Patents

Literature

98results about How to "Reduce shock vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

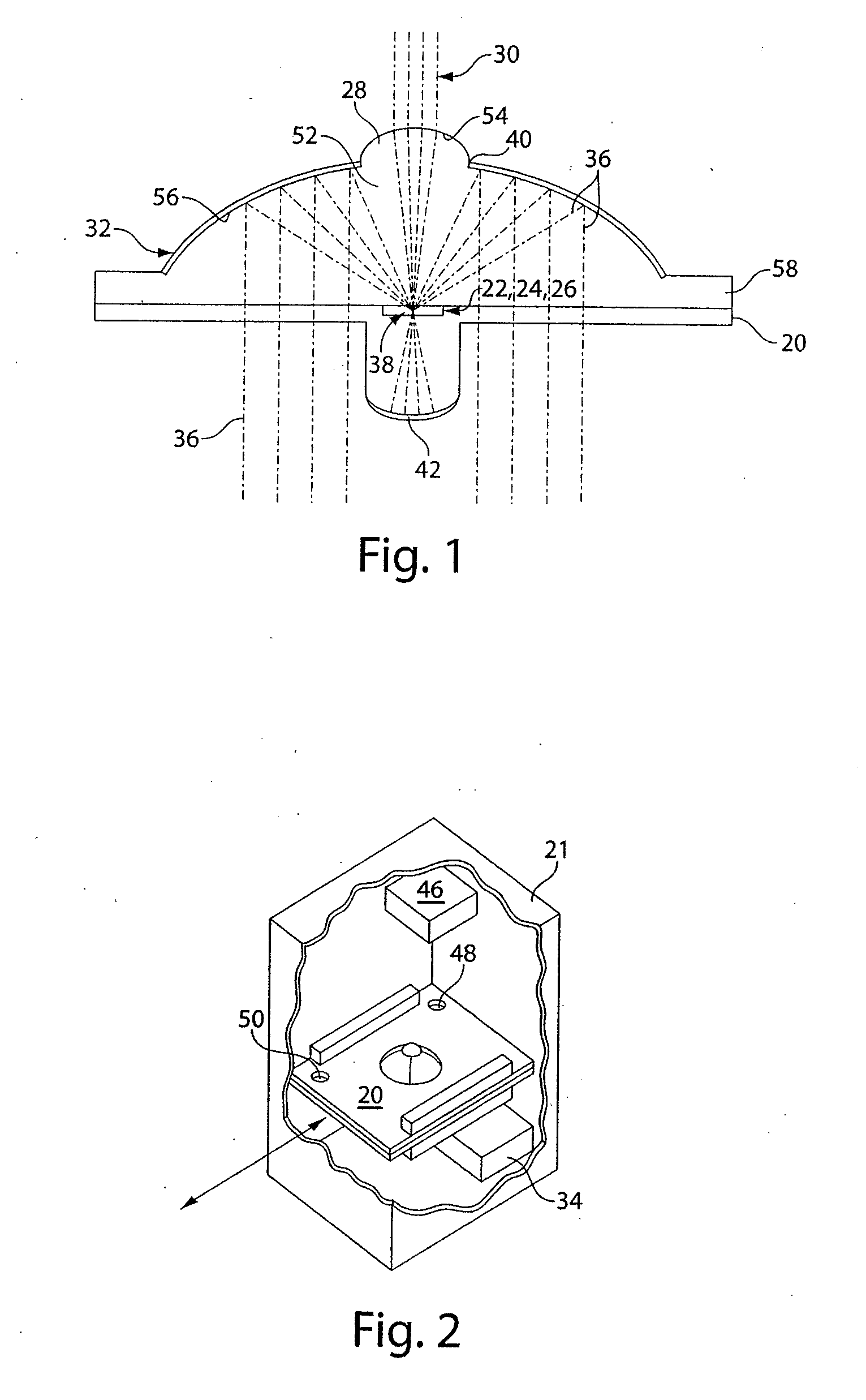

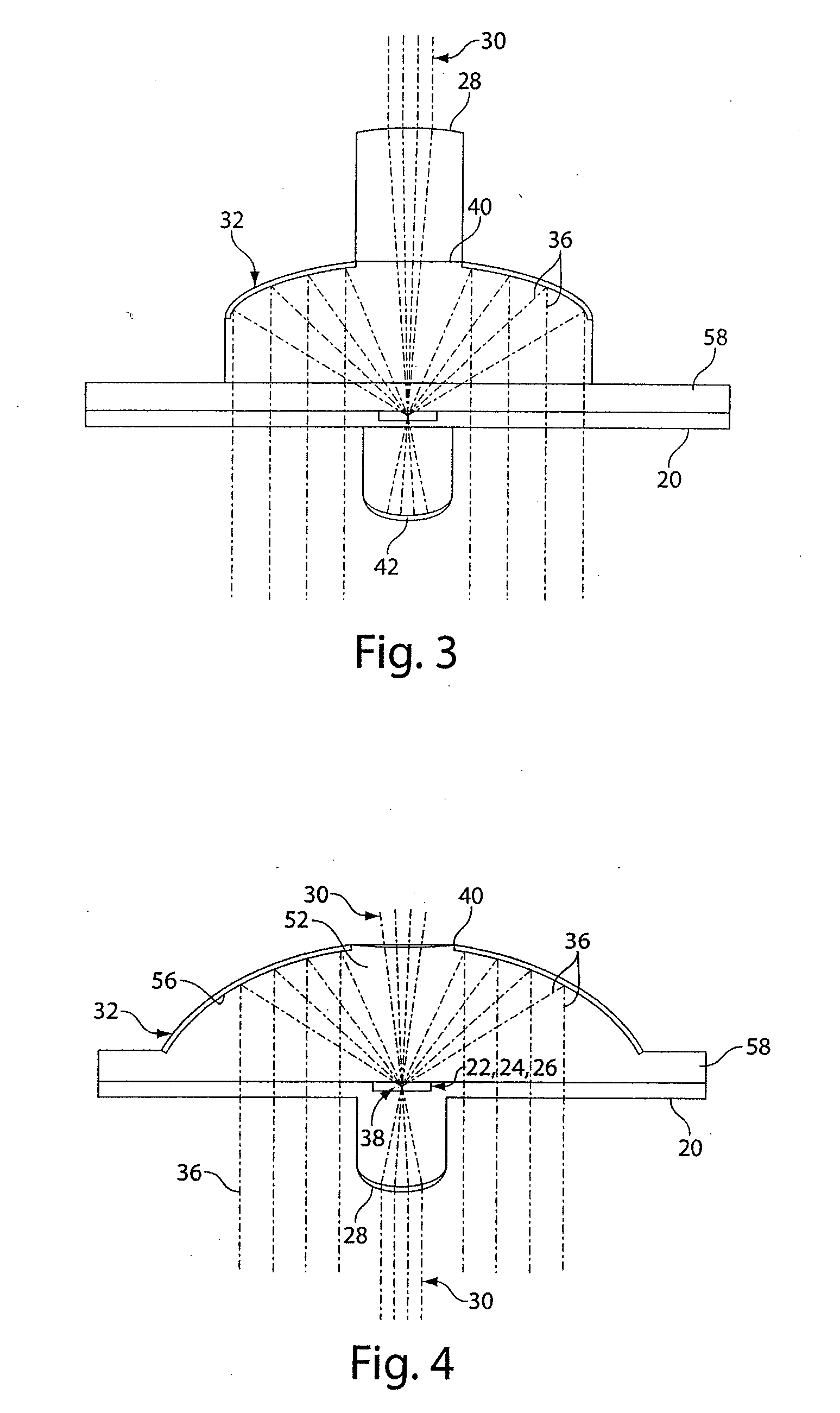

Systems and methods for measurement optimization

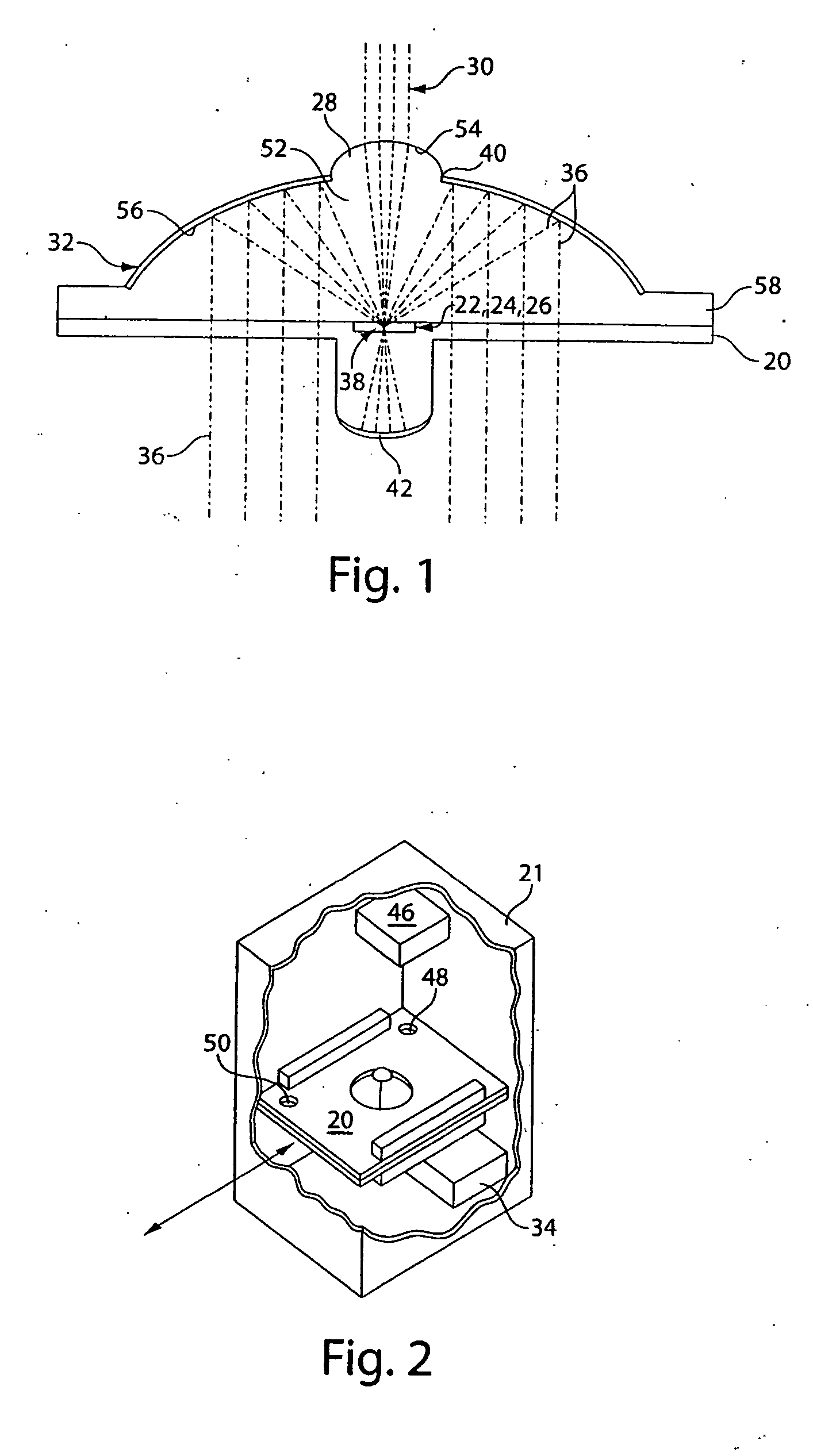

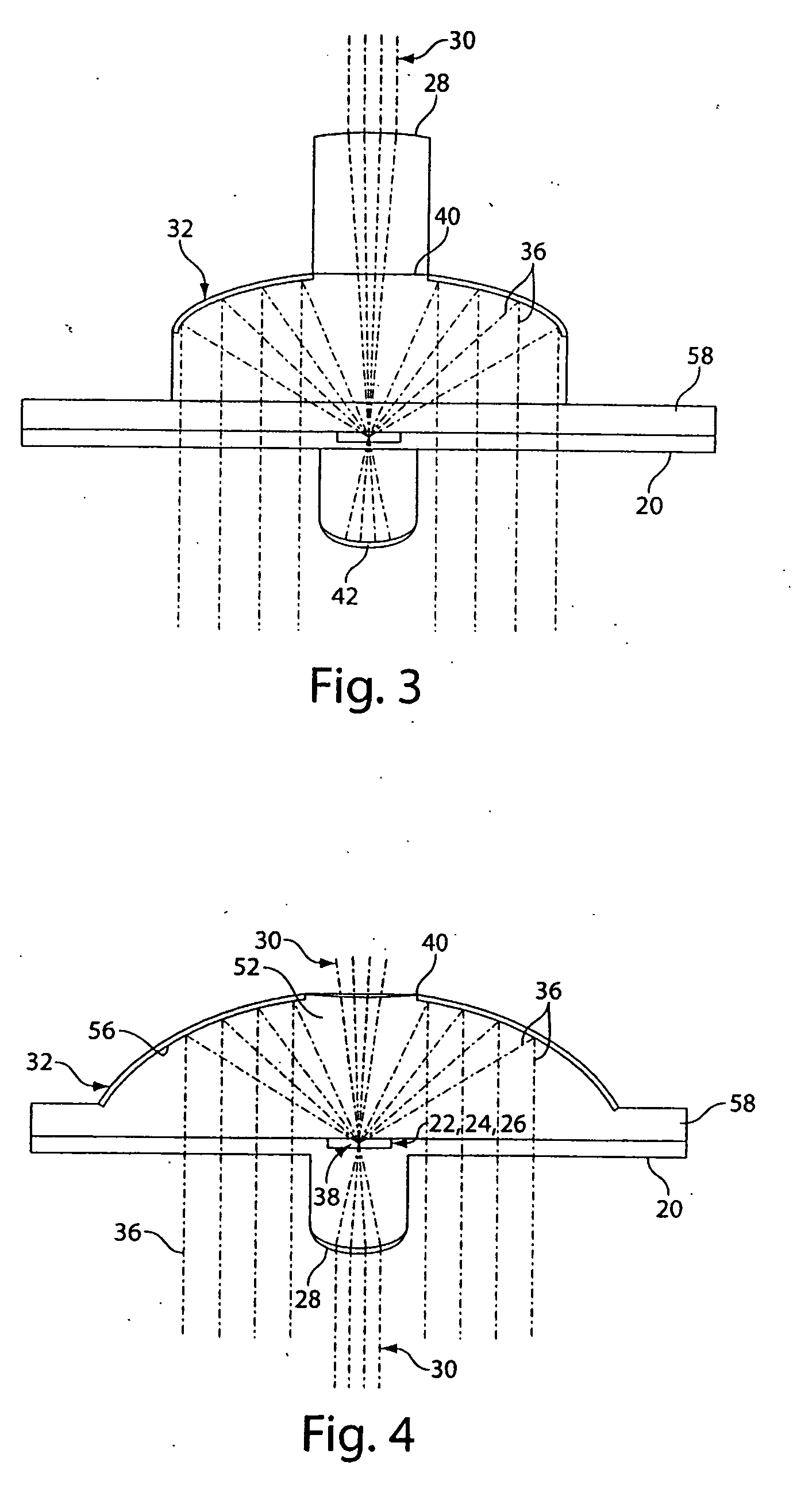

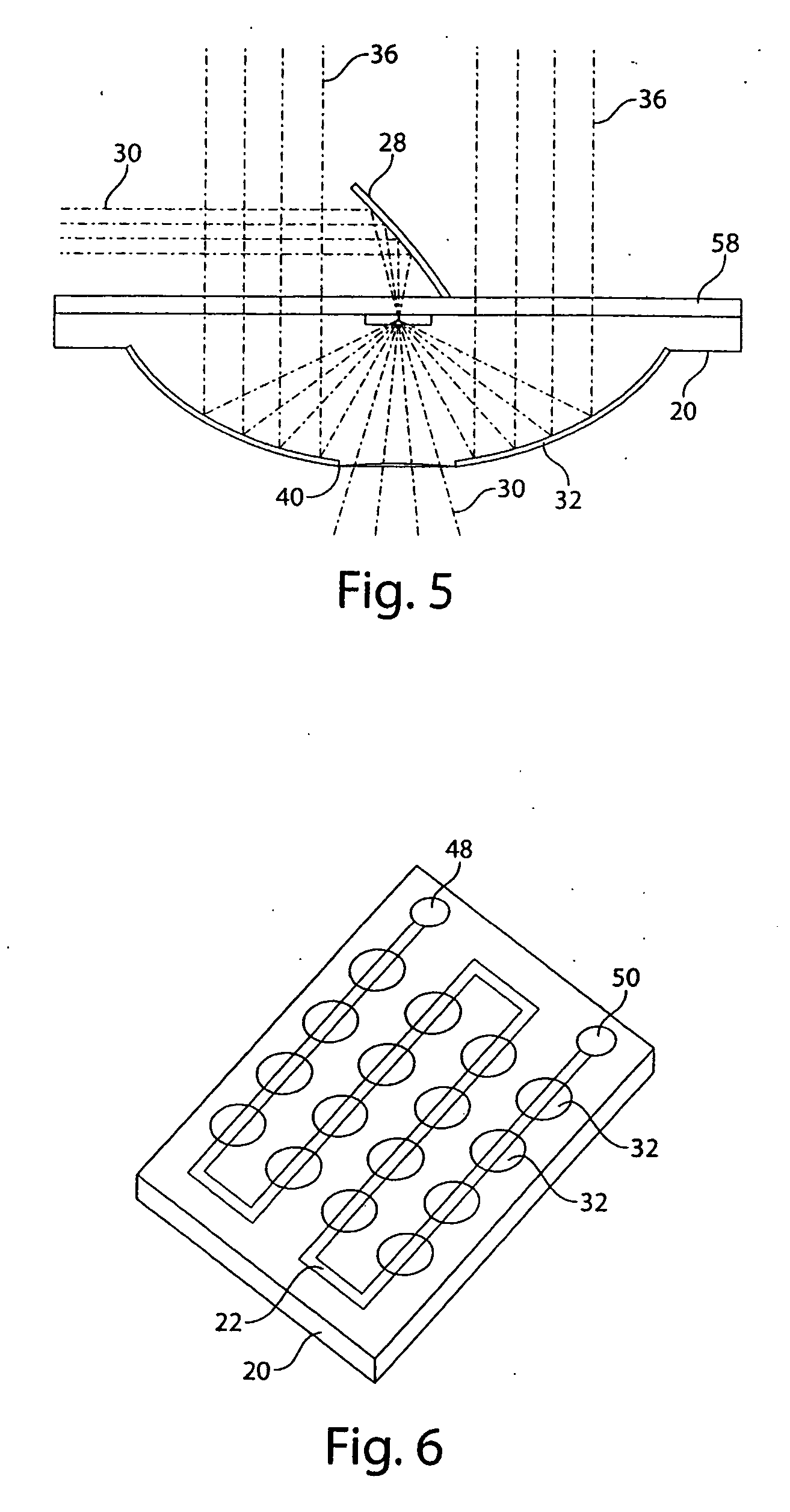

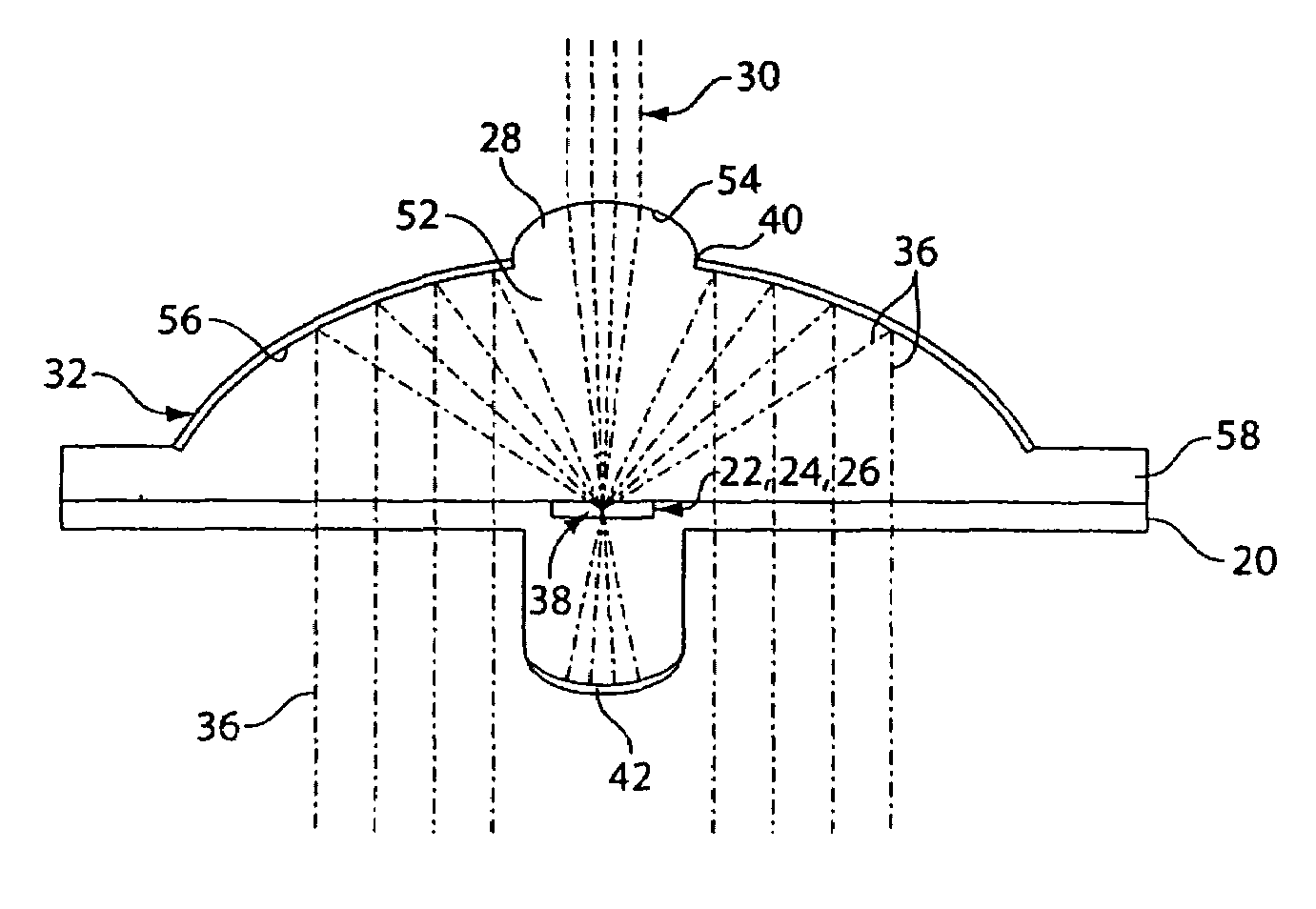

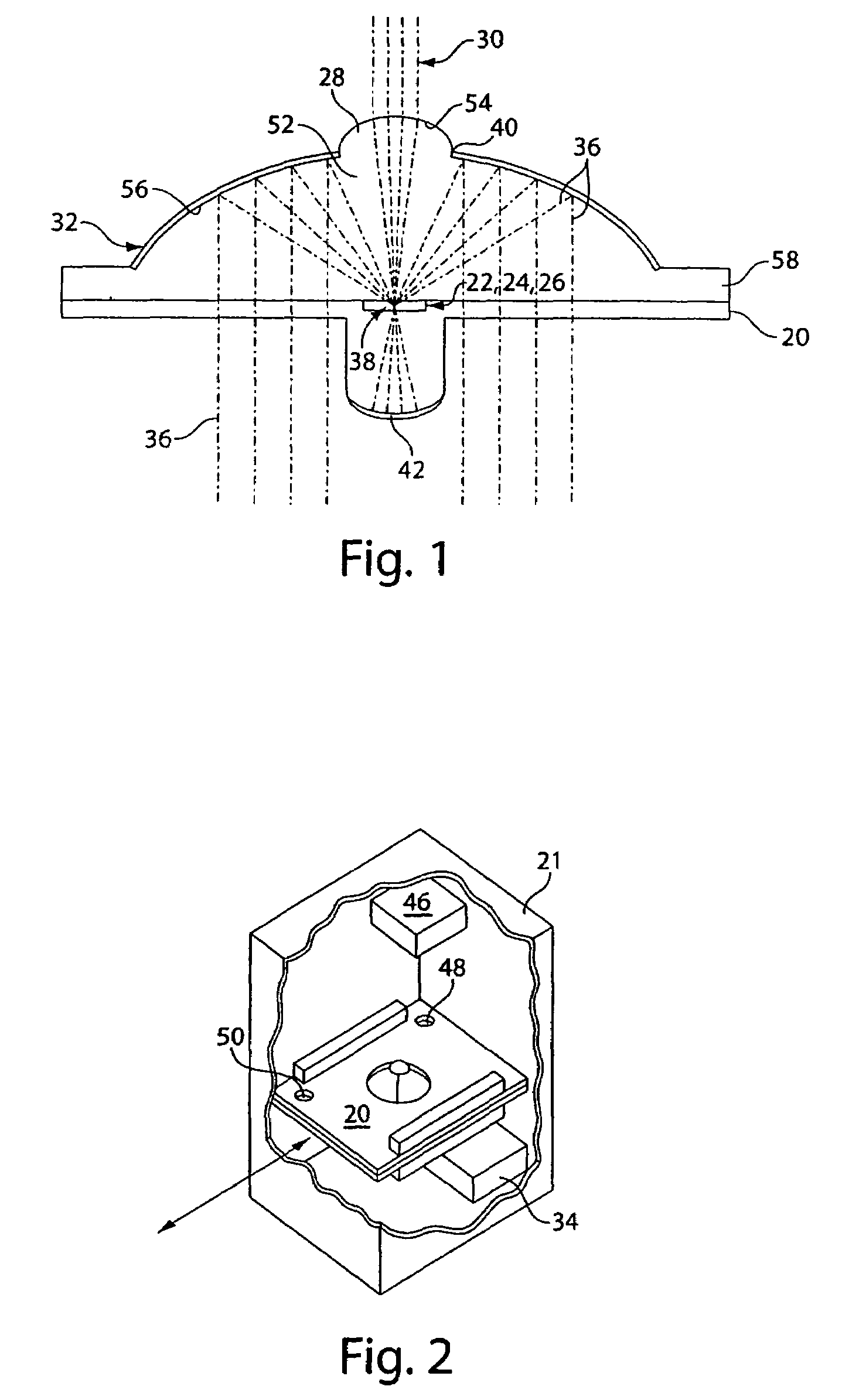

InactiveUS20060160209A1Rapid and reliable detection and analysisLow costBioreactor/fermenter combinationsRadiation pyrometryOptics

The invention relates to methods and systems for detecting and or analyzing an agent in a sample with a chip having optical components incorporated therein.

Owner:U S GENOMICS INC

Systems and methods for measurement optimization

InactiveUS7262859B2Rapid and reliable detection and analysisReduce shock vibrationScattering properties measurementsLaboratory glasswaresOptics

The invention relates to methods and systems for detecting and or analyzing an agent in a sample with a chip having optical components incorporated therein.

Owner:U S GENOMICS INC

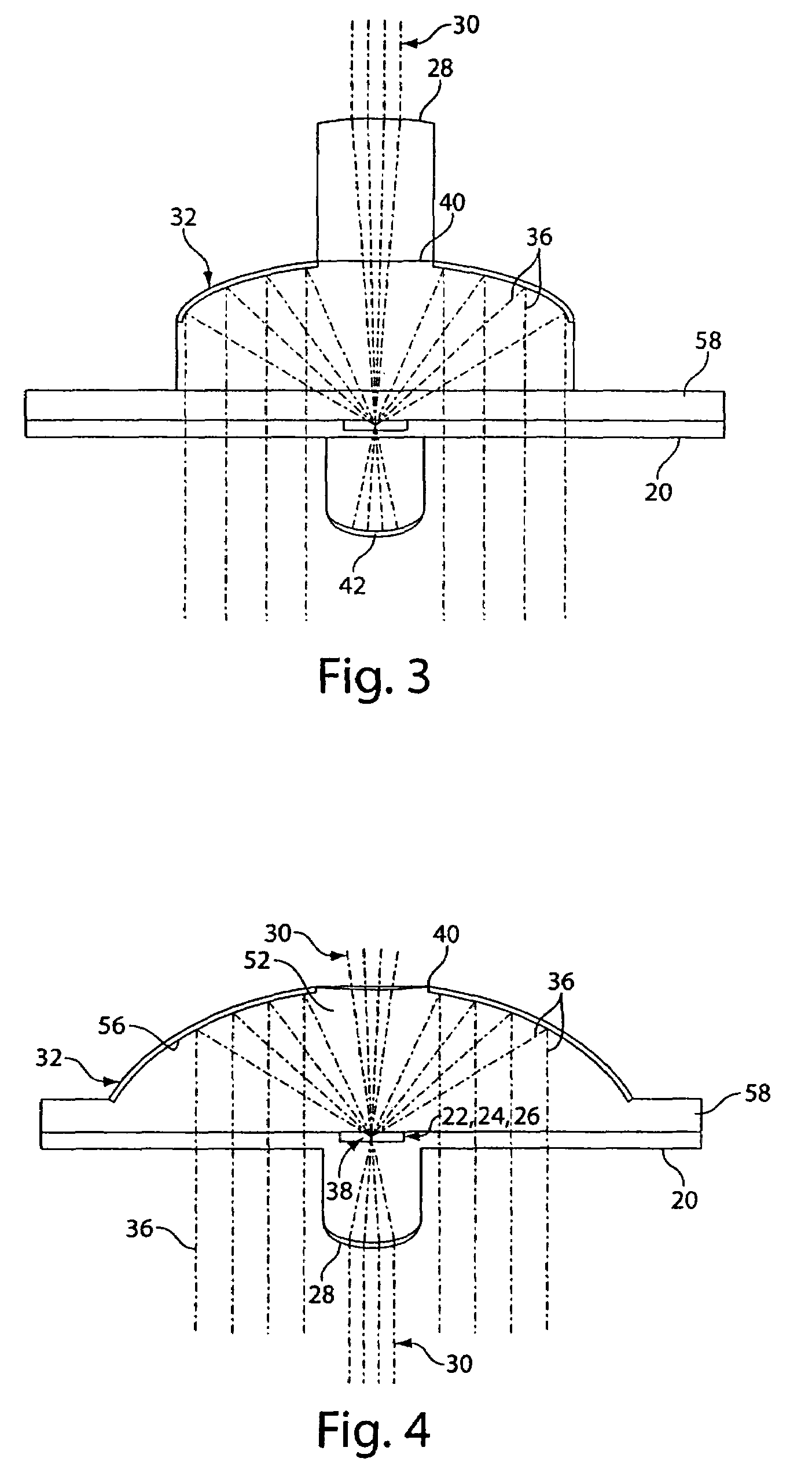

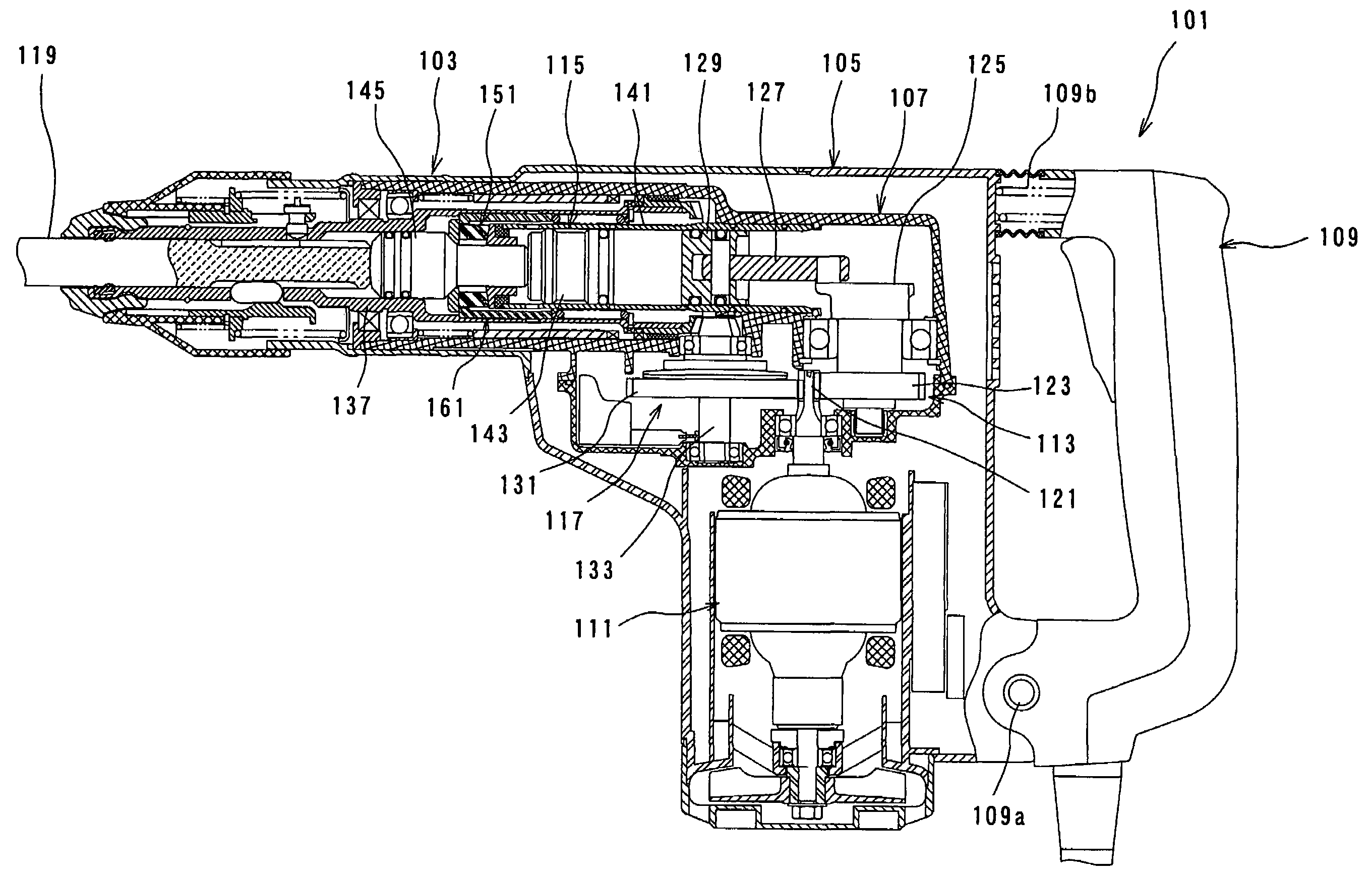

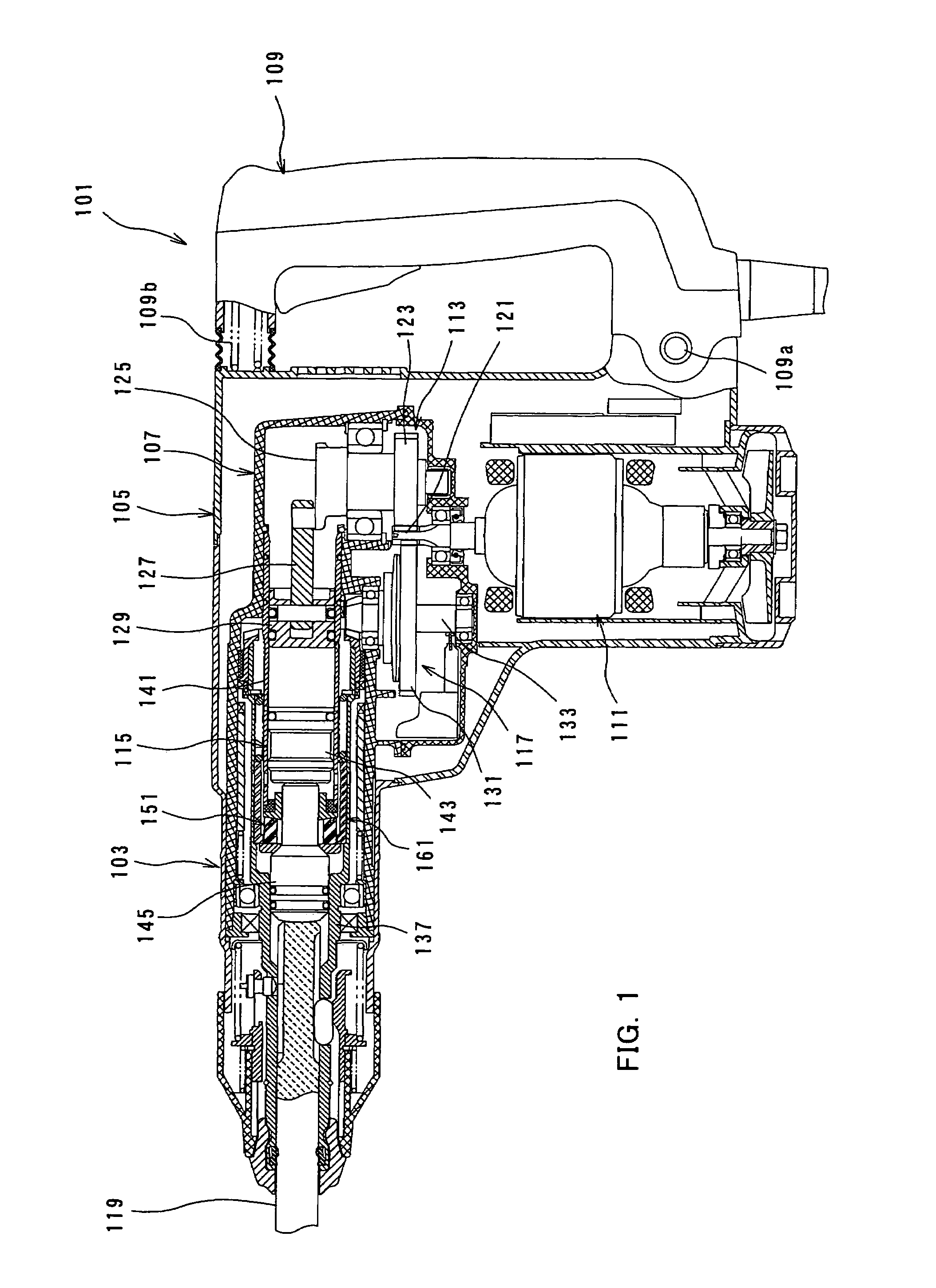

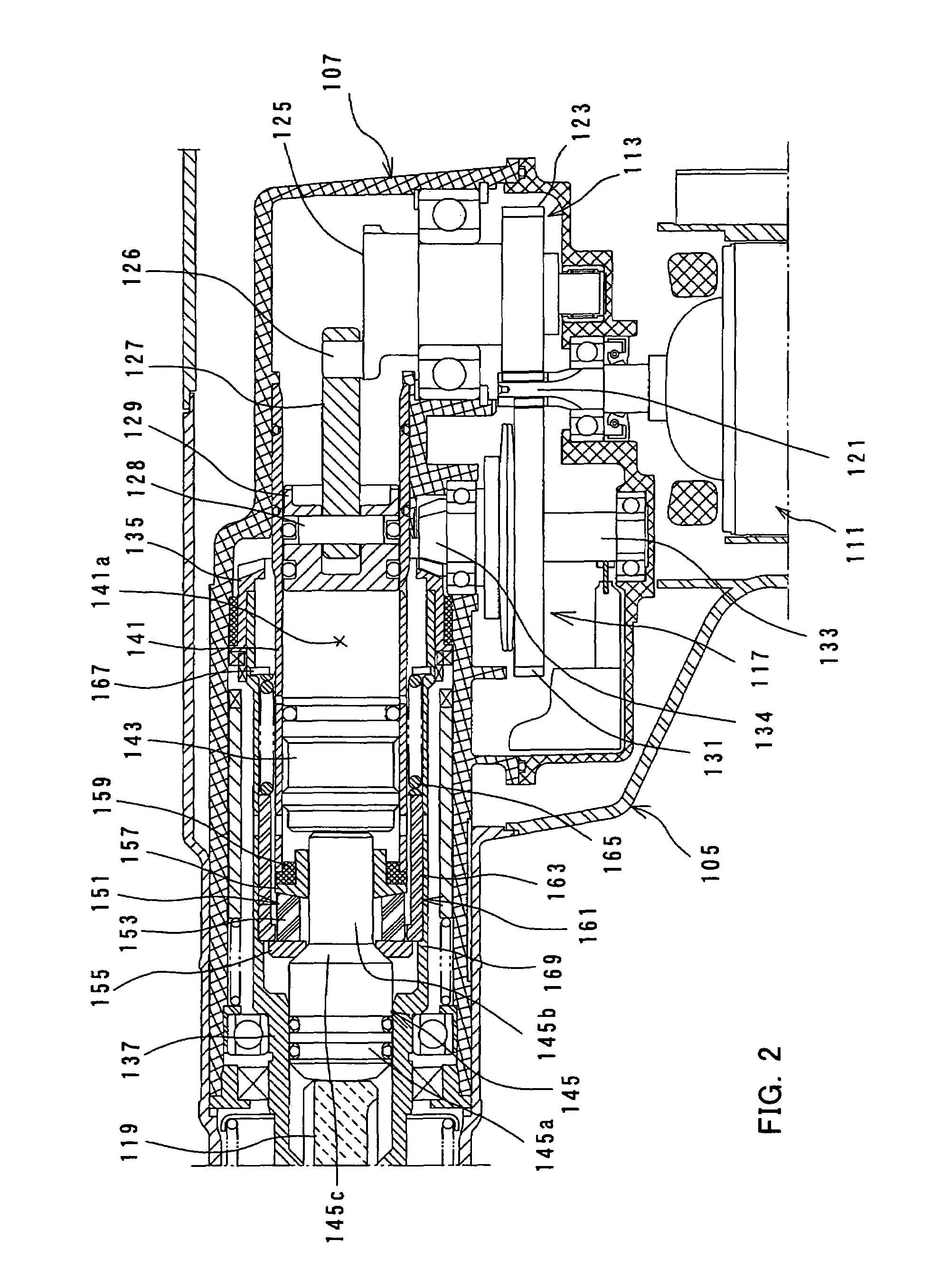

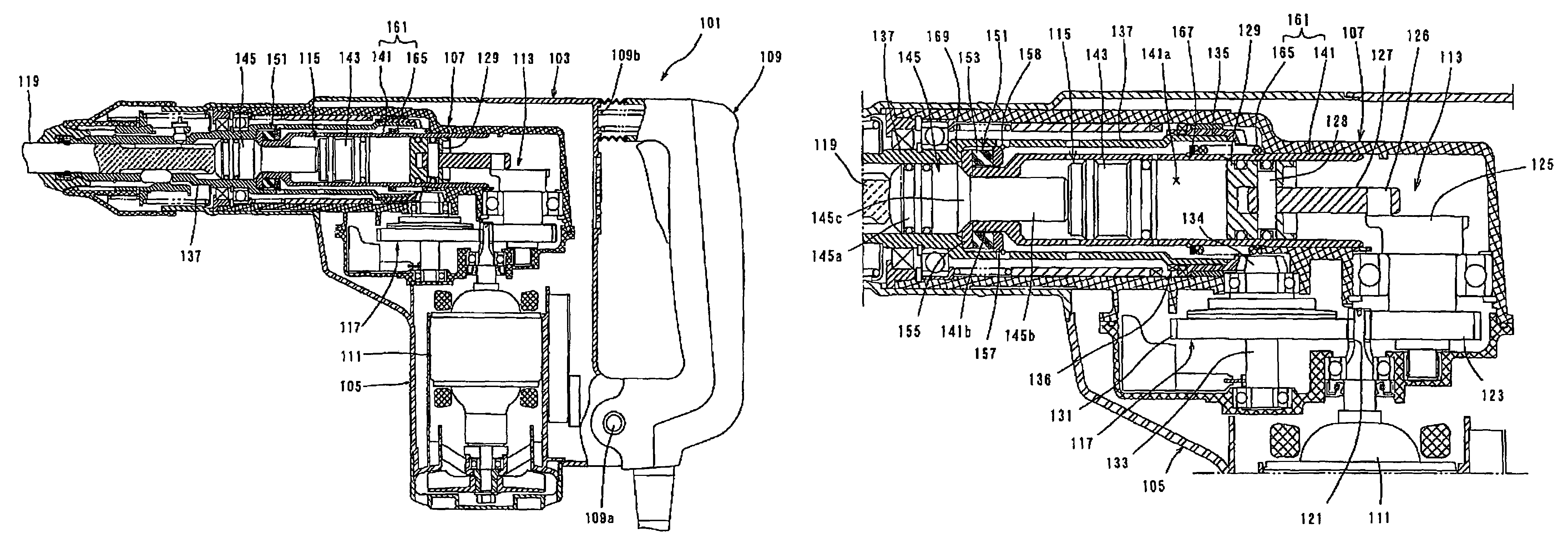

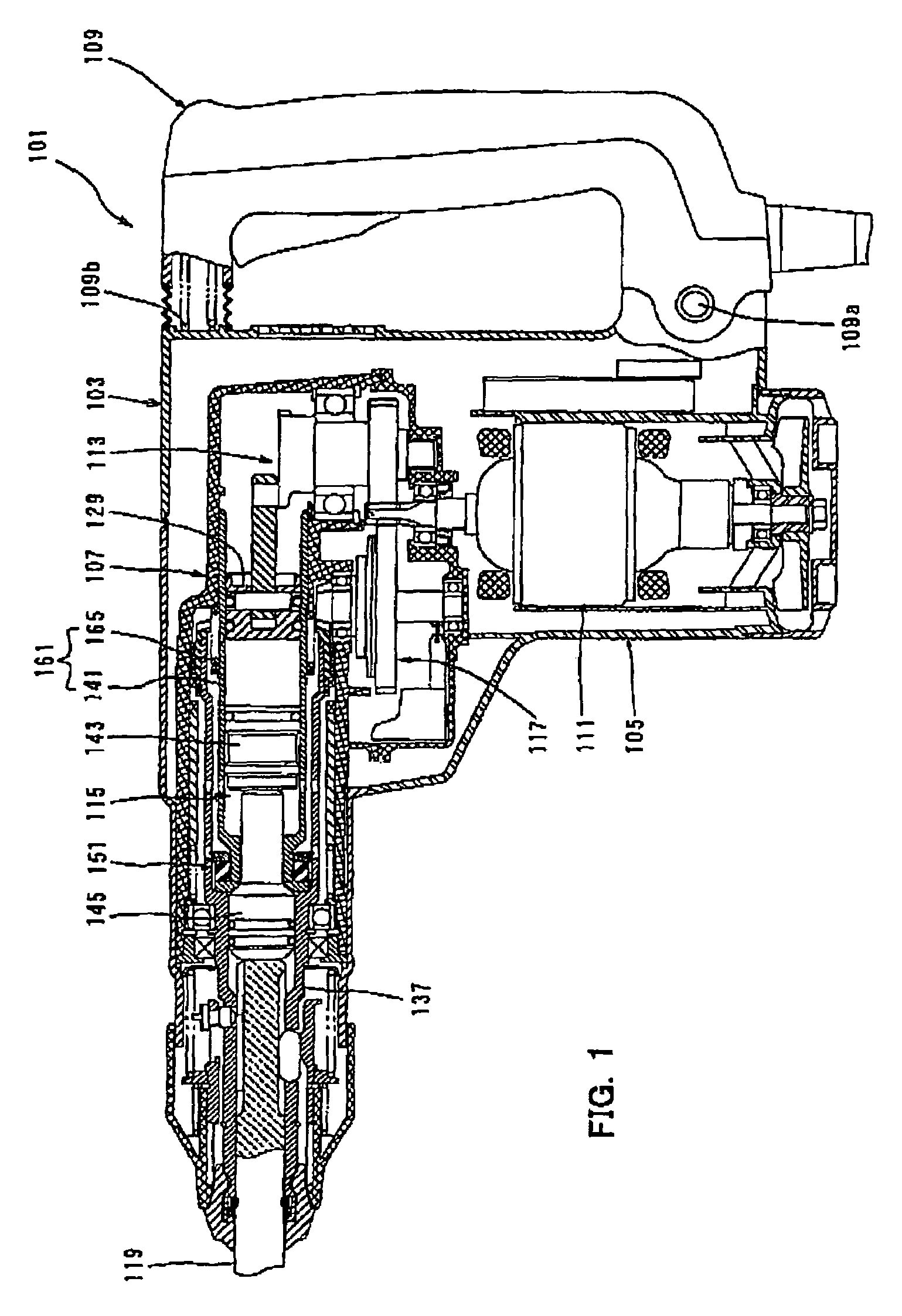

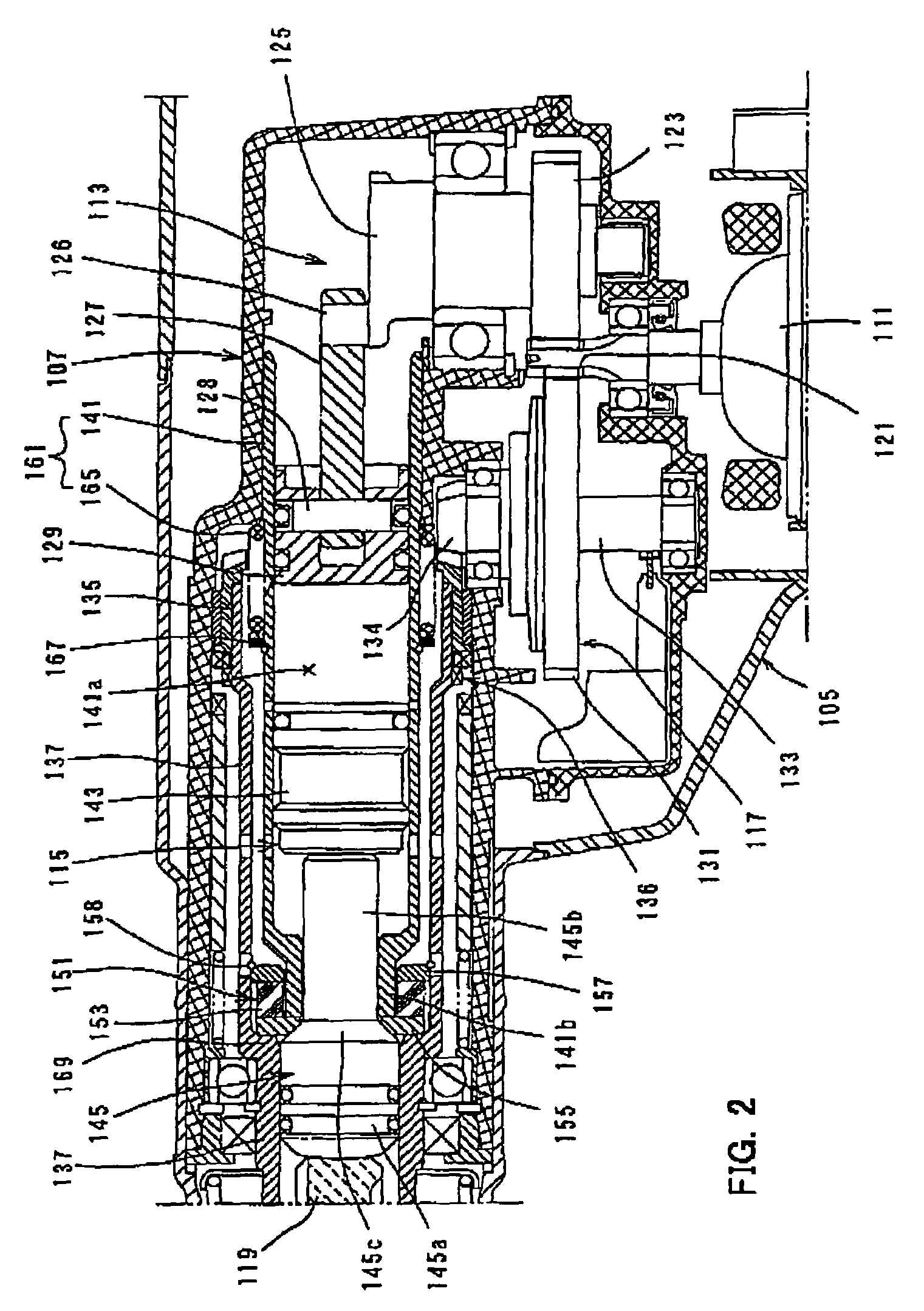

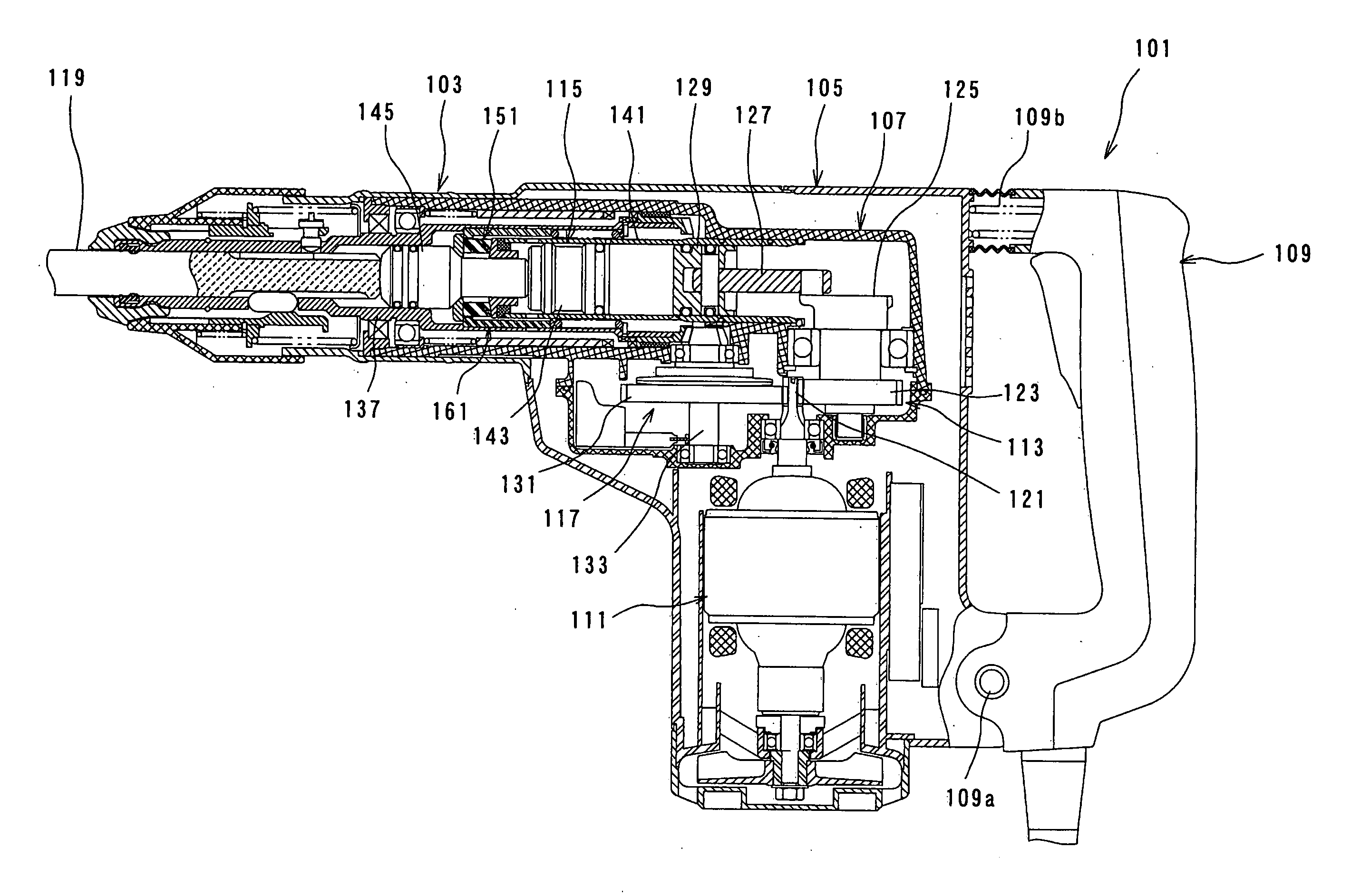

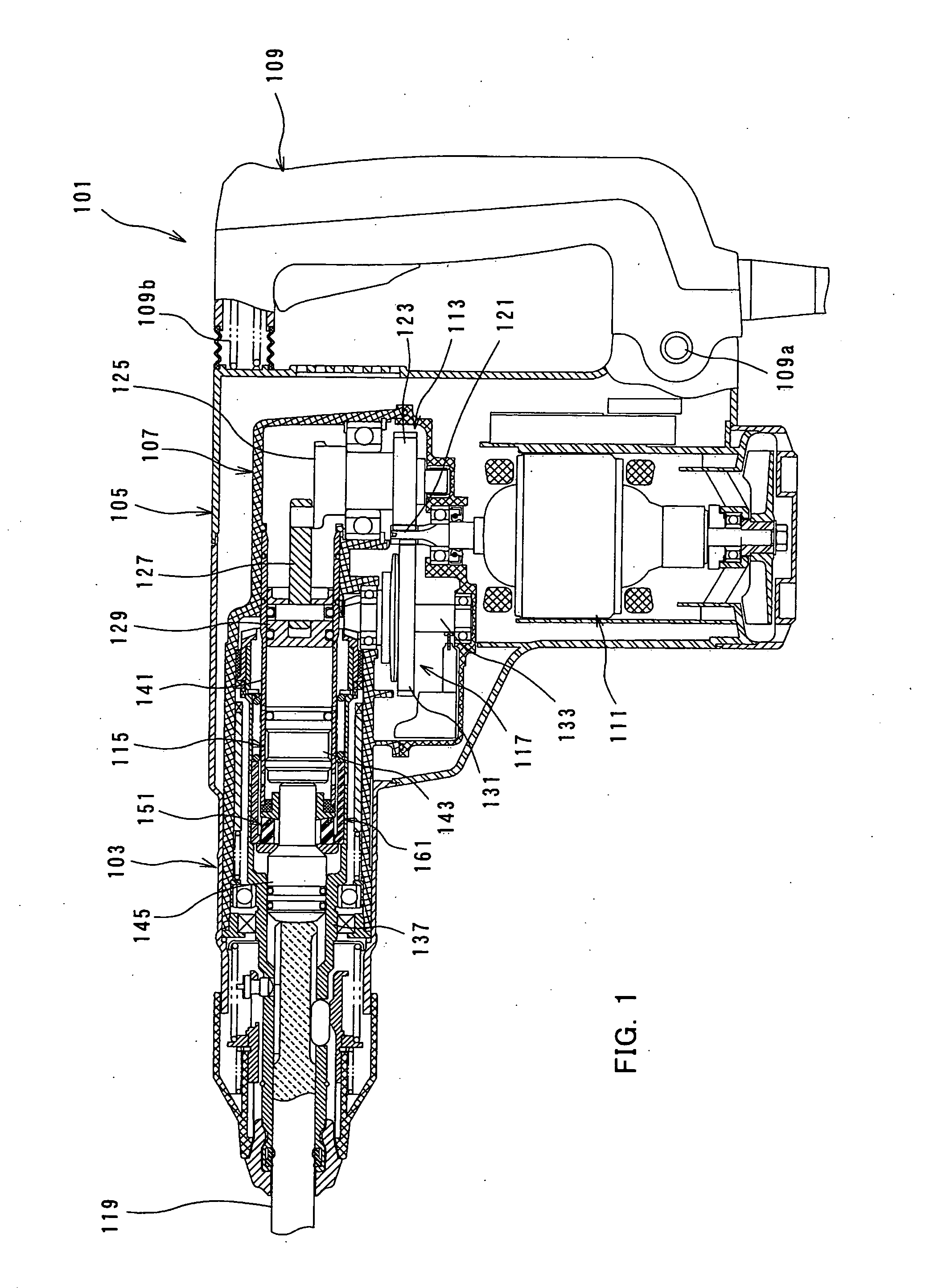

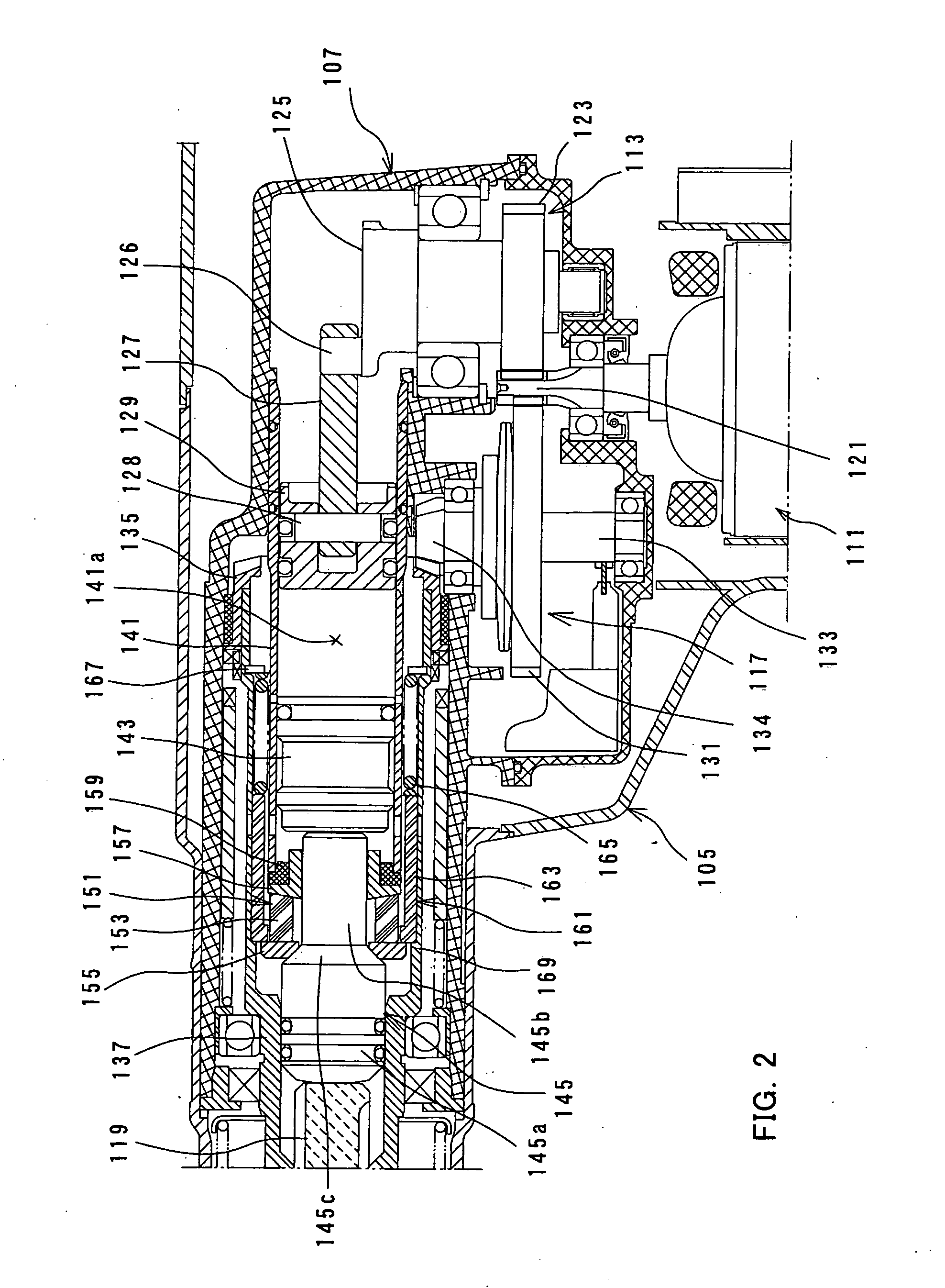

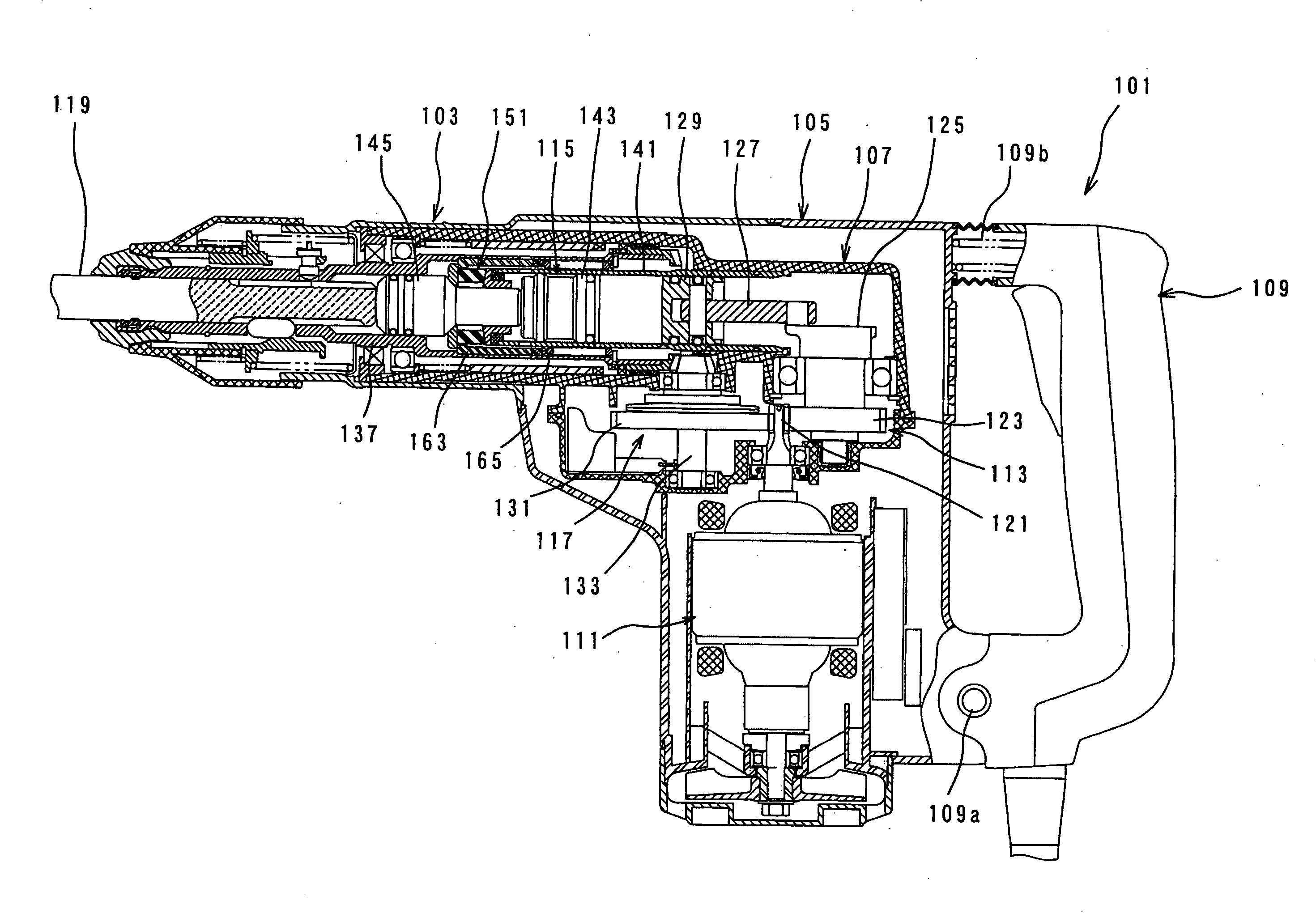

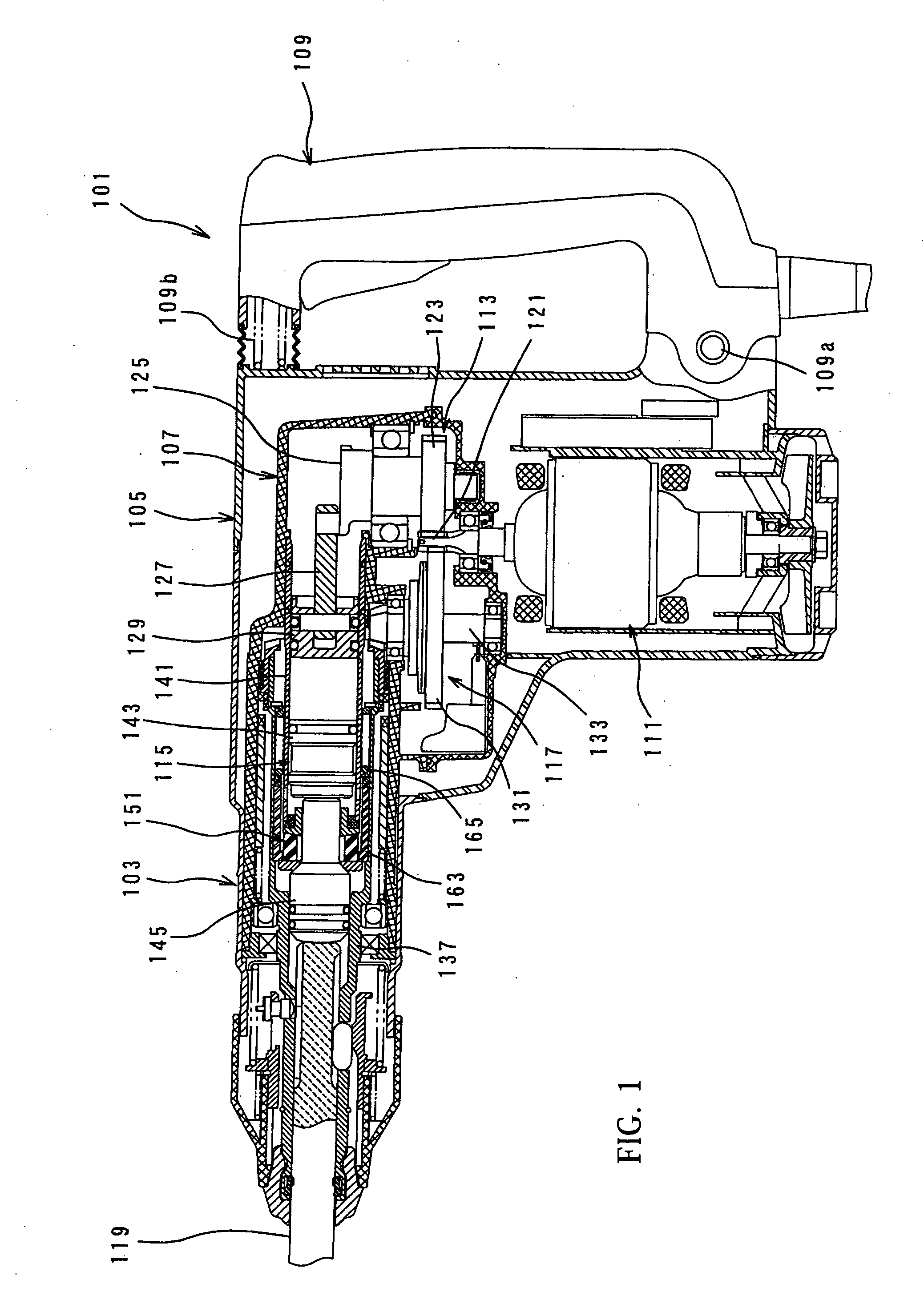

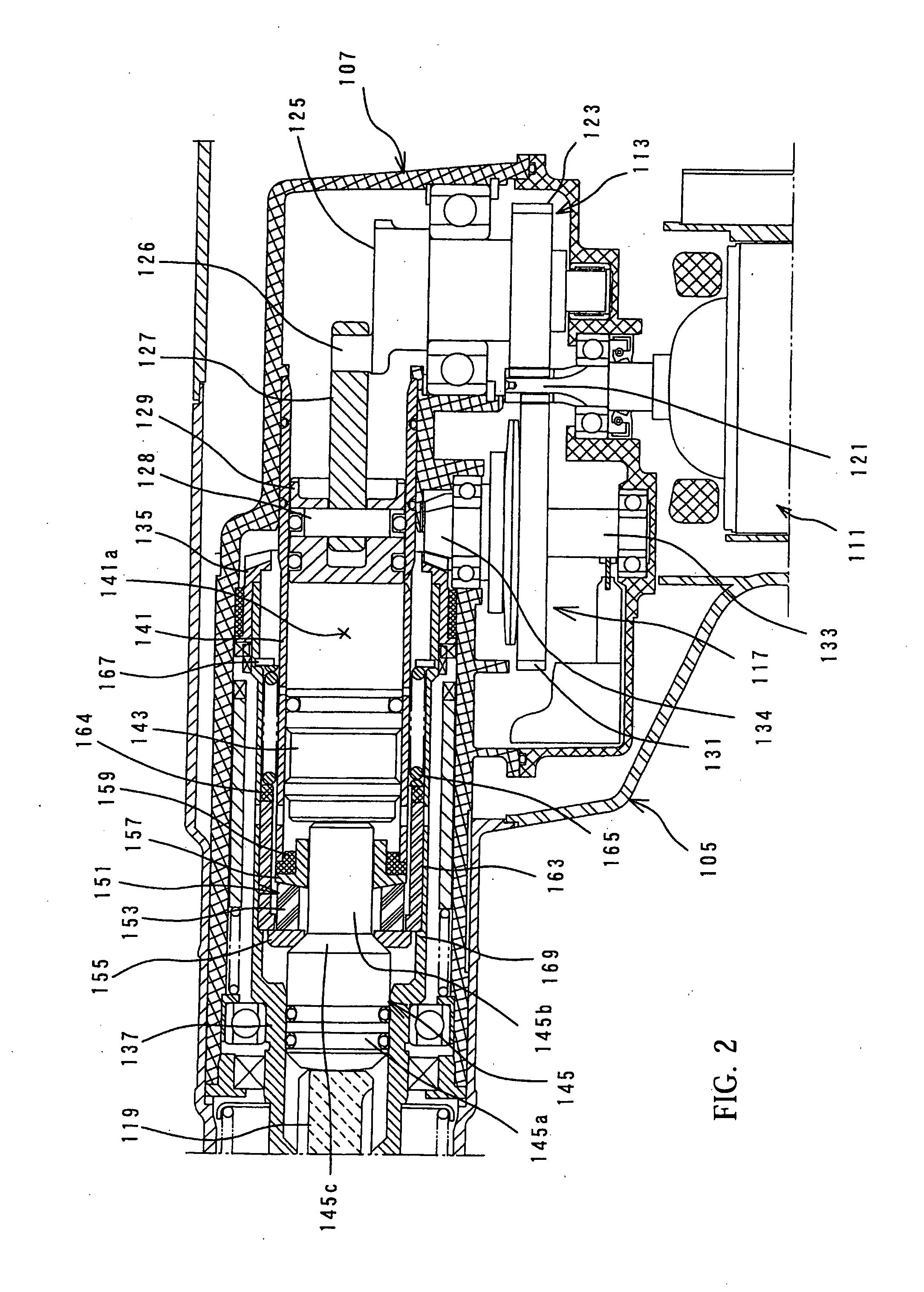

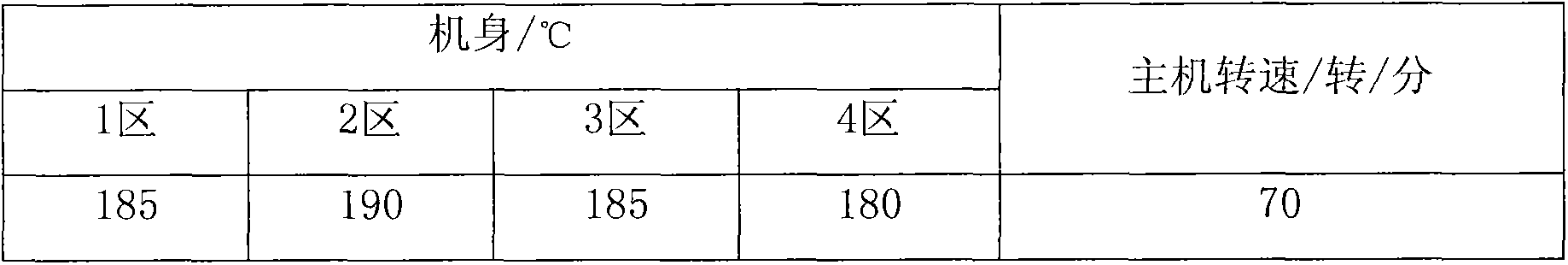

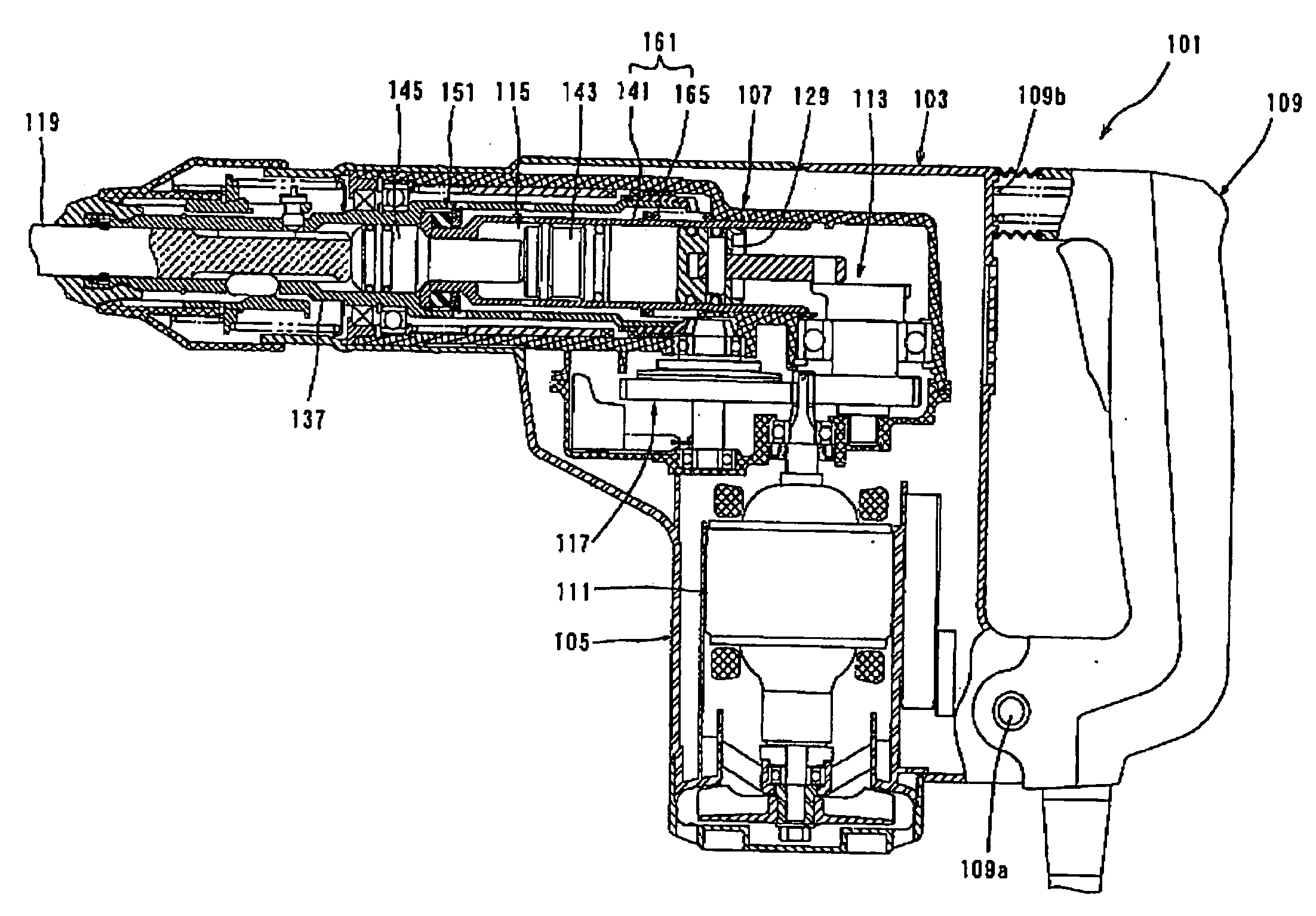

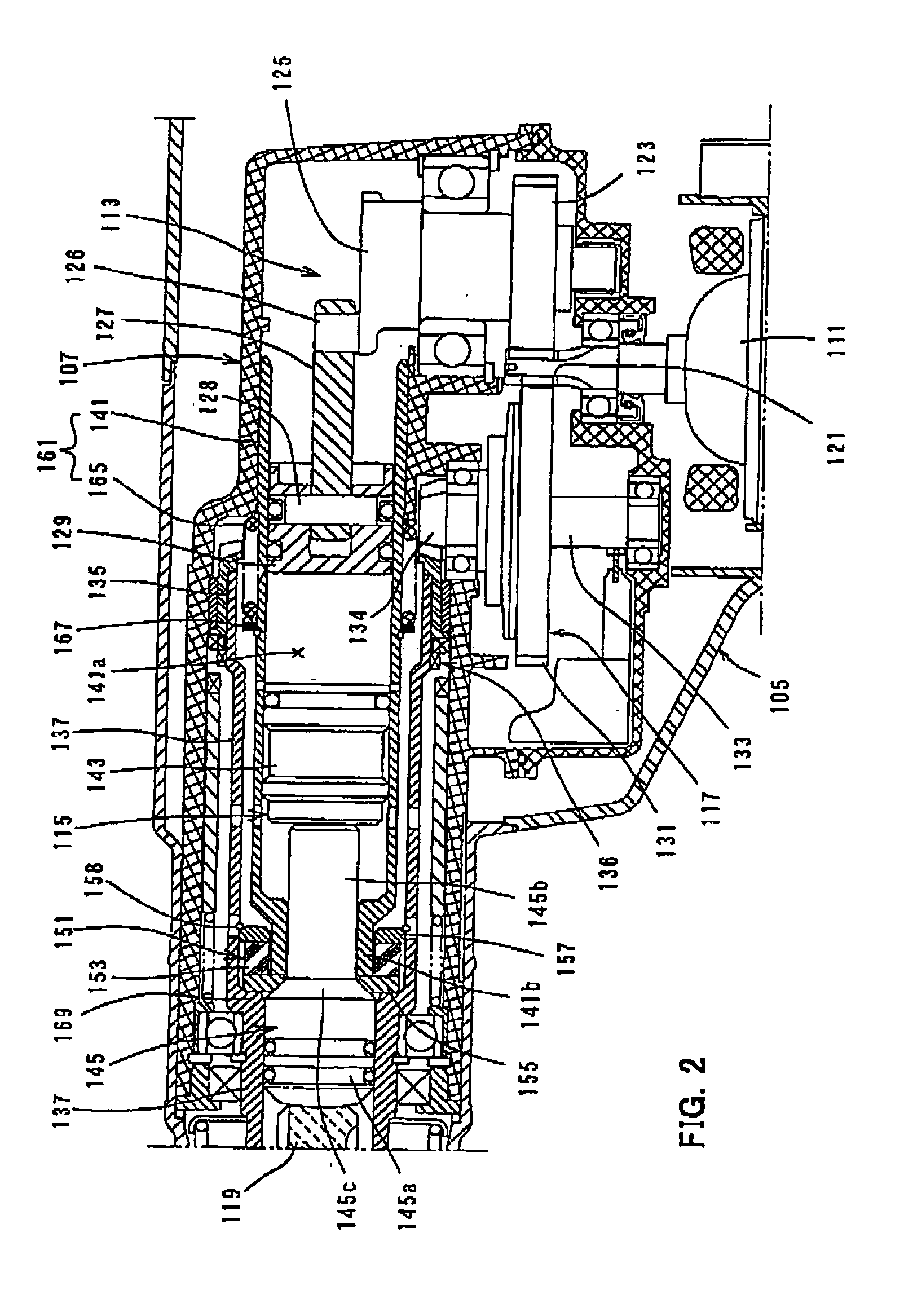

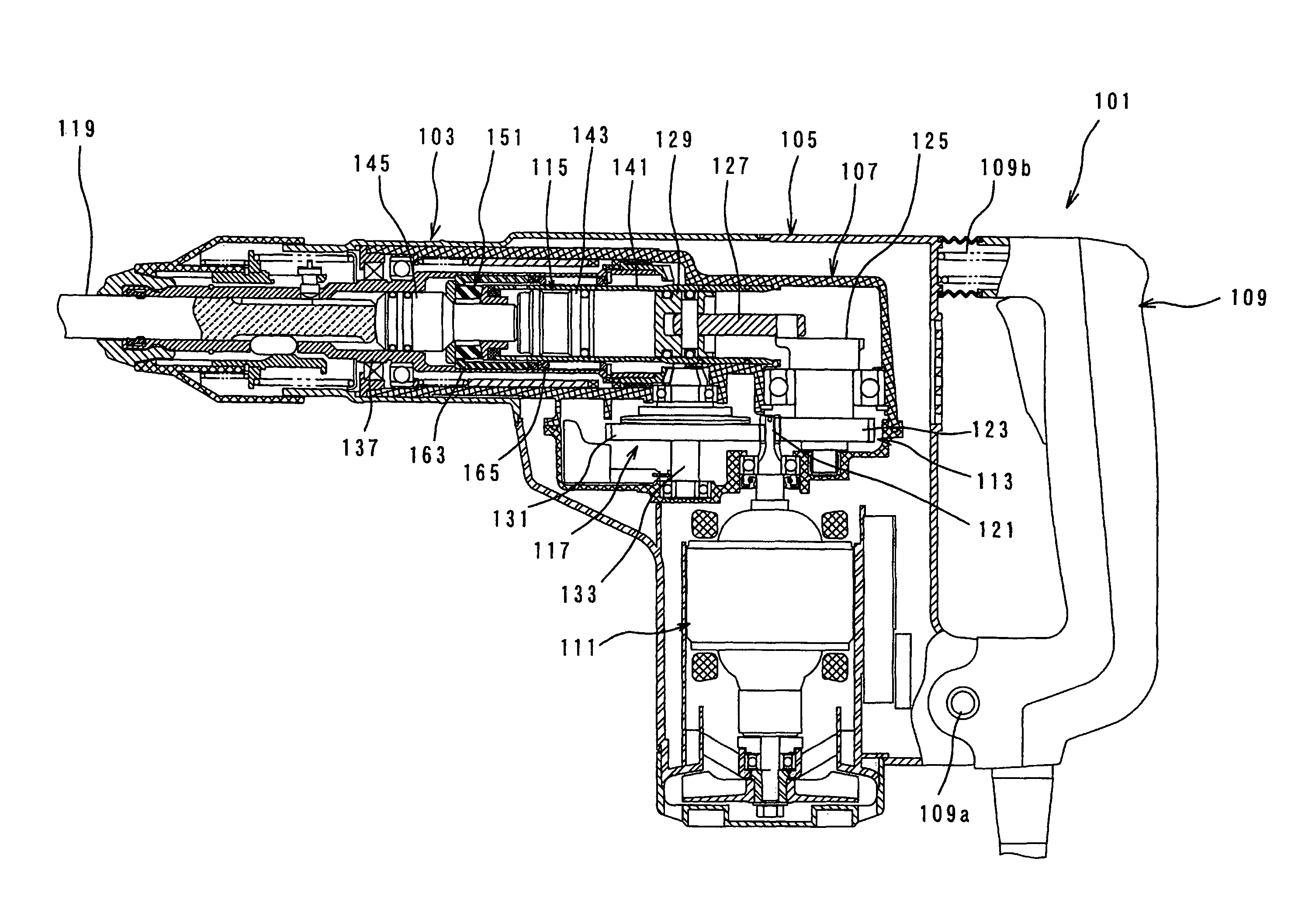

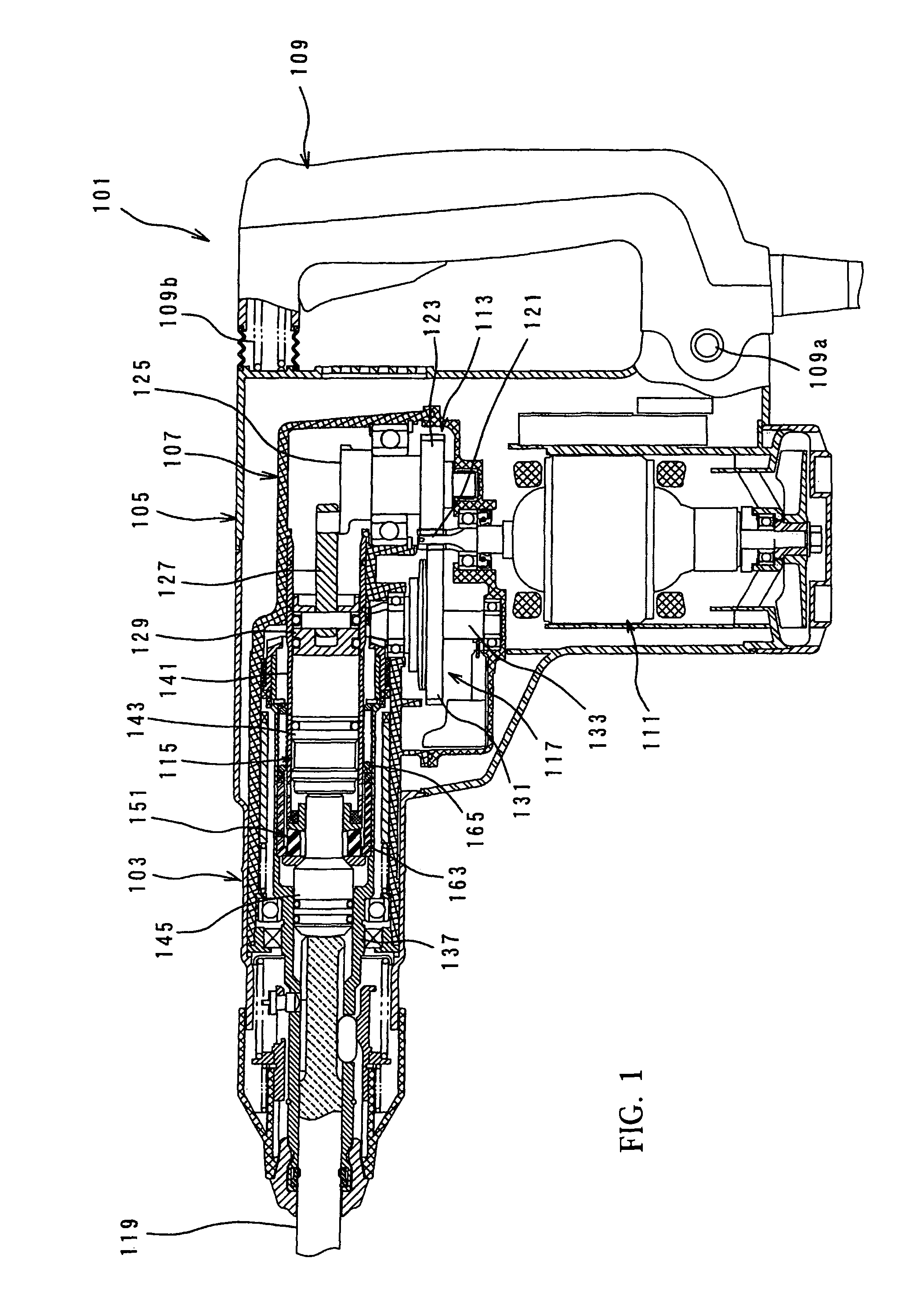

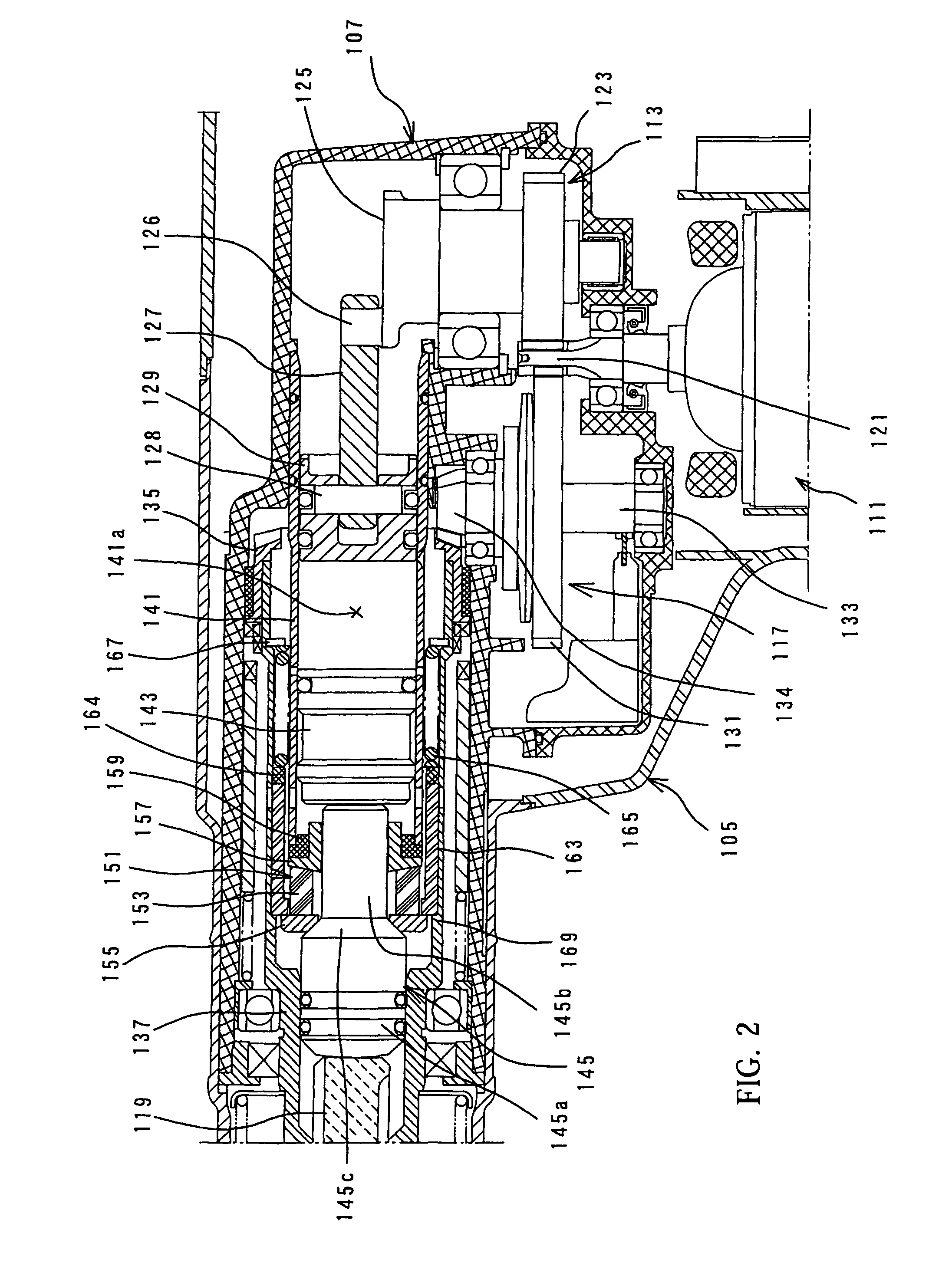

Impact power tool

ActiveUS7383895B2Reduce impactReduce shock vibrationReciprocating drilling machinesPortable percussive toolsEngineeringPower tool

It is an object of the invention to provide an improved technique for lessening an impact force caused by rebound of a tool bit after the striking movement of the tool bit. Representative impact power tool (101) includes a tool body (103), a hammer actuating member (119, 145), a driving mechanism (113, 115), a weight (163) and an elastic element (165). A reaction force that the hammer actuating member receives from the workpiece when performing a hammering operation is transmitted from the hammer actuating member to the weight (163) and then, the weight (163) is caused to move rearward to push the elastic element (165). As a result, the reaction force can be absorbed by the elastic element (165). The elastic force of the elastic element (165) is prevented from acting upon the weight (163) forward beyond the reaction force transmitting position.

Owner:MAKITA CORP

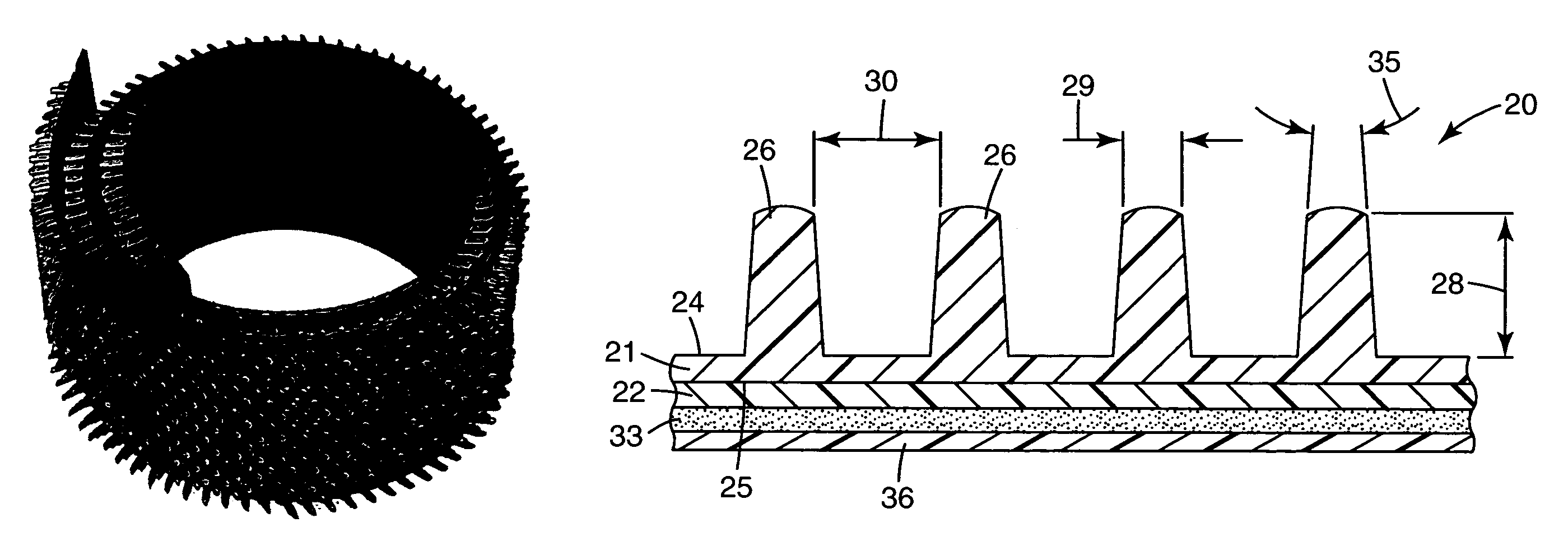

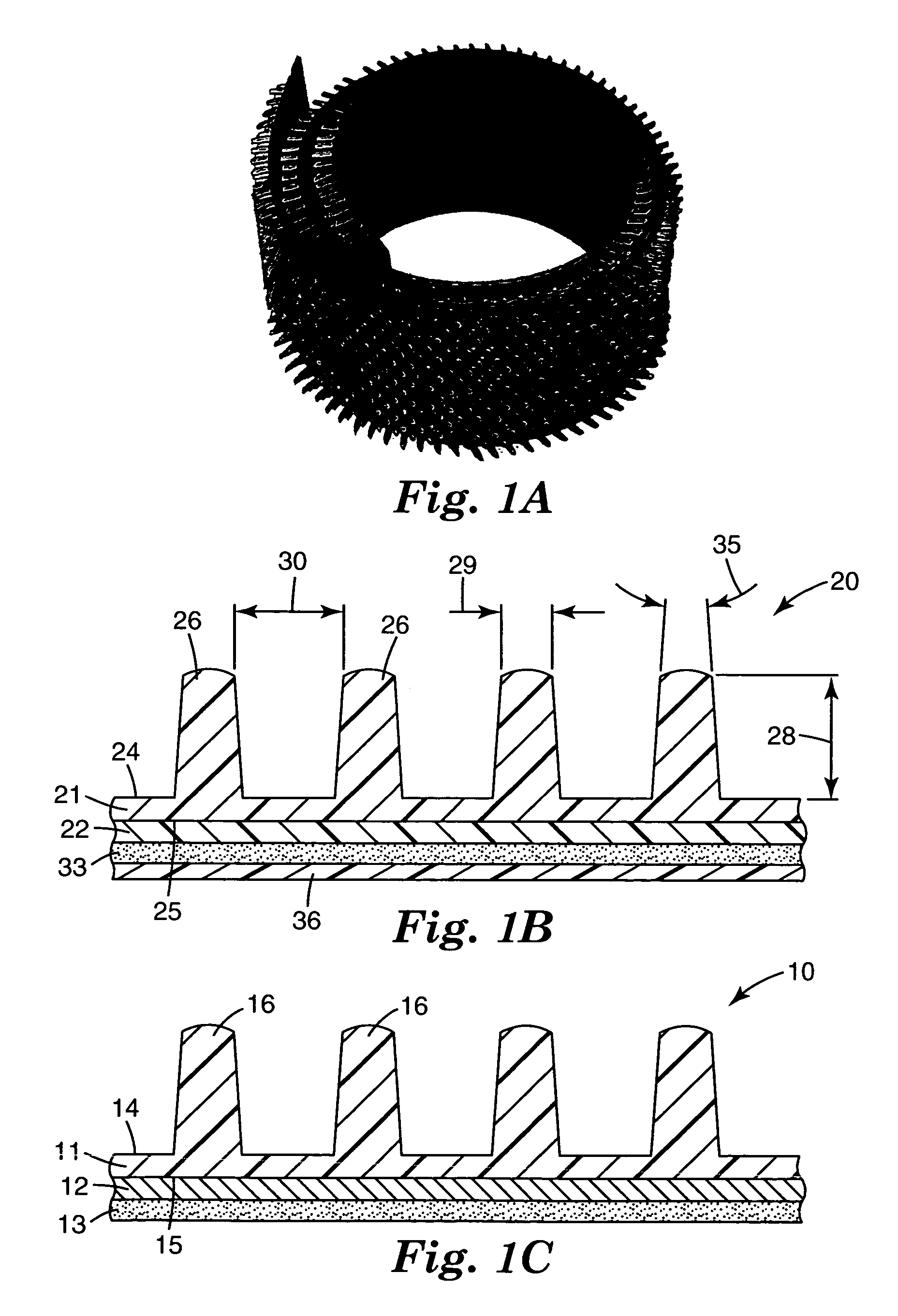

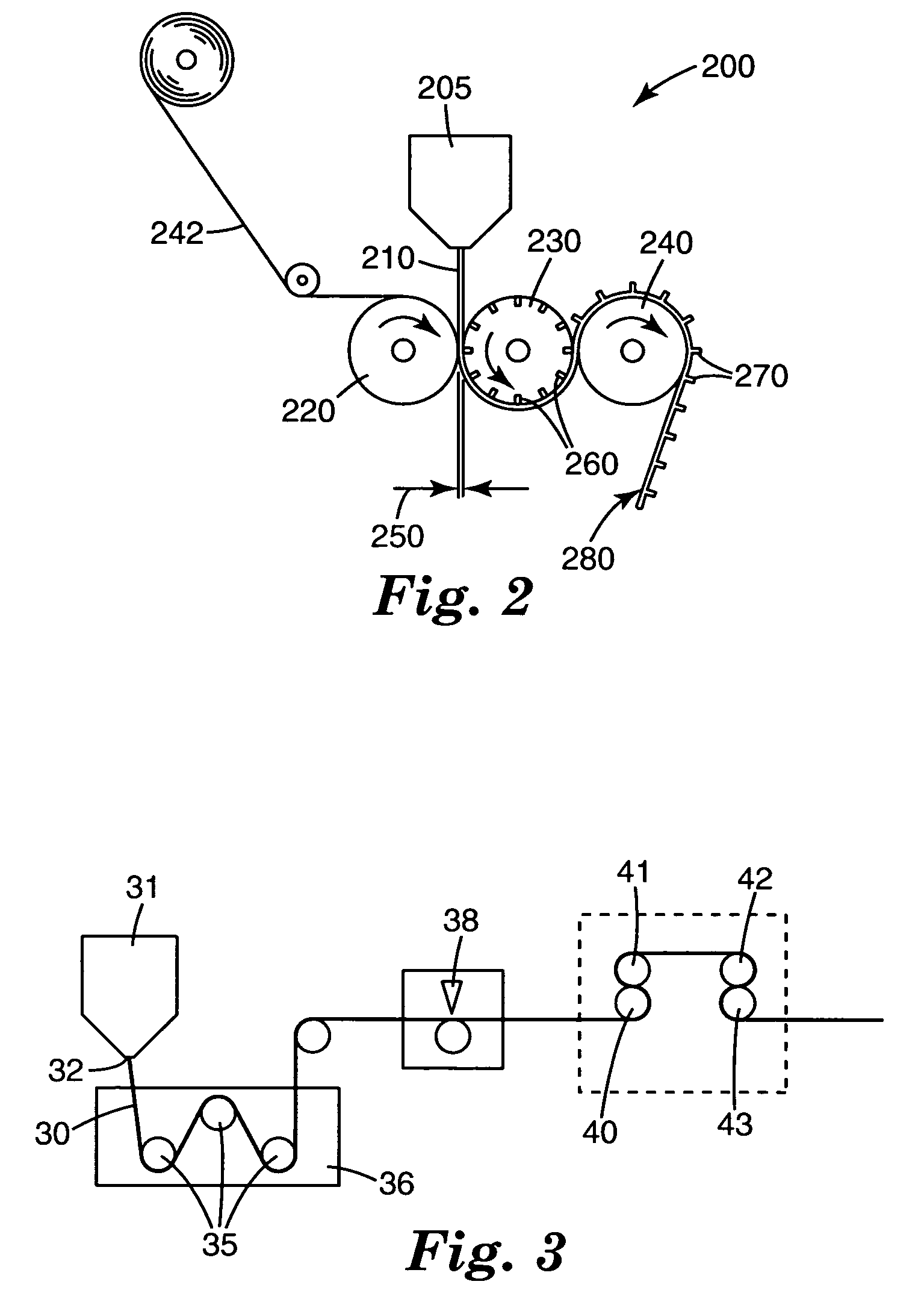

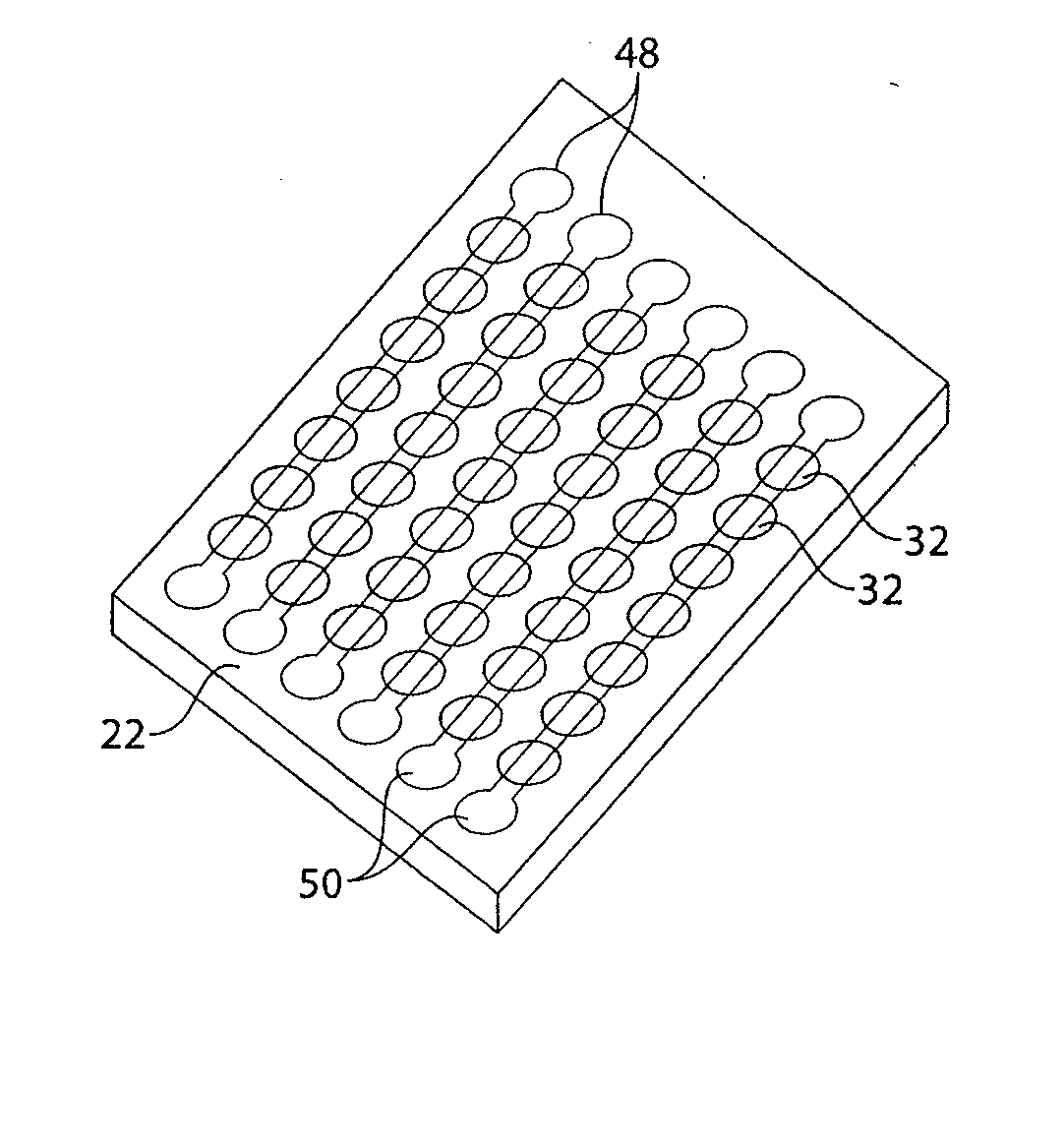

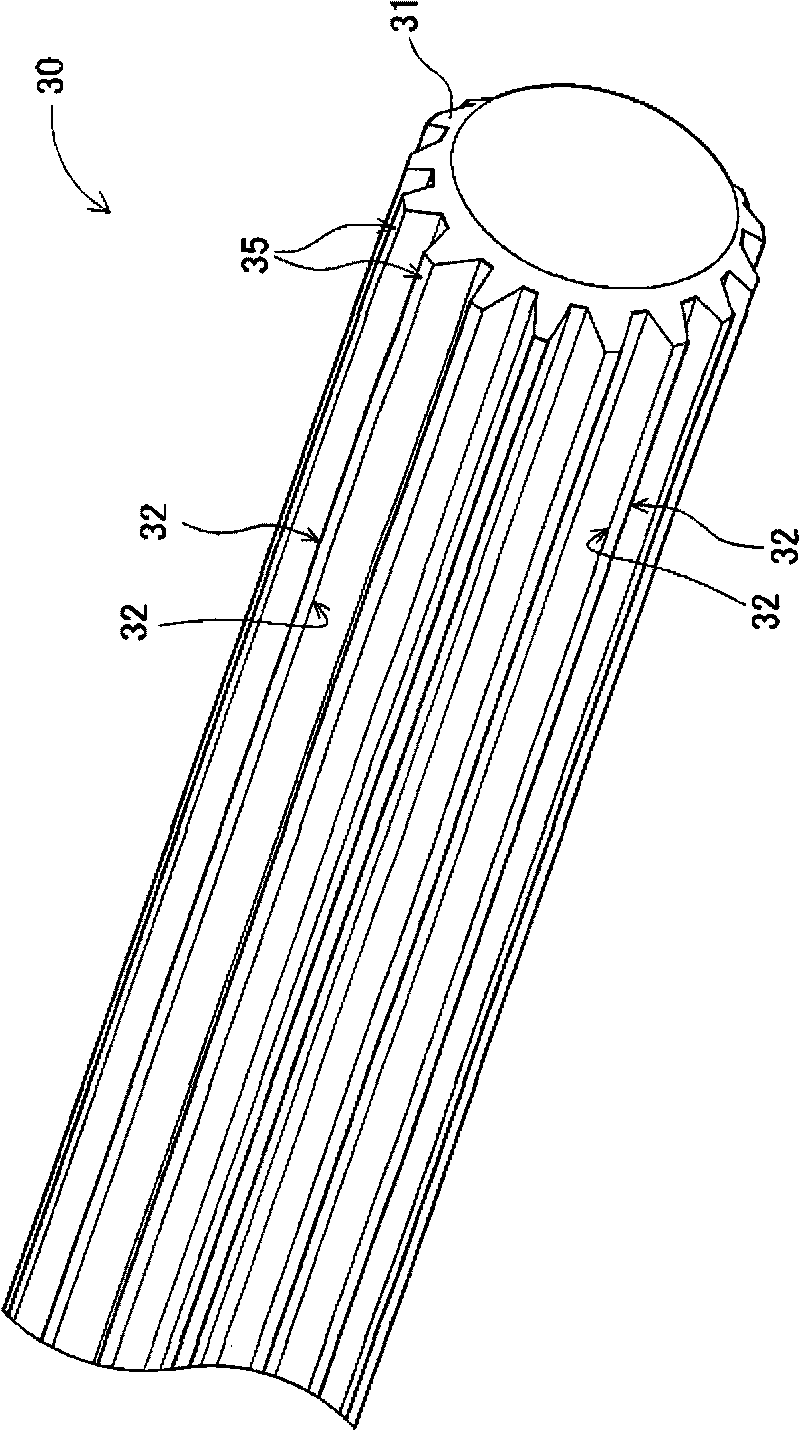

Flexible heat sink

InactiveUS7399919B2Reduce shock vibrationReduce noise transmissionSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

Provided is a flexible heat sink article comprising a base comprising a polymer and a plurality of polymeric protrusions extending away from the base, each protrusion having a major dimension and a minor dimension. The base comprises thermally conductive particles, and the protrusions comprise non-spherical thermally conductive particles substantially aligned in the direction of the major dimension within the protrusions. A thermal interface material may be provided contiguous with the base. Also provided is a flexible heat sink article comprising a base comprising a polymer and having a first surface and a second surface, a plurality of polymeric protrusions extending away from the first surface of the base, each protrusion having a major and a minor dimension, and a metallic layer contiguous with the second surface of the base, wherein the base and the protrusions comprise thermally conductive particles. Also provided is a method of making a flexible heat sink.

Owner:3M INNOVATIVE PROPERTIES CO

Systems and methods for measurement optimization

InactiveUS20080085552A1Rapid and reliable detection and analysisReduce shock vibrationBioreactor/fermenter combinationsBiological substance pretreatmentsOptics

The invention relates to methods and systems for detecting and or analyzing an agent in a sample with a chip having optical components incorporated therein.

Owner:U S GENOMICS INC

Impact power tool

InactiveUS7523791B2Reduce impactReduce shock vibrationReciprocating drilling machinesConstructionsEngineeringPower tool

An object of the invention is to provide an improved technique for lessening an impact force caused by rebound of a tool bit after its striking movement in an impact power tool. The representative impact power tool comprises a tool body, a hammer actuating member, a tool holder, a driving mechanism, a weight placed in contact with the hammer actuating member to move rearward by a reaction force transmitted from the hammer actuating member when the hammer actuating member performs a hammering operation on the workpiece and an elastic element elastically deformed when the weight moves rearward in the tool body to push the elastic element such that the elastic element absorbs the reaction force transmitted to the weight. The weight is defined one or both of the cylinder and the tool holder.

Owner:MAKITA CORP

Impact power tool

ActiveUS20070039749A1Reduce impactReduce shock vibrationReciprocating drilling machinesPortable percussive toolsEngineeringPower tool

It is an object of the invention to provide an improved technique for lessening an impact force caused by rebound of a tool bit after the striking movement of the tool bit. Representative impact power tool (101) includes a tool body (103), a hammer actuating member (119, 145), a driving mechanism (113, 115), a weight (163) and an elastic element (165). A reaction force that the hammer actuating member receives from the workpiece when performing a hammering operation is transmitted from the hammer actuating member to the weight (163) and then, the weight (163) is caused to move rearward to push the elastic element (165). As a result, the reaction force can be absorbed by the elastic element (165). The elastic force of the elastic element (165) is prevented from acting upon the weight (163) forward beyond the reaction force transmitting position.

Owner:MAKITA CORP

Impact power tool

ActiveUS20080210451A1Reduce impactReduce shock vibrationReciprocating drilling machinesPortable percussive toolsEngineeringPower tool

It is an object of the invention to provide a technique for a reduction of an impact force cased by rebound of a tool bit after its striking movement in an impact power tool. The representative impact power tool includes a tool body, a hammer actuating member, a striker, a weight and an elastic element. A reaction force is transmitted from the hammer actuating member to the weight and the elastic element is elastically deformed when the weight moves ward by the reaction to absorb the reaction force. The invention is characterized in that the mass of the weight is set to about 40% or more of the mass of the stiker.

Owner:MAKITA CORP

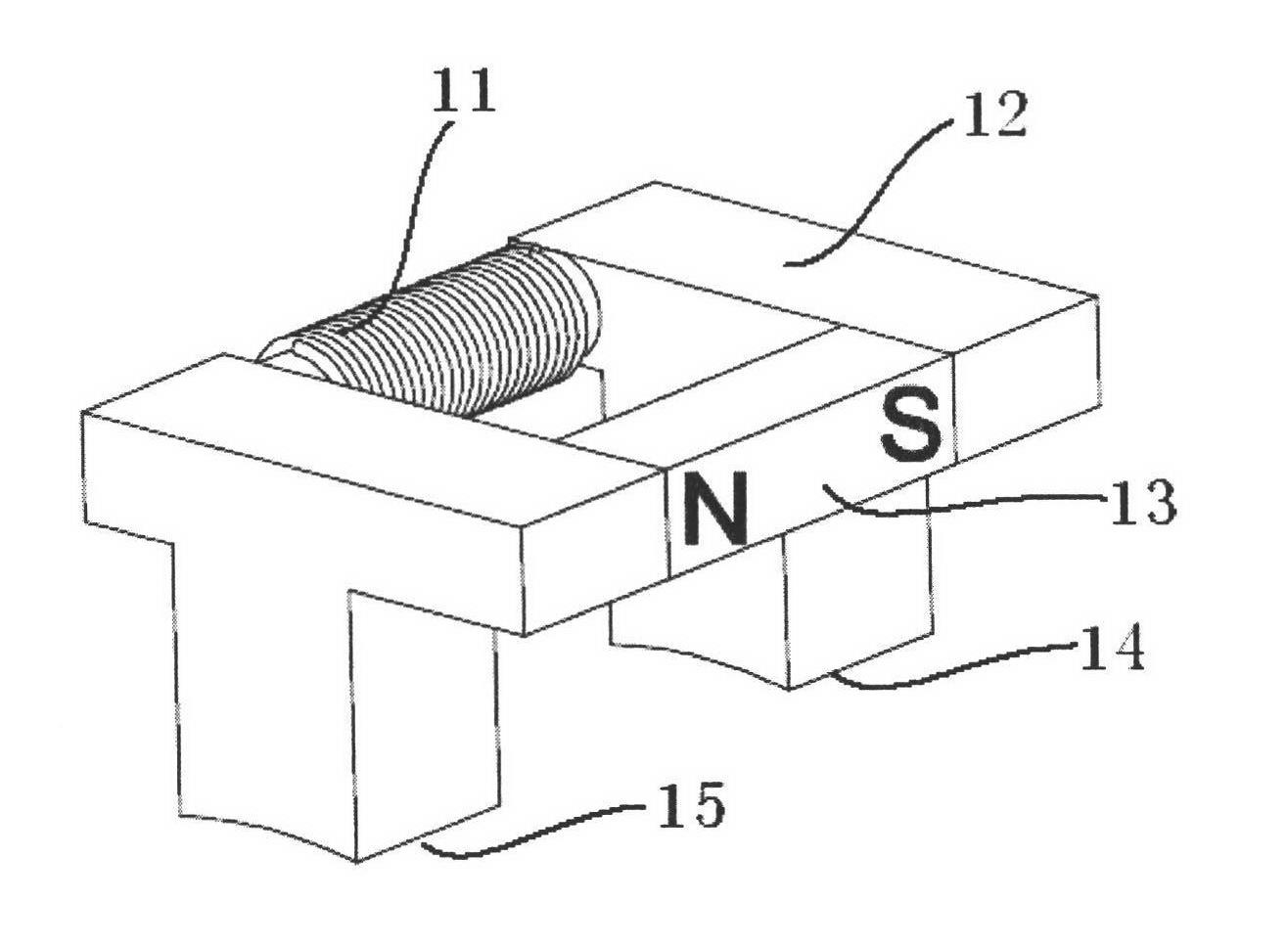

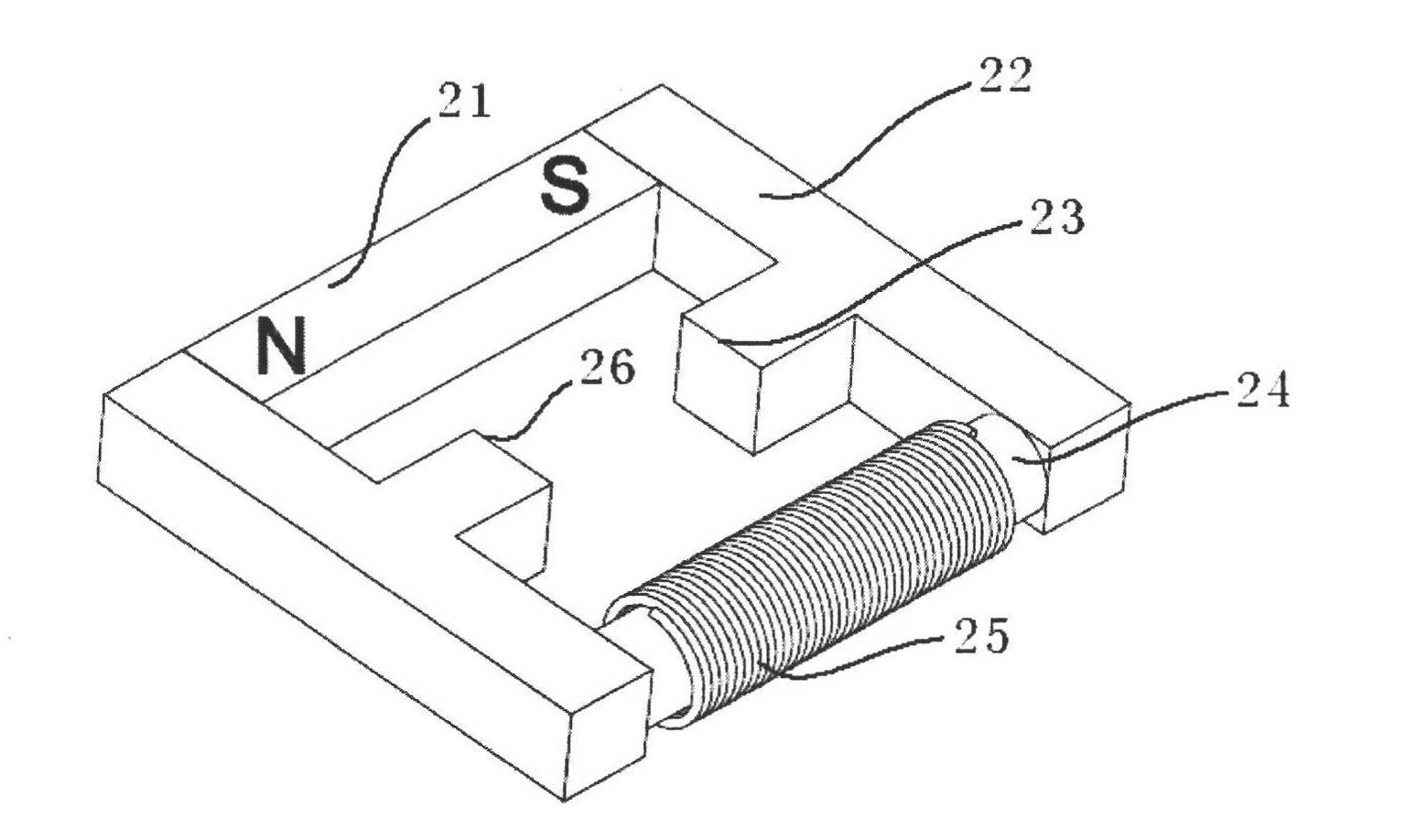

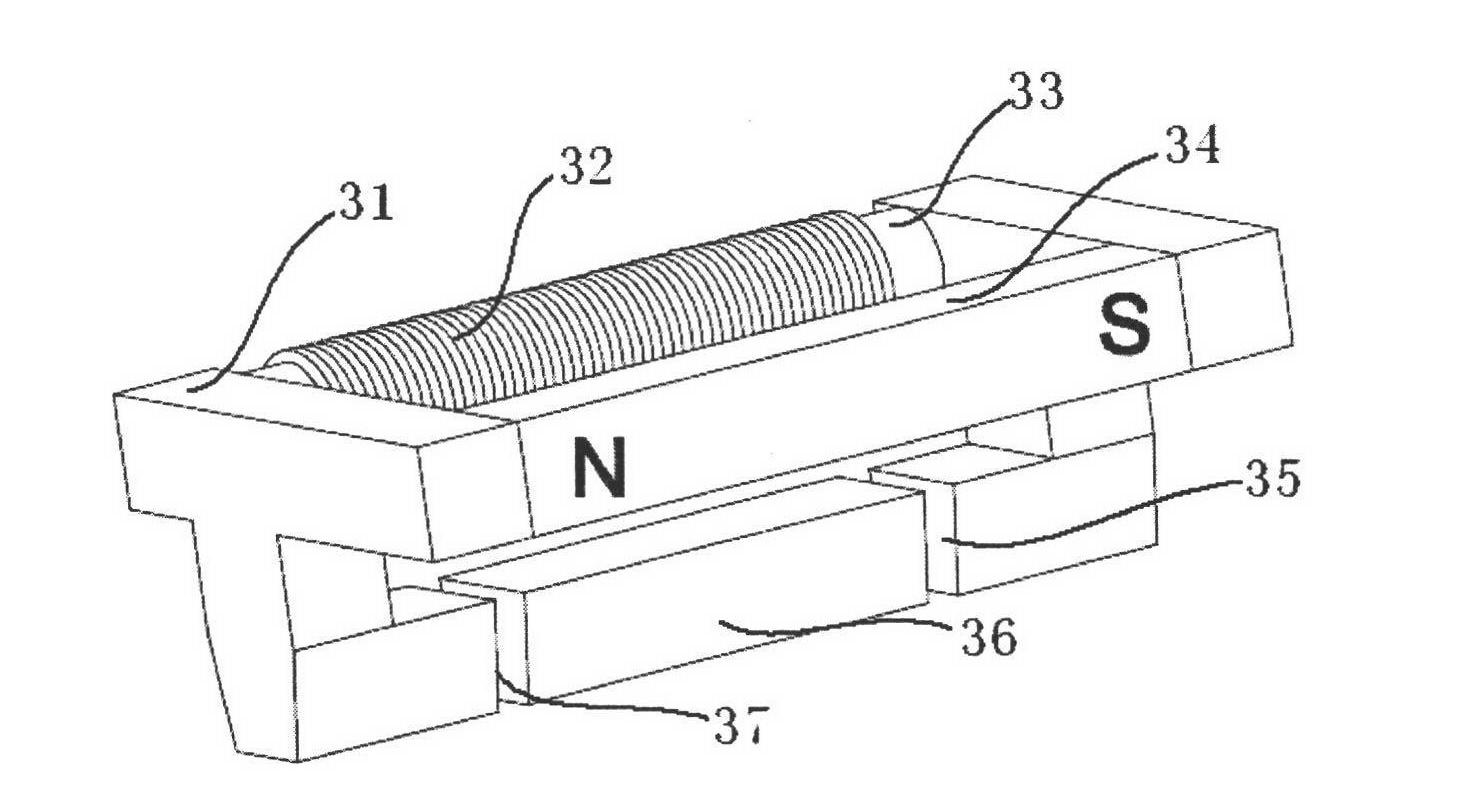

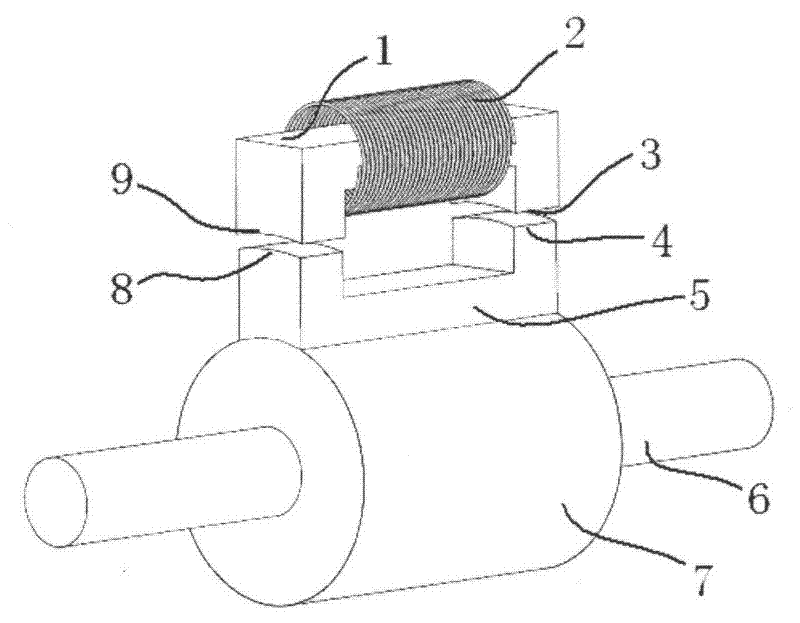

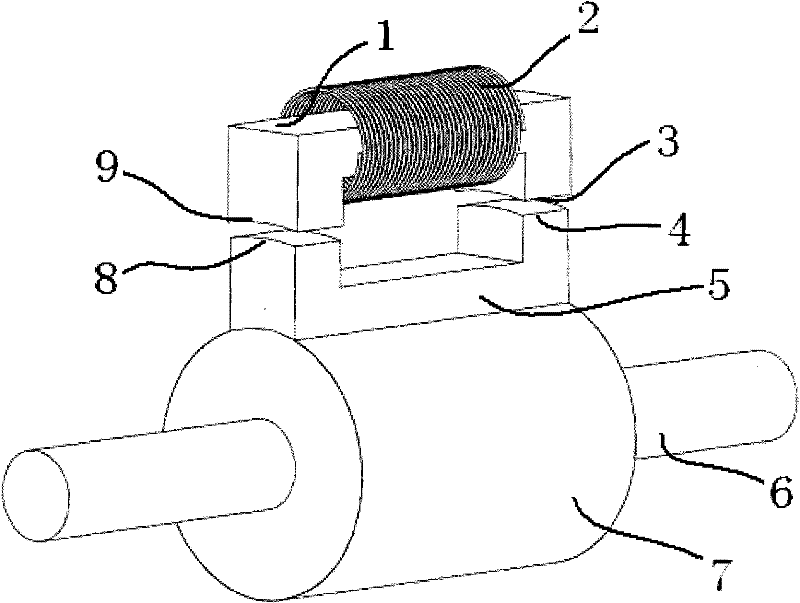

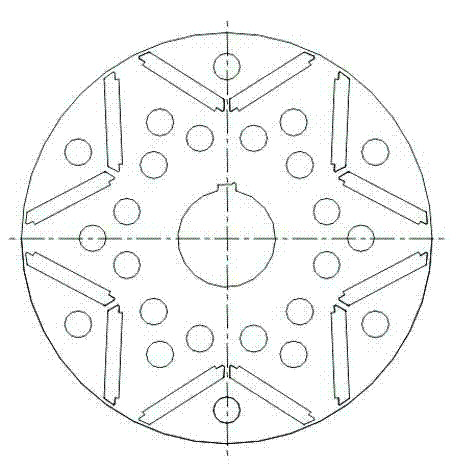

Electric excitation permanent magnet switch, reluctance motor for electric excitation permanent magnet switch and electric excitation method

InactiveCN102184809AWith energy saving effectShorten the reluctance ratioMagnetic circuitSynchronous machinesElectricityControl power

The invention relates to an electric excitation permanent magnet switch, a reluctance motor for the electric excitation permanent magnet switch and an electric excitation method. In the electric excitation permanent magnet switch, two magnetic poles of a permanent magnet are respectively connected with both ends of an iron core on which magnet exciting coils are wound by two soft magnets; and salient poles are arranged on the soft magnets. In the reluctance motor, the switch is used as basic components of a stator and a rotor, and the two magnetic salient poles of each component are arranged in an axial direction; the salient poles of the stator component and the rotor component are arranged oppositely, and air gaps are reserved between the salient poles; and the magnet exciting coils of the stator component and the rotor component at the axial symmetrical position are connected in series or in parallel and then are used as a phase line respectively to be connected to an excitation control power supply. The invention also provides a combination motor formed by connecting motor monomers by using a shaft in a rotary and dislocation mode and a method for the simultaneous diphase electric excitation of the stator component. The switch and the motor save energy, and have low magnetic loss and high magnetic efficiency; and the combination motor with the diphase electric excitation realizes the subdivision of stepper angles, and improves running stability, control accuracy and output power.

Owner:戴珊珊

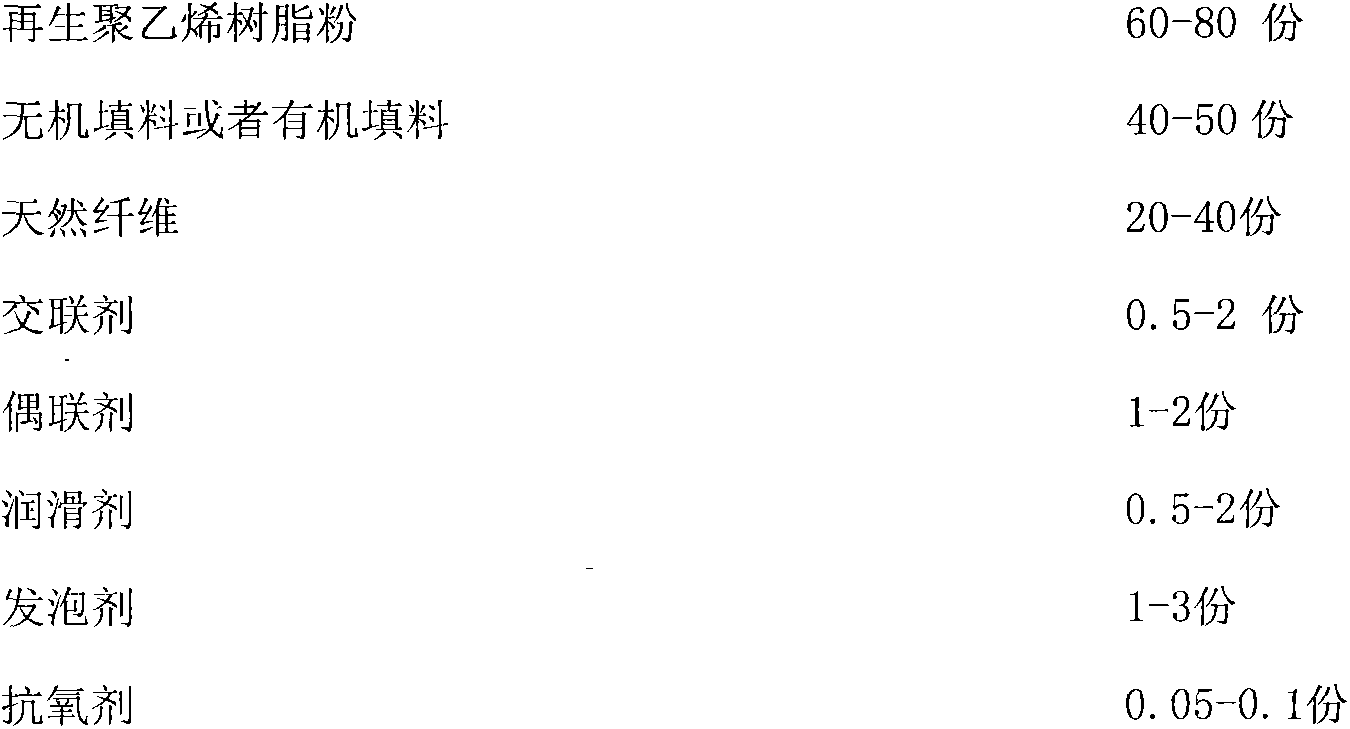

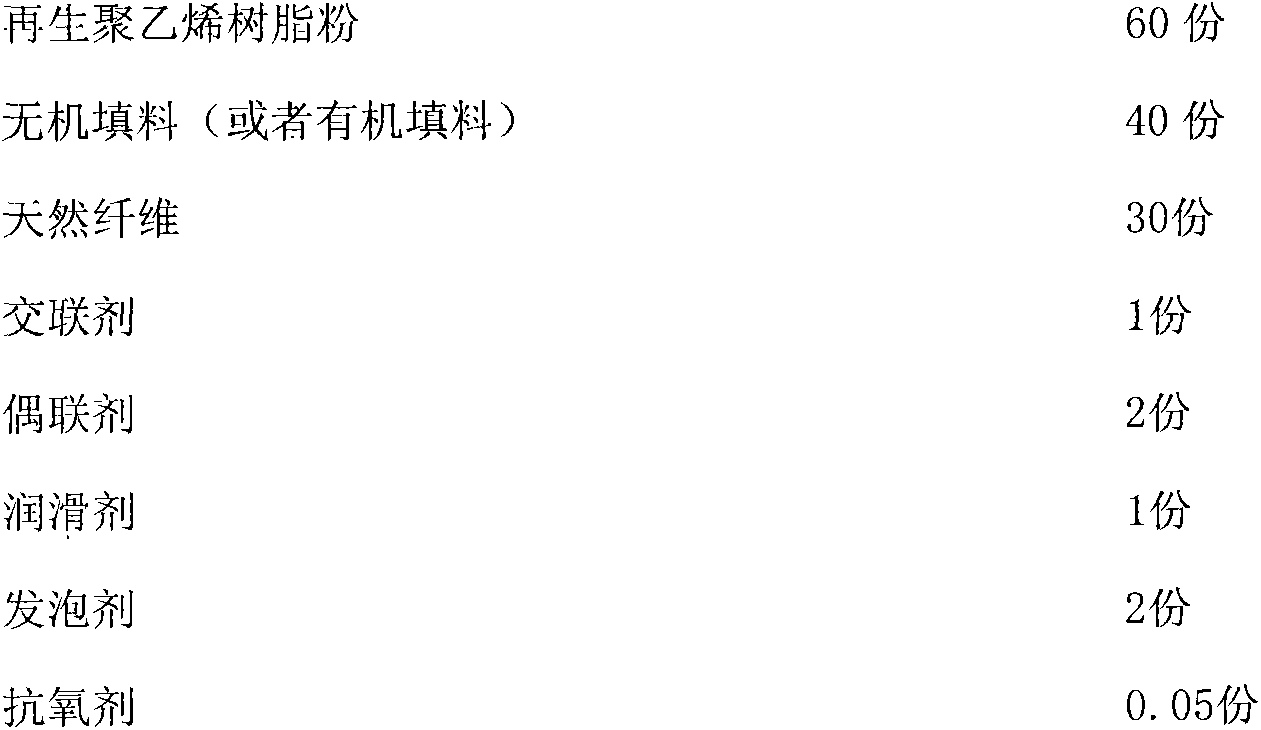

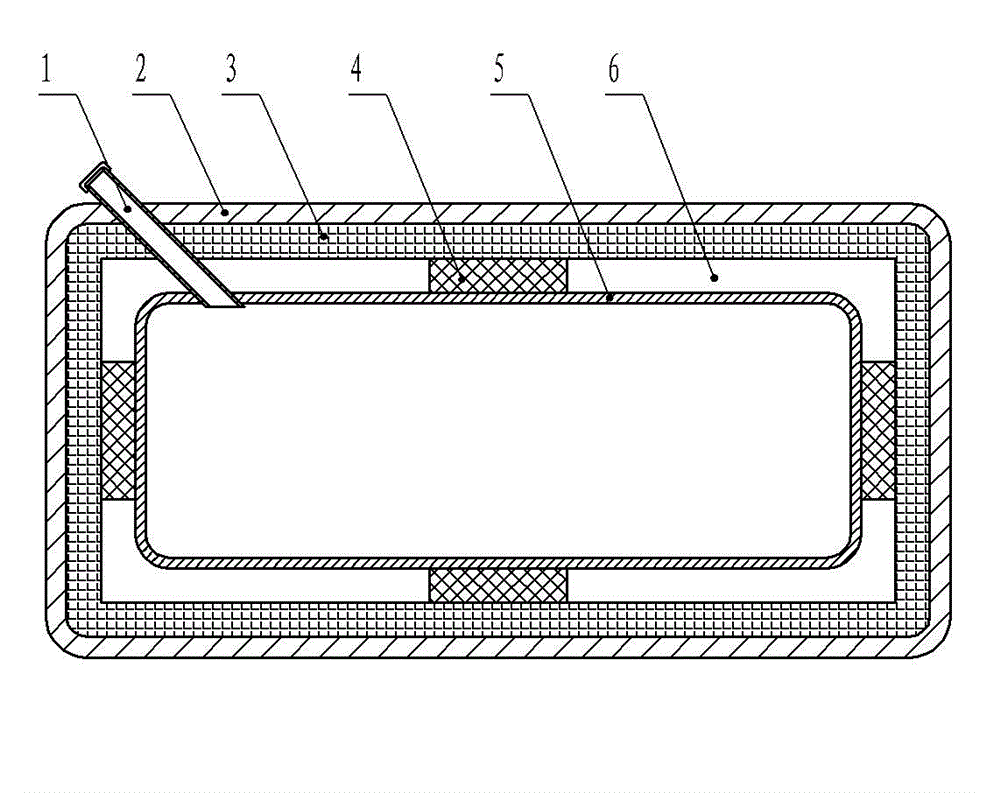

Superstrong-muting PE (polyethylene) core layer micro-foamed drainage pipe and manufacturing method thereof

The invention belongs to the field of pipes, relates to an enhanced drainage pipe and mainly relates to a superstrong-muting PE (polyethylene) core layer micro-foamed drainage pipe which is suitable for wastewater discharging, engineering transforming projects and home decoration of villa communities, high-rise residential communities, high-grade residential apartment communities and the like and industrial building fields like water discharging, sewage discharging, waste discharging and the like of industrial enterprises. The superstrong-muting PE composite drainage pipe is a multilayer composite body formed by a high-density polyethylene resin inner layer, a middle PE micro-foamed layer and a high-density polyethylene resin outer layer, the thickness ratio of the inner layer, the middle layer and the outer layer is 1:4:1, and the PE micro-foamed layer is composed of regenerated polyethylene resin powder, inorganic filler or organic filler, natural fibers, a cross-linking agent, a coupling agent, a lubricating agent, a foaming agent and an antioxidant. The superstrong-muting PE core layer micro-foamed drainage pipe has excellent denoising and muting performance, superstrong resistance to chemical corrosion and good impact resistance.

Owner:LINYI DONGLI PLASTIC BUILDING MATERIAL CO LTD

Impact power tool

InactiveUS20070175647A1Reduce impactReduce shock vibrationReciprocating drilling machinesConstructionsEngineeringPower tool

An object of the invention is to provide an improved technique for lessening an imp force caused by rebound of a tool bit after its striking movement in an impact power tool. representative impact power tool comprises a tool body, a hammer actuating member, a holder, a driving mechanism, a weight placed in contact with the hammer actuating member move rearward by a reaction force transmitted from the hammer actuating member when hammer actuating member performs a hammering operation on the workpiece and an ela element elastically deformed when the weight moves rearward in the tool body to push the ela element such that the elastic element absorbs the reaction force transmitted to the weight. weight is defined one or both of the cylinder and the tool holder.

Owner:MAKITA CORP

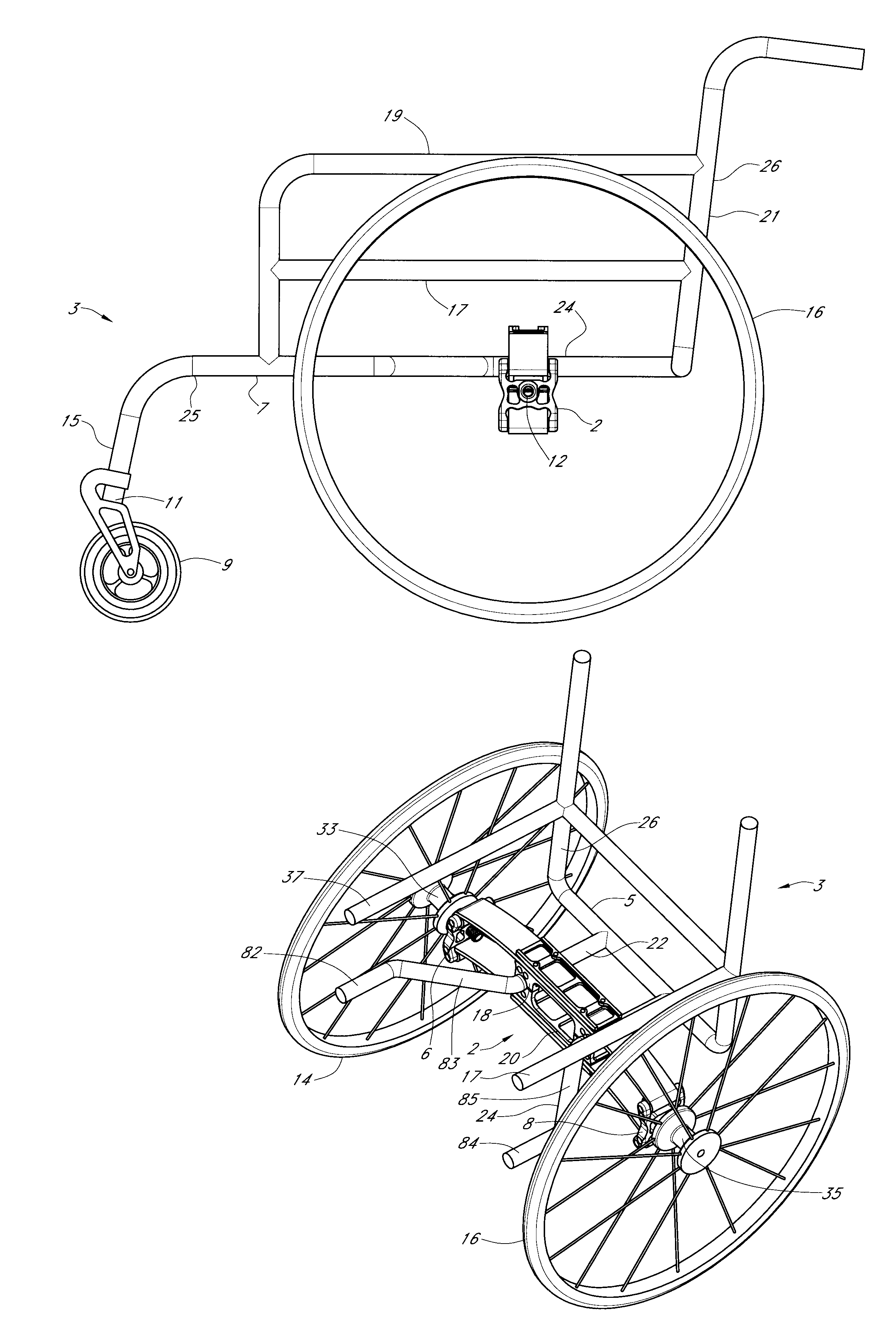

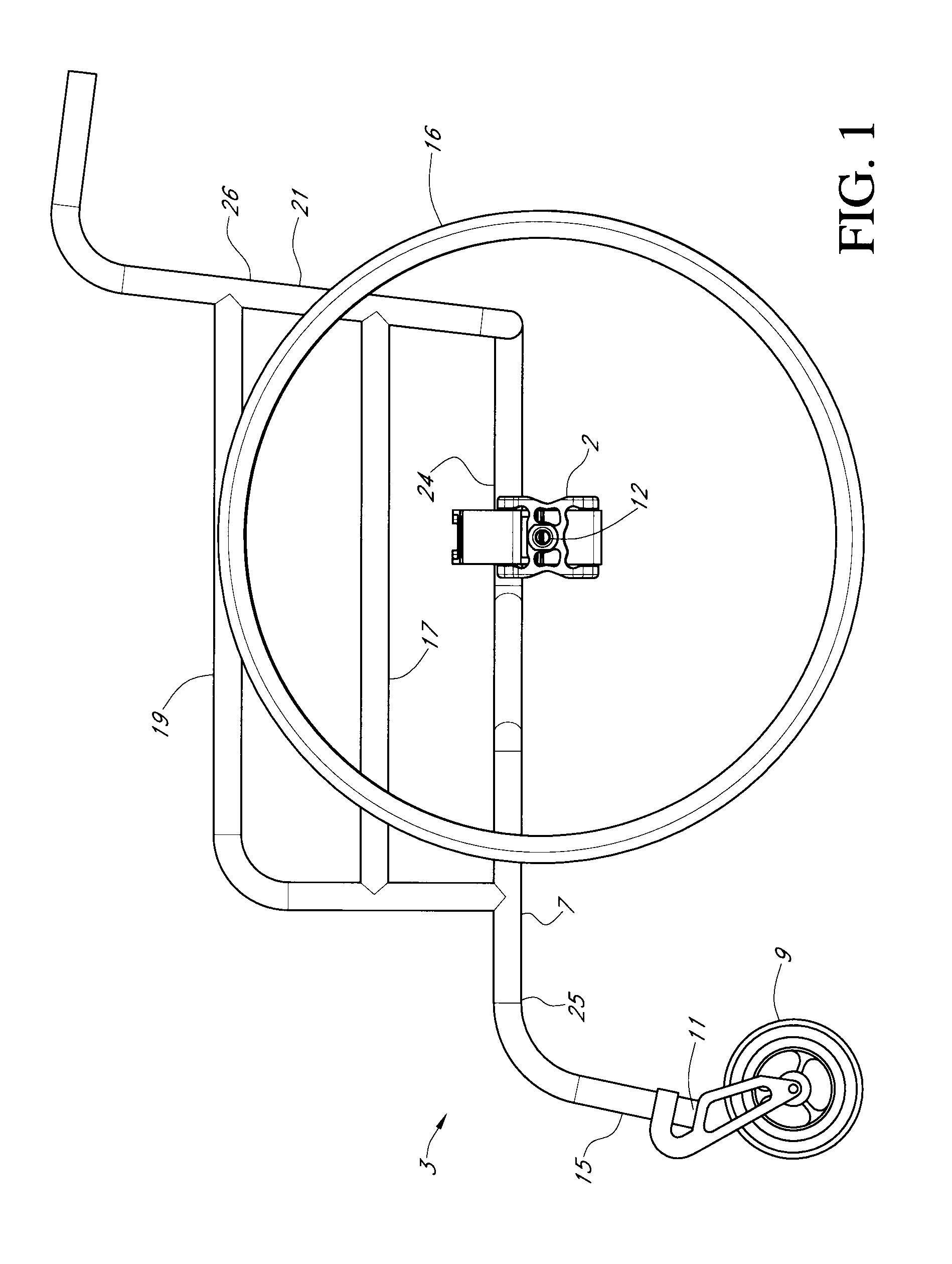

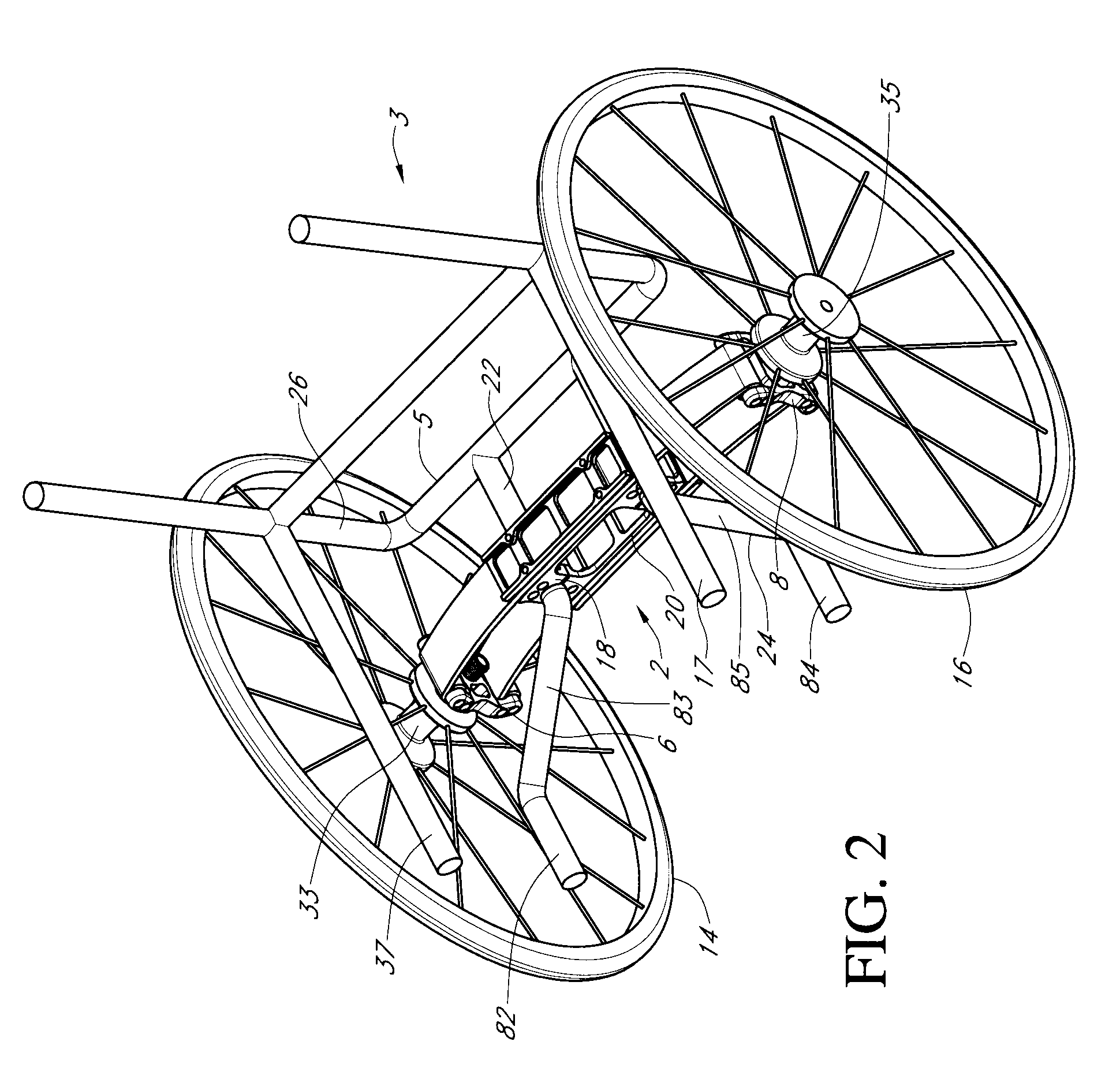

Wheelchair suspension system

InactiveUS20100123296A1Reduce shockReduce vibrationWheelchairs/patient conveyanceConvertible cyclesCamber angleEngineering

A wheelchair suspension system includes a suspension member which clamps to longitudinal bars of the wheelchair frame located below the seat of the wheelchair. The suspension member is elongate with upper and lower parallel leaf springs extending between the opposing ends of the suspension member. An axle support member is hinged to each end of the suspension member, by pivotal connection to each of the leaf springs. Each axle support member receives the axle of one of the opposing large rear wheels of the wheelchair. As the large wheels encounter uneven areas on the ground surface on which the wheelchair moves, the leaf springs flex reducing vibrations and shock to the wheelchair occupant. The axle support members maintain their generally upright orientation as the leaf springs flex so that camber angle of the rear wheels does not change.

Owner:CHELGREN ERIC MARK

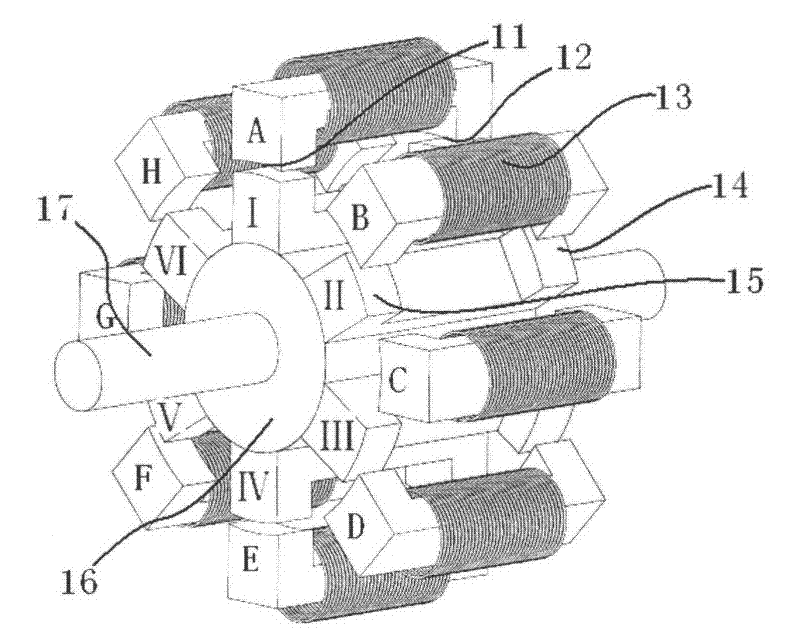

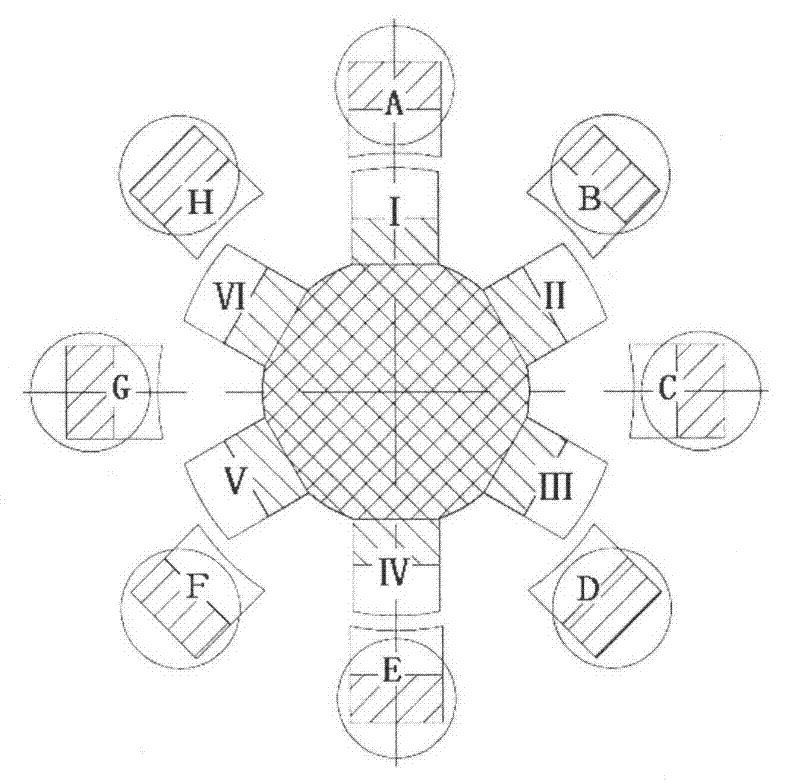

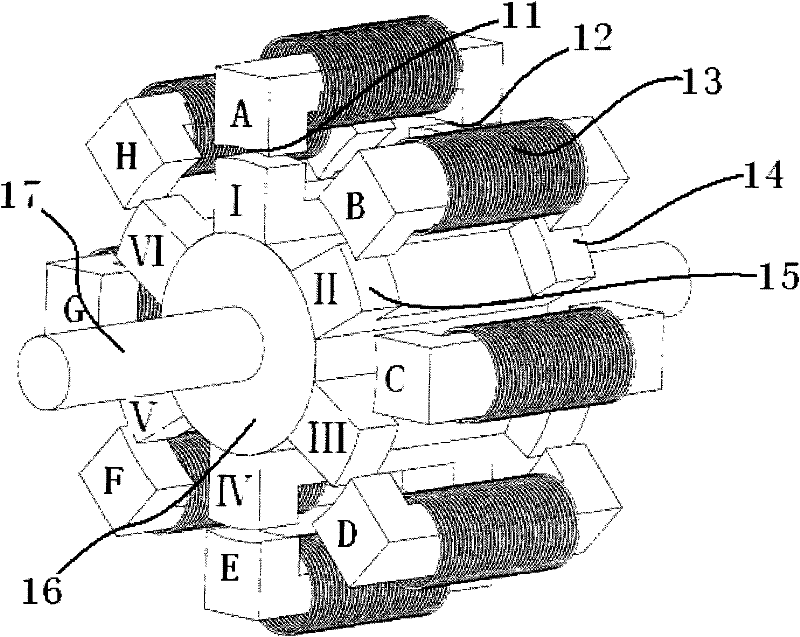

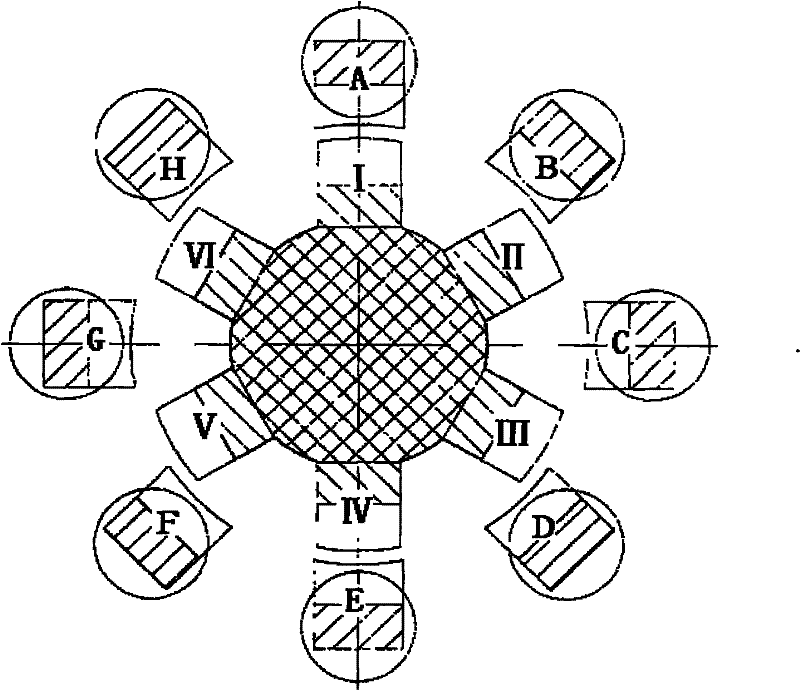

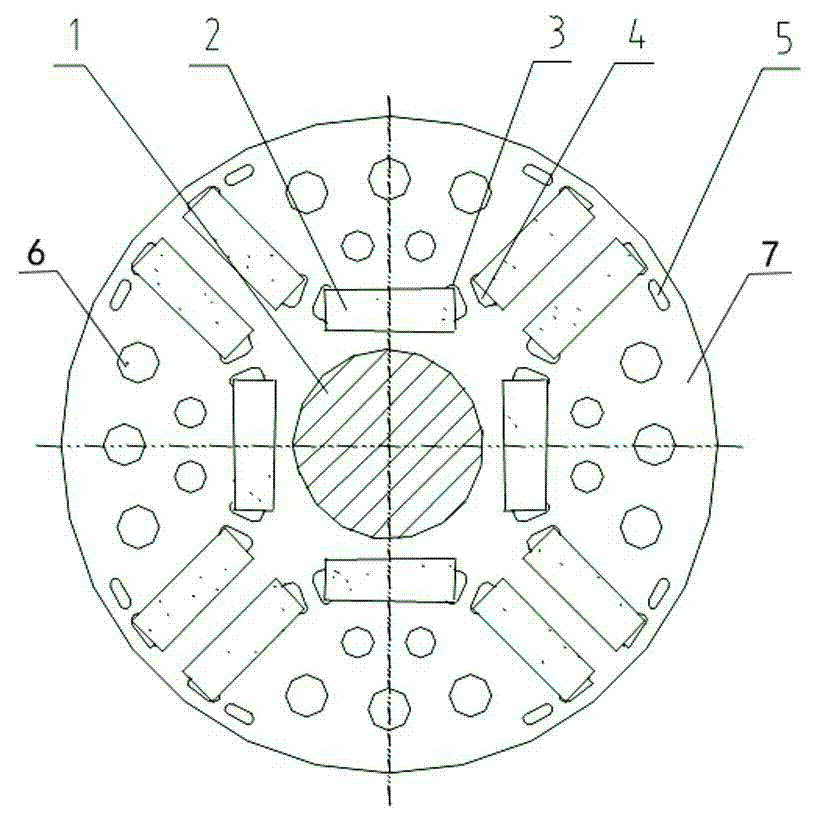

Torque-enhanced SRM (switched reluctance motor)

InactiveCN102214979AReduce lossImprove efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsControl powerReluctance motor

The invention relates to a torque-enhanced SRM (switched reluctance motor) which is characterized in that the stator of the SRM is formed by even biconvex pole iron core assemblies with magnet exciting coils, wherein the even biconvex pole iron core assemblies are magnetically separated mutually and uniformly arranged on the inner wall of a motor shell annularly; two magnetic salient poles of each assembly are arranged in an axial direction; the rotor of the SRM is formed by even stripped biconvex pole iron cores which are arranged uniformly in a radial direction along an axis of rotation, and two convex poles at two ends of each stripped biconvex pole iron core are arranged in the axial direction; two magnetic convex poles of each assembly on the stator are arranged opposite to the two convex poles at two ends of each stripped biconvex pole iron core, and air gaps exist between the two magnetic convex poles of each assembly on the stator and the two convex poles at two ends of each stripped biconvex pole iron core; and the magnet exciting coils of two stator assemblies in an axial symmetry mode are connected in series or in parallel and then taken as one phase which is accessed to an excitation control power supply. In the invention, the biconvex pole iron core assemblies with the magnet exciting coils are used for replacing the stripped biconvex pole iron cores on the rotor, thus creating a motor in a similar structure. The enhanced SRM is less in magnetic loss, high in efficiency, low in impact jitter, stable in dynamic rotation and high in control accuracy.

Owner:戴珊珊

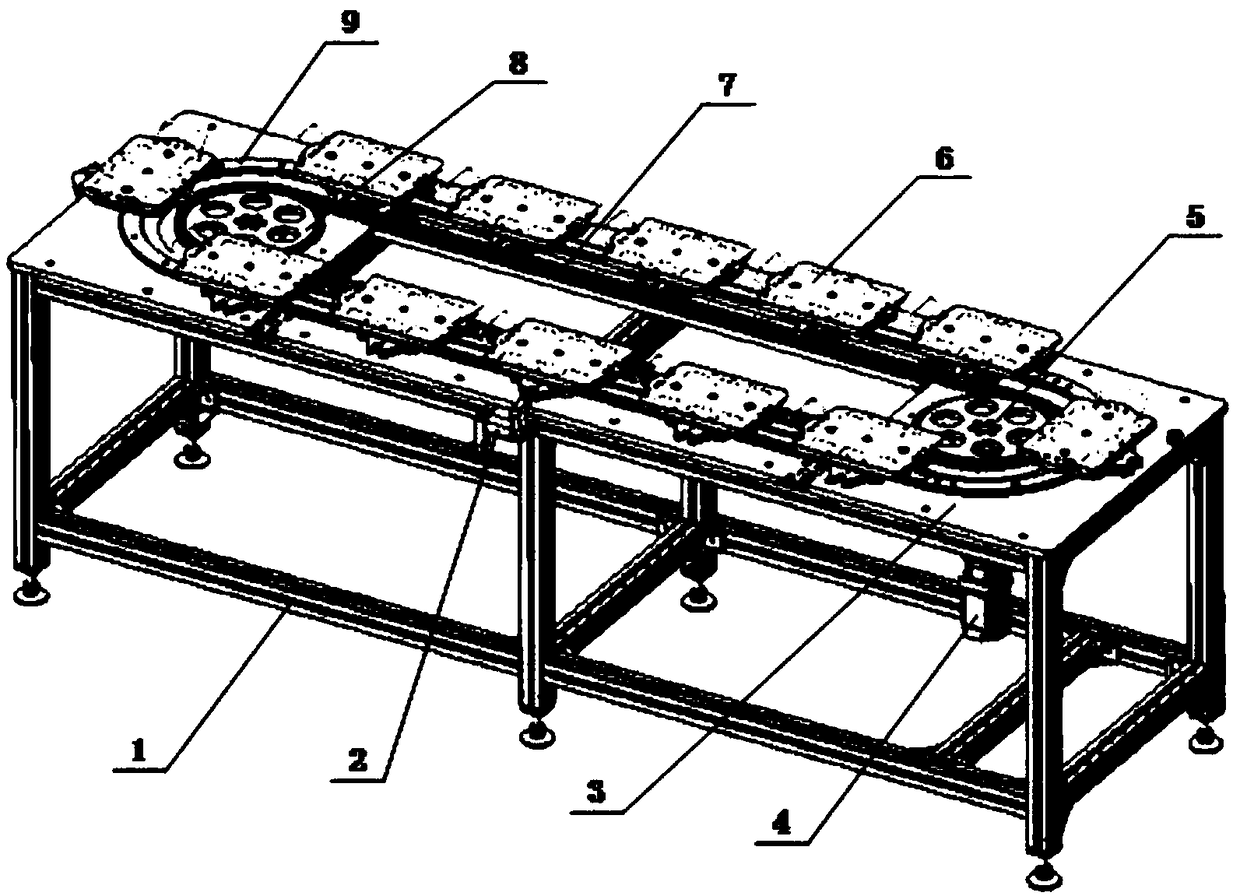

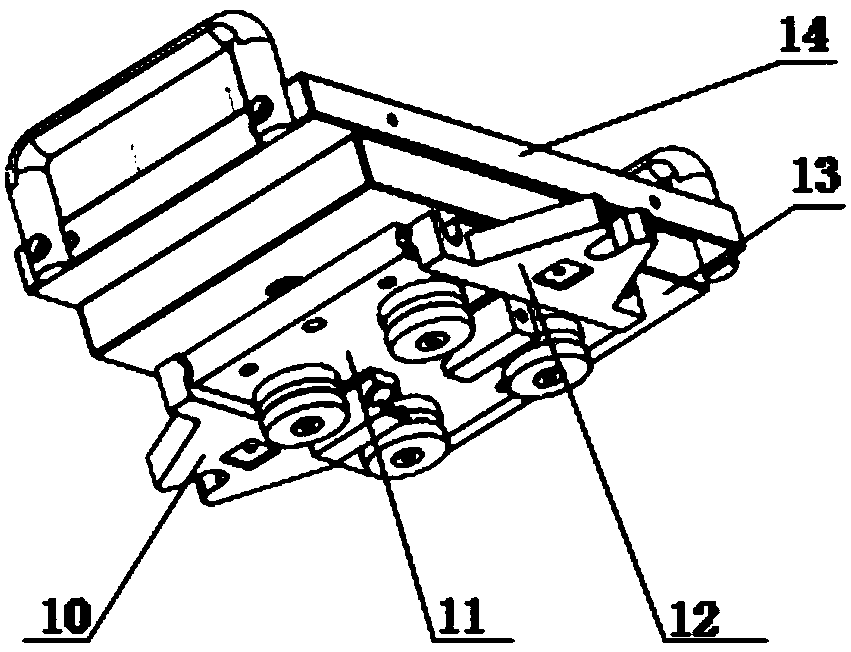

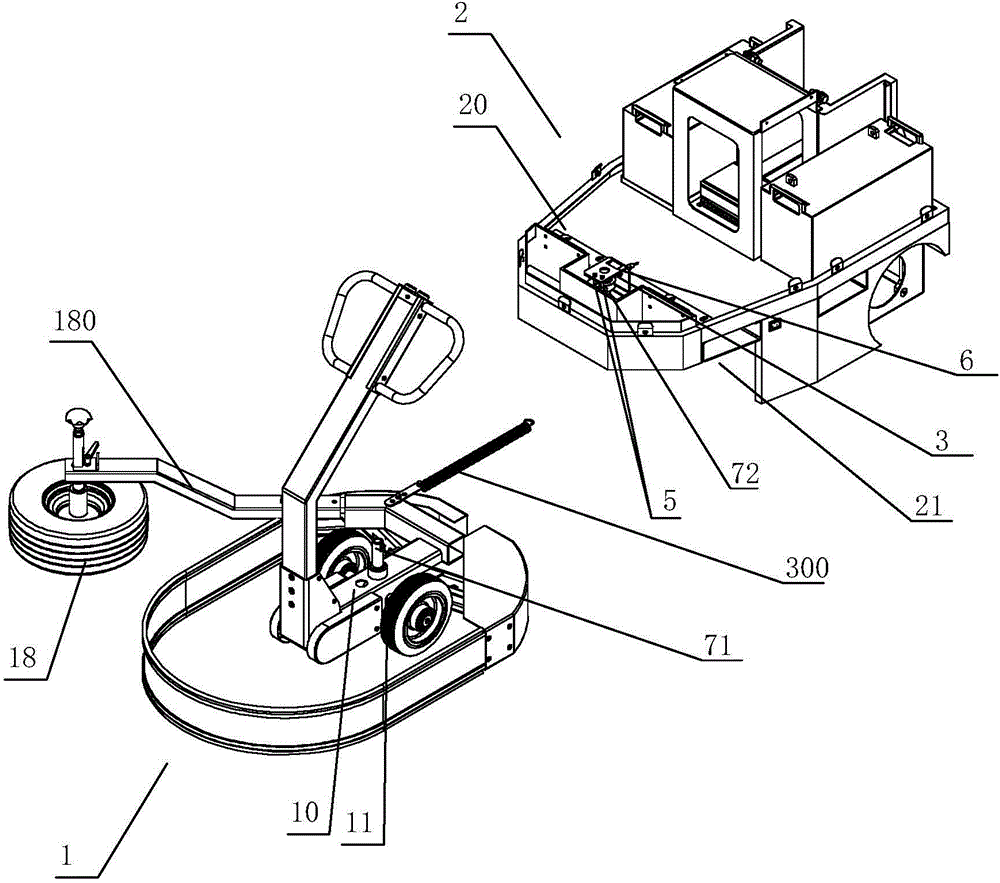

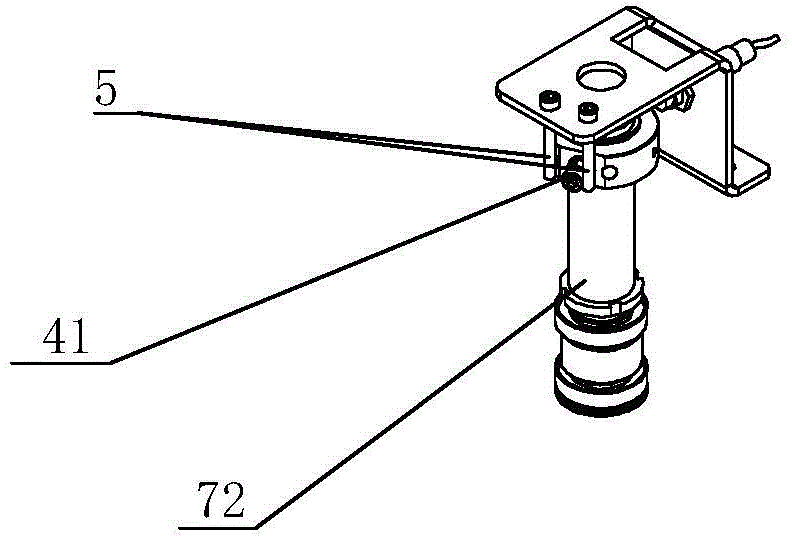

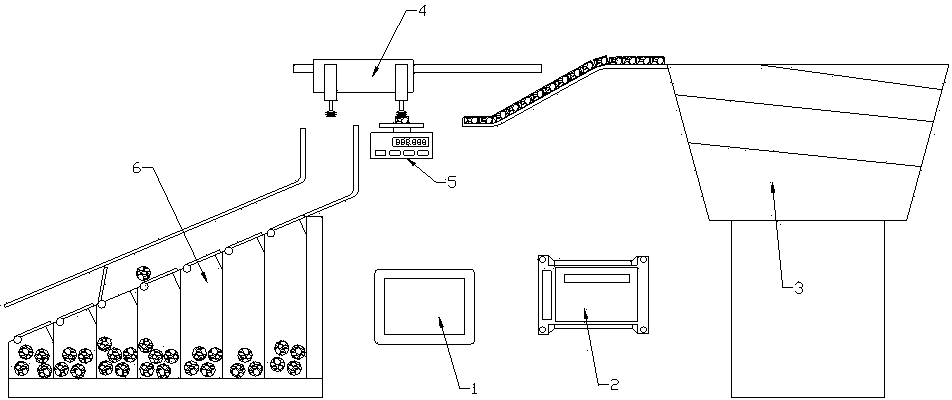

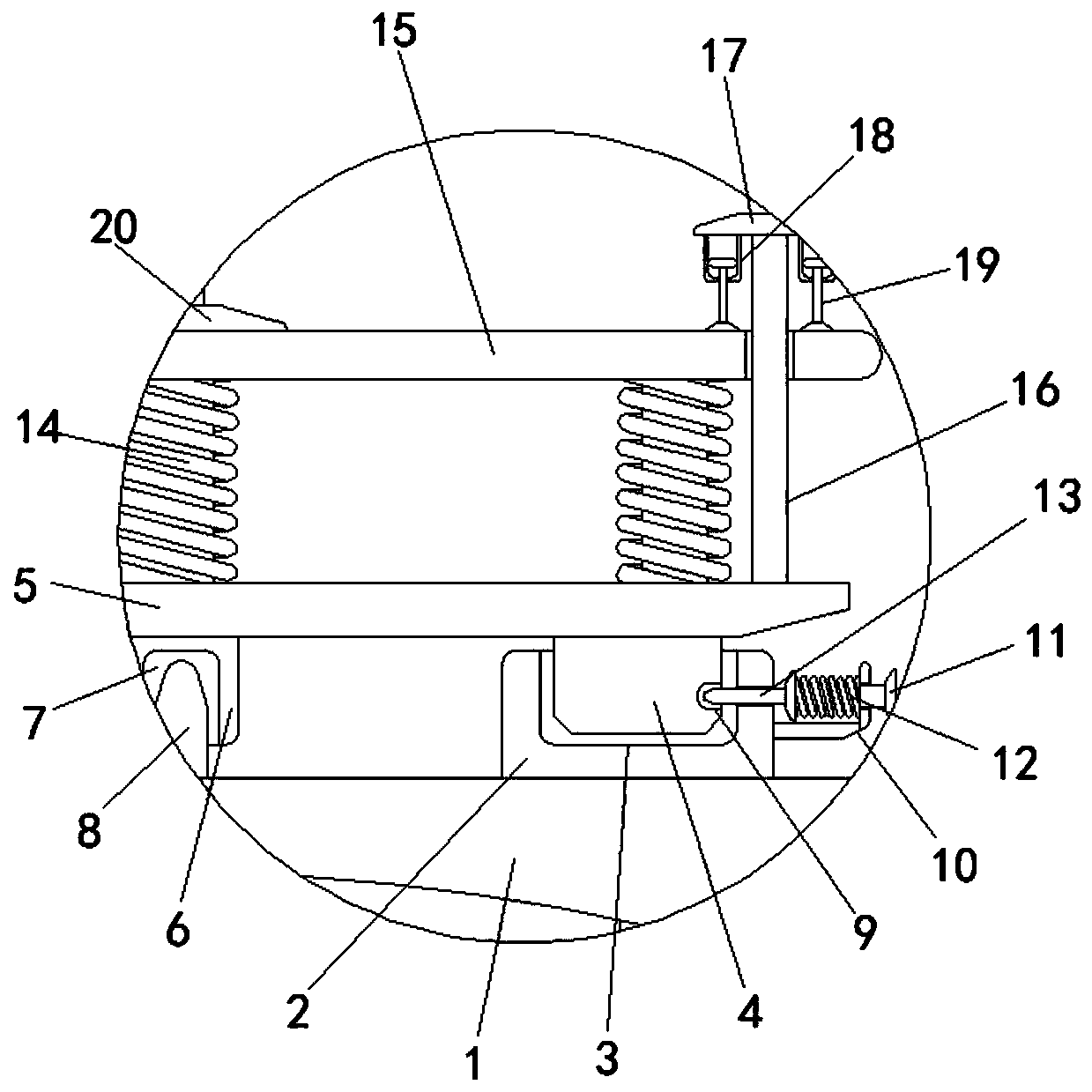

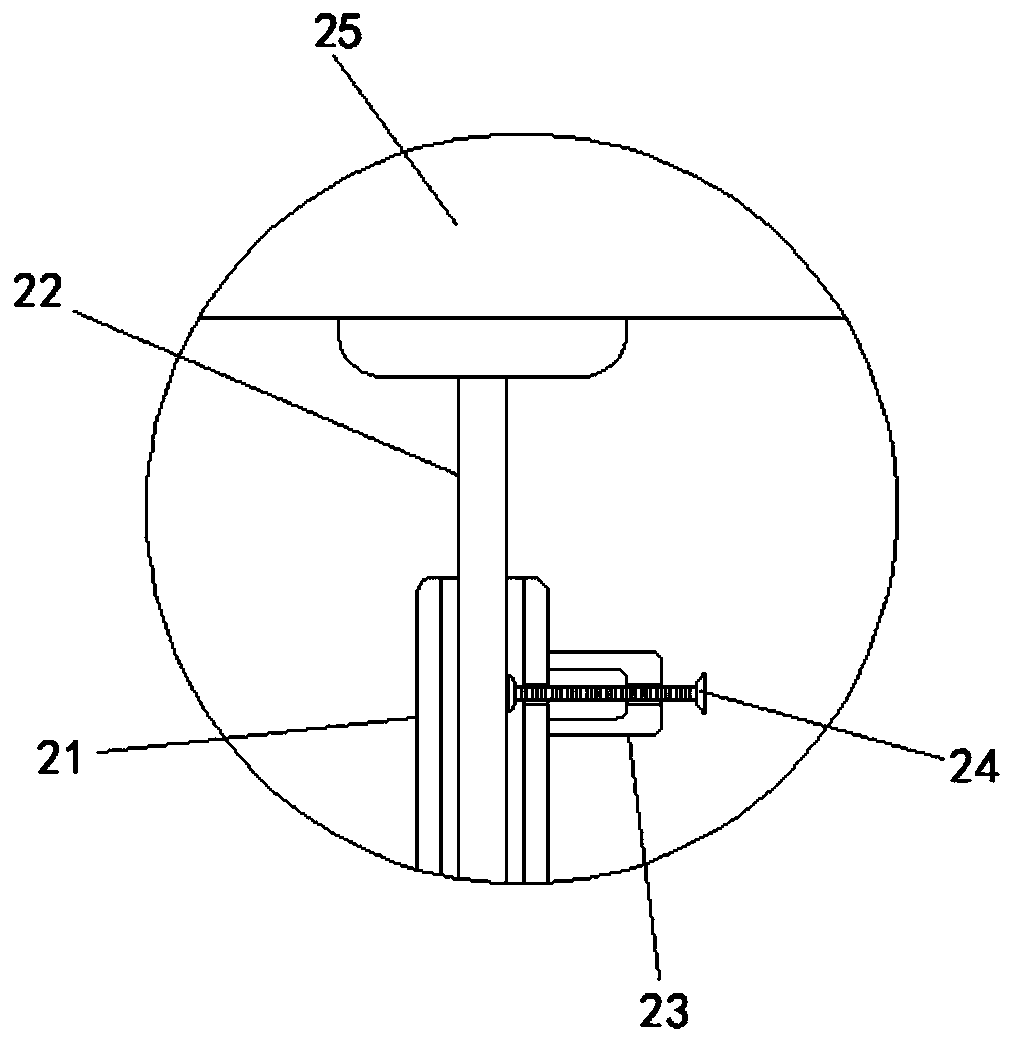

Annular storing device based on circular arc guide rail

ActiveCN108146993AReduce shock vibrationImprove the efficiency of automatic loading and unloadingConveyorsSystems designSprocket

The invention discloses an annular storing device based on a circular arc guide rail. The annular storing device based on the circular arc guide rail comprises a rack, wherein a positioning mechanismis arranged on a pick-and-place point of the rack; a horizontal guide rail support plate is arranged above the rack; an annular guide rail structure is arranged on the guide rail support plate; two same circular arc roller guide rails are symmetrically arranged on two ends of the annular guide rail structure and are connected through two parallel linear roller guide rails; a sprocket-chain transmission device is arranged in the annular guide rail structure, and comprises a chain; and the chain and the annular guide rail structure have the same shape and are equidistant. According to the device, a complexity degree of an annular storage system design is reduced, the operating speed of annular storing is improved, the positioning accuracy of a sliding seat is improved, the operating resistance is reduced, an impact shock produced by a sudden change of working speeds of a linear segment and a circular arc segment is reduced, and the stability and the reliability of the system are improved.

Owner:西安精雕软件科技有限公司

Torque-enhanced type switched reluctance motor

InactiveCN102570761AReduce lossImprove efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsReluctance motorMagnet

The invention relates to a torque-enhanced type switched reluctance motor. A stator of the motor is composed of even numbers of double-salient-pole iron core assemblies which are magnetically isolated to each other, provided with magnet exciting coils and uniformly and annularly arranged along the inner wall of a shell of the motor, and double salient poles of each assembly are axially arranged; a rotor of the motor is composed of even numbers of stripped double-salient-pole iron cores which are uniformly arranged along the radial direction of a rotating shaft, and double salient poles at two ends of each stripped double-salient-pole iron core are axially arranged; the double magnetic salient poles of each assembly on the stator and the salient poles at two ends of each stripped double-salient-pole iron core on the rotor are arranged oppositely and provided with gaps interbetween; and the magnet exciting coils of the two stator assemblies on axisymmetric positions are connected in series or parallel to be used as a phase to be connected to an excitation control power supply. A motor with a similar structure is provided through replacing the stripped double-salient-pole iron cores on the rotor with the double-salient-pole iron core assemblies provided with the magnet exciting coils. The motor provided by the invention is low in magnetic loss, high in efficiency, low in impact chatter, stable in rotation and high in control precision.

Owner:戴珊珊

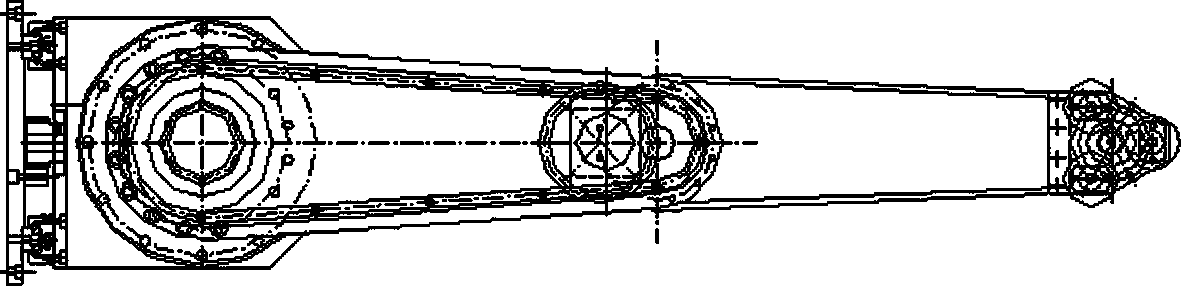

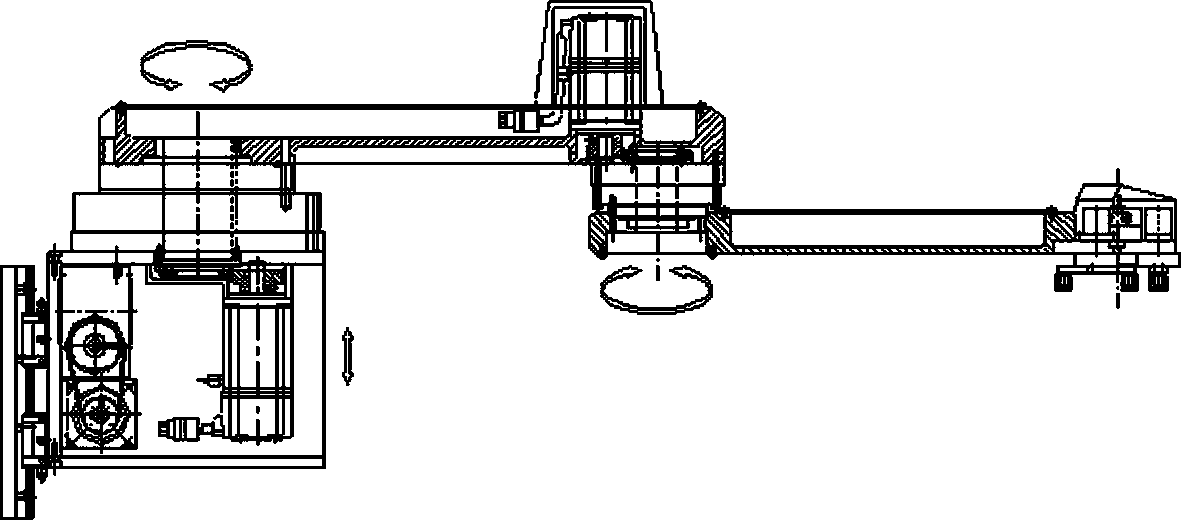

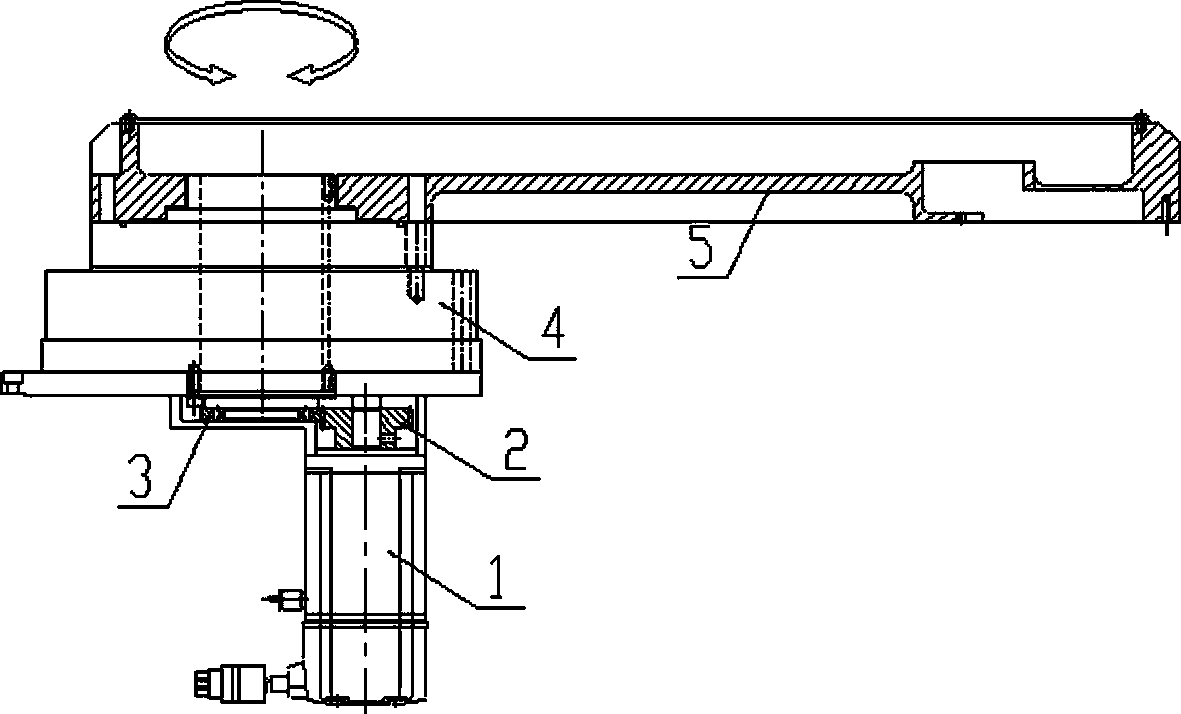

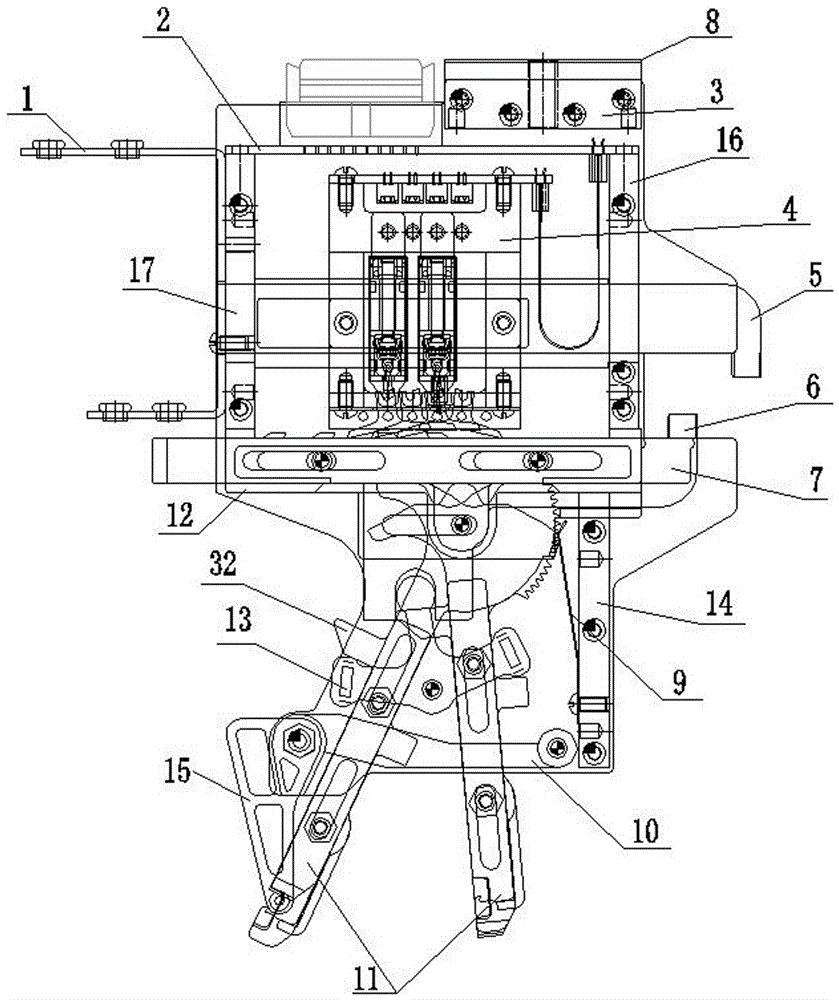

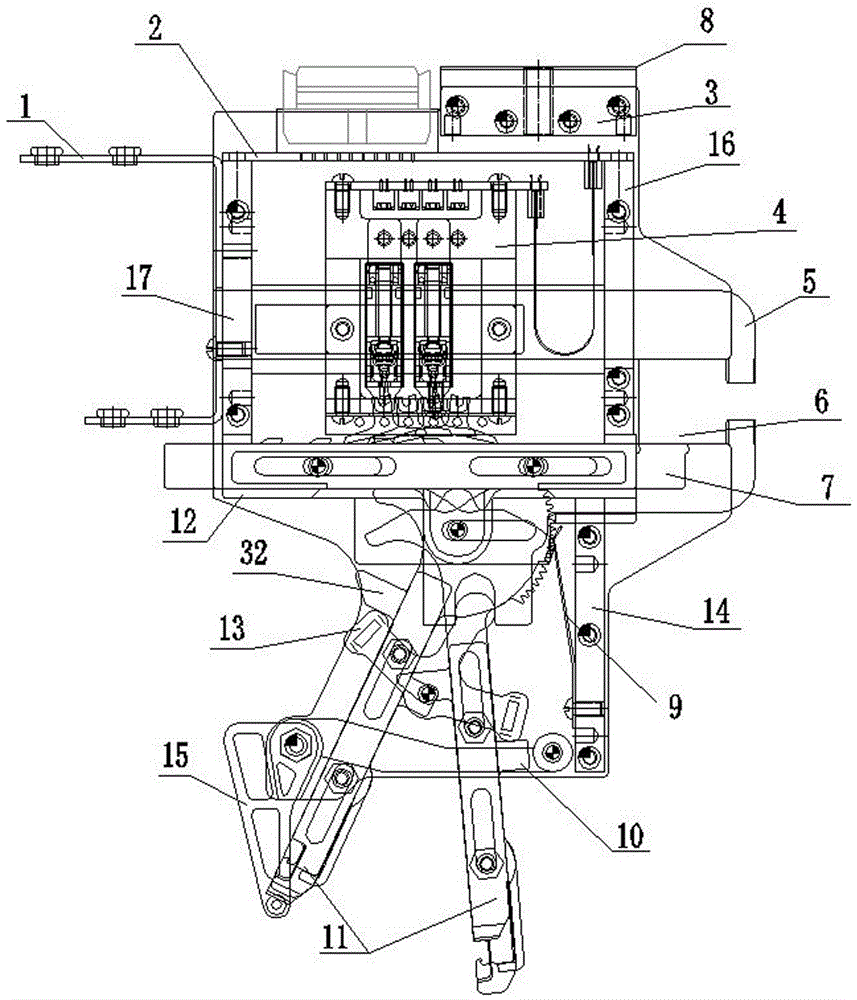

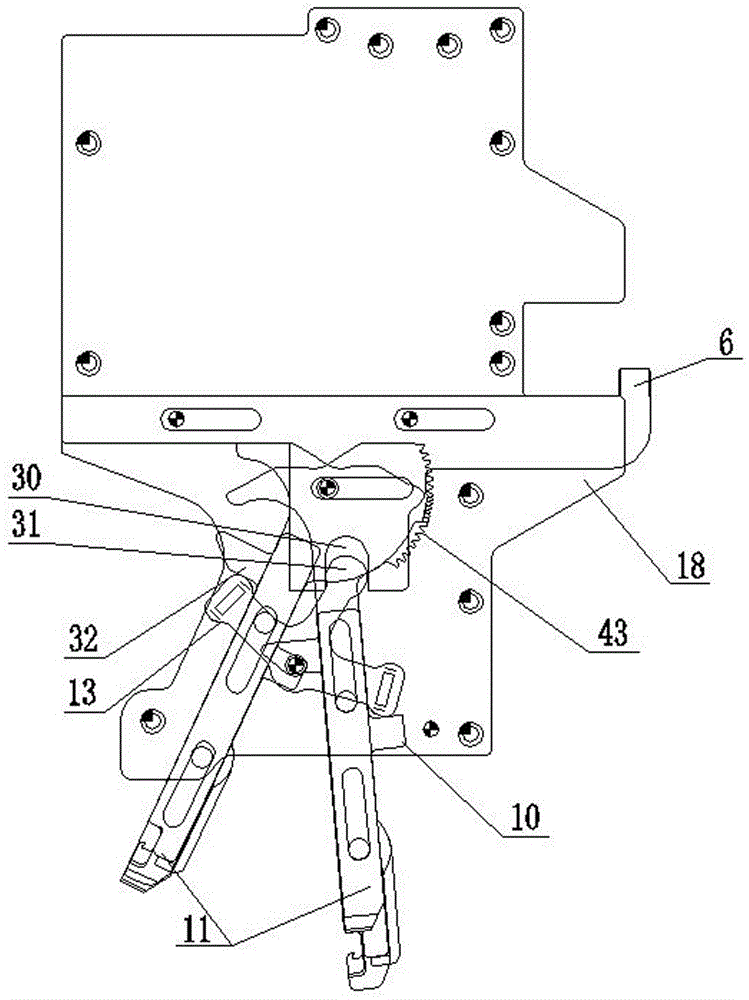

Hot forging feeding electric-joint manipulator and operating method thereof

ActiveCN103895011AReduce shock vibrationRealize positioning at any point in spaceProgramme-controlled manipulatorHandling devicesVertical motionManipulator

A hot forging feeding electric-joint manipulator comprises a large arm rotation mechanism J1, a small arm rotation mechanism J2, and a claw vertical motion mechanism J3. The hot forging feeding electric-joint manipulator is characterized in that a servo motor (6) of the small arm rotation mechanism J2 is mounted on a shaft large arm (5) of the large arm rotation mechanism J1 through a shaft. A case of a drive worm-gear reducer (16) of the claw vertical motion mechanism J3 is mounted below a case of a drive worm-gear reducer (4) of the large arm rotation mechanism J1. The hot forging feeding electric-joint manipulator has the advantages that a shaft J3 is perpendicular to planes J1 and J2, and a cylindrical space coordinate system is formed, namely and tri-axial motion can be positioned at any spatial point; motion tracks of the manipulator are all edited with software and stored in a PLC, and the motion tracks can be changed just by changing corresponding software programs; the electric shafts of the manipulator are all digital alternating-current servo motors, positions of the claws of the manipulator are all marked in number, any point or multiple operating points can be repeatedly positioned with high precision; impact shock in quick positioning can also be reduced, and feeding rhythm is automatically regulated as required.

Owner:WUHAN KYOWA SYNCHRONIZER RING

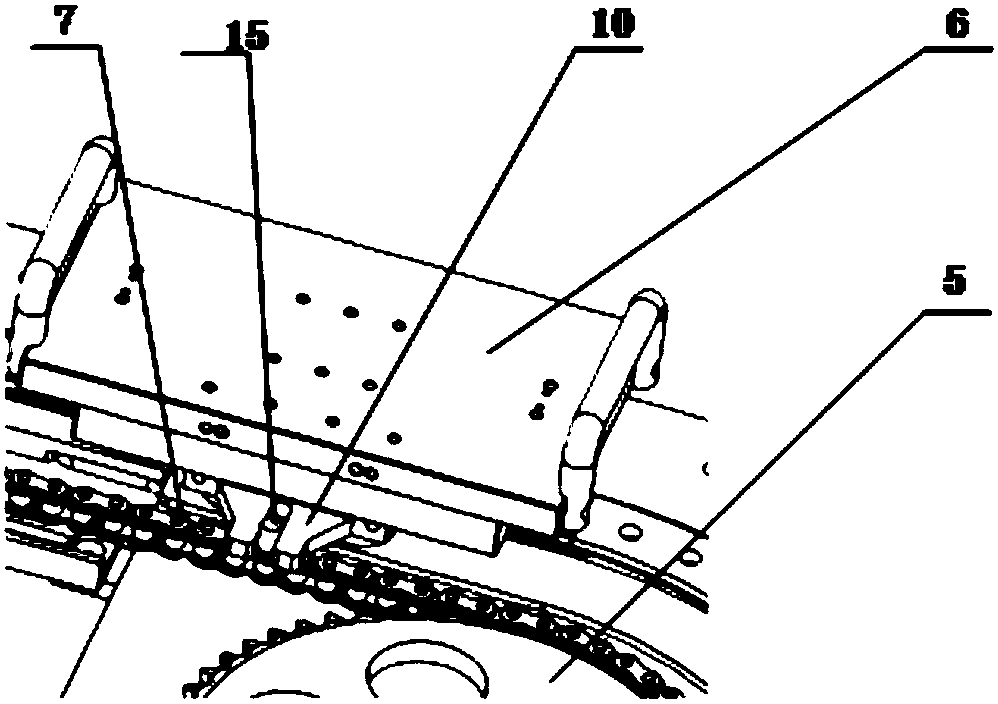

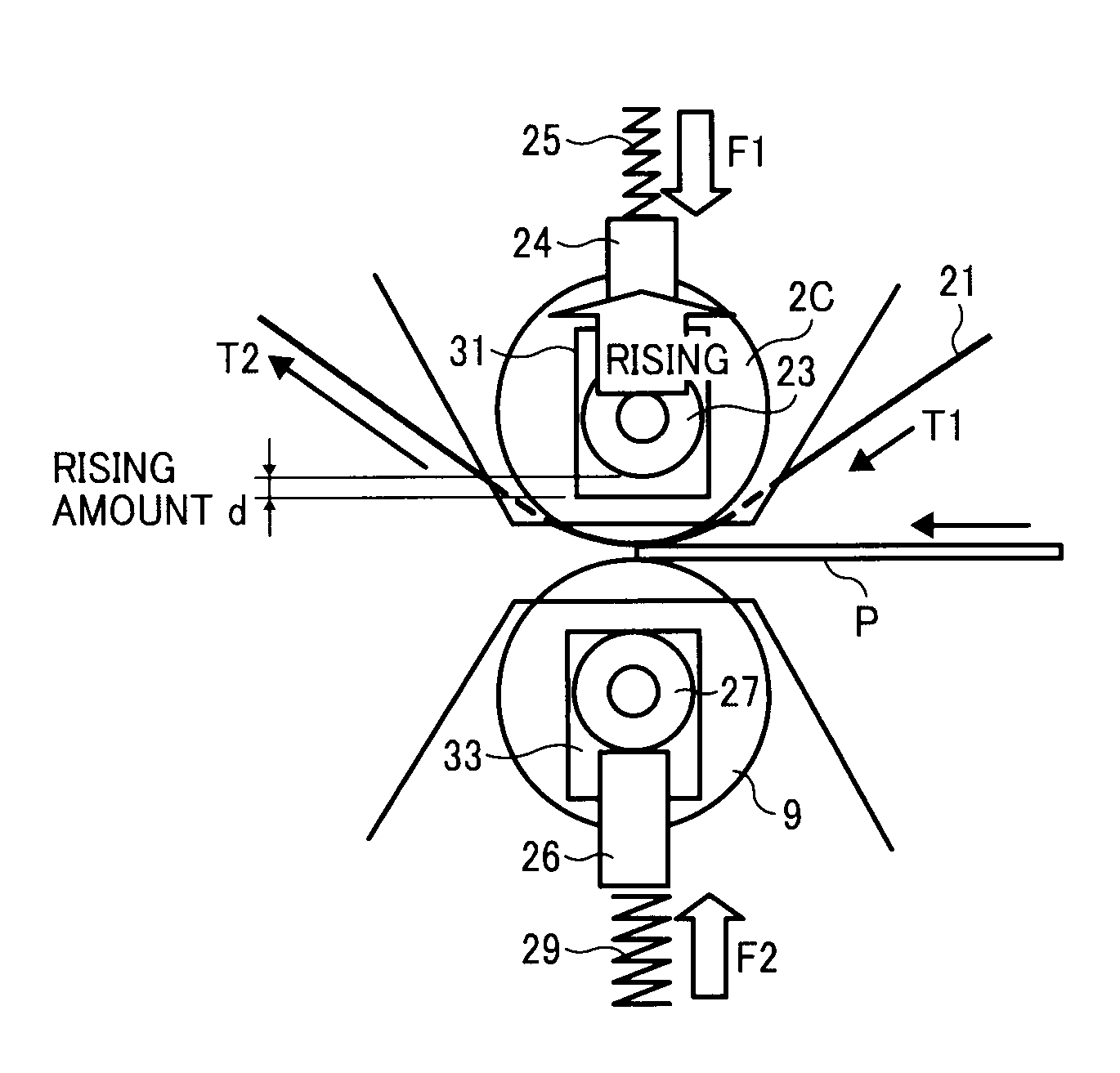

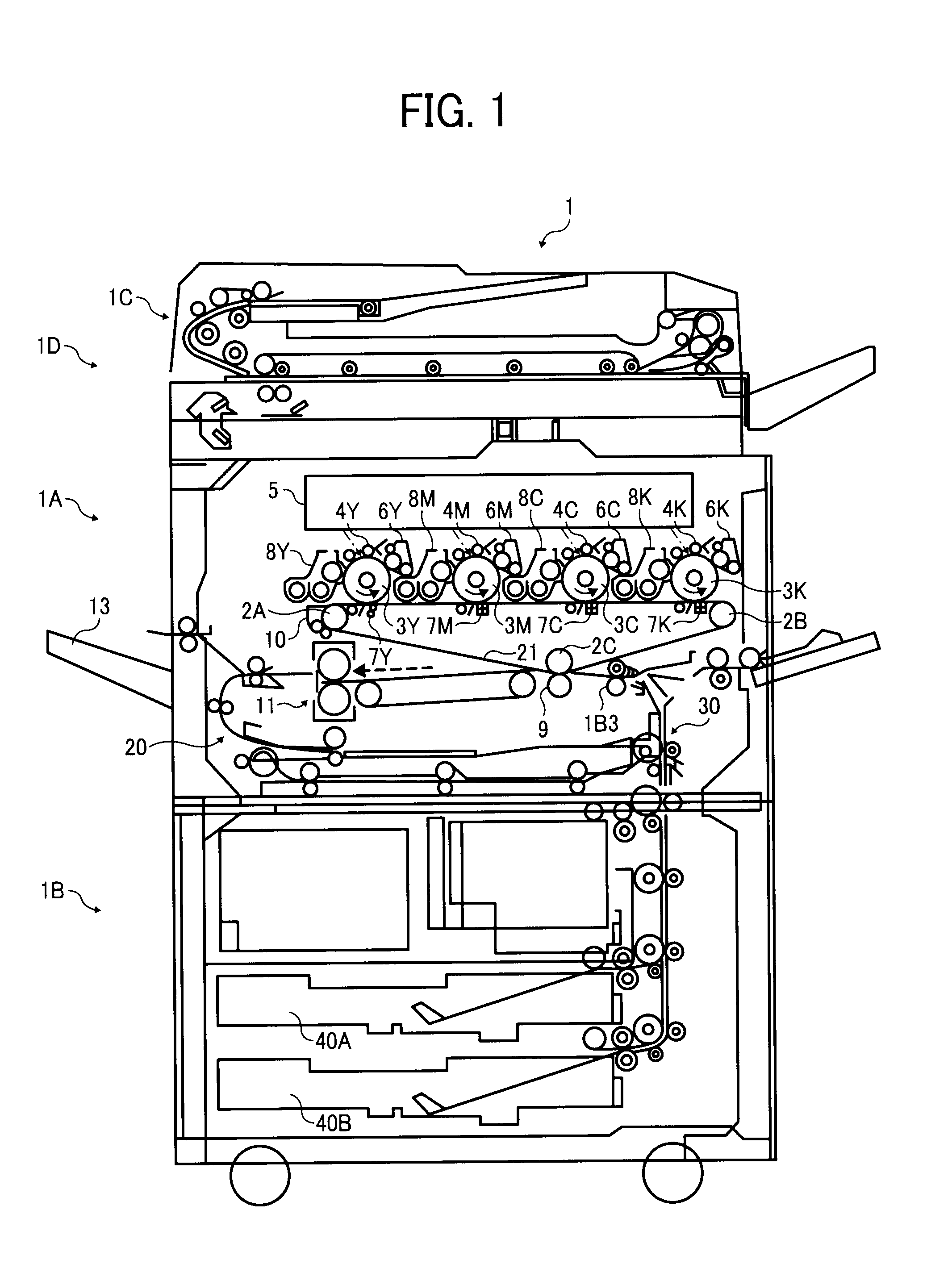

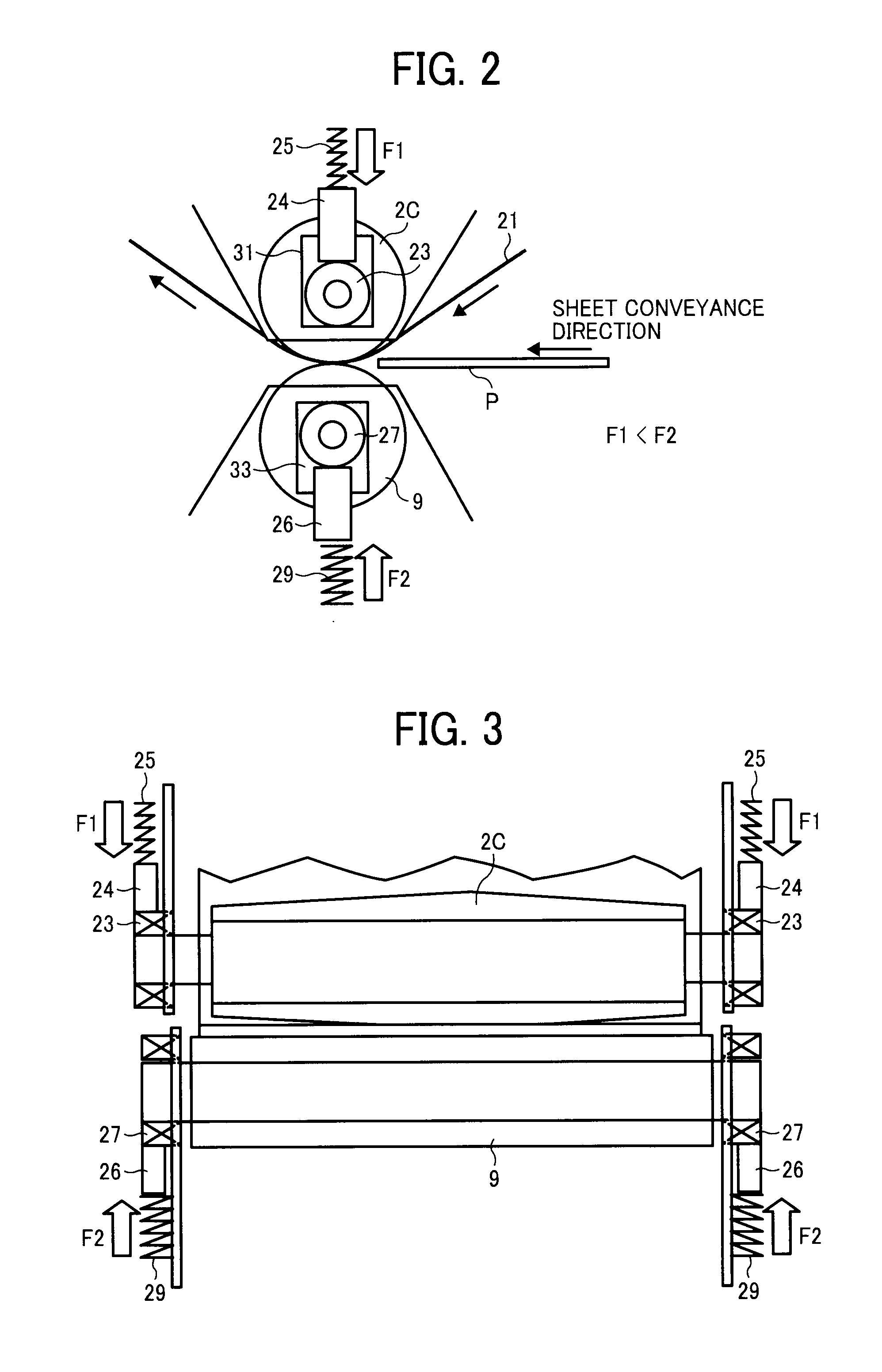

Image forming apparatus

InactiveUS20120189358A1Optimal toner image transferabilityReduce shock vibrationElectrographic process apparatusEngineeringMechanical engineering

Owner:RICOH KK

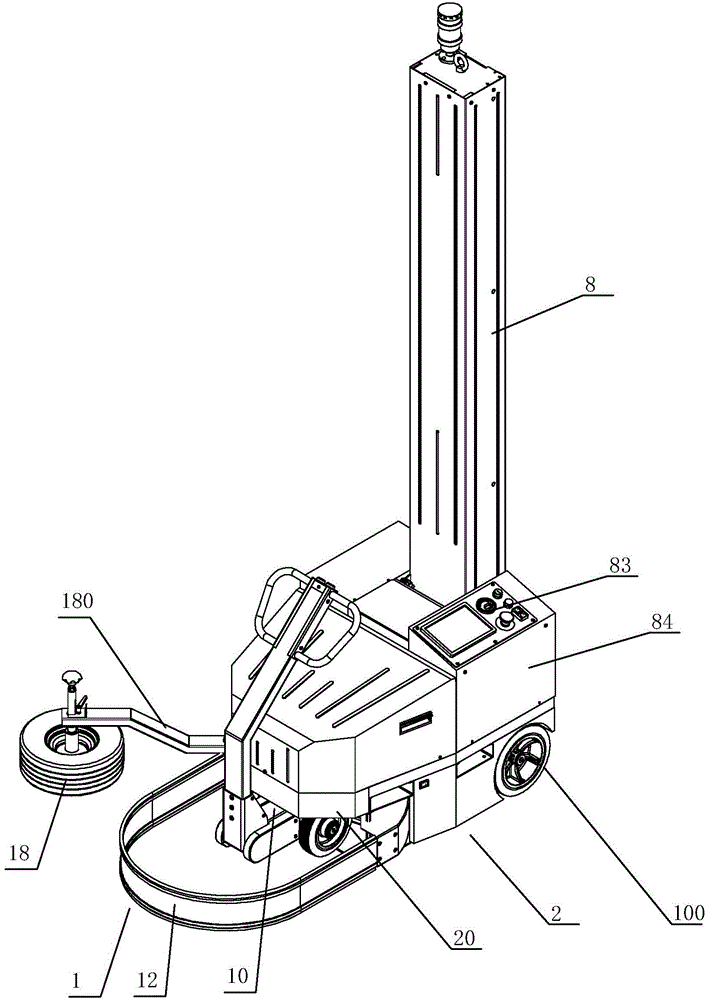

Novel walking type winding machine

ActiveCN104369892AImprove walking sensitivityGuaranteed protection functionWrapping material feeding apparatusWeb rotation wrappingWinding machineVehicle frame

The invention provides a novel walking type winding machine. A protection ring on the front portion of the novel walking type winding machine is fixed to a frame of a steering portion. The novel walking type winding machine is provided with a steering counting device. The steering counting device is provided with a first sensor which senses the steering of a vehicle body, the first sensor is connected with a controller of the novel walking type winding machine and used for making the controller determine the number of steering times. A second sensor is arranged in the steering portion. The second sensor or a part fixedly connected with the second sensor is supported by an elastic part so that the second sensor can be movably installed on the steering portion, and the second sensor is used for sensing the backward movement, relative to the second sensor, of the frame of the steering portion or a part fixedly connected with the frame. By means of the novel walking type winding machine, the film winding route of the novel walking type winding machine can be easily and accurately controlled, the important part of the steering portion can be protected, the walking direction changing flexibility of the novel walking type winding machine can be improved, and the impact exerted on the vehicle body when the novel walking type winding machine comes across barriers can be reduced.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP

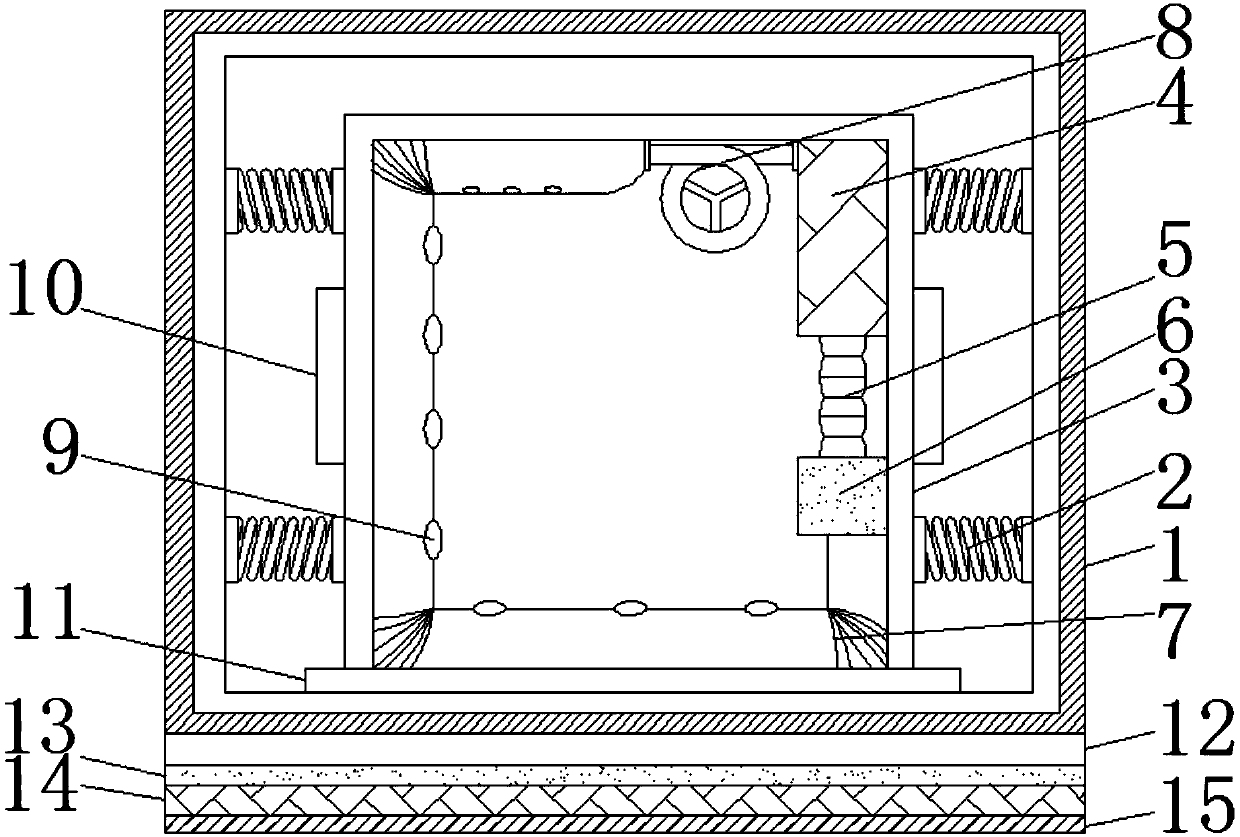

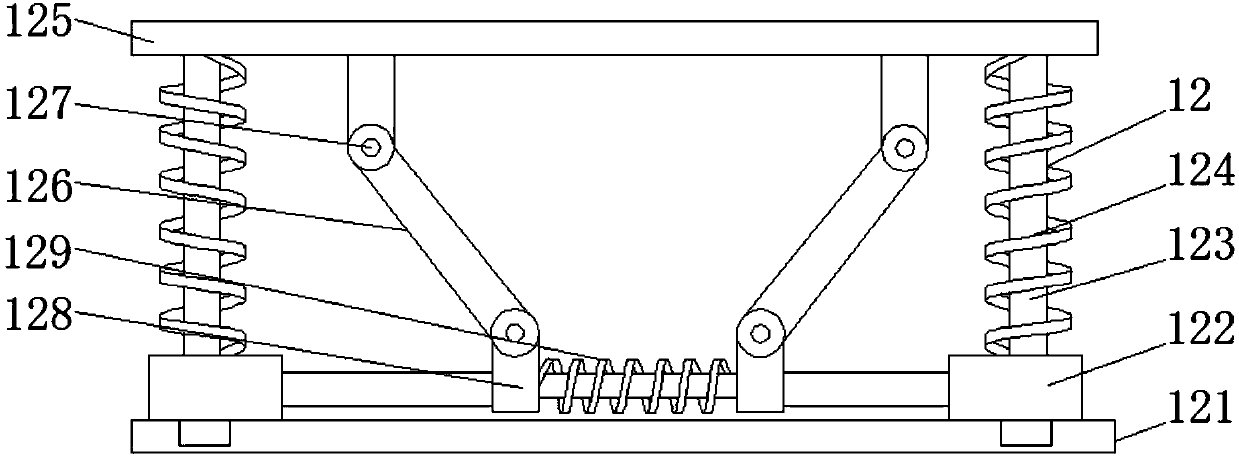

Medicine transportation equipment

InactiveCN107697412AReduce shock vibrationTransportation safetyShock-sensitive articlesContainers to prevent mechanical damageAir cycleCold air

The invention relates to the technical field of medical intelligent and discloses medicine transportation equipment. The medicine transportation equipment comprises a sound-proofing cabin. Sidewall damping springs are fixedly connected to the interior of the sound-proofing cabin. One end of each sidewall damping spring is fixedly connected with a transportation cabin. A refrigerating unit is fixedly mounted in the transportation cabin. One end of an air outlet of the refrigerating unit is fixedly connected with an air supply pipe. One end of the air supply pipe is fixedly connected with an airdryer. One end of the air dryer is fixedly connected with a circulation hose. The medicine transportation equipment is provided with the refrigerating unit, the air supply pipe, the air dryer, the circulation hose, a suction fan and semiconductor chilling plates; circulation of cold air in the transportation cabin is achieved after air is refrigerated through the refrigerating unit and dried through the air dryer; moreover, the semiconductor chilling plates assist in refrigerating to prevent the situation that water mist is formed by a too large temperature difference between the transportation cabin and the sound-proofing cabin, circulating flow refrigeration of the air is achieved, and the purposes of energy conservation and environmental protection are achieved accordingly.

Owner:林孝振

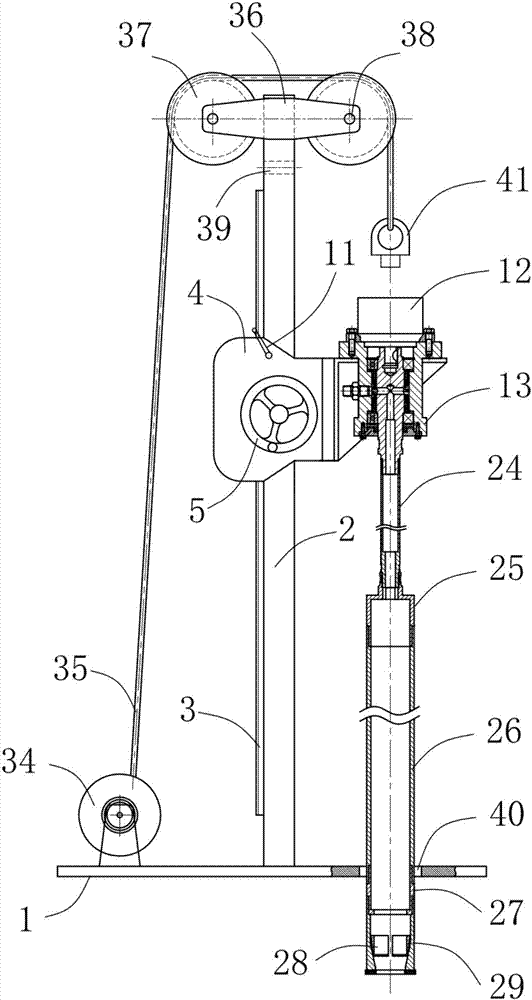

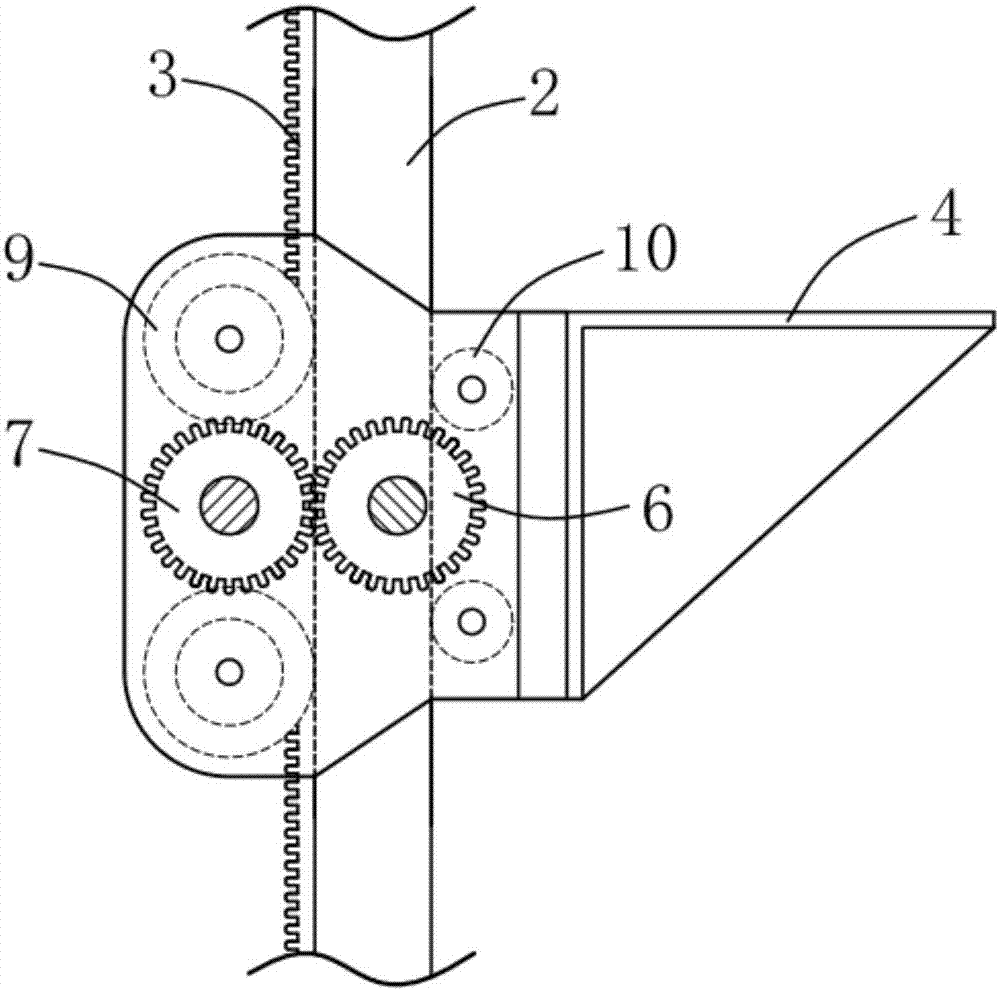

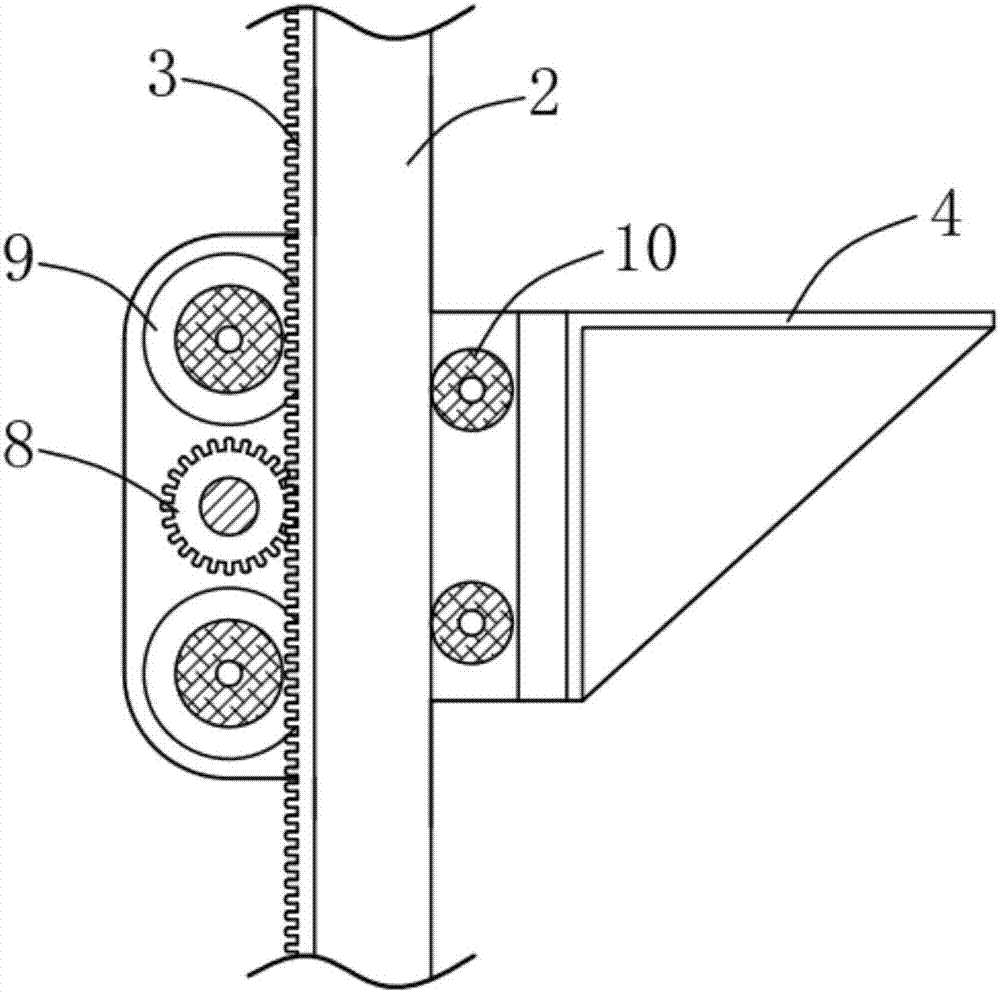

Portable hydraulic drive underwater drilling machine

PendingCN107386976AReduce operationImprove drill efficiencyDrilling rodsConstructionsEngineeringDrill pipe

The invention discloses a portable hydraulic drive underwater drilling machine which comprises a base, a mast, a main lifting mechanism, an auxiliary drill pipe lifting mechanism and a drilling machine body, wherein the mast is vertically mounted on the base, the main lifting mechanism and the auxiliary drill pipe lifting mechanism are mounted on the mast, and the drilling machine body is mounted on the main lifting mechanism and comprises a hydraulic motor, a power head and a drilling tool. The power head is mounted on a bearing support, drives the drilling tool to rotate by the hydraulic motor and drives the drilling tool to vertically move by the main lifting mechanism. According to the portable hydraulic drive underwater drilling machine, underwater staff and machinery are stabilized by the aid of an underwater operation platform comprising the base, the main lifting mechanism and the auxiliary drill pipe lifting mechanism, cores can be easily sampled in the presence of flashy flow, the drilling machine can automatically advance downwards along the lifting mechanism under the action of dead weight, operation of the underwater staff is decreased, advance speed can be freely adjusted by the main lifting mechanism, and drilling efficiency is improved.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI +1

Novel rotor of permanent magnet motor

InactiveCN104767305ASpeed up the boot processImprove overload capacityMagnetic circuit rotating partsStress concentrationInterference fit

The invention relates to permanent magnet motors, in particular to rotors of the permanent magnet motors, provides a novel rotor of a permanent magnet motor and solves the problems caused by structural defects of rotors in existing permanent magnet motors. The rotor of the permanent magnet motor comprises a revolving shaft, a rotor sheet and magnetic steel, wherein the rotor sheet is fitted with the revolving shaft in a superimposed mode, magnetic steel grooves and vent holes are formed in the rotor sheet, and the magnetic steel is inserted in the magnetic steel grooves; the rotor sheet is of a U-shaped magnetic structure, namely every three magnetic steel grooves which are distributed in a U shape form a magnetic pole; two magnetism isolating bridge holes are formed below each magnetic pole, and the rotor sheet is in interference fit with the revolving shaft; the magnetic steel is in clearance fit with the rotor sheet, and gaps at the two ends of each section of the magnetic steel are sealed up with silicone rubber in a pouring mode. Fillets used for eliminating stress concentration are formed at the two ends of each magnetic steel groove. By means of the novel rotor of the permanent magnet motor, the realistic basis is provided for research and development of permanent magnet motors with higher power and higher rotating speed.

Owner:CRRC YONGJI ELECTRIC CO LTD

Automobile fuel tank

The invention discloses an automobile fuel tank and relates to the technical field of automobile manufacturing. The automobile fuel tank comprises a fuel tank oil inlet, a fuel tank inner cavity and a fuel tank shell, wherein a fire-retardant layer is arranged between the fuel tank shell and the fuel tank inner cavity, a cushion chamber is formed between the fire-retardant layer and the fuel tank inner cavity, and a buffer unit is arranged between the inner portion of the cushion chamber and at least one side surface of the fuel tank inner cavity. The automobile fuel tank can solve the problems that the impact resistance is poor and fire cannot be prevented for the existing automobile fuel tank.

Owner:LIUZHOU JULONG TECH

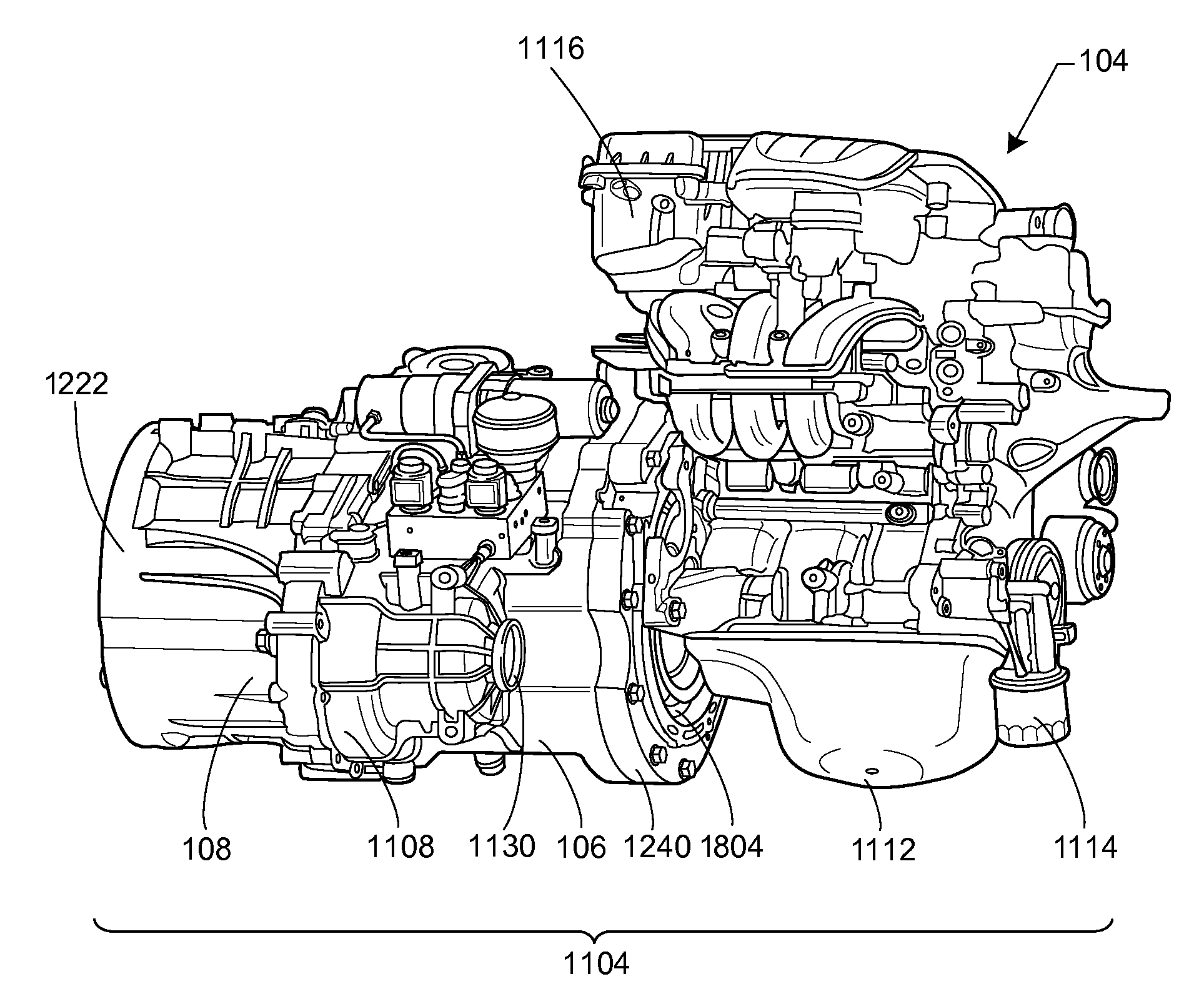

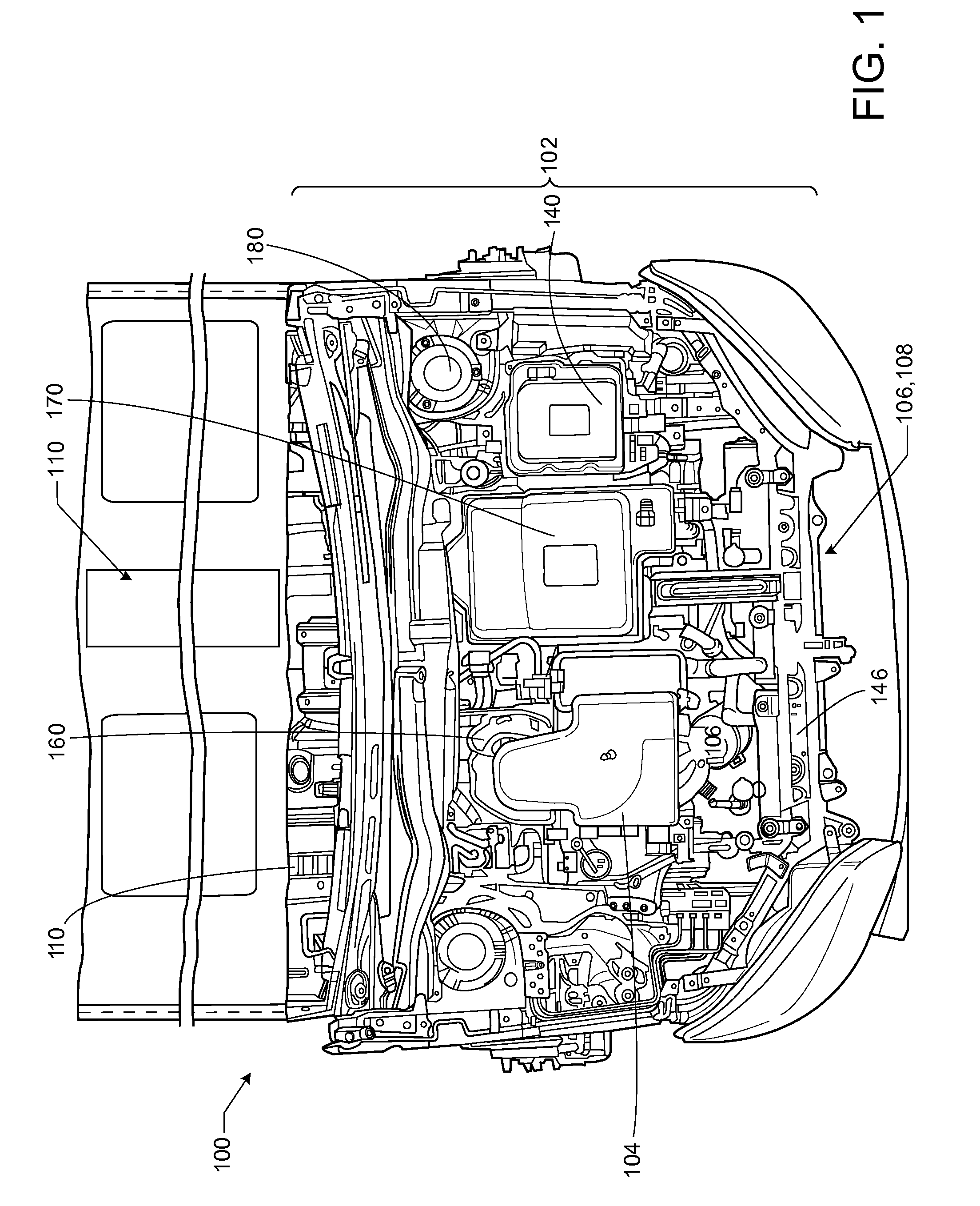

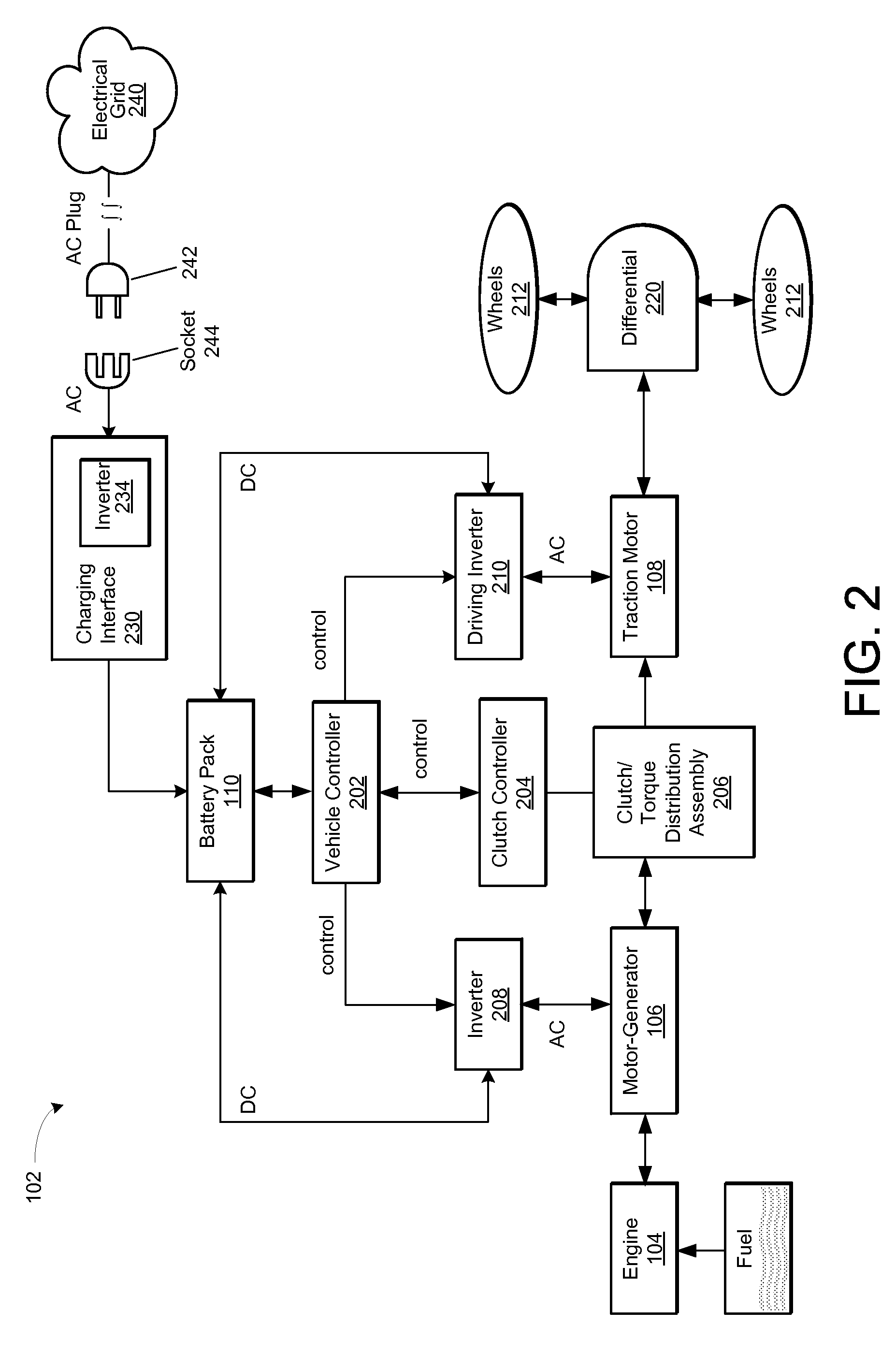

Hybrid Vehicle Having Torsional Coupling Between Engine Assembly And Motor-Generator

A hybrid vehicle has a power system with a torsional coupling. The power system includes a battery system for receiving, storing and providing electrical power, an internal combustion engine configured to provide rotational power through a flywheel, a first motor-generator, a second motor-generator, a control system, and a torsional coupling. The torsional coupling may absorb rotational shock caused by angular or rotational speed differences between the engine and the first motor-generator. The torsional coupling includes a driven plate assembly, a cover assembly and an interconnecting plate assembly. The interconnecting plate assembly may include a plurality of shock absorbing elements that absorb shock and vibration between the engine and the motor-generator.

Owner:BYD CO LTD

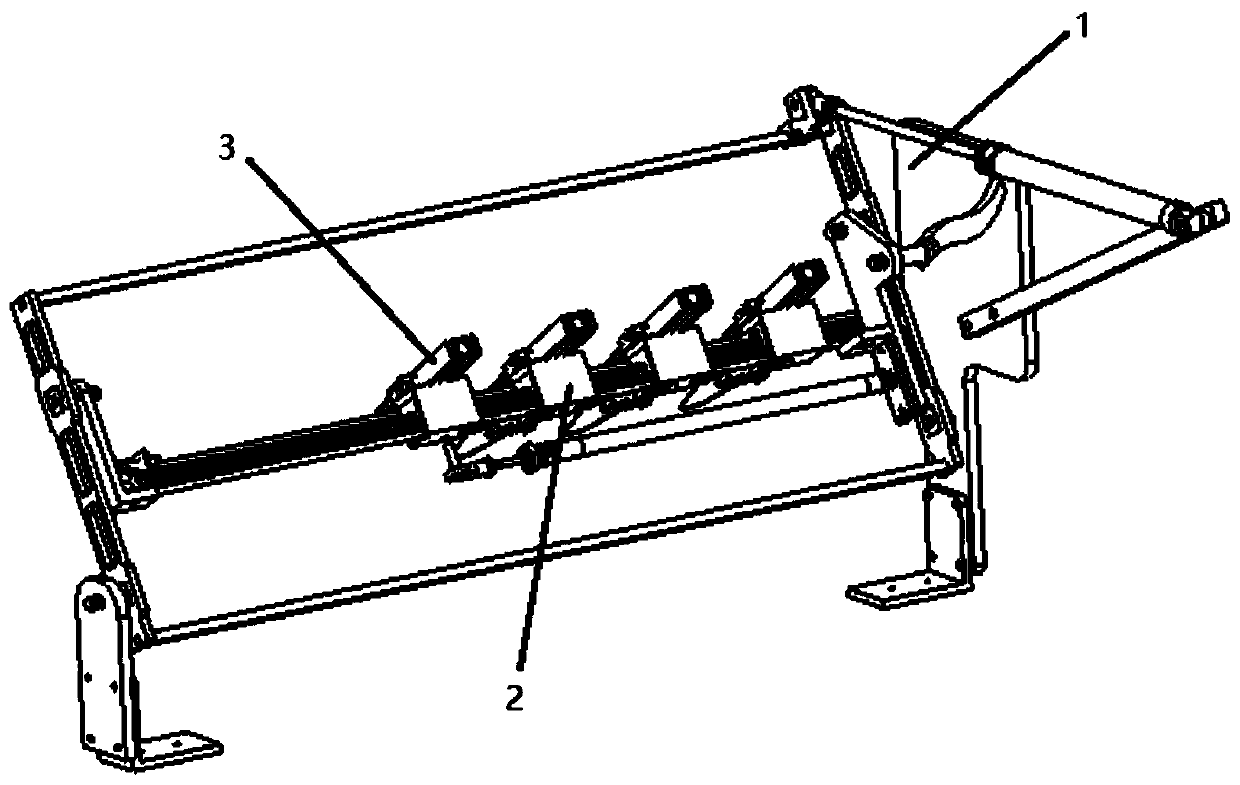

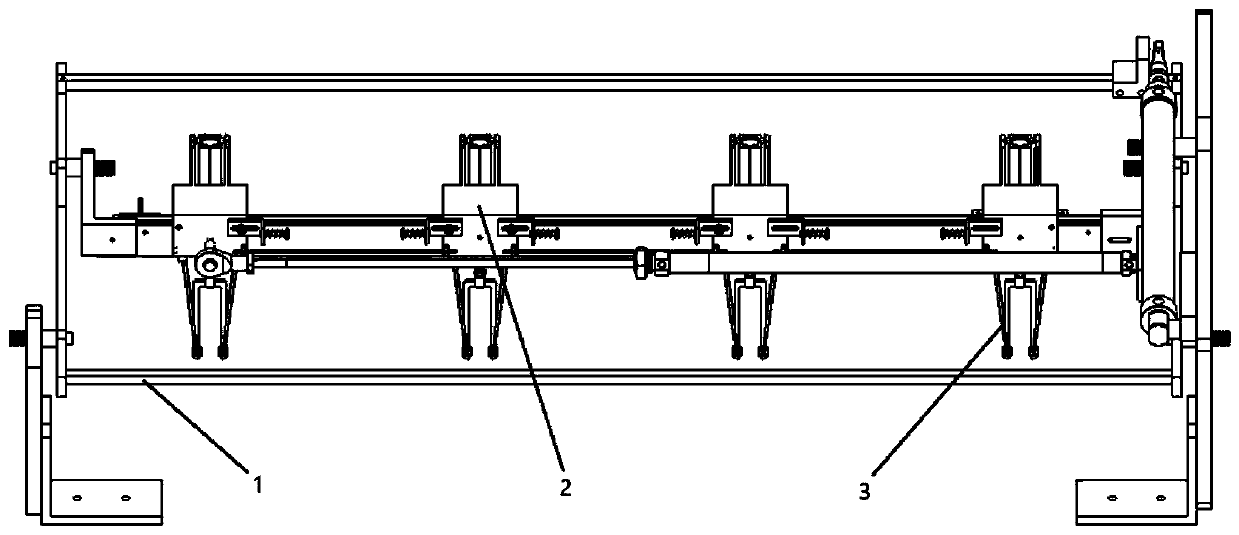

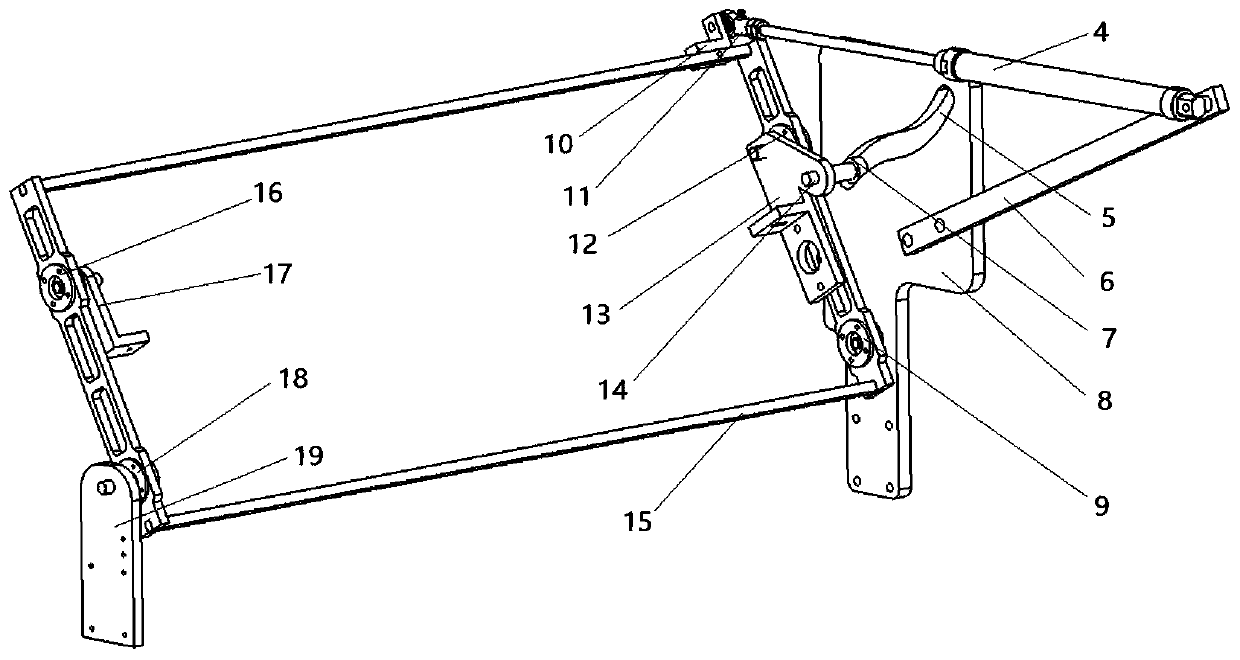

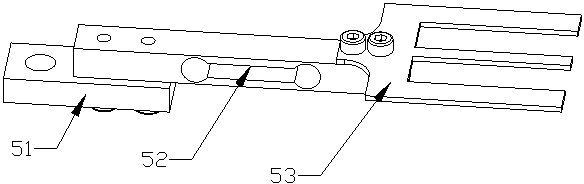

Space seedling taking and flexible variable-distance seedling throwing device and pot seedling transplanter

The invention provides a space seedling taking and flexible variable-distance seedling throwing device and a pot seedling transplanter. The device comprises a gantry type turnover device, a variable-distance device, a plurality of seedling taking claws and a control system; the seedling taking claws complete the seedling taking action when the gantry type turnover device operates to the lowest point, and the seedling taking claws start to execute the seedling throwing action when the gantry type turnover device operates to the highest point; the variable-distance device can adjust space between the adjacent seedling taking claws, space seedling taking is performed when the seedling taking claws are retracted and combined together, and variable-distance seedling throwing is performed when the seedling taking claws are scattered. The variable-distance device has lighter weight, produces small inertia force in a moving process and can reduce vibration caused by impact; flexible steel wireropes are adopted, and shock absorption mechanisms are added at the two moving tail ends of a variable-distance cylinder respectively, so that the flexible variable-distance and vibration reduction effects are realized. Besides, the space of the seedling taking claws during combining and scattering can be adjusted by the variable-distance device, and the device can be suitable for plug trays of different specifications and meet different line spacing requirements, is simple in structure and stable to operate and improves seedling taking and throwing efficiency.

Owner:JIANGSU UNIV

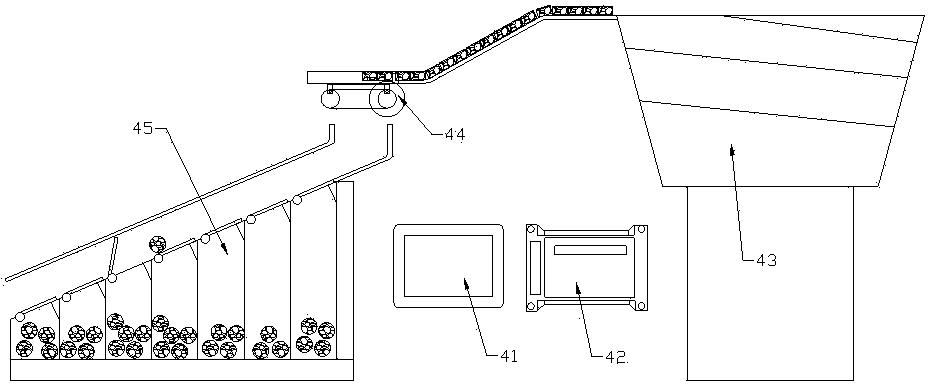

Weighing and sorting machine for cork sheet of badminton ball head

InactiveCN104190636AEfficient automatic weighing and sortingStable automatic weighing and sortingSortingSynchronous motorEngineering

The invention discloses a weighing and sorting machine for a cork sheet of a badminton ball head. The weighing and sorting machine comprises a vibration plate feeding device, a weighing device and a chute valve blanking device; the weighing device comprises a base plate, a weighing mechanism and a cork sheet transfer component, wherein the weighing mechanism and the cork sheet transfer component are arranged on the base plate; the weighing mechanism comprises a weighing sensor base fixed with the base plate, a weighing sensor arranged on the weighing sensor base and a weighing support frame connected with the weighing sensor; the cork sheet transfer component comprises a material pushing mechanism and a material moving mechanism; the material moving mechanism comprises a synchronous motor, a first shaft and a second shaft, wherein the first shaft and the second shaft are fixedly arranged on the base plate through a bearing pedestal; the tail ends of the first shaft and the second shaft are respectively connected with a first connecting rod and a second connecting rod; the tail ends of the first connecting rod and the second connecting rod are respectively connected with the two ends of a handling connecting rod. The invention provides the weighing and sorting machine for the cork sheet of the badminton ball head, which is efficient and stable.

Owner:YANTAI NANSHAN UNIV

Impact power tool

ActiveUS7878265B2Reduce impactReduce shock vibrationReciprocating drilling machinesPortable percussive toolsEngineeringPower tool

It is an object of the invention to provide a technique for a reduction of an impact force cased by rebound of a tool bit after its striking movement in an impact power tool. The representative impact power tool includes a tool body, a hammer actuating member, a striker, a weight and an elastic element. A reaction force is transmitted from the hammer actuating member to the weight and the elastic element is elastically deformed when the weight moves ward by the reaction to absorb the reaction force. The invention is characterized in that the mass of the weight is set to about 40% or more of the mass of the striker.

Owner:MAKITA CORP

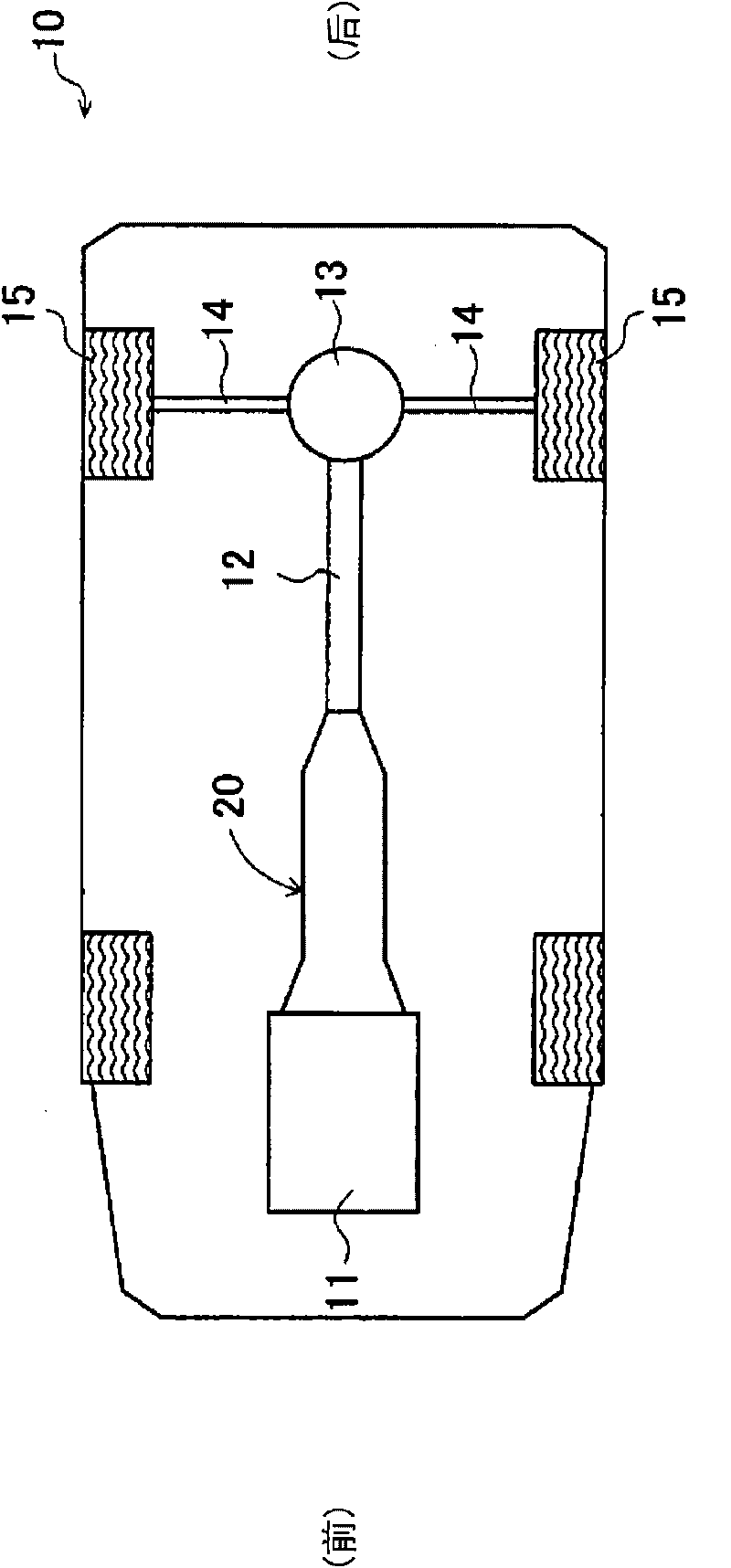

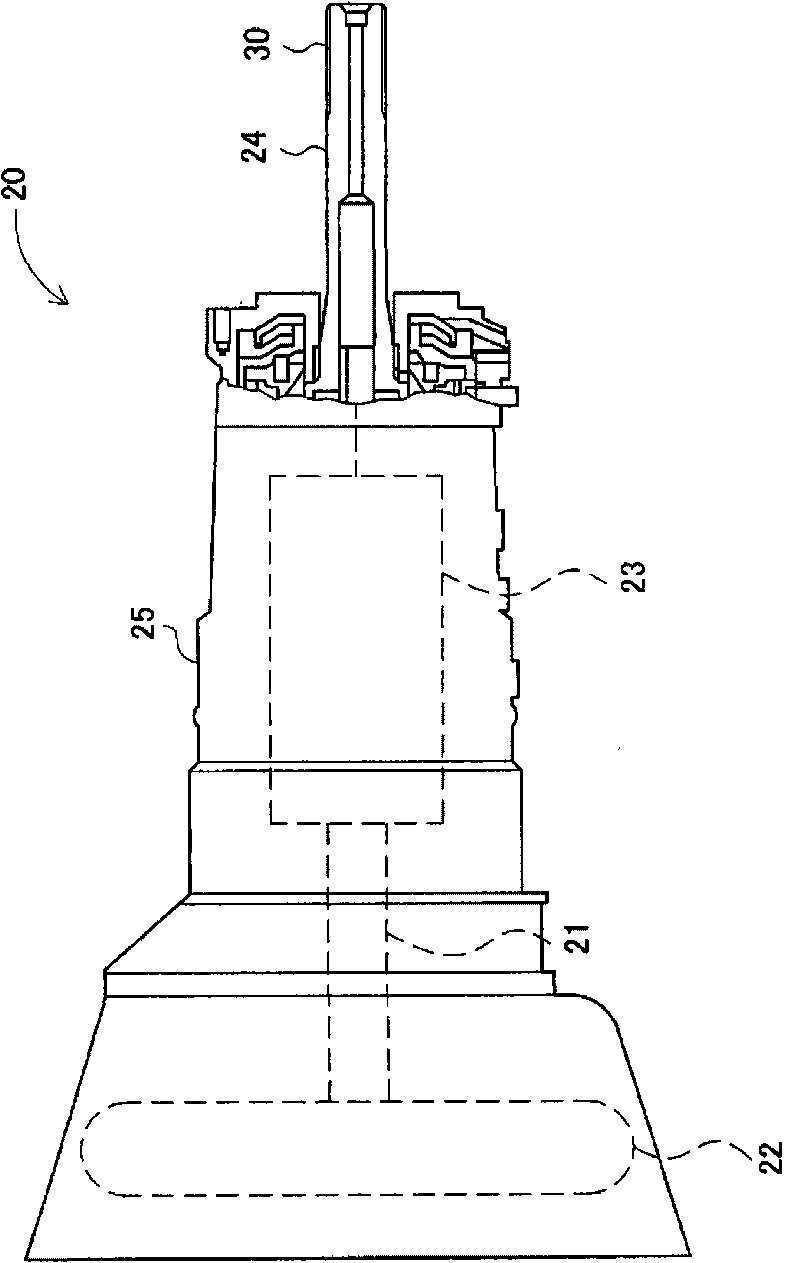

Automatic transmission

An automatic transmission which can be produced with a rise in costs thereof kept to a minimum and which produces a reduced impact when moved after a stop of the vehicle. The automatic transmission (20) is constructed such that hydraulic pressure controls a shift mechanism (23) to transmit the rotation of an input shaft (21) to shift positions, thereby transmitting the rotation to an output shaft(24). Splines (30) are formed in the output shaft (24) in that portion of the front end thereof which fits to a propeller shaft (12). A large diameter section (31) of the splines (30) has a two-step chamfer, and the corners (32, 32) on both sides of each spline tooth are chamfered.

Owner:AISIN AW CO LTD +1

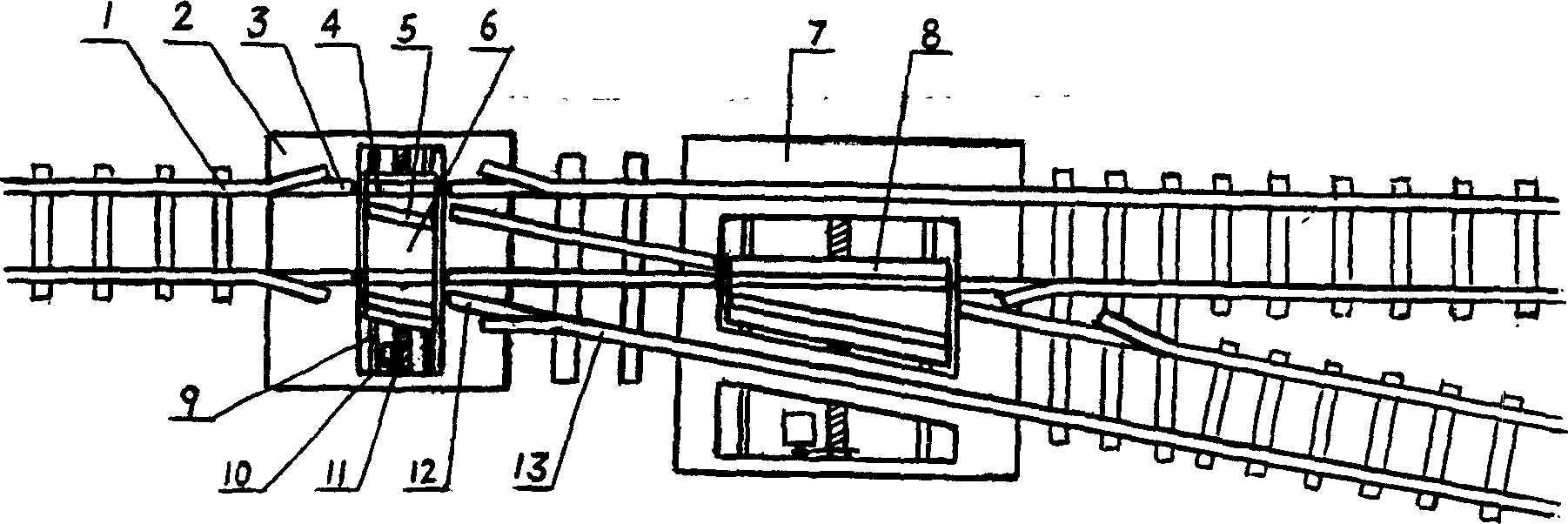

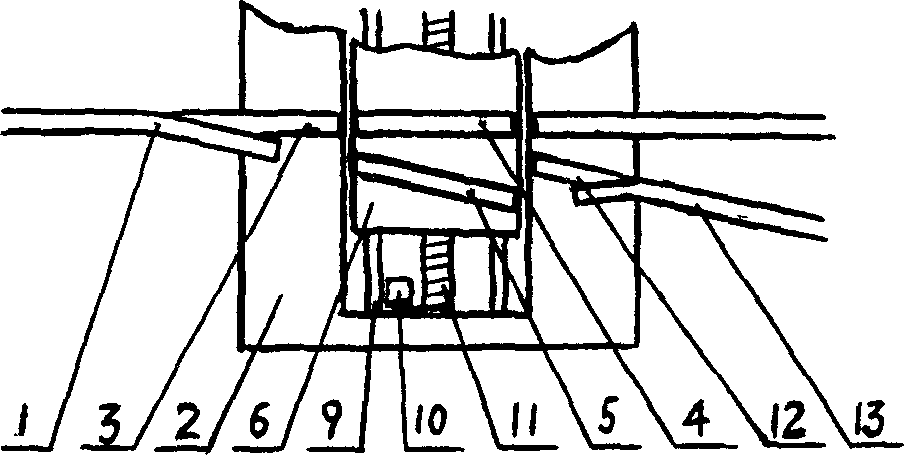

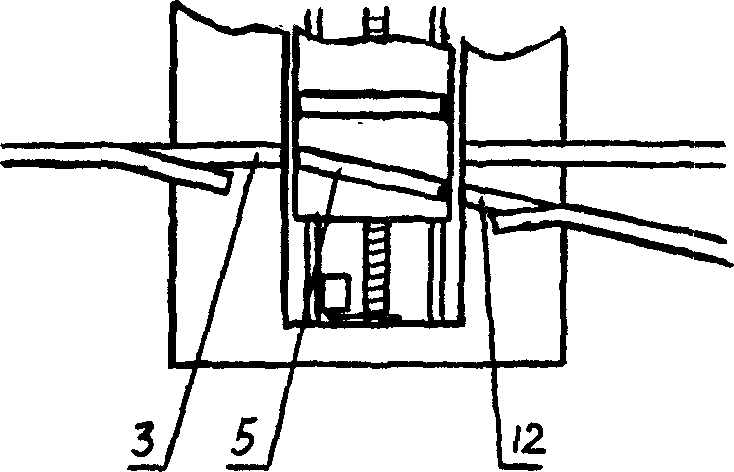

High speed safety shockproof turnout for railway

The high speed safe railroad switch consists of sleepers, sliding sleepers and transition rails, and features that the sliding sleepers are driven with some drier to move inside the sleeper grooves so as to drive the straight transition rails and the turnout transition rails to move separately in the straight line and the turnout line to realize switch conversion. The present invention has simple structure, stable and reliable operation, less vibration, swinging and noise, and makes it possible to raise the train passage speed limit from available 95-110 km / hr to 200-300 km / hr. The present invention is also suitable for subway, light railway and three rail high speed line.

Owner:HEFEI BOPU HIGH TECH

Self-controlled vertical thread adjusting device

The invention relates to a knitting machine, in particular to a self-controlled vertical thread adjusting device. The self-controlled vertical thread adjusting device comprises a front plate, a rear plate, a first supporting and positioning block, a second supporting and positioning block, a main circuit board, partition boards, a controller, a yarn clamping and shearing device, a push-and-pull rod and a linkage rod, wherein the first supporting and positioning block and the second supporting and positioning block are respectively installed between the front plate and the rear plate through bolts, the main circuit board is installed at the upper end of the first supporting and positioning block and the upper end of the second supporting and positioning block through bolts, two supporting shafts are installed between the front plate and the rear plate, the two supporting shafts are sleeved with the partition plates arranged at the lower end of the first supporting and positioning block and the lower end of the second supporting and positioning block, the first supporting and positioning block and the second supporting and positioning block form a sealed cavity with the front plate, the rear plate, the main circuit board, the partition boards and the linkage rod, and the controller is arranged in the sealed cavity. The self-controlled vertical thread adjusting device can prevent the controller, a yarn selecting knife and the linkage rod from being stained with oil or stuck by cotton fibers and soft flocks in working, ensures the action accuracy of the controller and improves the stability of textile production.

Owner:TANGSHAN WUGU ELECTROMECHANICAL EQUIP CO LTD

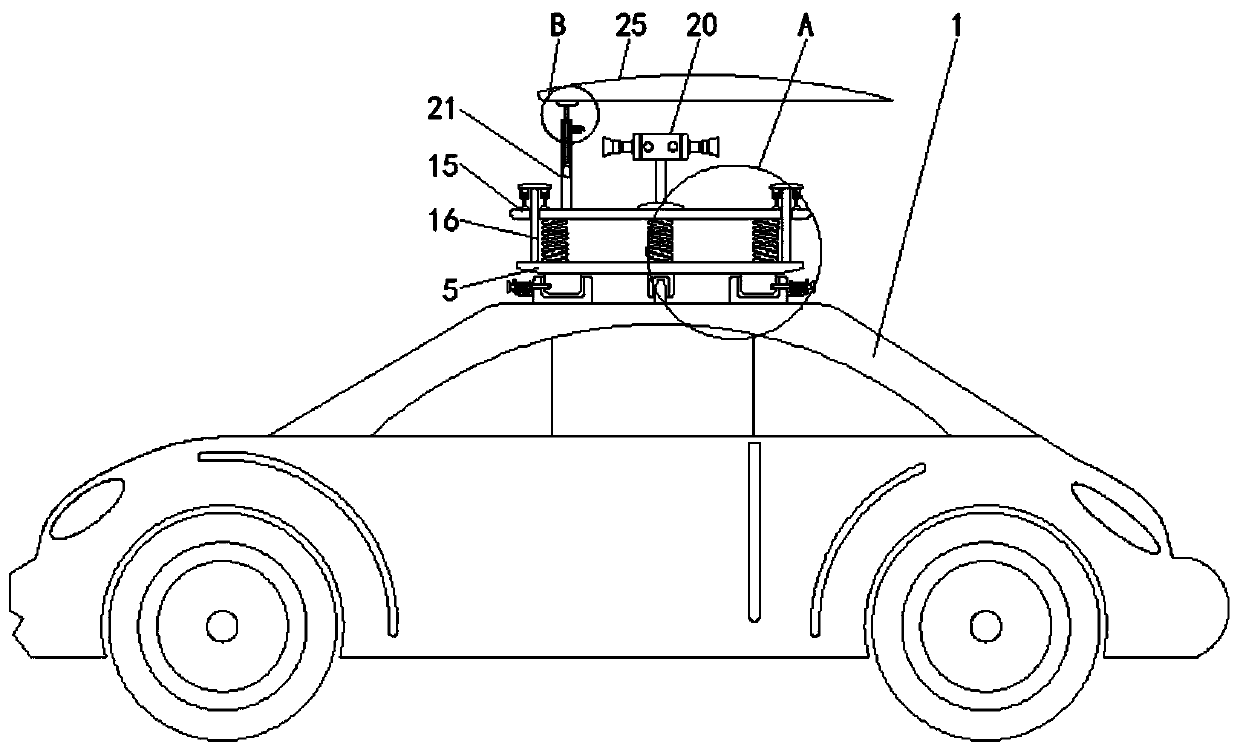

Automobile-networking-based new energy automobile with ultrasonic ranging function

ActiveCN109927642AWith ultrasonic ranging functionEasy to useVehicle componentsAcoustic wave reradiationNew energyButt joint

The invention relates to the technical field of automobiles and discloses an automobile-networking-based new energy automobile with an ultrasonic ranging function. The automobile comprises an automobile body, wherein the top of the automobile body is fixedly provided with two bearing blocks, the top of each bearing block is provided with a bearing groove, and a butt joint block with one end penetrating through the corresponding bearing block and extending to the upper portion of the bearing block is movably mounted in each bearing groove. According to the automobile-networking-based new energyautomobile with the ultrasonic ranging function, through arrangement of buffer sleeve rods on a transverse plate, when a user uses equipment and the automobile body runs on an uneven road, under thecondition that the transverse plate is shaken and impacted and a loading board moves downwards, the buffer sleeve rods are compressed to buffer a part of impact; when the loading board moves downwards, piston rods are pulled down, the air pressure in air cylinders is changed to counteract a part of the impact, the final impact shock performed on an ultrasonic range finder is greatly reduced, the ultrasonic range finder cannot be easily damaged, the troubles of a user are avoided, and convenience is provided for the user during use.

Owner:JIANGSU JINFENG ELECTROMECHANICAL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com