Automobile fuel tank

A technology for fuel tanks and automobiles, which is applied to vehicle components, the arrangement combined with the fuel supply of internal combustion engines, power devices, etc., which can solve the problems of poor impact resistance and non-flame retardancy, and achieve enhanced safety, improved life, and reduced shock and vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

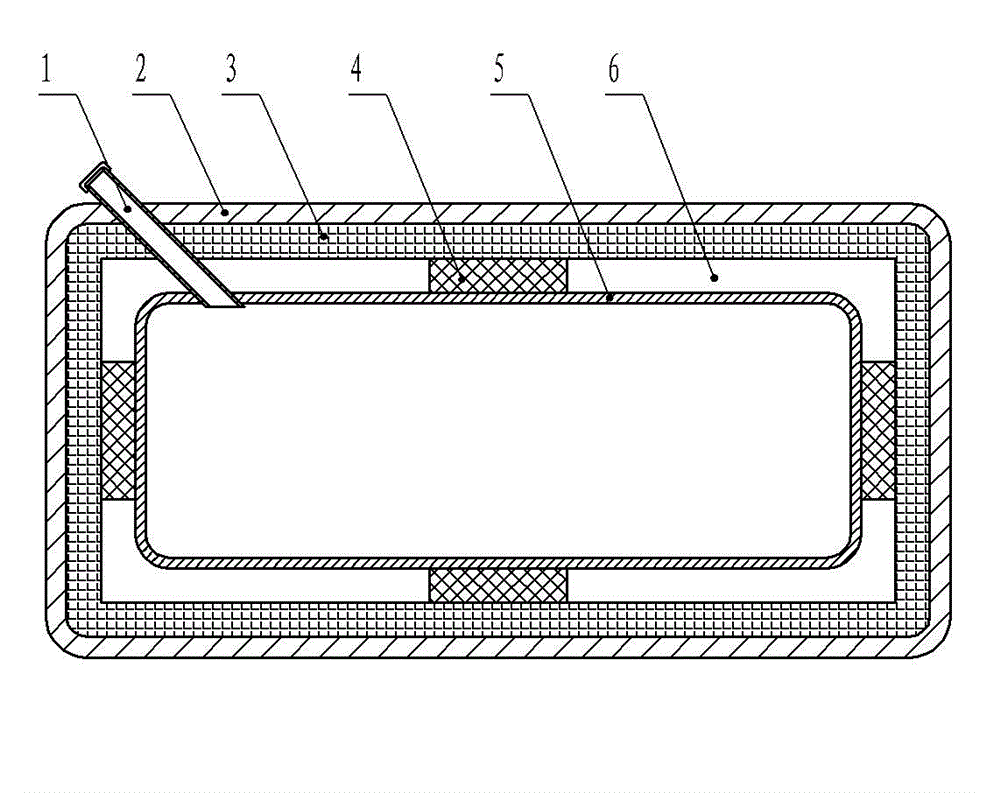

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail: as figure 1 as shown,

[0014] This automobile fuel tank includes a fuel tank oil inlet 1 and a fuel tank inner cavity 5, and also includes a fuel tank shell 2, the fuel tank shell 2 and the fuel tank inner cavity 5 are made of high-density polyethylene material, and the fuel tank shell 2 There is a flame-retardant layer 3 between the fuel tank inner cavity 5, and the flame-resistant layer 3 is made of asbestos material. There is a buffer cavity 6 between the flame-resistant layer 3 and the fuel tank inner cavity 5. In the buffer cavity 6, A buffer component 4 is provided on each side of the inner chamber of the fuel tank 5, and the buffer component 4 is made of flame-retardant rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com