Torque-enhanced SRM (switched reluctance motor)

A switched reluctance, motor technology, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve the problems of large magnetic loss, difficulty in further improving motor operation control accuracy, and long magnetic circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

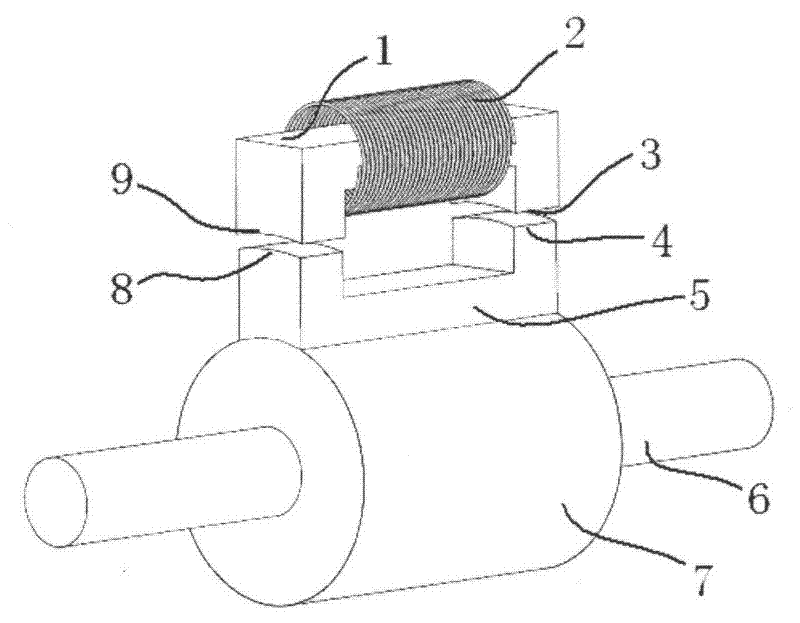

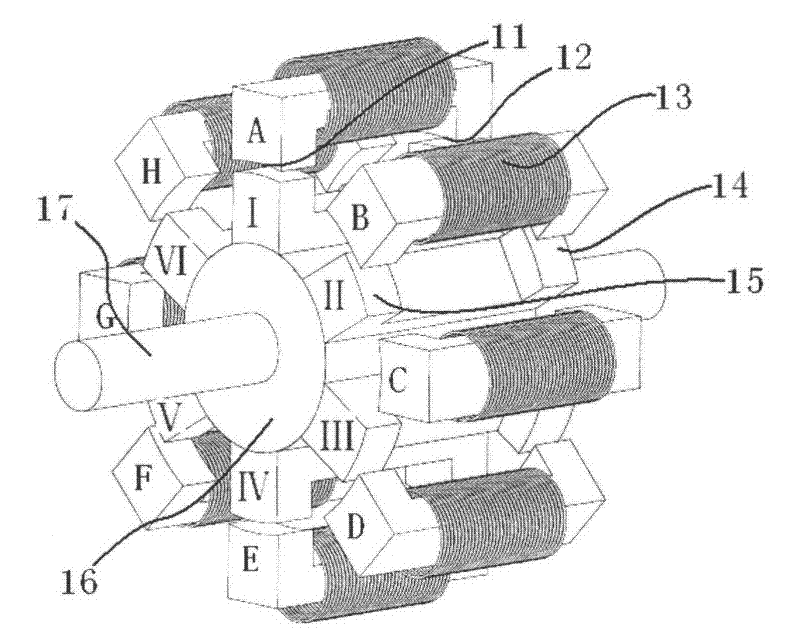

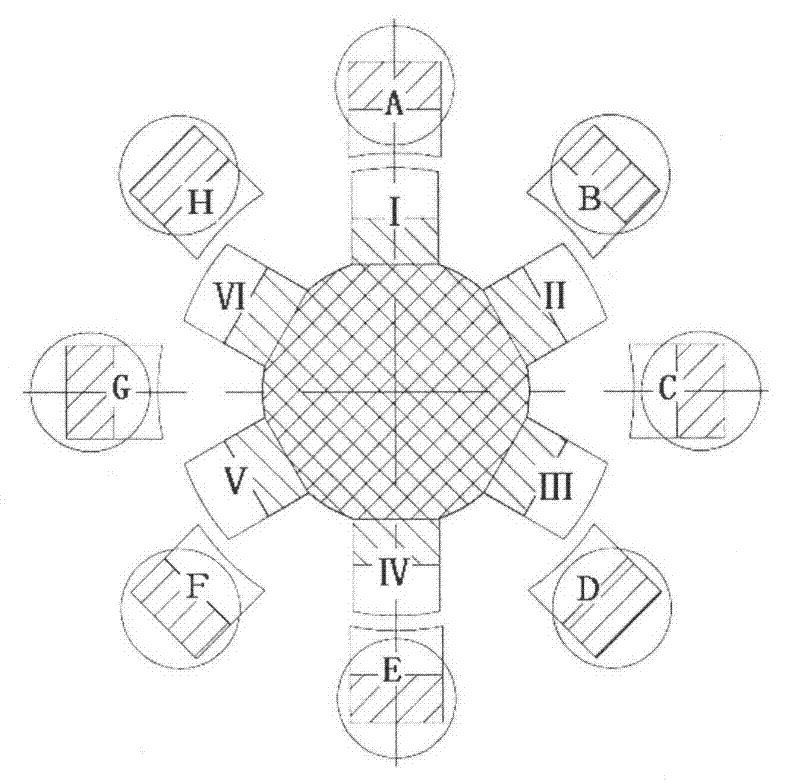

[0033] The structure of this embodiment is as attached figure 2 As shown, the structural section of this embodiment is as attached image 3 shown.

[0034] In the stator of this embodiment, there are eight doubly salient pole iron core assemblies wound with excitation coils, and these eight doubly salient pole iron core assemblies wound with excitation coils are symmetrically and evenly fixed on the inner wall of the motor housing, and the doubly salient pole iron core assemblies wound with excitation coils The magnetic salient poles 11 and 12 in the core assembly point to the motor shaft 17 . The rotor shaft seat 16 is fixed to the rotating shaft 17, and the six strip-shaped double-salient pole iron cores are symmetrically and evenly fixed on the rotor shaft seat 16 with the rotating shaft 17 as the axis of symmetry. Each strip-shaped double-salient pole iron core has two convex The protruding direction of the bar-shaped double salient core salient pole 14 and the bar-shap...

Embodiment 2

[0037] The structure of this embodiment is as attached Figure 4 shown.

[0038] This embodiment is further structured on the basis of the motor given in the first embodiment above. The motor given in the first embodiment above becomes a single motor in this embodiment. The three electric motors share one rotating shaft. as attached Figure 4 As shown, the relative positional relationship between the stators of the three motor units is exactly the same, that is, there is no rotation angle difference between the magnetic salient pole radial centerlines of the stator switch assemblies of the three motor units, and the rotors of the three motor units There is a rotation angle difference α between the radial centerlines of the salient poles of the strip-shaped double-salient pole iron core. Figure 5 A sectional view of the motor monomer at the front is given, with Figure 6 A sectional view of the motor monomer in the middle layer is given, with Figure 7 A sectional view o...

Embodiment 3

[0041] The structure of the torque-enhanced switched reluctance motor of this embodiment is the same as that of Embodiment 1 (attached figure 2 And attached image 3 As shown) the torque-enhanced switched reluctance motor is similar, the only difference is that the strip double salient pole iron core on the rotor is replaced by a double salient pole iron core assembly wound with an excitation coil.

[0042] The stator of this embodiment is composed of eight doubly salient pole iron core assemblies wound with excitation coils. The coil doubly salient pole iron core assemblies are magnetically isolated from each other, and the stator is wound with an excitation coil, and the protruding direction of the soft magnetic salient poles in the doubly salient pole iron core assembly points to the motor shaft. Each stator is wound with an excitation coil and has two magnetic salient poles. The two magnetic salient poles are axially distributed along the rotation axis. The eight assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com