Novel rotor of permanent magnet motor

A permanent magnet motor, a new type of technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electrical components, etc., can solve problems such as structural defects, achieve the effects of light weight, increased strength, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

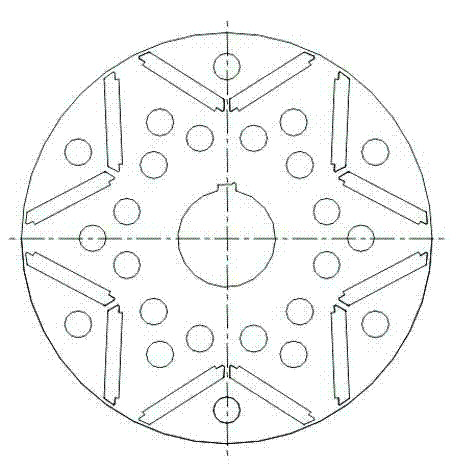

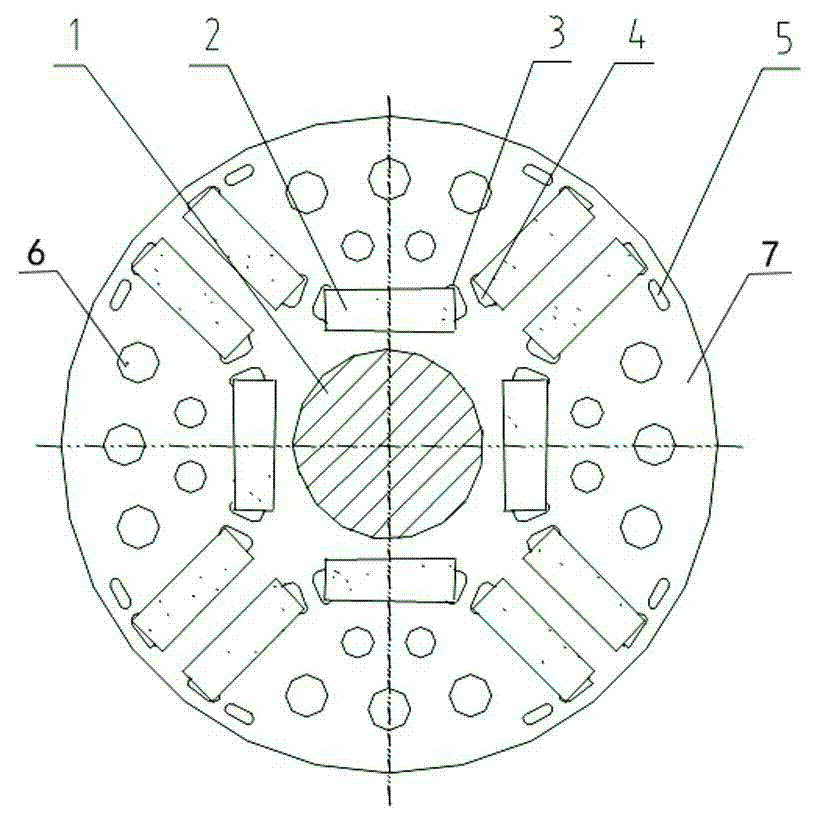

[0011] A rotor of a new type of permanent magnet motor, comprising a rotating shaft 1, a rotor punch 7 that is laminated on the rotating shaft 1 and has a magnetic steel groove 4 and a ventilation hole 6, and a magnetic steel 2 inserted in the magnetic steel groove ; The rotor punch is a U-shaped magnetic circuit structure, that is, three magnetic steel grooves distributed in a U shape form a magnetic pole; under each magnetic pole, within the range surrounded by three magnetic steel grooves distributed in a U shape, There are two magnetic isolation bridge holes 5, and the two magnetic isolation bridge holes are respectively located on the inner side of the magnetic steel slots on both sides of each magnetic pole (the three magnetic steel slots forming each magnetic pole are divided into two sides and the middle) and the rotor punching plate The outer edge; the rotor punch 7 and the rotating shaft 1 adopt an interference fit; the magnet steel 2 and the rotor punch have a gap fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com