Nuclear reactor control rod hydraulic driving system

A driving system and control rod technology, which is applied in the field of structural design of nuclear reactor control rod hydraulic drive system, can solve problems such as the complexity of driving characteristics, and achieve the effects of enhancing safety, avoiding rod popping accidents, and large overload capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific structure, working process and embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

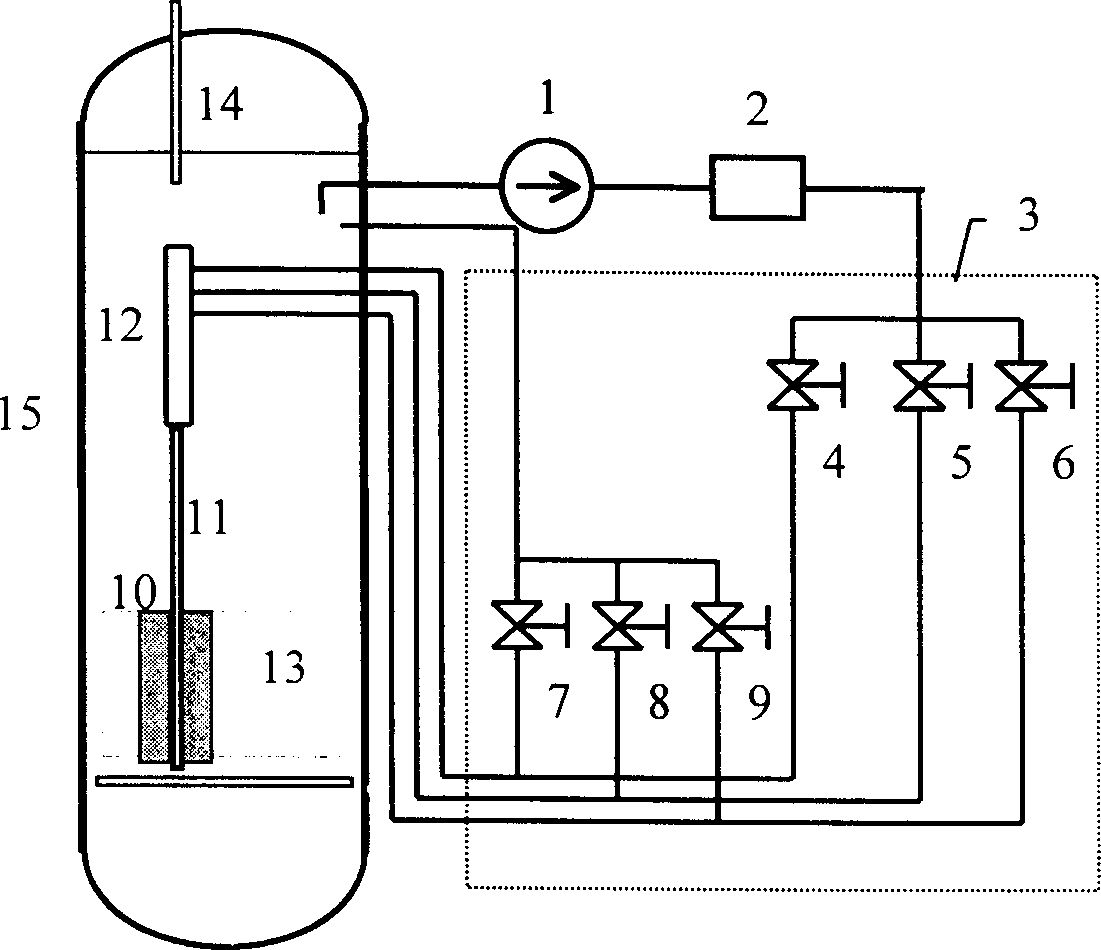

[0018] The hydraulic drive system of the present invention is as figure 1 As mentioned above, it mainly includes the core 13, the control rod 10, the drive shaft 11, the pressure vessel 15, the rod position measurement 14, the circulating water pump 1, the filter 2, the combination valve 3 and the like. The combination valve 3 is made up of three normally closed electromagnetic valves (4, 5, 6) connected in parallel and three normally open electromagnetic valves (7, 8, 9) connected in parallel. The water outlets of the three normally closed solenoid valves are respectively connected with the water inlets of the three pressure water cylinders, and the water outlets of the three normally open solenoid valves are connected with the pressure vessel 15 .

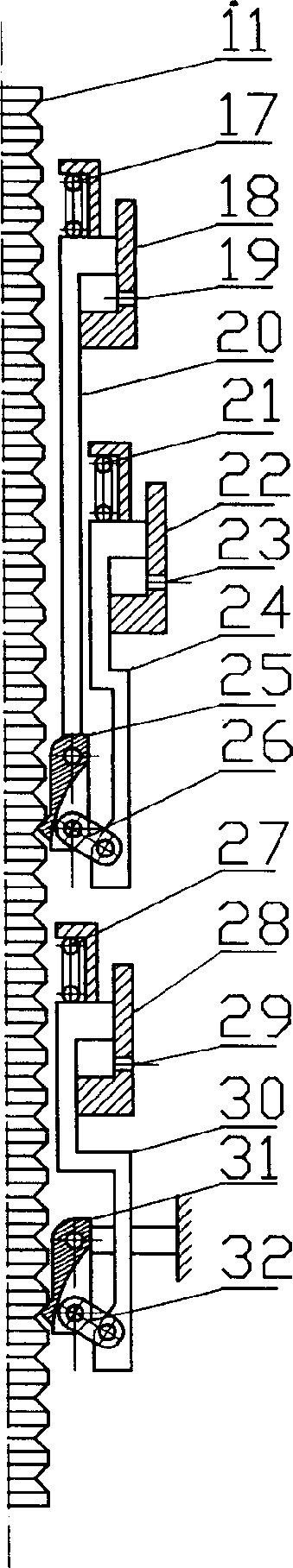

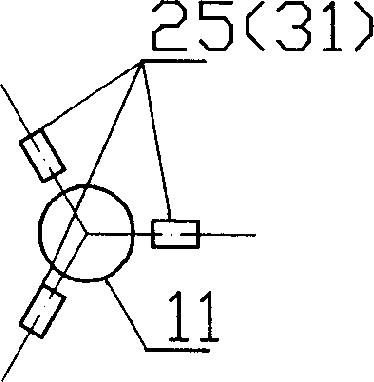

[0019] Drive mechanism 12 of the present invention is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com