Side wall of body of ore open wagon for railway

A technology of ore and car body, which is applied in the field of side wall of railway ore gondola car body, can solve the problems of adding end wall, bulky structure, increasing the weight of side wall, etc., achieves simplified welding manufacturing process, simple overall structure of car body, and improved The effect of corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

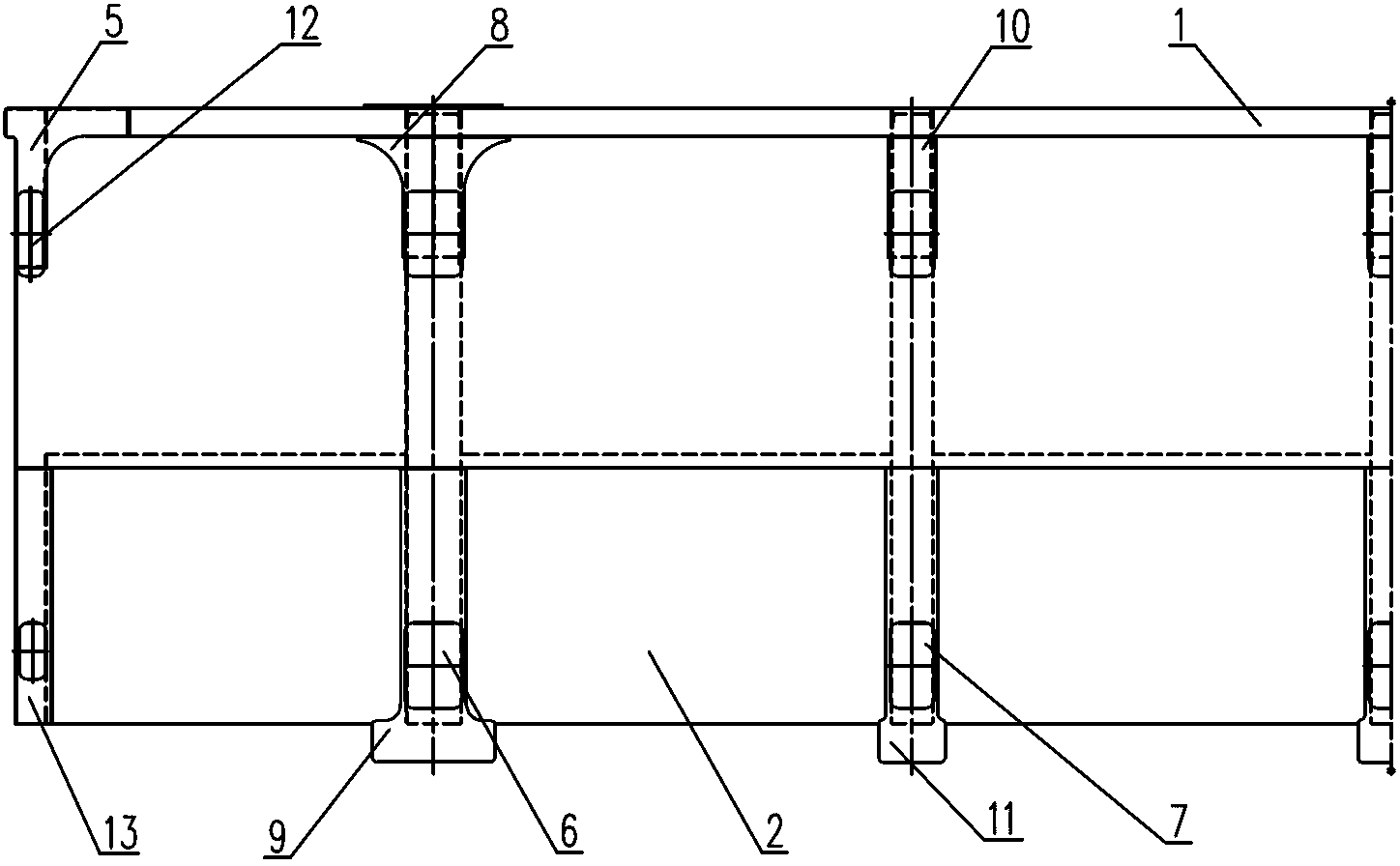

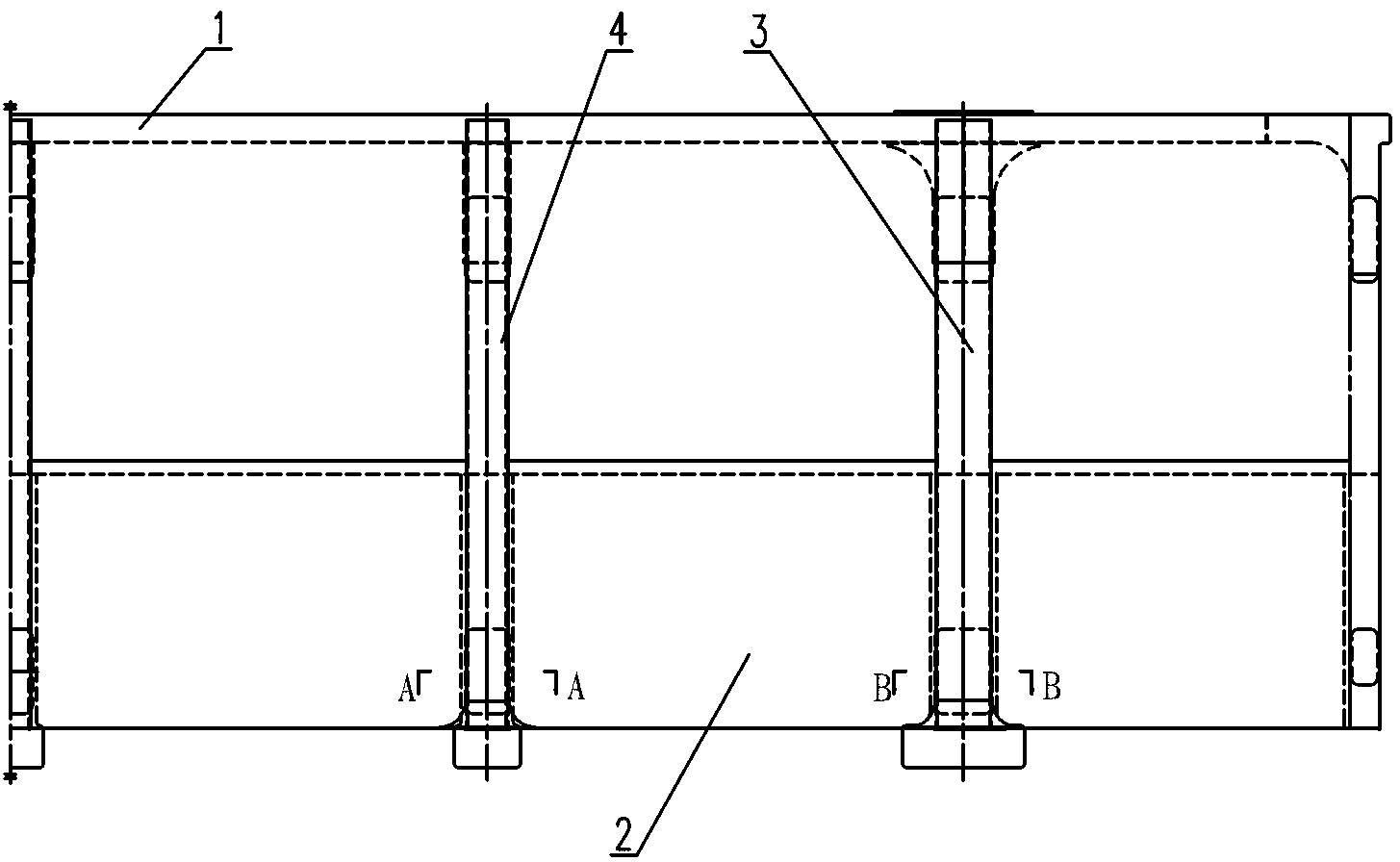

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The basic structure of the side wall of the railway ore gondola car body shown in the figure is as follows: it has an upper side beam 1 integrally formed by stainless steel plates, and one is arranged along the longitudinal sides of the upper side beam 1 Built-in bolsters 3, three built-in side columns 4 are arranged at intervals between two built-in bolsters 3, stainless steel plate The side wall panel 2 formed by integral pressing.

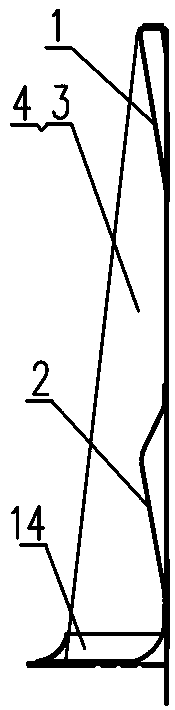

[0031]Specifically, the upper side beam 1 is integrally molded by an outer flanged plate 1a, an upper flat plate 1b, an inner inclined plate 1c and a lower vertical plate 1d. Among them, the outer flanging plate 1a and the lower vertical plate 1d are located in the same vertical plane, the upper flat plate 1b and the lower vertical plate 1d transition through the inner inclined plate 1c, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com