Patents

Literature

901results about How to "Improve overload capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

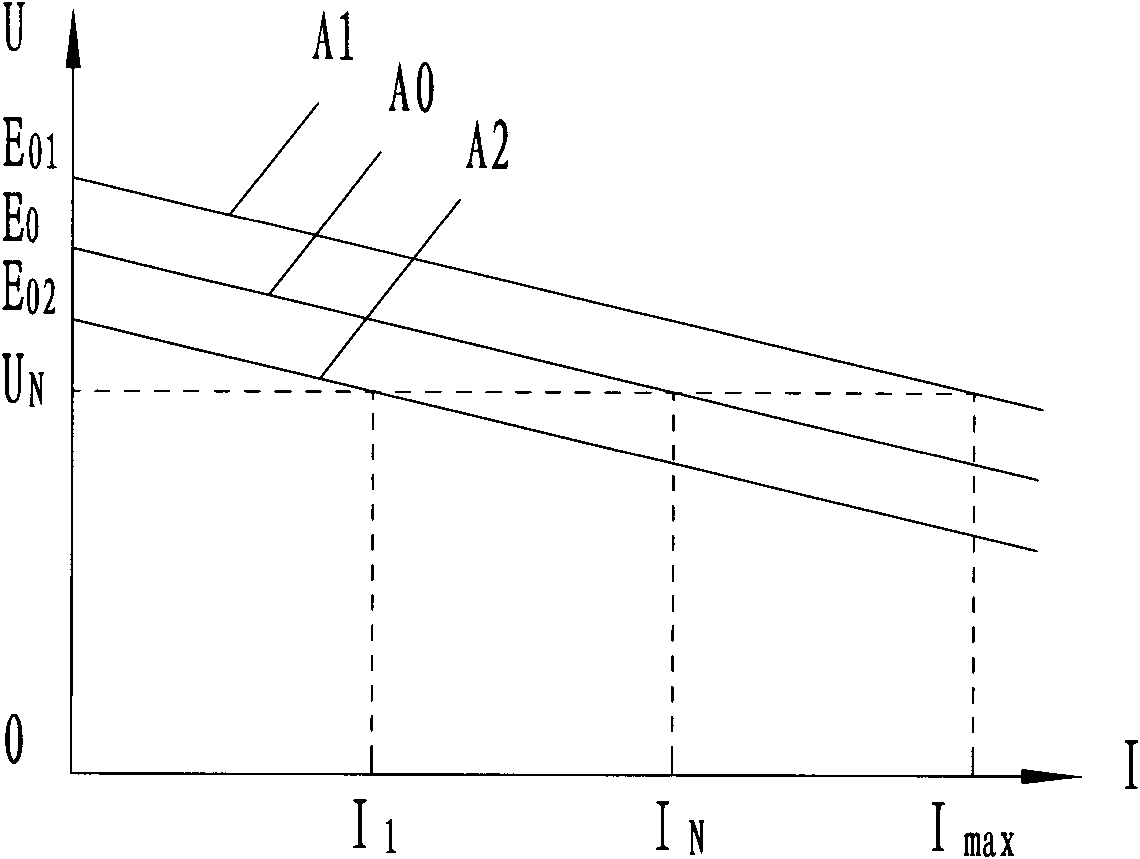

Maximum torque per ampere vector control system and control method for position sensor-free internal permanent magnet synchronous motor

InactiveCN102594250AImprove overload capacityImprove power densityElectronic commutation motor controlVector control systemsOperating pointAmpere

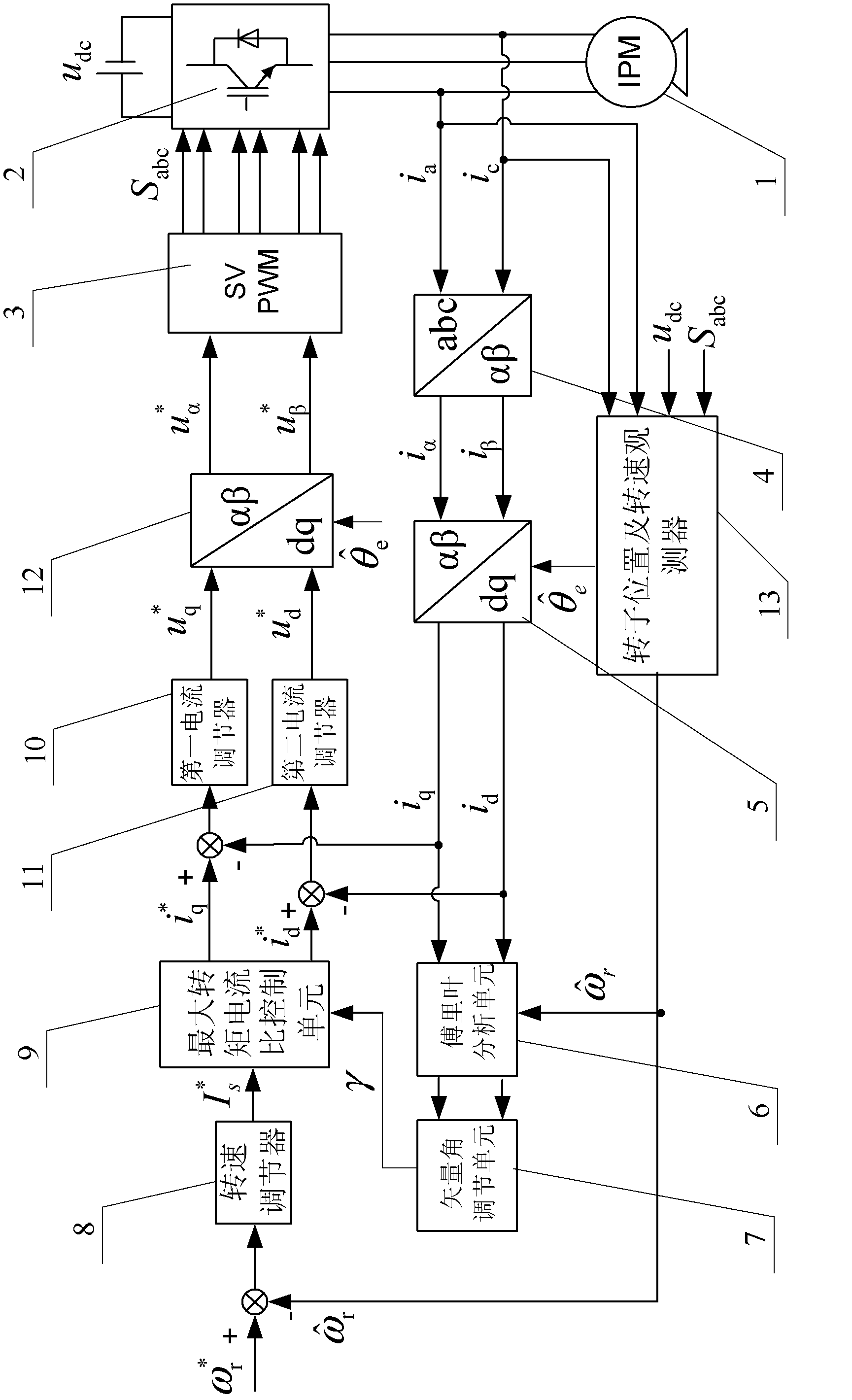

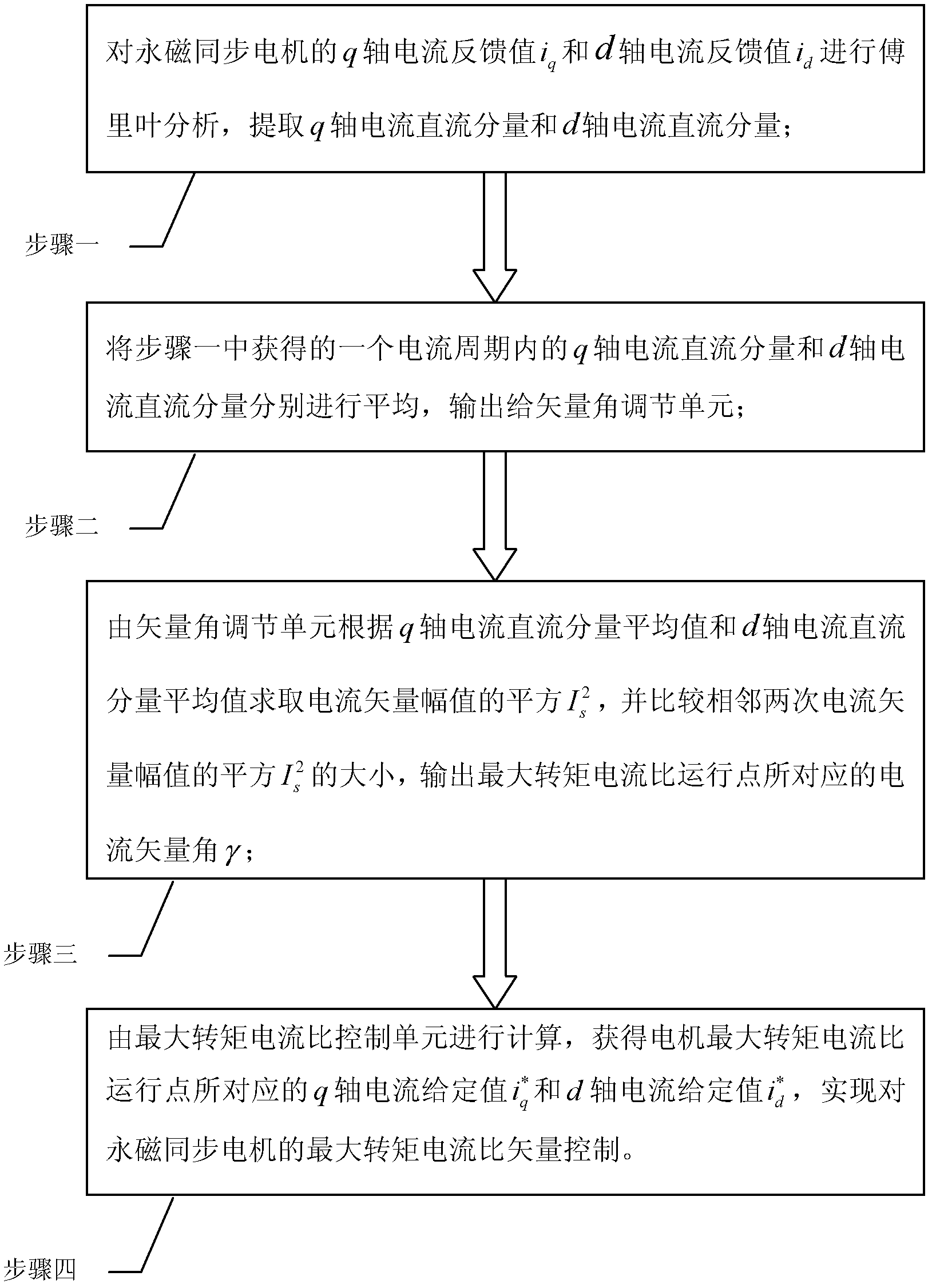

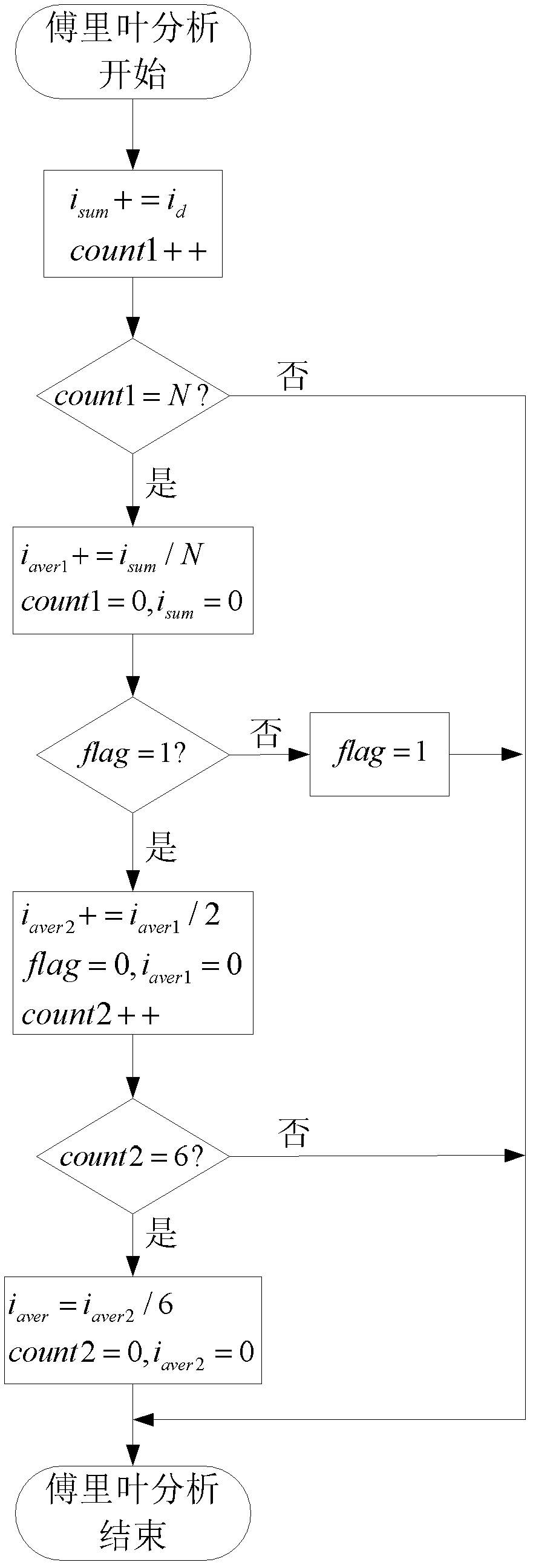

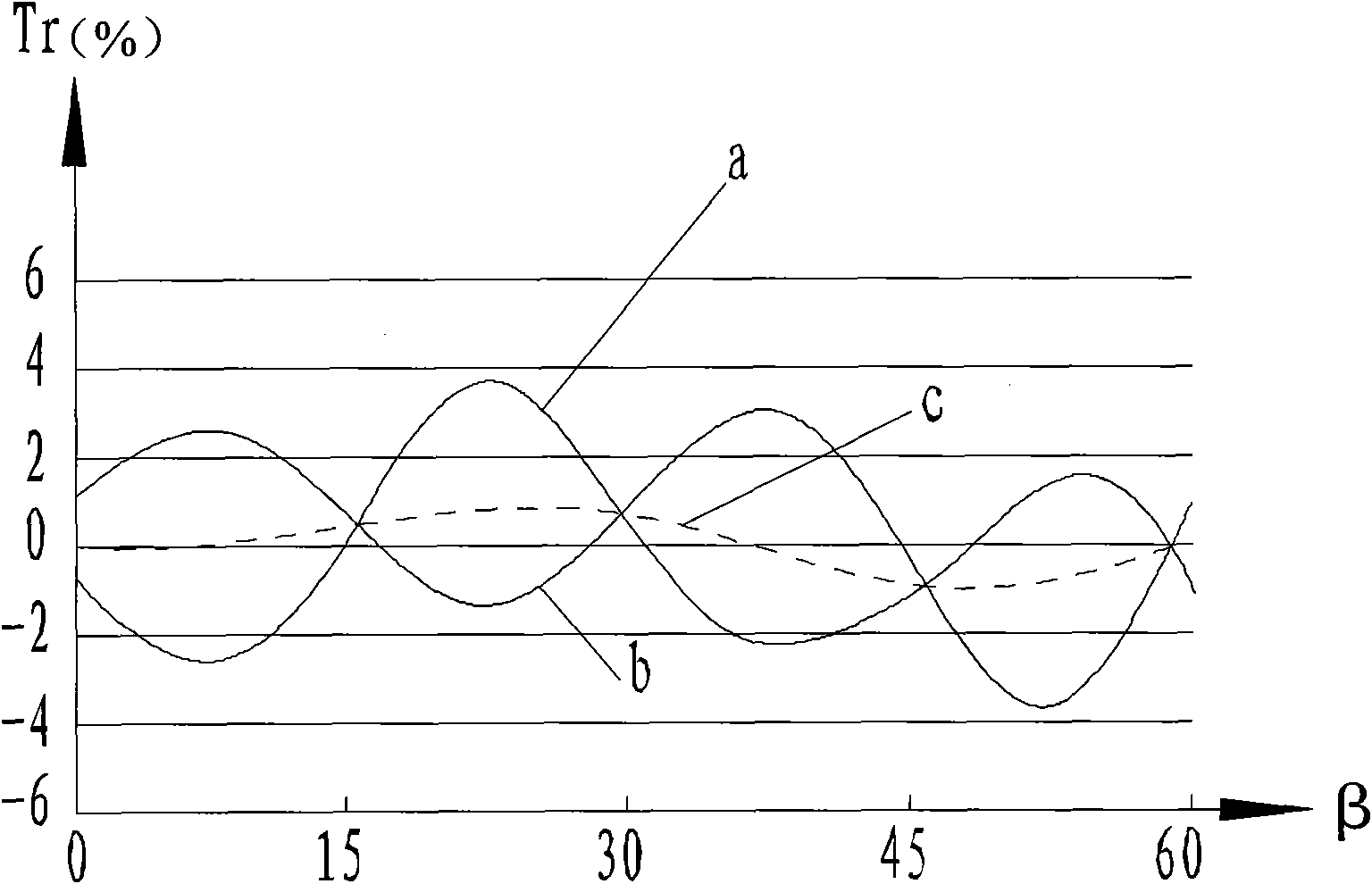

The invention discloses a control method of a maximum torque per ampere vector control system for a position sensor-free internal permanent magnet synchronous motor, and belongs to the field of motor control. The problems of complexity of a computing method and low accuracy of an obtained current set value in the conventional maximum torque per ampere control strategy are solved. The control system comprises a permanent magnet synchronous motor, an inverter, a space vector pulse width modulation unit, a three-phase-two-phase coordinate conversion unit, a static-rotational coordinate conversion unit, a Fourier analysis unit, a vector angle regulation unit, a rotating speed regulator, a maximum torque per ampere control unit, a first current regulator, a second current regulator, a rotational-static coordinate conversion unit and a rotor position and rotating speed observer. According to the control method, the magnitude of current amplitude is automatically regulated and compared on the basis of a current vector angle gamma, and an operating point with maximum torque per ampere is automatically searched. The system and the method are applied to maximum torque per ampere vector control over the motor.

Owner:HARBIN INST OF TECH

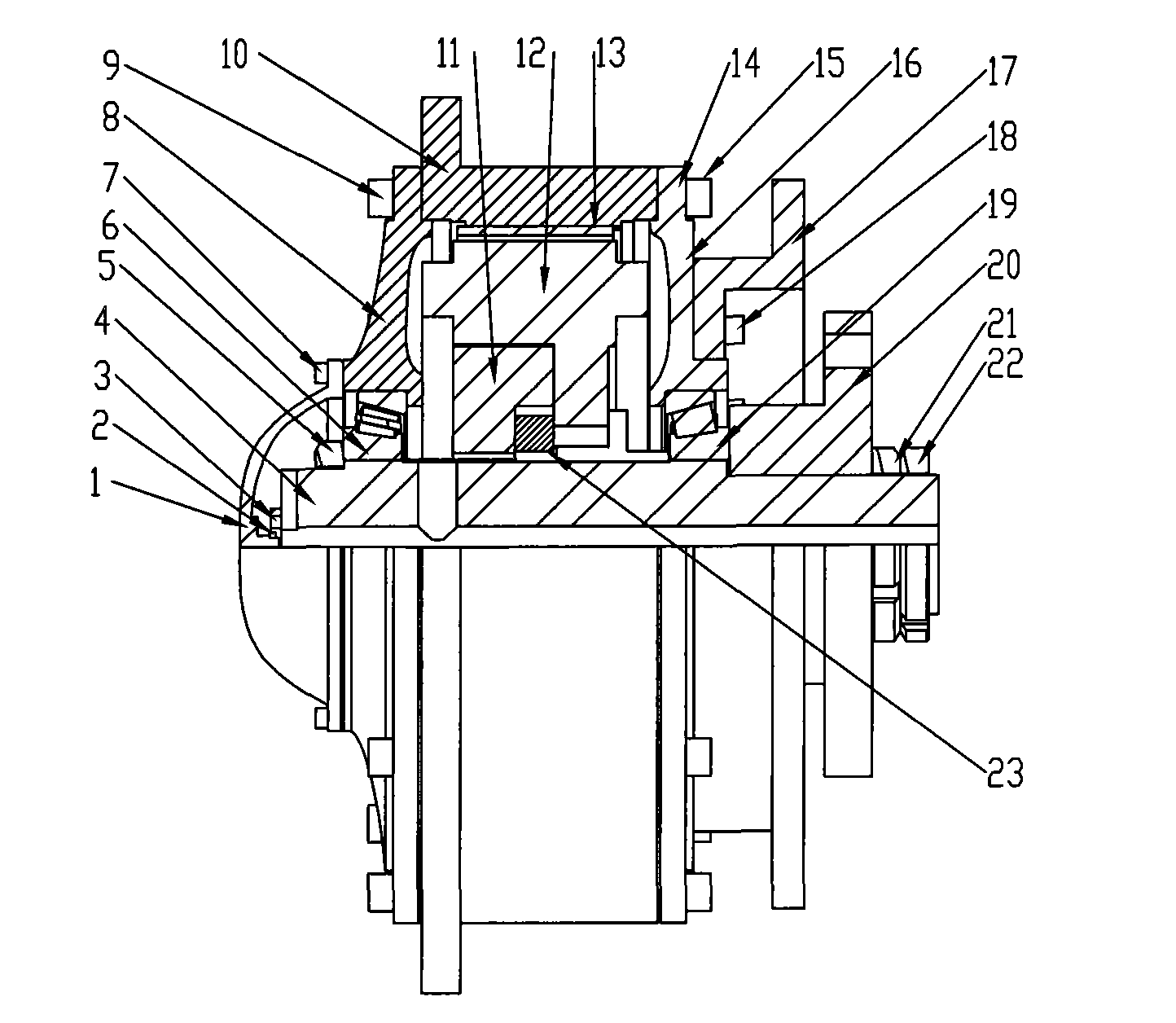

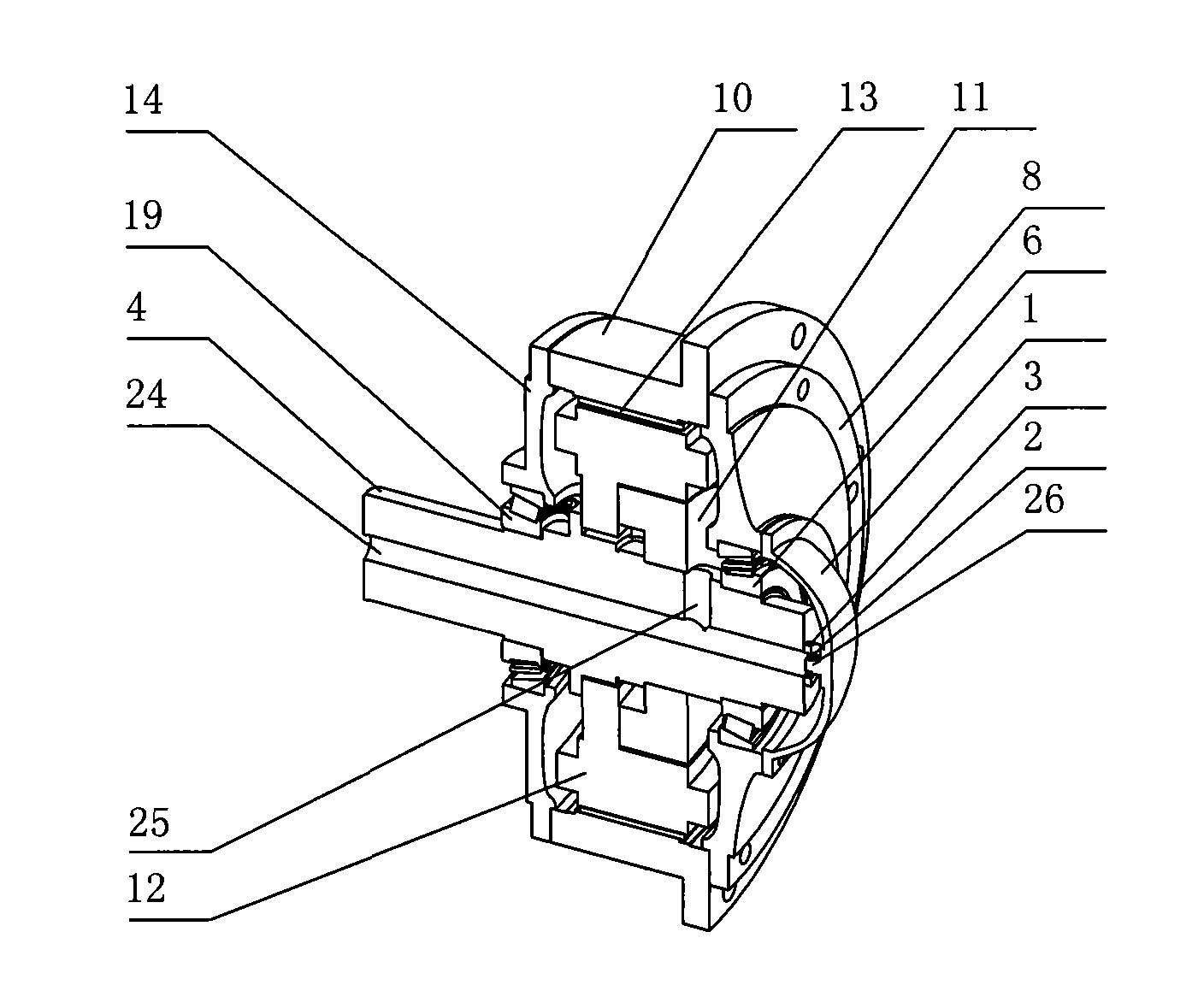

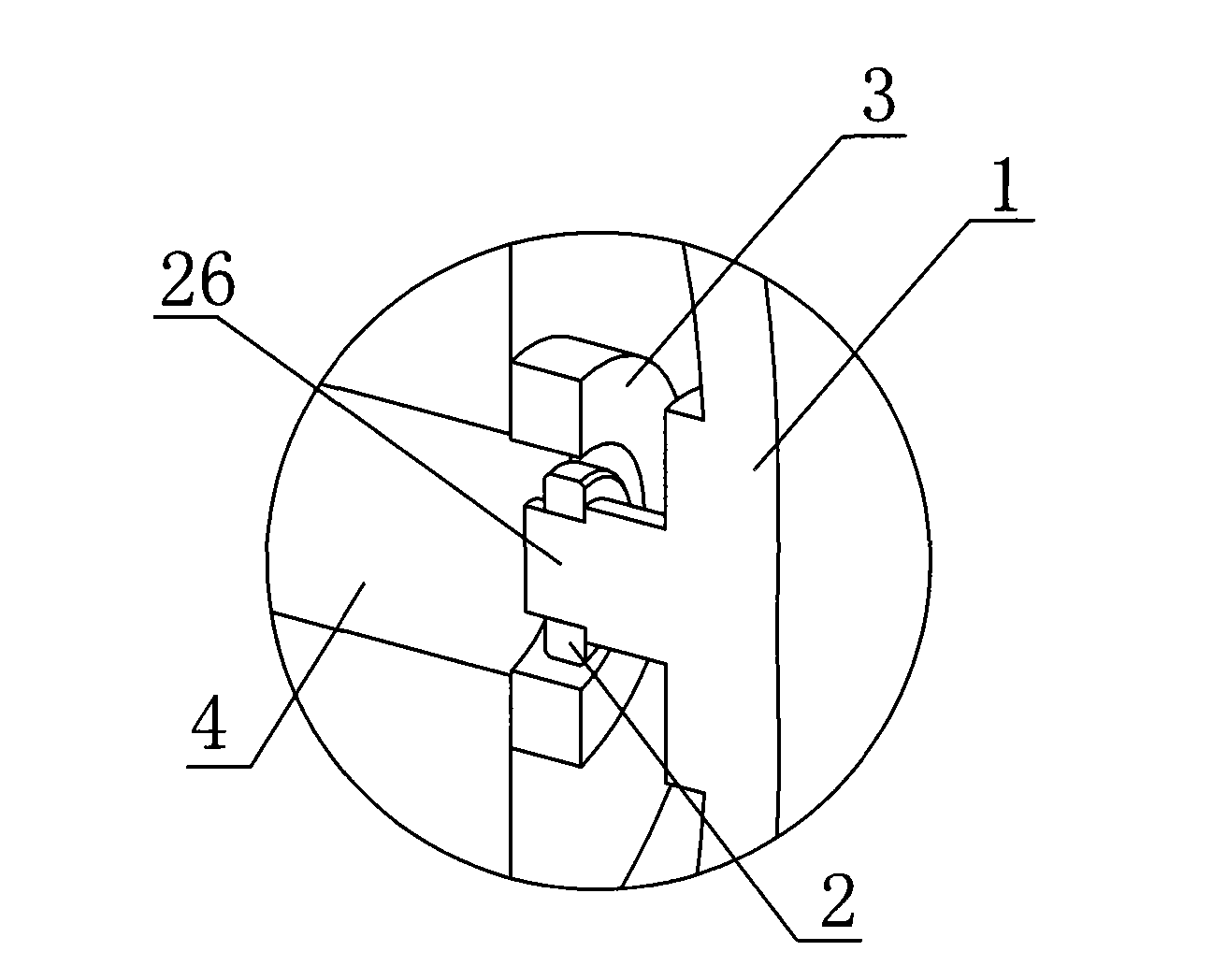

Integrated hub motor and control method thereof

InactiveCN101877524AEasy processing and installationImprove reliabilityElectronic commutation motor controlStructural associationLocation detectionControl theory

The invention provides an integrated hub motor and a control method thereof. The integrated hub motor comprises a motor shaft and a stator fixed on the motor shaft, wherein the stator is externally sheathed with a rotor casing; the front end and the rear end of the rotor casing are rotatablely fixed on the motor shaft by a rotor end cover and a bearing; two ends of the motor shaft protrude outside the rotor end cover to form a long end and a short end; a bearing end cover is fixed at the outer side of the rotor end cover; and the short end of the motor shaft is covered therein. The invention is characterized in that a bearing end cover shaft is arranged in the middle part of the bearing end cover in a protruding mode towards the direction of the motor shaft, and a position detection device is arranged at the corresponding position of the end part of the motor shaft and the bearing end cover shaft; the motor shaft is sheathed with a servo controller; and the position detection device senses rotation of the bearing end cover shaft and transmits the sensed signal to the servo controller to finally obtain the rotating angle or position of the rotor after being processed by the servo controller, thus achieving accurate control of the motor. The invention has the advantages of simple structure, energy conservation, good starting characteristic, small volume and high efficiency.

Owner:杭州桐聚科技有限公司

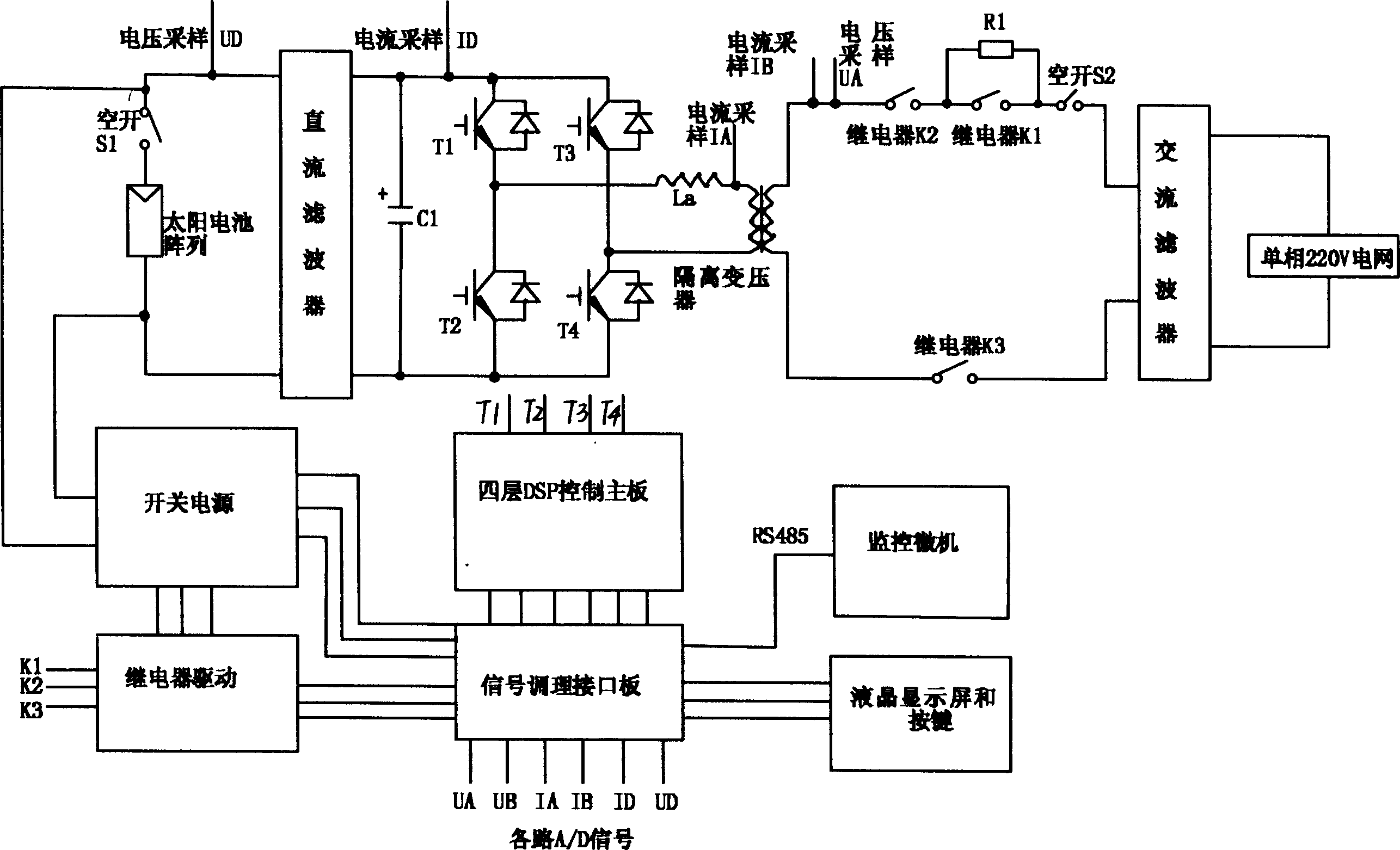

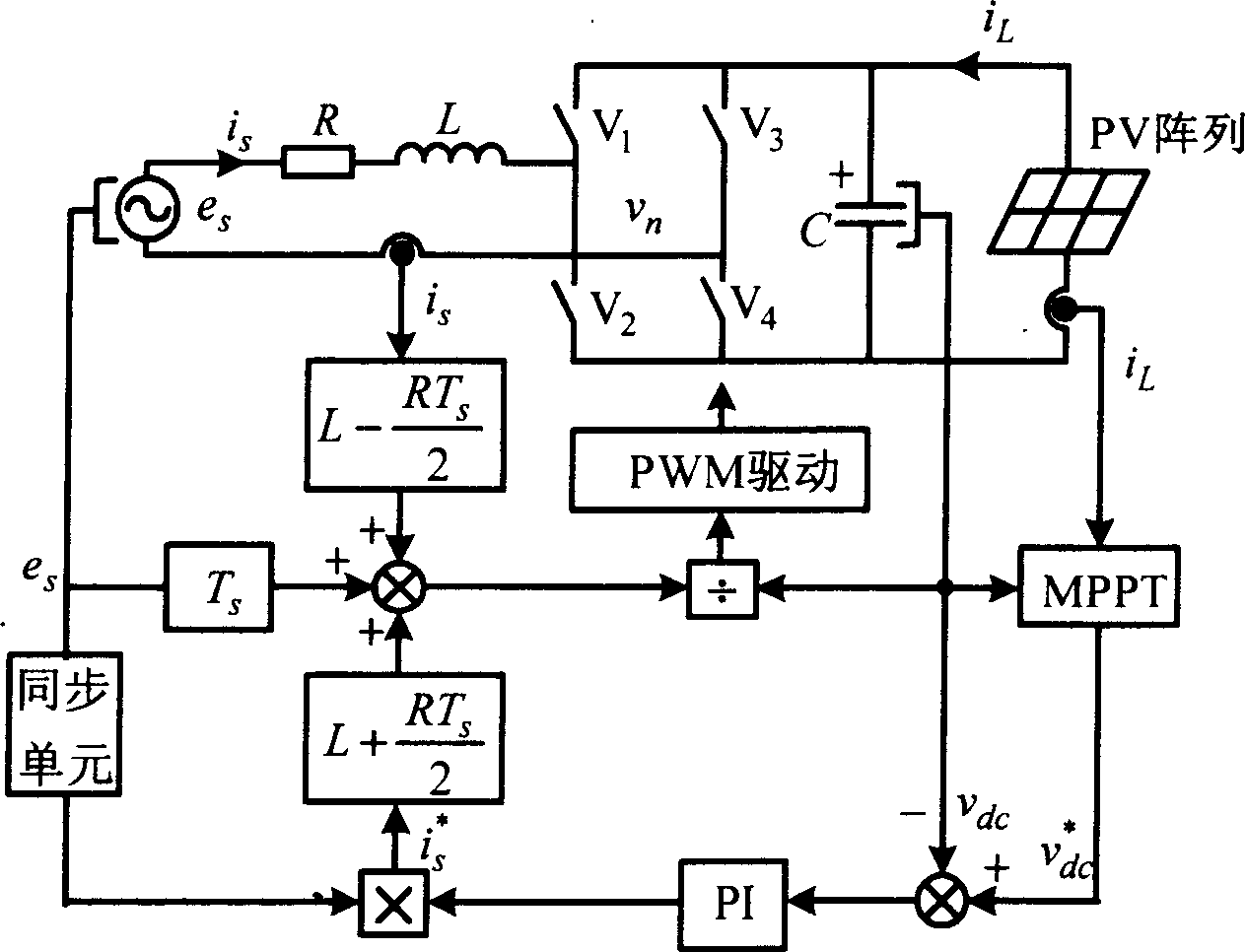

A method of photovoltaic grid-connected inversion

ActiveCN1671035AReduce Harmonic PollutionIncreased safety and overload capacityArrangements responsive to excess currentPhotovoltaic energy generationPower gridHarmonic pollution

This invention discloses a inversion method for photovoltaic parallel in network, which uses digital signal processor (DSP) as core, the power factor is one and having small harmonic pollution to electric network, said method is a high efficiency and high reliability inversion method.

Owner:SUNGROW POWER SUPPLY CO LTD

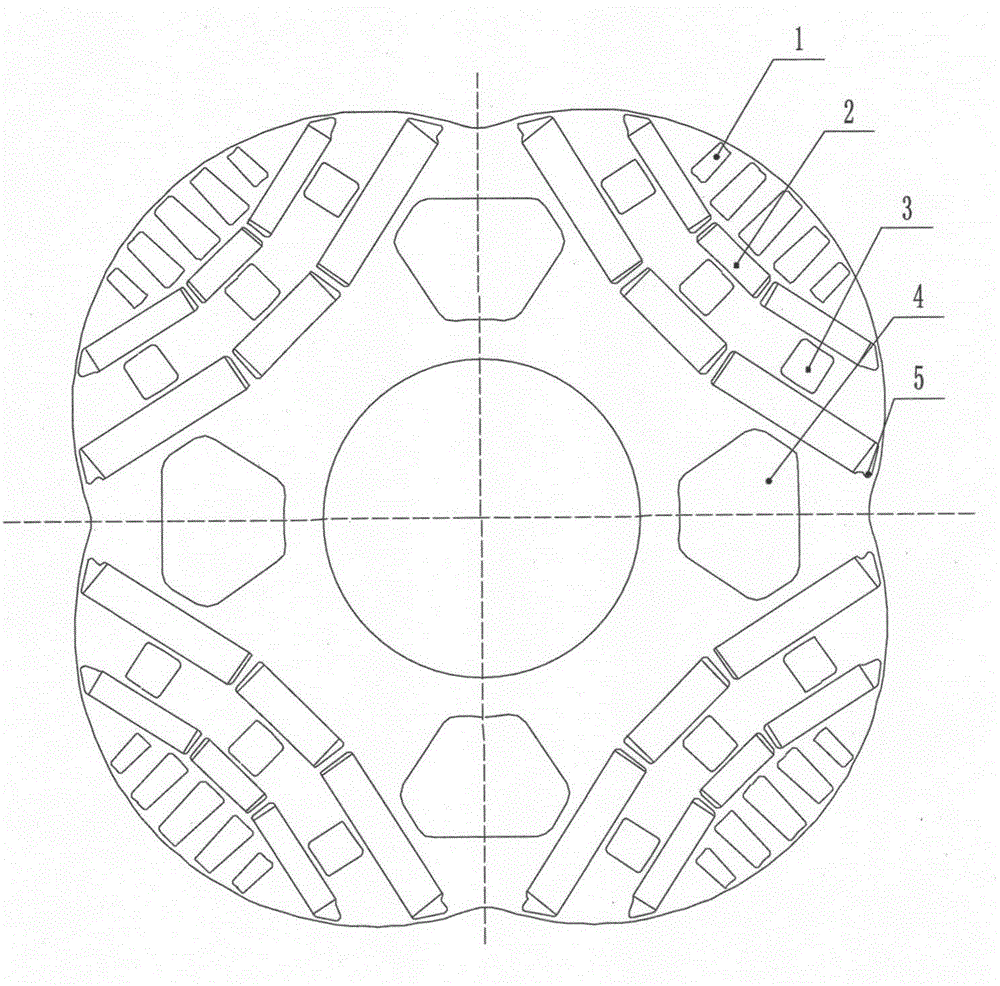

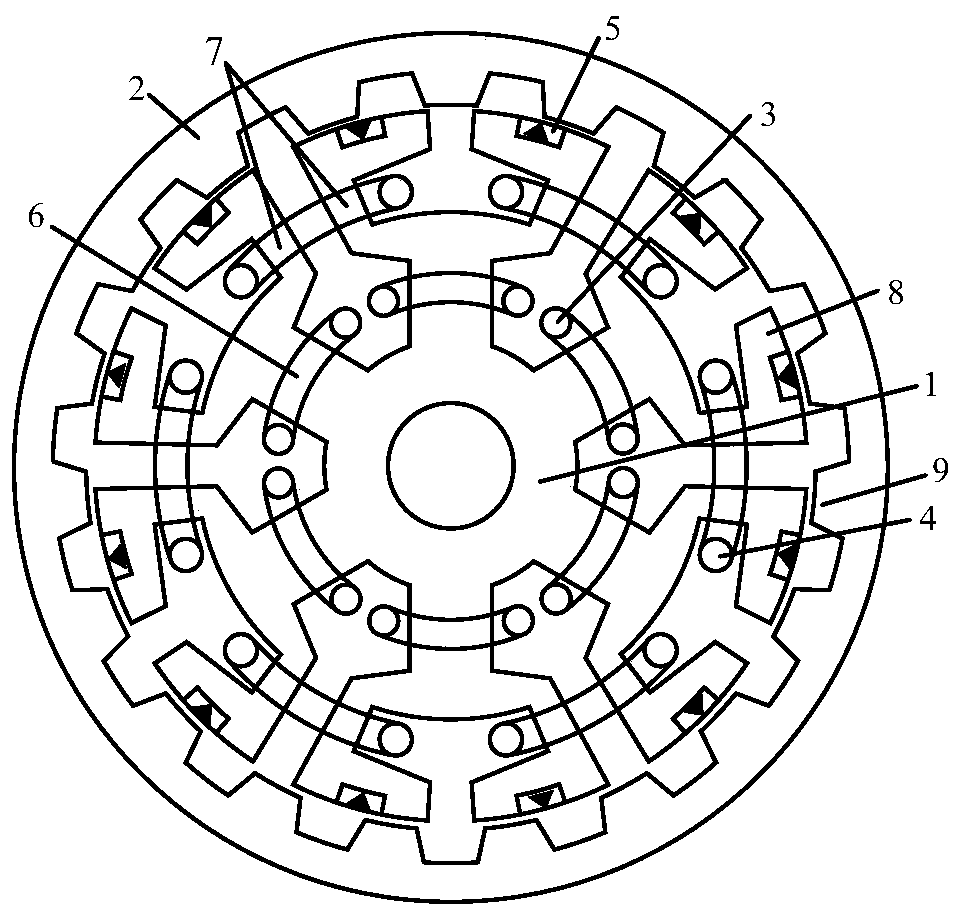

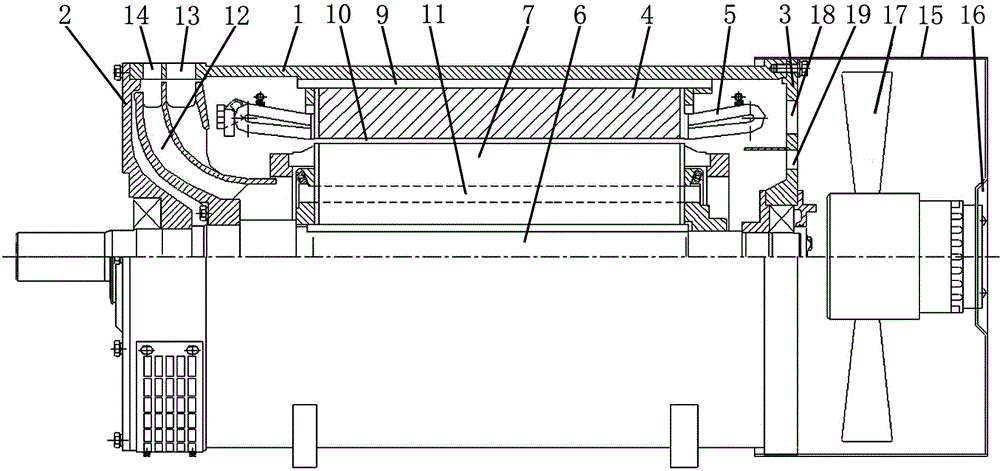

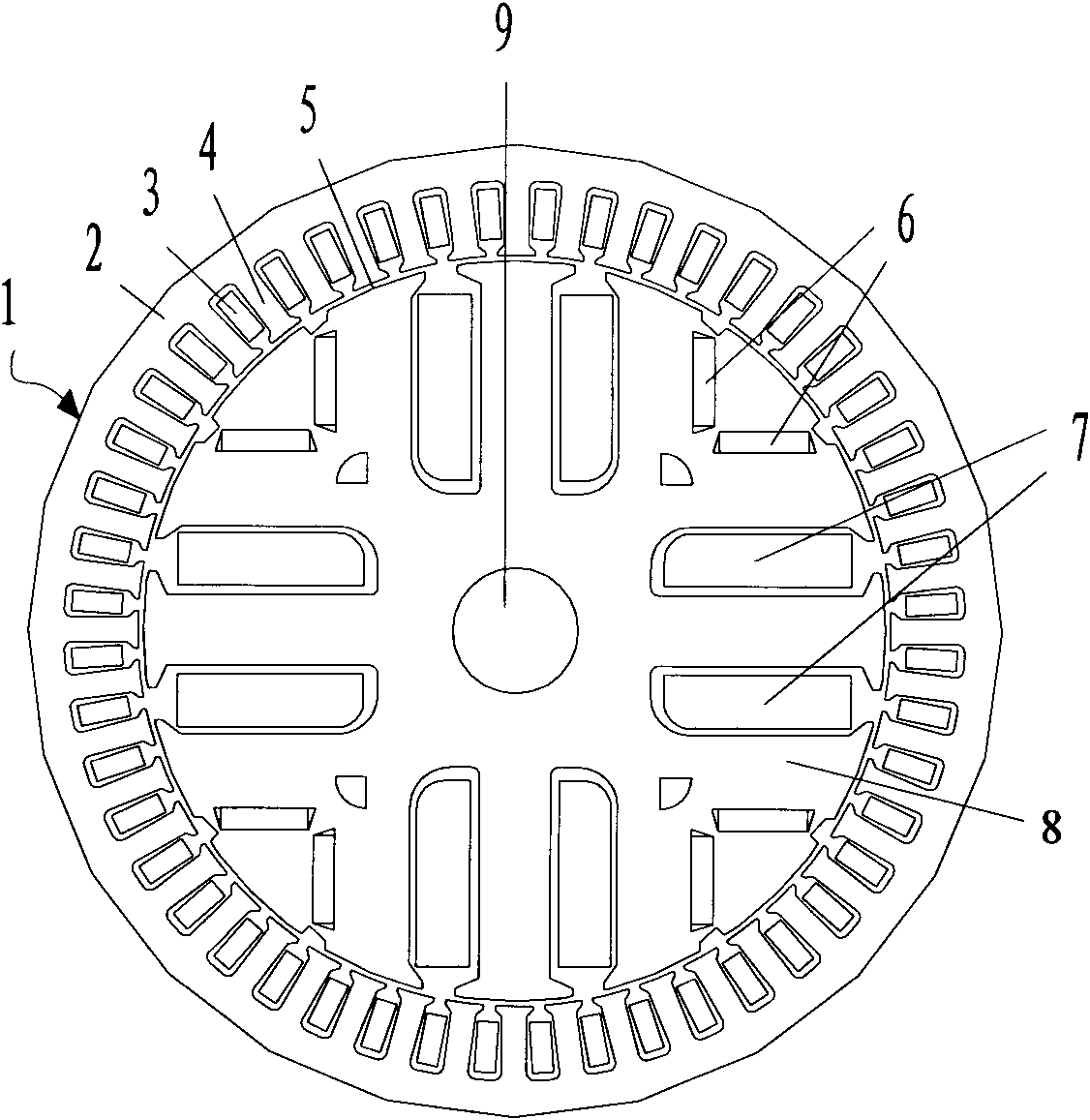

Rotor punching structure for permanent-magnet servo motor

ActiveCN104882981AImprove back EMF waveformReduce additional stray lossMagnetic circuit rotating partsPunchingCoupling

The invention provides a rotor punching structure for a permanent-magnet servo motor, and the structure comprises a rotor punching body. The peripheral surface of the rotor punching body is provided with permanent magnet tanks, and the interior of each permanent magnet tank is provided with a permanent magnet in an embedded manner. The external circle of the rotor punching body above the permanent magnet tanks is not concentric with the internal circle of a stator. The rotor punching body above the permanent magnet tanks is provided with magnetic isolation holes which are arranged horizontally, and the rotor punching body below the permanent magnet tanks is provided with an axial cooling channel. The permanent magnet tanks are radially arranged in a layered manner, and magnetic isolation tanks are respectively disposed between the adjacent permanent magnet tanks. Magnetic isolation bridges are disposed among the magnetic isolation tanks and the permanent magnet tanks. Through the improvement of the rotor punching structure and the control of the direction of a magnetic field, the nonlinear impact, caused by the coupling of quadrature-axis and direct-axis magnetic circuits, on motor parameters is reduced, and the space of a rotor punching is used fully for placing permanent magnets as many as possible. Moreover, the capability of resistance to demagnetizing and the overbearing capability of the permanent-magnet servo motor are improved, and the operation performance of the permanent-magnet servo motor is effectively improved.

Owner:SHANGHAI MOTOR SYST ENERGY SAVING ENG TECH RES CENT +2

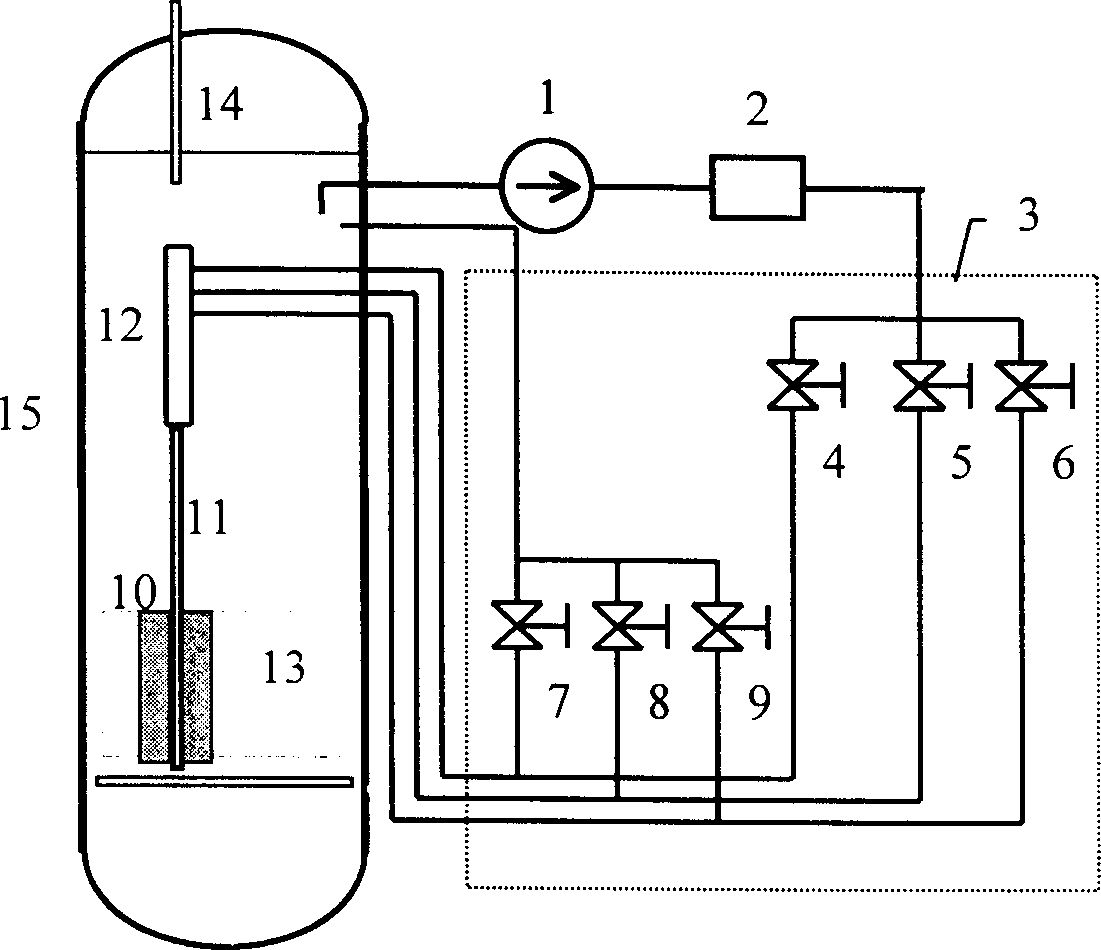

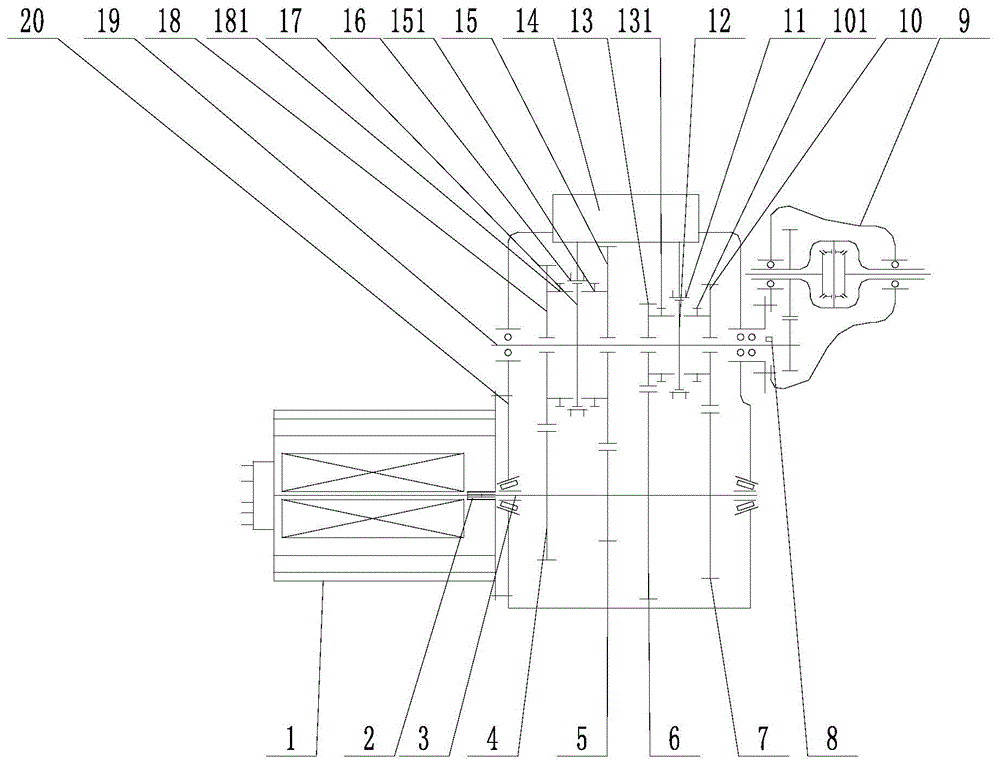

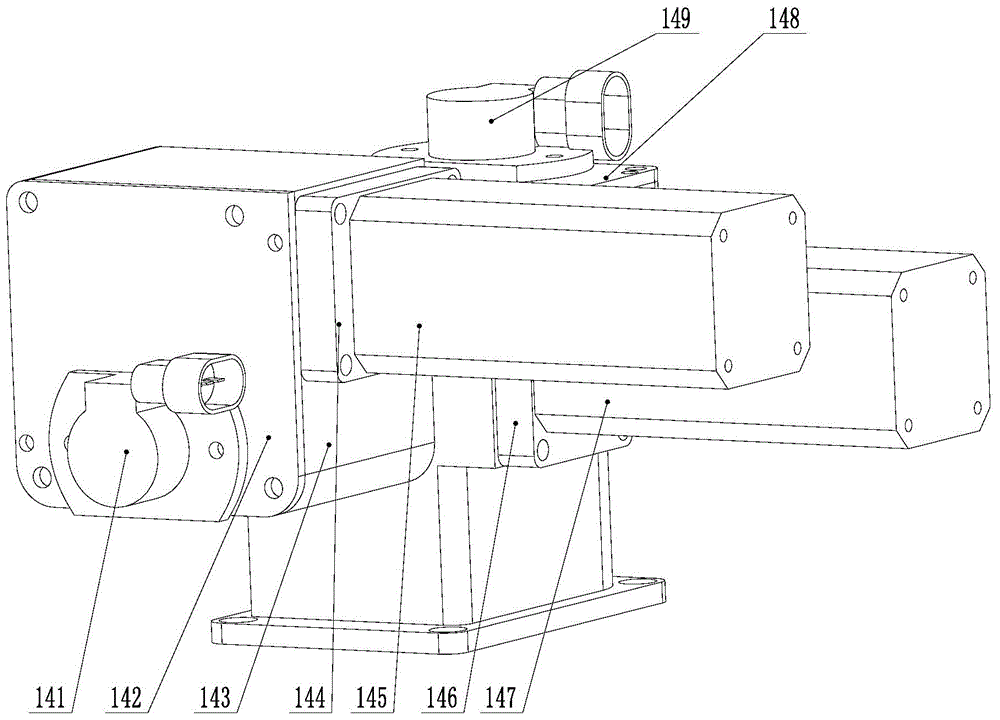

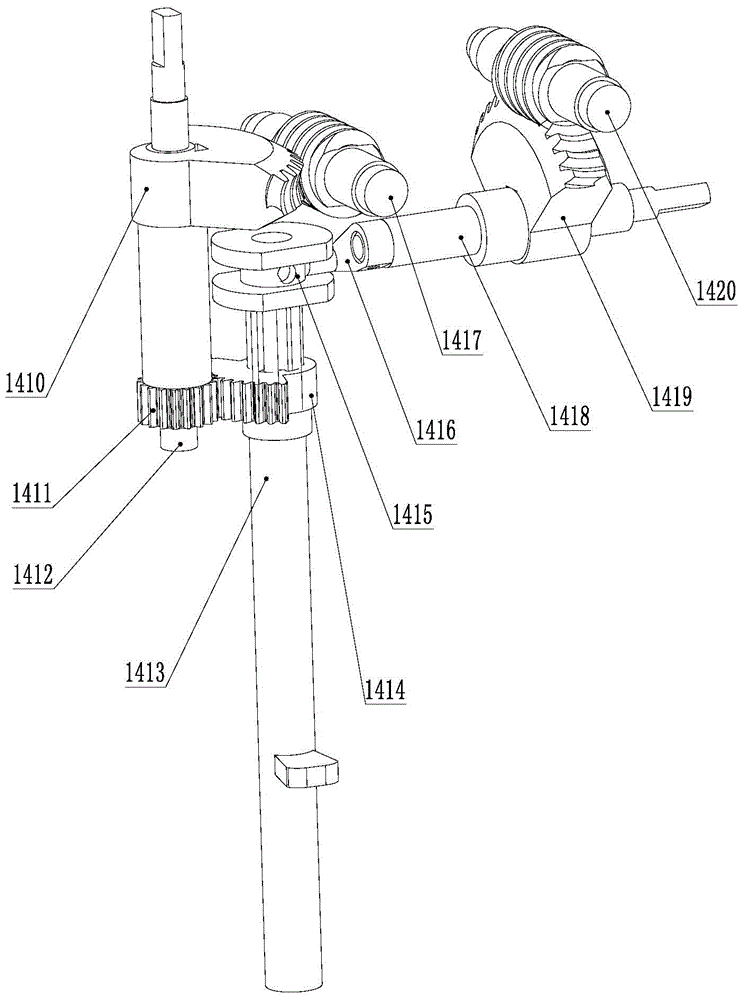

Nuclear reactor control rod hydraulic driving system

InactiveCN1442863APrecise positioningImprove overload capacityNuclear energy generationNuclear reaction controlHydraulic cylinderNuclear reactor

A hydraulic drive system for the control rods of nuclear reactor features that its drive mechanism has three hydraulic cylinders and two pinned jaw mechansms, its combined valve is composed of 3 parallel electromagnetic valves opened normally and 3 parallel electromagnetic valves closed normally, and said hydraulic cylinders are driven by the static pressure of water. Its advantages are correct location and step movement, high over-load power, short transfer distance, and high safety.

Owner:TSINGHUA UNIV

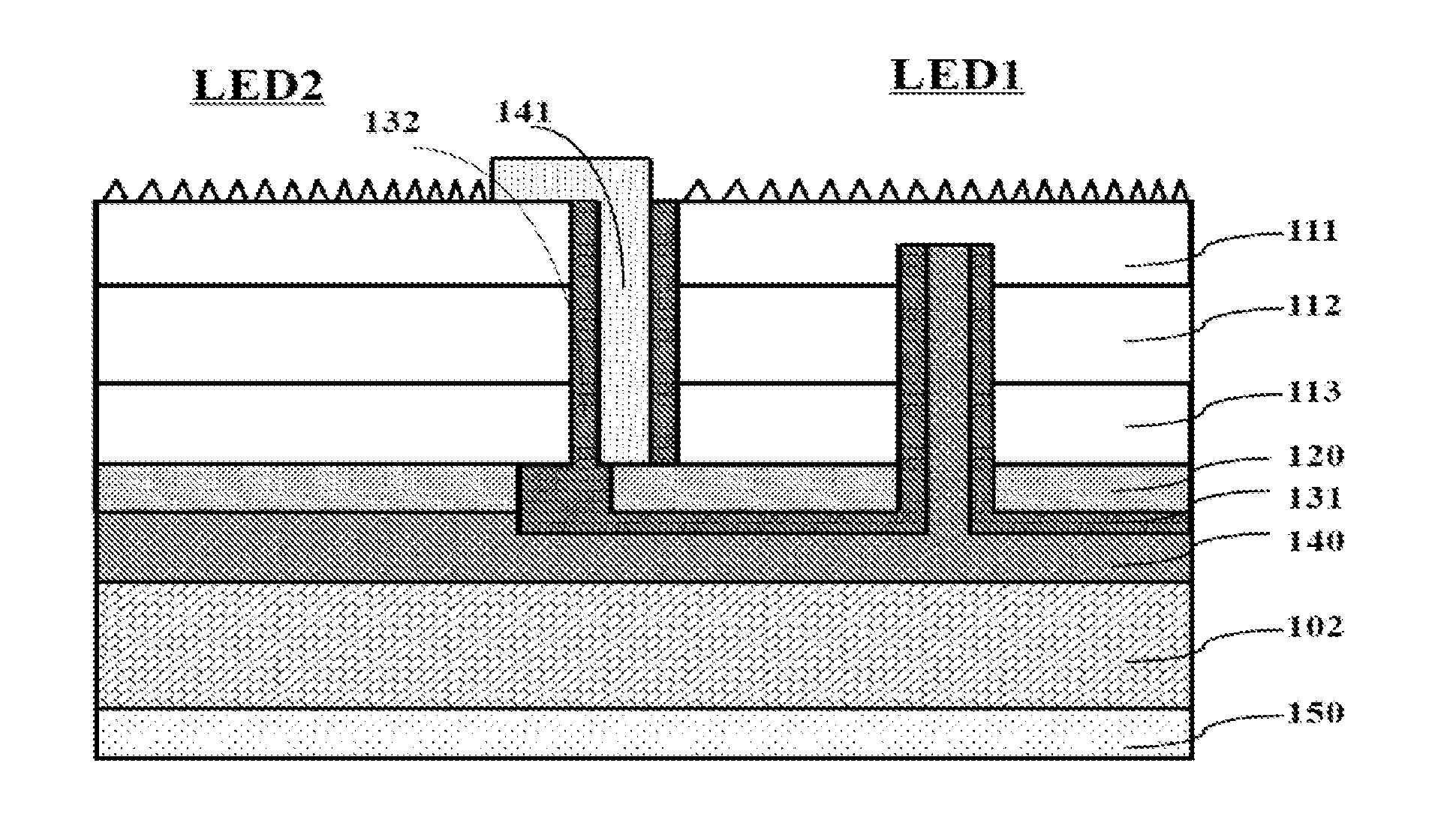

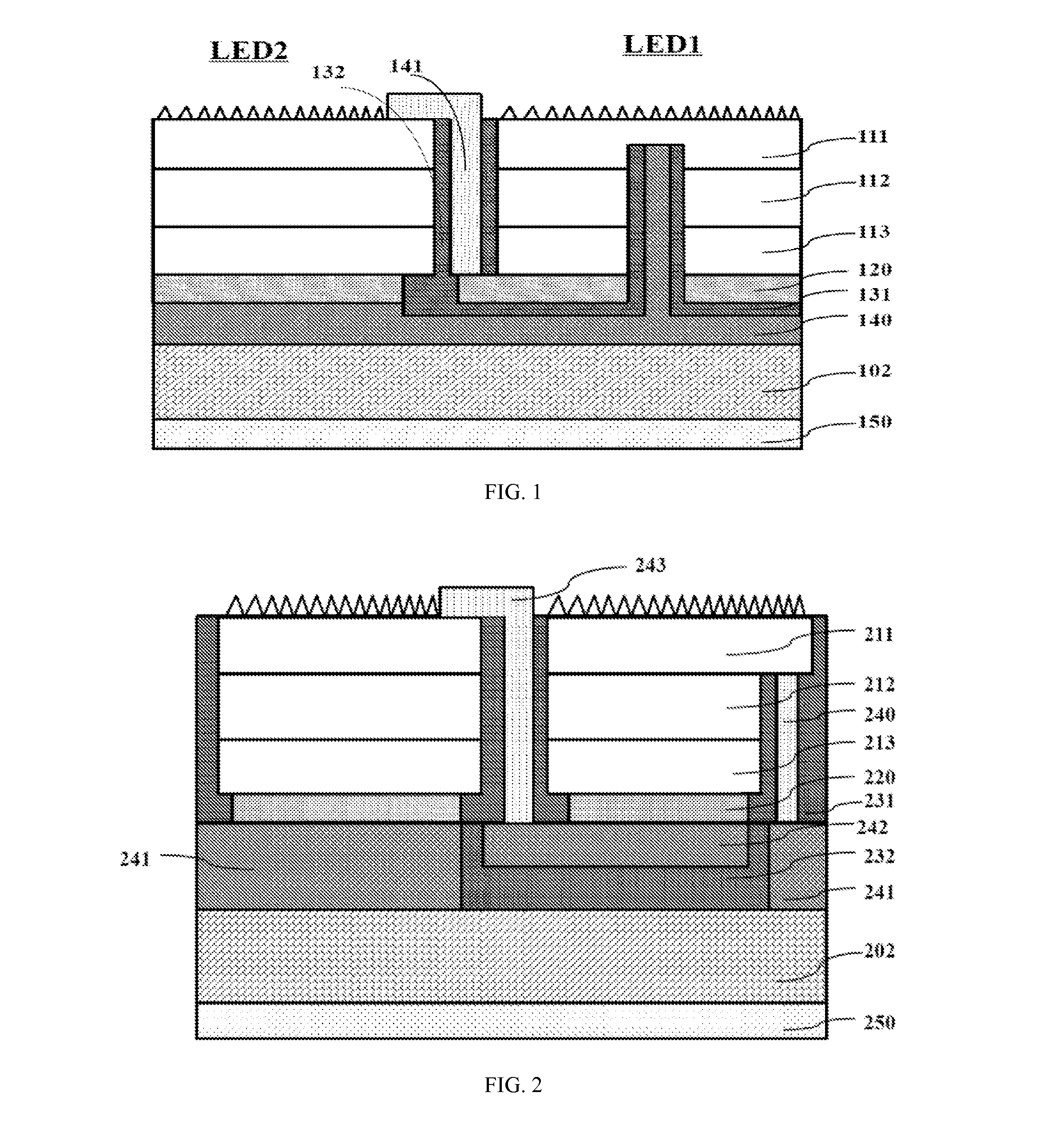

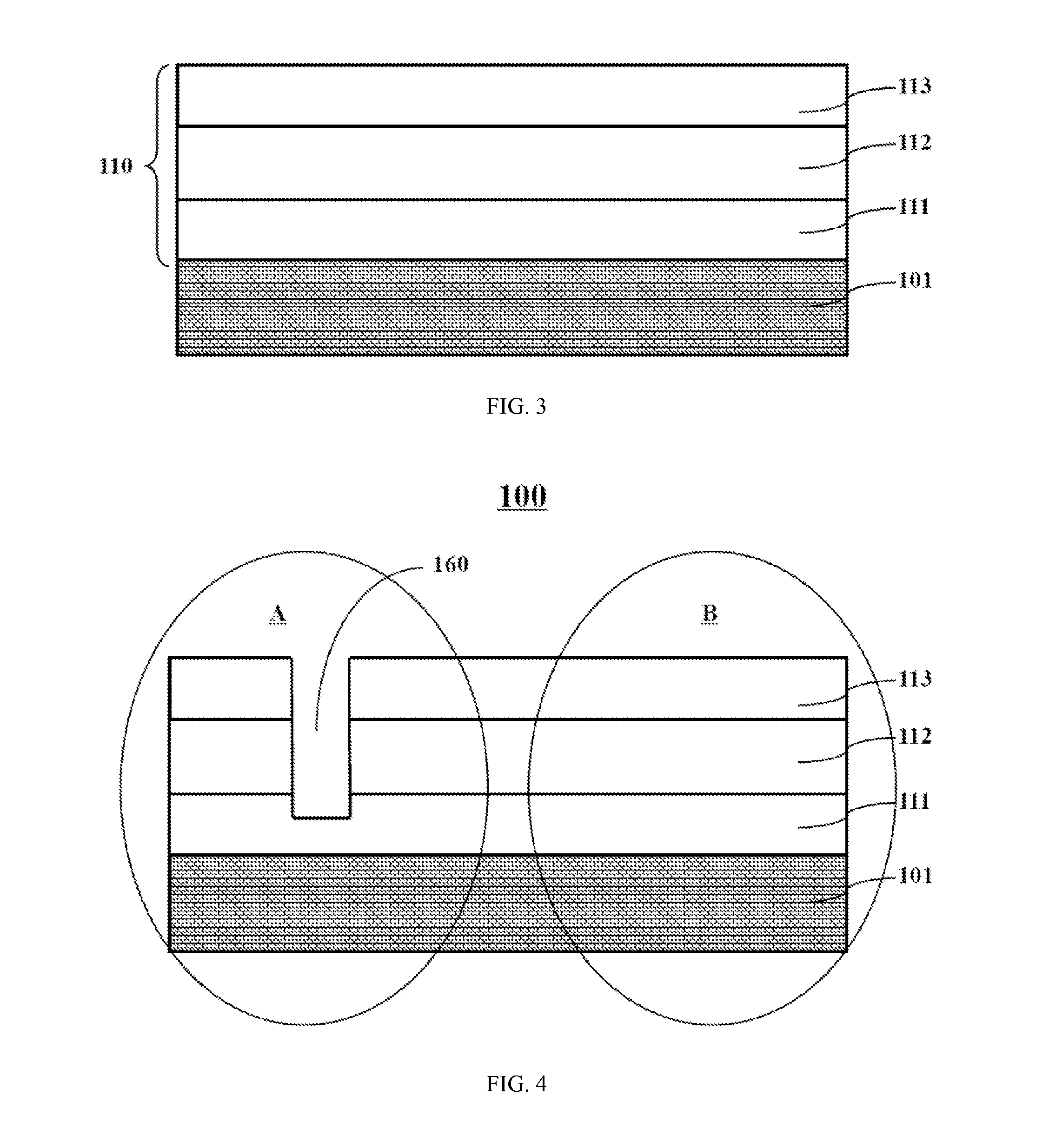

Vertical Type AC-LED Device and Manufacturing Method Thereof

ActiveUS20150144974A1Improve cooling effectImprove overload capacitySolid-state devicesSemiconductor/solid-state device manufacturingOhmic contactSemiconductor package

The present invention discloses a vertical AC LED element and fabrication method thereof, wherein the vertical AC LED element comprises a conductive substrate (102); a light-emitting module on the conductive substrate (102), including two horizontally arranged in parallel and mutually-isolated LEDs; wherein the first and second LEDs include a first semiconductor layer (111), a light-emitting layer (112) and a second semiconductor layer (113) from top down; a first insulating layer (131) is arranged between the second semiconductor layer (113) of the first LED and the conductive substrate (102) for mutual isolation; an ohmic contact is formed between the second semiconductor layer (113) of the second LED and the conductive substrate (102); a first conductive structure that connects the first semiconductor layer (111) of the first LED, the second semiconductor layer (113) of the second LED and the conductive substrate (102); and a second conductive structure that connects the second semiconductor layer (113) of the first LED and the first semiconductor layer (111) of the second LED.

Owner:QUANZHOU SANAN SEMICON TECH CO LTD

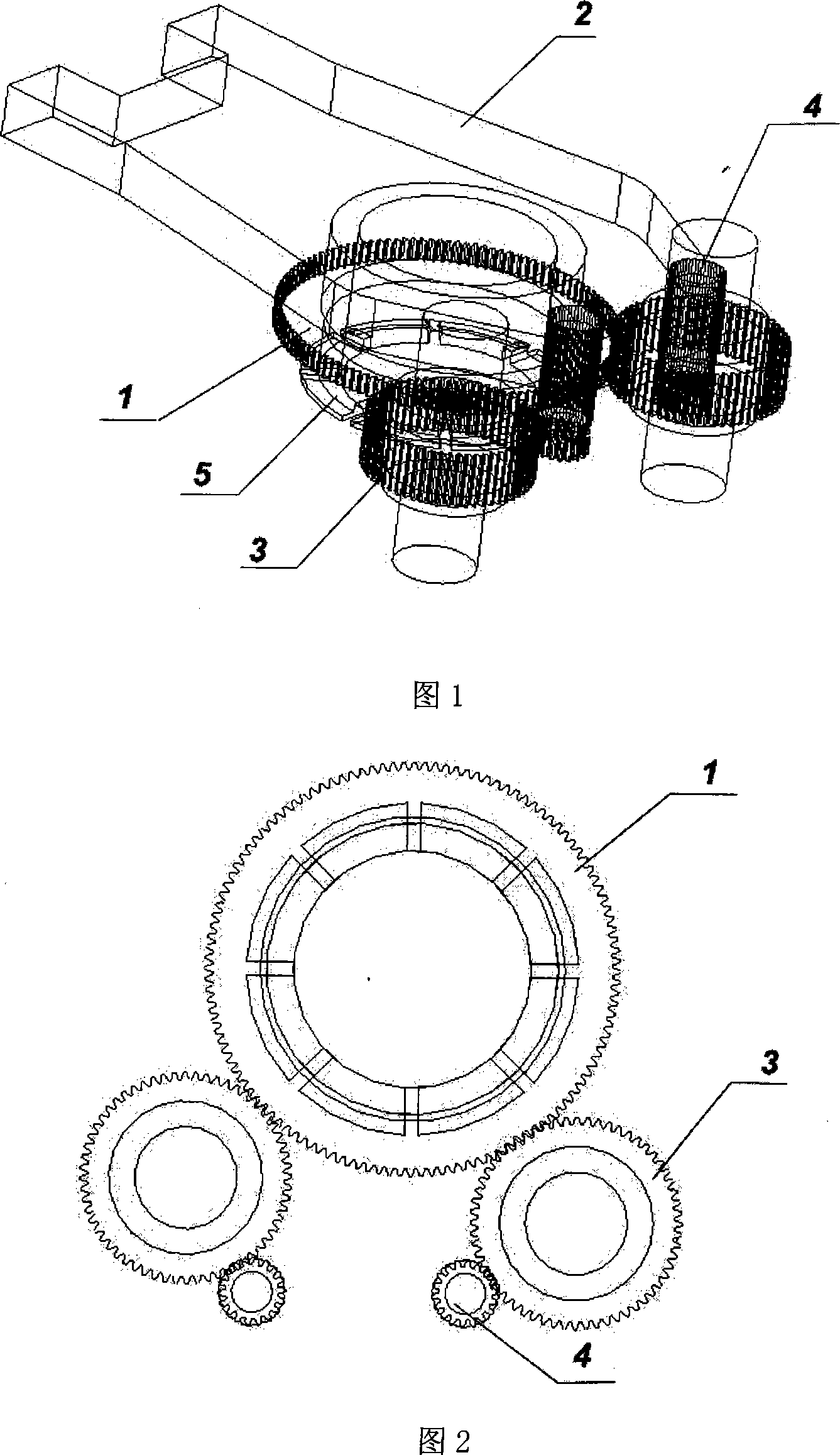

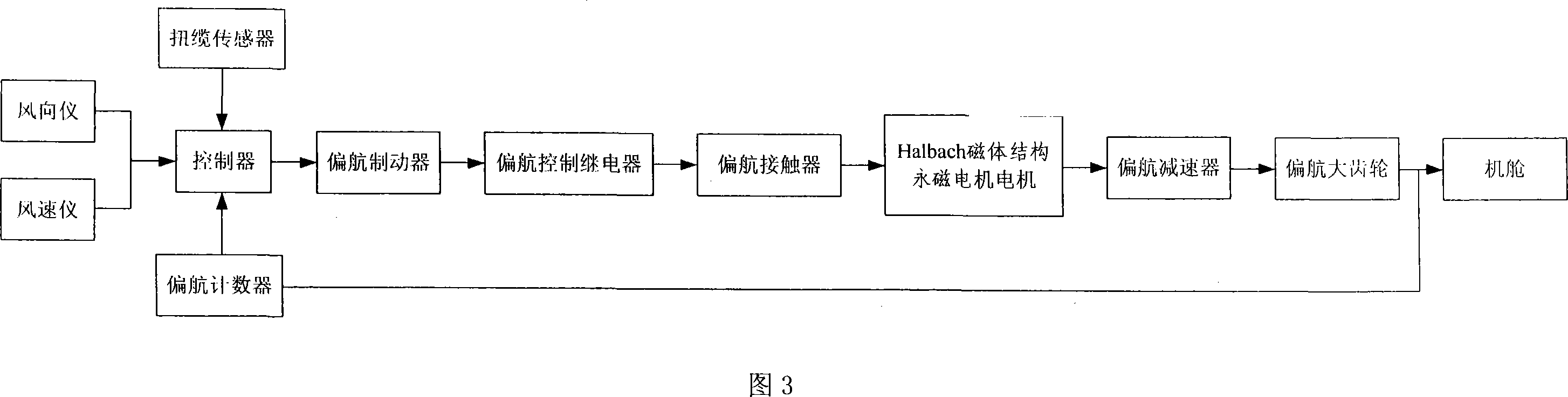

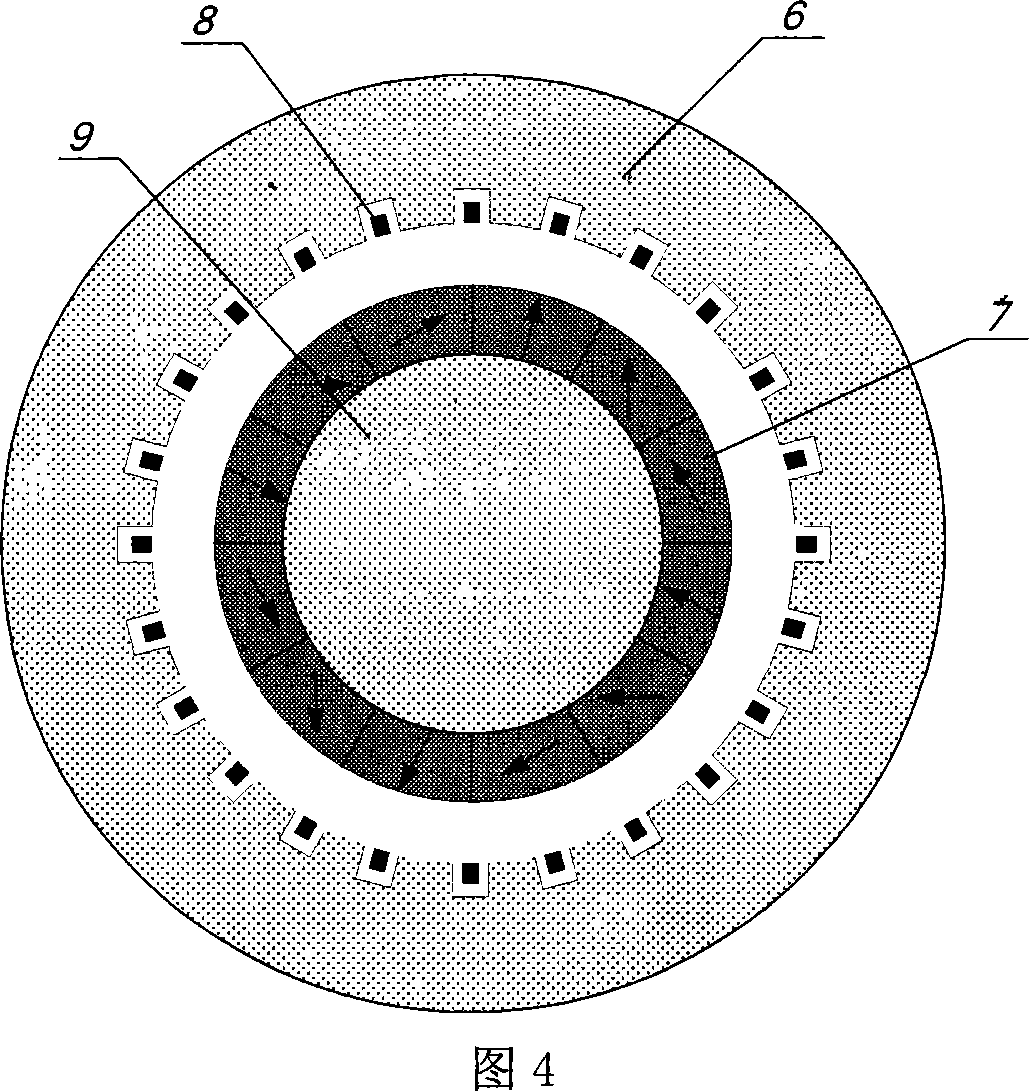

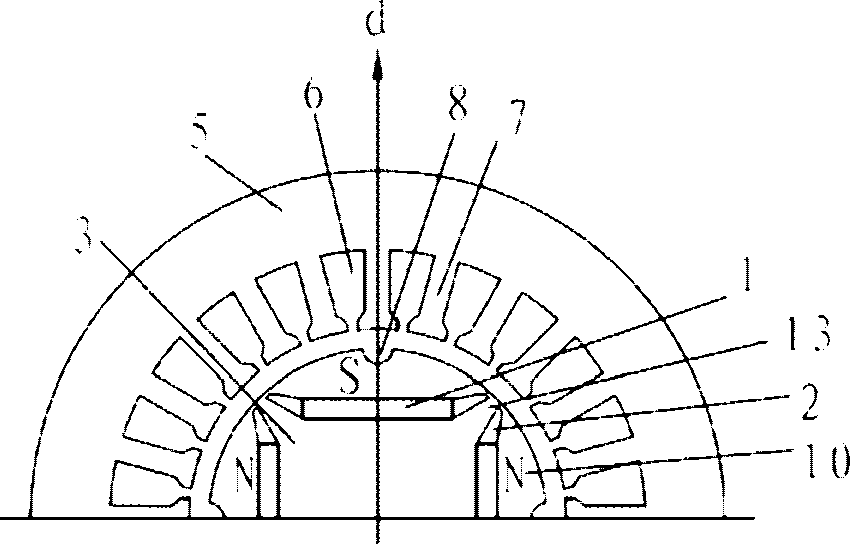

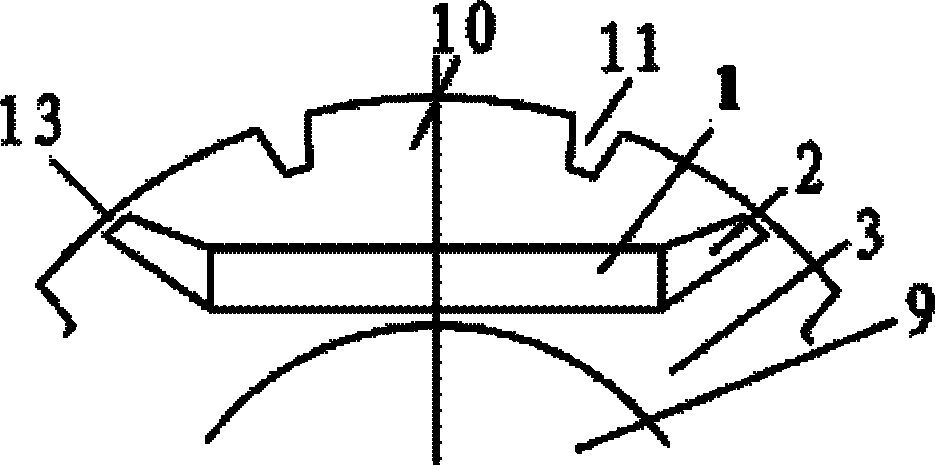

Wind generating set yaw device

InactiveCN101117945AImprove starting performanceImprove overload capacityWind motor controlMachines/enginesReduction driveYaw control

The present invention belongs to the technique field of wind power generation, and relates to a yawing device of an aerogenerator, which consists of a controller, a yawing arrester, a yawing pilot relay, a yawing contactor, a yawing electric motor, a yawing retarder, a yawing outer rotor, a yawing counter, a cable sensor, a dogvane, and an anemoscope. The electric motor is connected with the yawing retarder which is joggled with a big yawing rotor. The controller controls the yawing arrester according to the input signal of the dogvane or the anemoscope, and the operation of the yawing electric motor by the yawing pilot relay and the yawing contactor. The yawing electric motor drives the big yawing rotor by the yawing retarder. The electric motor is a magnetoelectric machine with the structure of Halbach magnet. The present invention can improve the starting performance of the yawing device and cause the yawing device to drive the main flight crew compartment to rotate easier under the work situation of frequent starts and stops; at the same time, the over loading capability of the yawing electric motor is improved and the malfunction rate of the yawing device is decreased to maintain the workload, and the operation life of the yawing electric motor is prolonged.

Owner:TIANJIN UNIV

Built-in permanent-magnetic motor rotor and motor comprising same

InactiveCN102355071AReduce noiseImproved air gap magnetic field waveformMagnetic circuit rotating partsSynchronous machinesWave shapeControl theory

The invention discloses a built-in permanent-magnetic motor rotor, which comprises a rotating shaft and a rotor iron core, wherein the rotor iron core comprises a pole shoe, at least one permanent magnet body is arranged inside the pole shoe, and the outer circle of the pole shoe is provided with a plurality of grooves. The invention also discloses a motor, which comprises a stator and the rotor. Due to the adoption of the built-in permanent-magnetic motor rotor, the waveform of an air gap field of the motor can be improved, fundamental wave times of the cogging torque fluctuation can be increased, the cogging fundamental wave and the ultra-harmonics torque amplitude can be reduced, and the torque fluctuation caused by the cogging can be reduced.

Owner:苏州和鑫电气股份有限公司

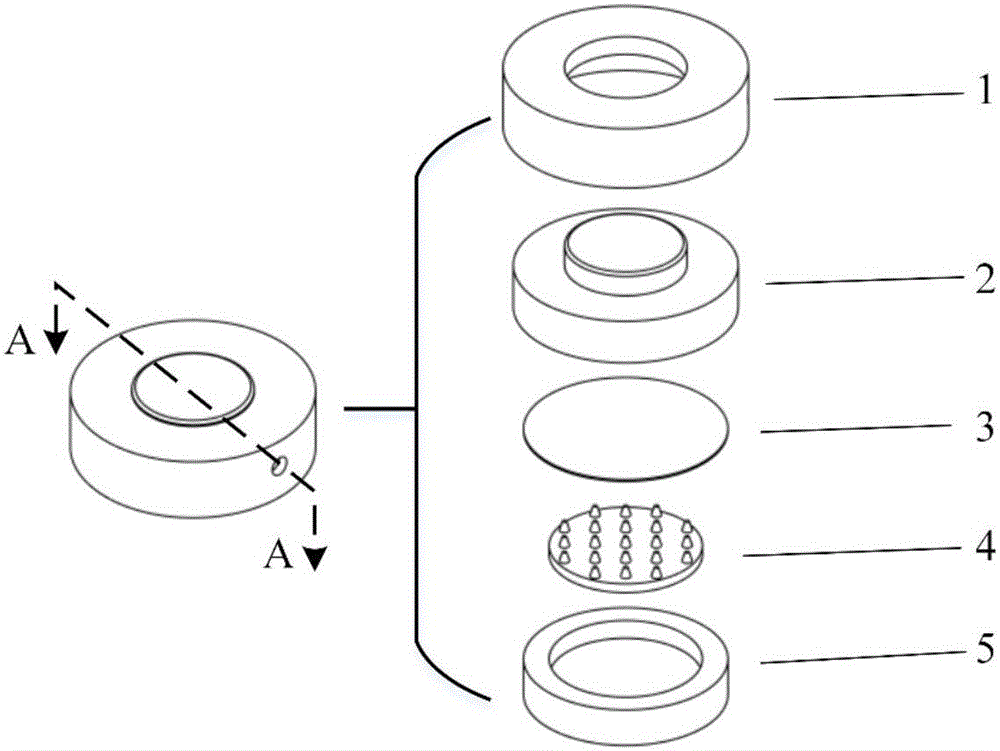

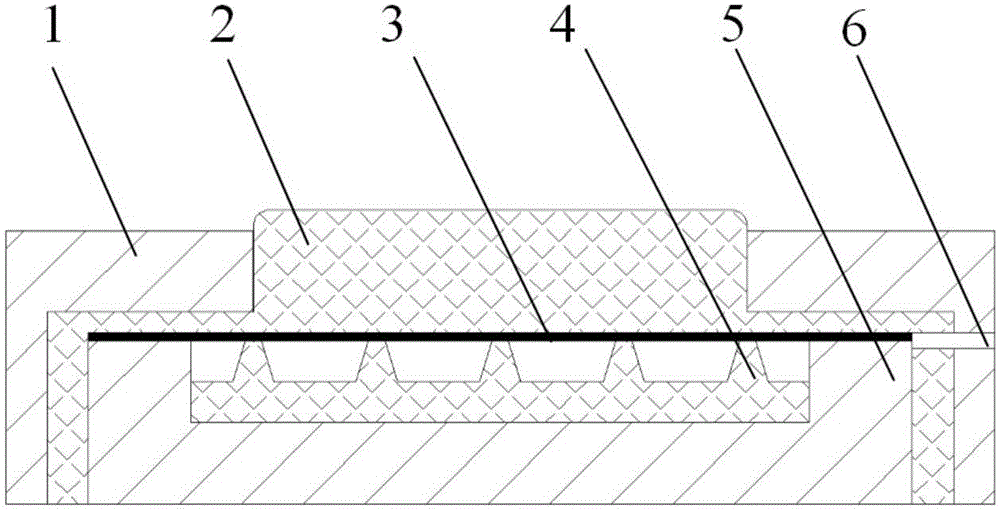

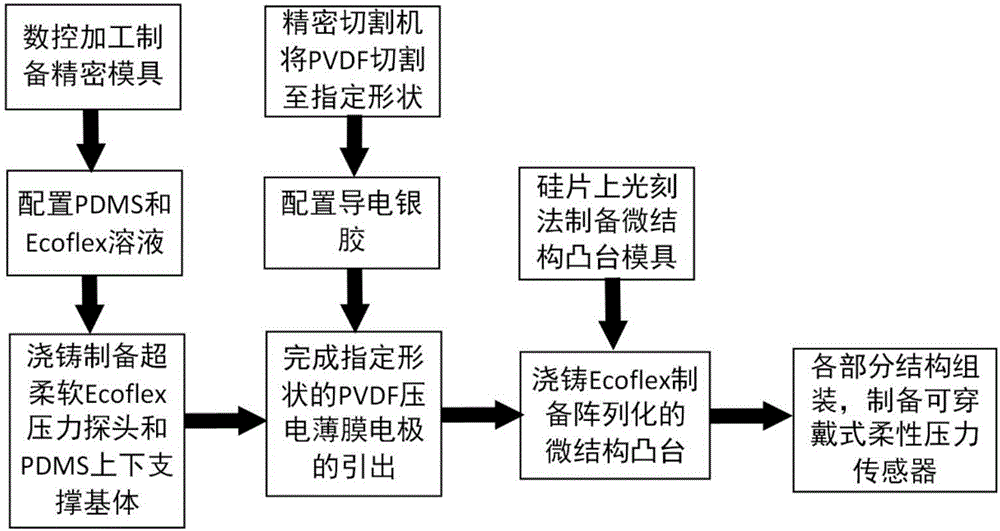

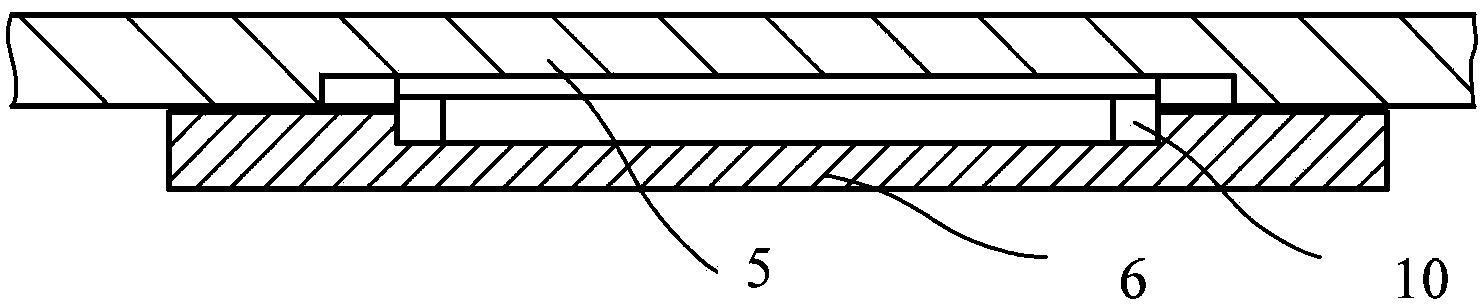

Wearing type flexible pressure sensor and preparing method thereof

ActiveCN106805954AExtended service lifeImprove overload capacityEvaluation of blood vesselsAngiographyElectricityEngineering

The invention belongs to the technical field of flexible electron sensors, and particularly relates to a wearing type flexible pressure sensor and a preparing method thereof. The wearing type flexible pressure sensor comprises five parts of an upper support substrate, a super soft Ecoflex pressure detection head, PVDF piezoelectric thin film, an array form micro boss support structure and a lower support substrate. The super flexible Ecoflex pressure detection head can sense pressure to deform, and further compress the PVDF piezoelectric thin film to output an electric signal. The invention further discloses the preparing method of the wearing type flexible pressure sensor. The super soft Ecoflex pressure detection head can very sensitively sense weak pulse visual skipping of a human body, and solve the problems that wearable intelligent equipment cannot measure a pressure signal and is not flexible. The wearing type flexible pressure sensor further has the advantages of being small and exquisite in size, comfortable to wear, long in service life, low in preparation cost and the like, and being suitable for being used in large-scale production.

Owner:HUAZHONG UNIV OF SCI & TECH

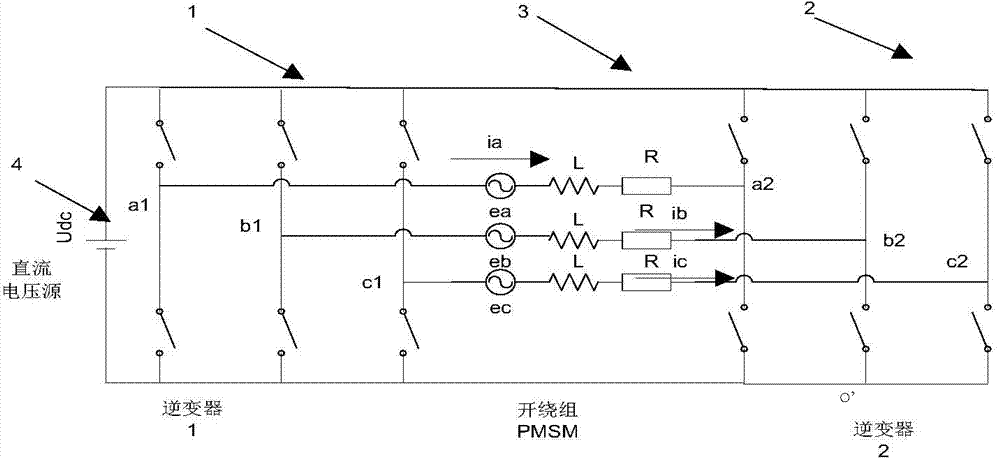

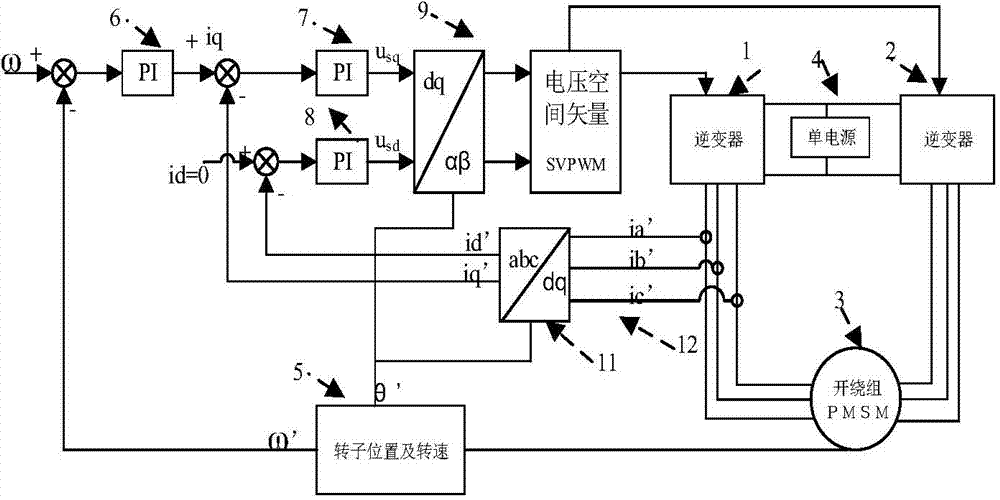

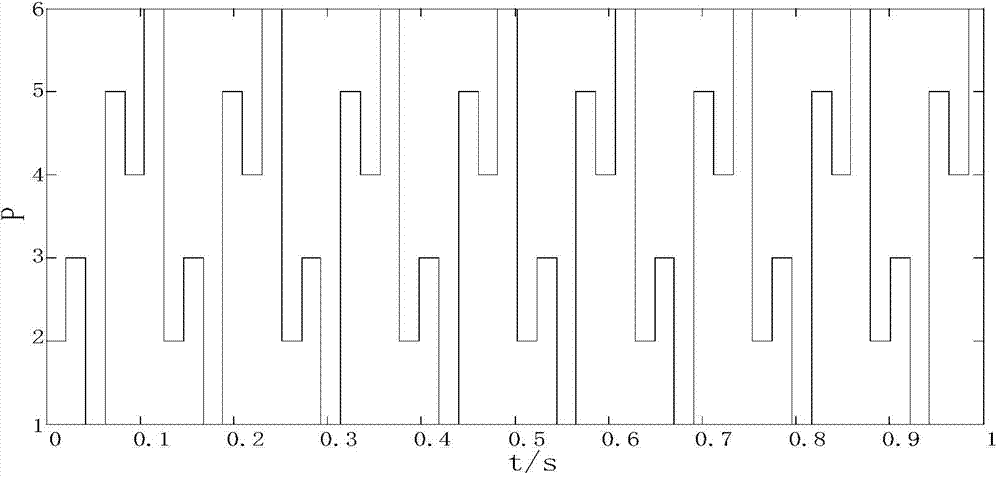

Electromobile driving system vector control method using double inverters

InactiveCN104753430AEasy to controlEliminate common mode voltageElectronic commutation motor controlVector control systemsStator voltageSynchronous motor

The invention discloses an electromobile driving system vector control method using double inverters. The electromobile driving system vector control method includes the following steps: collecting three-phase stator current, rotor position and rotating speed in an unwinding permanent magnetic synchronous motor, wherein the three-phase current is subjected to 3S / 2R conversion to acquire current under a two-phase rotating coordinate system. A system adopts the vector control method with id equal to 0, a stator voltage instruction under the two-phase rotating coordinate system is acquired through double closed-ring control of a rotating speed outer ring and a current inner ring, stator voltage under the two-phase static coordinate system is acquired through 2R / 2S coordinate conversion, control pulse of the double inverters is acquired through a single-power-source double-inverter SVPWM (space vector pulse width modulation) module, and switch devices of the double inverters are triggered to realize vector control of double-inverter SVPWM of the unwinding permanent magnetic synchronous motor. The electromobile driving system vector control method has the advantages that the unwinding permanent magnetic synchronous motor is quick to start, high in overload capability and good in speed adjusting performance; due to the single-power-source double-inverter SVPWM, voltage level of the system is increased, and safety and reliability of the system are guaranteed.

Owner:SOUTHEAST UNIV

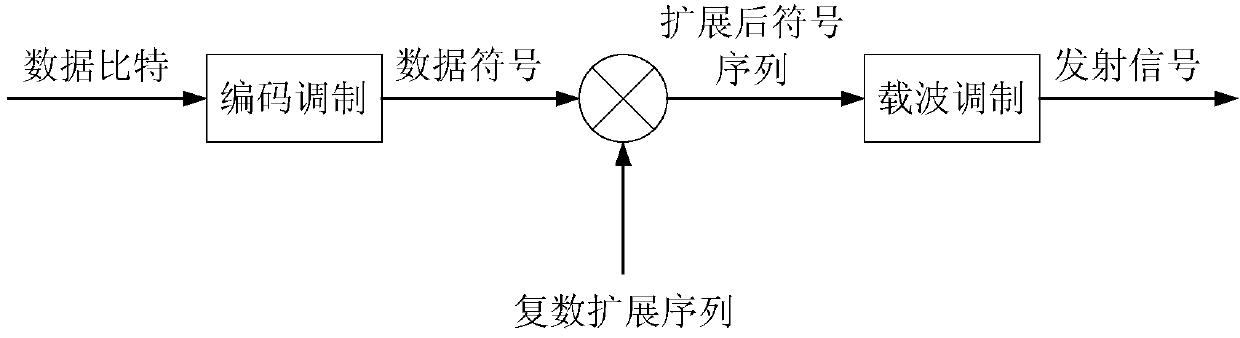

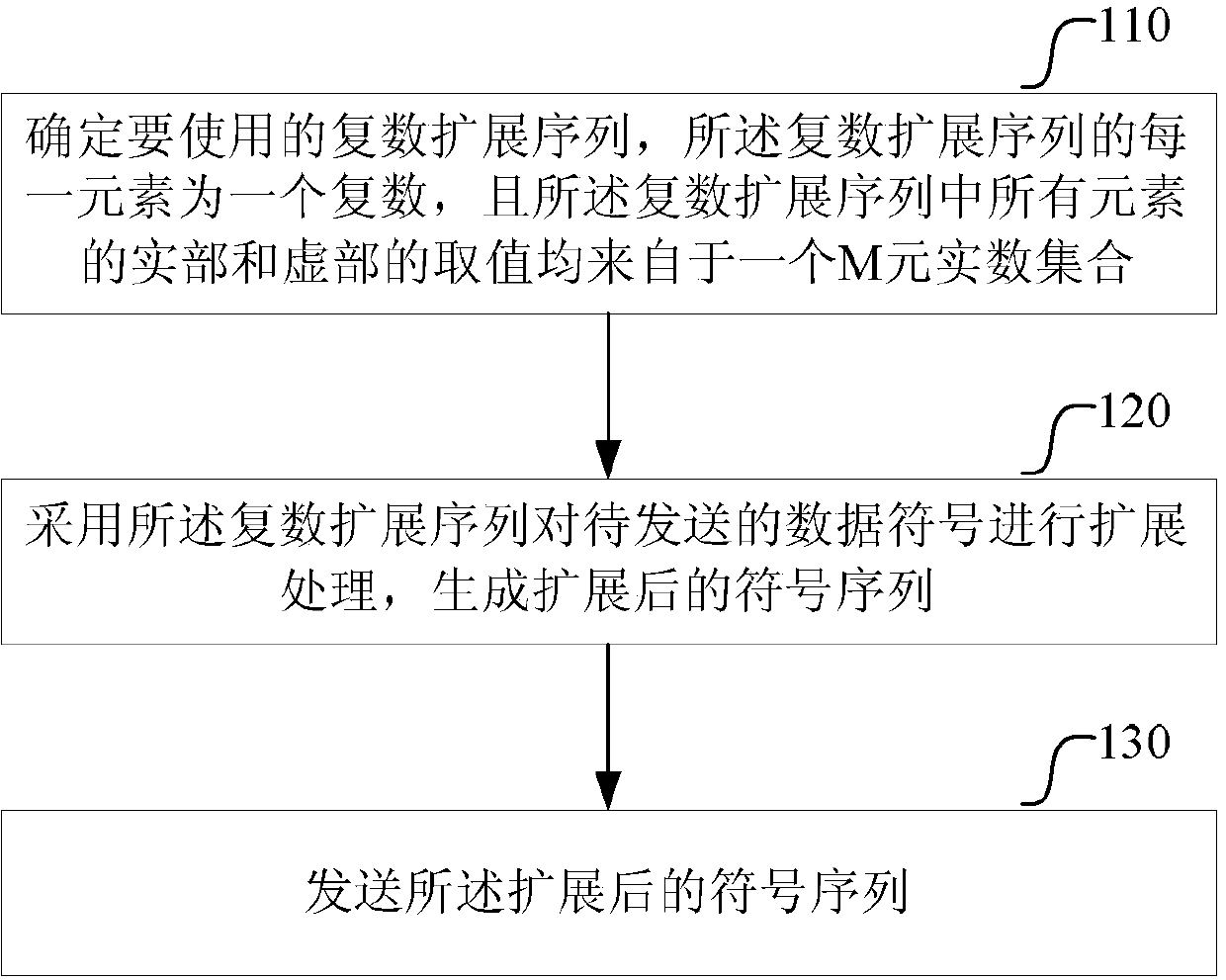

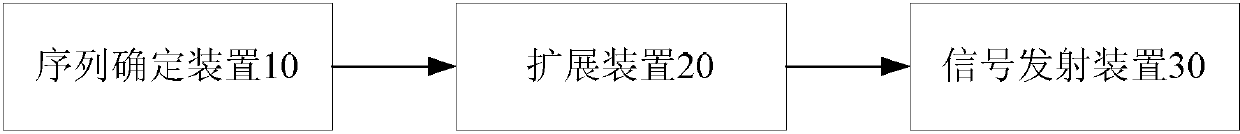

Multi-user CDMA (Code Division Multiple Access) communication method and corresponding transmitter and receiver

ActiveCN105515713AImprove communication experienceEasy to chooseMultiplex code generationMulti-frequency code systemsVIT signalsInterference elimination

The invention comprises a multi-user CDMA communication method, a corresponding transmitter and a corresponding receiver. The communication method comprises that the transmitter determines a complex number expansion sequence, each element of the complex number expansion sequence is a complex number, values of the rear part and the imaginary part of all the elements in the complex number expansion sequence are all from an M-element real number set, and M represents an integer greater than or equivalent to 2; data symbols to be sent are expanded by utilizing the complex number expansion sequence to generate an expanded symbol sequence; and the expanded symbol sequence is sent. The receiver receives signals from multiple transmitters, an interference elimination signal detector is used for reception and detection, and the complex number expansion sequences used by the transmitters are used during detection. The multi-user CDMA performance can be improved.

Owner:ZTE CORP

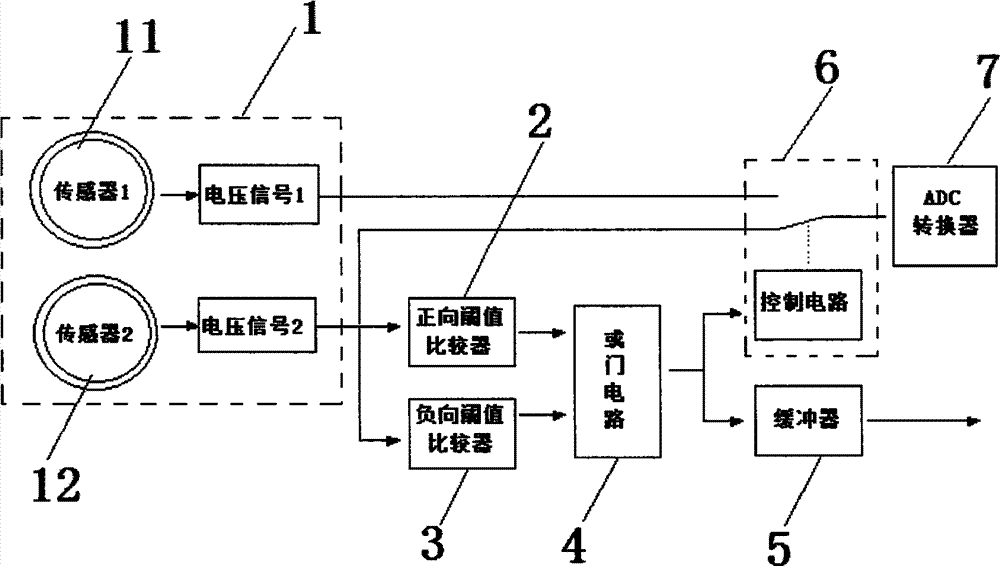

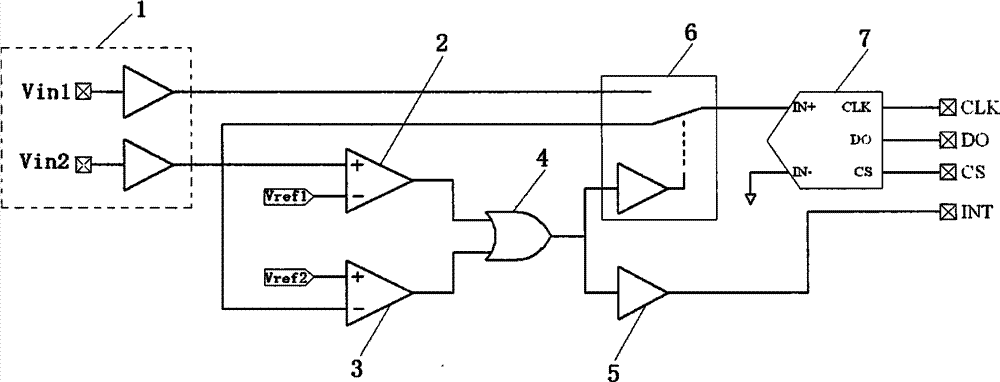

High-precision current sensor detecting circuit and detecting method thereof

ActiveCN104237623AIncrease reflectionImprove responsivenessMeasurement using digital techniquesCurrent sensorOpen contact

The invention provides a high-precision current sensor detecting circuit which comprises a combined magnetoelectricity conversion unit, a positive threshold comparator, a negative threshold comparator, an OR gate circuit, an output buffer, an analog switch and an ADC (analog-to-digital converter). The combined magnetoelectricity conversion unit comprises a large-range first current sensor and a small-range second current sensor. The output end of the first current sensor is connected to the input end of the ADC through the normally open contact of the analog switch. The output end of the second current sensor is connected to the input end of the ADC through the normally closed contact of the analog switch. The output end of the ADC is connected with the input end of a post-stage circuit. The invention further provides a detecting method of the high-precision current sensor detecting circuit. The high-precision current sensor detecting circuit is wide in measuring range, fast in response, high in measuring precision, good in linearity and dynamic performance, wide in working band, high in reliability, high in overload capacity, and the like.

Owner:武汉弈飞科技有限公司

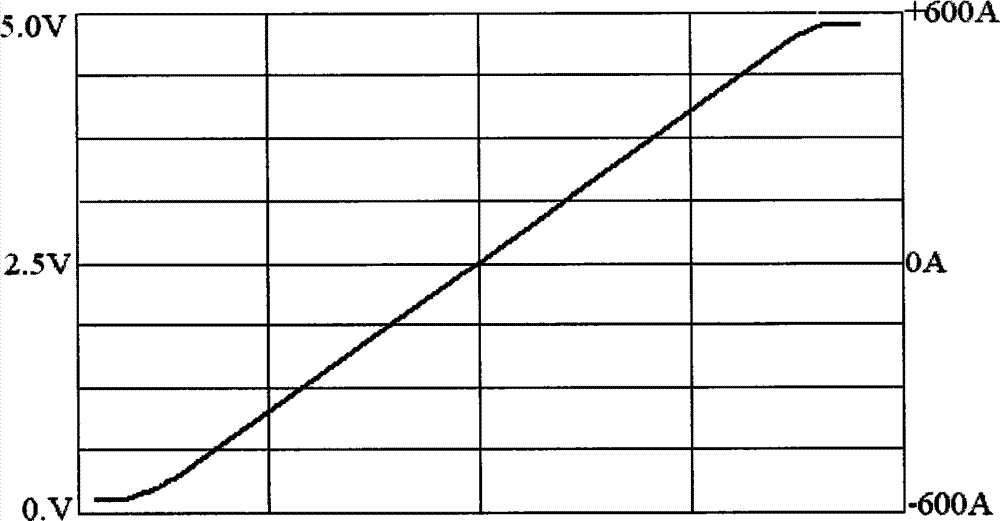

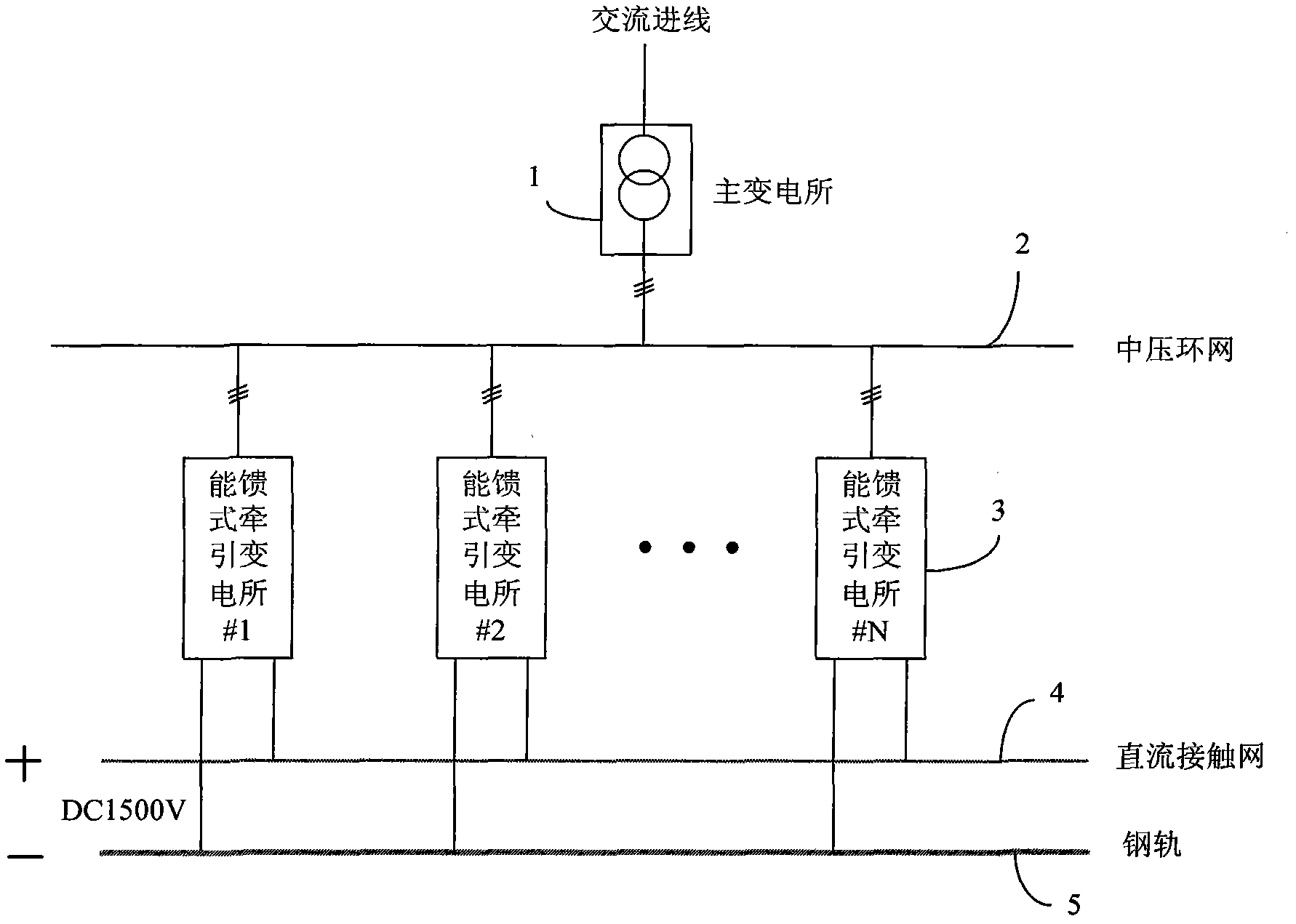

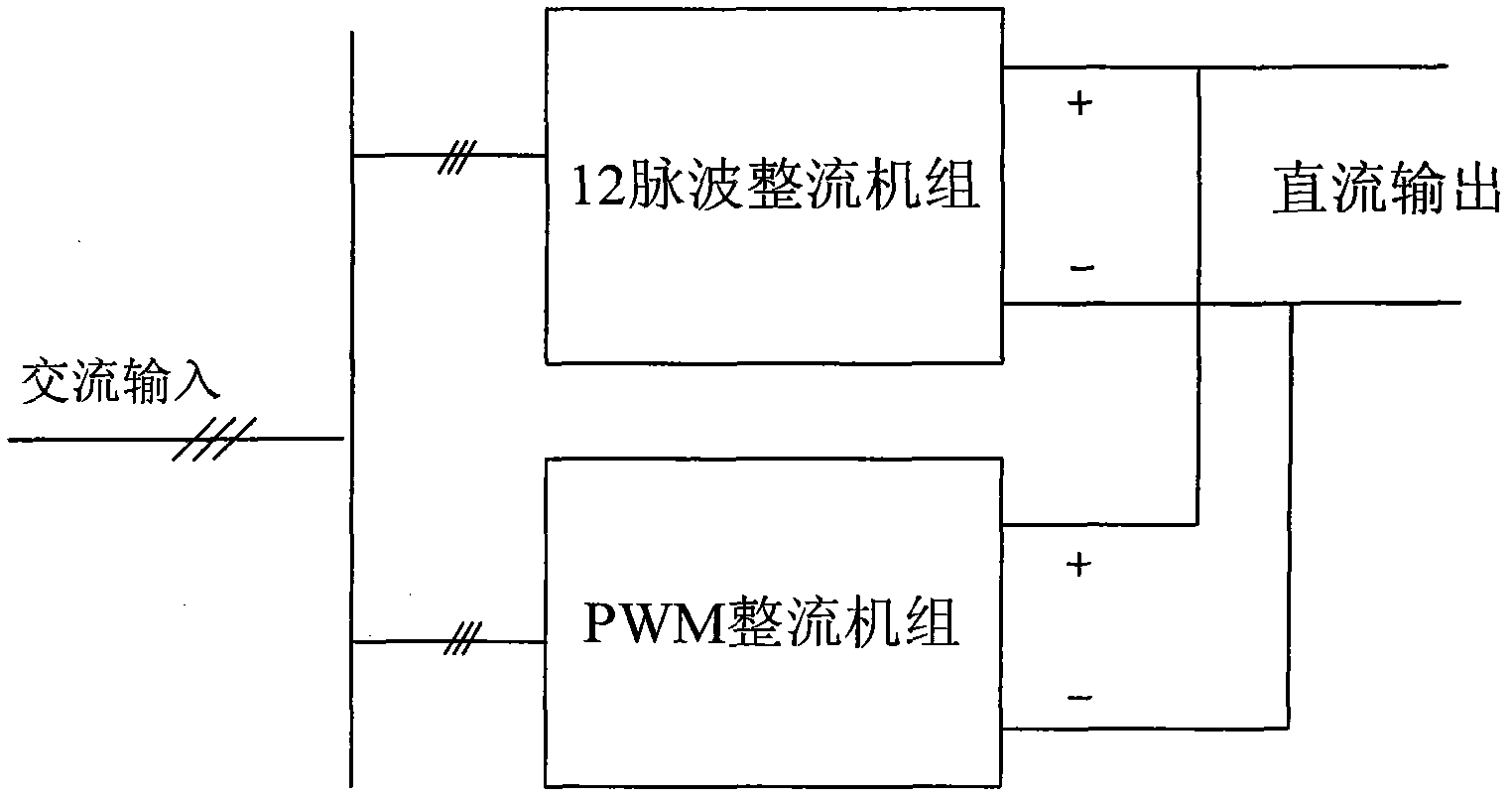

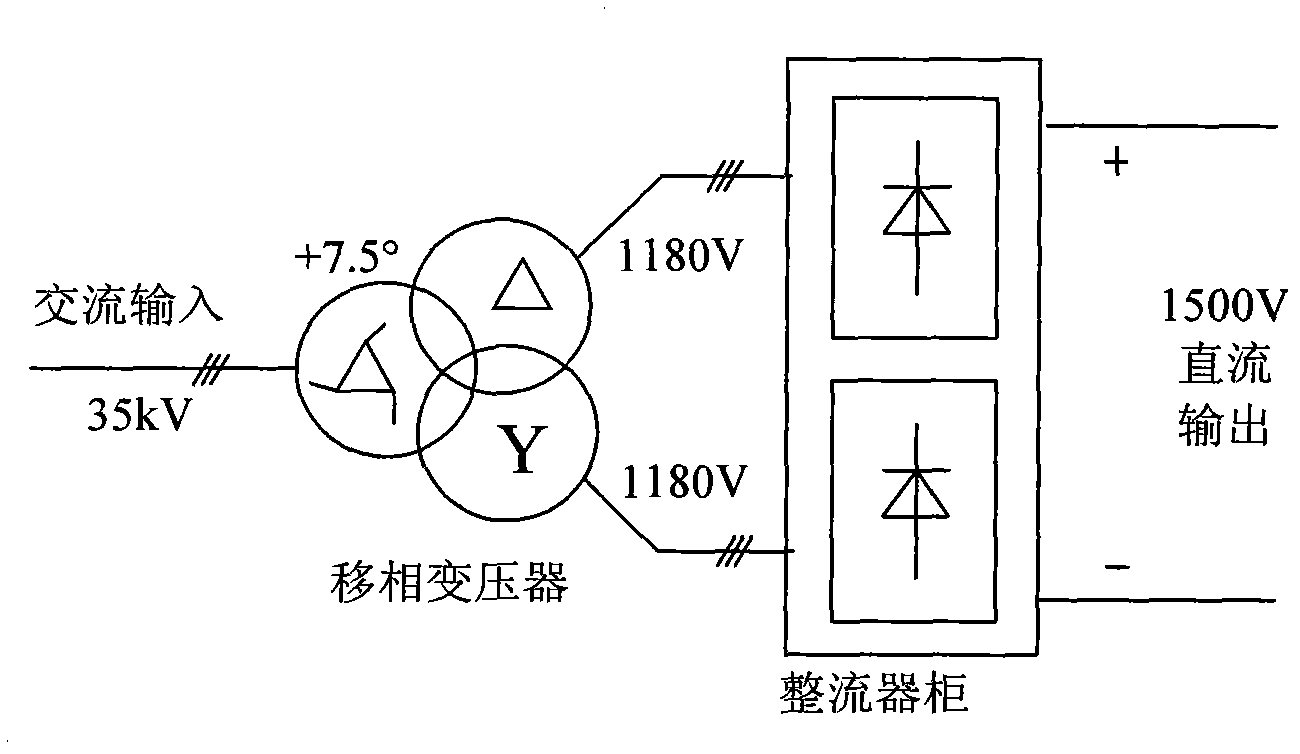

Energy-feedback tractive power supply system with high power factor and high cost performance

InactiveCN102328601AAchieving two-way flowSave electricityPower supply linesSingle network parallel feeding arrangementsContact networkRing network

The invention discloses an energy-feedback tractive power supply system with high power factor and high cost performance, relating to an energy-feedback tractive power supply system. The system comprises a main substation, a medium-voltage ring network, a first to an Nth energy-feedback tractive substations, a direct-current contact network and a steel rail. In the energy-feedback tractive substations, a set of 12-pulse-wave rectifier unit and a set of PWM (Pulse Width Modulation) unit are connected in parallel; by sufficiently utilizing respective advantages of the rectifier unit and the PWM unit, bidirectional flow of energy is realized on the one hand, braking energy of a train is fed back to an alternating-current grid, and electric energy is saved; on the other hand, the energy-feedback tractive power supply system integrates the advantages of simpleness and reliability, low cost and strong overload capability of a diode rectifier unit; beside, certain sensitive and capacitive reactive power is injected into the medium-voltage ring network by utilizing the PWM rectifier unit, and the power factor at the alternating-current incoming line of the main substation can be greatly increased. The whole tractive power supply system has higher cost performance.

Owner:BEIJING QIANSIYU ELECTRIC +1

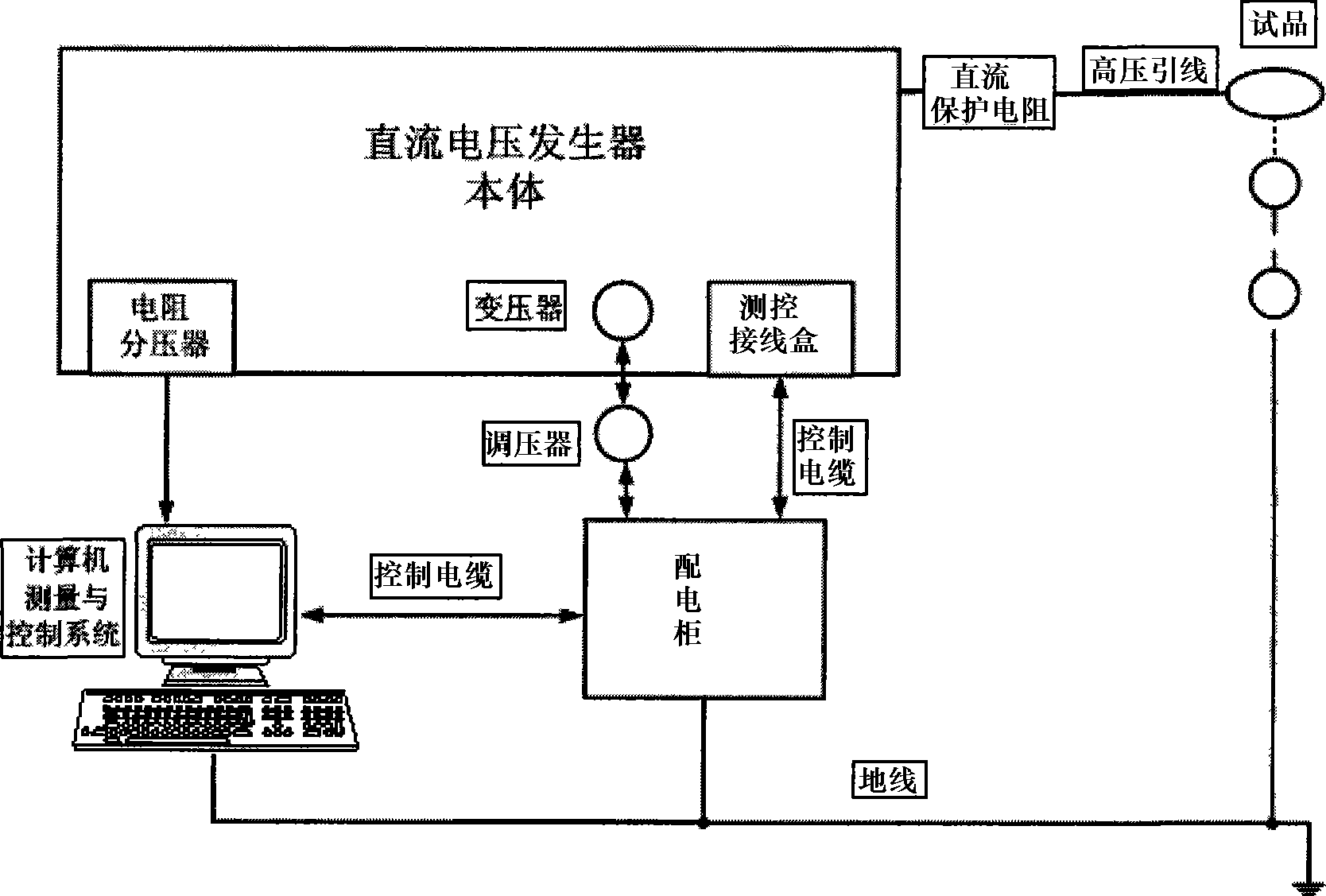

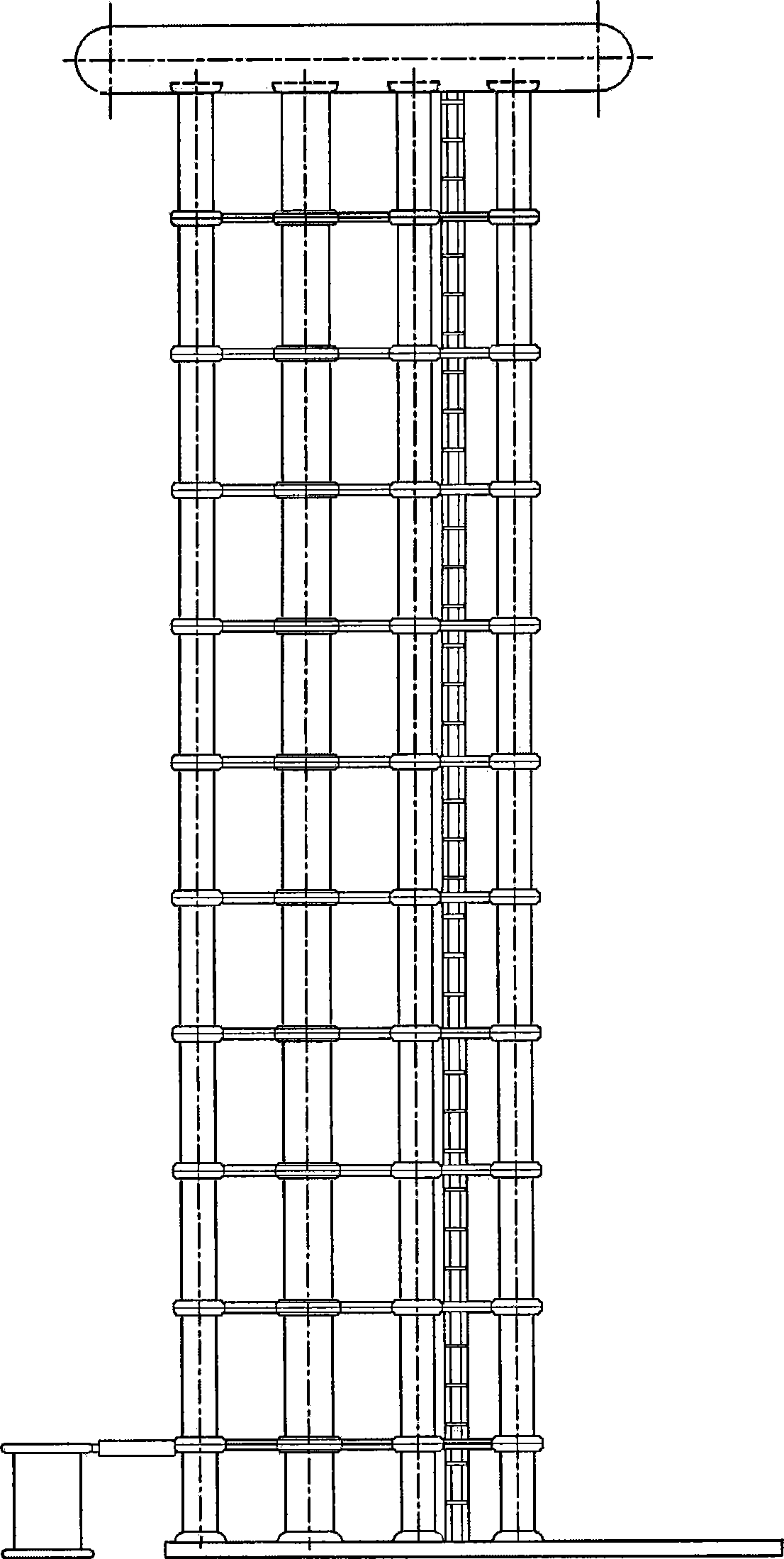

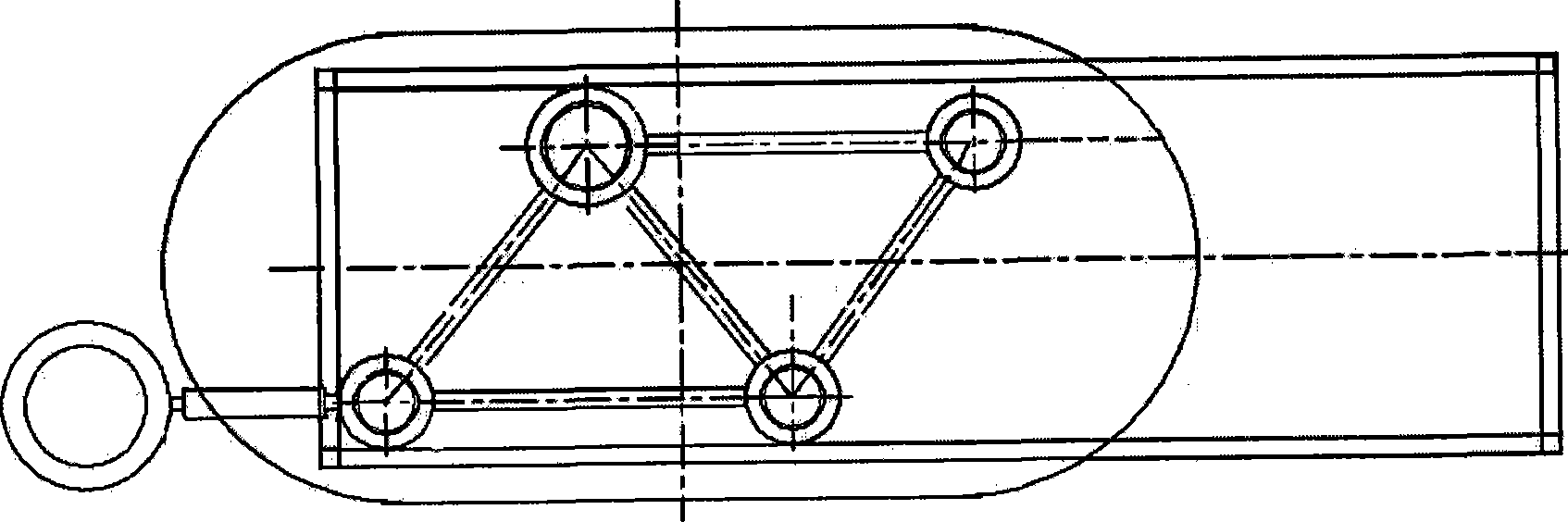

1600kv/50ma outdoor moving DC voltage generator

ActiveCN101425758AImprove mechanical stabilityImprove overload capacityAc-dc conversion without reversalConversion without intermediate conversion to dcEngineeringDc voltage

The invention relates to a 1600kV / 50mA outdoor mobile direct current voltage generator which comprises a direct current voltage generator body, a charging voltage regulation device and a computer measuring and controlling system; the direct current voltage generator body adopts a five-stage voltage doubling rectifying circuit with symmetrical single sides, the complete set of the test units adopts a tower type combined structure and a container transportation method as well as the modular design. A direct-current voltage generator body module, the charging voltage regulation device, a computer measuring and controlling system operating platform are respectively provided with hoisting devices, and the hoisting devices can be moved on a transport vehicle; the invention utilizes the 50Hz power frequency power supply as the rectifier source to obtain the direct-current voltage, the quality of the direct-current power supply is good, the capacity is large, and the demands of experimental investigation of the extra-high voltage direct current transmission project can be met; and due to the adoption of the modular design, the rapid assembly and disassembly can be realized on site, and the polarity can be changed according to the complete set of the test units with required testing voltage.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID QINGHAI ELECTRIC POWER COMPANY +1

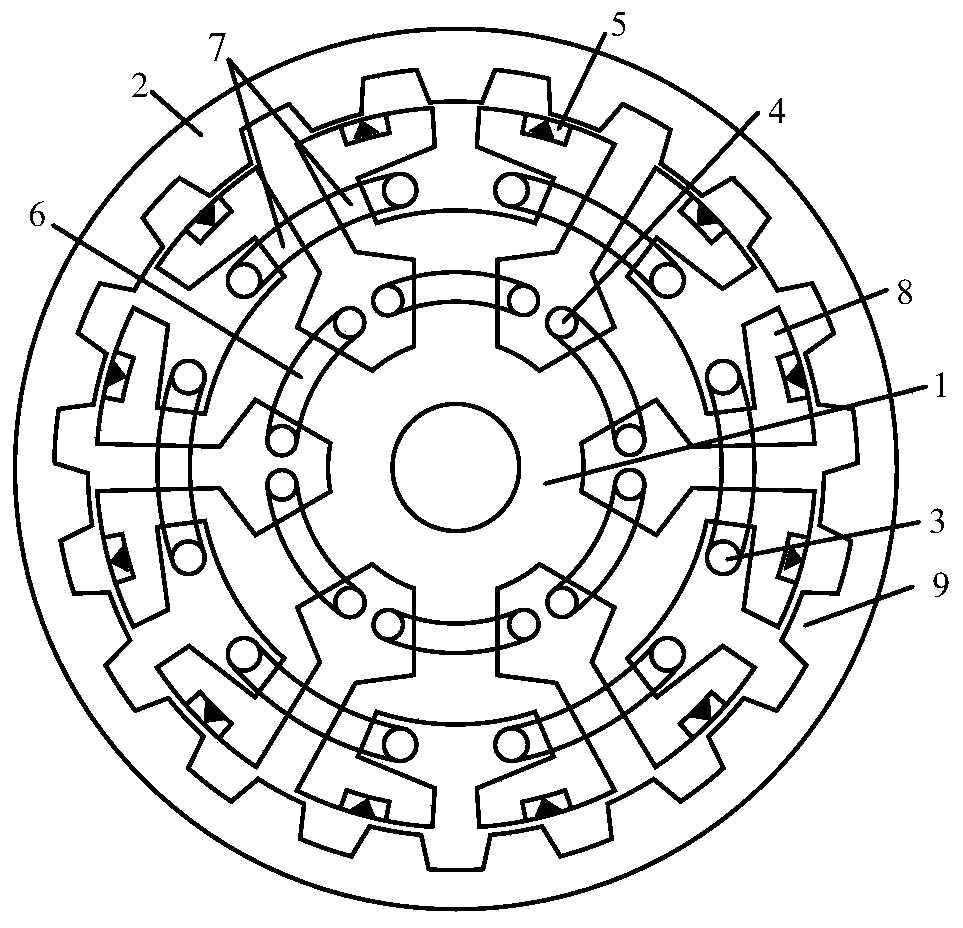

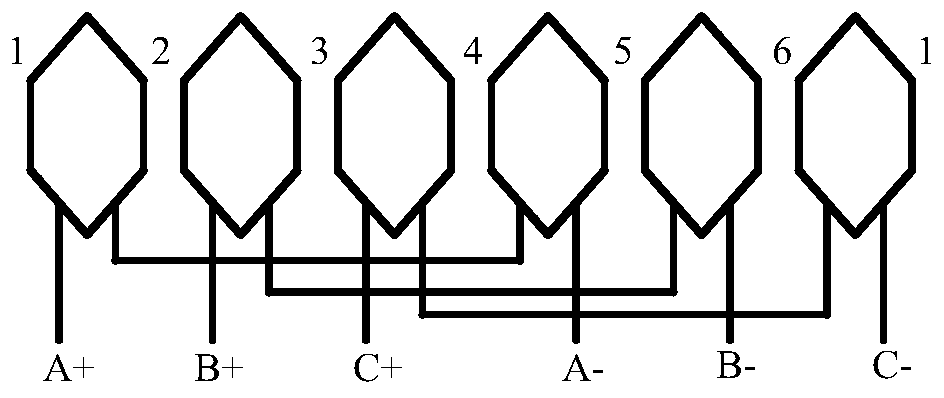

Magnetic field modulation hybrid excitation motor and multi-working-wave design method thereof

ActiveCN111509941AIncreased working air gap areaIncrease output torqueSynchronous machine detailsMagnetic circuit stationary partsMagnetoEngineering

The invention discloses a magnetic field modulation hybrid excitation motor and a multi-working-wave design method thereof. The motor comprises a stator and a rotor, wherein the stator comprises a stator iron core, two sets of windings and permanent magnets, the two sets of windings comprise an armature winding and an exciting winding, the stator iron core is designed as an open slot, one set of windings is distributed in the open slot of the stator iron core, and is wound on one stator tooth in a centralized manner, the outer surface of each stator tooth is provided with a groove, the other set of windings is placed in the groove of the stator tooth, each stator tooth is split into two modulation teeth through the groove, one permanent magnet is placed on each modulation tooth, the otherwinding is wound on two adjacent modulation teeth formed by splitting different stator teeth in a centralized mode, and the magnetizing direction of the permanent magnets is consistent with or opposite to the direction of a magnetic field formed by the excitation winding on the modulation teeth. According to the invention, the permanent magnet magnetomotive force and the excitation magnetomotive force are connected in parallel on the magnetic circuit and are independent from each other, so that the risk of irreversible demagnetization caused by the introduction of an excitation current permanent magnet is avoided, and the effective exertion of the magnetic regulation capability is ensured.

Owner:JIANGSU UNIV

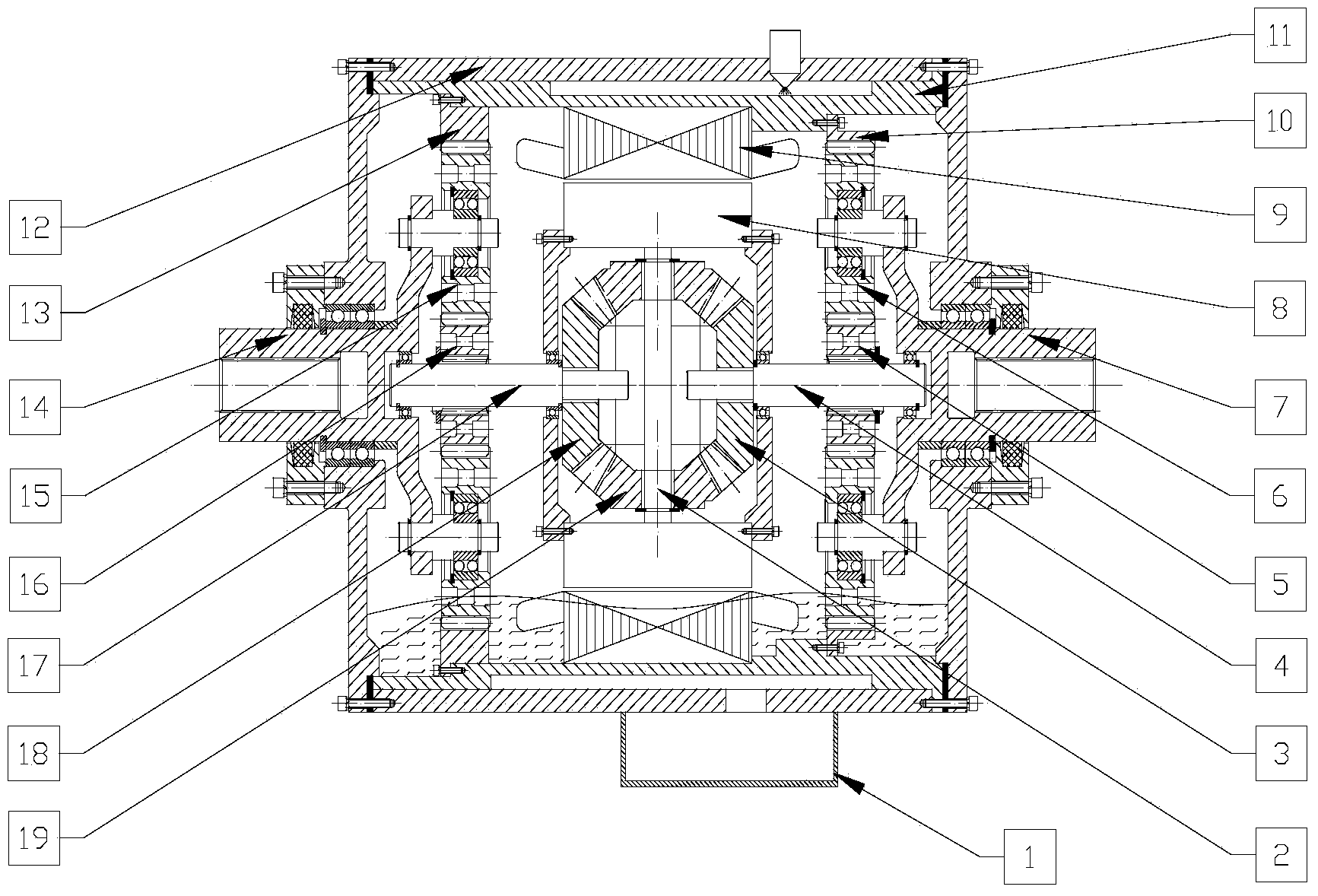

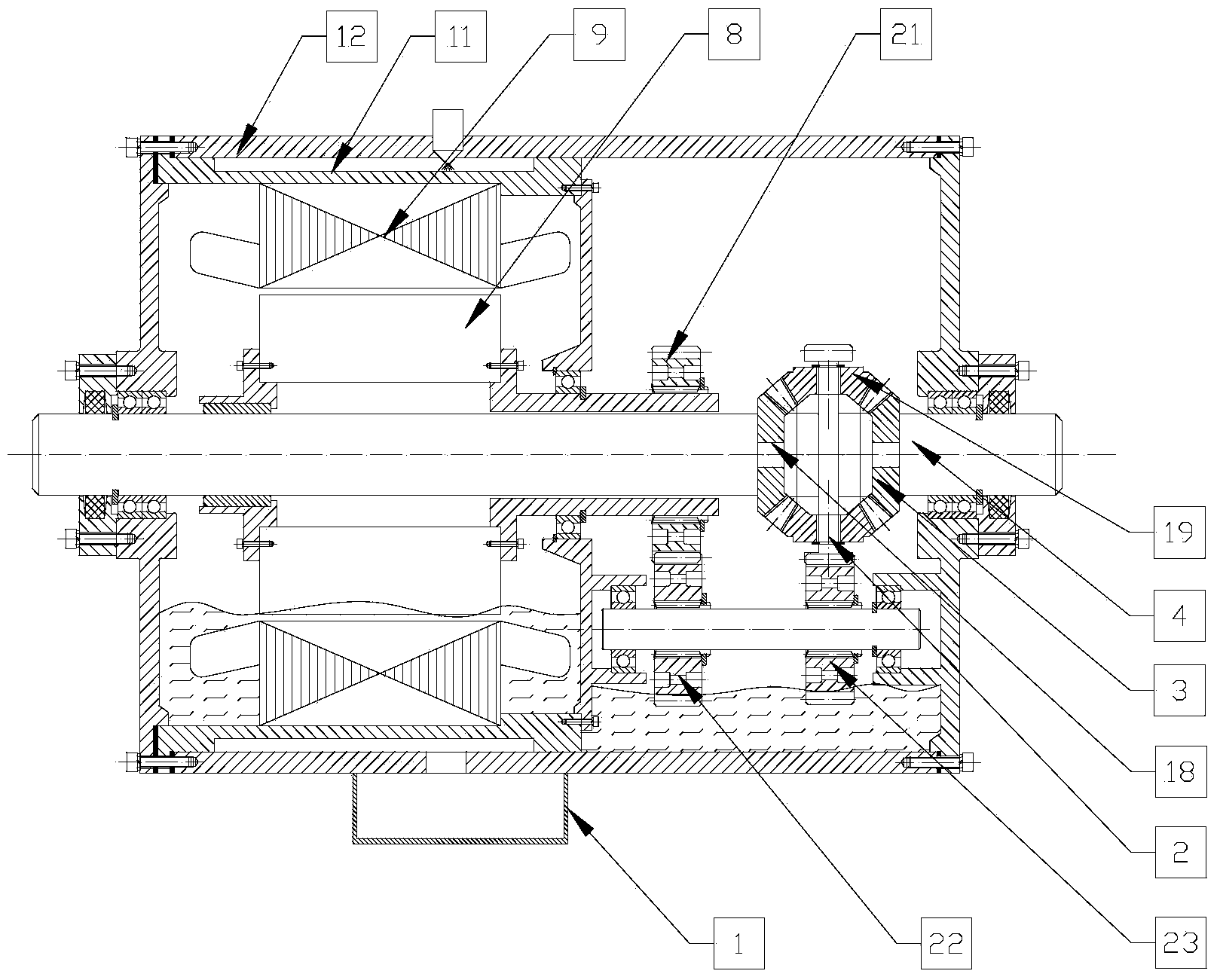

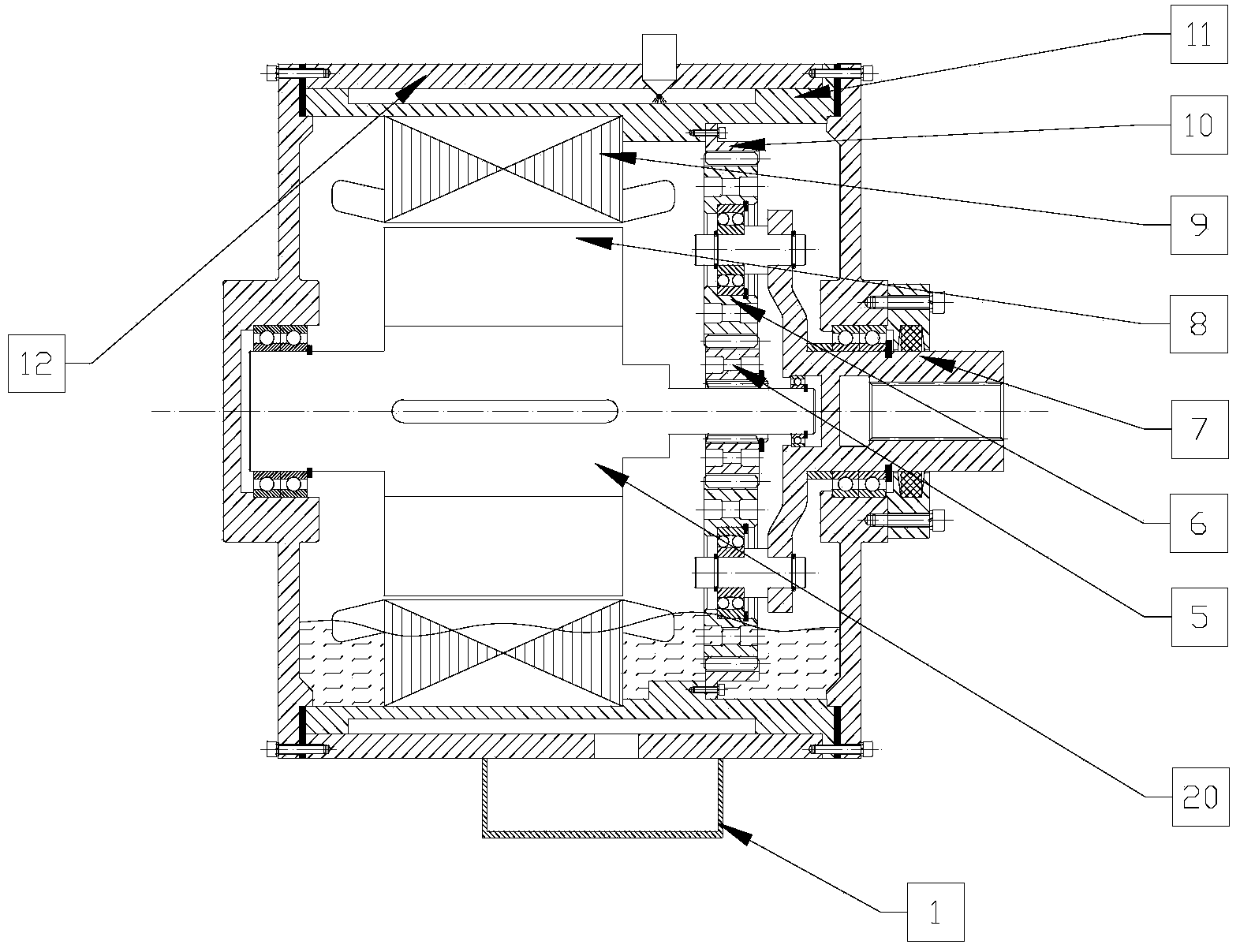

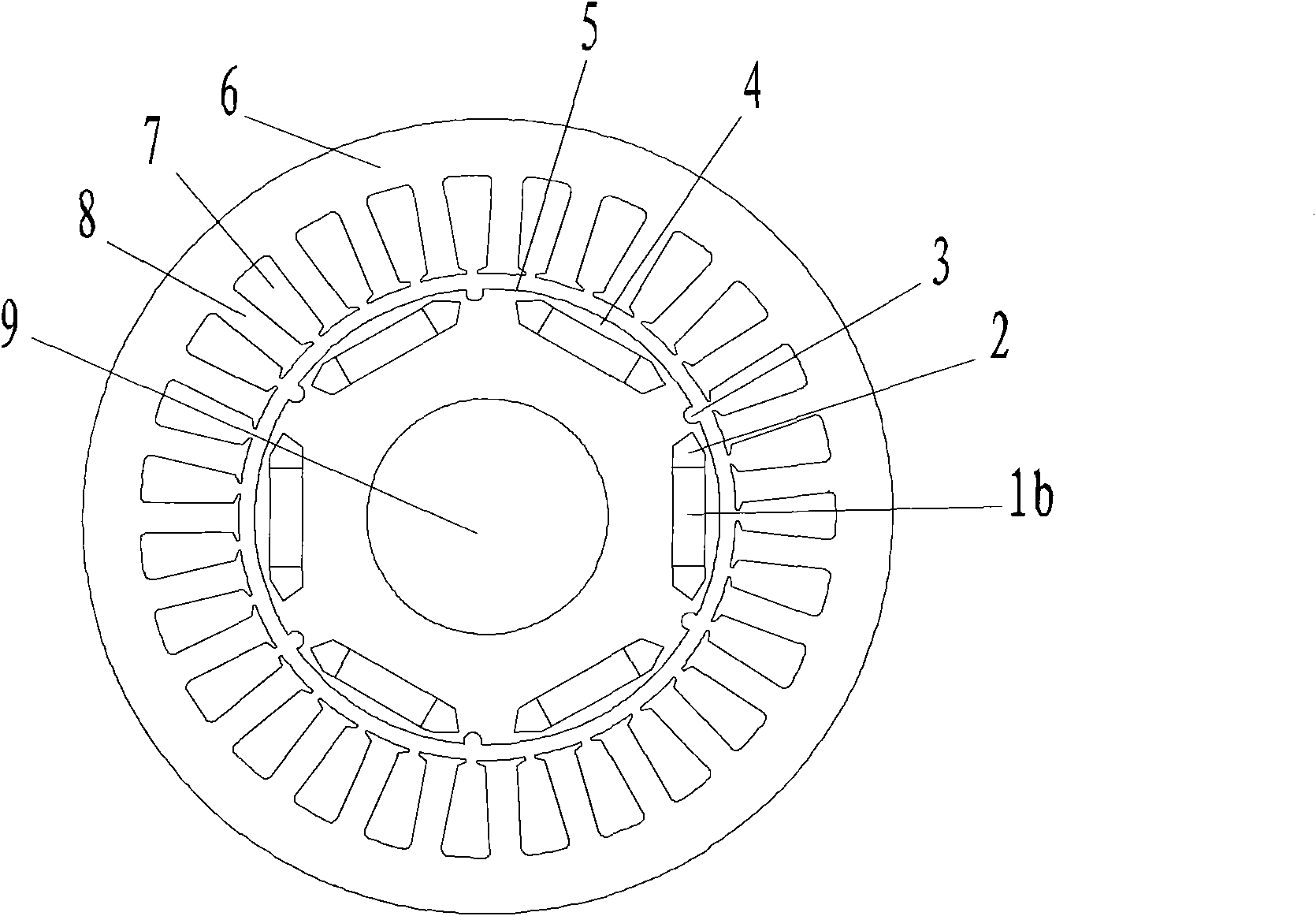

Electric vehicle driving motor internally provided with differential and reducer assembly

ActiveCN103633775AImprove power densityPowertrain is lightweightElectric machinesMechanical energy handlingReduction driveCooling effect

The invention relate to an electric vehicle driving motor internally provided with a differential and reducer assembly. The electric vehicle driving motor comprises a driving motor, a differential and a planet gear or fixed shaft gear reducer; a motor stator, a motor rotor, the differential and the planet gear or fixed shaft gear reducer are arranged in an enclosure; the differential is embedded in the motor rotor; left and right output shafts of the differential are respectively connected with a planet reducer arranged in the motor, or the motor rotor is connected with the fixed shaft gear reducer, and the differential is used for outputting motor power towards two sides. The electric vehicle driving motor internally provided with the differential and reducer assembly integrates driving, speed reducing and differential speed functions, and selected insulation engine oil can lubricate rolling bearing or a sliding bearing in the motor or a reducer gear, so the integration of cooling and lubricating of the motor power assembly is realized. The electric vehicle driving motor internally provided with the differential and reducer assembly has the advantages of compact structure, high power density, good lubricating and cooling effects and the like.

Owner:SOUTH CHINA UNIV OF TECH

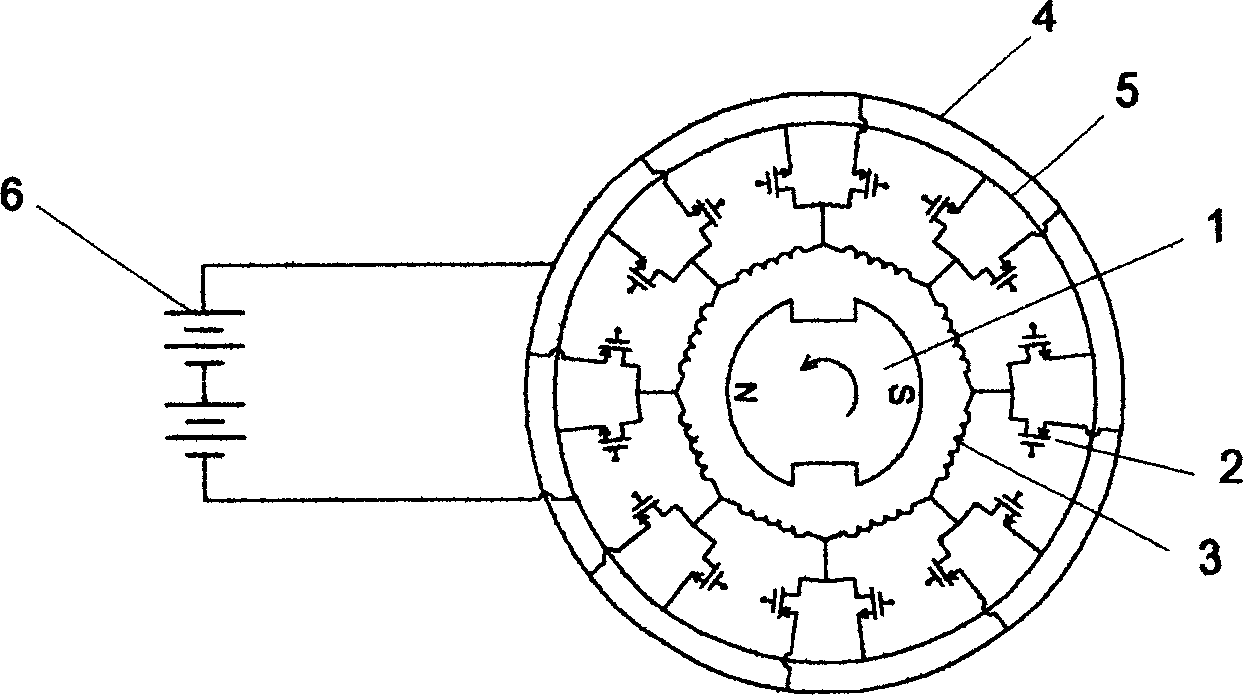

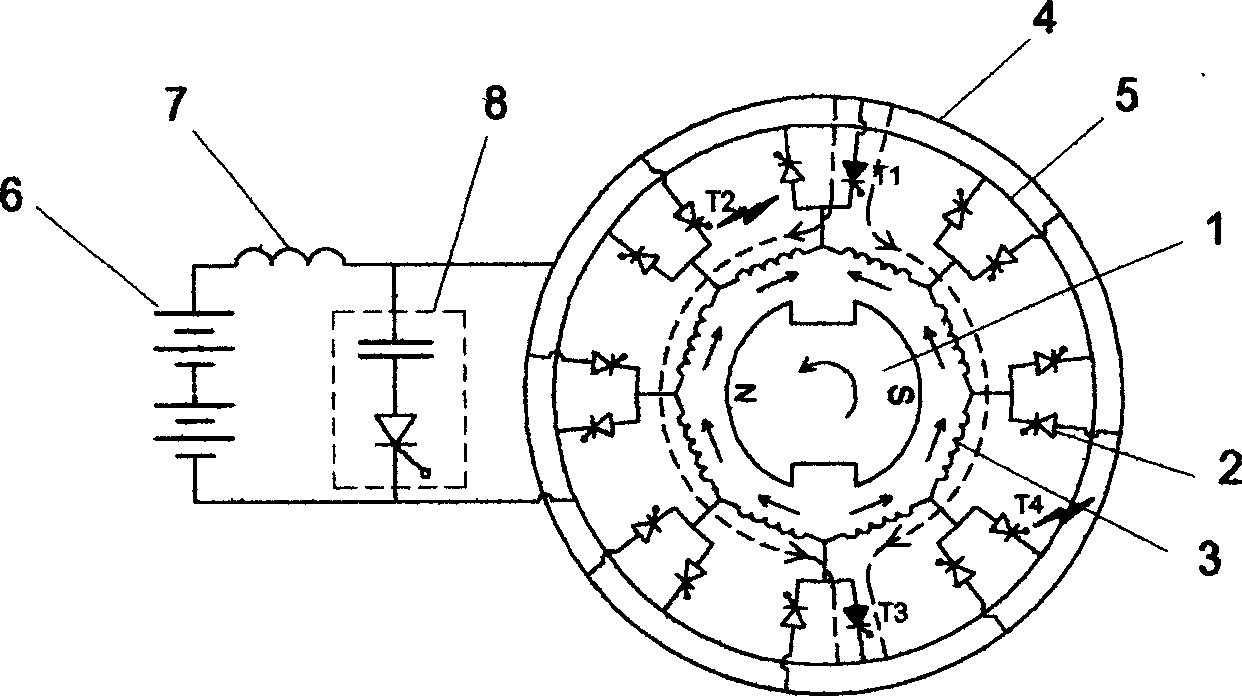

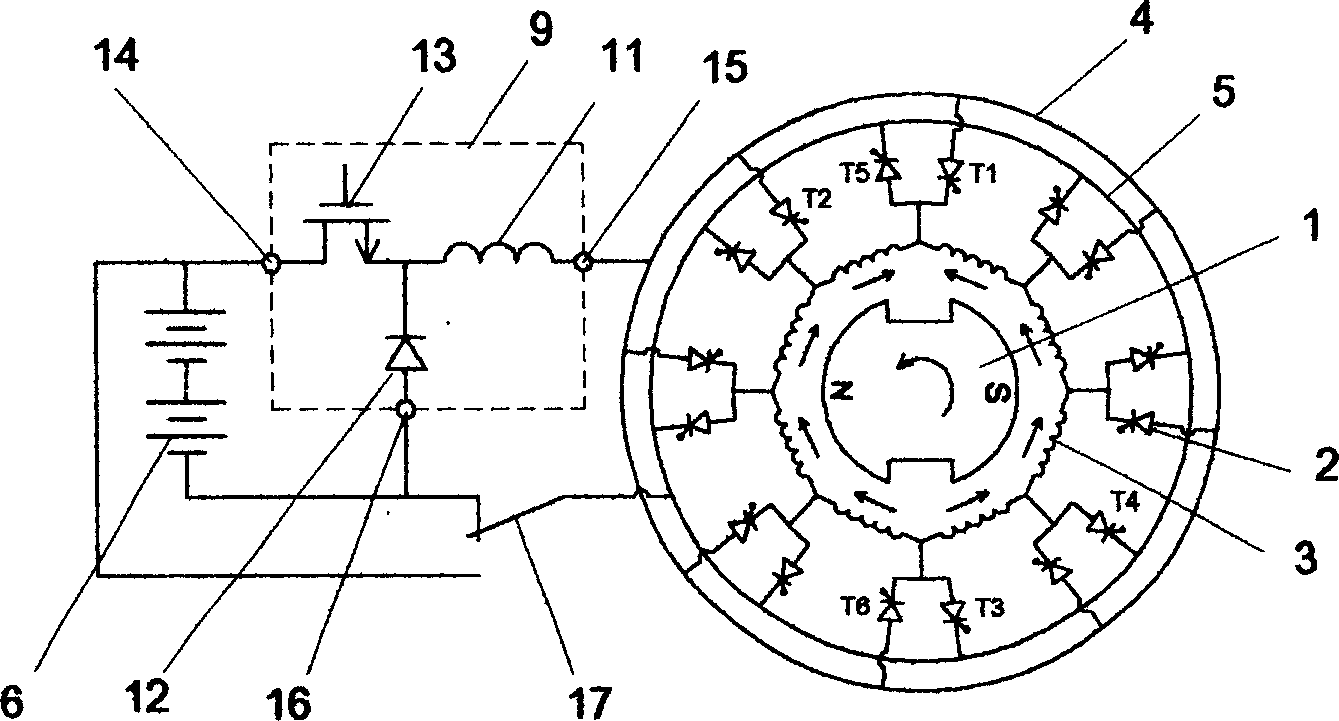

Brushless DC motor and its current converting and controlling method thereof

InactiveCN1787345AMaintain good propertiesHigh control powerElectronic commutation motor controlAssociation with control/drive circuitsLow speedClosed loop

This invention discloses a brushless DC motor and its current conversion and control method used in the field needing regulating the speed of the work or the field not needing regulating the speed yet it is higher than 3000t / m including multiple winding elements with their head and tail elements connected to a closed loop and power electronic switches connected with it, other magnetic structure is the same with the DC motor of a machinery commutator. When it works normally, it utilizes the armature potential to turn off a necessary switch, such as using a thyristor to finish the commutation and when the switch is turned on, the forward voltage born by the switch is far smaller than the supply voltage and the supply control circuit is used to control the operation of the conversion when it starts or operates at low speed and a reversal speed control system can be set up combining with a thyristor commutation device.

Owner:李荟敏

Motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and driving method

InactiveCN103552448ASmall sizeFlexible and convenient layoutSpeed controllerElectric propulsion mountingBrushless motorsElectric machine

The invention discloses a motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and a motor and AMT integration-based electric vehicle driving method. The driving system comprises a driving motor, a motor controller, a transmission drive assembly, a gear selection and shifting execution mechanism and a controller for the gear selection and shifting execution mechanism, wherein the transmission drive assembly comprises driving and driven gears of four gears, two splined hubs, two jointing sleeves and an output sensor; the driving motor is a direct current brushless motor; an output shaft of the driving motor is provided with an internal spline; a shell of the driving motor is integrally and directly connected with a transmission case through fine thread screws after being positioned through fixing pins; the output shaft, with the internal spline, of the motor is positioned in the motor; an input shaft of a transmission is directly inserted into the motor to be connected with the output shaft, with the internal spline, of the motor. According to the system, a clutch is eliminated, so that power interruption time during gear shifting is reduced, and the cost is also lowered; the jointing sleeves and the gears of a target gear can be synchronized during gear shifting by actively regulating the speed of the driving motor, and a synchronizer with high requirements on materials is eliminated from the transmission, so that the cost is further lowered.

Owner:张利鹏 +1

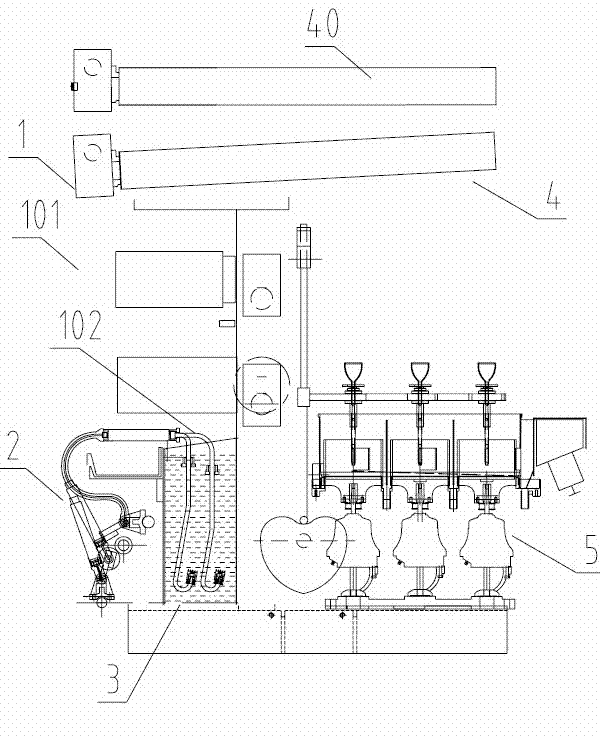

Spinning process of bamboo-like flat filaments produced by semi-continuous high-speed spinning machine

ActiveCN103290495AEasy maintenanceLow cost of spinningArtificial thread manufacturing machinesArtificial filaments from viscoseFrequency changerPolymer science

The invention relates to a spinning process of bamboo-like flat filaments produced by a semi-continuous high-speed spinning machine and belongs to the technical field of spinning of semi-continuous spinning machines. The spinning process comprises glue supply, filament strip forming, spinning and winding. The spinning process is characterized in that the glue supply is achieved through a glue supply device which comprises a metering pump, a glue supply tube and a filter; the metering pump is connected with a frequency converter which is used for controlling the amount of the glue supply of the metering pump; the frequency converter controls the metering pump to perform intermittent glue supply; the spinning is achieved through a spinning device which comprises at least one spinning roller which is horizontally arranged relative to an operating surface of a spinning surface; and filament strips surround the spinning roller to achieve drafting, solidification and deacidification in the spinning processes under the rotation of the spinning roller. The spinning process of the bamboo-like flat filaments produced by the semi-continuous high-speed spinning machine has the advantages of solving the problems that the filament strips of the semi-continuous spinning machines are inadequate in response, so that the spinning speed cannot be improved and the production efficiency and product quality cannot be integrated, enabling the arrangement direction of the spinning roller to be changed to enable the spinning speed of the spinning machine to be improved and enabling the high quality bamboo-like flat filaments to be spun out.

Owner:YIBIN HIEST FIBER +2

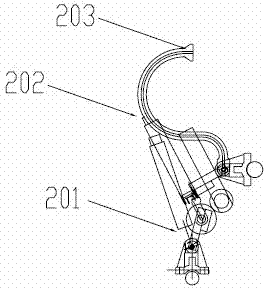

Efficient cooling motor with three independent wind-path structures

ActiveCN103607073ASolve the cooling problemSolve power problemsMagnetic circuit rotating partsElectric machinesElectric vehicleConductor Coil

The invention relates to a motor, in particular to an efficient cooling motor with three independent wind-path structures. The problems that an existing electric vehicle traction motor is poor in cooling capability, low in output power, small in output torque, weak in overload capacity, large in size, high in weight and high in cost are solved. The efficient cooling motor with the three independent wind-path structures comprises a base, a front end cover, a rear end cover, a stator assembly and a rotor assembly. The stator assembly comprises a stator iron core and a stator winding. The rotor assembly comprises a rotary shaft and a rotor iron core. An outer-layer axial air gap is reserved between the surface of the inner circle of the base and the surface of the outer circle of the stator iron core, and an inner-layer axial air gap is reserved between the surface of the inner circle of the stator iron core and the surface of the outer circle of the rotor iron core. An axial air duct is formed in the end face of the rotor iron core in a penetrating through mode, a centrifugal fan is installed in an inner cavity in the front portion of the base, an air channel is installed on the surface of the outer circle of the rear portion of the base, and an axial flow fan is installed in an inner cavity of the air channel. The efficient cooling motor with the three independent wind-path structures is suitable for electric vehicles.

Owner:CRRC YONGJI ELECTRIC CO LTD

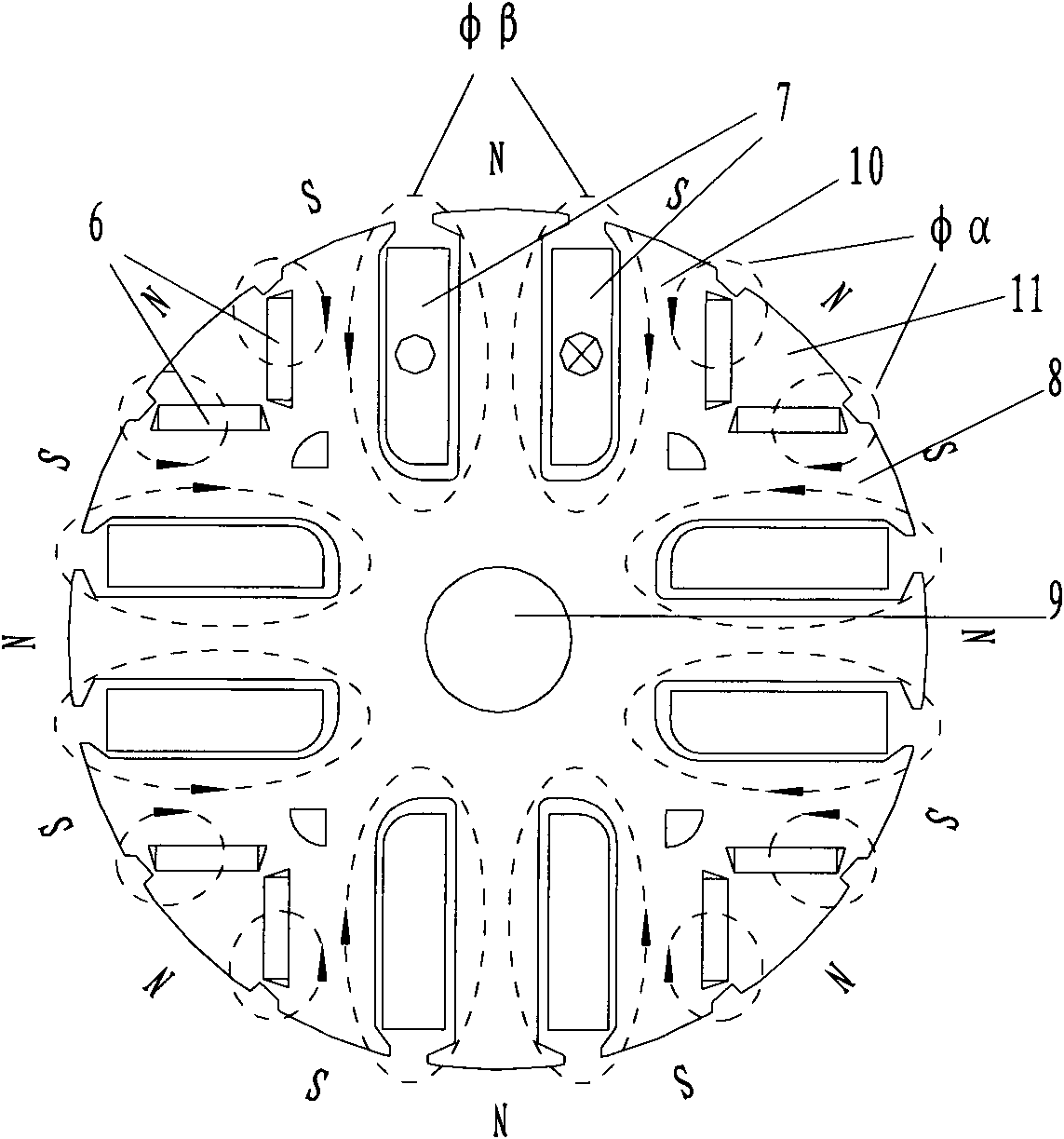

Compound excitation permanent magnet synchronous generator for electric vehicles

InactiveCN101662197AHighlight substantive featuresSignificant progressMagnetic circuit rotating partsElectric machinesPermanent magnet rotorElectrical conductor

The invention relates to a compound excitation permanent magnet synchronous generator for electric vehicles. An auxiliary electric excitation winding and built-in V-shaped magnetic steel are arrangedin a rotor iron core in the circumferential direction; the built-in V-shaped magnetic steel and a pole shoe form a permanent magnet pole, and the auxiliary electric excitation winding and an interwinding iron core form an excitation pole; the permanent magnet and the auxiliary electric excitation winding together generate armature induction potential, the air gap magnetic field can be adjusted conveniently by adjusting the magnitude and the direction of the DC excitation current in the electric excitation winding, and the purposes of high efficiency, energy saving and high-precision adjustmentof the voltage at an output end are achieved; meanwhile, the permanent magnet rotor is made of the V-shaped segmented magnetic steel, and holes are arranged in the pole shoe to lighten the weight ofthe rotor to avoid the high-speed deformation of the rotor; a groove is formed at the center of the pole shoe in the radial direction, and nonmagnetic good conductors are filled in the groove; and magnetism isolating grooves are arranged at two ends of the V-shaped magnetic steel, thereby inhibiting the static and dynamic armature reaction, improving the output voltage waveform, increasing the airgap magnetic density, reducing the magnetic leakage and increasing the output power. The compound excitation permanent magnet synchronous generator can smoothly operate at high power density, speed and precision.

Owner:苏州工业园区美能新能源有限公司 +1

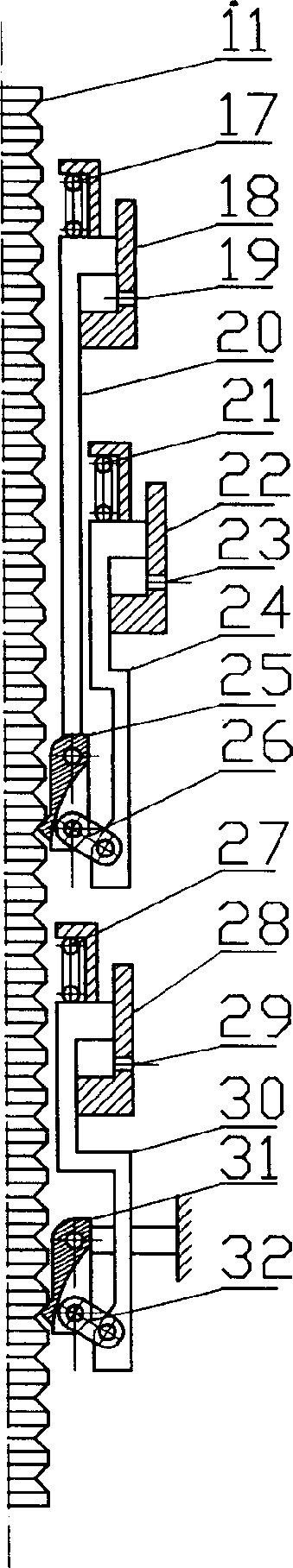

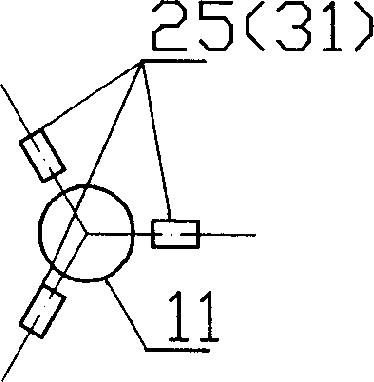

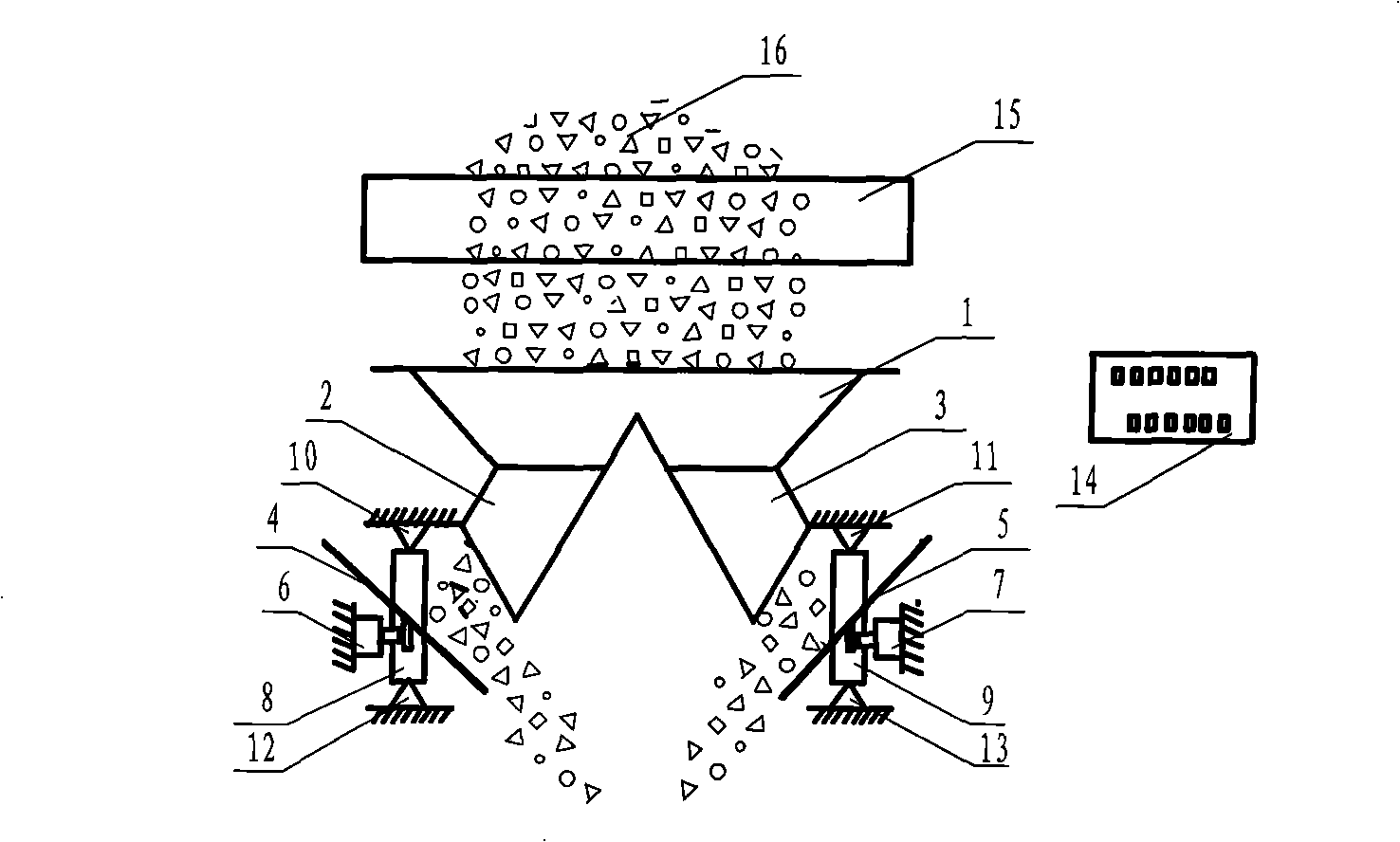

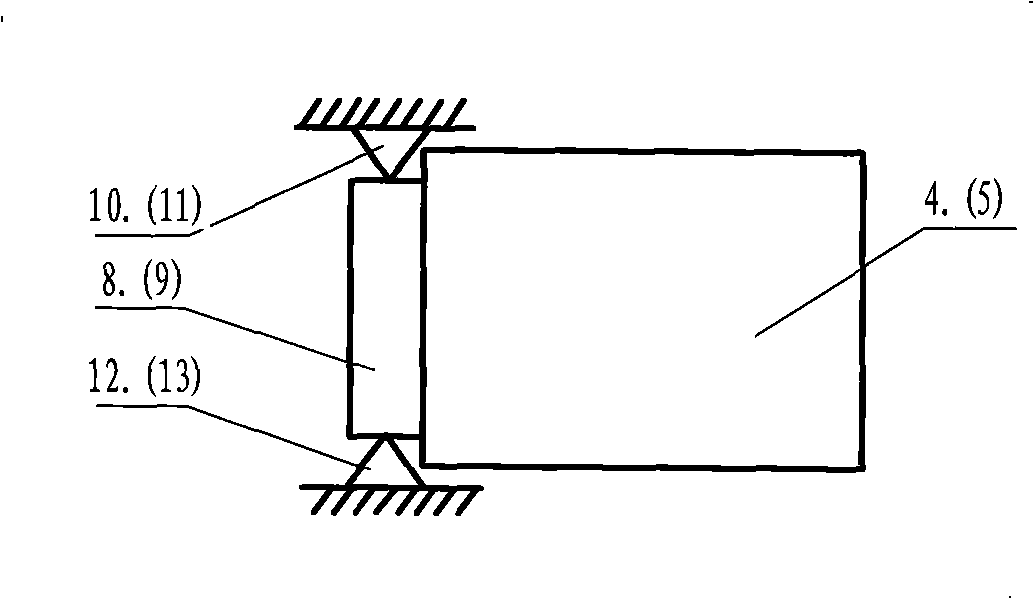

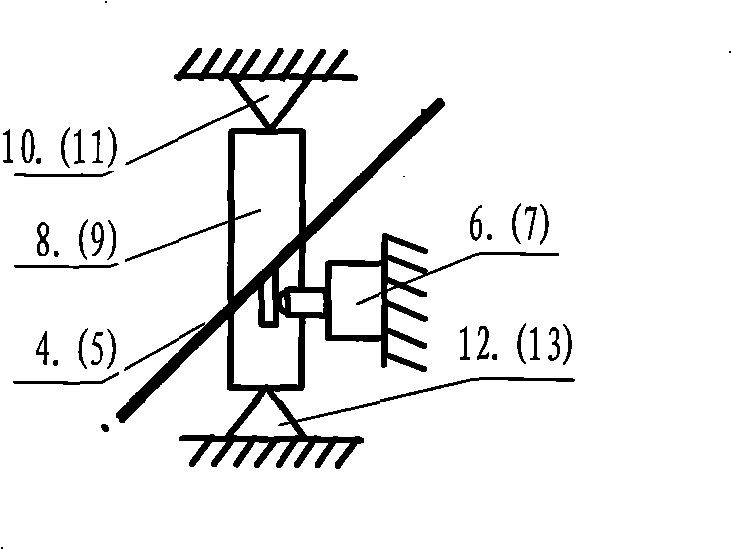

Continuous dynamic intelligent metering mechanism

InactiveCN101266160AHigh precisionReasonable structureMass flow measurement devicesWeighing apparatus for materials with special property/formElectricityPunching

A scattered solid material intelligent metering device belongs to the automation detection metering technology field, which can be applied widely to industries using a belt transporter for example coal, metallurgy, power generation, characterized in that the device is composed of a funnel 1, downspoutings 2, 3, punchings 4, 5, weighing sensors 6, 7 and an intelligent measuring and control instrument 14. The funnel 1 and the punching 4, 5 form weighing frame structure; the weighing sensor 6, 7 and the intelligent measuring and control instrument 14 form the measuring system; the invention not only has high precision, wide measuring range, reasonable structure, strong overload capacity but also does not change original on site devices. The invention is applied to continuously dynamic scattered solid material metering for example the coal, the dock, the electricity power plant, which replaces traditional electronic belt weigh meter and nuclear scale. The metering device can be used even under condition that the belt weigh meter can not be used, for example, various material transporter and storage material feeding opening of chain board, scrapping board, screw and so on.

Owner:TAIYUAN UNIV OF TECH

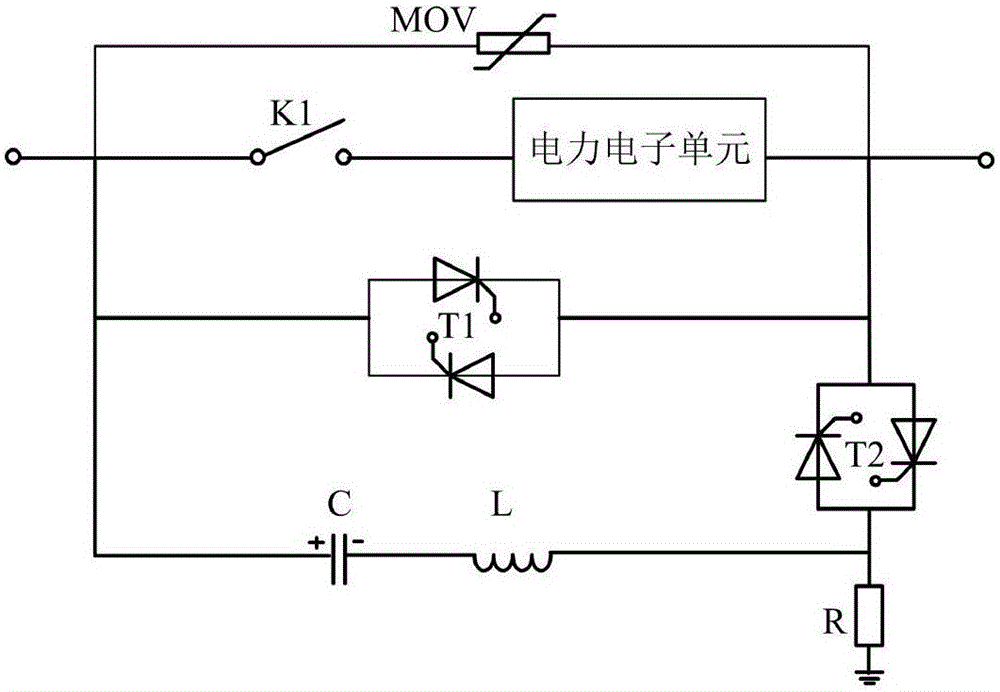

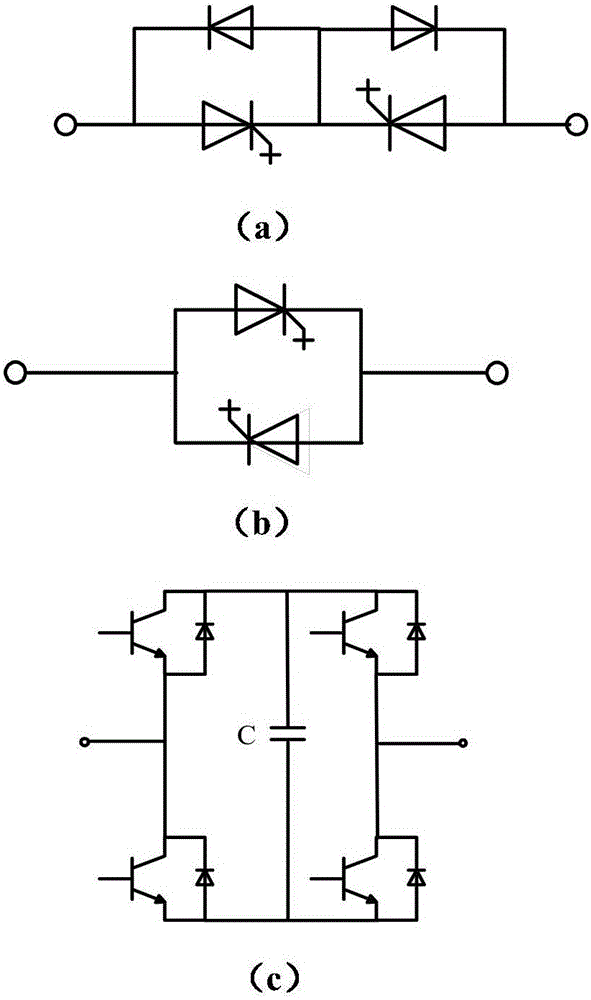

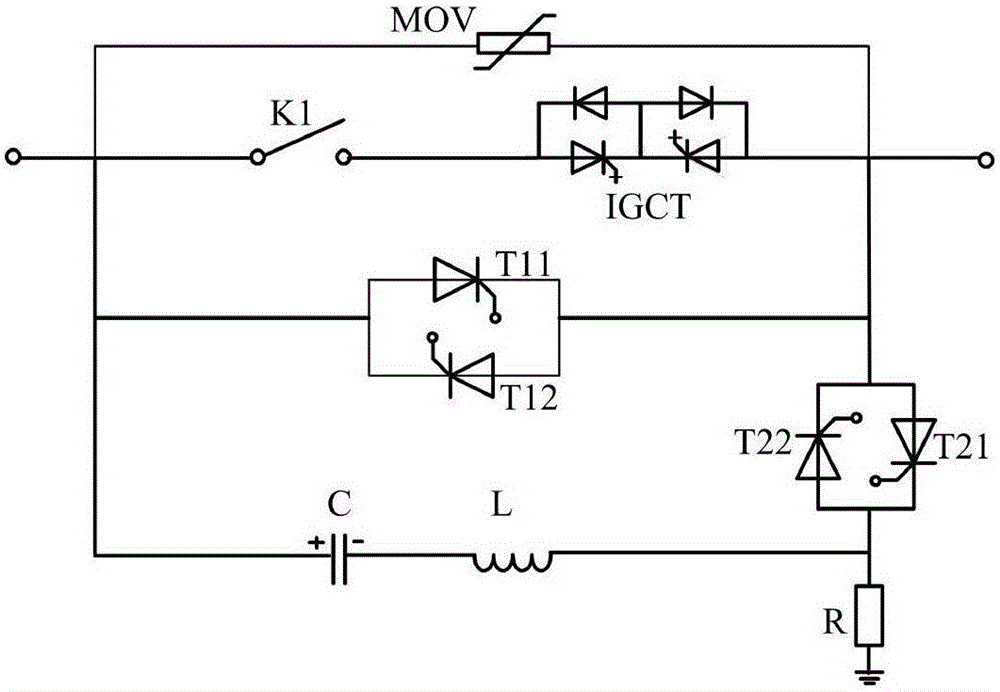

Thyristor-based passive hybrid direct current circuit breaker and application method therefor

ActiveCN105870877ATwo-way breakFast and arc-free breakingEmergency protective arrangements for automatic disconnectionHybrid typeEnergy absorption

The invention relates to a thyristor-based passive hybrid direct current circuit breaker and an application method therefor. The passive hybrid direct current circuit breaker comprises a main through-flow branch, a first transfer current branch, a second transfer branch and an energy absorption branch which are connected in parallel, wherein the main through-flow branch consists of a rapid mechanical switch K and a small amount of fully-controlled power electronic units which are connected in series; the first transfer current branch consists of two groups of thyristor valves T1 which are connected in an anti-parallel manner; the second transfer current branch consists of a capacitor C, an inductor L and a group of thyristor valves T2 which are connected in an anti-parallel manner; the inductor and a thyristor valve connecting line are connected with one end of a resistor while the other end of the resistor R is grounded; and the energy absorption branch consists of series-wound arrester groups. By adoption of the technical scheme provided by the invention, the problem that the current breaking capability of the existing hybrid type direct current circuit breaker is limited by the turn-off capability of a single fully-controlled device and the problem of relatively low current breaking capability are solved.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

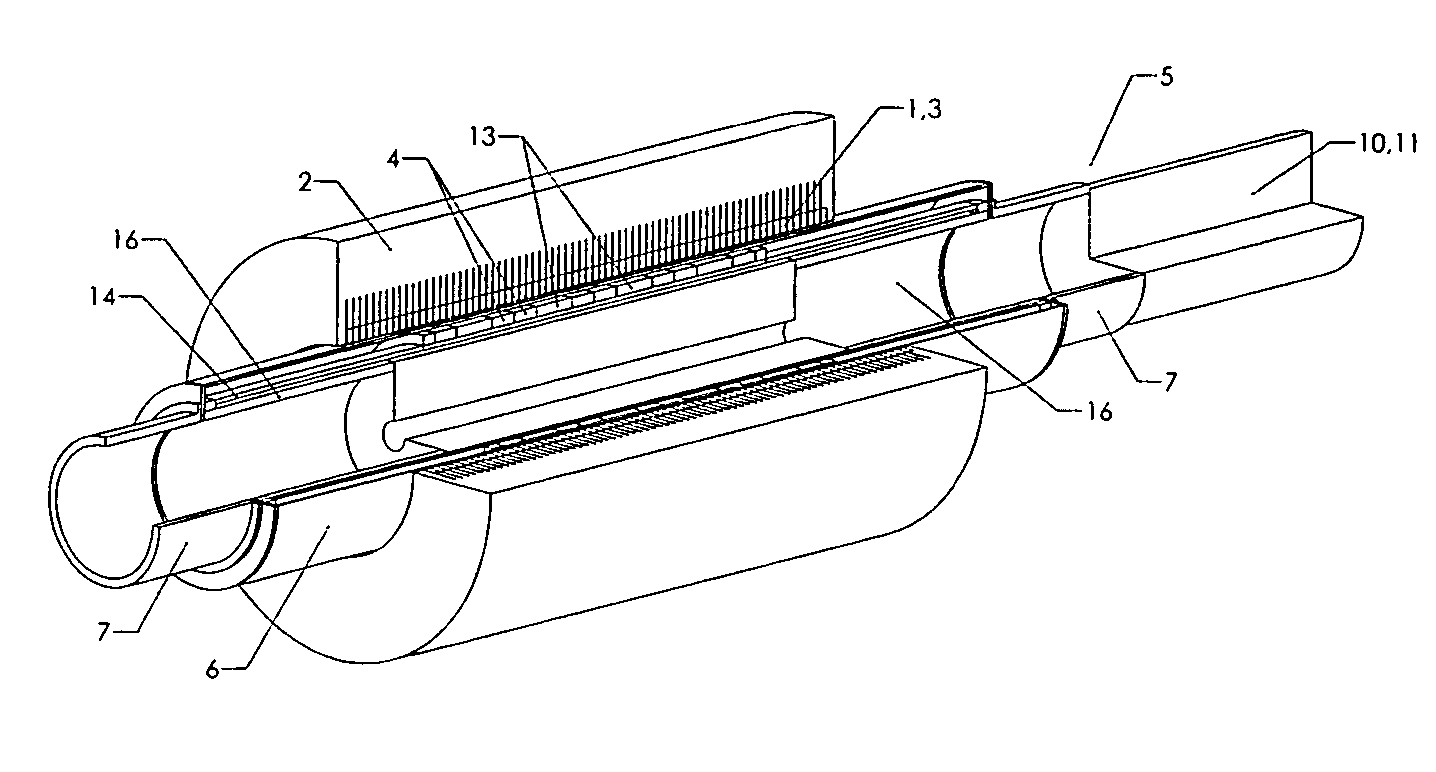

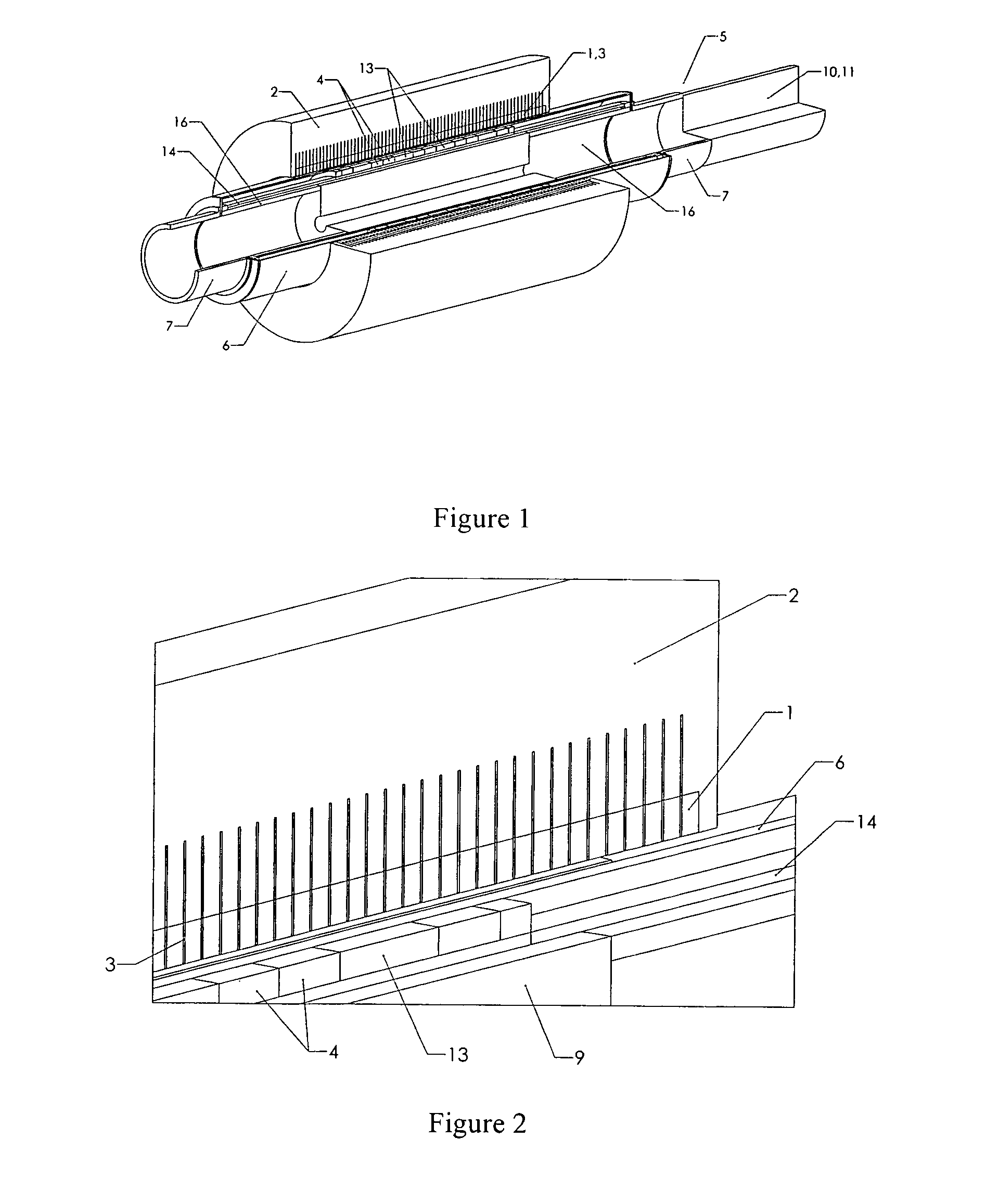

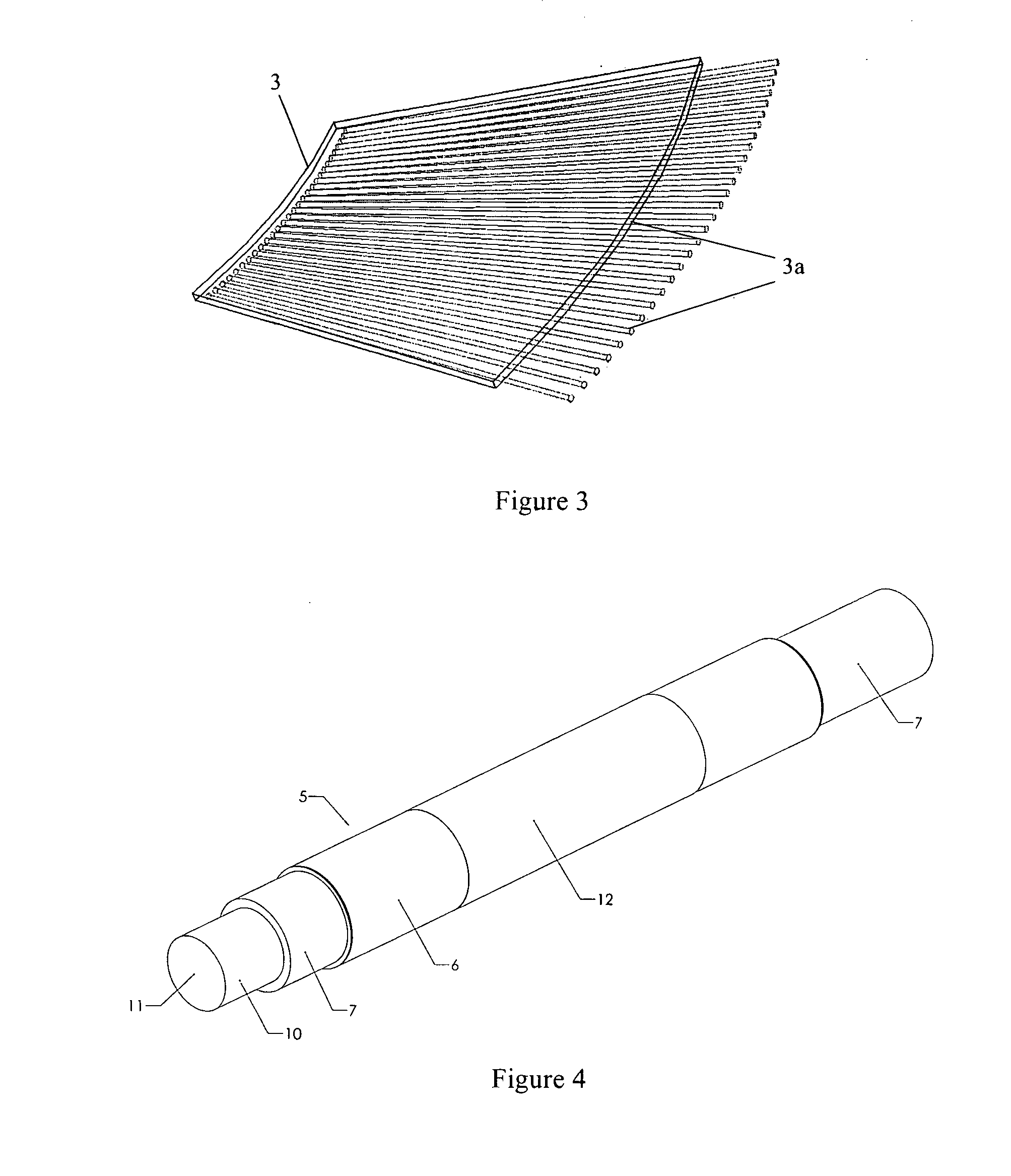

Tubular electrical machines

InactiveUS20070164615A1Heat dissipationEliminate the problemReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit rotating partsSuperconducting CoilsMagnet

An improved synchronous tubular electrical machine comprises a radially outer member that has a substantially cylindrical inner surface and radially inner member that is substantially cylindrical and is coaxially disposed within the outer member such that it may move reciprocally relative to the outer member in the axial direction. A plurality of axially spaced circumferential armature coils are electrically insulated from one another and are formed as part of one of the outer member and the inner member. A plurality of axially spaced circumferential superconducting coils are formed as part of the other of the outer member and the inner member. During operation of the tubular machine, each superconducting coil is maintained in a superconducting state and an electrical current is supplied to each superconducting coil in such a manner that the current flowing around each coil is in the opposite direction to the current flowing around the coils adjacent to it. Such tubular machines may be significantly more efficient, have higher peak-mean power ratios and be much smaller than current permanent magnet based synchronous tubular electrical machines.

Owner:GE POWER CONVERSION

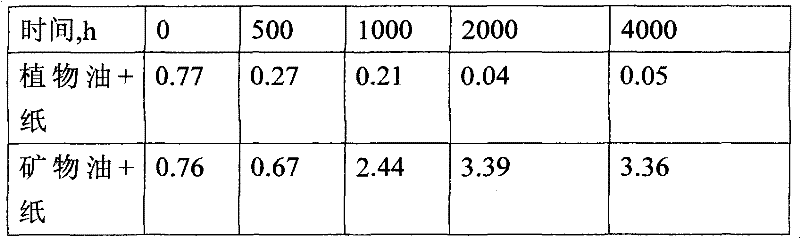

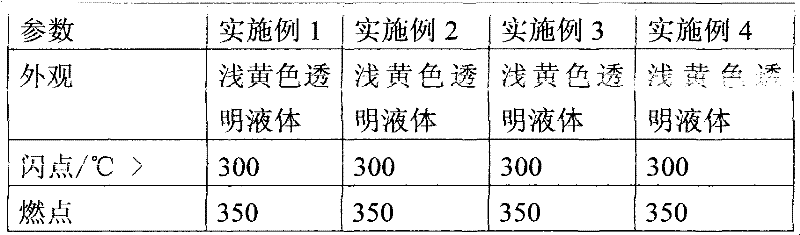

Vegetable insulating oil and preparation method thereof

InactiveCN102543262AGreenLow-carbon and energy-savingLiquid organic insulatorsTransformers/inductances coils/windings/connectionsVegetable oilTransformer

The invention discloses vegetable insulating oil, which is mainly prepared from the following raw materials in percentage by weight: 90 to 95 percent of vegetable oil and 2 to 5 percent of antioxidant. The invention also provides a method for preparing the vegetable insulating oil. The product is a novel vegetable insulating oil, is insulating oil for a transformer, is a high-performance insulating material extracted from renewable plants, and has the characteristics of environment friendliness, safe operation, long service life, high overload capacity, low carbon, energy saving and the like.

Owner:GUANGDONG JOOYN NEW MATERIAL TECH CO LTD

Permanent magnet drive motor for solar tracking system

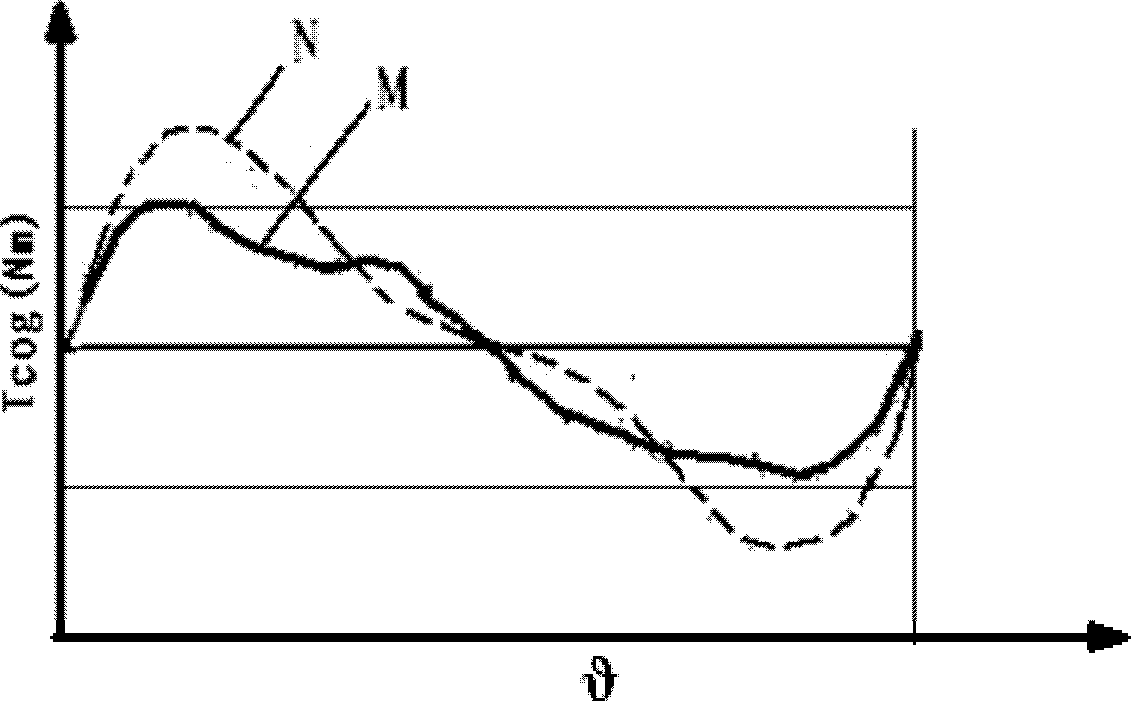

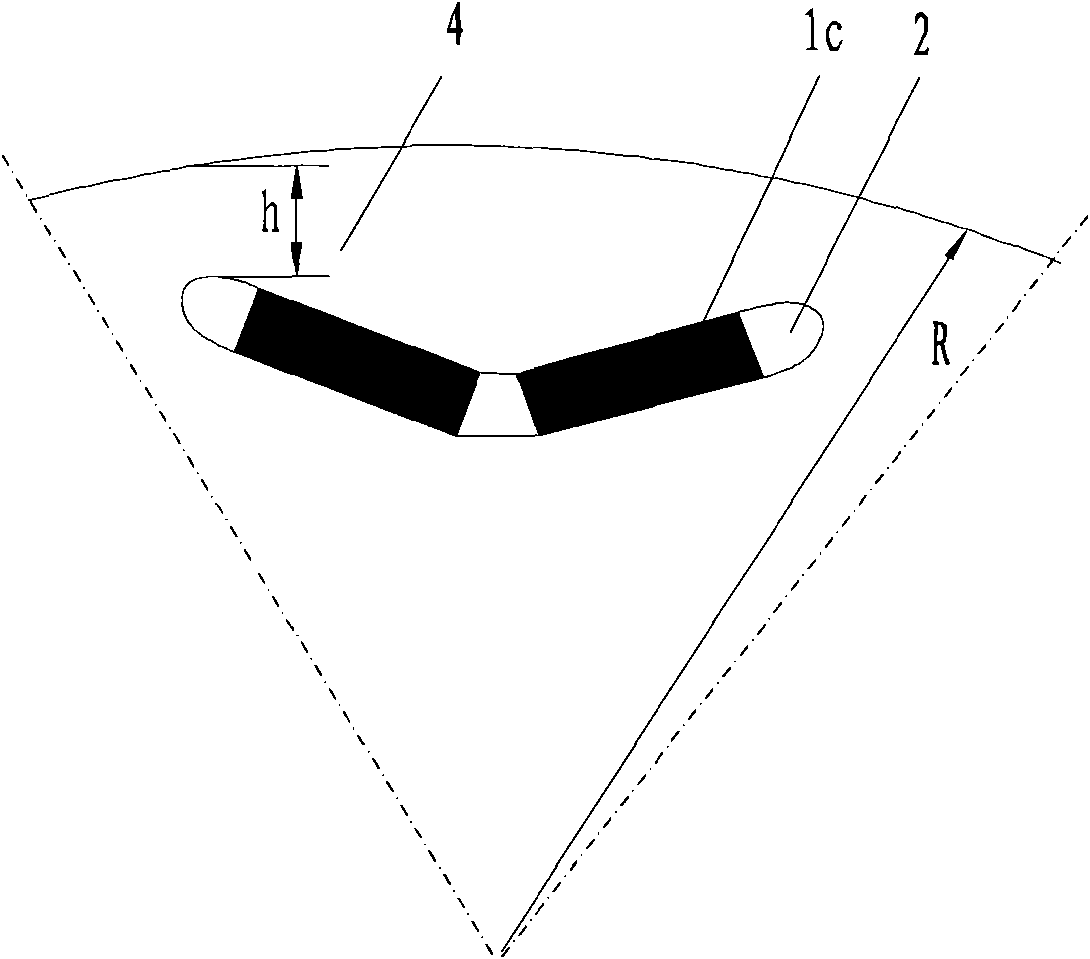

ActiveCN101917076AReduced resultant torque fluctuationSmall torque fluctuationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSEMI-CIRCLEDrive motor

The invention relates to a permanent magnet drive motor for a solar tracking system, which comprises an enclosure, a stator and a rotor which are arranged in the enclosure, wherein, the stator comprises a stator core and a stator winding which are fixed on an inner wall of the enclosure, and the stator core comprises a stator magnetic yoke, a stator slot and stator teeth; the rotor comprises a rotating shaft and a rotor core, and a permanent magnet slot is uniformly arranged along the periphery of the rotor core; the permanent magnet slot is internally inlaid with radial magnetized rectangular strip magnetic steel, the radial magnetized rectangular strip magnetic steel and a pole piece form a permanent magnet pole, and an excircle of a rotor pole piece is in a concentric or excentric arc curved surface shape to form uniformly or non-uniformly symmetrical air gap; semi-circle grooves are arranged on two ends of the permanent magnet slot in which one of two pieces of adjacent radial magnetized rectangular strip magnetic steel is arranged; and rectangular supporting bars are radially inserted in the permanent magnet slot in which the V-shaped radial magnetized rectangular strip magnetic steel is arranged. The permanent magnet drive motor has the characteristics of high efficiency, high output power, high reliability, low moment fluctuation and the like.

Owner:苏州和鑫电气股份有限公司 +1

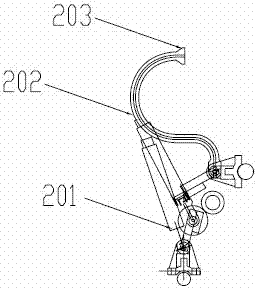

Three-transfer-one-shift four-degree-of-freedom heavy-load static-balance parallel motion simulation stand mechanism

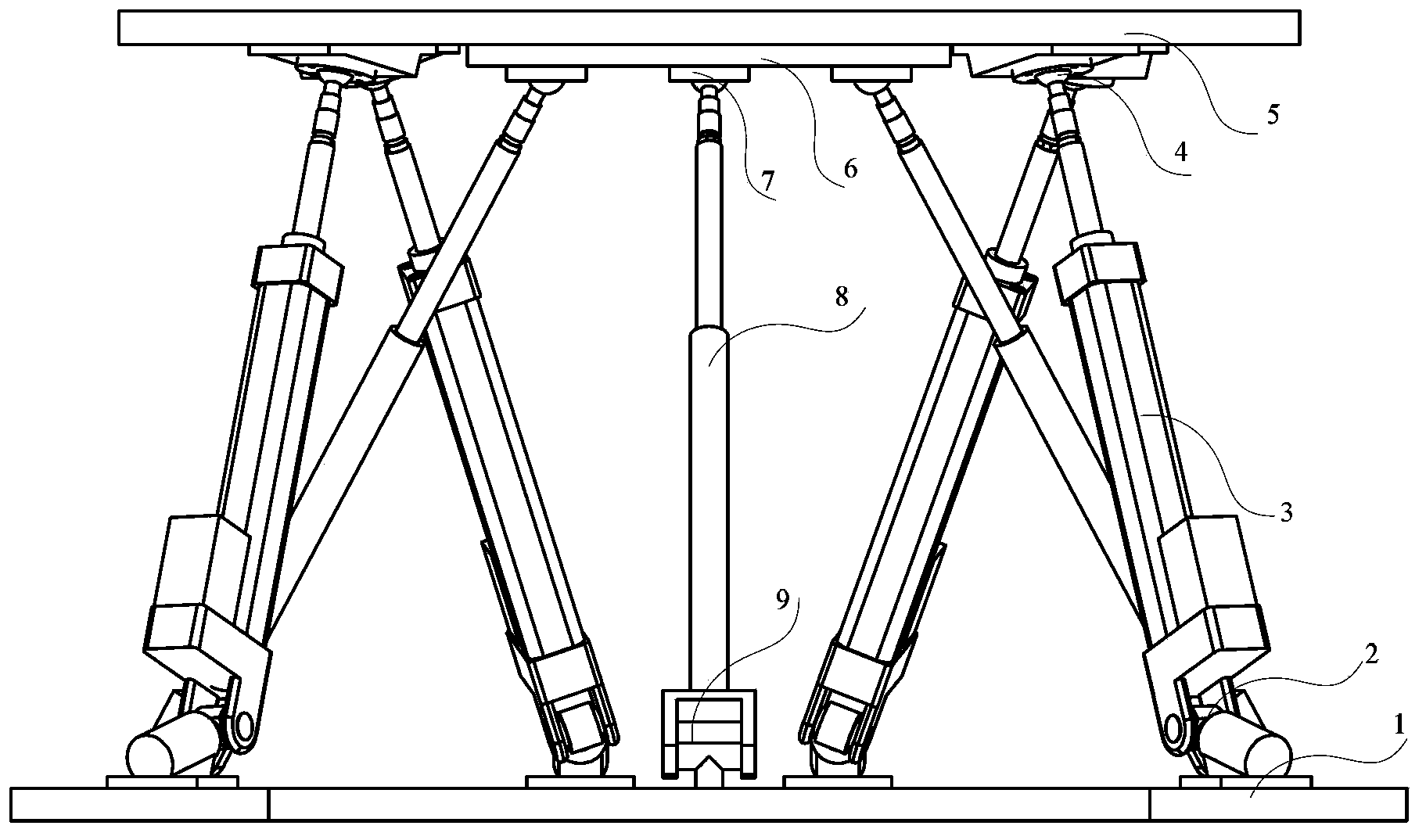

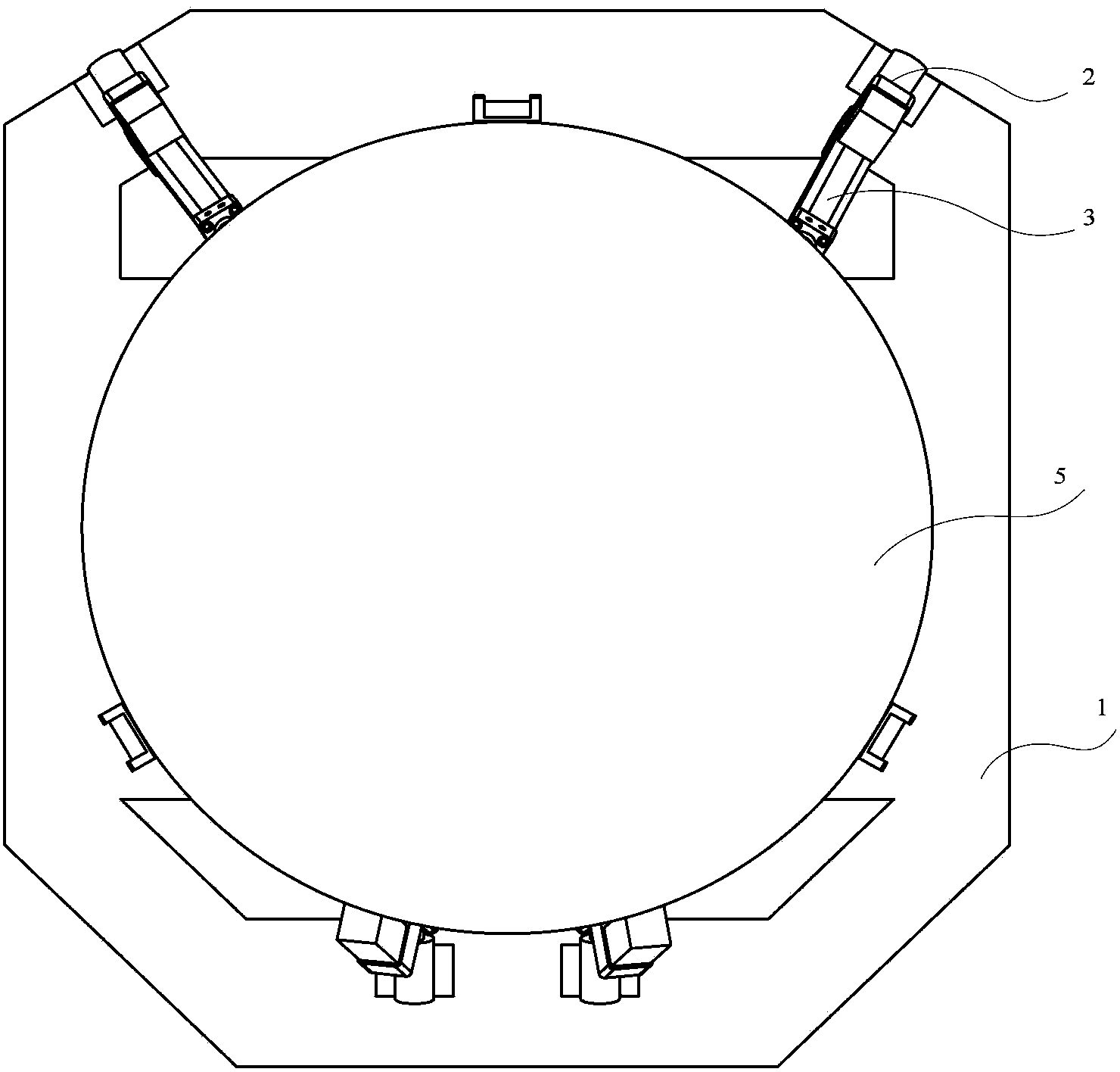

ActiveCN103383827AAvoid singularitiesPlay the role of security protectionEducational modelsHydraulic cylinderEngineering

A three-transfer-one-shift four-degree-of-freedom heavy-load static-balance parallel motion simulation stand mechanism mainly comprises a basic platform, a motion platform, a load-bearing platform, four driving branches in identical structures and three balancing branches in identical structures. The four driving branches are connected with the motion platform and the basic platform to form a parallel driving mechanism. The three balancing branches are connected with the load-bearing platform and the basic platform to form a parallel balancing mechanism. The four driving branches are in uninterrupted power supply (UPS) structures and are composed of electric cylinders, first spherical hinges and universal hinges. The balancing branches are in RPS structures and are composed of balancing hydraulic cylinders or balancing air cylinders, first revolving pairs and second spherical hinges. The motion platform is connected with the load-bearing platform through a second revolving pair. The mechanism is high in bearing capacity, fast in dynamic response speed, simple to control, capable of preventing the three balancing branches from generating moments of rotation around a shaft and reducing the inertia force (moment) of a parallel load-bearing mechanism simultaneously and applicable to motion simulation of large devices, and the mechanism can be used indoors or in a field environment.

Owner:YANSHAN UNIV

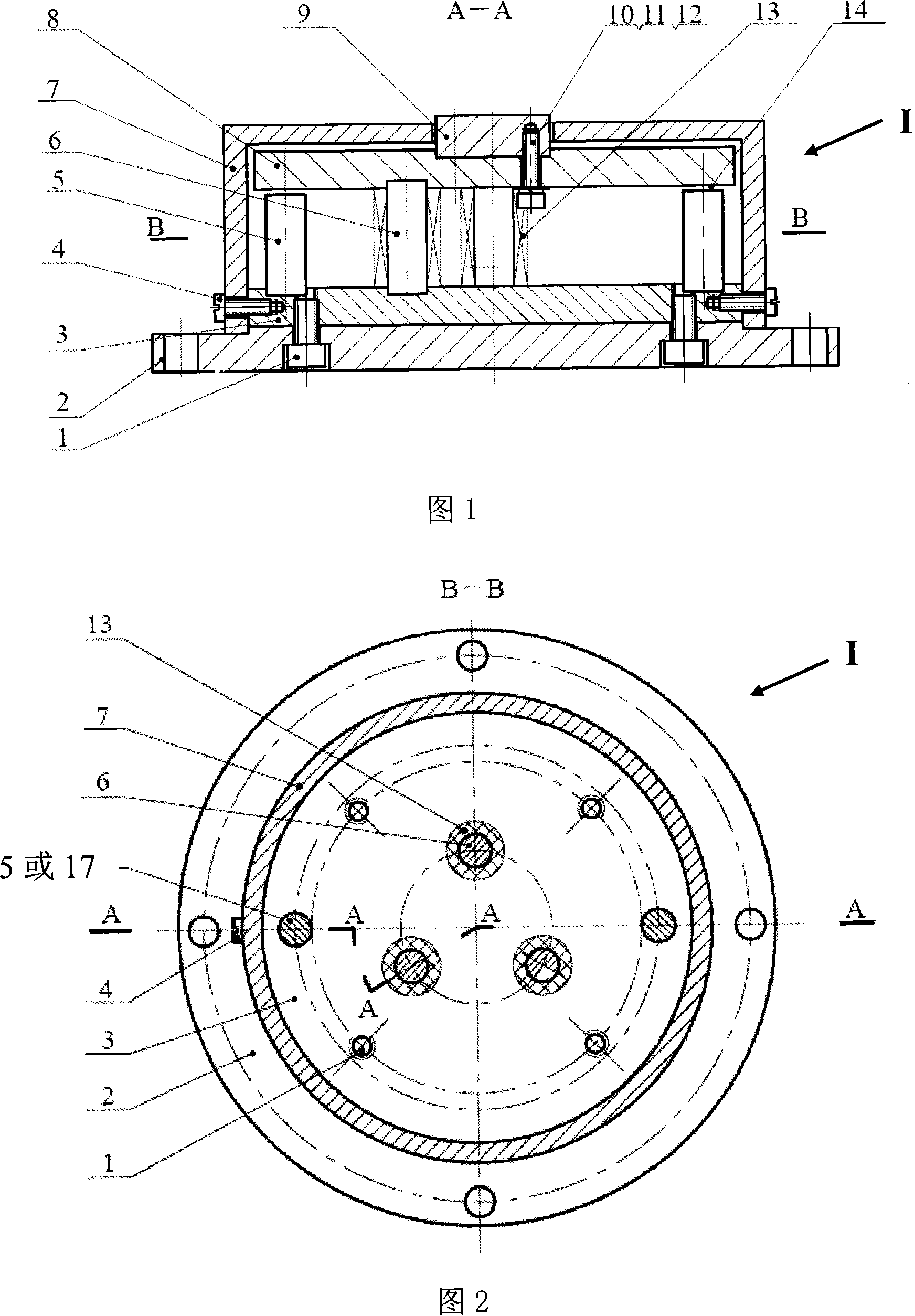

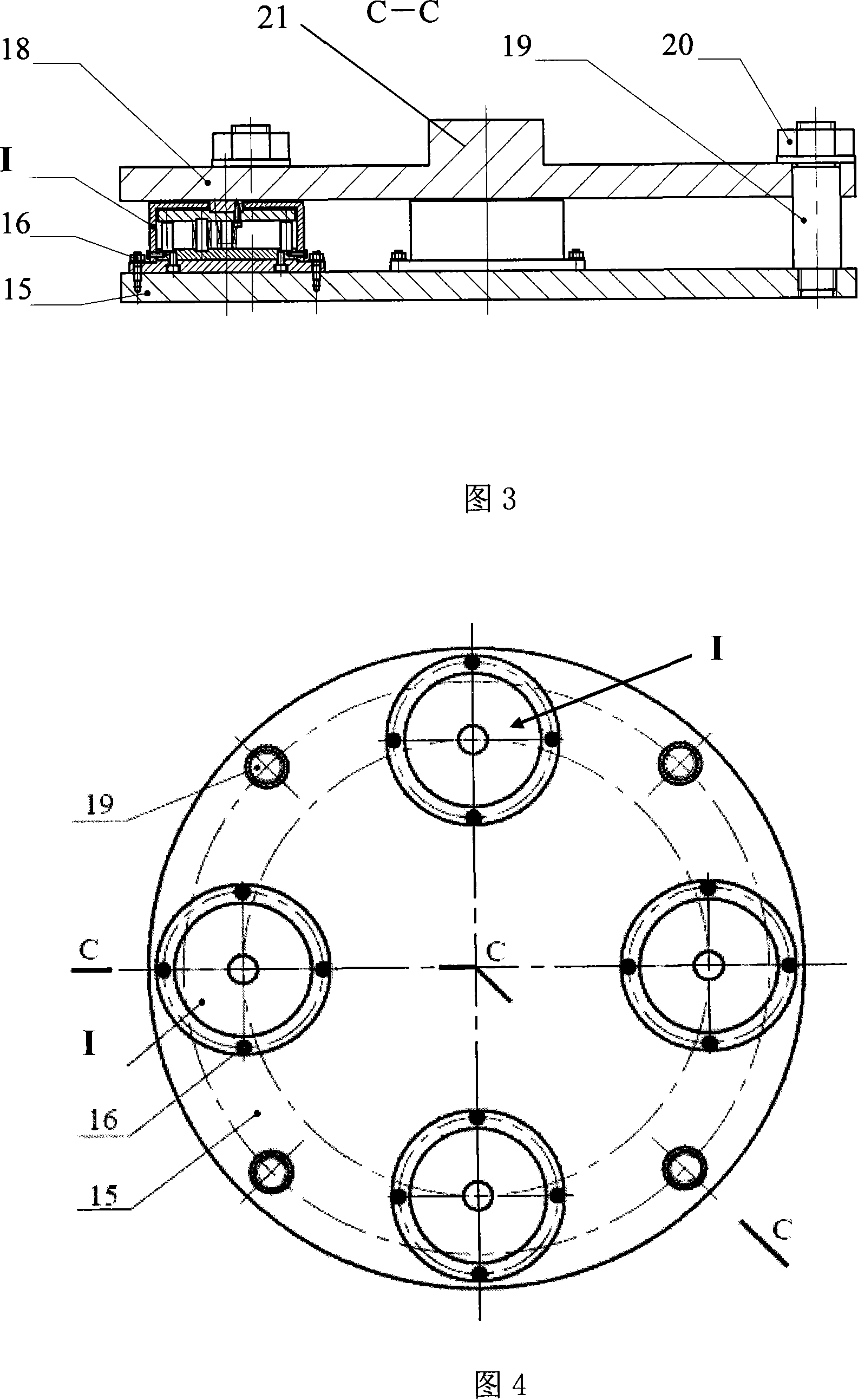

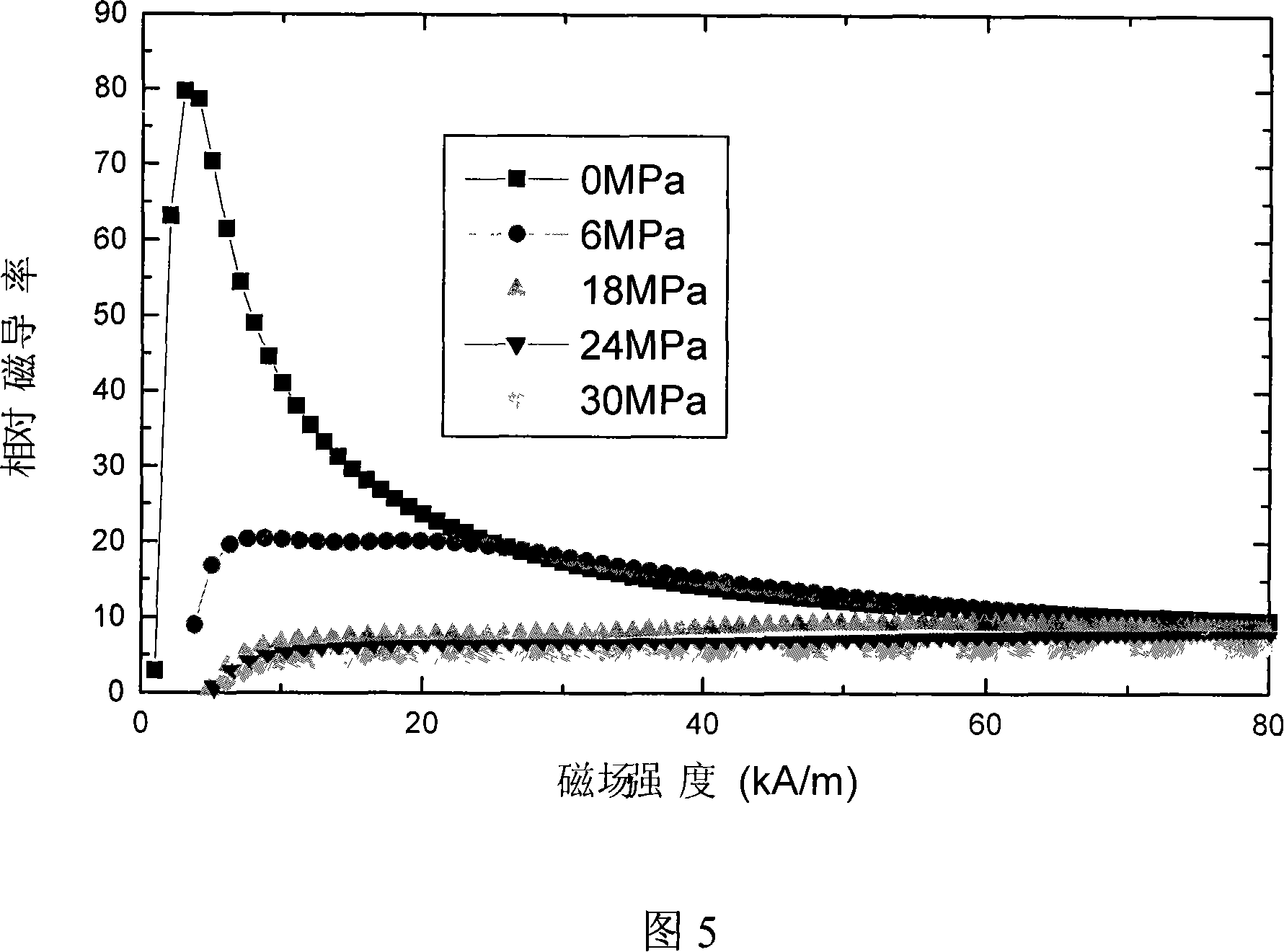

Magnetostrictive stress sensor

InactiveCN101153824AHigh sensitivityHigh precisionForce measurement by measuring magnetic property varationFluid pressure measurement by electric/magnetic elementsEngineeringNon magnetic

The invention relates to a giant magnctostrictivc material pressure sensor, which is characterized in that three giant magnctostrictivc material rods are vertically and evenly arranged on an inner circle of a sensor base and two permanent magnetic rods or two excitation windings are arranged vertically and systemically on three giant magnctostrictivc material rods; upper and lower disk magnetic inductive plates are respectively arranged on the above and at the bottom of the three giant magnctostrictivc material rods and the radiuses are a little bit bigger than the mounting radiuses of the permanent magnetic rods or the excitation windings; the magnetizing directions of the two permanent magnetic rods are axial and are the same; the two excitation windings have the same coiling direction and also the same current direction; the length of the permanent magnetic rods or the excitation windings is a little bit shorter than the length of the giant magnctostrictivc material rods to enable a gap between the top of permanent magnetic rods or the excitation windings and the bottom of the upper disk magnetic inductive plat; non-magnetic inductive glue is filled in the gaps to glue Hall units; inductive windings are coiled on the giant magnctostrictivc material rods; the upper disk magnetic inductive plate are arranged on a bearing block, the lower disk magnetic inductive plates are arranged on the base, an outer cover is arranged on the lower disk magnetic inductive plates, and encloses all parts on the base as a whole but the bearing block protrudes out of the upper surface of the outer cover.

Owner:HEBEI UNIV OF TECH +1

Copper-magnesium alloy strand production process thereof

InactiveCN1401803AImprove overload capacityImprove corrosion resistanceNon-insulated conductorsMetal/alloy conductorsContact networkThermal stability

A twisted CuMg alloy wire used as the messenger cable and sling of contact network for electrified railway contains Cu (greater than 99%) and Mg (0.45-0.55%), and is made through smelting CuMg alloy to prepare intermediate alloy, smelting intermediate alloy, conticasting to obtain rod blank, cold rolling, drawing, rewinding and twisting. Its advantages are high strength, small cross-section area, light weight, and high current carrying performance, over load power, thermal stability and elasticity.

Owner:JIANGYIN ELECTRICAL ALLOY

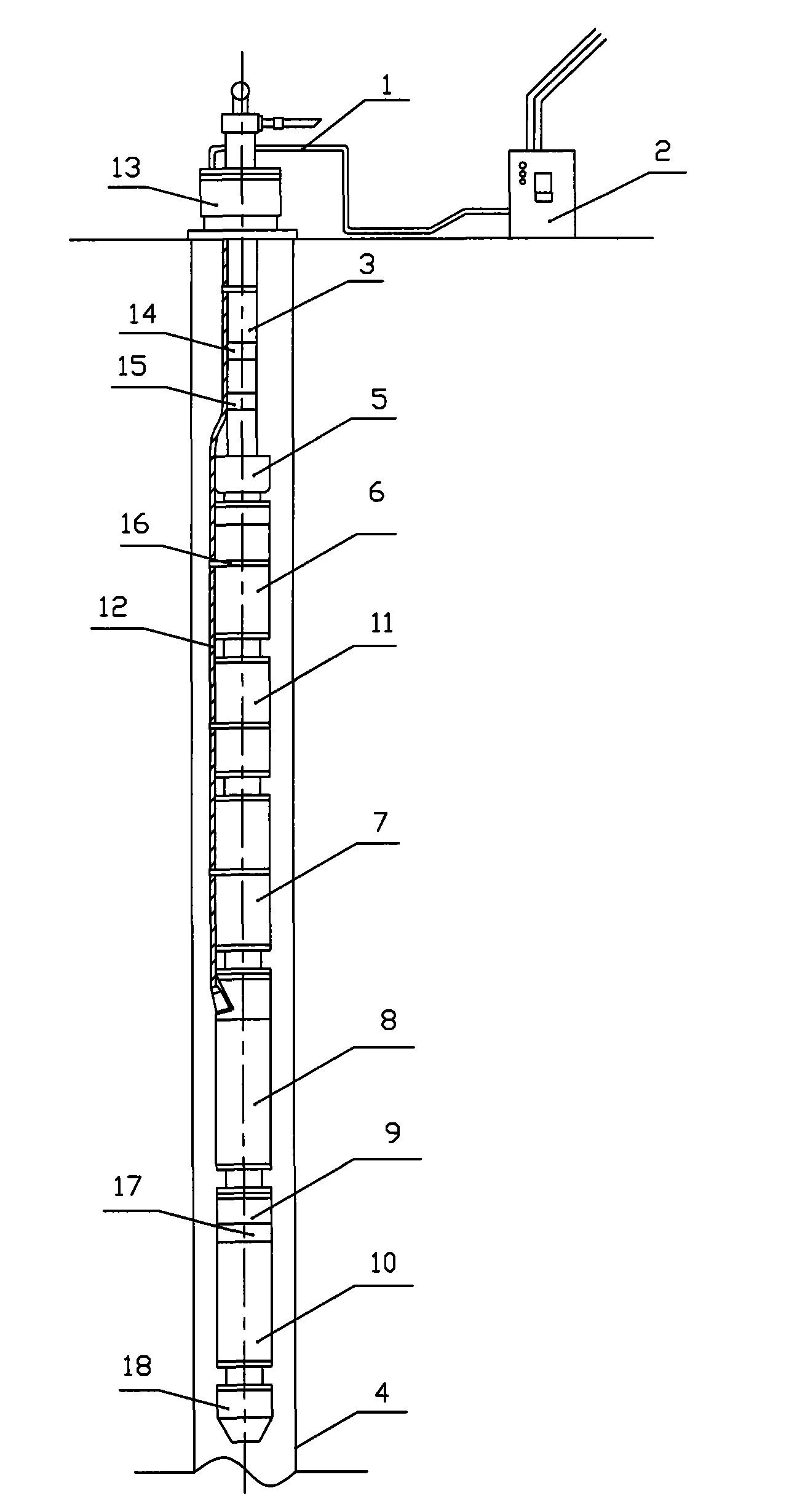

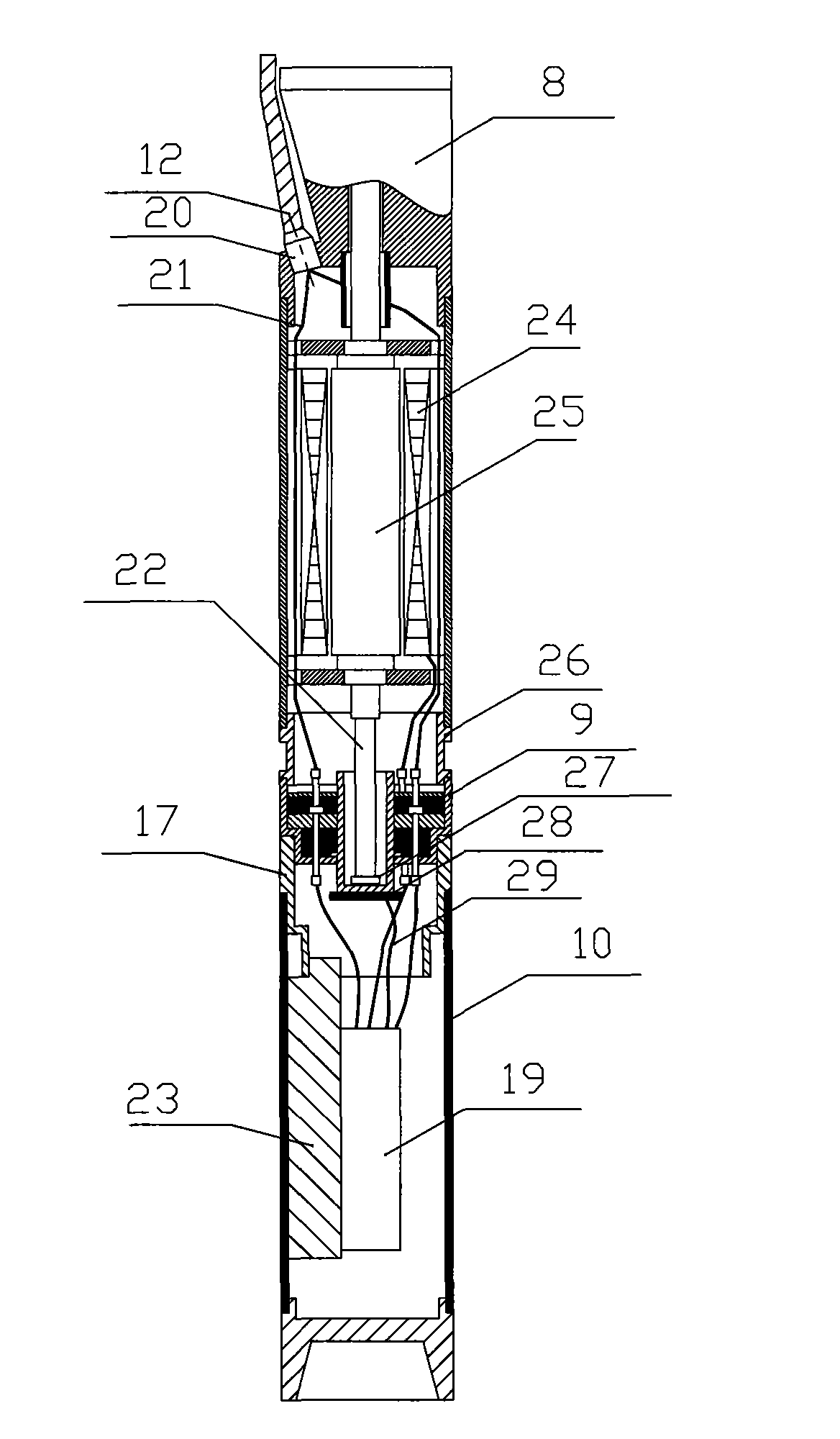

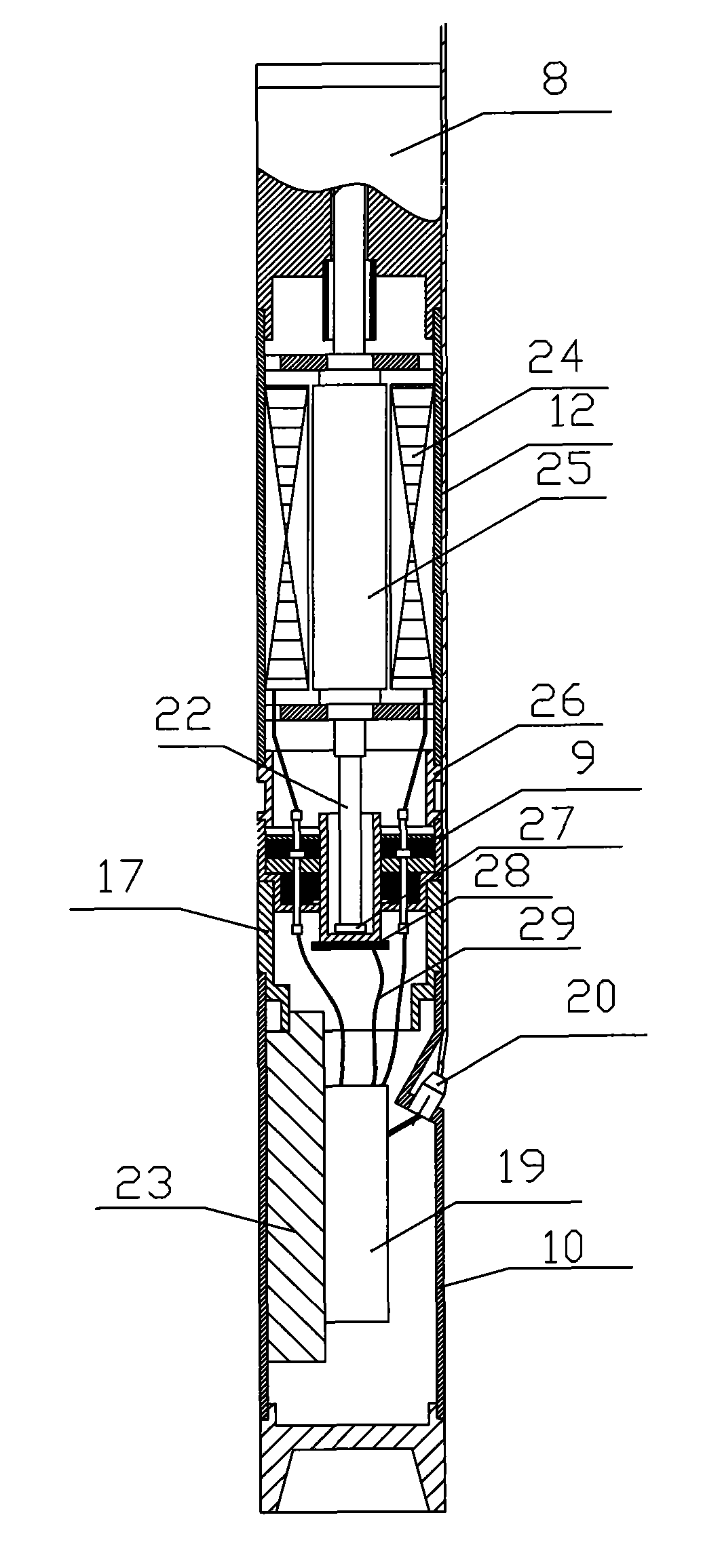

Control system of pumping system

InactiveCN101876243AImprove efficiencyImprove power densityFluid removalAutomatic control for drillingOperational costsControl system

The invention discloses an oil field control system which comprises a central control station and a plurality of underground submersible servodrive control subsystems communicating with the central control station, wherein each underground submersible servodrive control subsystem is connected with a production module in the well where the underground submersible servodrive control subsystem is, and the underground submersible servodrive control subsystem transmits the underground condition to the central control station according to the command and controlling parameters received from the central control station or a man machine interaction interface of the subsystem when controlling the operation of the production module. Through the invention, the operation condition of the submersible servodrive system in each well in the whole oil field can be accurately monitored and reasonably controlled by an operator, thus being favorable for improving the production efficiency and saving the operating cost.

Owner:杭州坤泽采油设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com