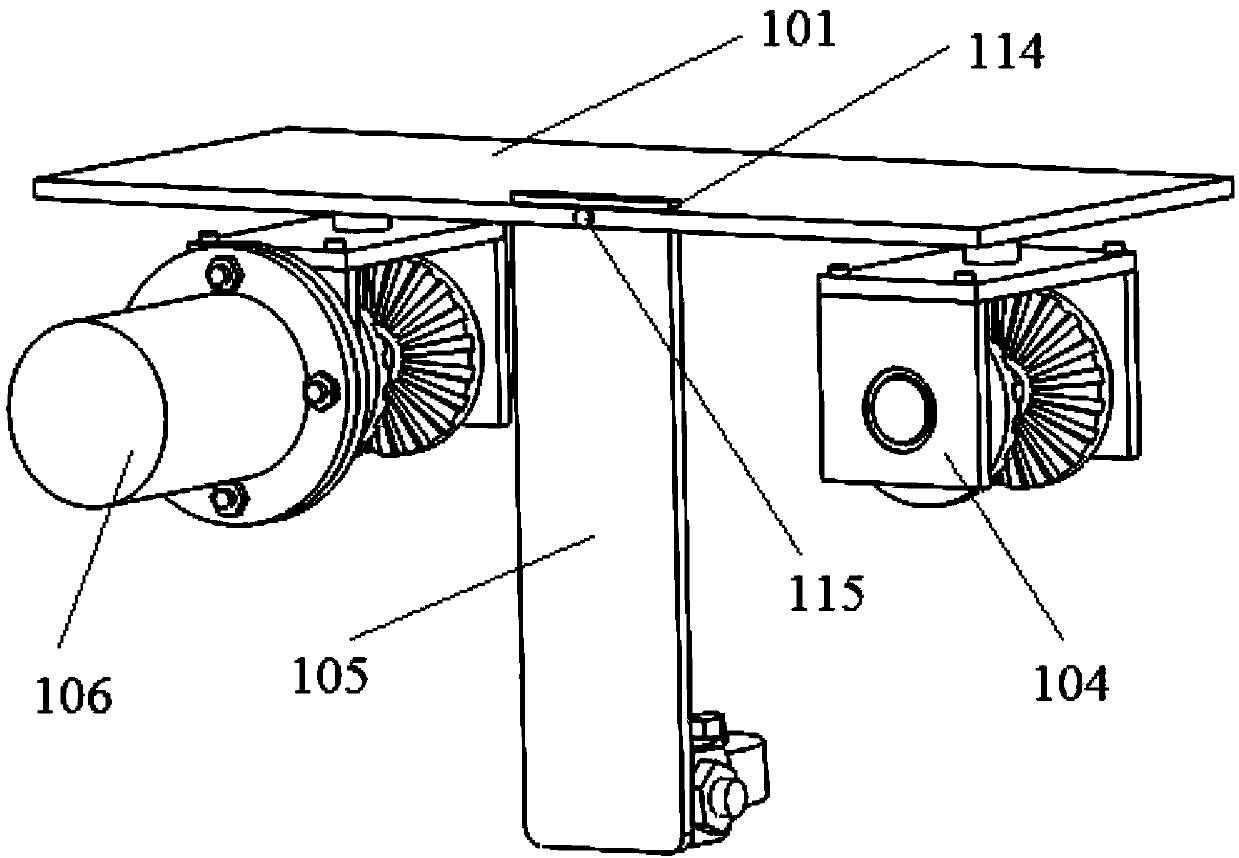

[0029] like Figure 1 to Figure 7 As shown, a portable head grinding belt machine includes a grinding mechanism 2, a traveling mechanism 1 and an attitude adjustment mechanism 3. The traveling mechanism 1 includes a flat plate 101 and a walking wheel set, an auxiliary wheel 103, an auxiliary wheel 103, The walking wheel base 104 and the auxiliary wheel base 105, the two walking wheel bases 104 are respectively installed on the bottom of the two ends of the flat plate 101 through the rotating shaft (the specific rotating shaft is installed at the bottom of the flat plate through the bearing, and the walking wheel base 104 is fixed on the rotating shaft), so that the walking wheel base 104 is fixed on the rotating shaft. 104 can be rotated to adjust the posture of the walking wheel set, so that the two walking wheels 102 are just stuck on the inner and outer sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com