Superstrong-muting PE (polyethylene) core layer micro-foamed drainage pipe and manufacturing method thereof

A drainage pipe, ultra-quiet technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of poor chemical corrosion resistance and strength, large noise of drainage pipes, etc., achieve good chemical corrosion resistance, increase density and Rigidity, the effect of reducing shock and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

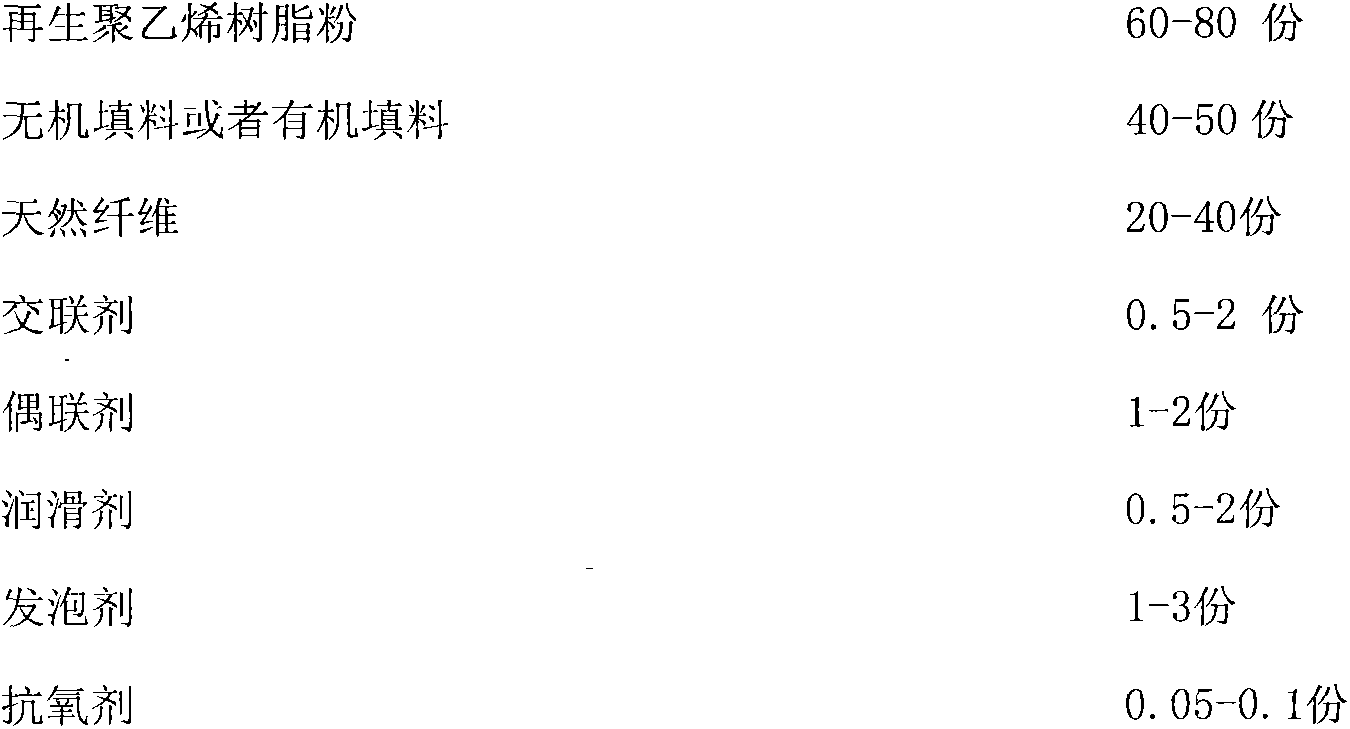

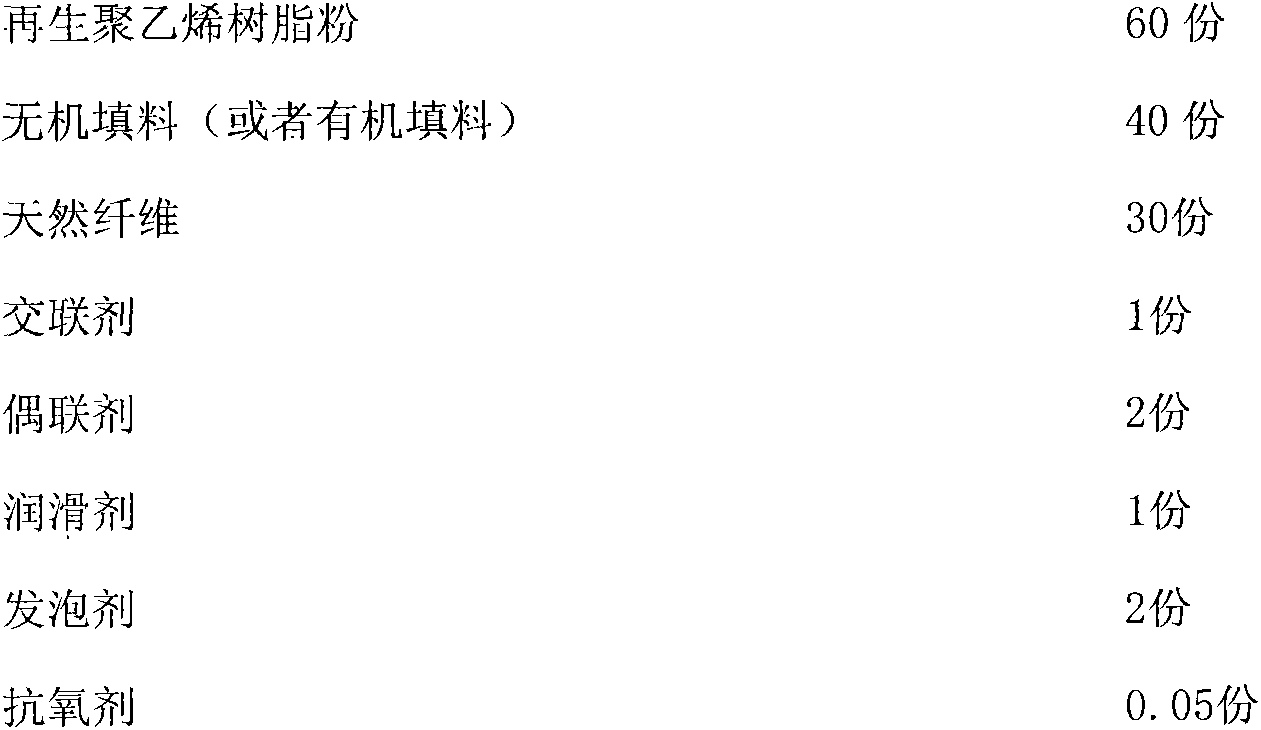

[0055] Embodiment: preparation of intermediate microfoaming layer mixture

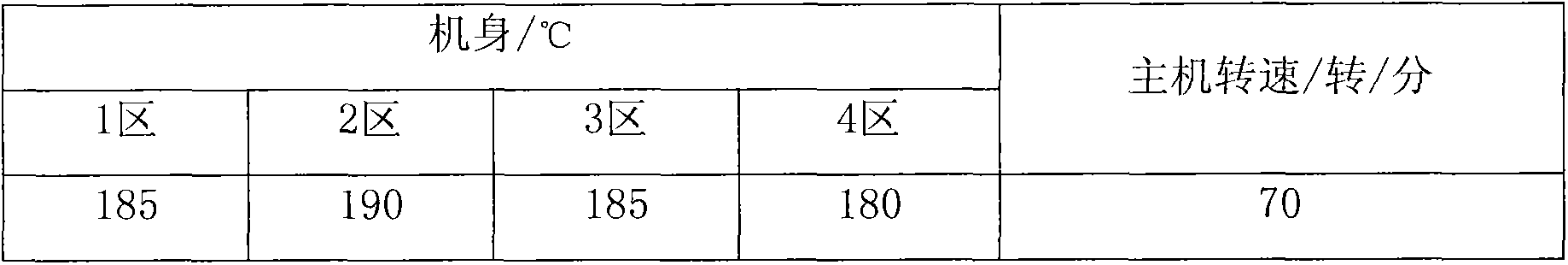

[0056] Crush 30 parts of natural fiber and pass through a 250-500um sieve, and dry at 80°C until the moisture content is less than 0.6%, to obtain natural fiber powder; then add 40 parts of inorganic filler (280-300 mesh) and treat with 2 parts of coupling agent. Then add 60 parts of polyethylene, 1 part of lubricant and 1 part of crosslinking agent respectively according to the mass ratio, heat mix the above-mentioned mixture at 110°C and discharge it to a cold mixing system at 40°C for cooling to obtain a premix; Extruded and granulated by a parallel twin-screw extruder, the process temperature is set at 180-200°C to produce semi-finished pellets; the semi-finished pellets are mixed with 2 parts of chemical foaming agent, 0.05 part of antioxidant and other additives Finally, it is added to the conical twin-screw in step 2 for extrusion molding, the process temperature is set at 140-180°C, and it is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com