Patents

Literature

253 results about "Reactor safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

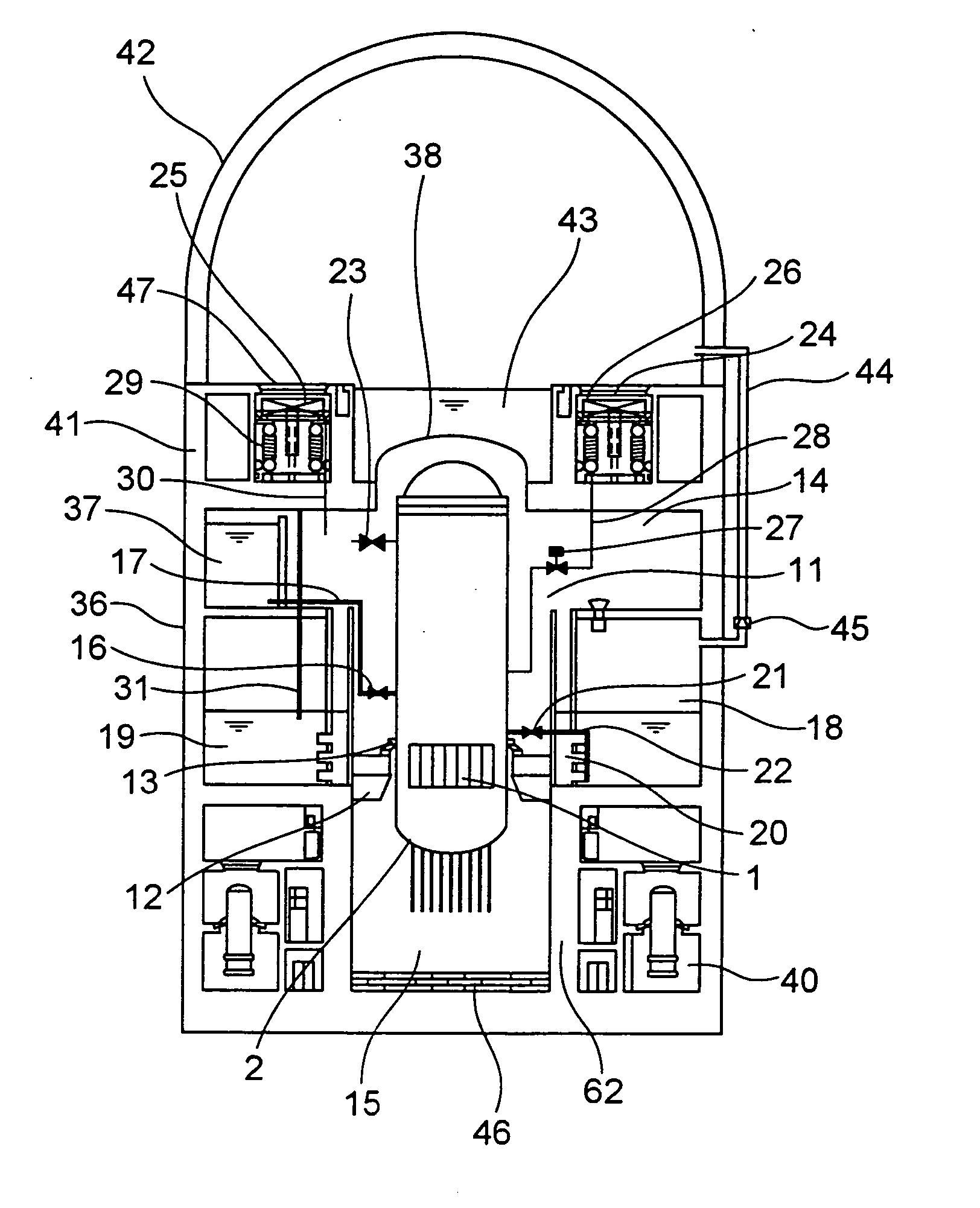

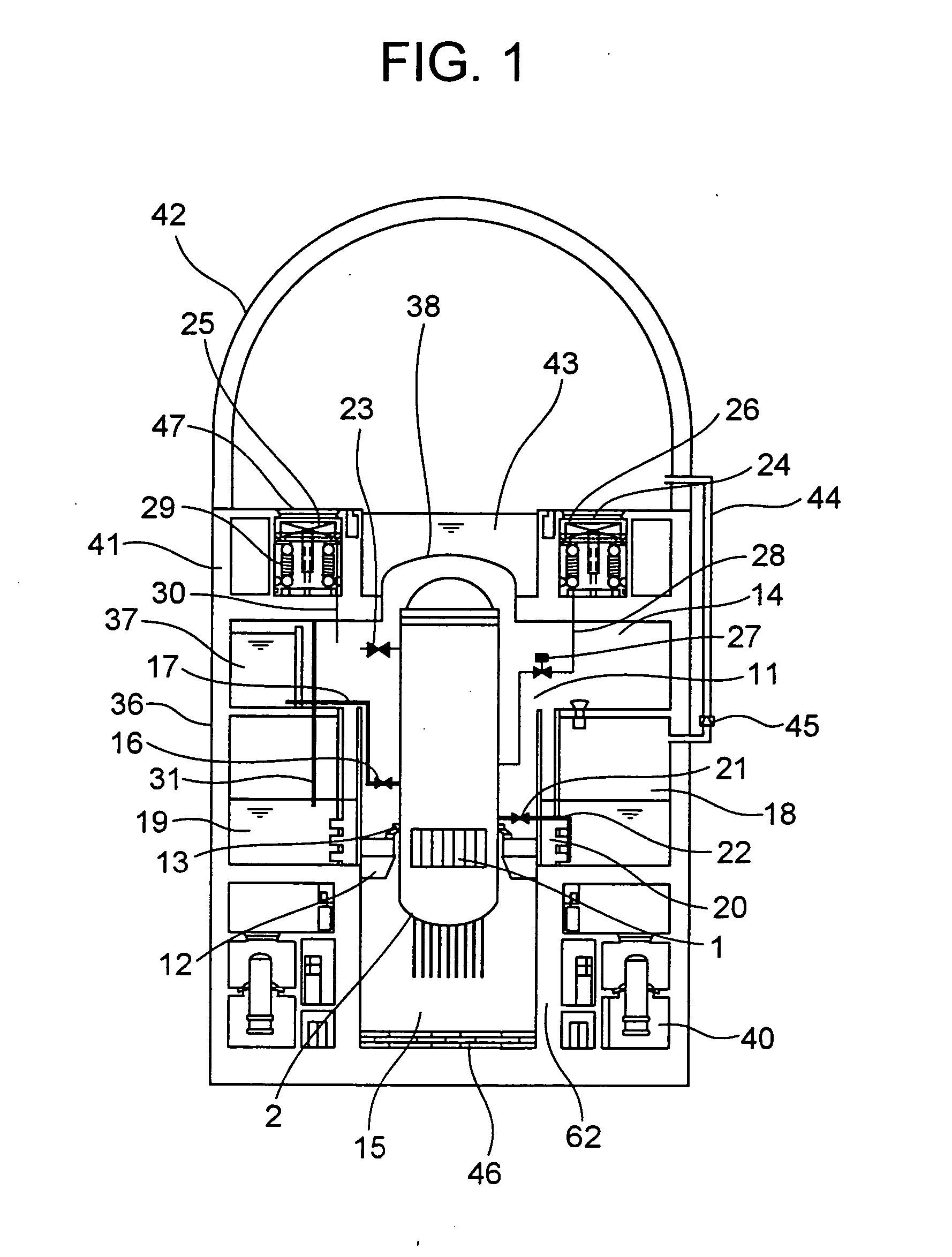

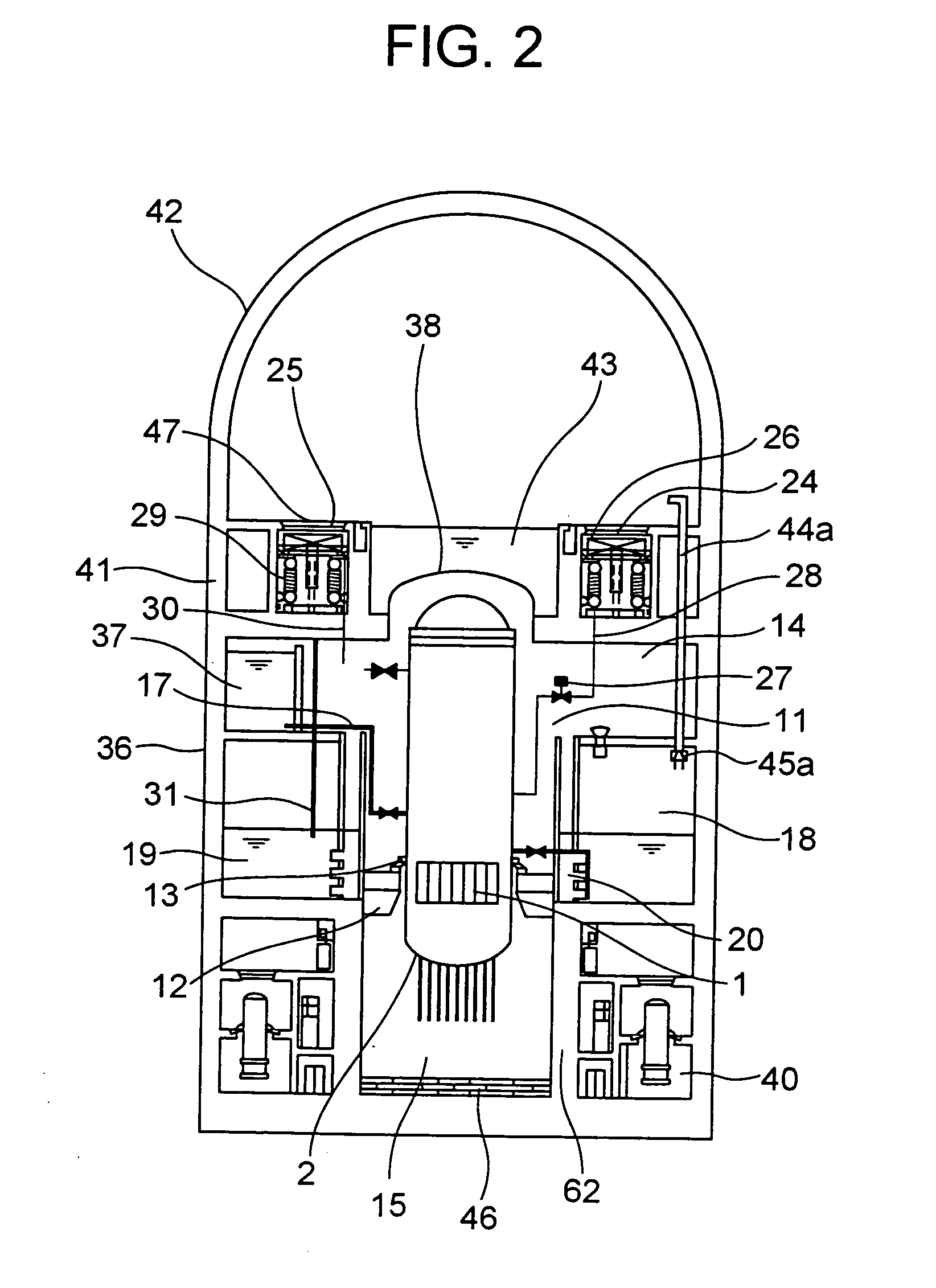

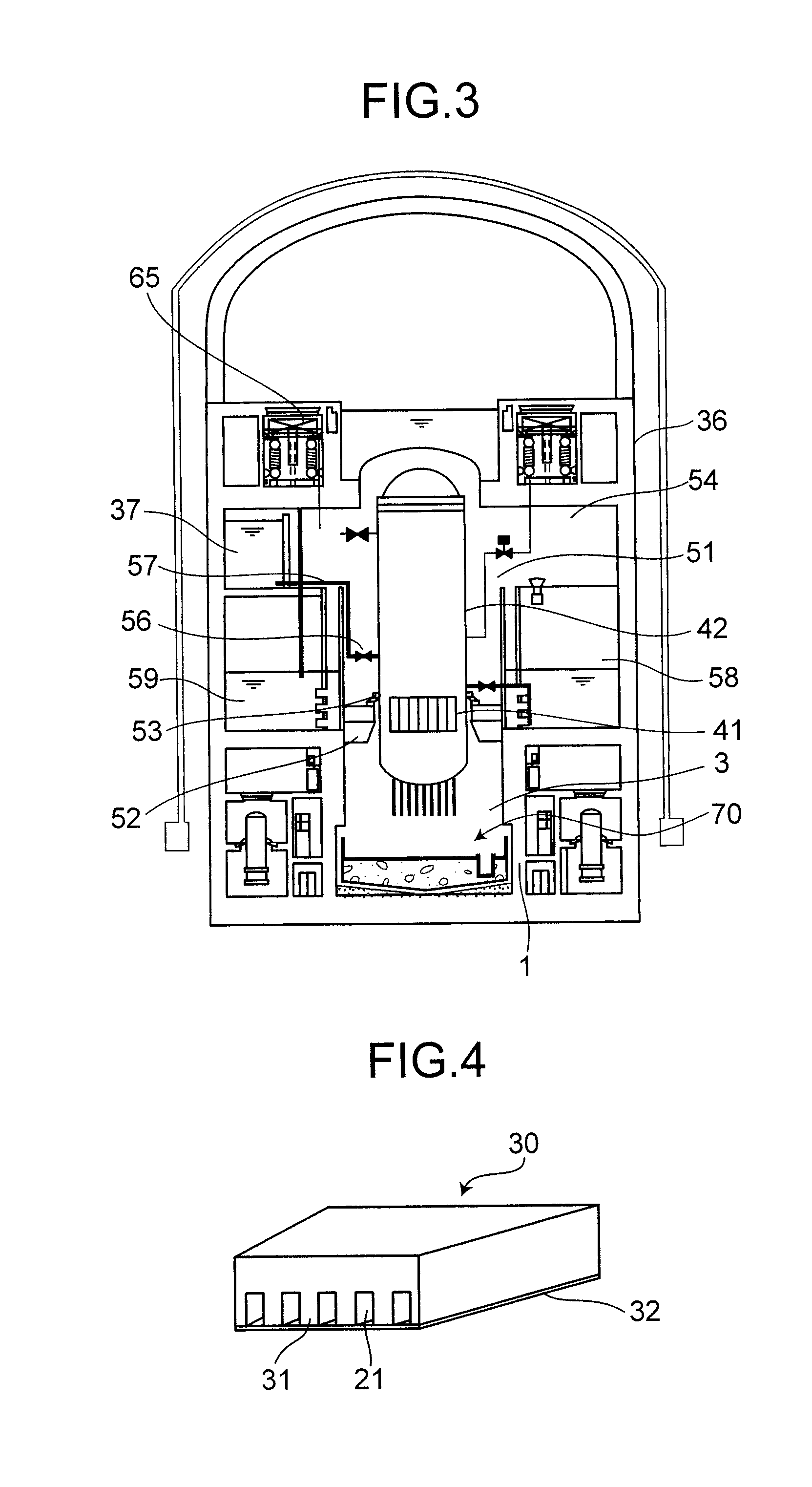

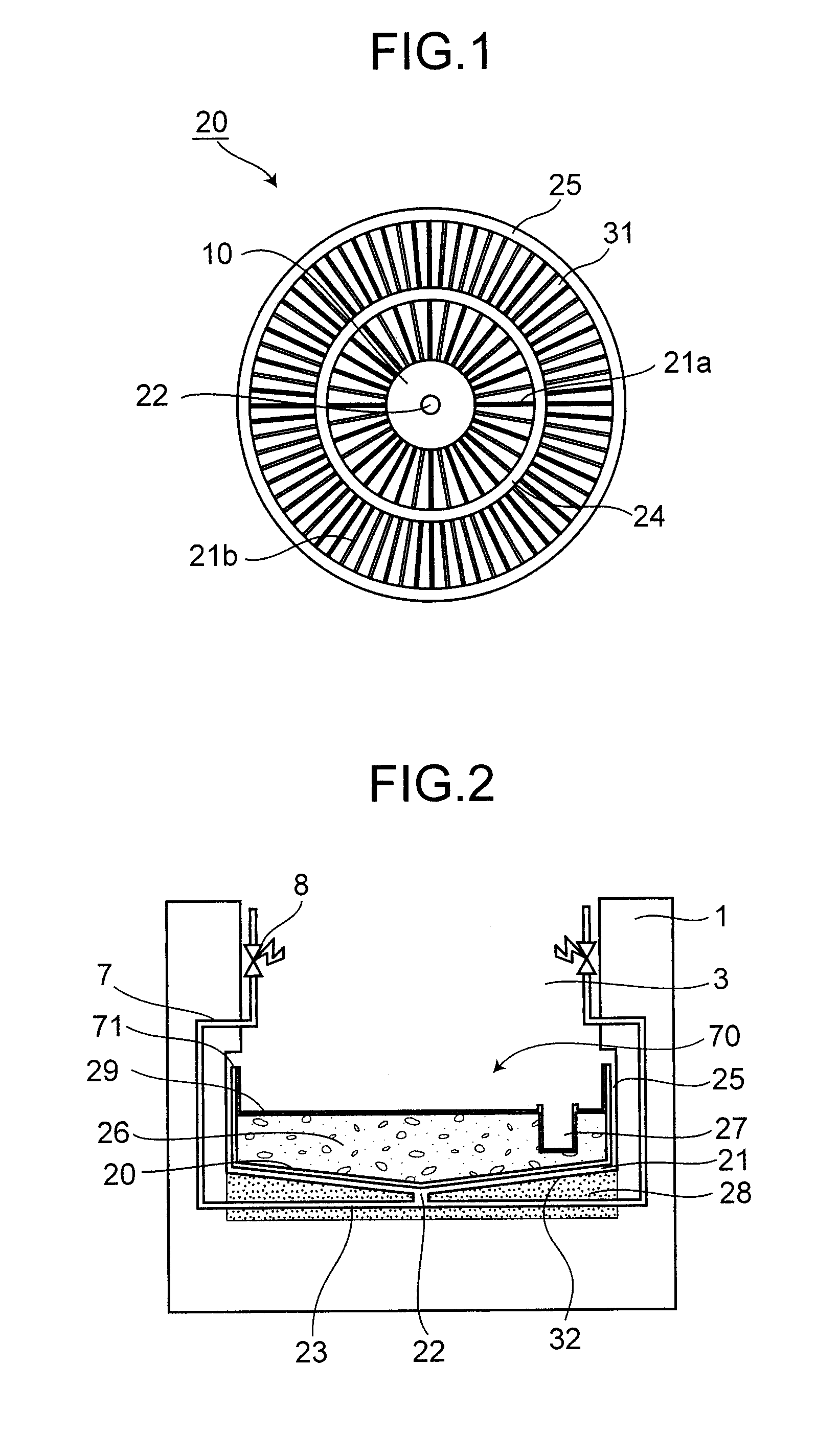

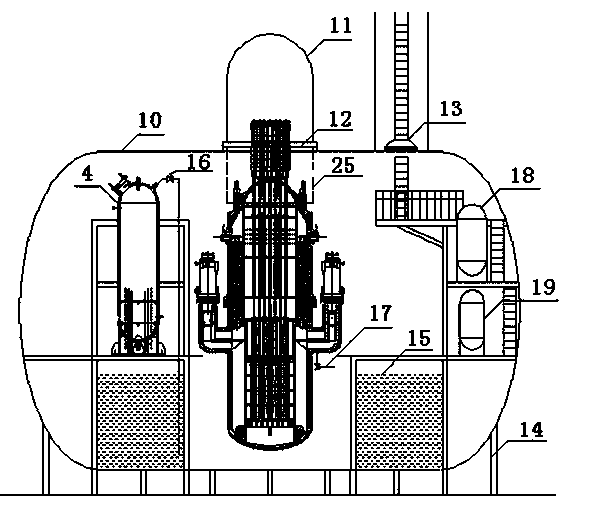

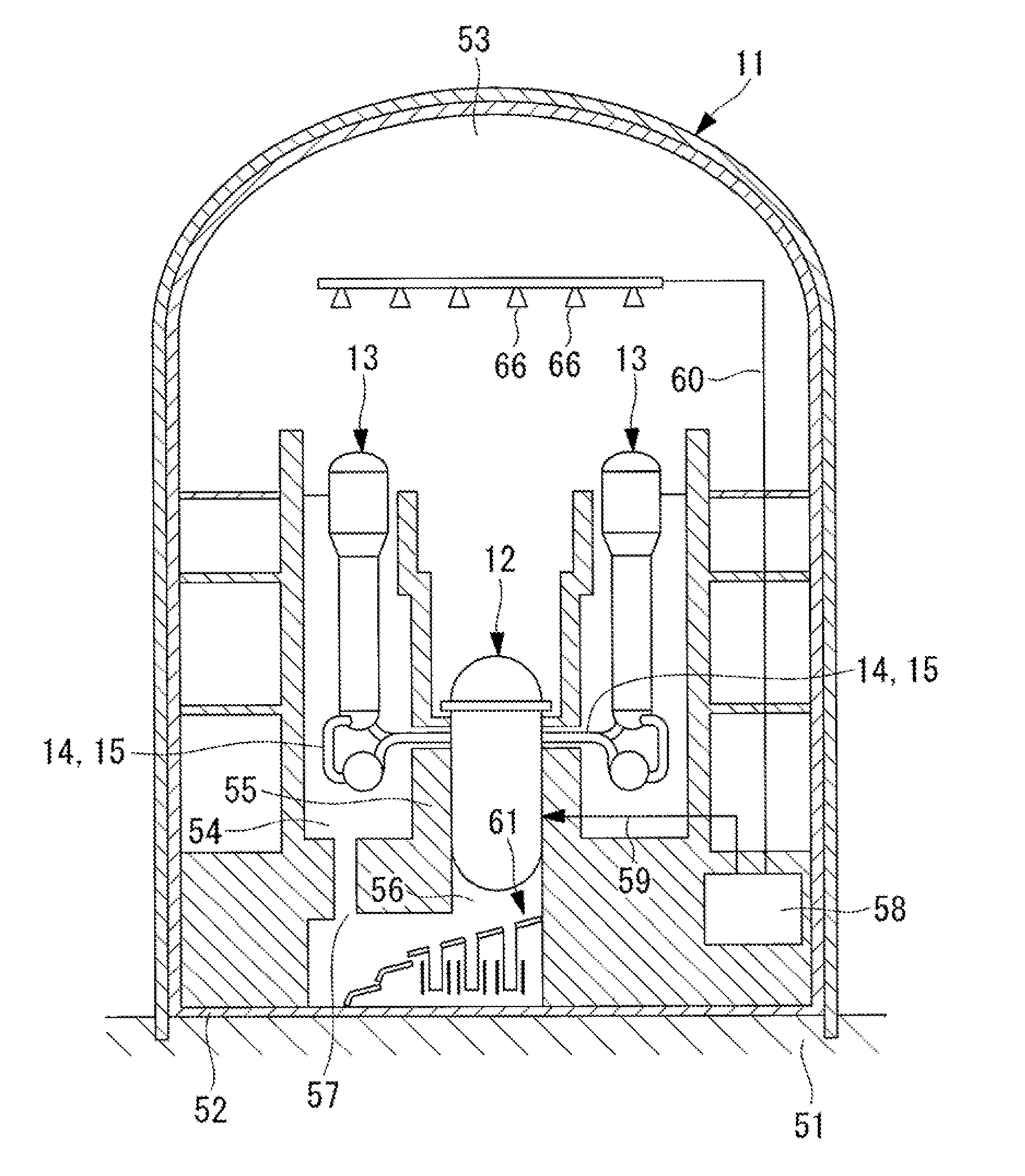

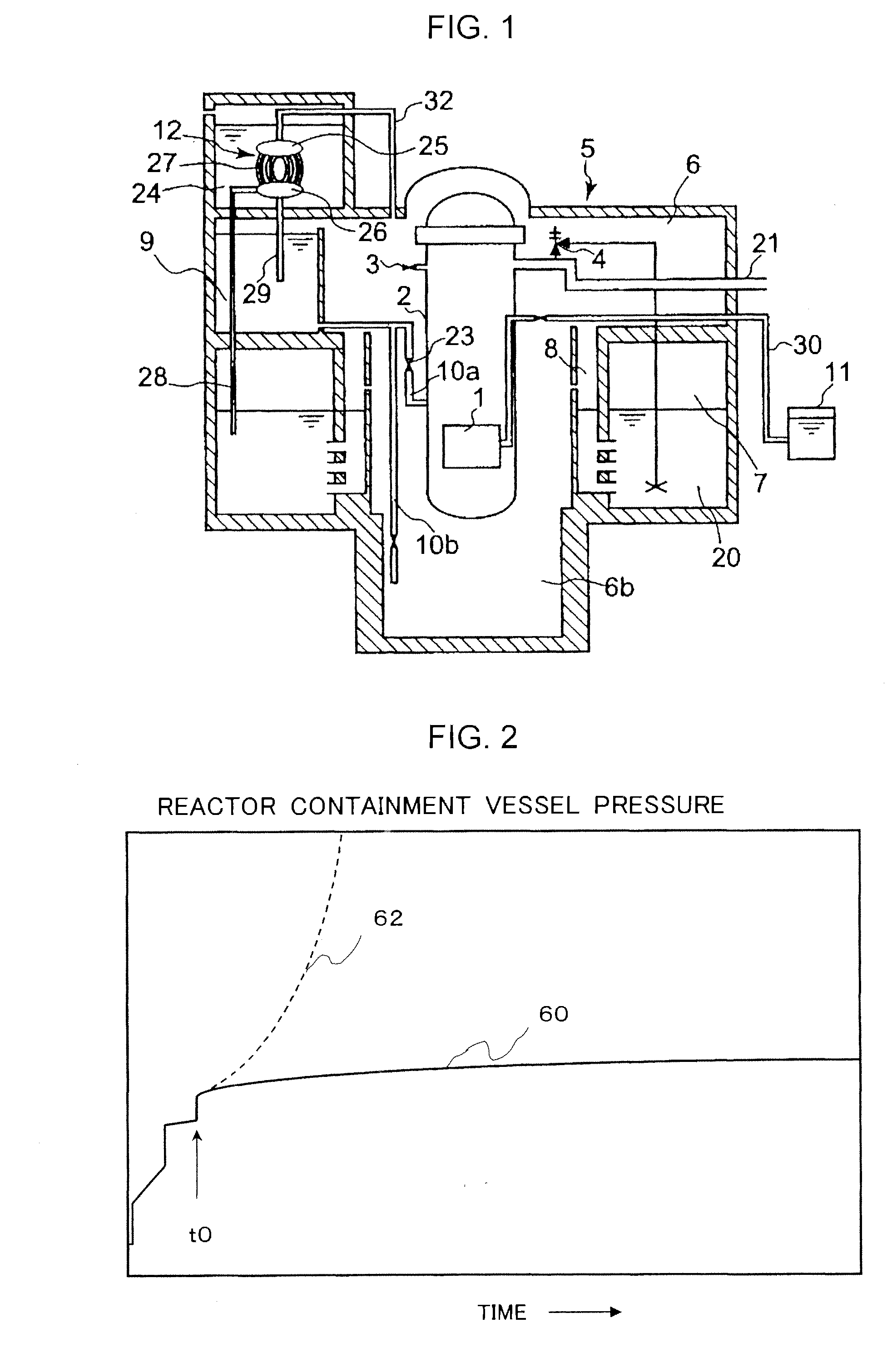

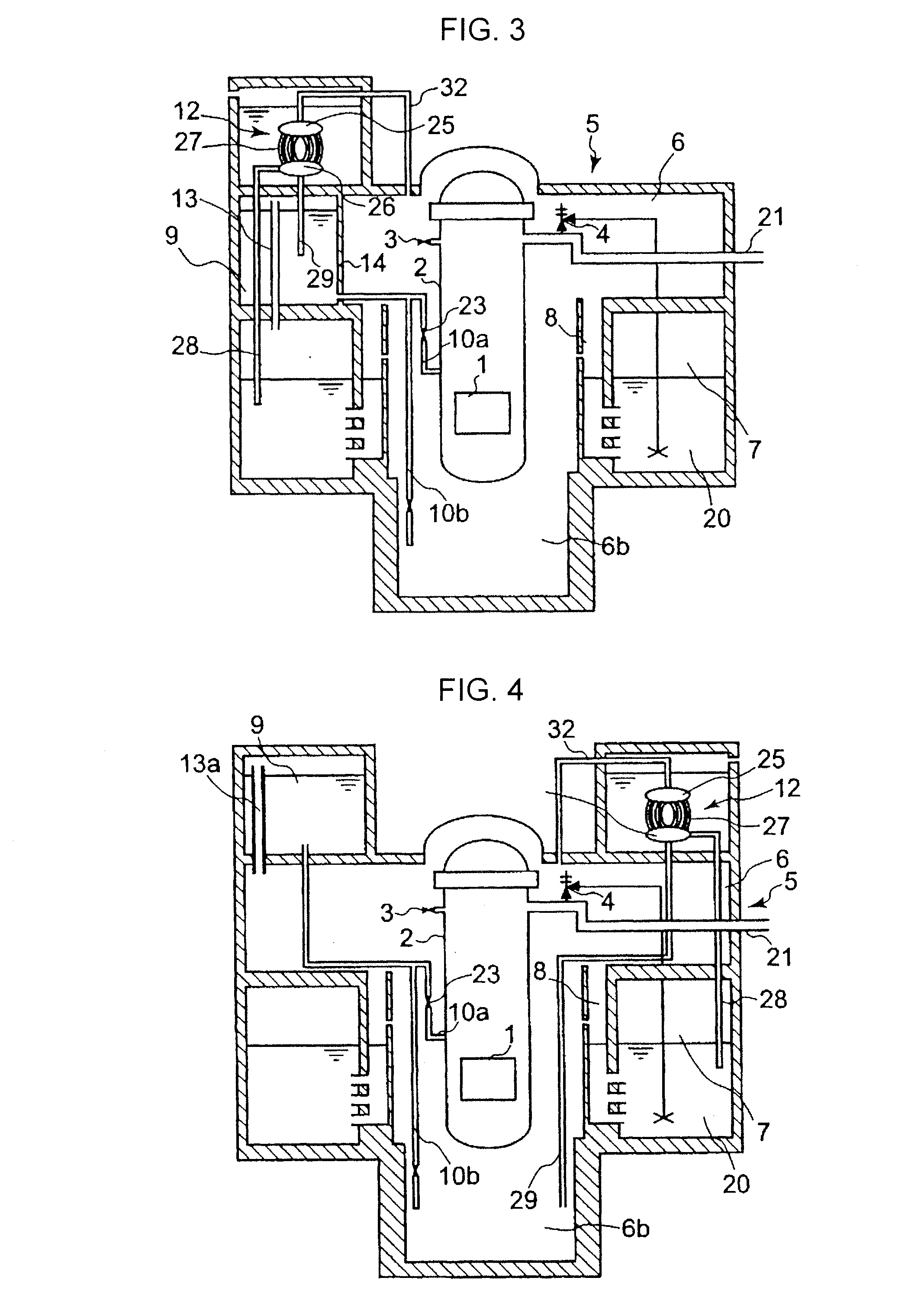

Reactor containment vessel and boiling water reactor power plant

ActiveUS20070092053A1Nuclear energy generationNuclear engineering problemsPower stationReactor pressure vessel

A containment vessel includes a primary containment vessel containing a reactor pressure vessel, an upper secondary containment vessel arranged above the primary containment vessel, and a gas-phase vent pipe linking the primary containment vessel and the upper secondary containment vessel by way of an isolation and connection switching system. The gas-phase vent pipe may be arranged either inside or outside the primary containment vessel and the upper secondary containment vessel. Alternatively, it may be embedded in the wall. An igniter may be arranged in the upper secondary containment vessel. The air in the upper secondary containment vessel may be replaced by nitrogen. A gravity-driven flooding system pool may be arranged in the upper secondary containment vessel and cooling water may be led from the inside of the pool to the inside of the primary containment vessel.

Owner:KK TOSHIBA

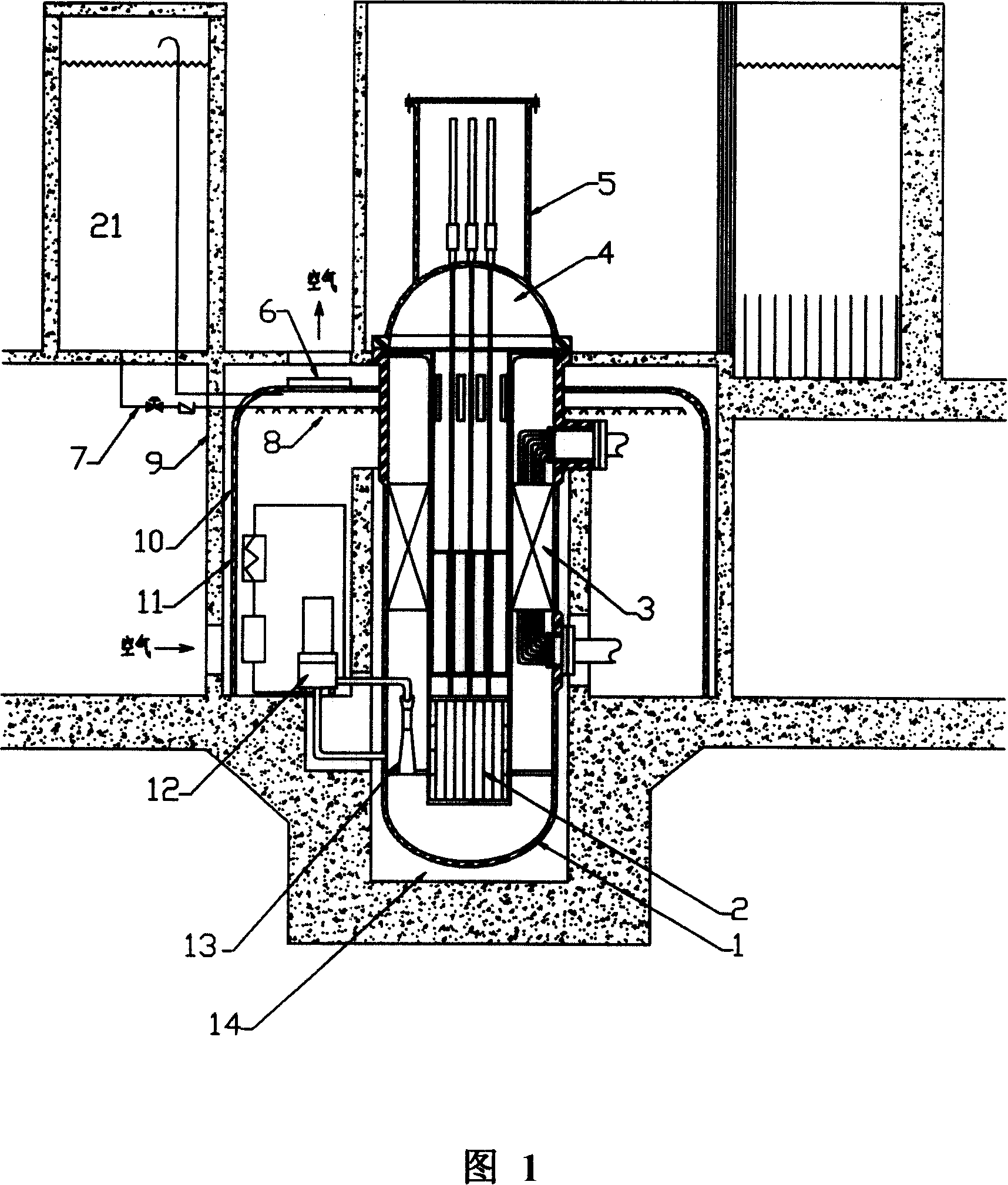

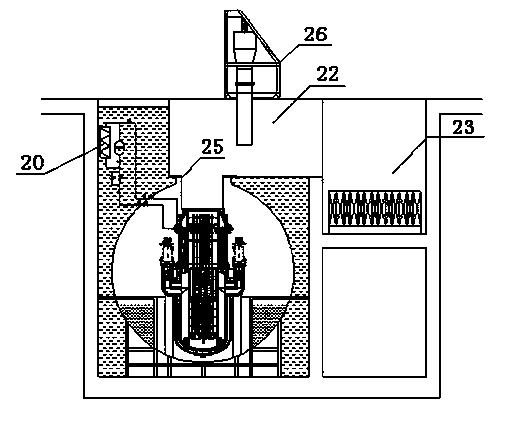

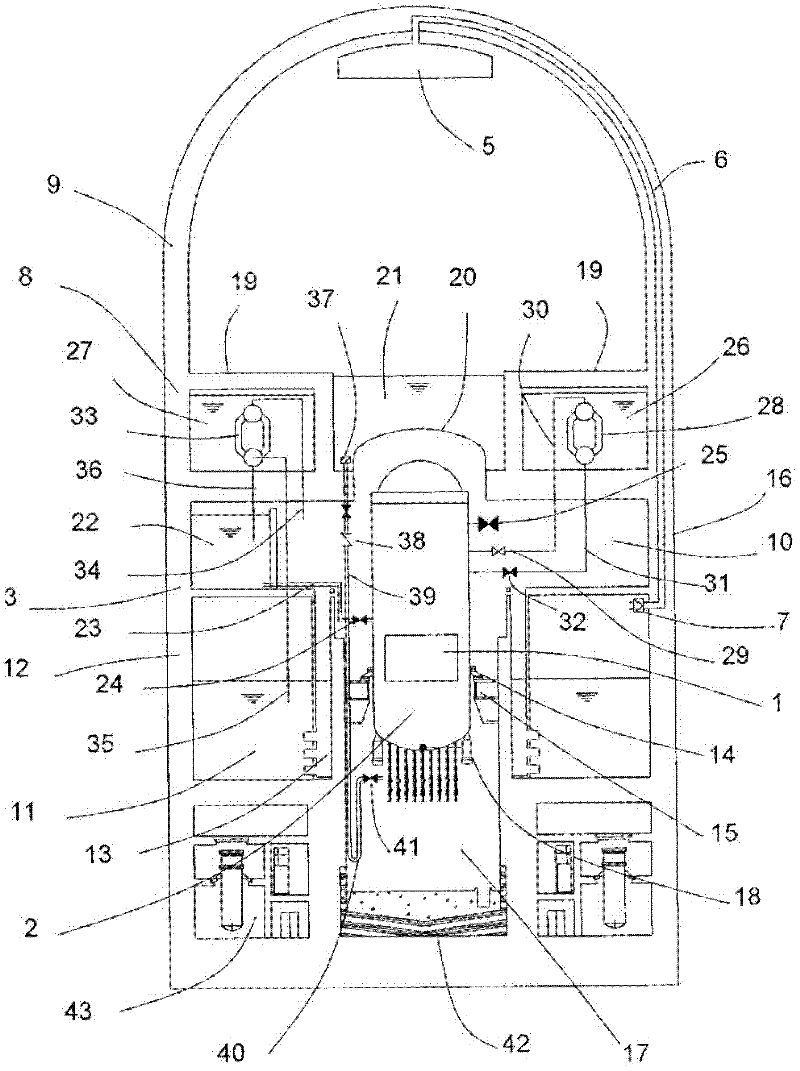

Integrated low-temperature nuclear heat supplying pile

ActiveCN101154472ASmall sizeCompact layoutIntegral reactorsNuclear energy generationReactor pressure vesselPressurized water reactor

The invention discloses an integral low-temperature nuclear heat reactor with the circuit equipment adopting integral arrangement and belonging to the low- and medium-parameter pressurized-water reactor, wherein, a reactor core adopts the mature nuclear power plant fuel component and control rod component; a main heat exchanger is of integral coil type; a voltage stabilizer is a built-in nitrogen partial pressure control voltage stabilizer; coolant circulation is completed by a built-in jet apparatus and the equipment of an external drive circuit; the drive circuit and the equipment and a main circuit auxiliary system are arranged at the circumference of a reactor pressure vessel; a containment vessel consists of a reactor body containment vessel and a reactor top containment vessel; the reactor body containment vessel which is a structure combined by a reactor vault of reinforced concrete structure and a casing of steel structure is connected with a sealed refueling water storage pool through a pipe and a valve. The thermal power of the reactor can be selected between 50MW and 500MW at will and the outlet temperature of the reactor can be selected between 100 DEG C to 200 DEG C according to application, requirement and power.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

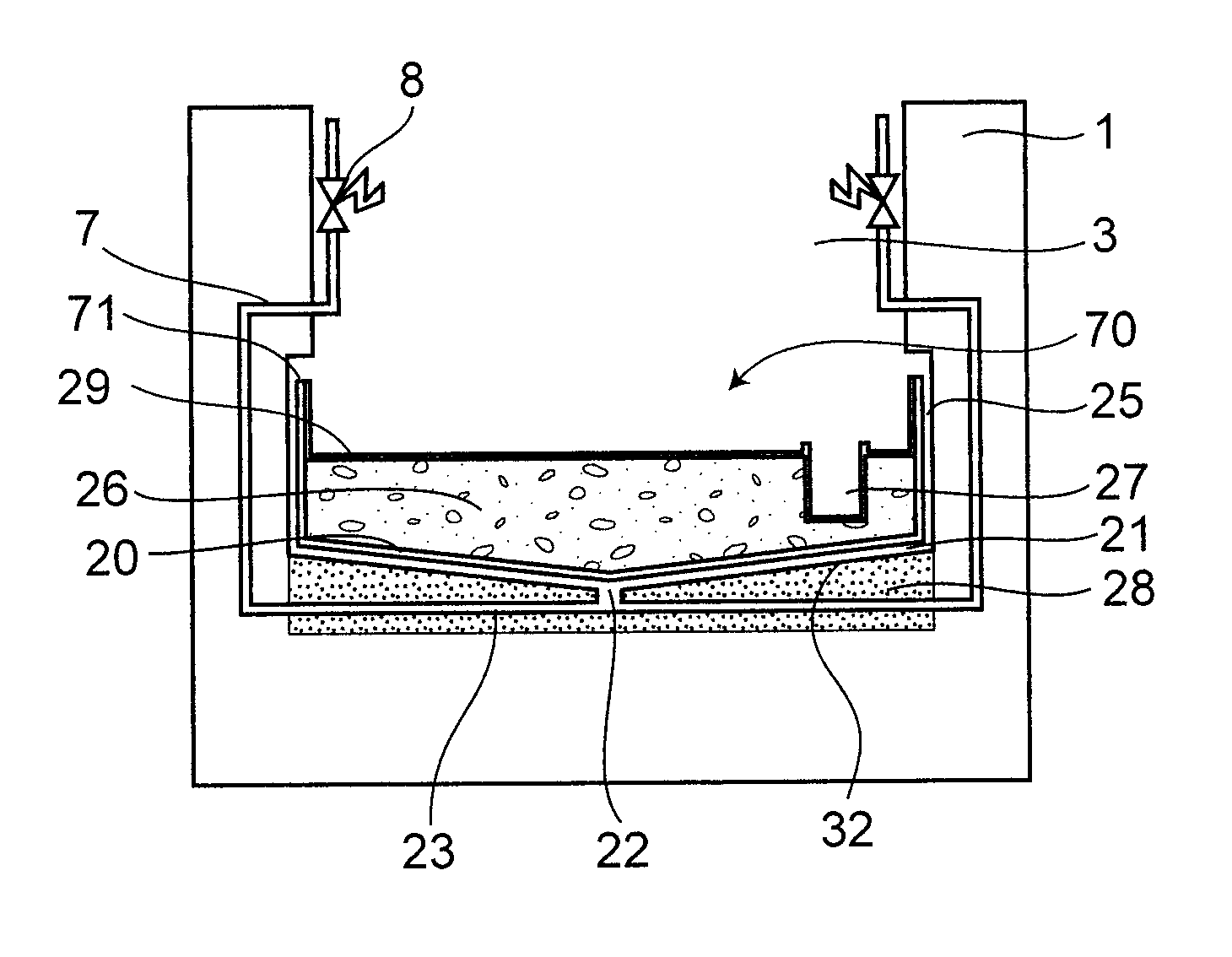

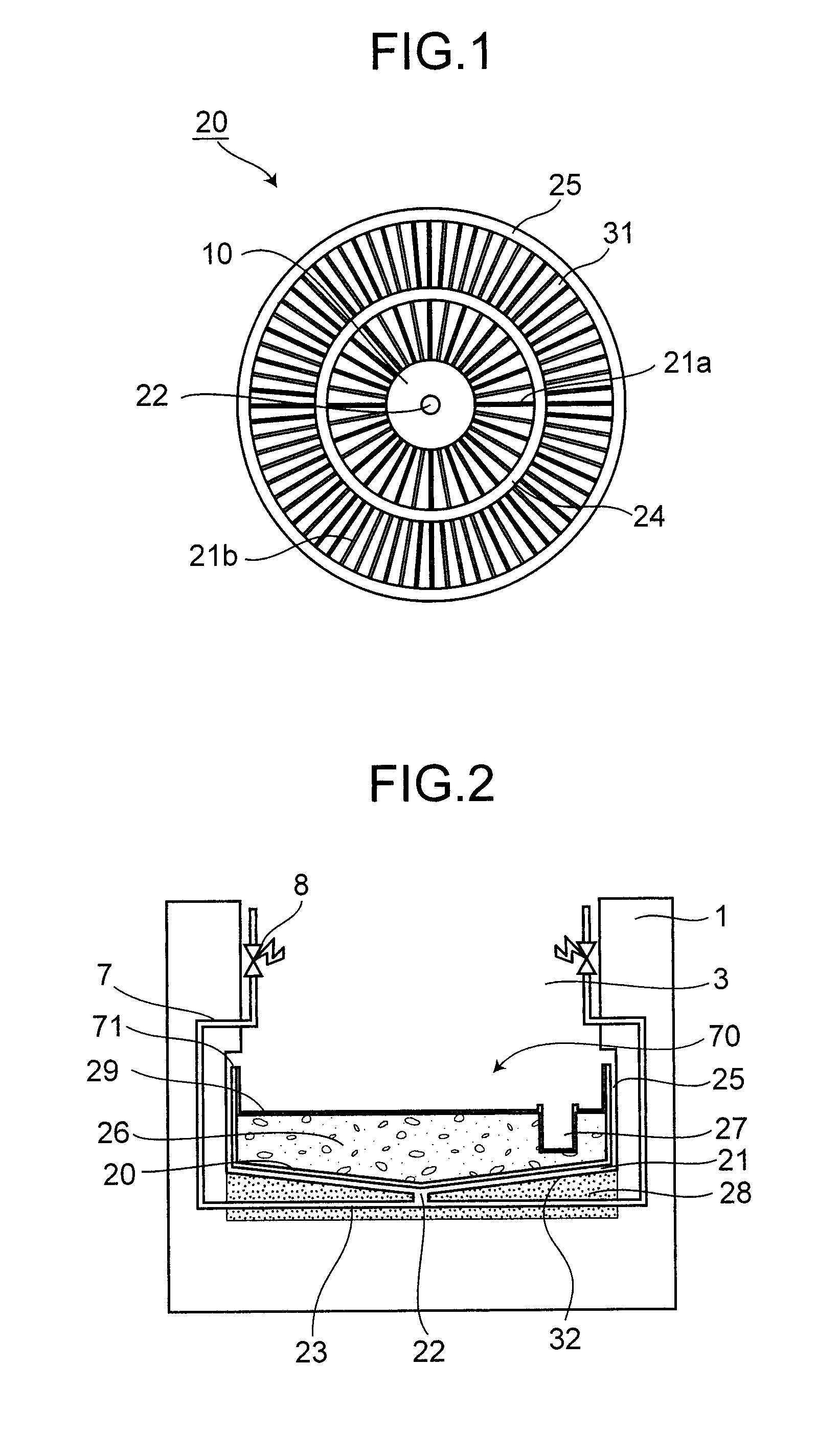

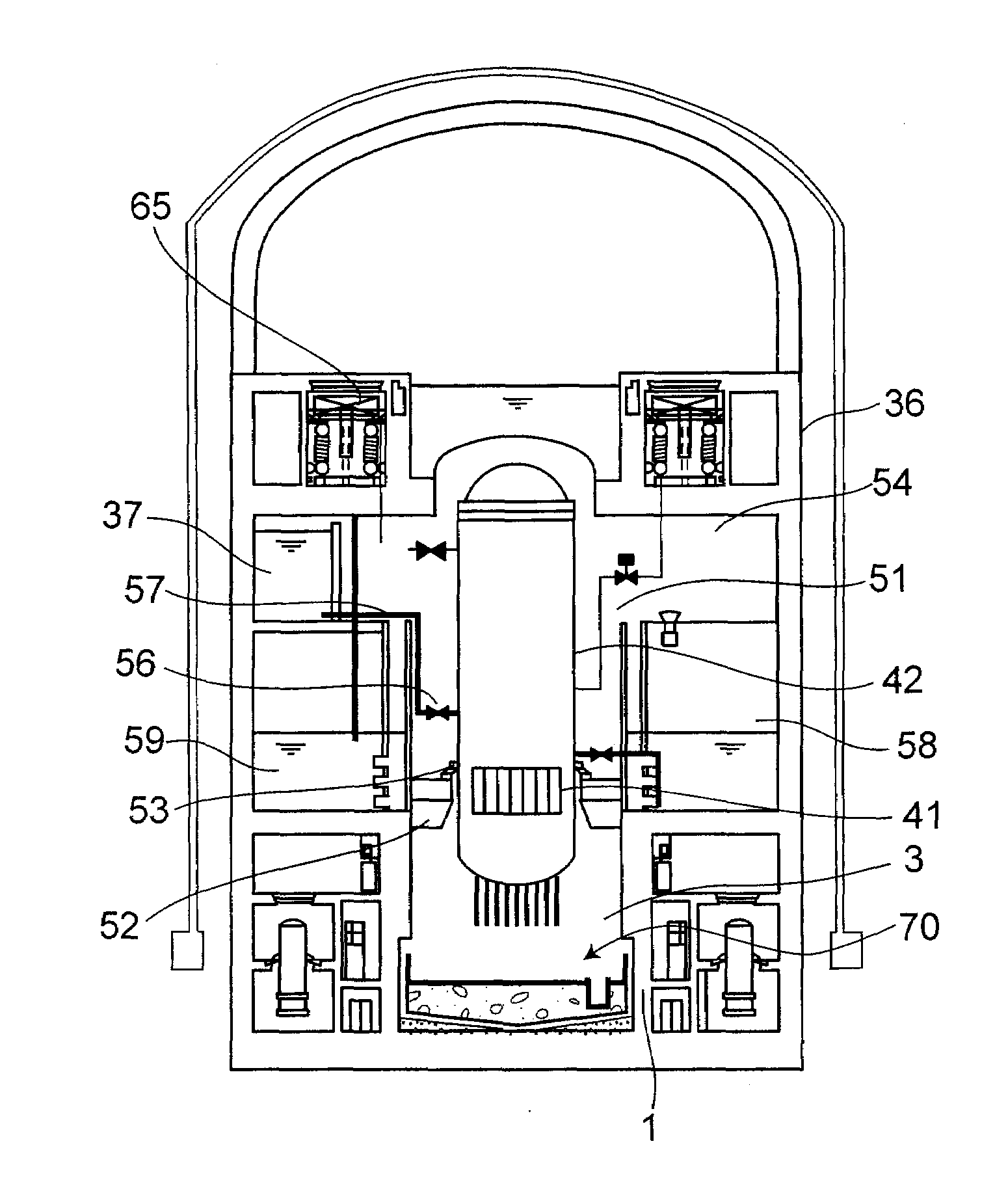

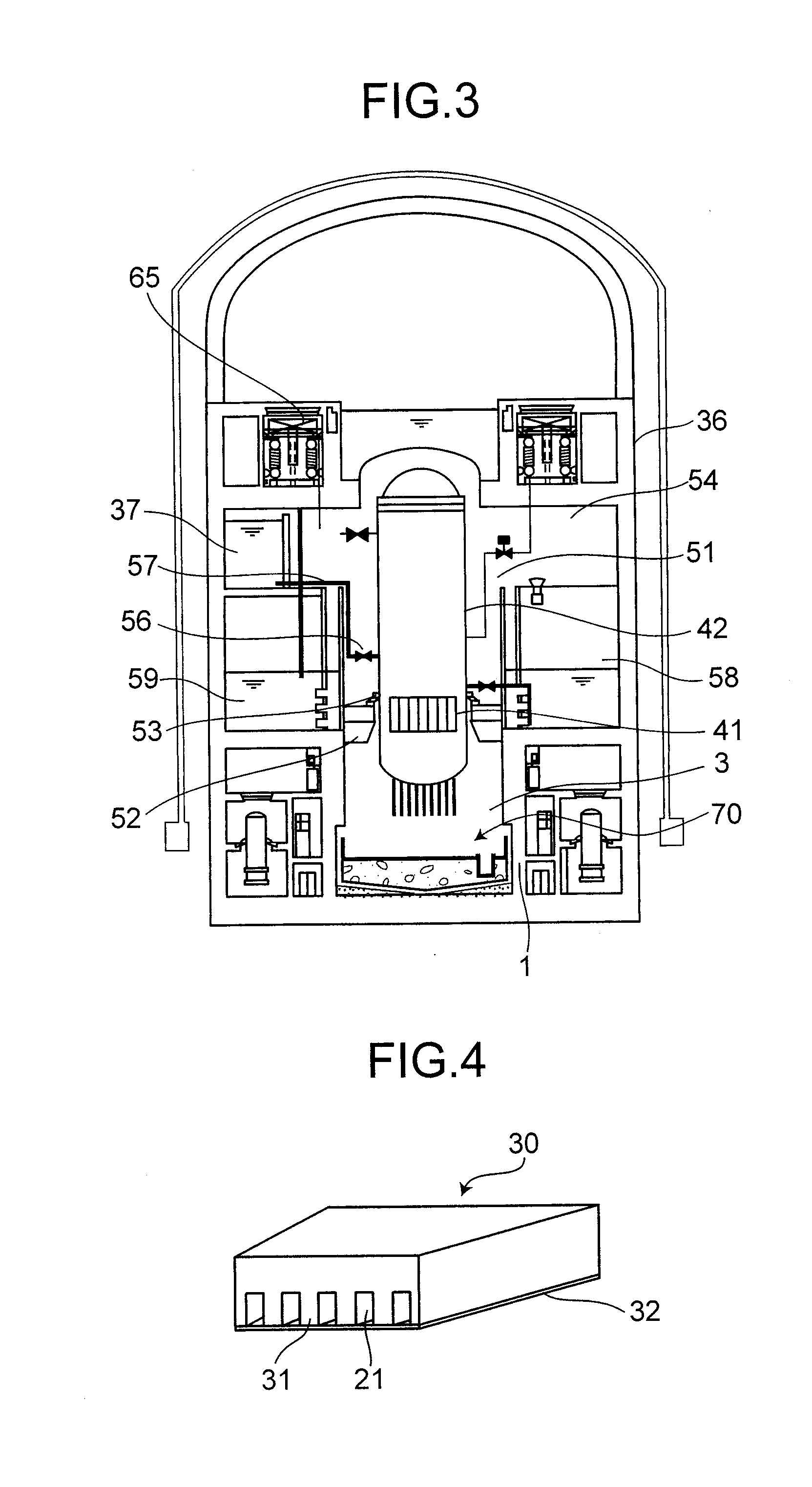

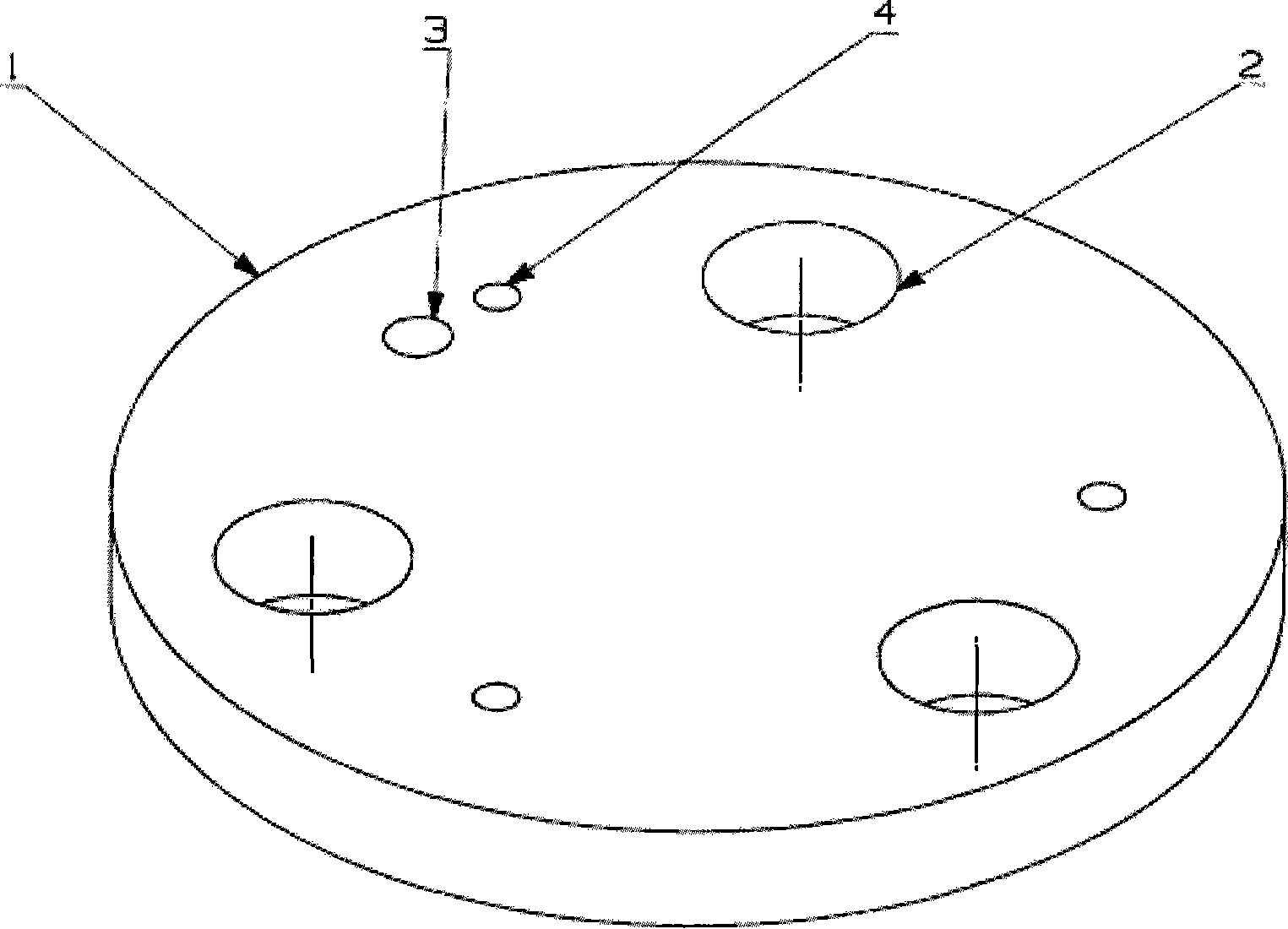

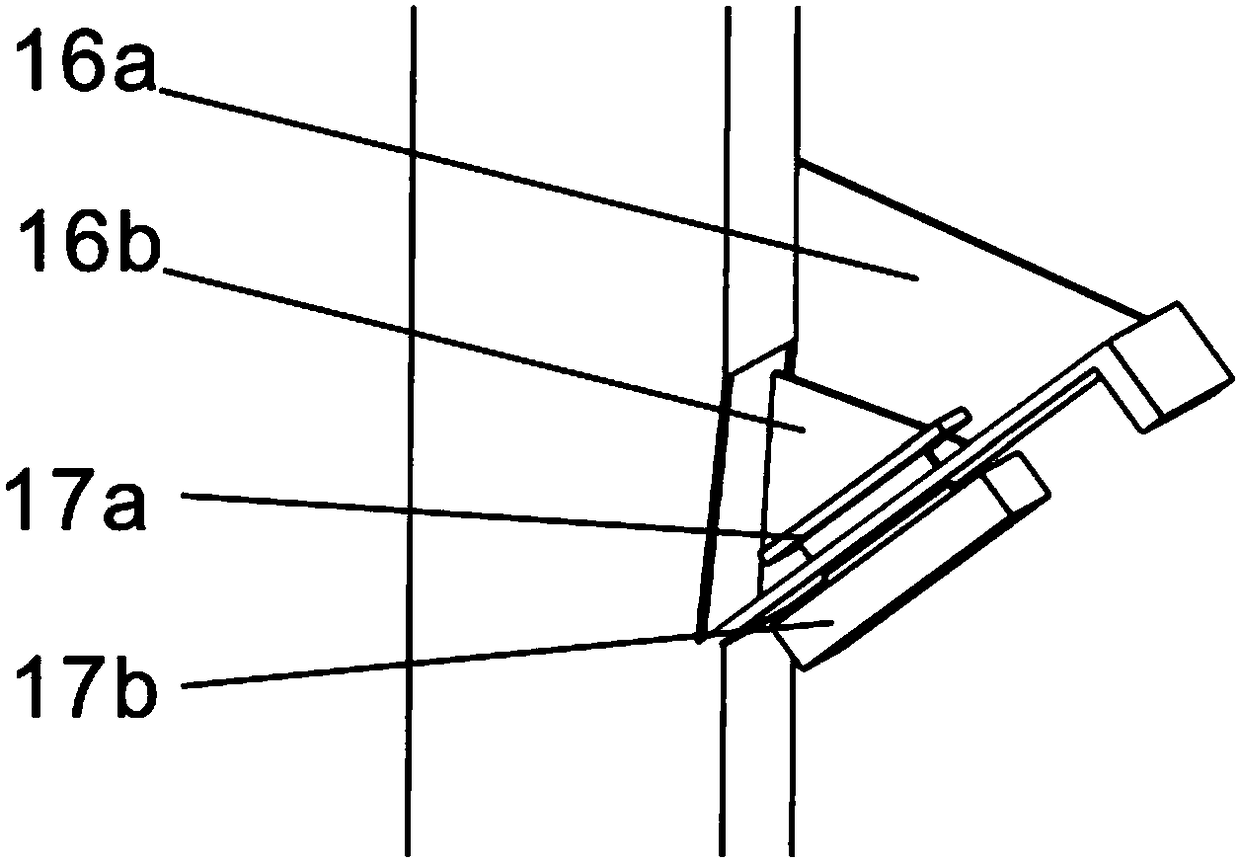

Core catcher, manufacturing method thereof, reactor containment vessel and manufacturing method thereof

Core debris generated during a molten reactor core in a reactor containment vessel penetrating the reactor containment vessel is configured to be caught by a core catcher located beneath the reactor containment vessel which has a main body having first stage cooling water channels and second stage surrounded by cooling fins extending radially. The number of the second stage cooling channels is larger than that of the first stage cooling channels. Cooling water is supplied from a cooling water injection opening and distributed to the first cooling water channels at a distributor. An intermediate header is formed between the first and the second cooling water channels, and the cooling water is distributed to the second cooling water channels uniformly.

Owner:KK TOSHIBA

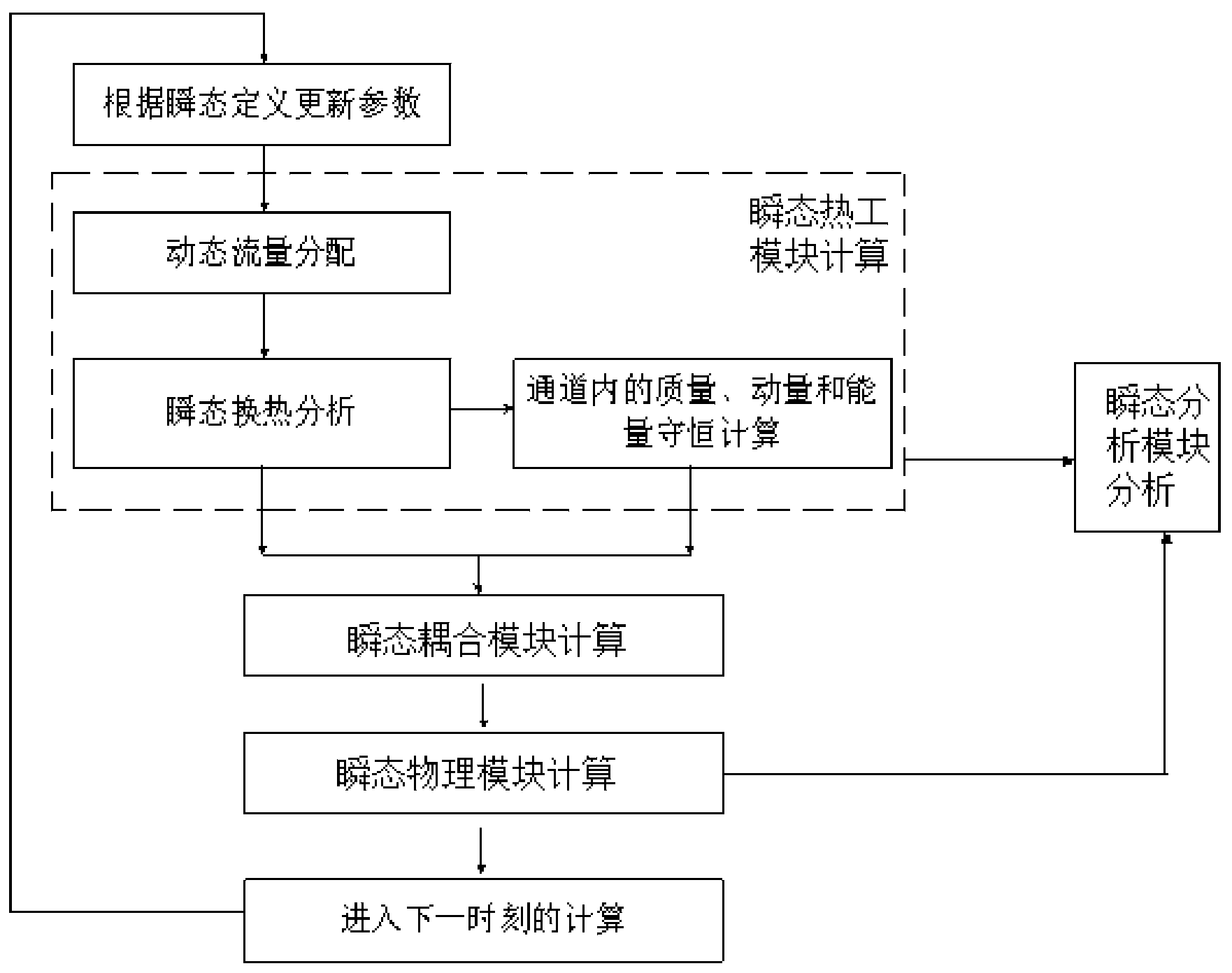

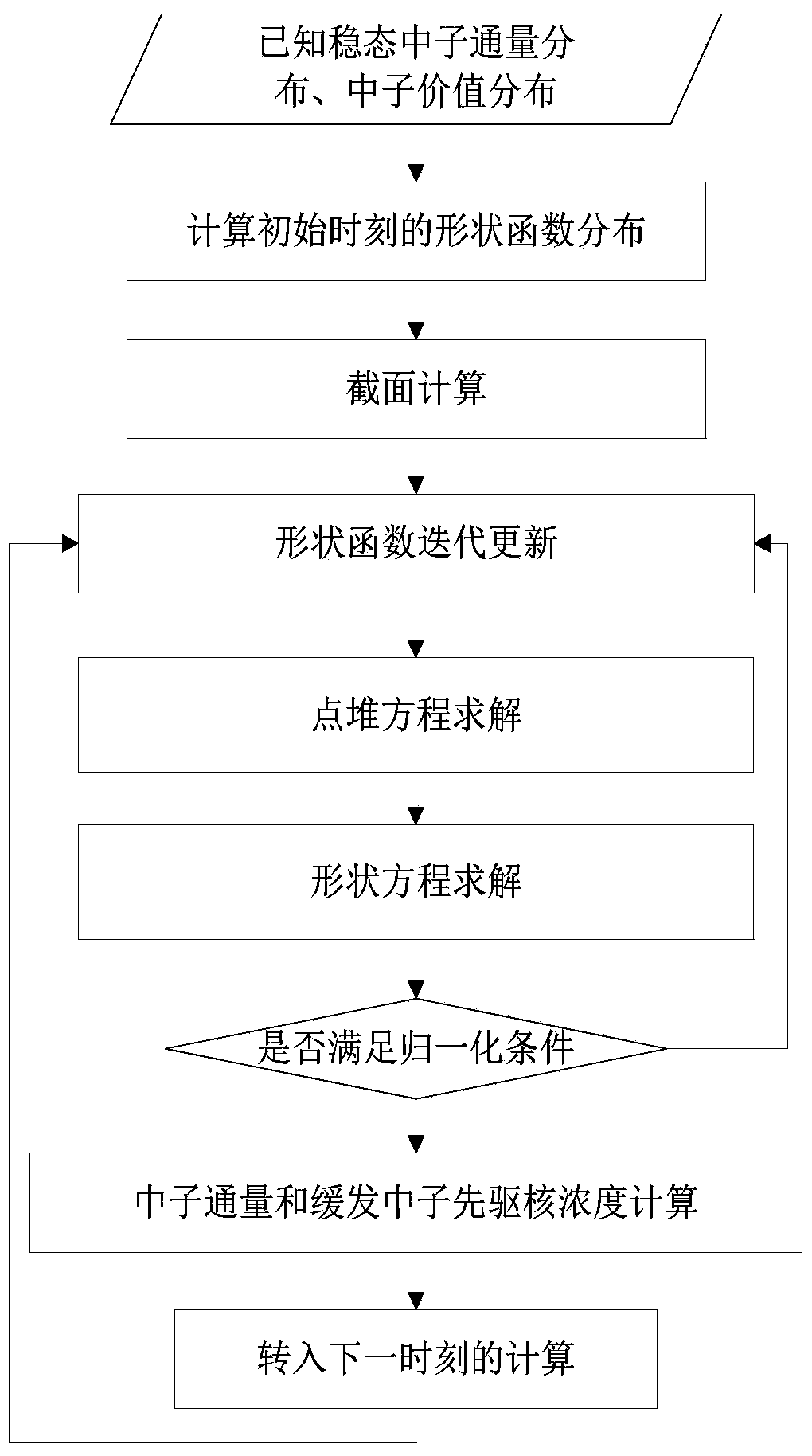

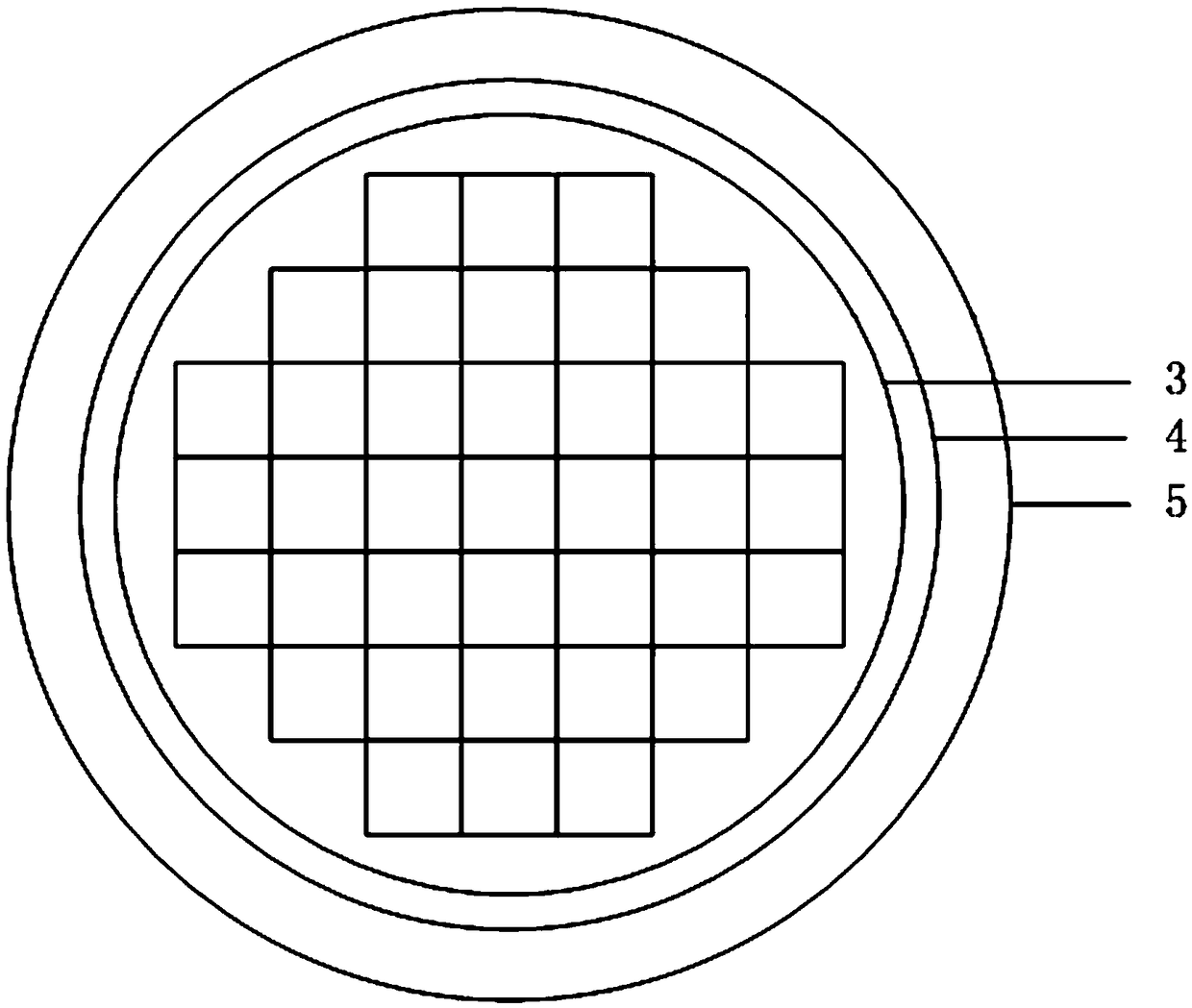

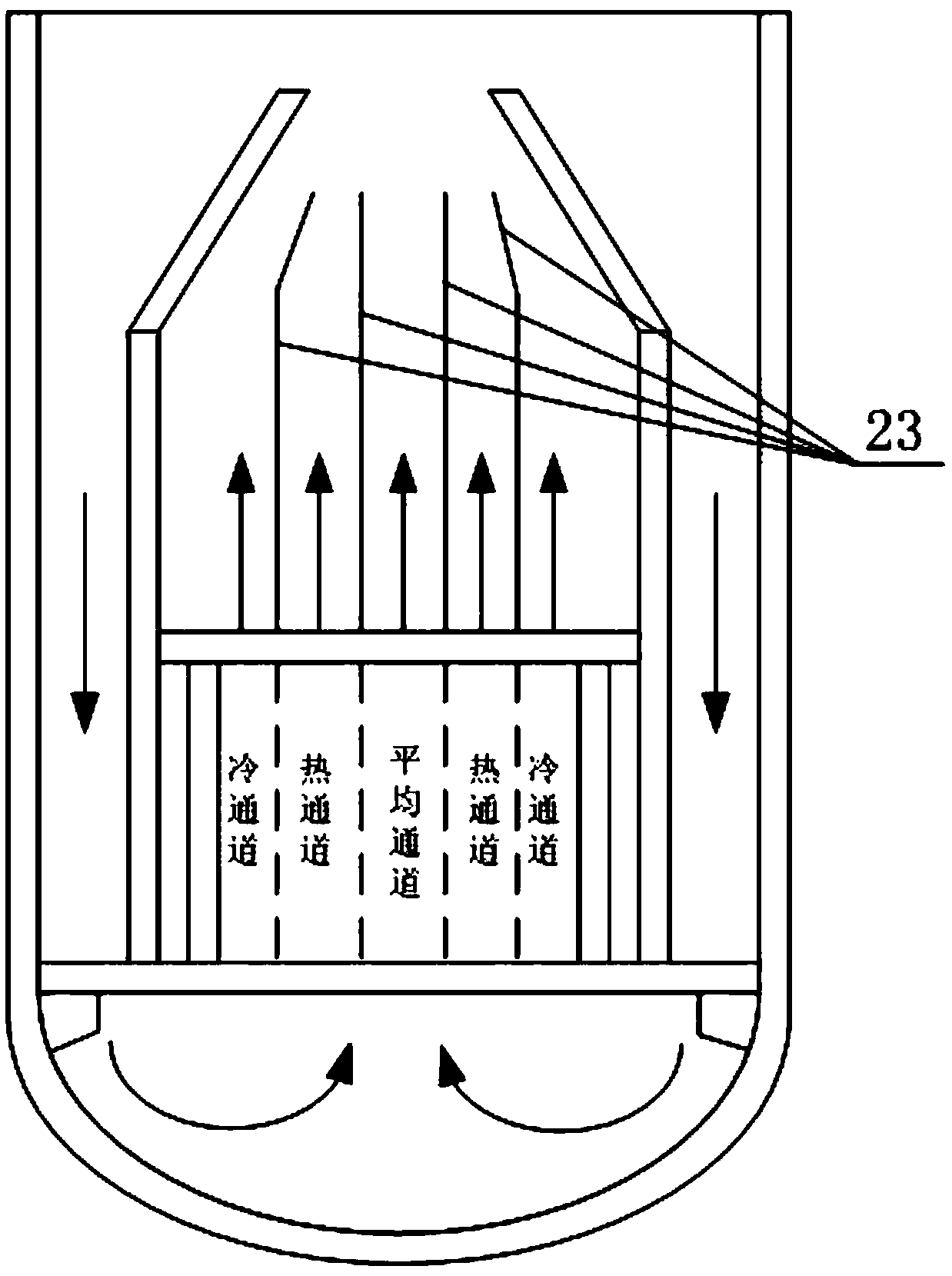

Safety analysis calculating device for transient nuclear heat coupling of supercritical water reactor

InactiveCN103902784AImprove economyImprove reliabilitySpecial data processing applicationsInformation technology support systemSystems analysisCoupling

The invention discloses a safety analysis calculating device for transient nuclear heat coupling of a supercritical water reactor, and belongs to the field of nuclear power plant design and reactor safety analysis. The safety analysis calculating device for transient nuclear heat coupling of the supercritical water reactor is applicable to the supercritical water reactor. According to the safety analysis calculating device, a transient physical analysis program is built by using the space-time disperse solution of a double-group space-time kinetic equation, a transient heat engineering analysis program is built through calculation of flow distribution among channels and the solution of flowing heat exchange inside the channels, on this basis, a physical calculation program is embedded into a transient system analysis program to build a supercritical transient coupling analysis program so as to analyze safety of a system. Particularly, due to the fact that a space-time kinetics quasi-static solution model built through the double-group neutron space-time kinetic equation is combined with a multi-channel analysis method, compared with a sub-channel model, the calculation time is shortened on the basis that precision is ensured, then economy of the supercritical water reactor design is improved, and the safety analysis calculating device accords with the development trend of safety analysis.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

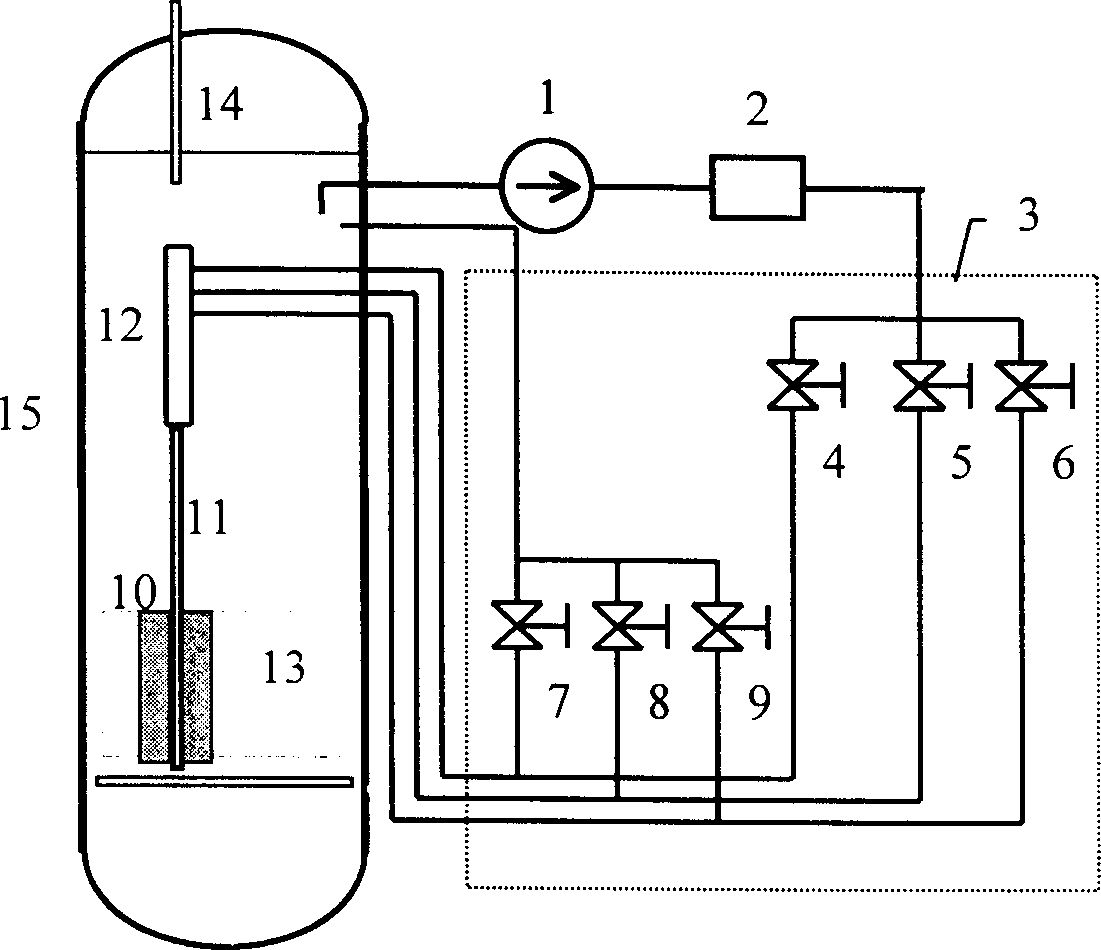

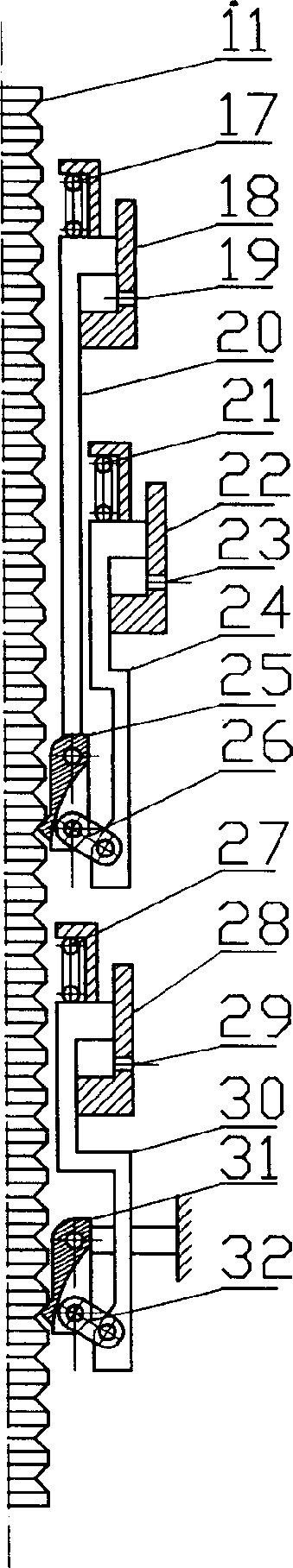

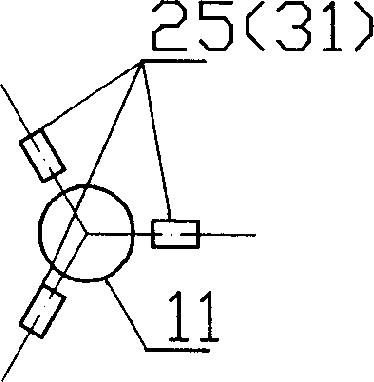

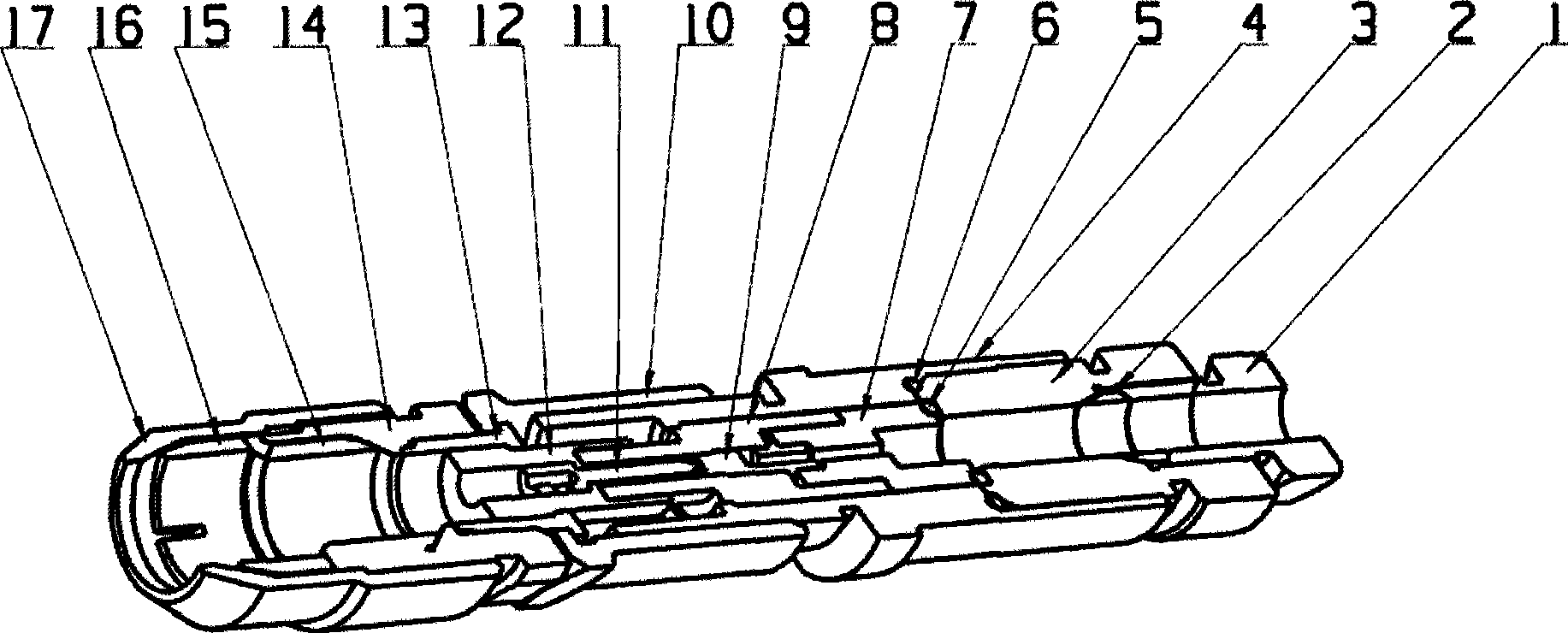

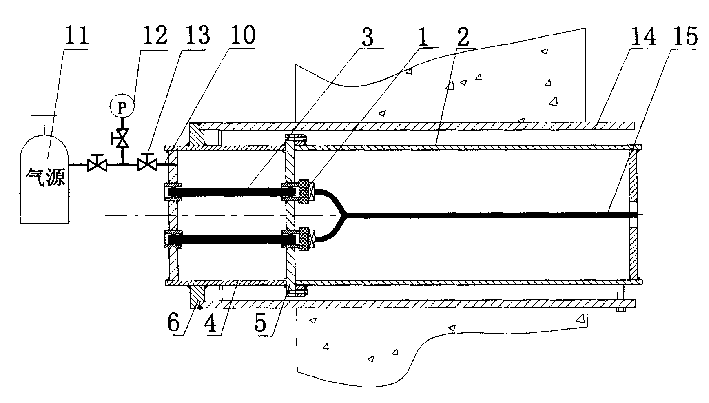

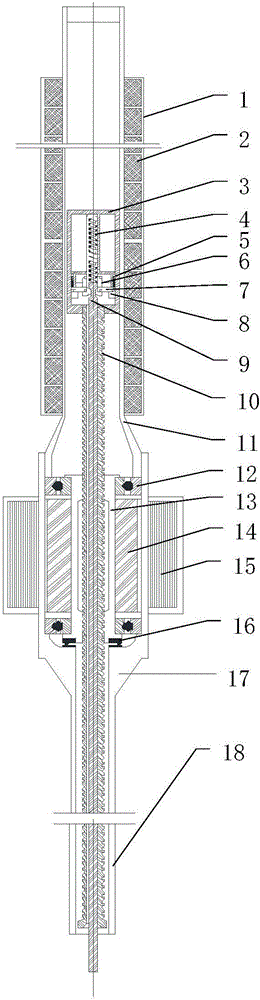

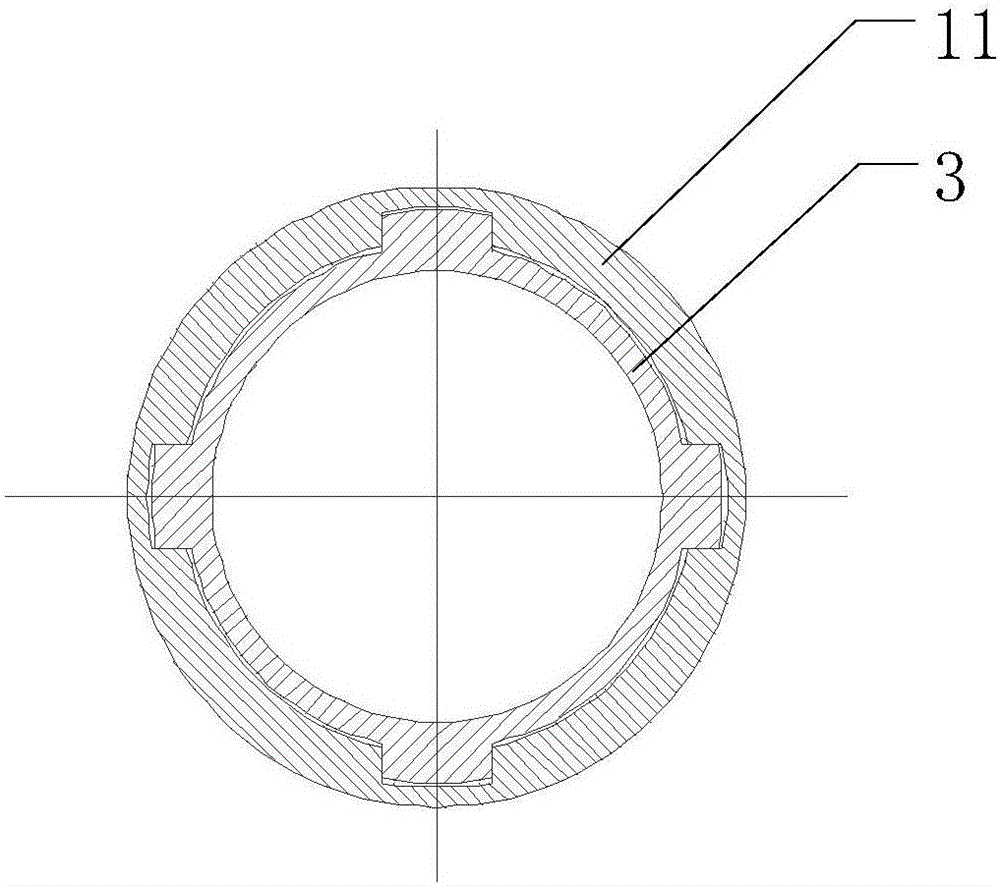

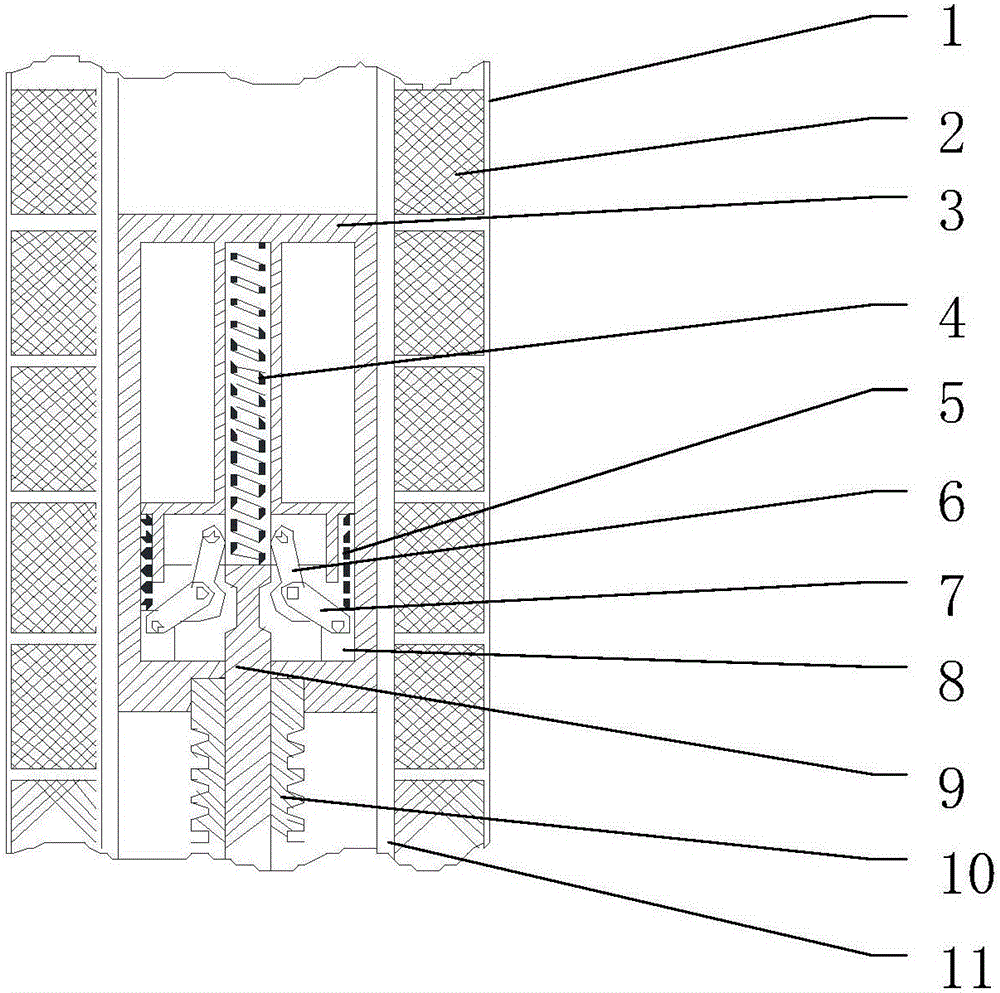

Nuclear reactor control rod hydraulic driving system

InactiveCN1442863APrecise positioningImprove overload capacityNuclear energy generationNuclear reaction controlHydraulic cylinderNuclear reactor

A hydraulic drive system for the control rods of nuclear reactor features that its drive mechanism has three hydraulic cylinders and two pinned jaw mechansms, its combined valve is composed of 3 parallel electromagnetic valves opened normally and 3 parallel electromagnetic valves closed normally, and said hydraulic cylinders are driven by the static pressure of water. Its advantages are correct location and step movement, high over-load power, short transfer distance, and high safety.

Owner:TSINGHUA UNIV

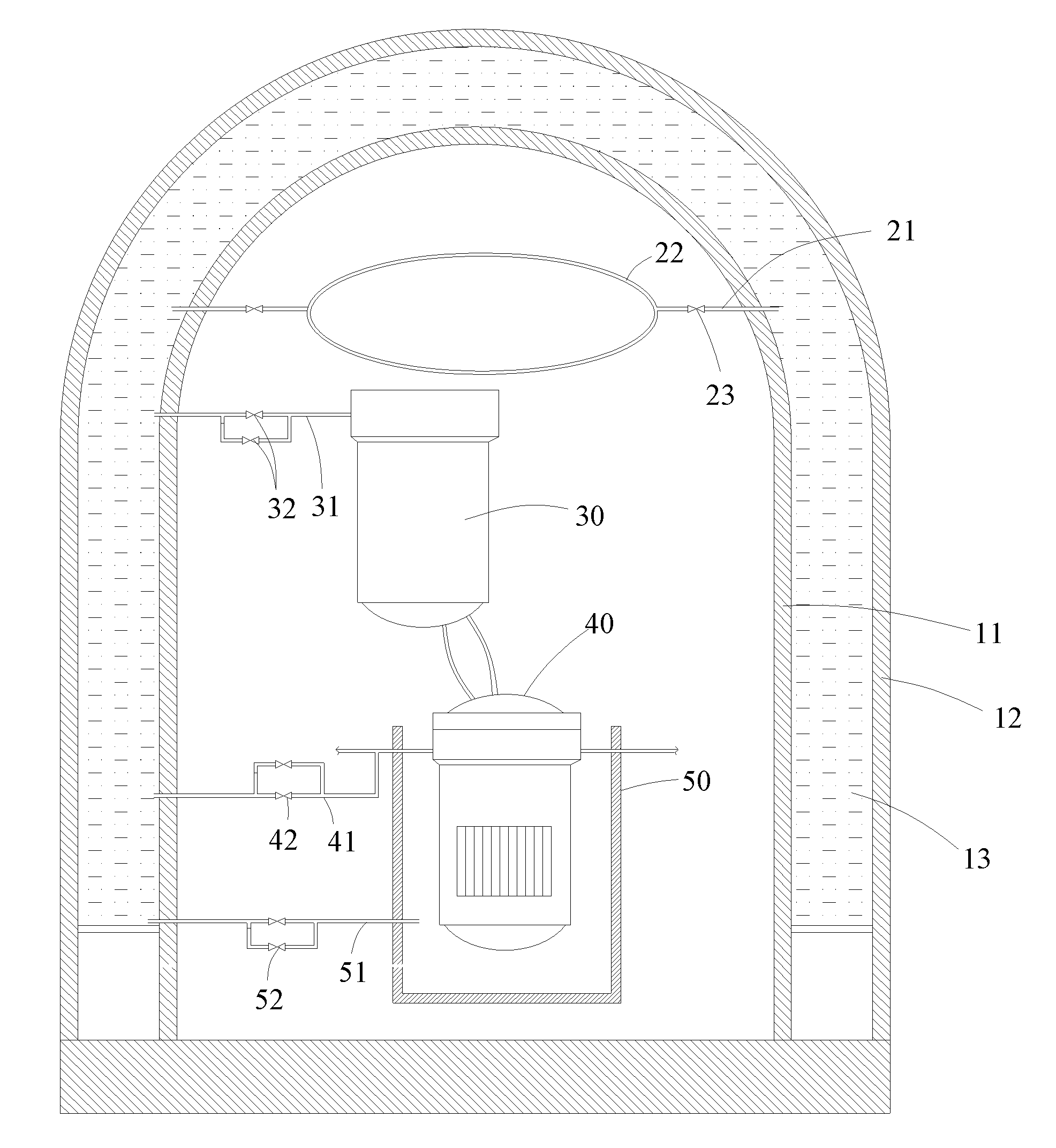

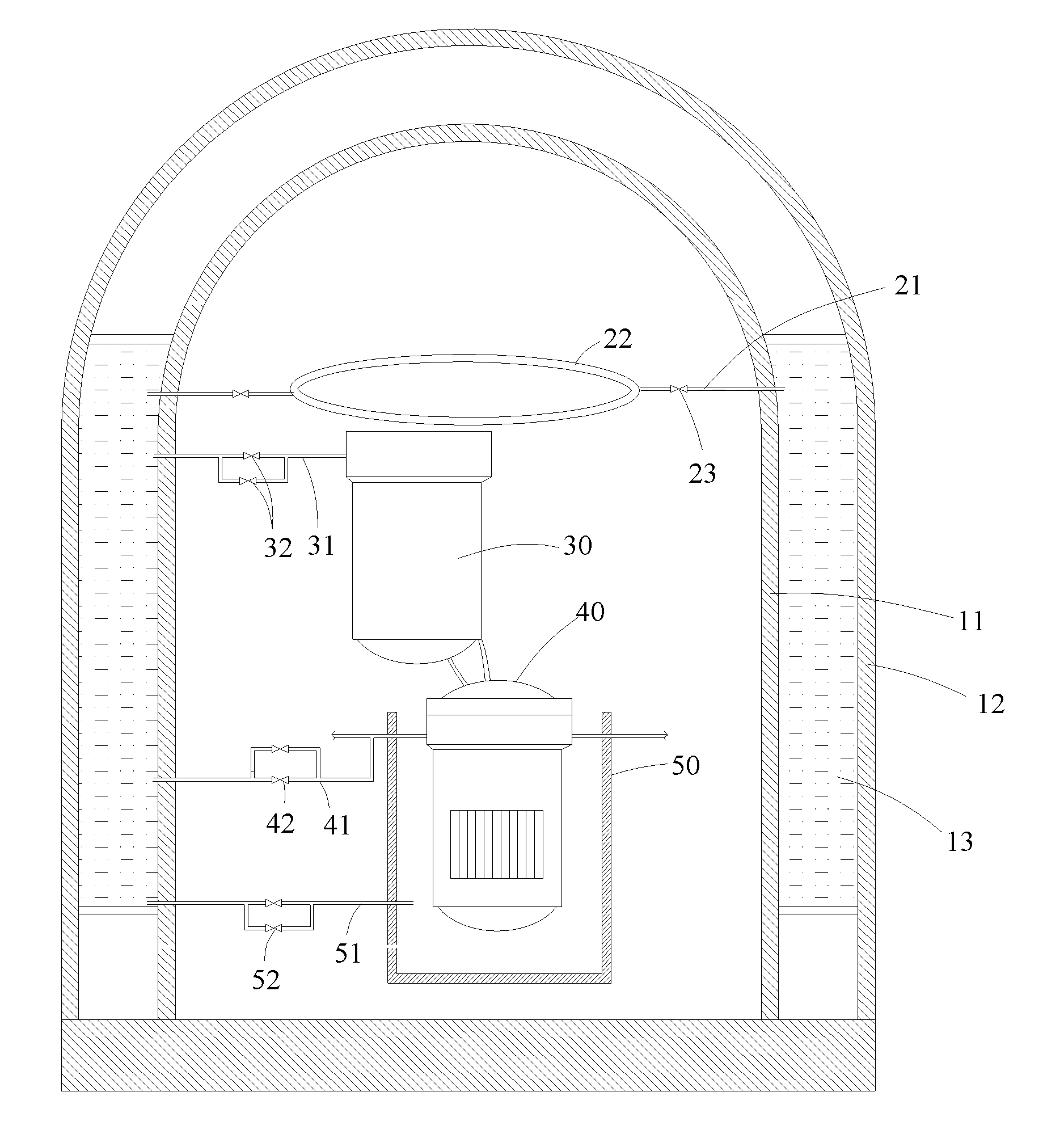

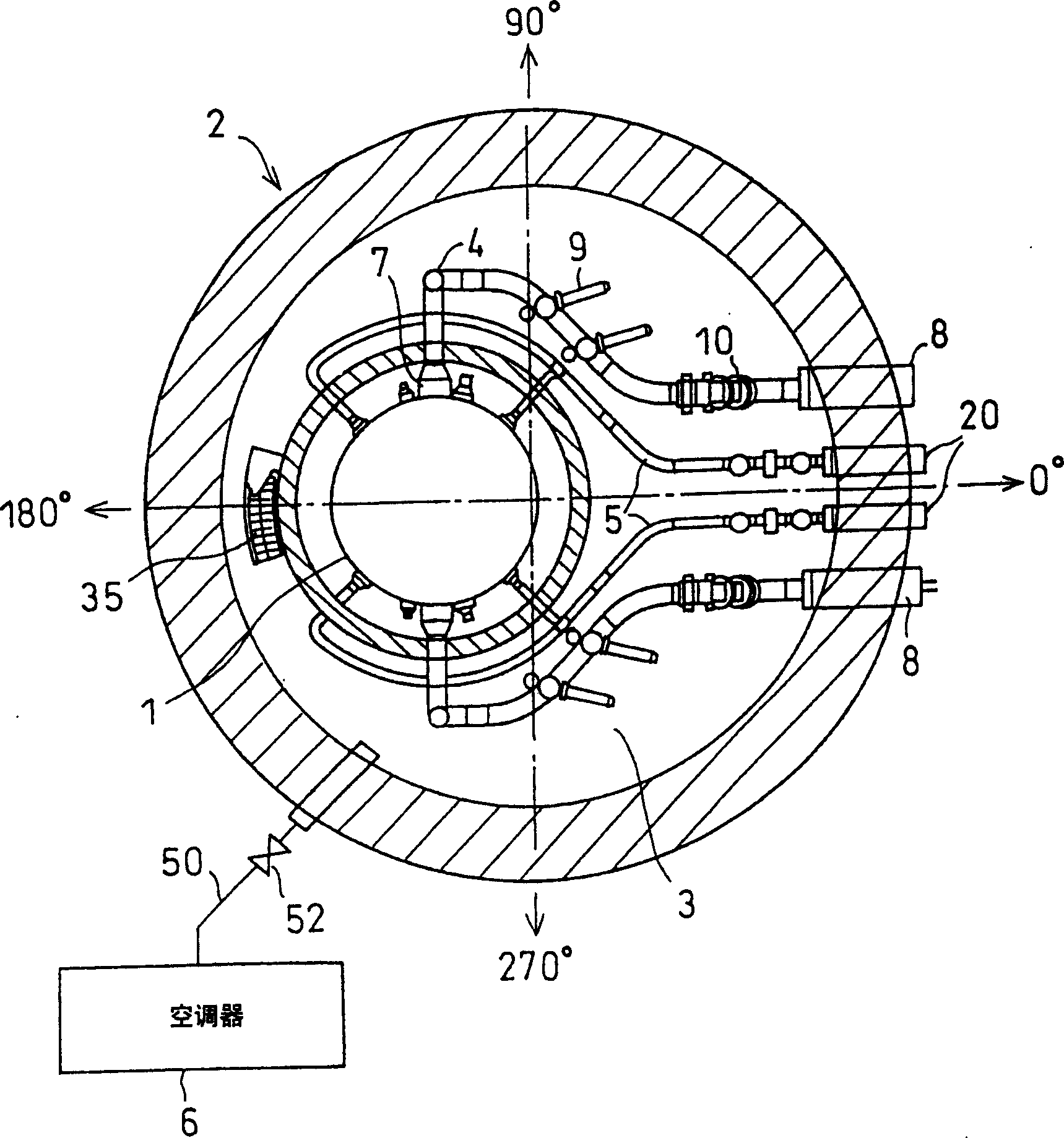

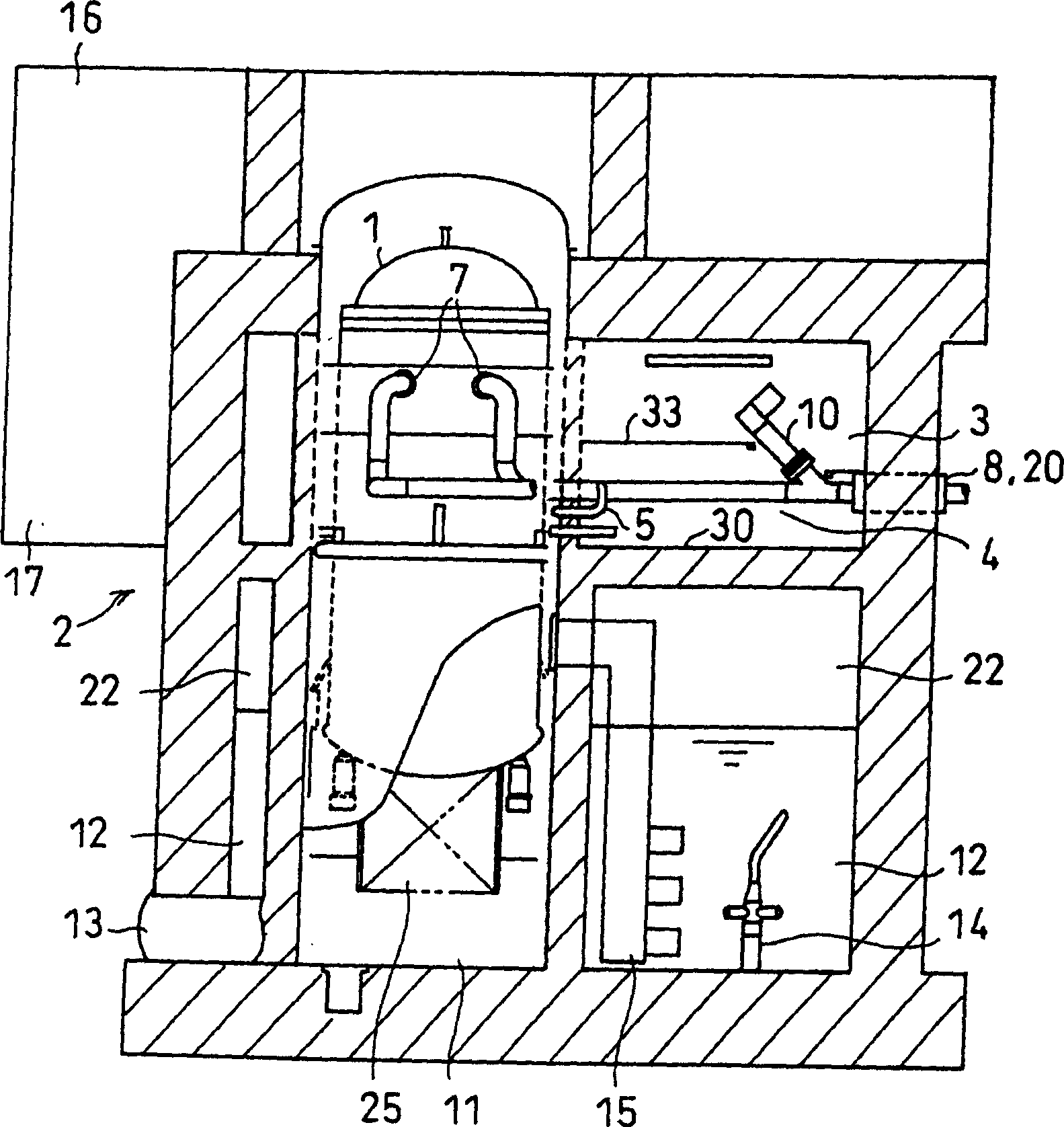

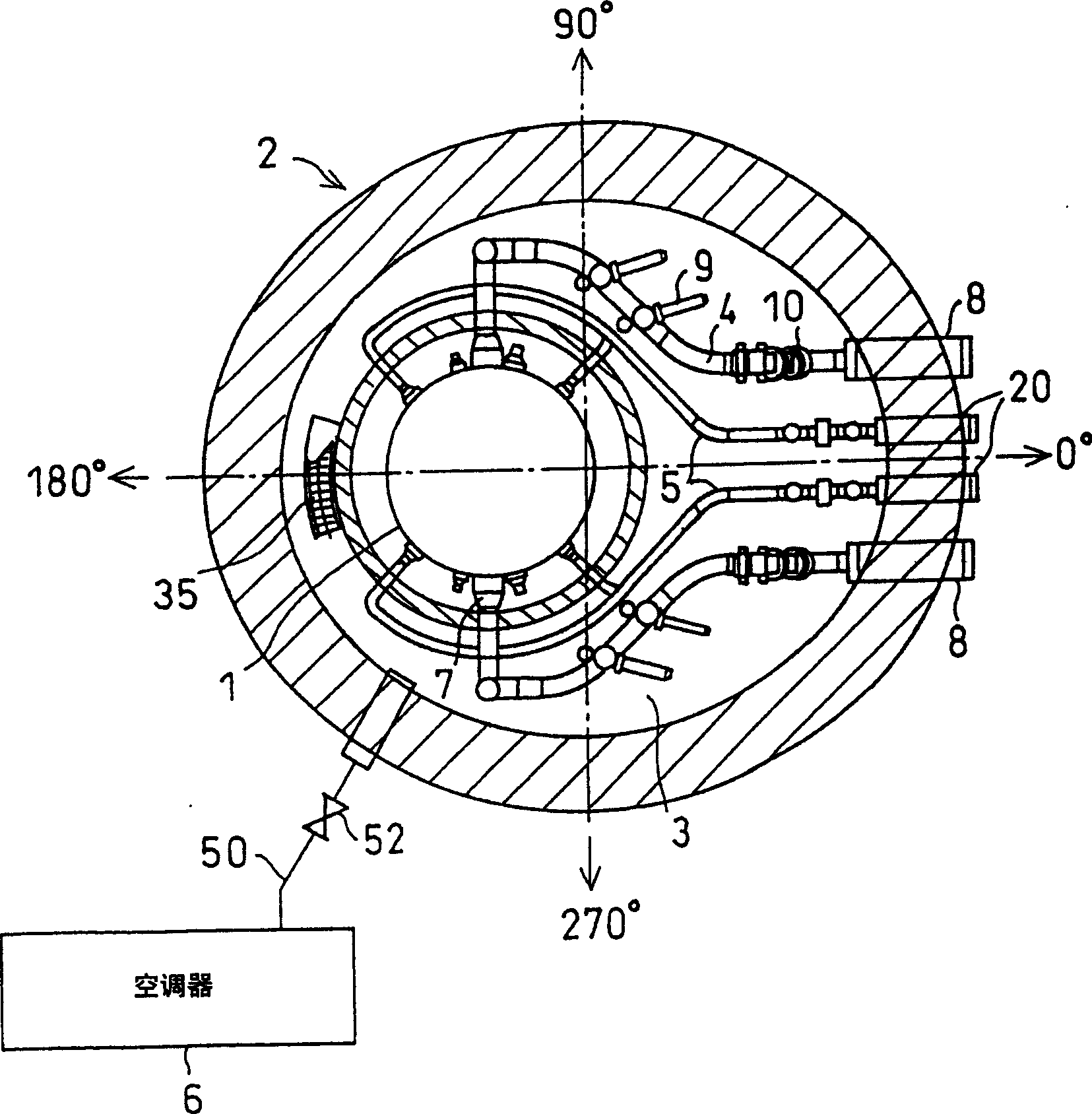

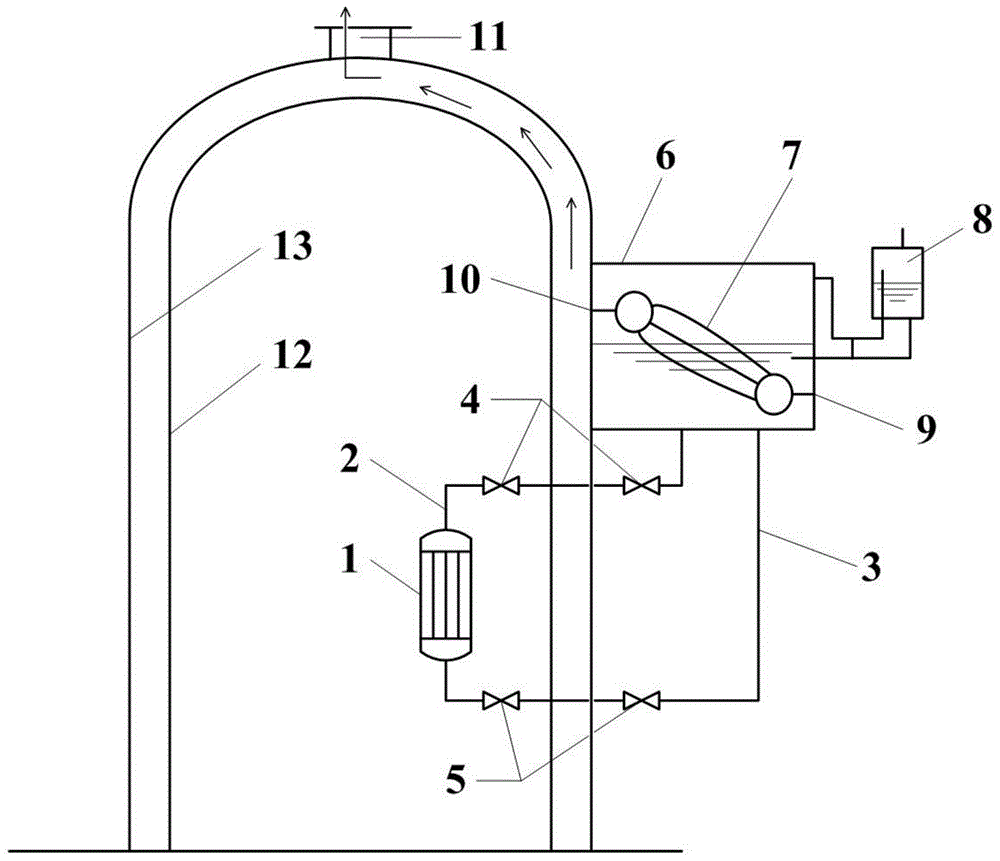

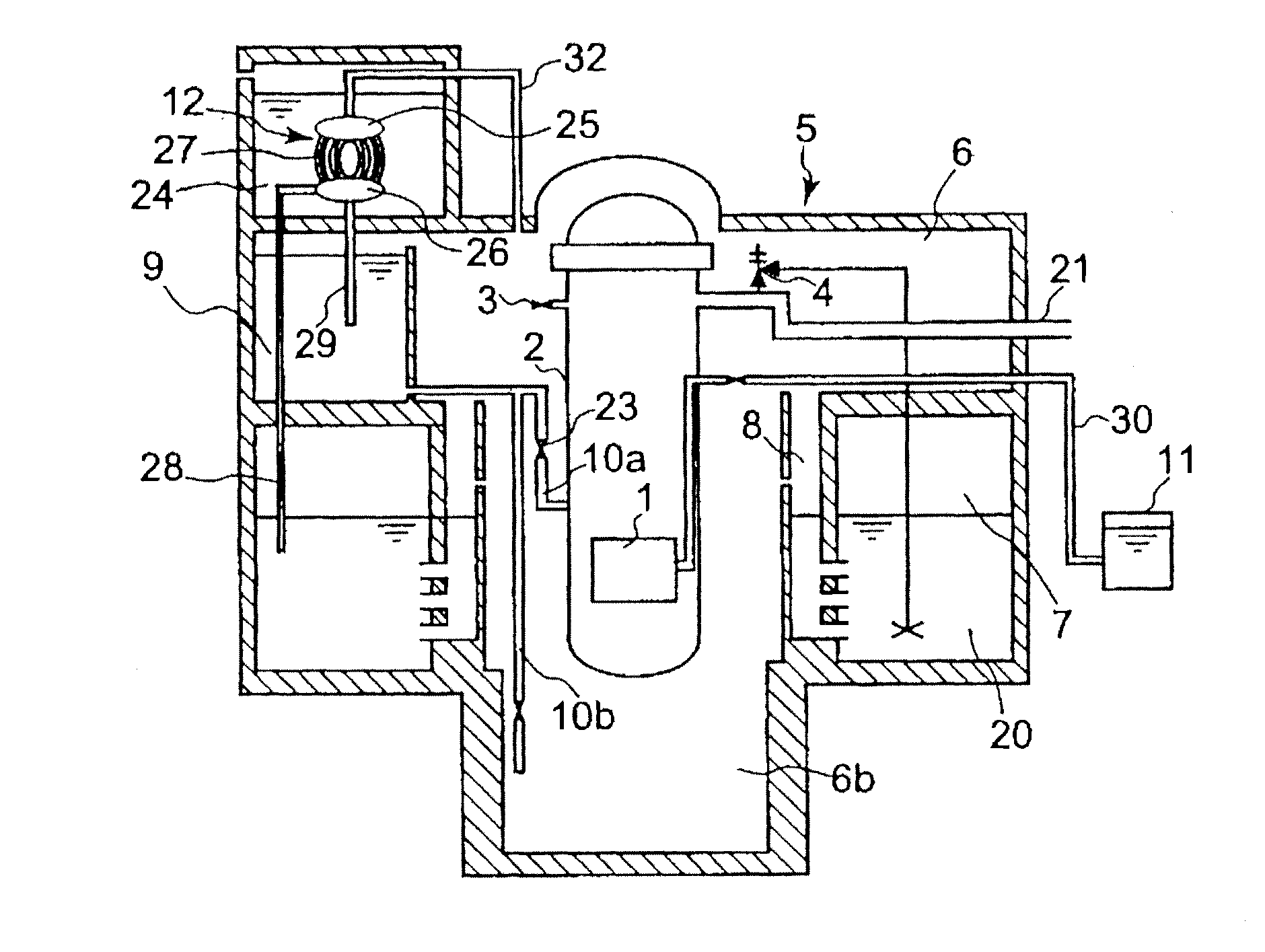

Reactor safety system

ActiveCN102194533AInhibition releaseAvoid coolingNuclear energy generationCooling arrangementNuclear powerReactor safety

The invention relates to a reactor safety system, which comprises a safety shell, a steam generator arranged in the safety shell, a reactor core, a reactor cavity and a cooling pipeline; the safety shell comprises an inner safety shell wall and an outer safety shell wall arranged at the periphery of the inner safety shell wall; an accommodating space is formed between the inner safety shell wall and the outer safety shell; and the accommodating space is filled with cooling liquid to form a passive cooling water tank; and the cooling pipeline is communicated with the accommodating space and injects the cooling liquid into the safety shell. The system can be used as a containment spraying system, and is used for injecting into the steam generator and the reactor core to carry away heat fromthe reactor core, and injecting into the reactor cavity to carry way heat outside a pressure vessel so as to prevent the pressure of the safety shell from rising, the reactor core from damage and thepressure vessel from out of work. Moreover, the system has the functions of preventing radioactive release and cooling the safety shell, so that the reliability and the safety of a nuclear power station are greatly improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

Steel plate for third-generation nuclear power station reactor containments and manufacturing method thereof

InactiveCN102776441AAchieve productionReduce carbon contentManufacturing convertersNiobiumNuclear power

The invention belongs to the field of steel plate smelting, and specifically relates to a steel plate for third-generation nuclear power station reactor containments and a manufacturing method for the steel plate. The steel plate for the third-generation nuclear power station reactor containments contains the following components by weight: 0.08-0.12% of carbon (C), 0.15-0.55% of silicon (Si), 0.9-1.5% of manganese (Mn), less than or equal to 0.007% of phosphorus (P), less than or equal to 0.004% of sulphur (S), 0.1-0.5% of nickel (Ni), 0.0-0.3% of chromium (Cr), 0.10-0.35% of molybdenum (Mo), 0.010-0.050% of vanadium (V), 0.010-0.030% of niobium (Nb), 0.008-0.035% of titanium (Ti), 0.020-0.050% of aluminum (Al), less than or equal to 0.006% of nitrogen (N), and less than or equal to 0.08% of Nb+V; and the balance of iron and unavoidable impurities. The steel plate has benefits that the steel plate, containing combinations of components by weight percentage mentioned above and being manufactured by the method provided by the invention, is characterized by low carbon content, high-temperature resistant performance against 200 degrees centigrade, low cost and excellent welding performance; and tensile strength of the steel plate is higher than 600MPa.

Owner:JIGANG GRP

Core catcher, manufacturing method thereof, reactor containment vessel and manufacturing method thereof

Core debris generated during a molten reactor core in a reactor containment vessel penetrating the reactor containment vessel is configured to be caught by a core catcher located beneath the reactor containment vessel which has a main body having first stage cooling water channels and second stage surrounded by cooling fins extending radially. The number of the second stage cooling channels is larger than that of the first stage cooling channels. Cooling water is supplied from a cooling water injection opening and distributed to the first cooling water channels at a distributor. An intermediate header is formed between the first and the second cooling water channels, and the cooling water is distributed to the second cooling water channels uniformly.

Owner:KK TOSHIBA

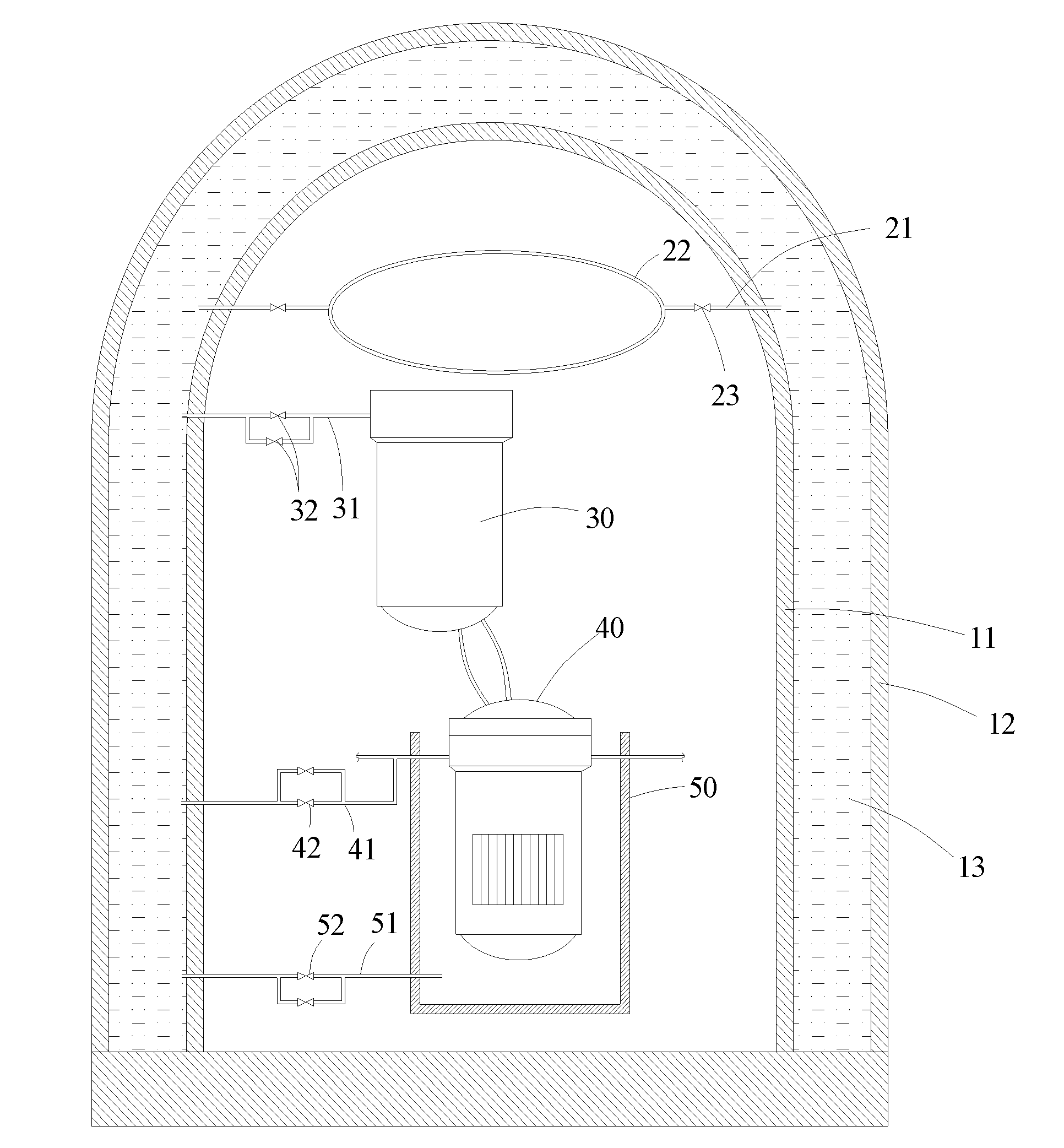

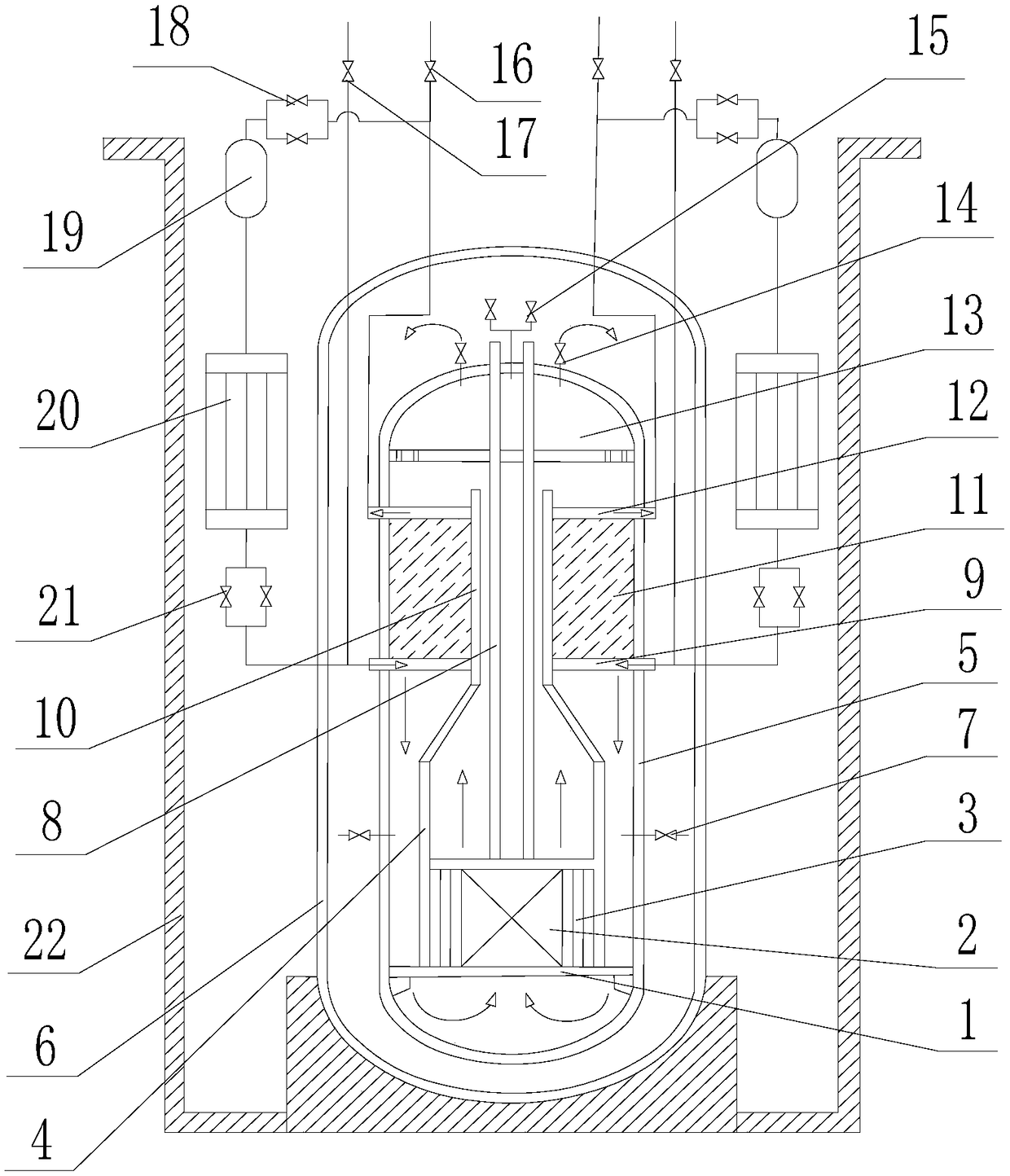

All natural circulation-type modular small reactor

ActiveCN108648837AReduce resistanceImprove natural circulationNuclear energy generationCooling arrangementPotential differenceHeat transmission

The invention discloses an all natural circulation-type modular small reactor. The all natural circulation-type modular small reactor comprises a reactor main body, a safe shell, a water tank and a passive safety system. The reactor main body comprises a pressure vessel. A reactor core, a direct current steam generator and a voltage stabilizer are orderly arranged in the pressure vessel from bottom to top. One end of a control rod driving mechanism matched with the reactor core is arranged at a top cover of the pressure vessel. The pressure vessel is arranged in the safe shell. The safe shellis immersed in the water tank. The passive safety system comprises a passive residual heat removal system and a passive safe shell heat transmission system. The reactor is free of forced circulation of a path of a cooling agent driven by a main pump, and utilizes density contrast of cooling agents between the direct current steam generator and the reactor core and cold and hot core potential difference to drive the cooling agents to all naturally circulate in the pressure vessel so that the reactor safety is improved. The passive safety system realizes a lasting submerged state of the reactorcore and carries out the residual heat of the reactor core to prevent core damage.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

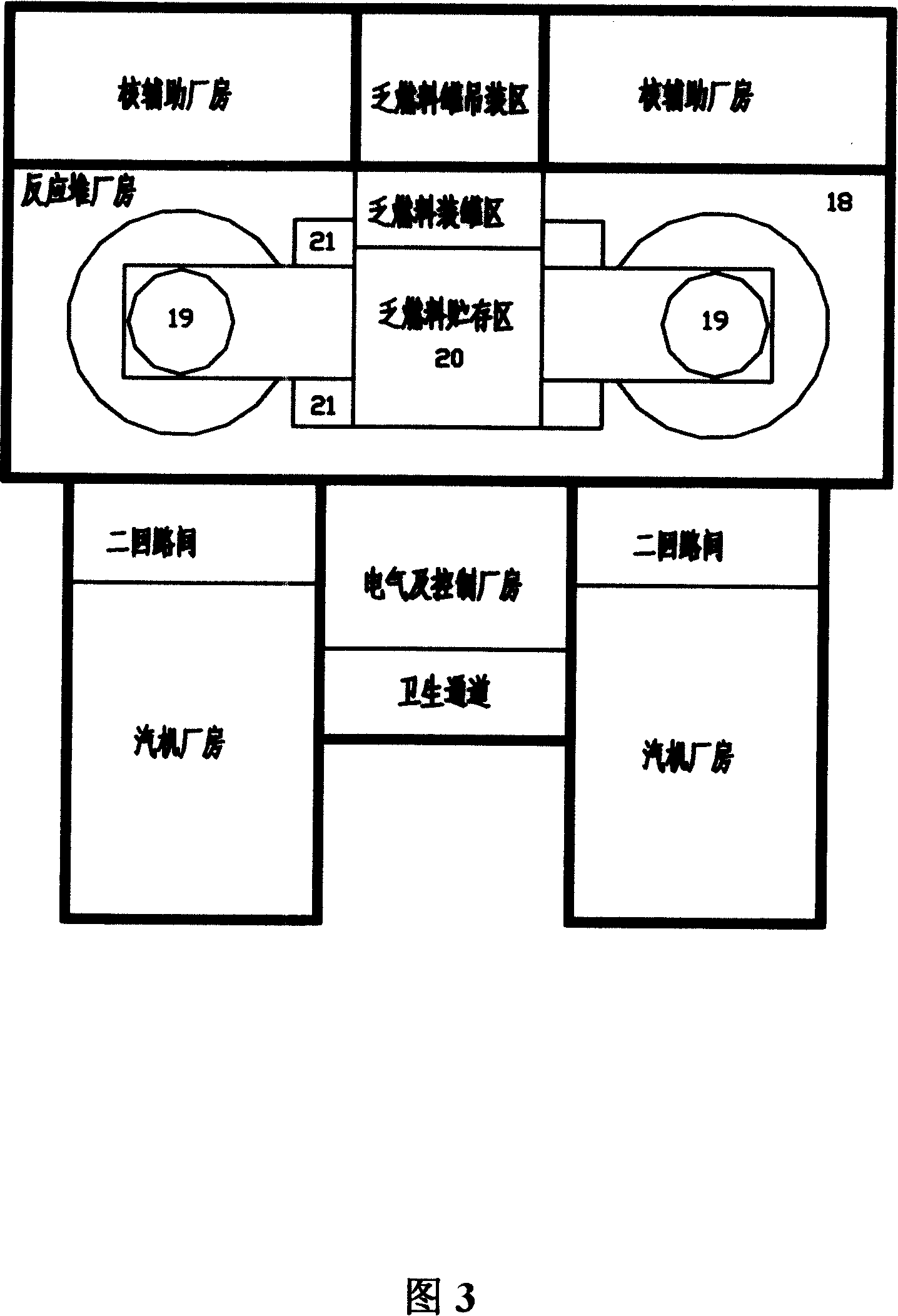

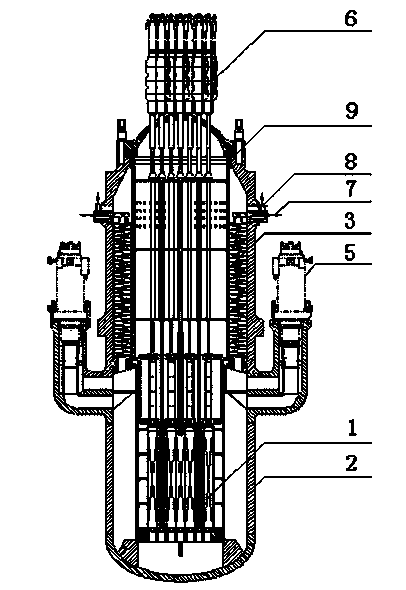

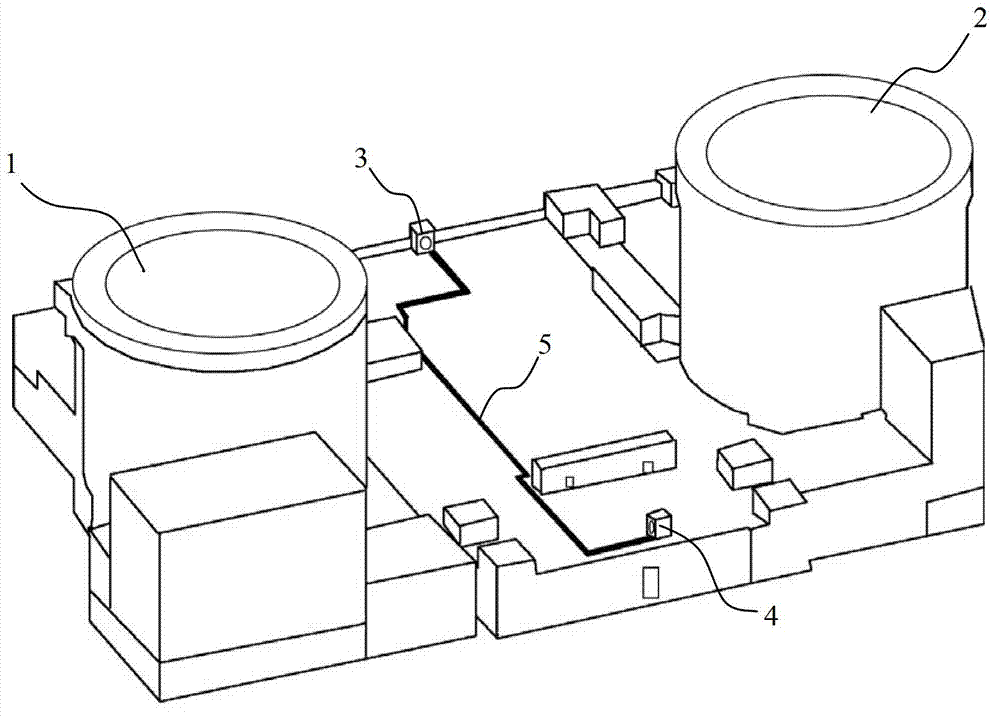

Module type pressurized water reactor

ActiveCN103489488ABig free spaceOptimize layoutNuclear energy generationCooling arrangementPressurized water reactorProcess engineering

The invention provides a module type pressurized water reactor. A reactor module is composed of a reactor body, a cooling agent system, and a safety system, the reactor body, the cooling agent system, and the safety system are all enclosed in a steel safety shell, and the whole reactor module is immersed in a reactor safety water pool, taking the pool water as the final hot trap for heat discharging of accidents. Emergency core cooling and emergency excess heat discharging are achieved by adopting a complete passive way, and the pressure inhibition and long-term heat discharging of the safety shell are achieved through repressing the water in the water pool and the reactor safety water pool; and during the processes of reloading and maintenance of reactor, through arranging a reloading water jacket between the safety shell reloading channel flange and the reactor container flange, direct-moving underwater fuel lifting operation is achieved between the safety shell and the spent fuel pool. A reactor factory can be provided with a plurality of reactor modules, all reactor modules co-use material loading equipment and other nuclear auxiliary systems, and the safety and economy of the reactor are improved through modularized combination arrangement. The module type pressurized water reactor is suitable for being applied to the fields of nuclear electricity generation, gas application, heat application, sea water desalination, and the like.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

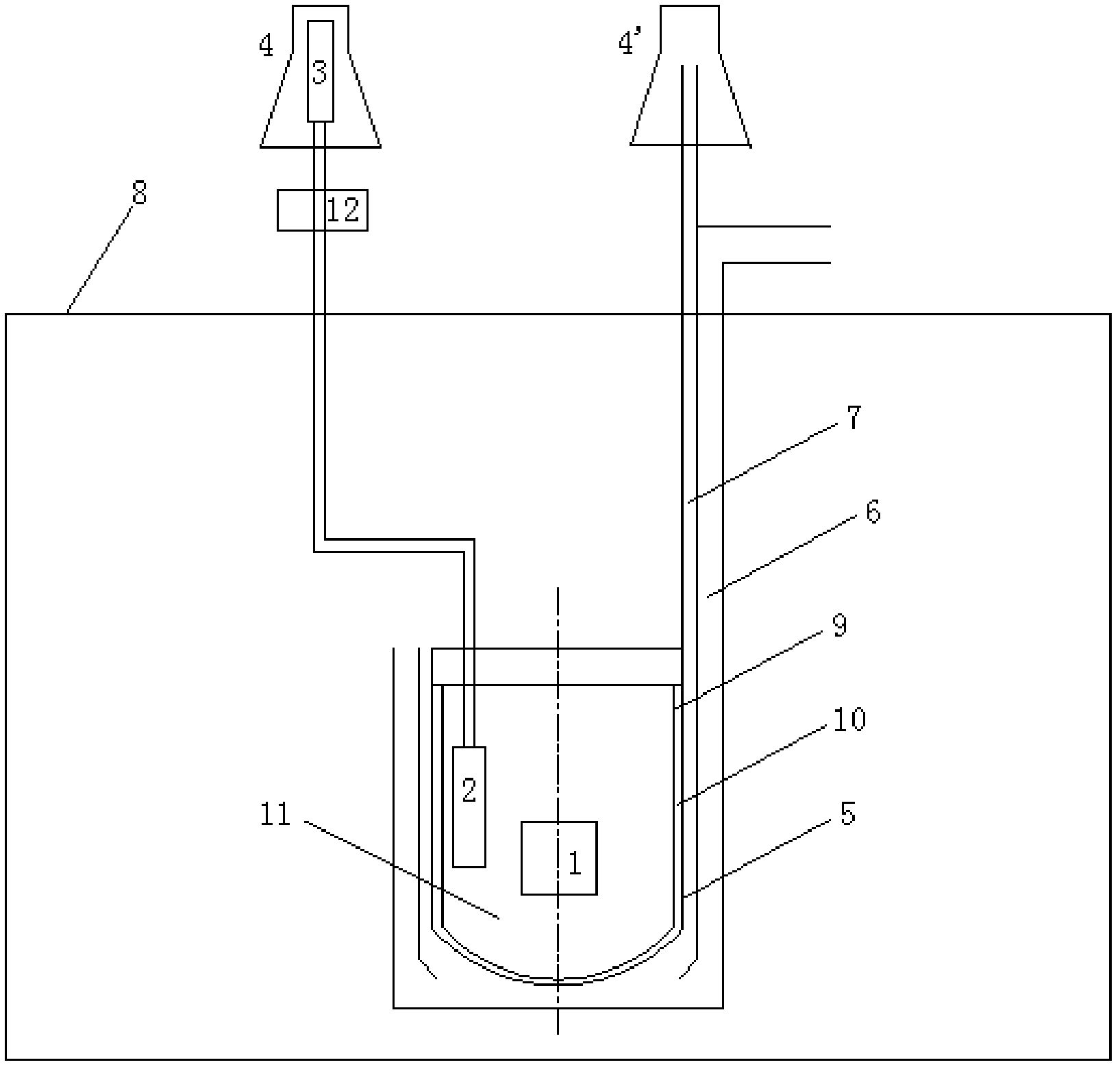

Temperature-triggered passive accident residual heat removal system for pool type reactor

ActiveCN104269194AImprove reliabilityEfficient take awayNuclear energy generationCooling arrangementSystems designFree cooling

The invention discloses a temperature-triggered passive accident residual heat removal system for a pool type reactor. The system consists of a direct reactor core cooling system and an auxiliary reactor safety container cooling system. The system has the significant advantage that the direct reactor core cooling system and the auxiliary reactor safety container cooling system share one air cooling system, so that the system design of the reactor is greatly simplified, and the construction cost is saved. The auxiliary reactor safety container cooling system realizes natural cooling through ambient air on the outer side of a safety container, and the process has the characteristic of passiveness. The passive accident residual heat removal system is passive, independent, high in efficiency and high in reliability and meets the safety design requirement for the pool type reactor.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

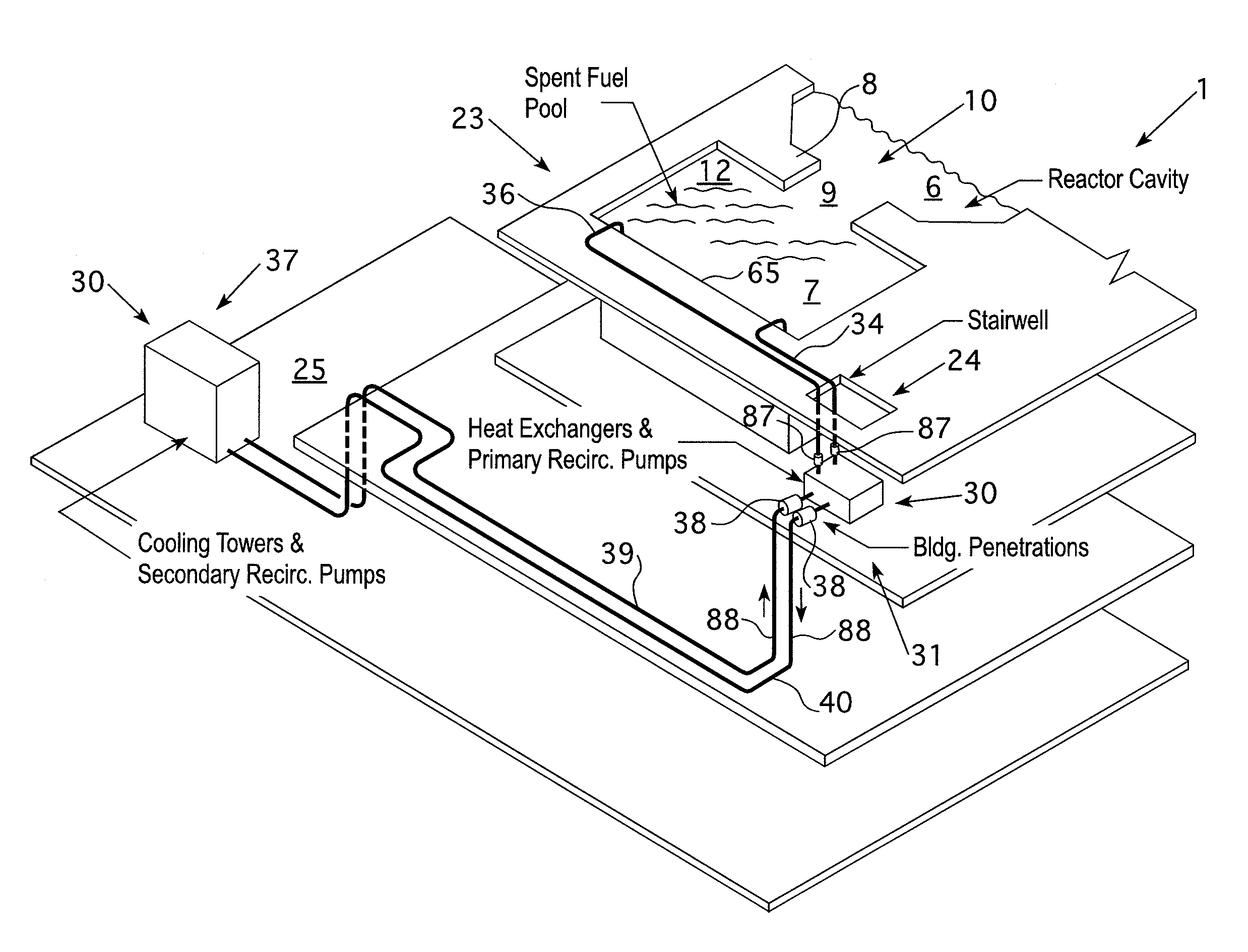

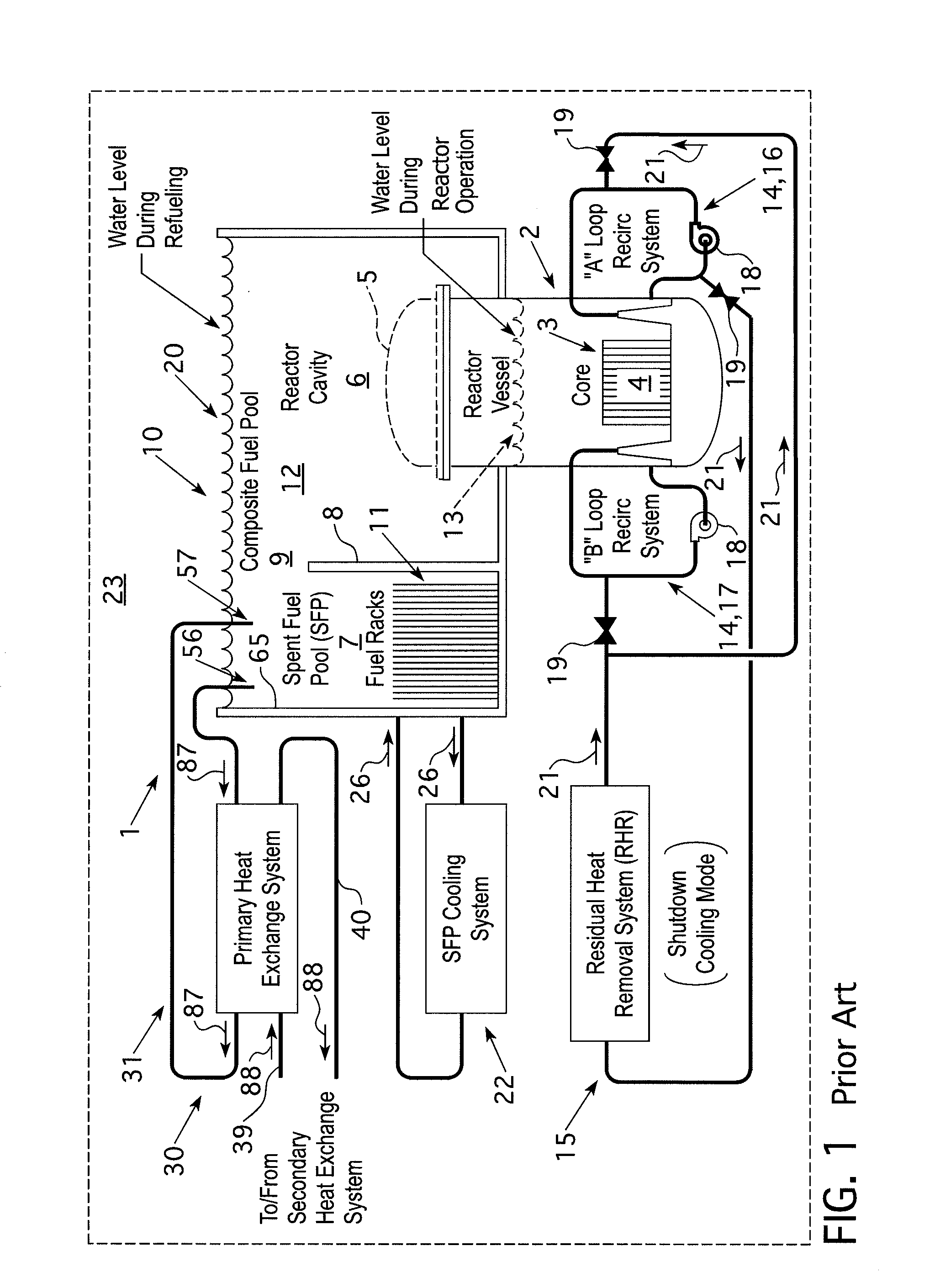

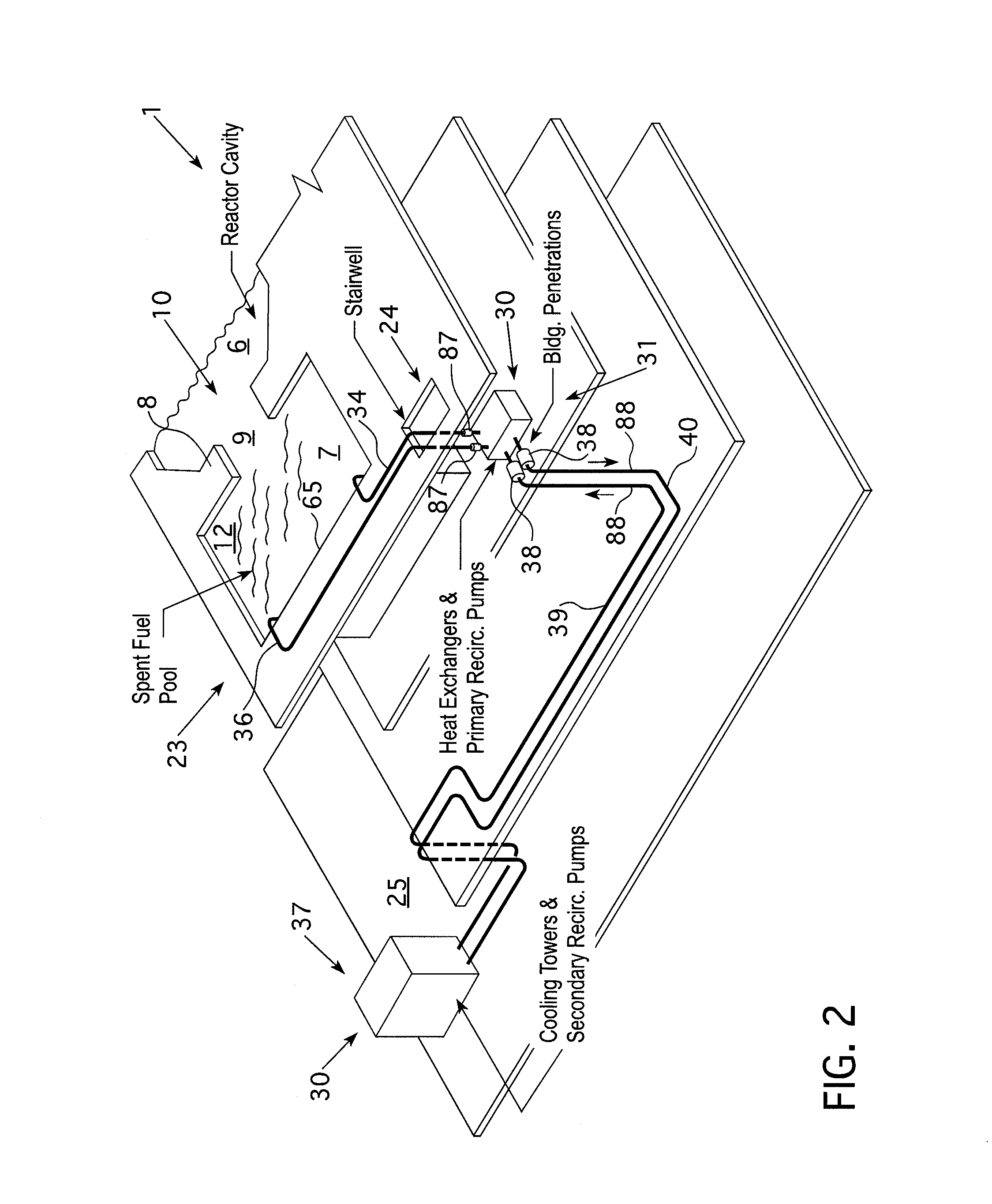

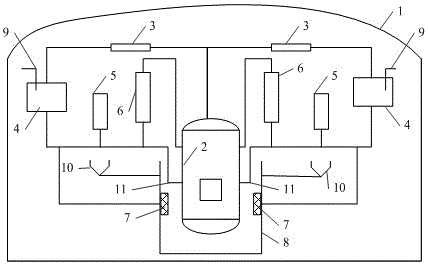

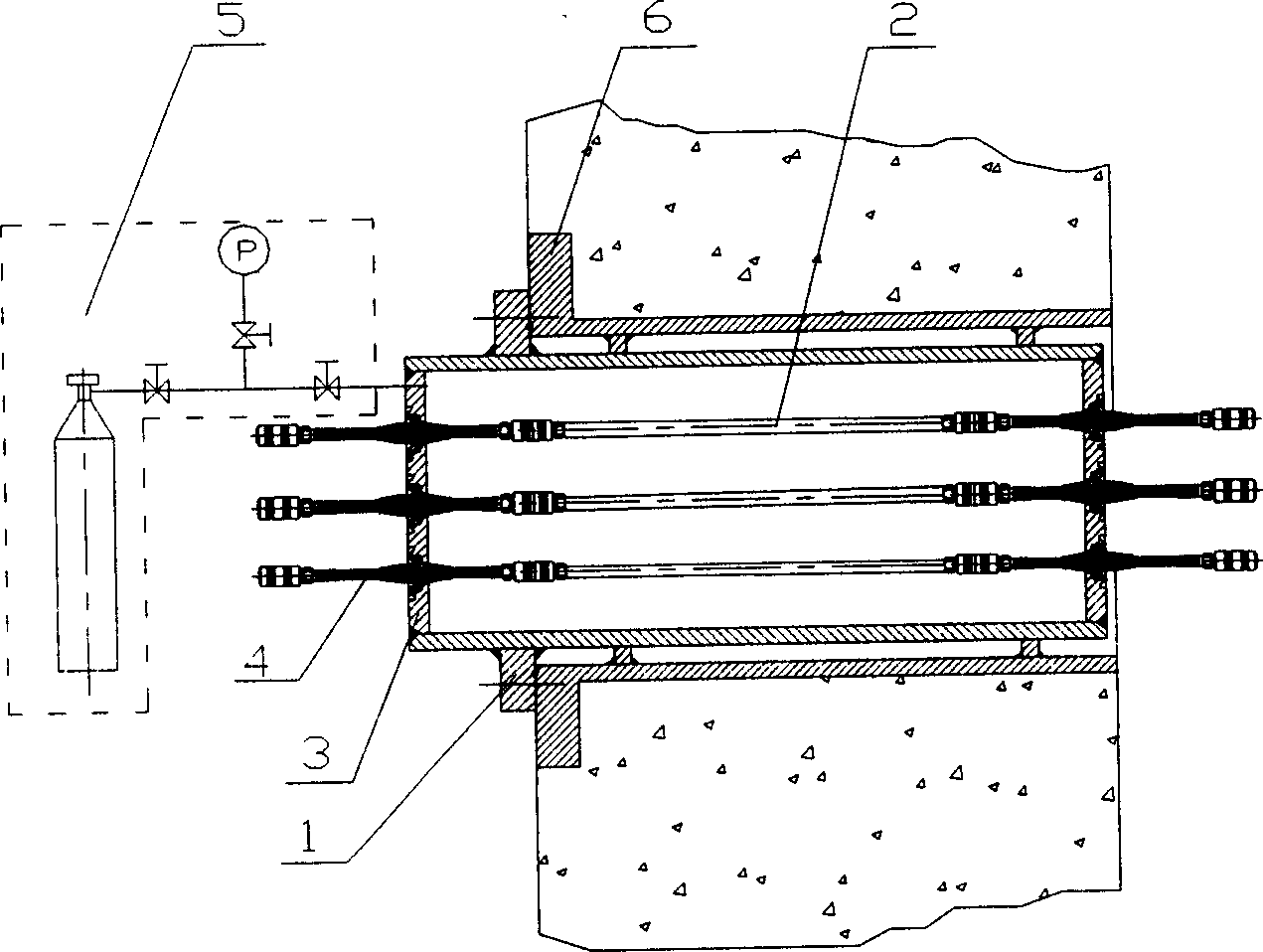

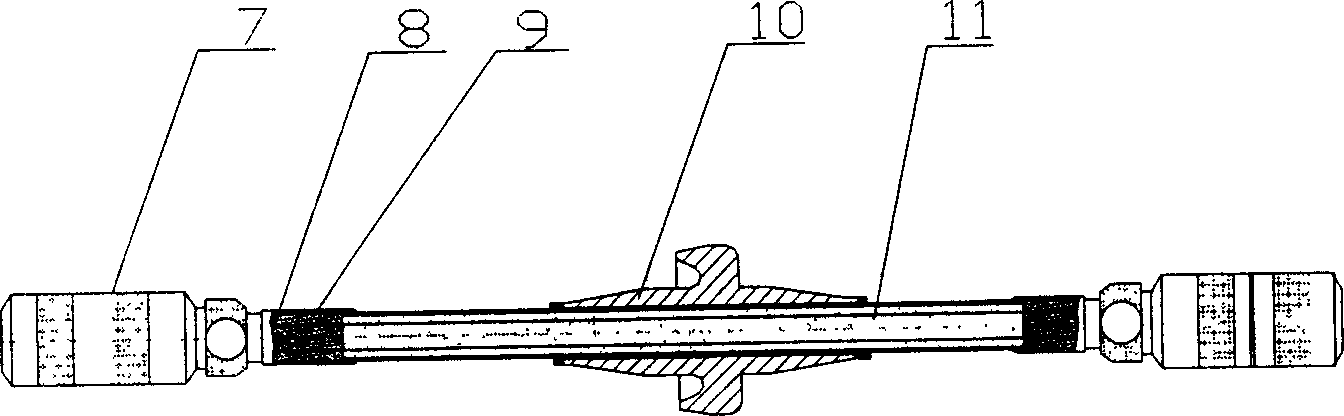

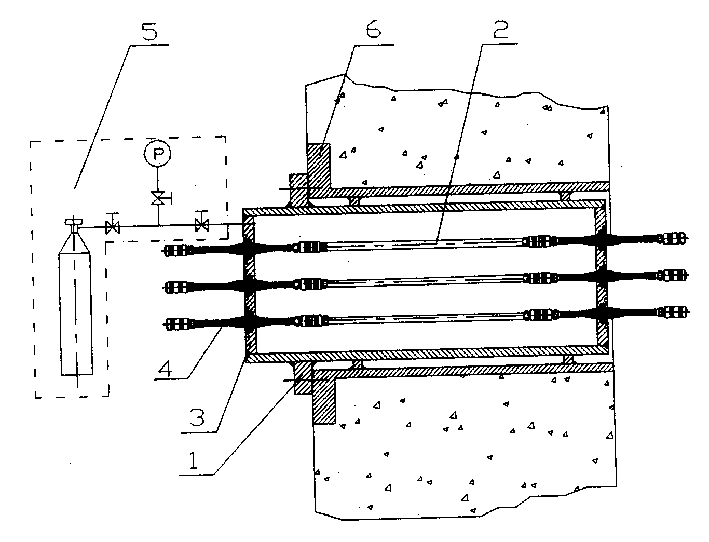

Semi-portable emergency cooling system for removing decay heat from a nuclear reactor

ActiveUS20130121454A1Power plant safety arrangementNuclear energy generationNuclear reactor coreNuclear reactor

An emergency temporary spent fuel pool cooling system for a nuclear power generating facility that has a permanently installed primary loop within the nuclear containment and a mobile temporary secondary loop. The secondary loop is housed in transport vehicles that can be stored off site and is connectable in heat exchange relationship with the primary loop through quick disconnect couplings that are accessible on the outside of the reactor containment. The transport vehicles also include self-contained power and compressed air sources for powering and controlling the entire emergency cooling system. The system also has a make-up water injection capability for refueling the spent fuel pool and secondary loop.

Owner:WESTINGHOUSE ELECTRIC CORP

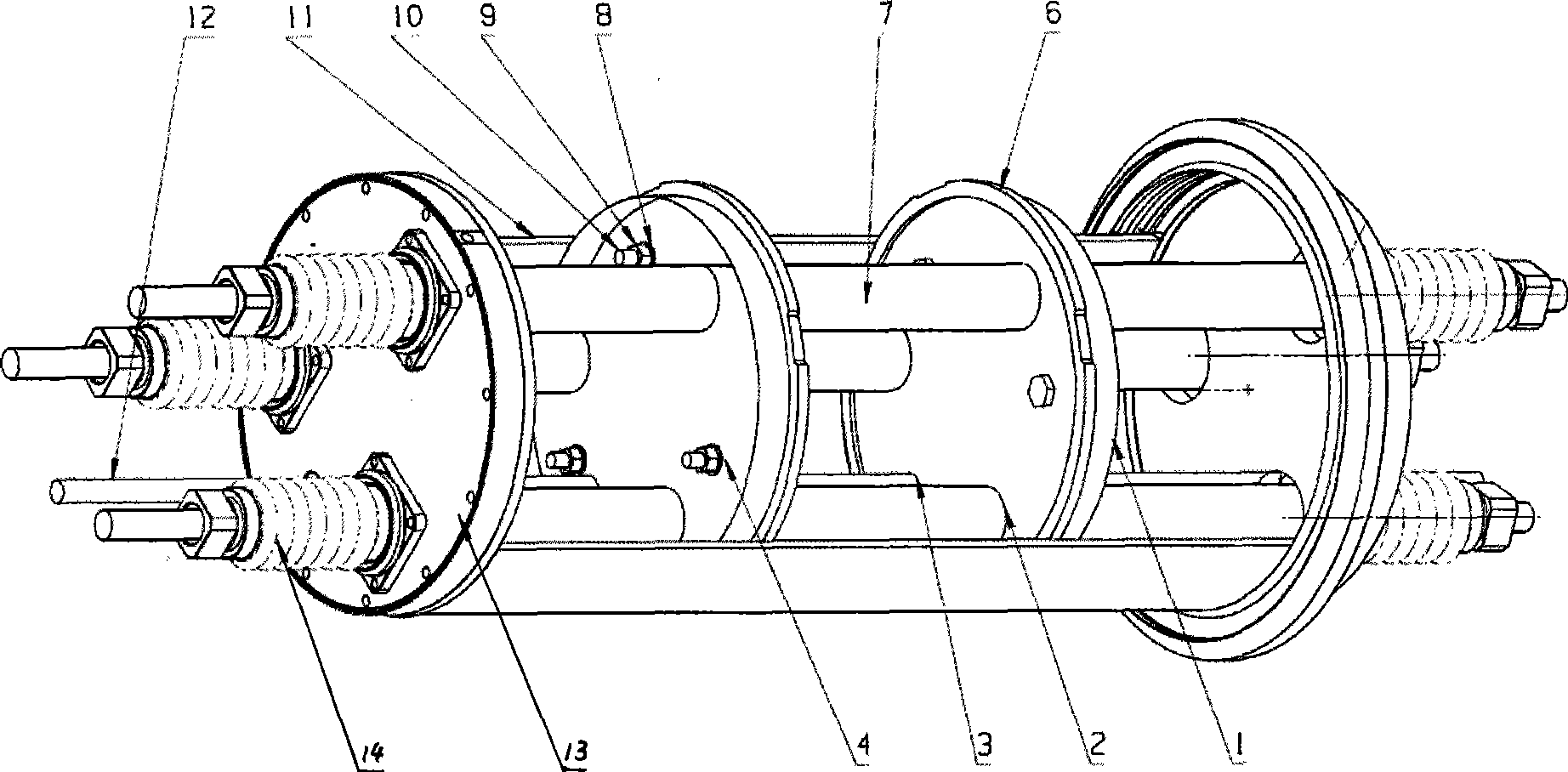

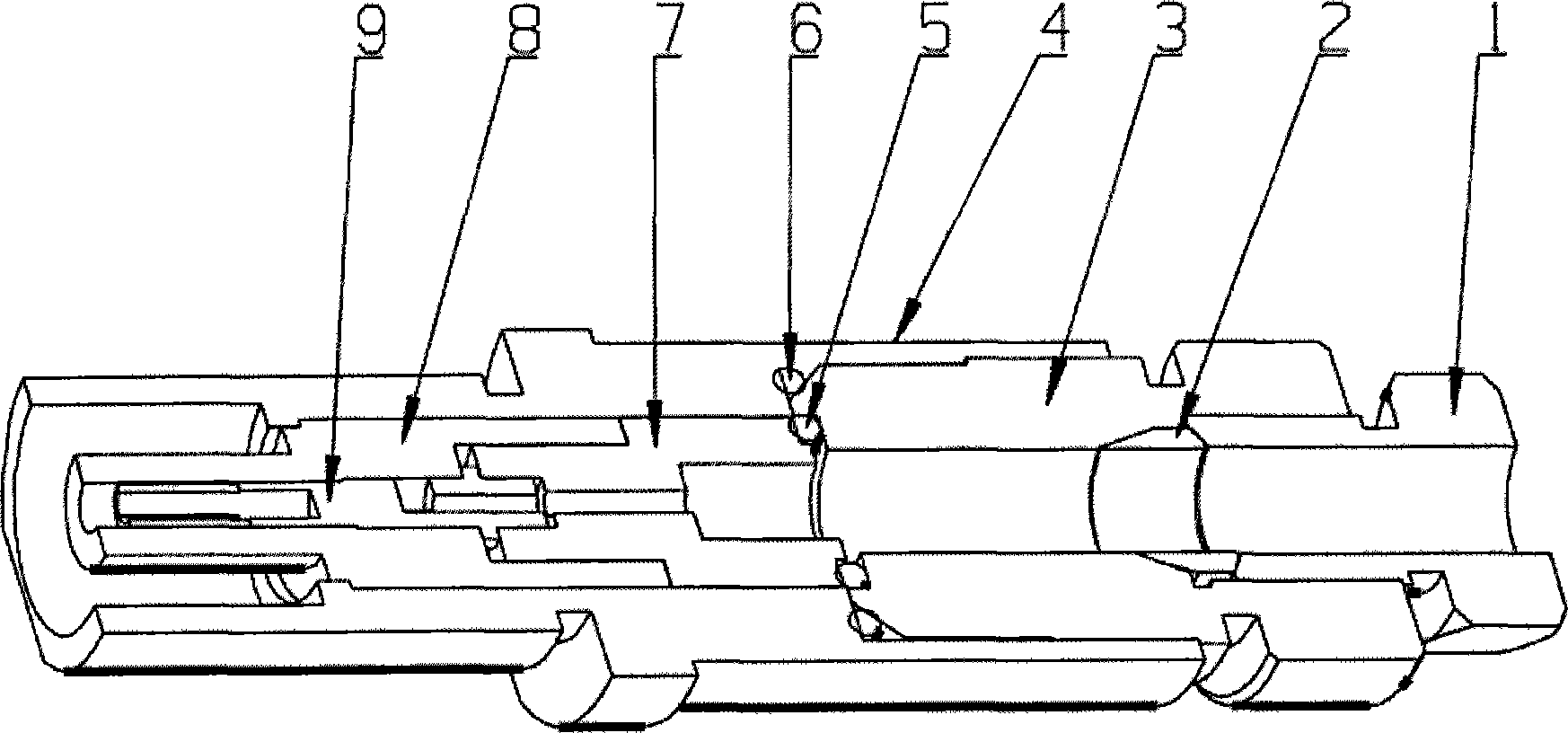

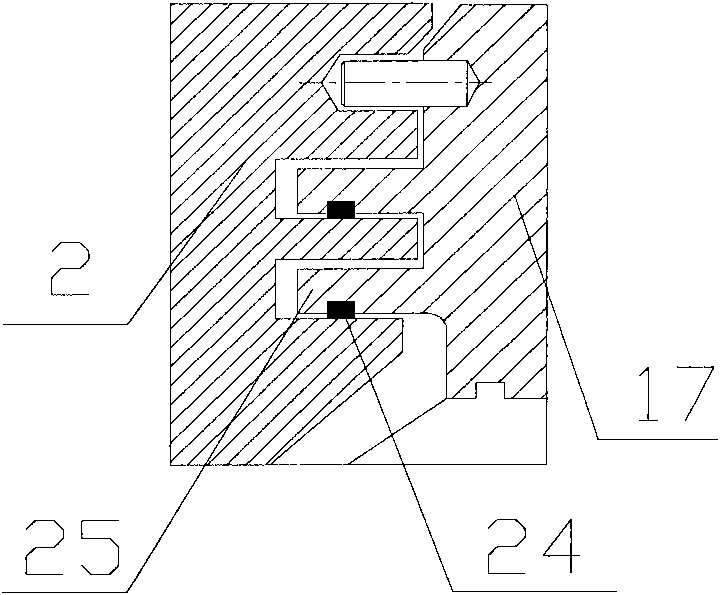

Electric penetration piece with radiation shielding structure

ActiveCN101430939AGood radiation protectionReduce radiation doseNuclear energy generationShieldingElectrical conductorEngineering

The invention discloses an electrical penetration assembly with a radiation shielding structure. The electrical penetration assembly mainly consists of a cylinder body, flanges which encapsulate two ends of the cylinder body, a conductor component which is encapsulated in the cylinder body, and an earthing conductor; wherein, a radiation division plate is vertically arranged along the axial direction of the cylinder body in the cylinder body, the conductor component encapsulated in the cylinder body and the earthing conductor penetrate the radiation division plate, and ends at two sides of the conductor component and the earthing conductor extend out of the flanges at the two ends of the cylinder body. The radiation division plate can be a lead plate fixed on a support division plate, or a high boron stainless steel plate welded on the inner wall of the cylinder body, or the high boron stainless steel plate produced with any one of coatings which are B4C, WC, FeNiB, TiC and iron-nickel-aluminum metallic compounds on the surface. The electrical penetration assembly has the outstanding advantages of simple structure, convenient assembly, lower cost and high radiation resistant capability, and can form a complete reactor radiation shielding system with a reactor safety containment, thus effectively shielding reactor radiation of nuclear reactors.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

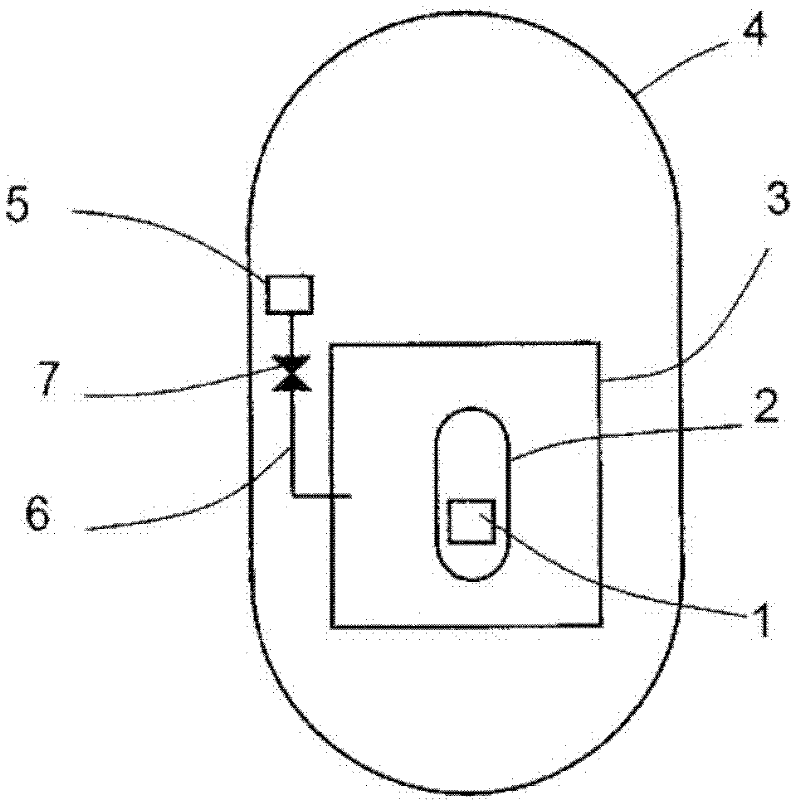

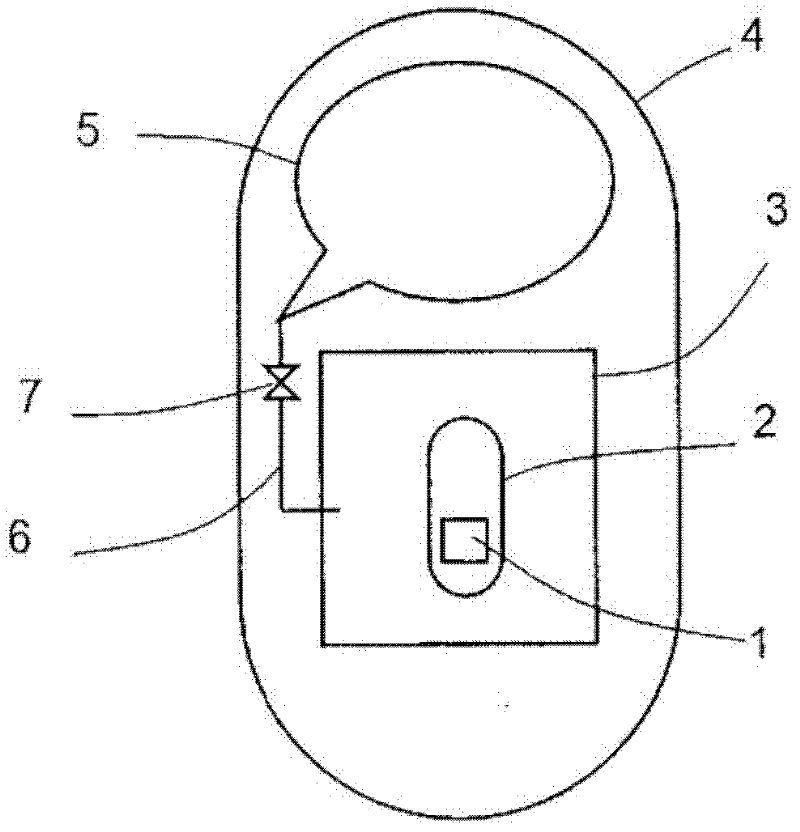

Nuclear reactor containment vessel and nuclear power plant using same

InactiveCN102483963ANuclear energy generationEmergency protection arrangementsNuclear reactor coreReactor pressure vessel

A nuclear reactor containment vessel (8) comprises a nuclear reactor's primary containment vessel (3) which contains a nuclear reactor pressure vessel (2), a nuclear reactor's secondary containment vessel (4) which is disposed outside the nuclear reactor's primary containment vessel (3) and which has the pressure resistant properties and the air-tightness which are equivalent to those of the nuclear reactor's primary containment vessel (3), an airbag (5) which is disposed within the nuclear reactor's secondary containment vessel (4) and which, when a failure occurs in the nuclear reactor's primary containment vessel (3), expands while receiving and encapsulating a high-pressure gas discharged from the inside of the nuclear reactor's primary containment vessel (3), and a gas phase vent pipe (6) which connects the nuclear reactor's primary containment vessel (3) and the airbag (5).

Owner:KK TOSHIBA

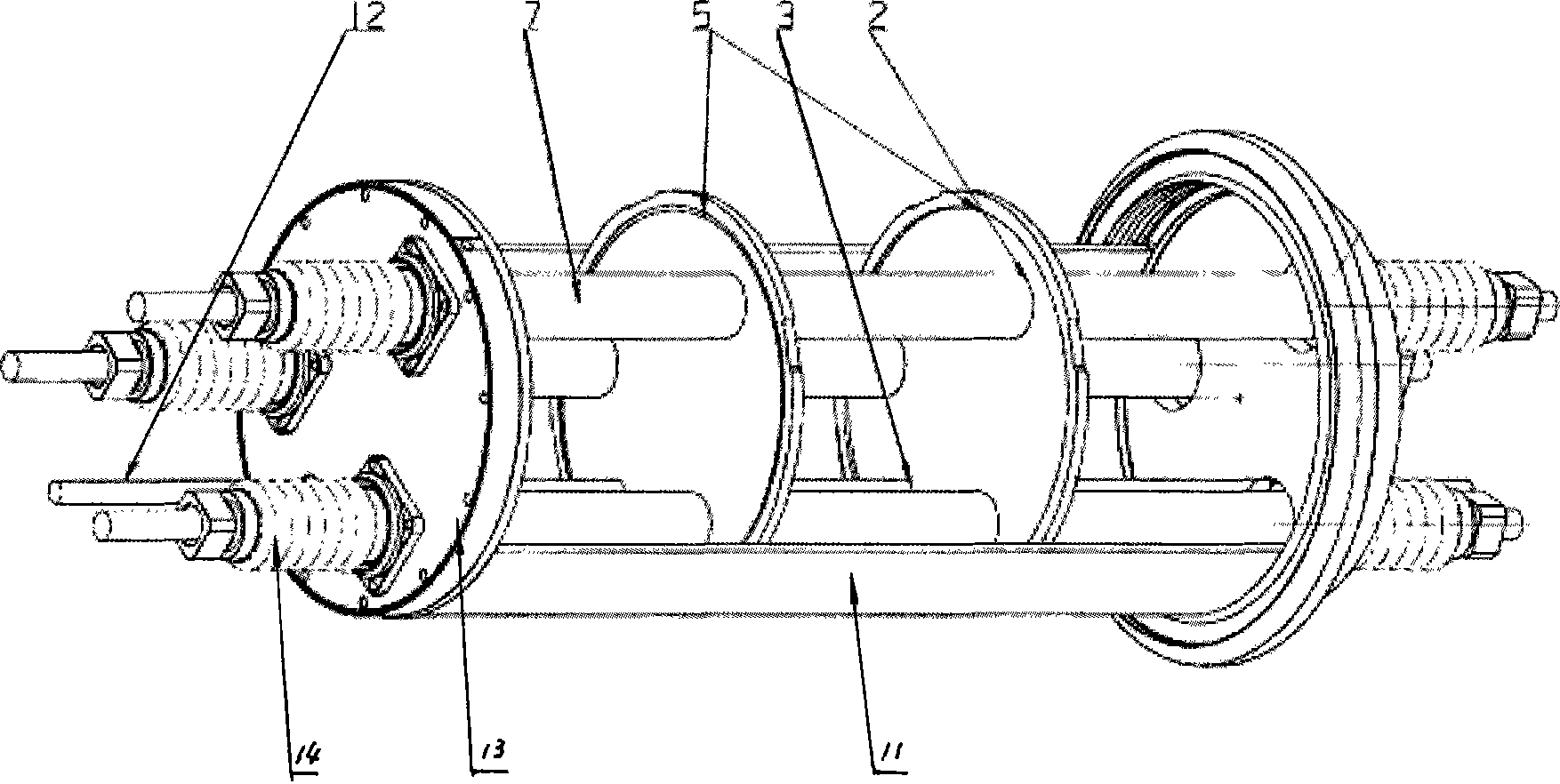

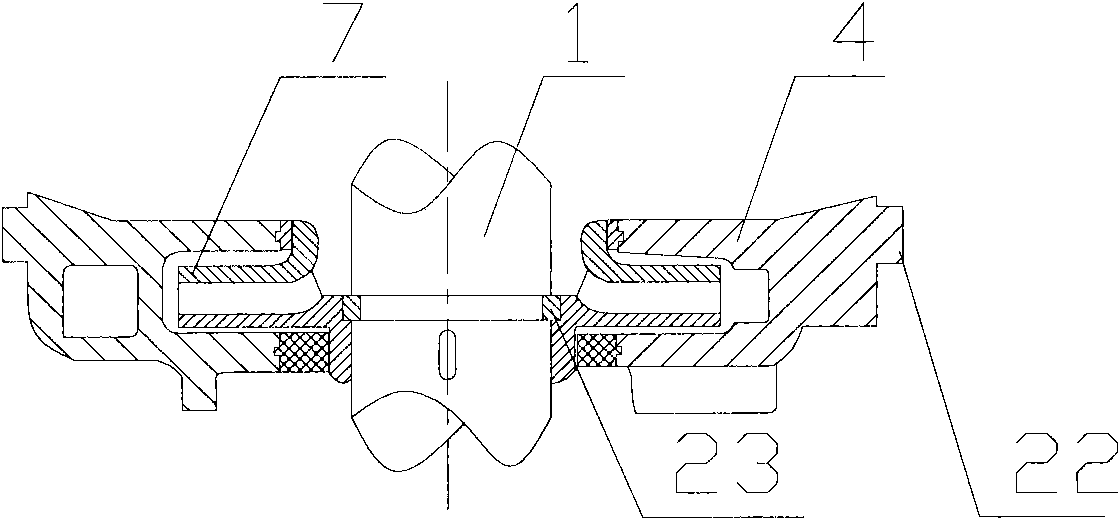

Coaxial conductor joint

ActiveCN101414721AImprove insulation performanceImprove radiation resistanceCoupling device detailsTwo-part coupling devicesElectrical conductorCoaxial cable

The invention discloses a coaxial conductor joint which comprises a coaxial socket and a coaxial plug. The coaxial socket comprises a socket compaction nut, a compaction nut cutting sleeve, a cutting sleeve nut, an outer shielding housing, a built-in O-shaped obturating ring, an outlay O-shaped obturating ring, a rigid conductor insulating envelope, a lock pin insulating envelope and a metal lock pin; the coaxial plug comprises a connecting nut, a metal contact pin, a inner insulating contact pin seat, an outer contact pin seat, a connecting sleeve, a compaction bolt, a compaction bolt cutting sleeve and a plug compaction nut. The insulating envelopes adopts high-performance polyether-ether-ketone plastic; coaxial socket sealing is realized by the metal cutting sleeves and the obturating rings, and the electrical connecting from a coaxial cable to a rigid conductor is realized by the lock pin matching with the contact pin. The invention has simple structure, good leak tightness, convenient operation, long service life, good anti-interference and irradiation resistance, is convenient for part maintenance and interchanging, and suitable to be used on an electrical perforating piece of a reactor safe shell, and also can be used on relative equipment of spaceflight and chemical engineering.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

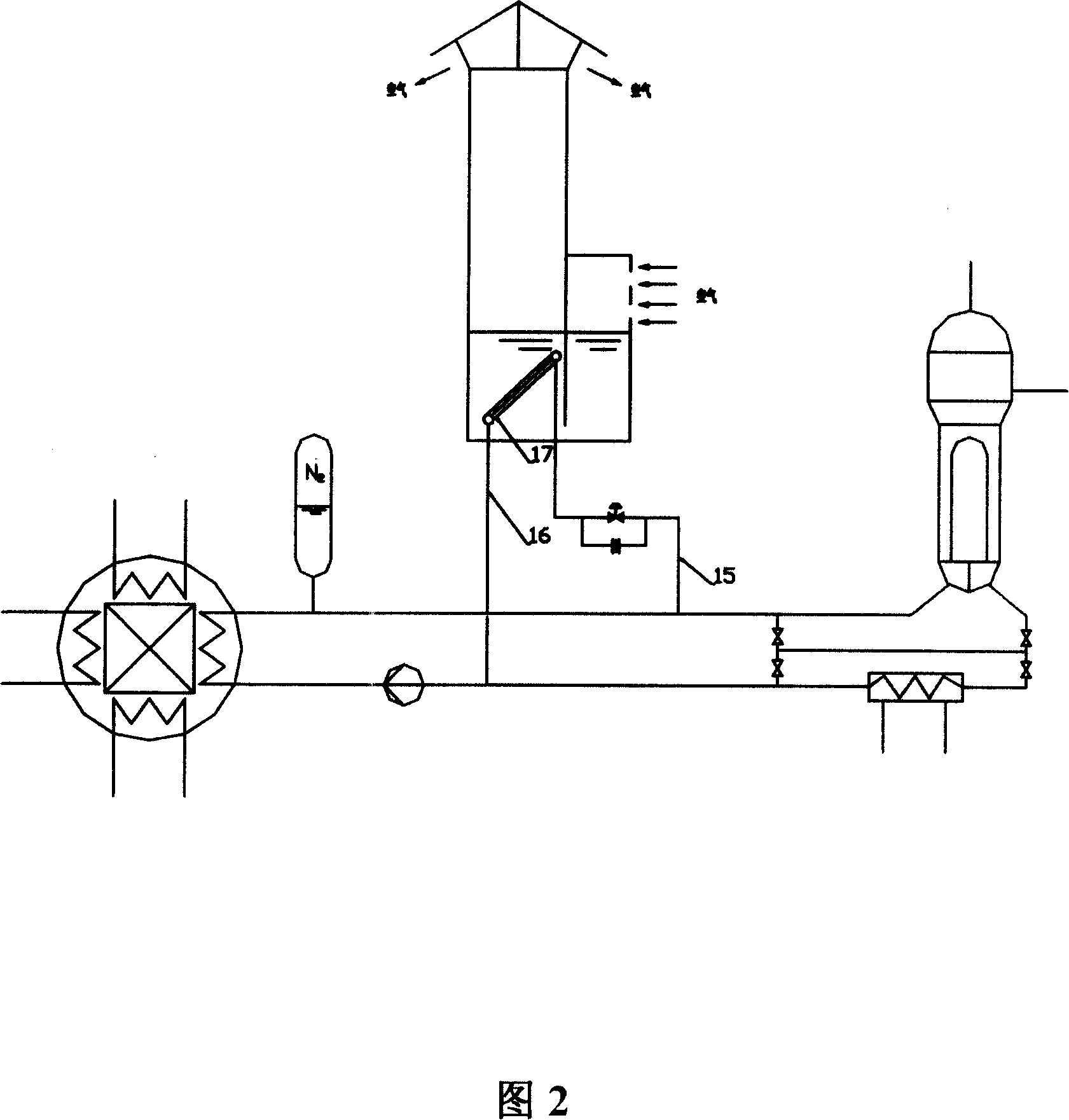

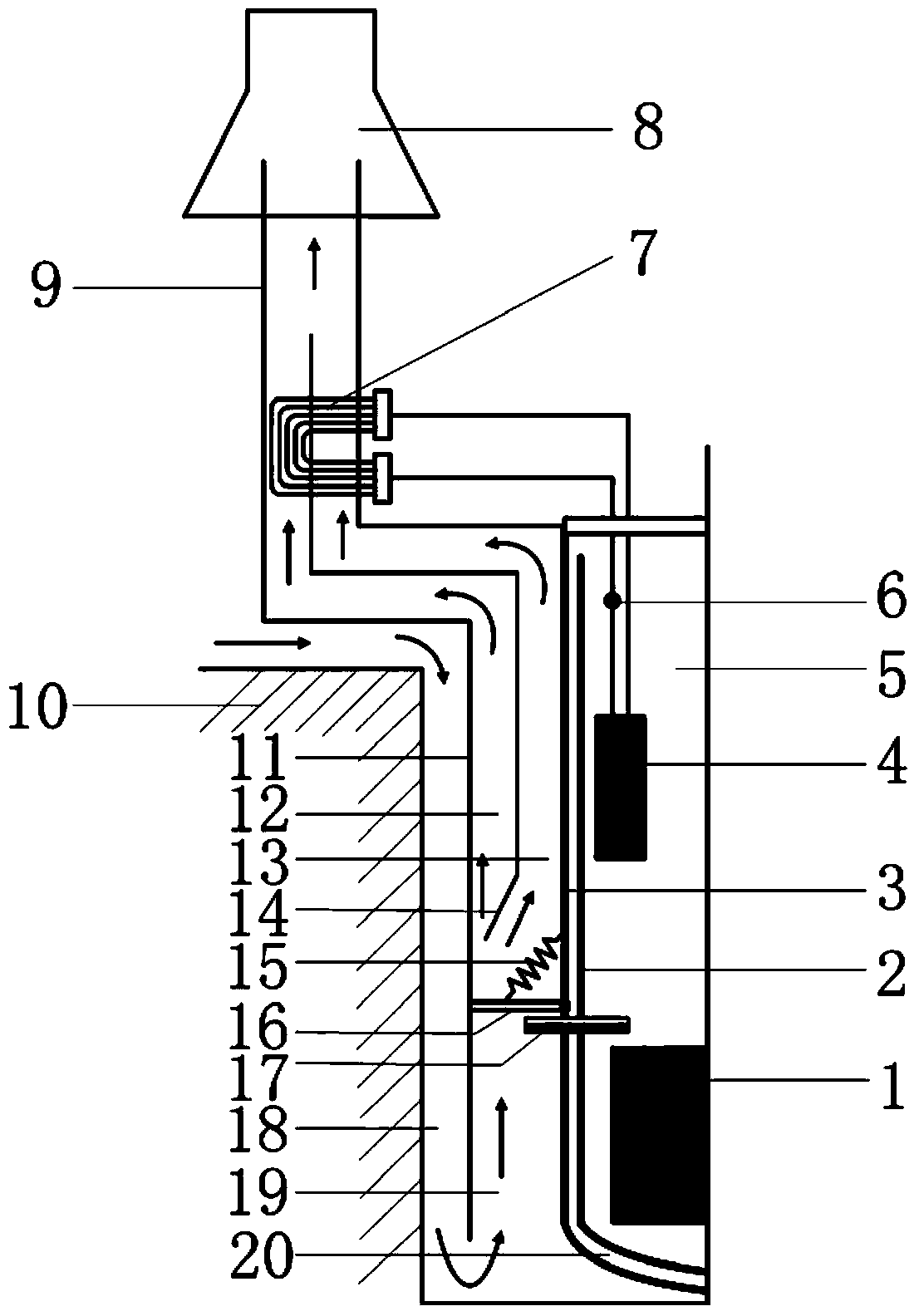

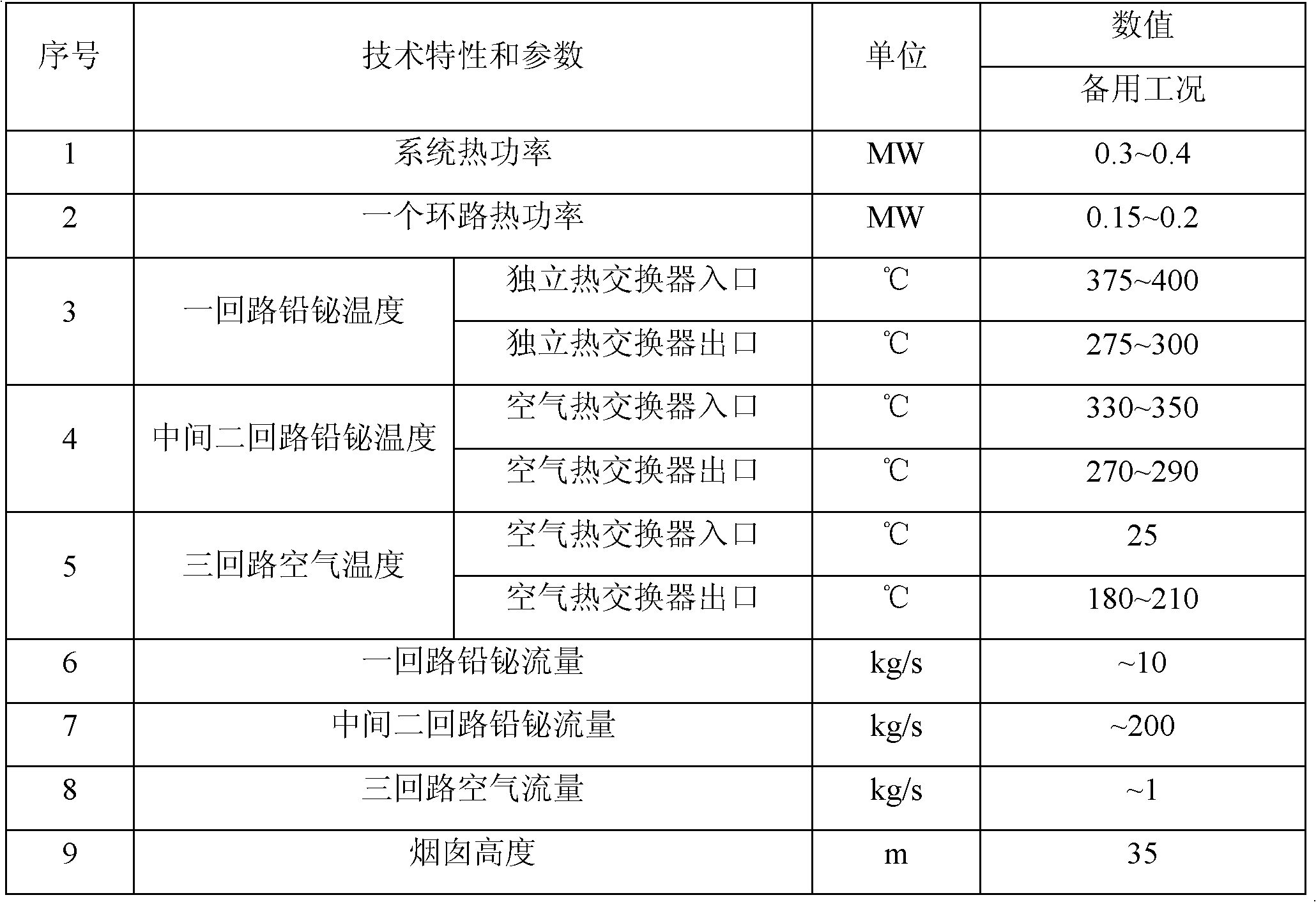

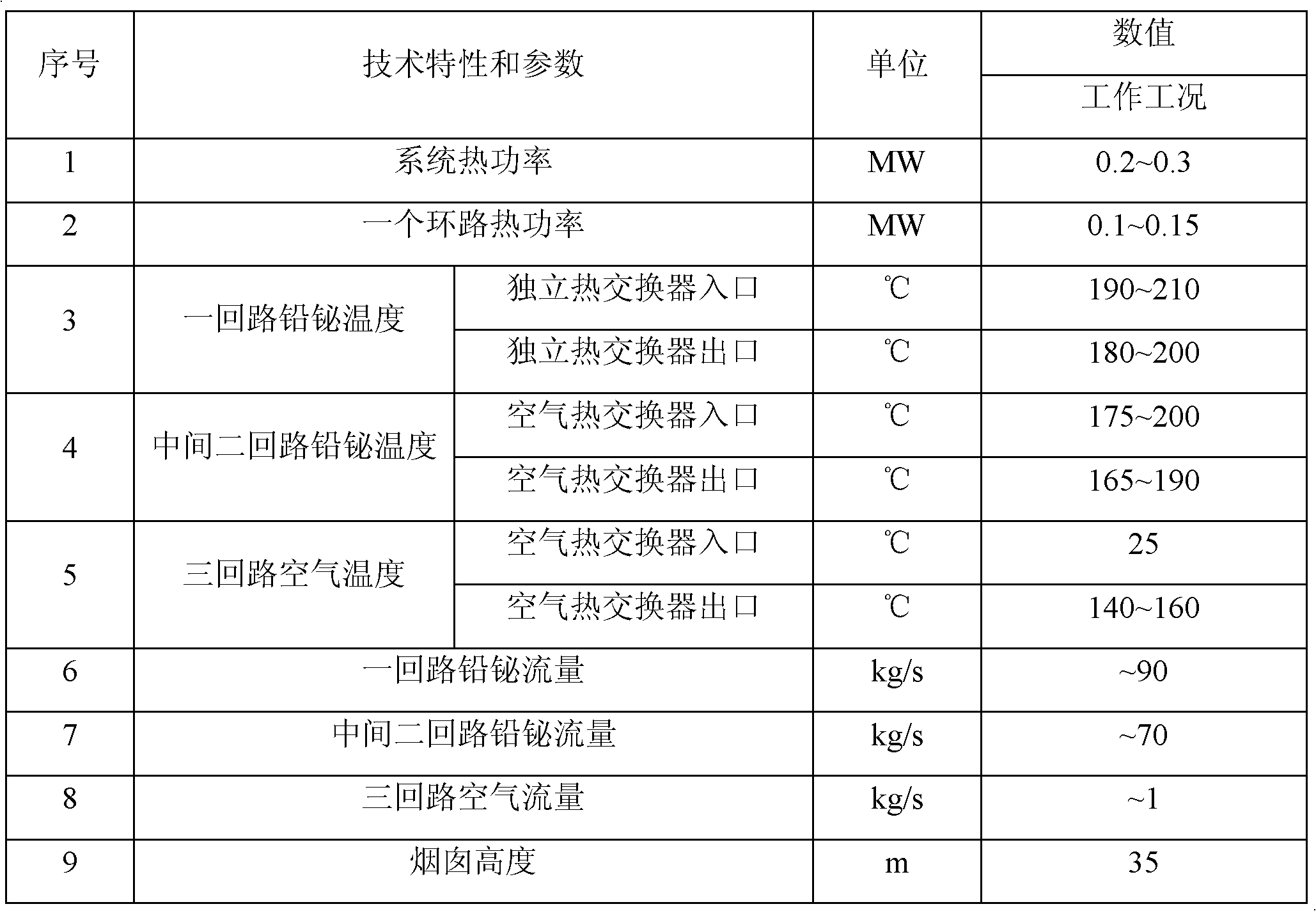

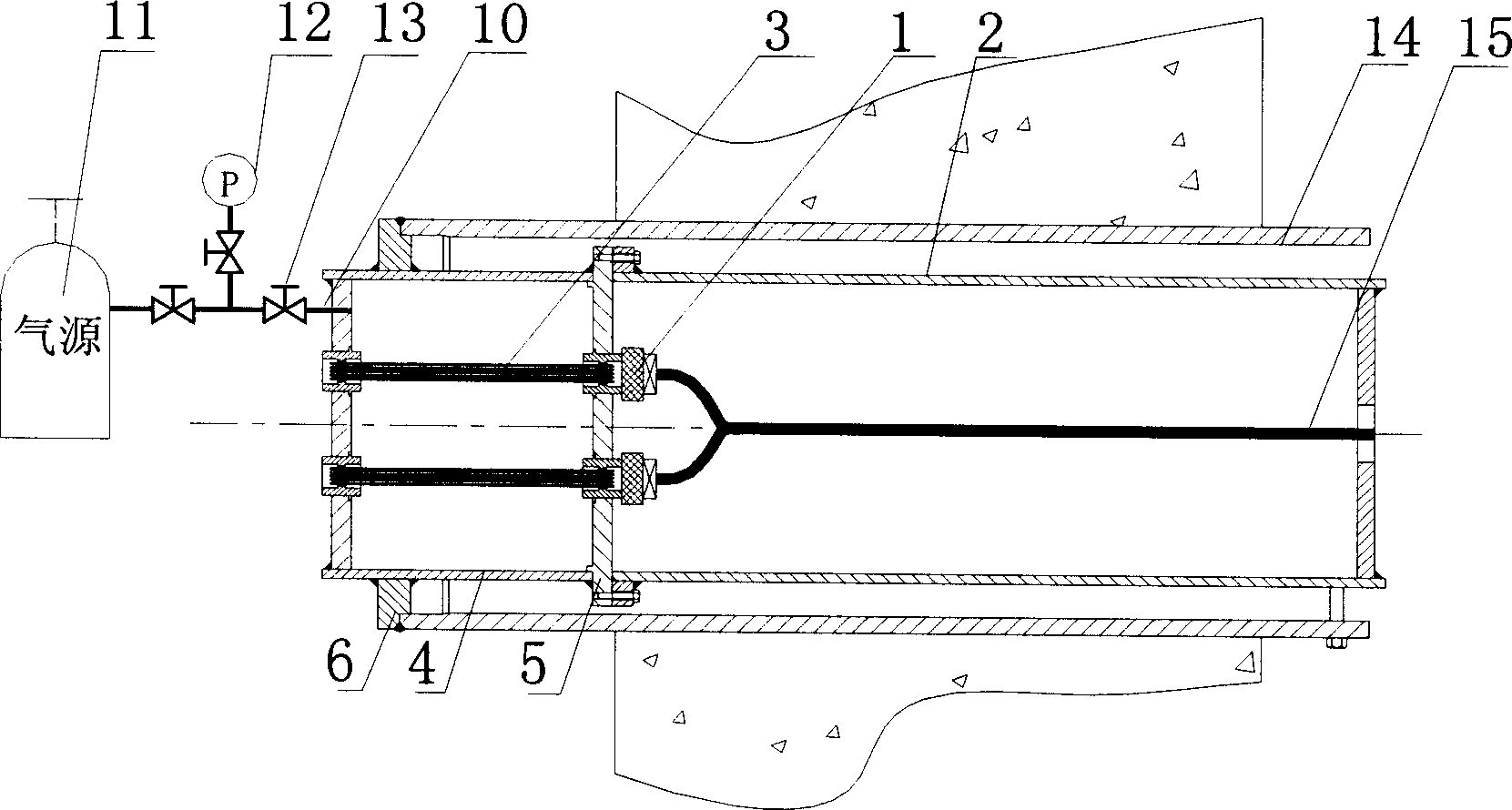

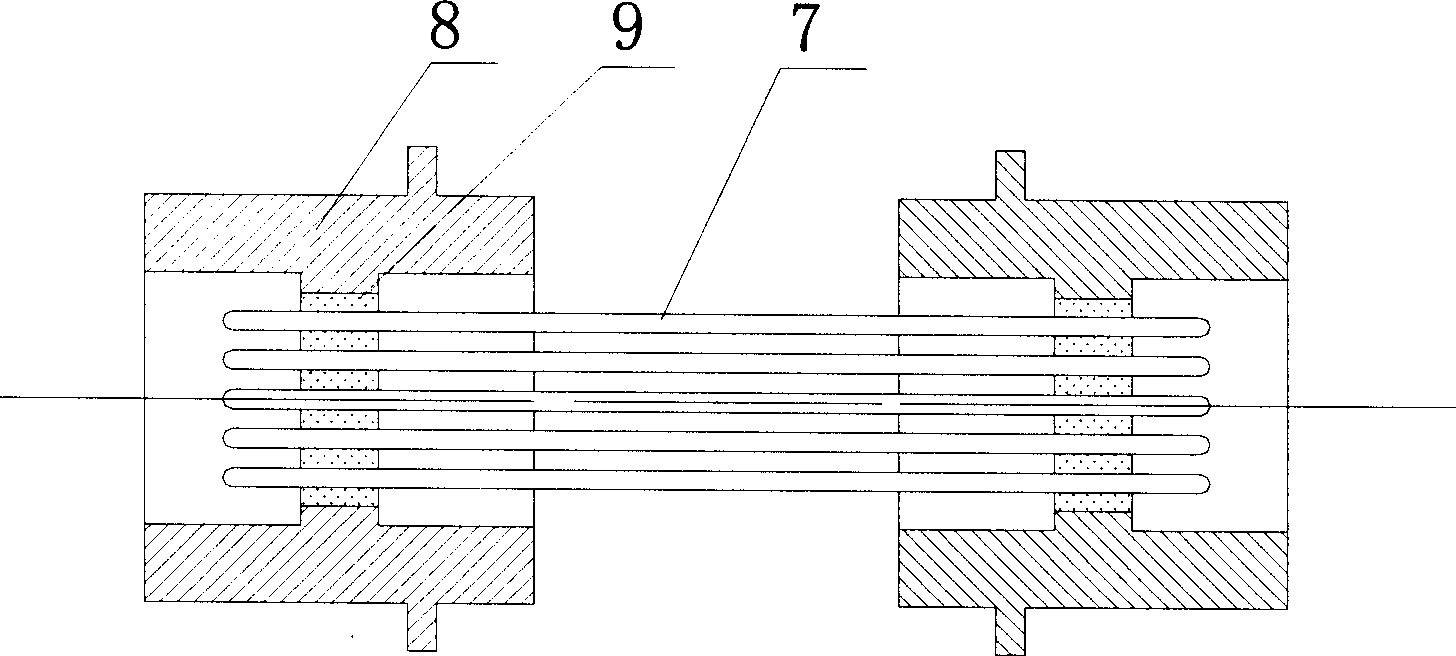

Compound accident residual heat removal system for accelerator-driven sub-critical reactor

InactiveCN102623072AReduce the maximum possible temperatureMeet safety design requirementsNuclear energy generationCooling arrangementCold airFree cooling

The invention relates to a compound accident residual heat removal system for an accelerator-driven sub-critical reactor. The system consists of a reactor core direct cooling system and a reactor safe container auxiliary cooling system. The reactor core direct cooling system is connected with a main loop and consists of an independent heat exchanger, an air heat exchanger, a smoke discharge chimney and a connecting pipe. In addition, the reactor safe container auxiliary cooling system realizes natural cooling by virtue of ambient air outside the safe container, cold air reaches the bottom of the container through a descending pipe, hot air flows out of a safety shell through an ascending pipe, and the process has the characteristic of being non-active. The compound residual heat removal system has high efficiency, non-activity, independence and high reliability, and meets the safety design requirements of an accelerator-driven sub-critical reactor.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

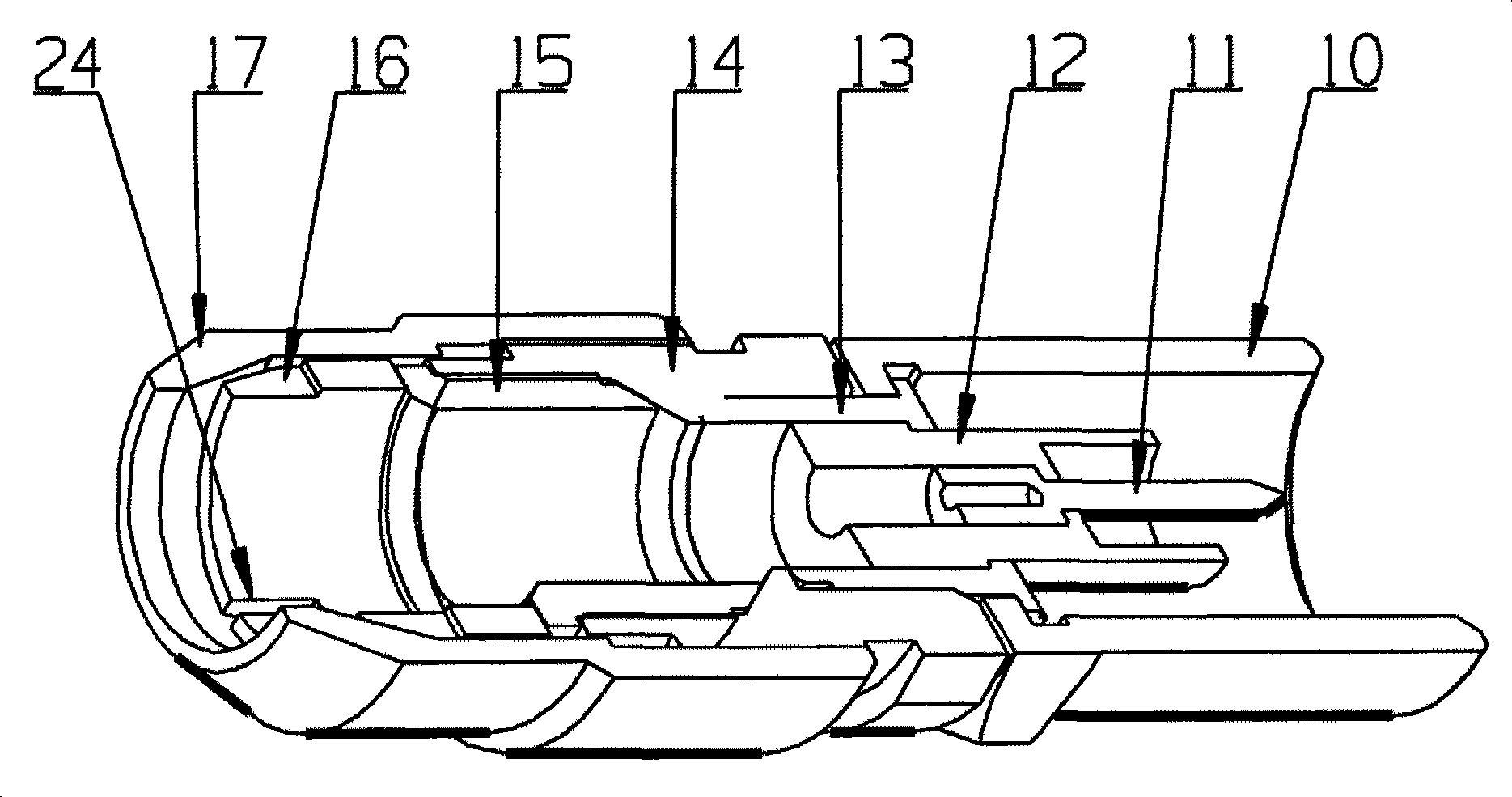

Glass or ceramic sintered electric through piece for reactor safety shell

InactiveCN1405789AImprove pressure resistanceReduce gas leakage rateNuclear energy generationContainmentCeramic sinteringRadiation resistant

The penetration piece comprises the protection cover buried in the tube, the leak detection set, the connecting flange, the cable plug, the conductor assembly and the body of the penetration piece etc. The conductor assembly contains one or more H type conductor unit. Each H type conductor unit comprises the one or more electrical conductor and the connector socket. The agglomeration of glass or pottery and porcelain is used to connect the conductor with the socket. Since the dual seal and insulation of the agglomeration or the solder method are accepted as well as no organic material is used in the penetration piece, the invention possesses the features of higher withstanding voltage, low gas leakage rate, high temperature and radiation resistant.

Owner:TSINGHUA UNIV

Nuclear reactor safety casing

A reactor containment vessel of a boiling water reactor configured to contain a reactor pressure vessel. The reactor pressure vessel is connected to at least one main steam pipe which penetrates the reactor containment vessel at a main-steam-line penetration point. The main-steam-line penetration point is disposed on a first side of the reactor containment vessel. Distance between outer surface of the reactor pressure vessel and inner surface of the reactor containment vessel on the first side is longer than the distance on a second side which is opposite to the first side.

Owner:KK TOSHIBA

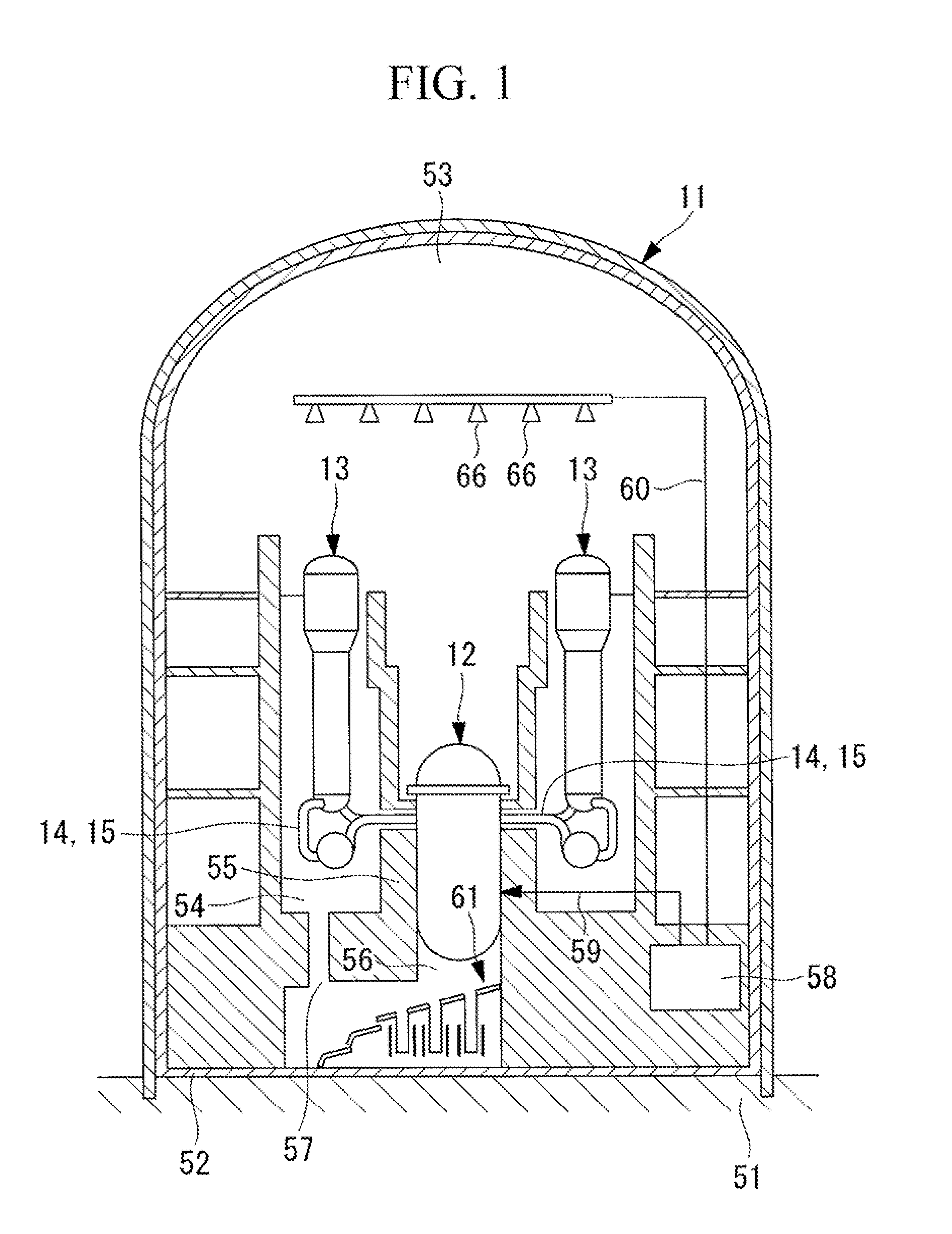

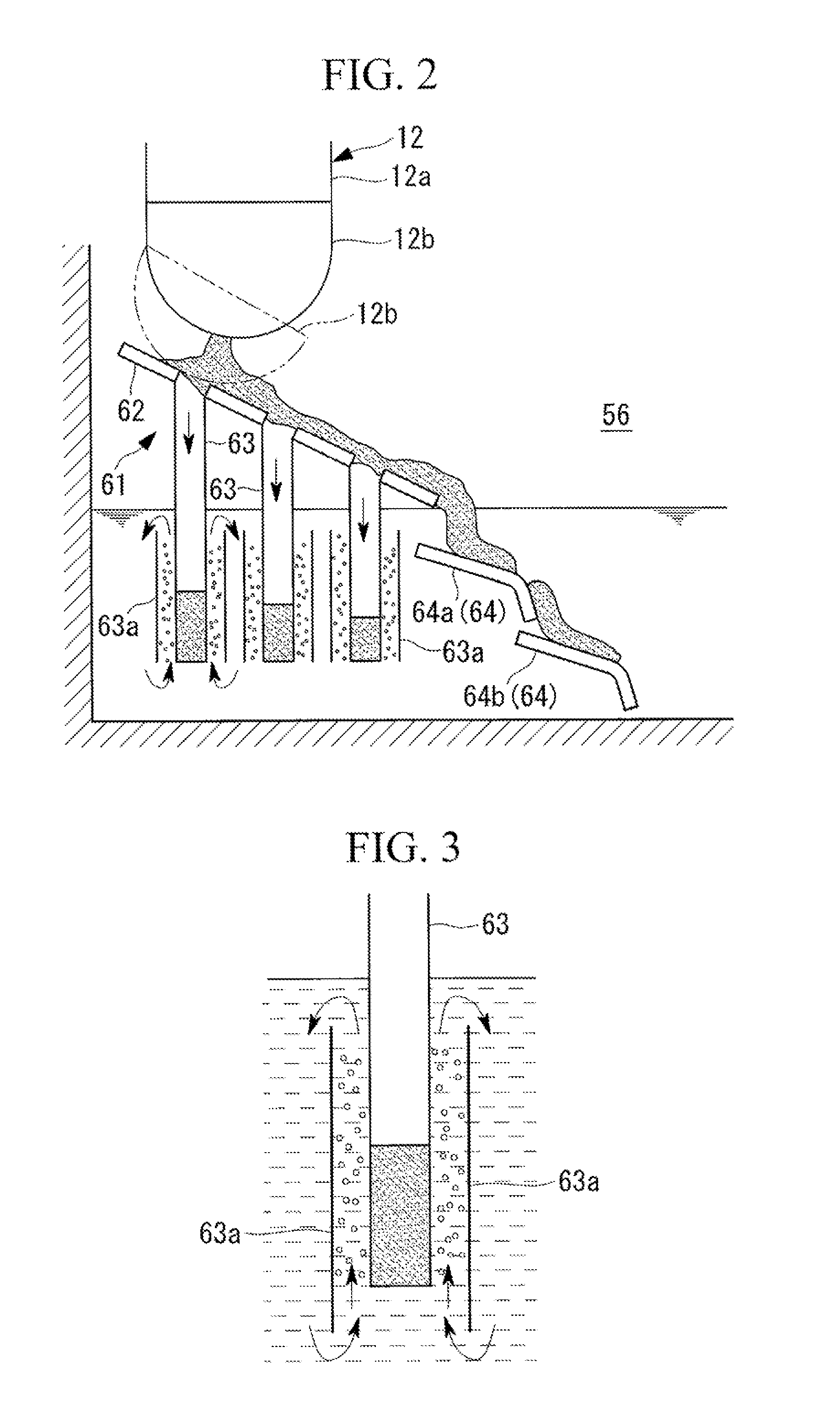

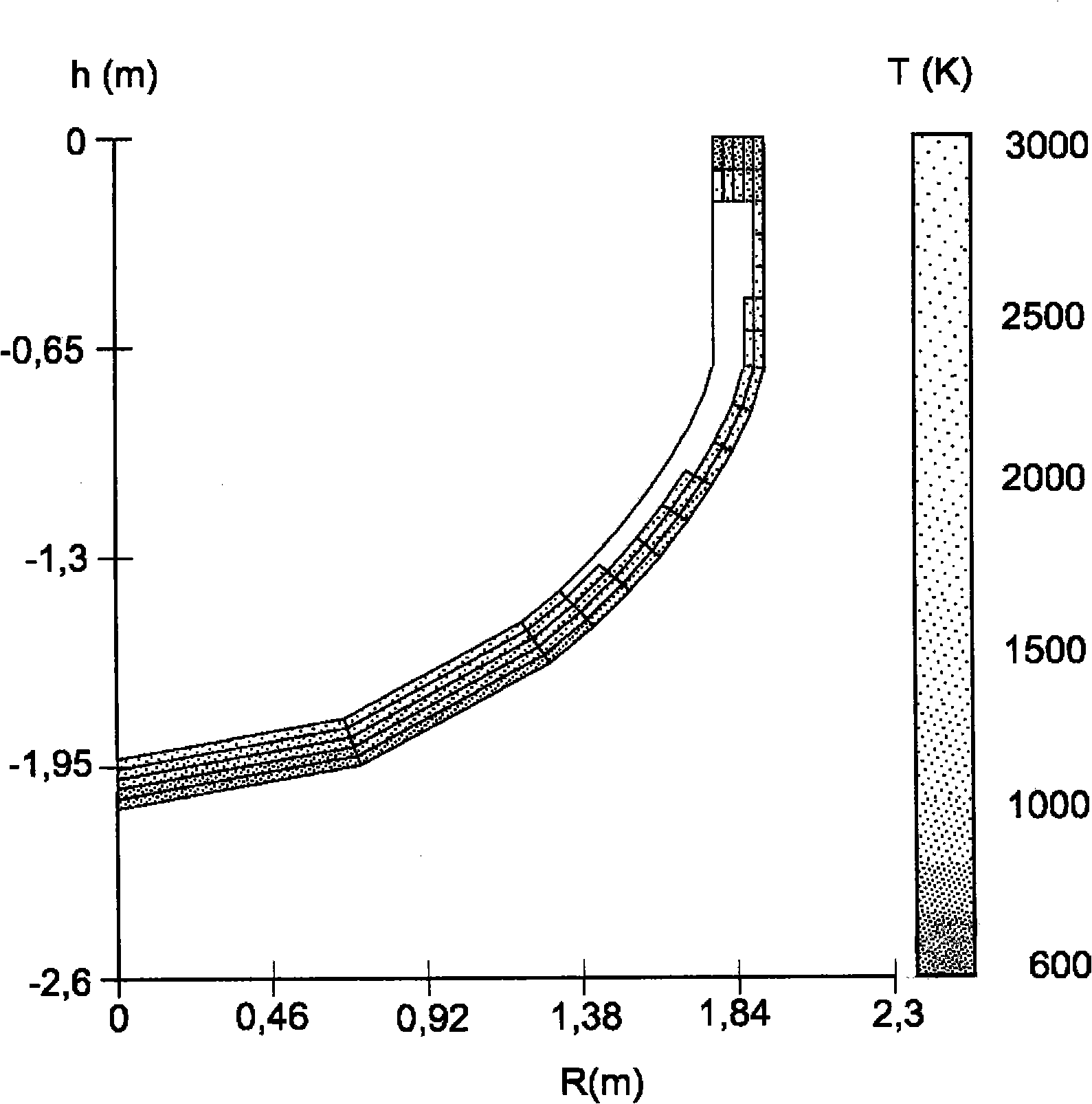

Corium cooling structure, reactor containment vessel provided with the same, and nuclear power plant provided with the same

InactiveUS20120269312A1Avoid accumulationImprove cooling efficiencyNuclear energy generationEmergency protection arrangementsNuclear plantNuclear power

An object is to provide a corium cooling structure that is capable of accumulating corium and debris that have flowed out from a reactor in small divided portions and of sufficiently cooling the high-temperature corium and debris, a reactor containment vessel provided with the same, and a nuclear power plant provided with the same. A capture portion that captures the corium that has flowed out from a reactor and a plurality of pipe portions that are provided in a coolant storing portion and into which the corium flows via the capture portion are provided.

Owner:MITSUBISHI HEAVY IND LTD

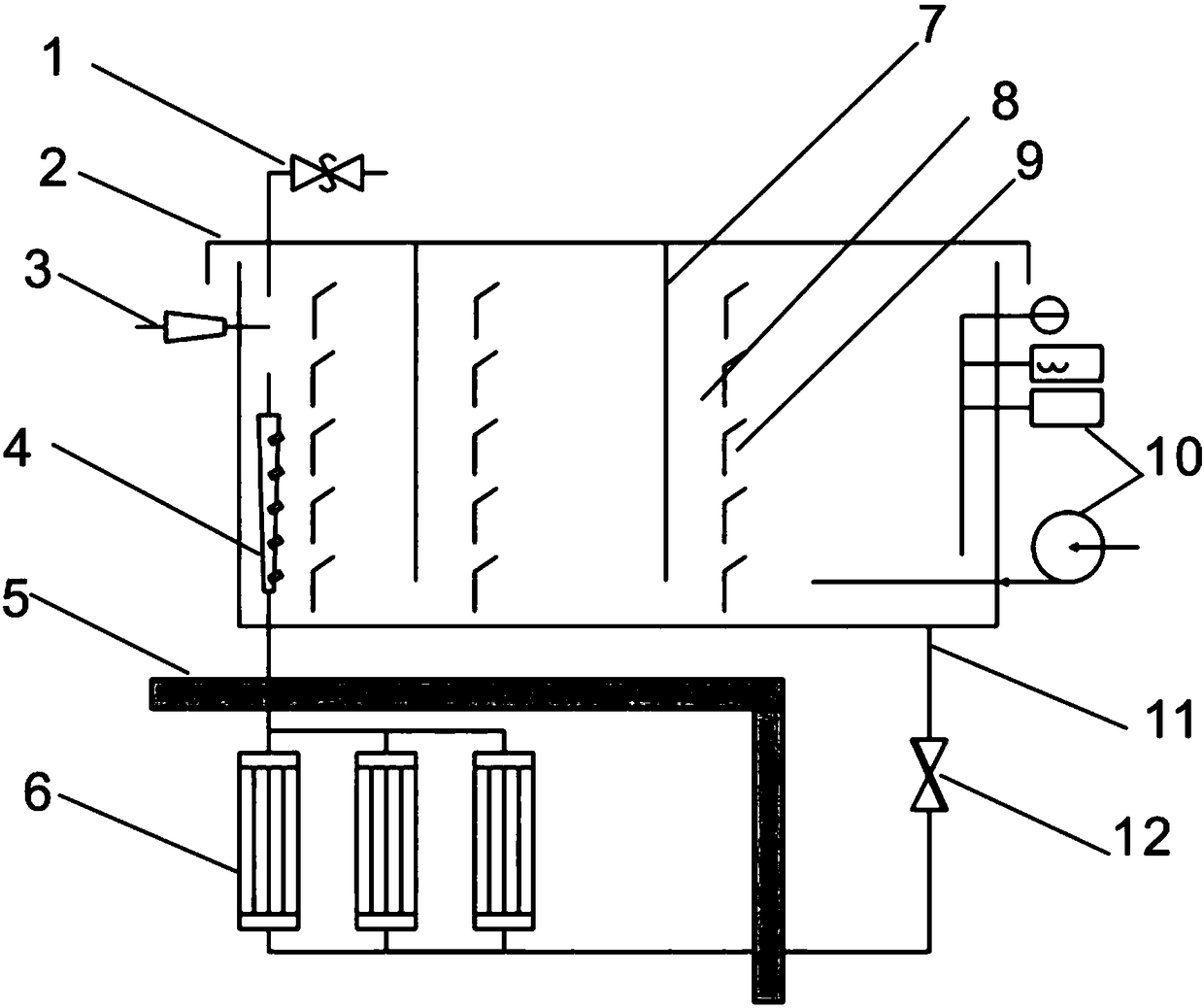

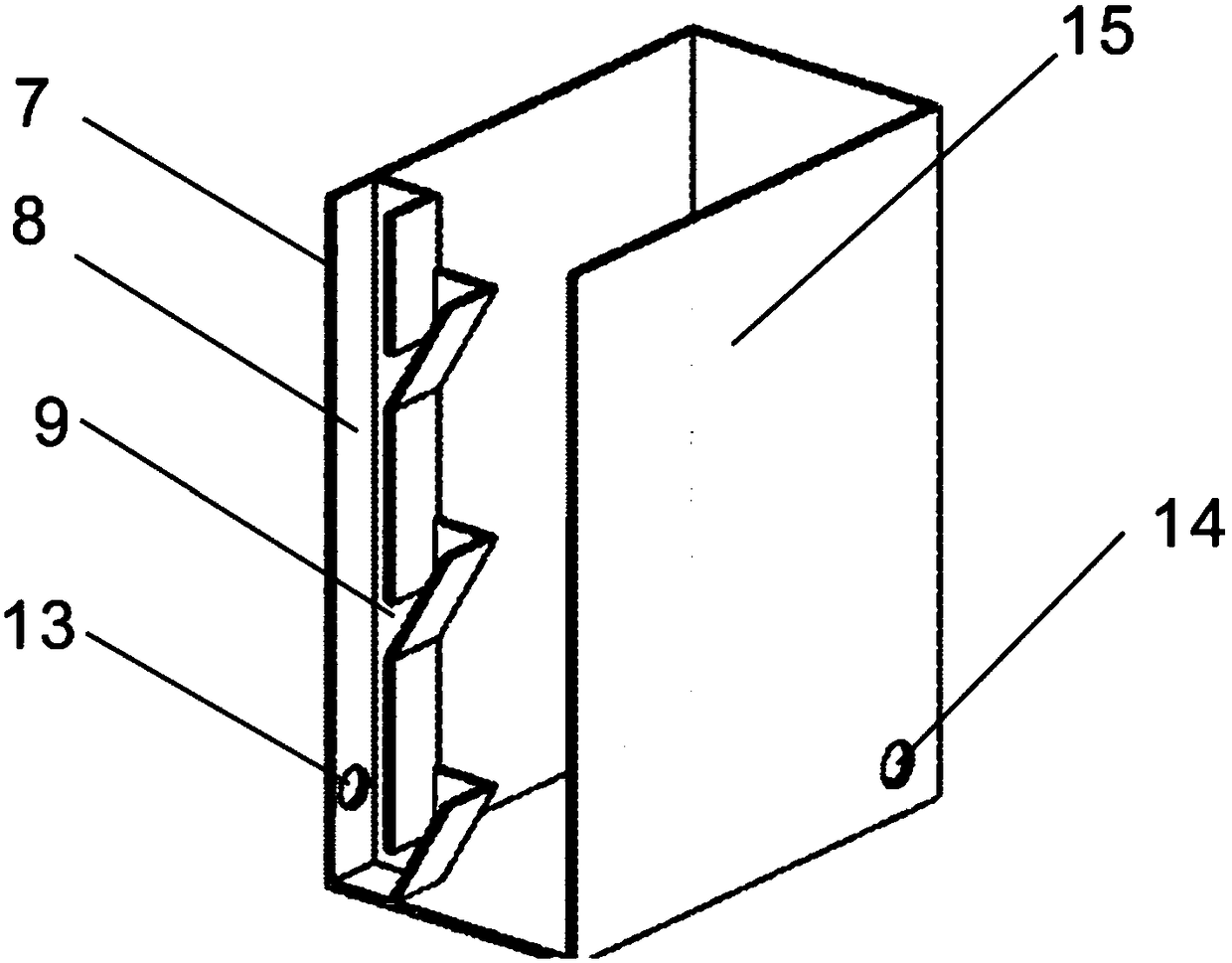

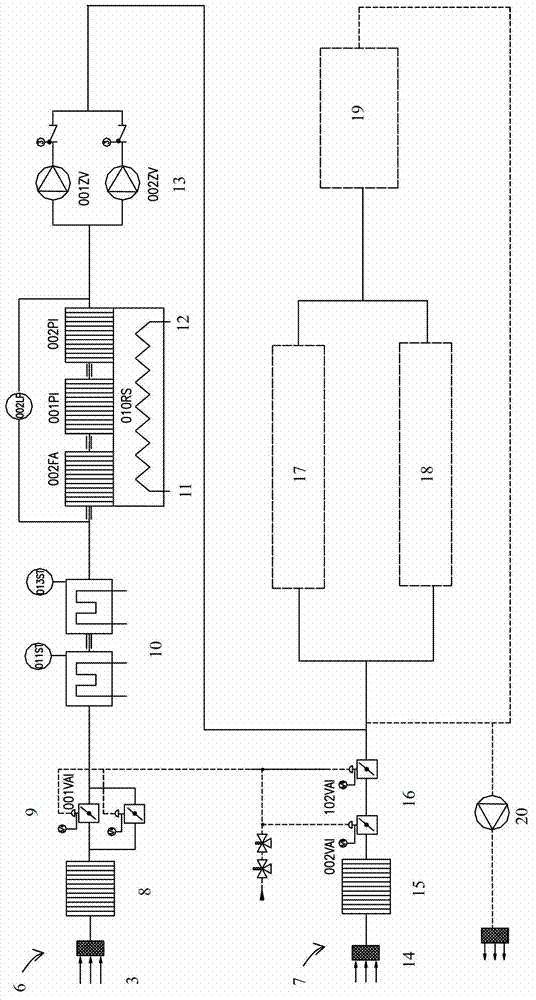

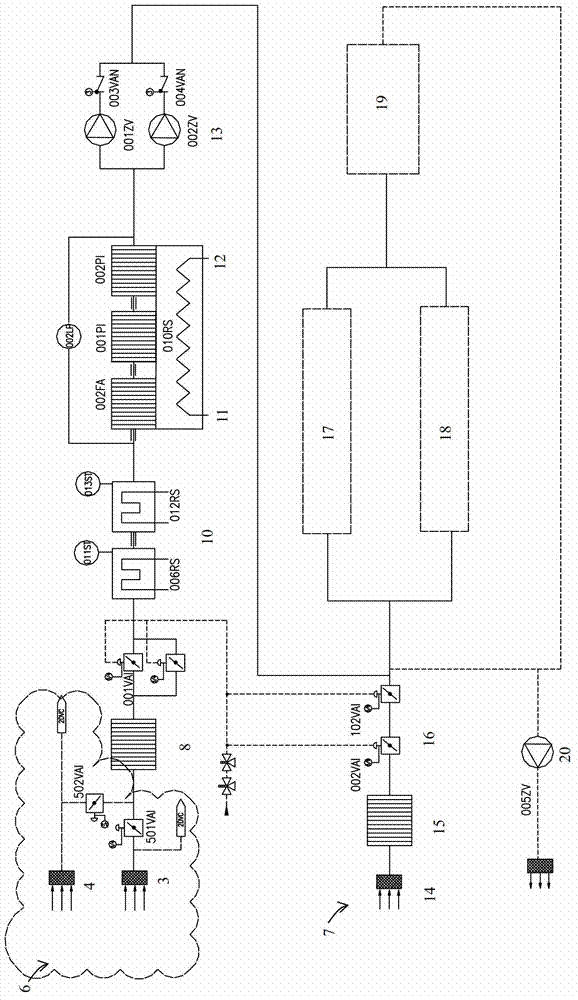

Heat derivation system for long-term passive containment

ActiveCN104103325AIntegrity guaranteedIncrease heat transfer powerNuclear energy generationCooling arrangementIsolation valveEnhanced heat transfer

The invention aims to provide a heat derivation system for a long-term passive containment. The system mainly comprises a cooling water box (6), separating valves (5 and 6), an internal heat exchanger (1) and an external air cooling condenser-cooler (7), wherein the internal heat exchanger and the external air cooling condenser-cooler both adopt high-efficiency enhanced heat transfer pipes to improve the heat transfer efficiency and reduce the size of the heat exchanger; steam guide plates used for guiding the flow direction of internal airflow and protecting devices and pipelines are arranged inside an internal concrete containment. When accidents, such as LOCA and MSLB, happen, the system can provide long-term and efficient cooling for the containment without external power; temperature and pressure inside the reactor containment are always maintained under the permissible limit under a condition that human intervention and other external cooling measures are eliminated, so that integrity of the containment is maintained.

Owner:HARBIN ENG UNIV

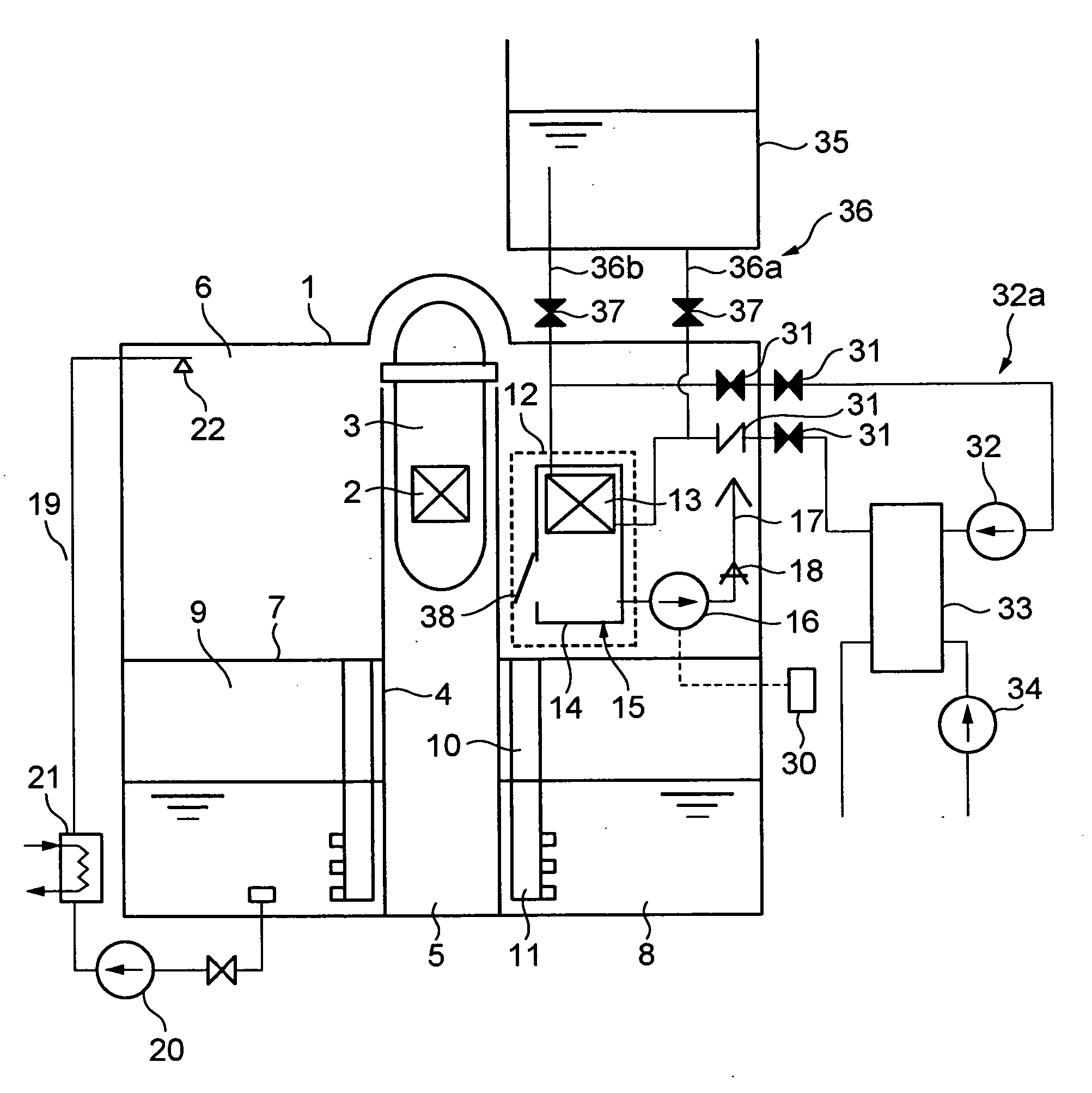

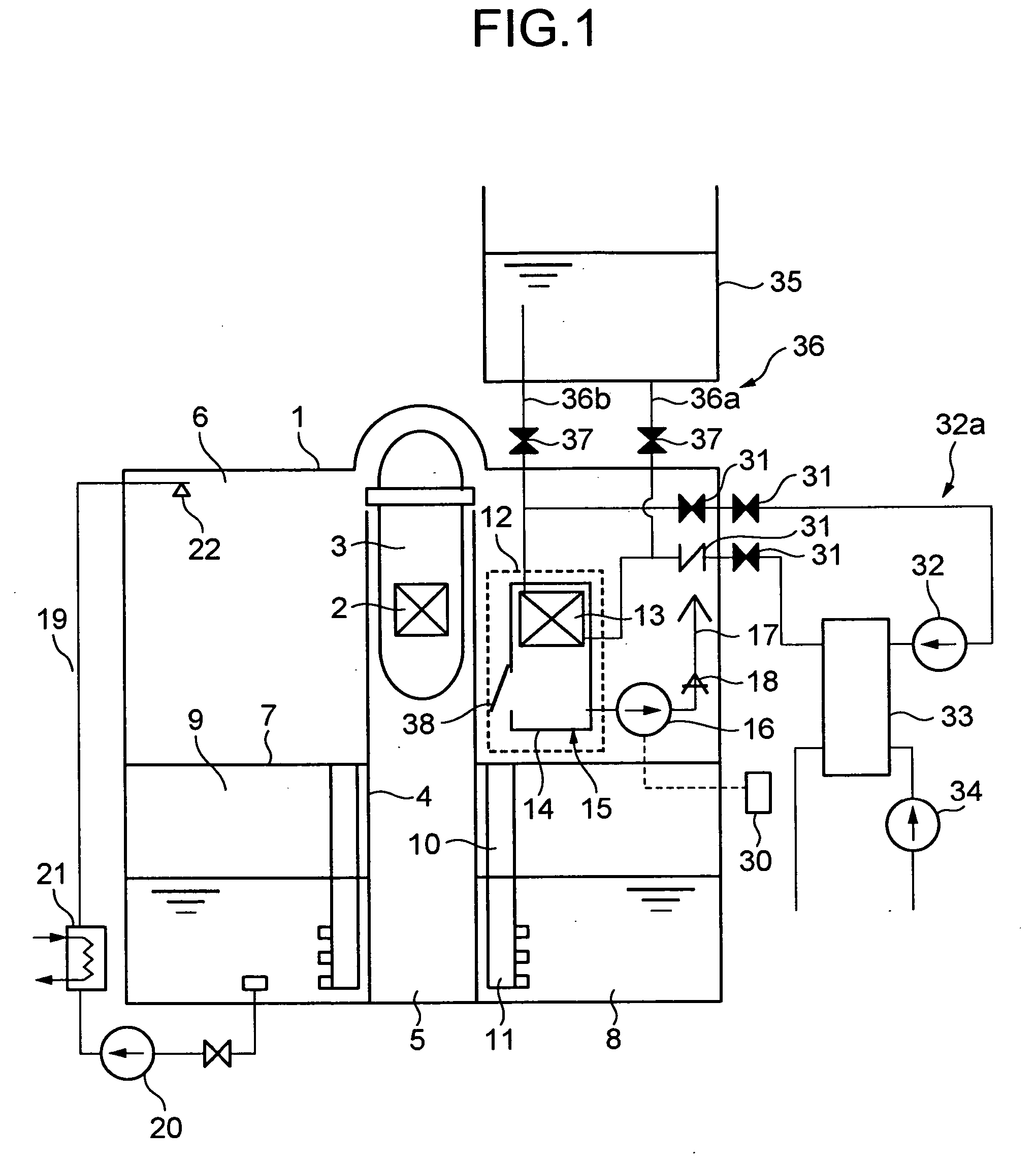

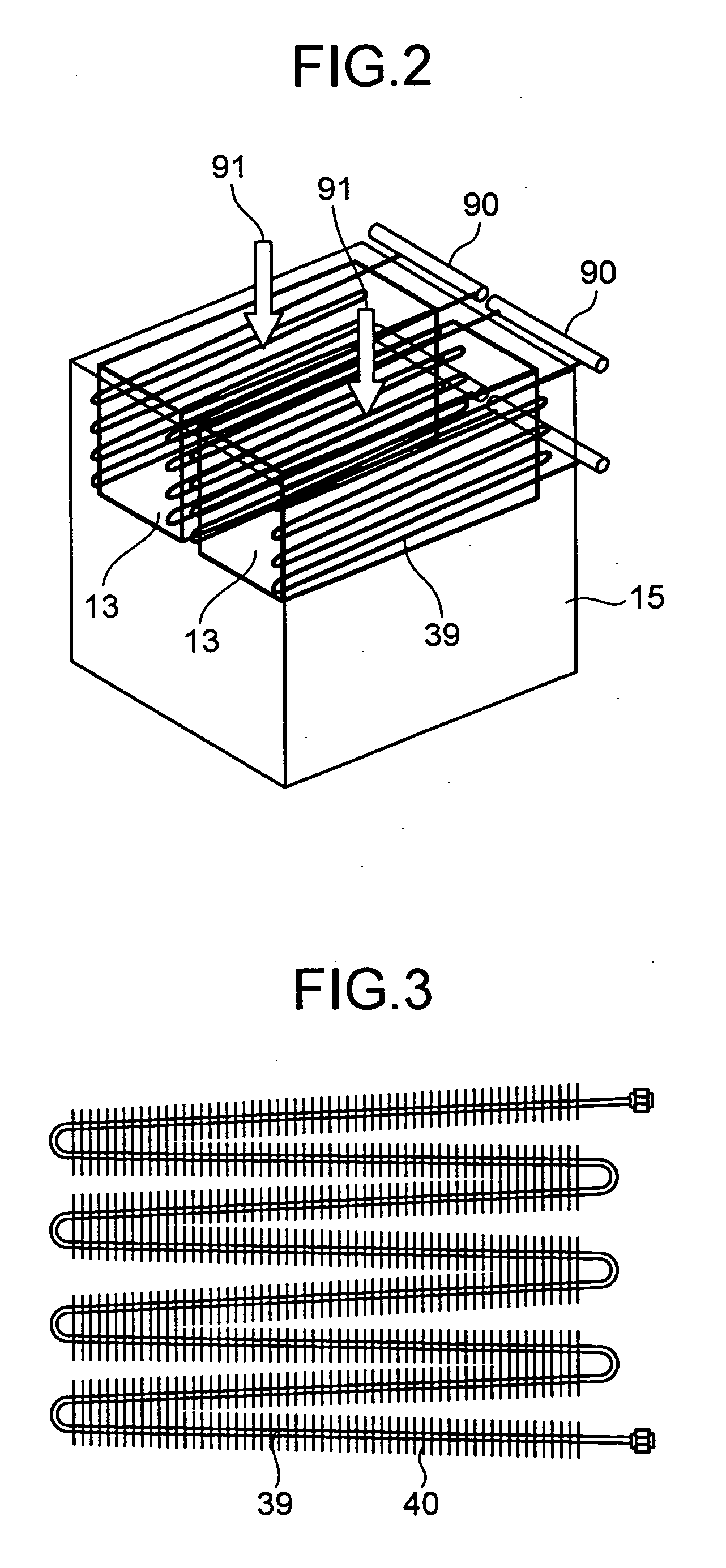

Reactor containment vessel cooling equipment

InactiveUS20070076835A1Reduce steam pressureNuclear energy generationEmergency protection arrangementsNuclear reactorWater circulation

A nuclear reactor containment vessel cooling equipment has: a dry well cooler casing in a containment vessel, having an opening at its top and a shutter at its lower part; a heat transfer tube arranged at an upper part in the dry well cooler casing; a forced cooling water circulation system for feeding cooling water from outside of the containment vessel into the heat transfer tube by a pump; a blower for mobilizing gas around the heat transfer tube; an external pool container arranged outside the containment vessel and above the heat transfer tube and containing cooling water; and a gravity-driven cooling system to supply cooling water in the external pool container into the heat transfer tube, utilizing gravity.

Owner:KK TOSHIBA

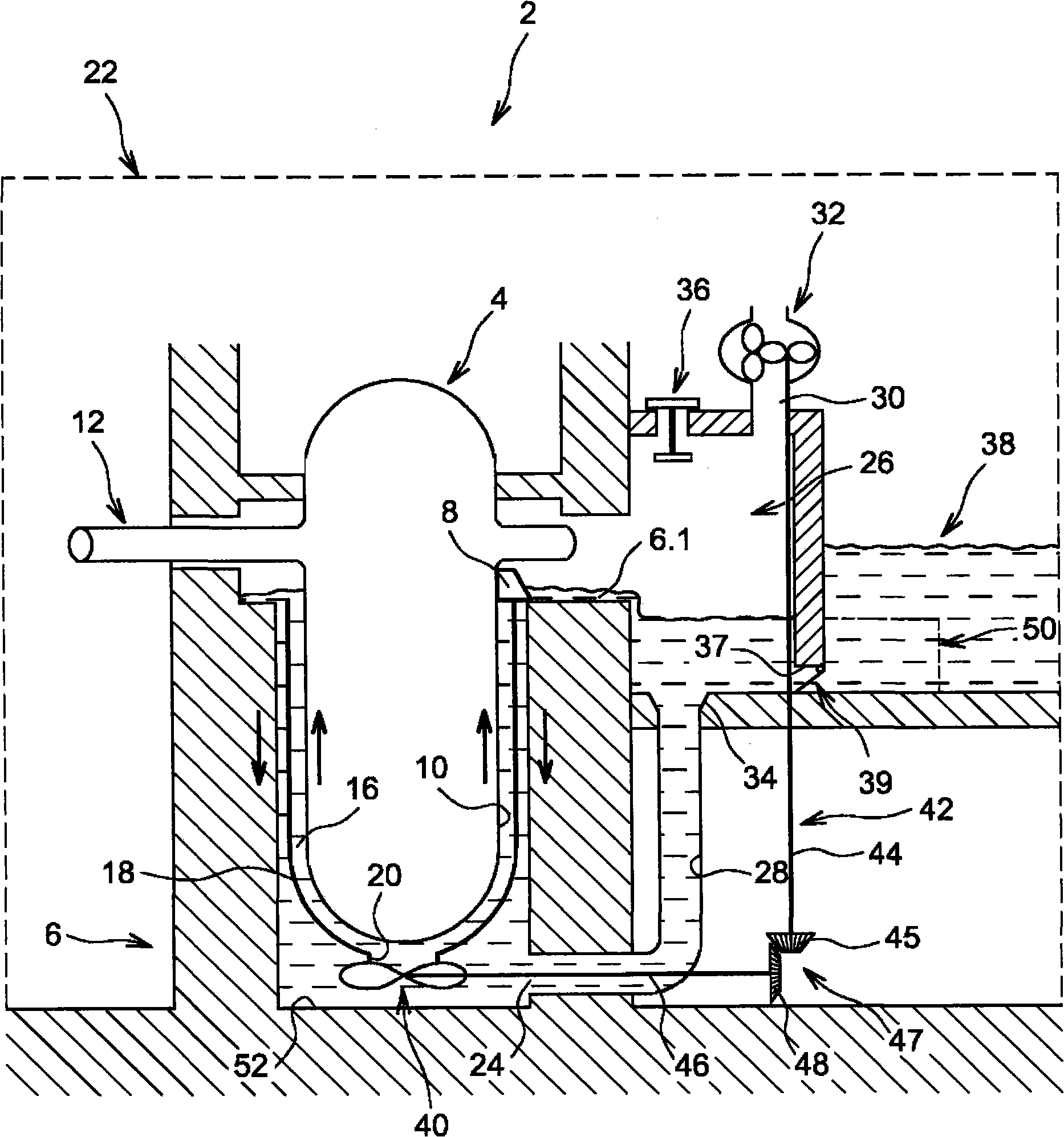

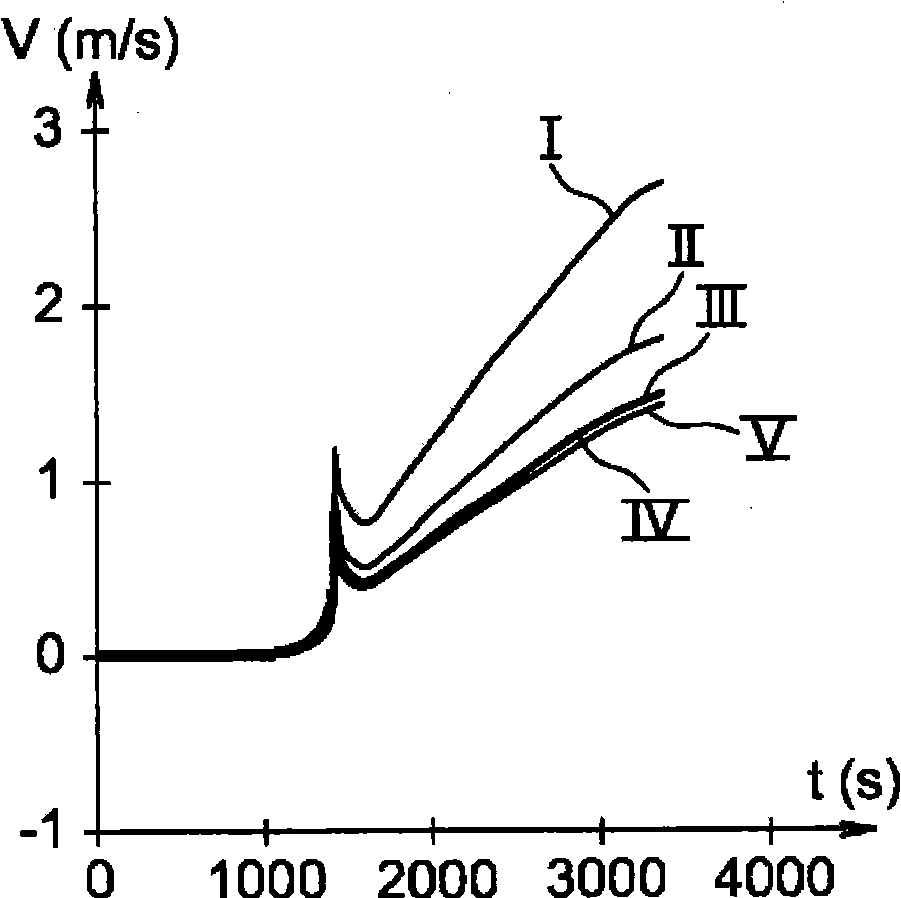

Nuclear reactor with improved cooling in an accident situation

InactiveCN101836262ARobustGuaranteed uptimeNuclear energy generationNuclear engineering problemsNuclear reactorForce convection

Nuclear reactor comprising: a reactor vessel (4) designed to hold a reactor core; a primary system for cooling the reactor; a reactor pit (6) in which the vessel (4) is placed; an annular channel (16) surrounding a lower portion of the reactor vessel (4) in the reactor pit (6), said channel (16) being intended to act as a thermal shield in normal operation and intended for the ascending flow of a liquid in the event of an accident; a reserve of liquid capable of filling the reactor pit; a reactor containment (22, not drawn); a manifold (26) for collecting the steam generated at an upper end of the reactor pit (6), said manifold being separate from the containment (22); a circulating pump (40) capable of generating a forced convection of the liquid in the annular channel (16); and a lobe pump or steam piston machine or turbine (32) for actuating the circulating pump (40) and capable of generating forced convection by means of said collected steam.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Cooling water tank for passive containment cooling system

ActiveCN108122622AImprove natural circulationIncrease powerNuclear energy generationNuclear monitoringHeat managementWater source

The invention discloses a cooling water tank for a passive containment cooling system. The cooling water tank comprises a state monitoring and water supplementing system and a closed box body arrangedon the outer side of a reactor containment wall body capable of realizing automatic heat management, wherein the state monitoring and water supplementing system is used for monitoring the state of cooling water in the closed box body and supplementing water according to the state; the closed box body is connected to a heat exchanger arranged on the inner side of the reactor containment wall bodythrough a circular pipeline; the closed box body is divided into at least two water body units through a water body partition plate, and the water body units are connected to an overflow outlet and anincoming flow inlet; and the effluent circular pipeline of the closed box body and the return circular pipeline of the closed box body are separately connected to the two different water body units.The cooling water tank provided by the invention has the beneficial effects that cooling return water is layered for heat management through the water body units, and a low-temperature cooling water source can be provided to the system put into operation all the way, so that the system can obtain a relatively high natural circulating ability and heat exhaust power.

Owner:CHINA NUCLEAR POWER ENG CO LTD

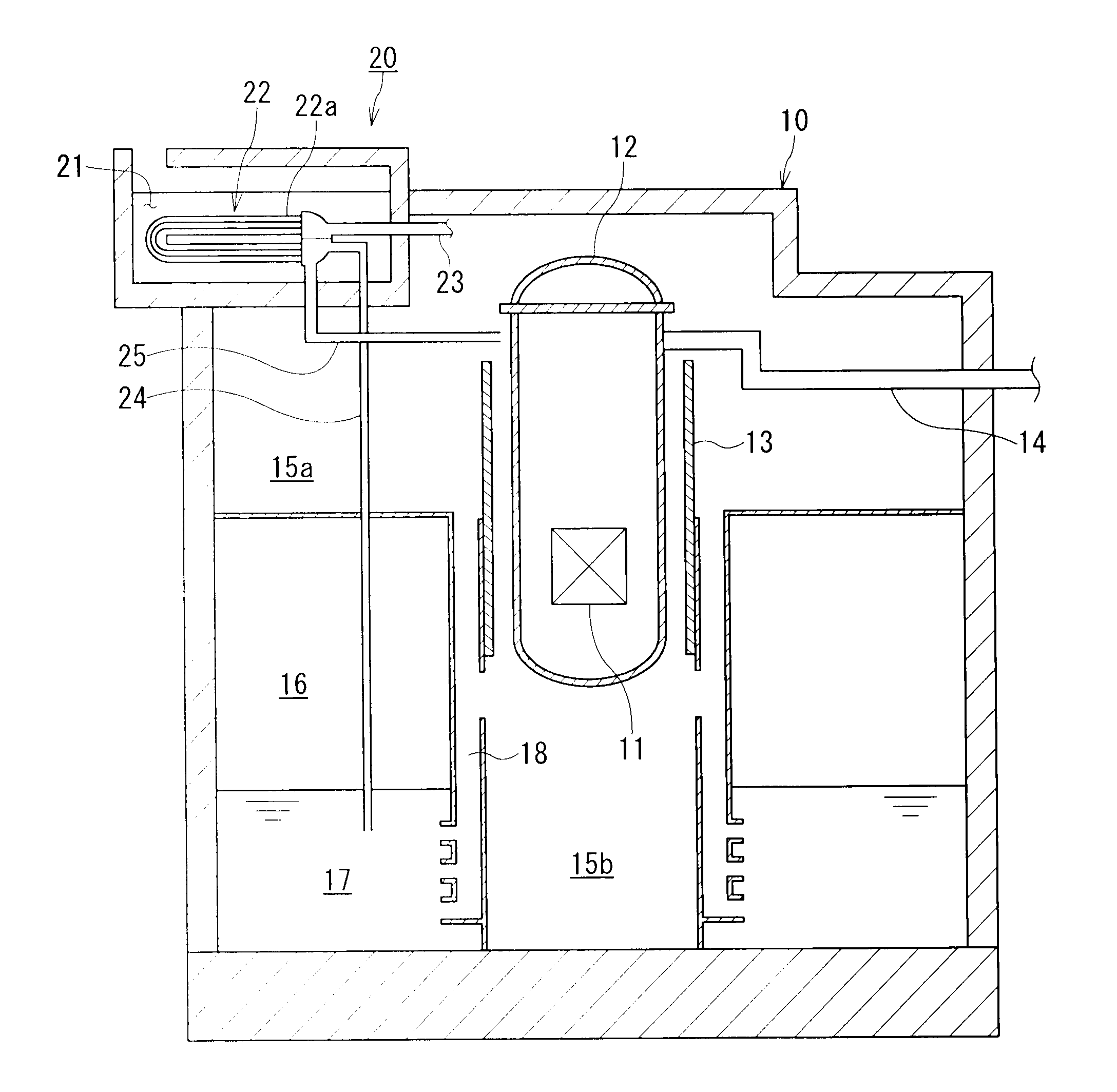

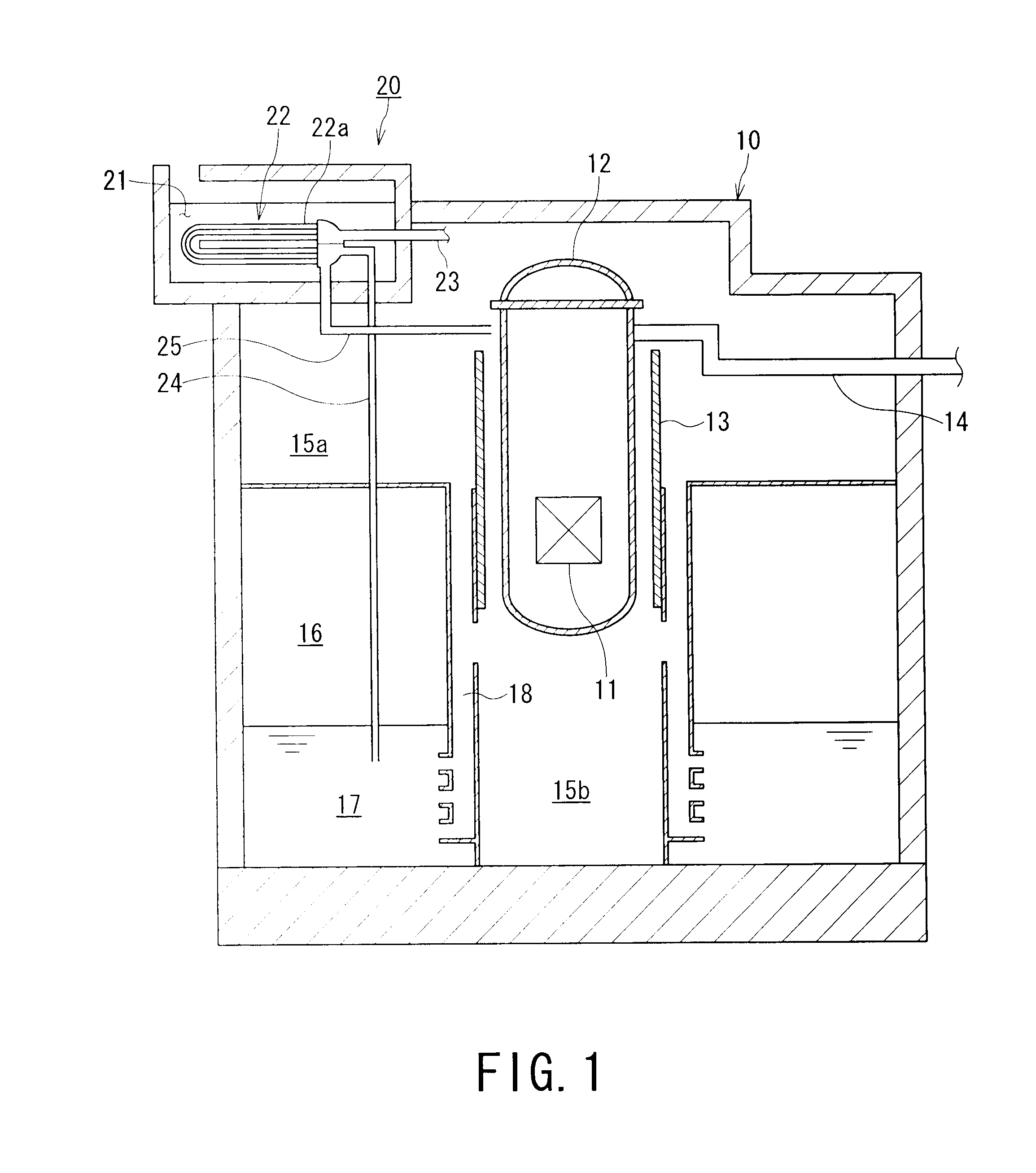

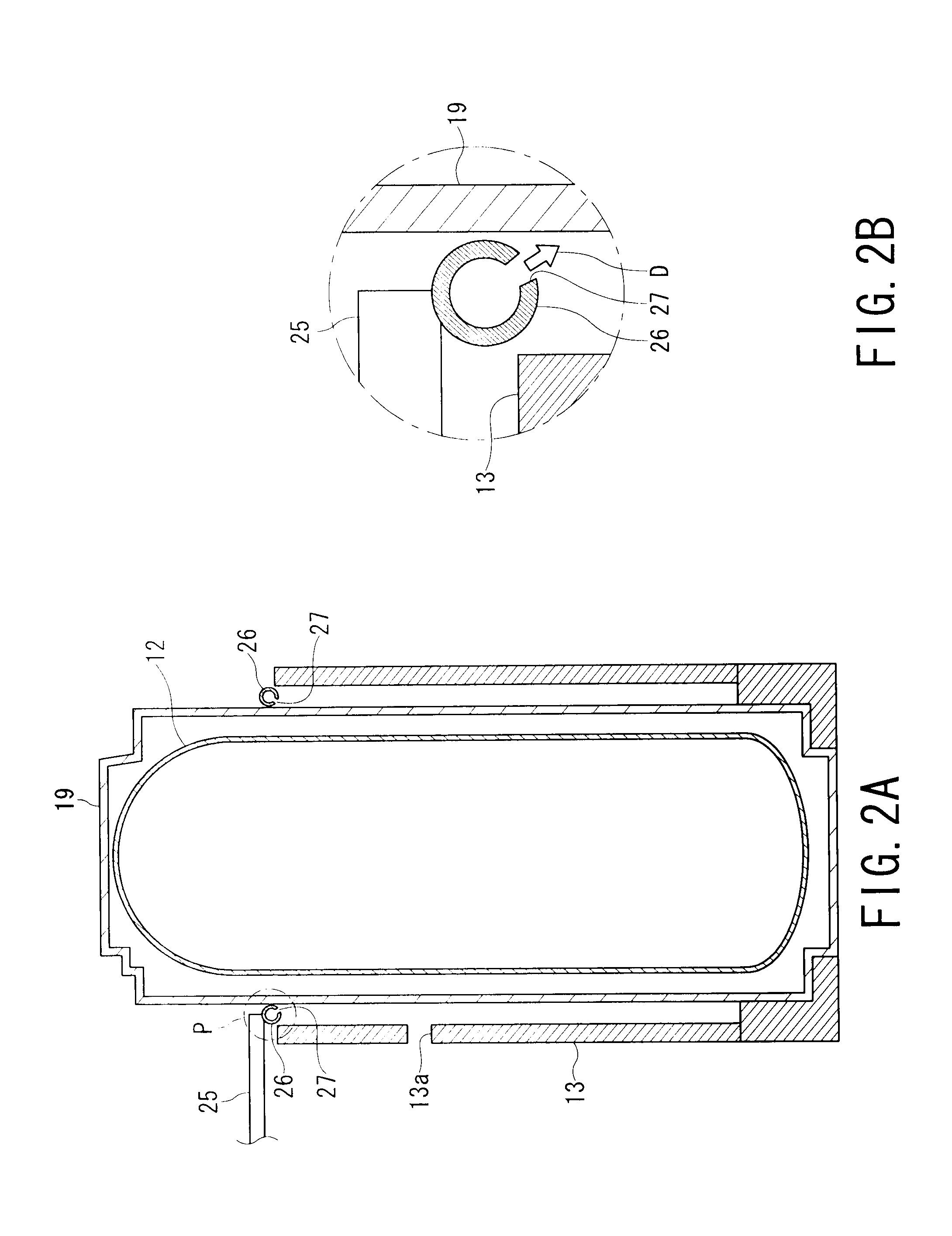

Reactor containment vessel cooling system, reactor containment vessel, and reactor containment vessel cooling method

InactiveUS20110314858A1Prevent capabilityPrevent integrityDomestic cooling apparatusLighting and heating apparatusReactor pressure vesselEngineering

A reactor containment vessel cooling technology for preventing the cooling capability and structural integrity of a reactor containment vessel cooling system from decreasing by lowering the temperature of water vapor and gases acquired by the reactor containment vessel cooling system is provided. Based on the technology, the present invention provides a reactor containment vessel cooling system that acquires water vapor in a reactor containment vessel by using water vapor pressure in the vessel as a drive force, condenses the acquired water vapor into condensate, and cools the reactor containment vessel with the condensate. The reactor containment vessel cooling system includes a heat exchange pool 21 that is arranged apart from a dry well 15 and a suppression chamber 16 in the reactor containment vessel 10 and stores a medium for cooling water vapor, a heat exchanger 22 that is immersed in the heat exchange pool 21, acquires water vapor from the dry well 15 in the reactor containment vessel 10, and performs heat exchange between the eater vapor and the cooling medium in the heat exchange pool 21 to generate condensate, and a condensate drain pipe 25 that extracts the condensate from the heat exchanger 22 and guides and discharges the condensate toward a reactor pressure vessel 12.

Owner:KK TOSHIBA

Pressure suppression and safe injection system

ActiveCN105957564ASolve technical problems with large size and poor economySmall sizeNuclear energy generationEmergency protection arrangementsReactor safetyCondensed water

The invention discloses a pressure suppression and safe injection system. The system includes a safety shell, and the safety shell is internally provided with: a pressure suppression pool, a reactor core water-replenishing tank, a safety injection tank, a pressure vessel catch pit, a primary loop pressure relief device, and a reactor pressure vessel; wherein, the pressure suppression pool is used for absorbing the heat released by the reactor system under the circumstances of accidents, and water in the pressure suppression pool is injected into the reactor core through gravity to realize low pressure injection function. The reactor core water-replenishing tank provides the water source for passive high-pressure safety injection. The safety injection tank provides the water source for passive medium-pressure safety injection. The pressure vessel catch pit is used for collecting condensed water condensed by a safety shell cooling system to provide the water source for recycling long-term cooling, realizes melt retention in the pressure vessel. The reactor safety system involved in the invention achieves reasonable design, simple system configuration, small safety shell size, and good economical efficiency, and satisfies the required technical effect of melt retention in the pressure vessel.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Reactor safe case electric thermo-couple through parts

InactiveCN1490822ASimple structureMature production processNuclear energy generationContainmentEngineeringHigh pressure

The present invention is a thermocouple penetrating piece used in the containing vessel of the reactor in the technical field of measuring processing variables in the nuclear engineering. In order to provide a thermocouple penetrating piece having simple structure, mature manufacturing process, low cost, reliable properties and good gas-sealing and pressure-bearing properties, the thermocouple penetrating piece used in the containing vessel of the reactor disclosed by the present invention comprises a pre-buried tube, a leakage detecting device, a connecting flange, a body of the penetrating piece and a thermocouple penetrating assembly connected to a thermocouple cable, the thermocouple penetrating assembly comprising a thermocouple connector integrally formed with the sealing connecting material and the mechanical socket, an armored thermocouple and its sealing tube and a transition tube welded with the sleeve of said armored thermocouple. The end plates in both ends of the body of the penetrating piece are welded with the transition tube of the thermocouple penetrating assembly to form a gas-sealing chamber which is connected to the leakage detecting device through a connecting pipe. The present invention has the higher pressure-bearing ability and the lower gas leaking rate, its producing process being mature, its properties being reliable and its manufacturing cost being low.

Owner:TSINGHUA UNIV

Control rod driving mechanism of floating type reactor

PendingCN105788667AAchieve powerRealize functionNuclear energy generationNuclear reaction controlDrive motorReactor safety

The invention provides a control rod driving mechanism of a floating type reactor. The control rod driving mechanism of the floating type reactor comprises a pressure bearing shell part, a driving motor part, a rod dropping and releasing mechanism part, a magnet yoke coil part and a driving screw part. The control rod driving mechanism of the floating type reactor is reliable in driving action, high in operation accuracy, and simple and practical in structure; the power control and the reactor safety control function of the floating type reactor under various working conditions can be implemented.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

Boiling water nuclear reactor and emergency core cooling system of the same

ActiveUS20100272226A1Nuclear energy generationEmergency protection arrangementsReactor pressure vesselNuclear reactor

Owner:KK TOSHIBA

Emergency fresh air pipeline of ventilation system of main control room of nuclear power station

InactiveCN102820068AReduced risk of loss of habitabilityImprove reliabilityDucting arrangementsLighting and heating apparatusIsolation valveNuclear power

The invention relates to structural design of an emergency fresh air pipeline of a ventilation system of a main control room of a nuclear power station. The emergency fresh air pipeline comprises two accident air taking ports at different positions of a plant roof of the nuclear power station, and the two accident air taking ports are opened or closed through isolating valves respectively; the two accident air taking ports are connected by an air pipe and share one identical emergency air sending pipeline and are connected with an emergency accident air blower, the emergency accident air blower introduces fresh air from the outdoor into the main control room, and an iodine absorption device is arranged on the emergency air sending pipeline; and the two accident air taking ports are arranged in opposite directions relative to a reactor containment. The emergency fresh air pipeline disclosed by the invention reduces the risk of losing habitability of the main control room under the working condition of the accident, and improves the reliability and safety of the ventilation system of the main control room.

Owner:CHINA NUCLEAR POWER ENG CO LTD

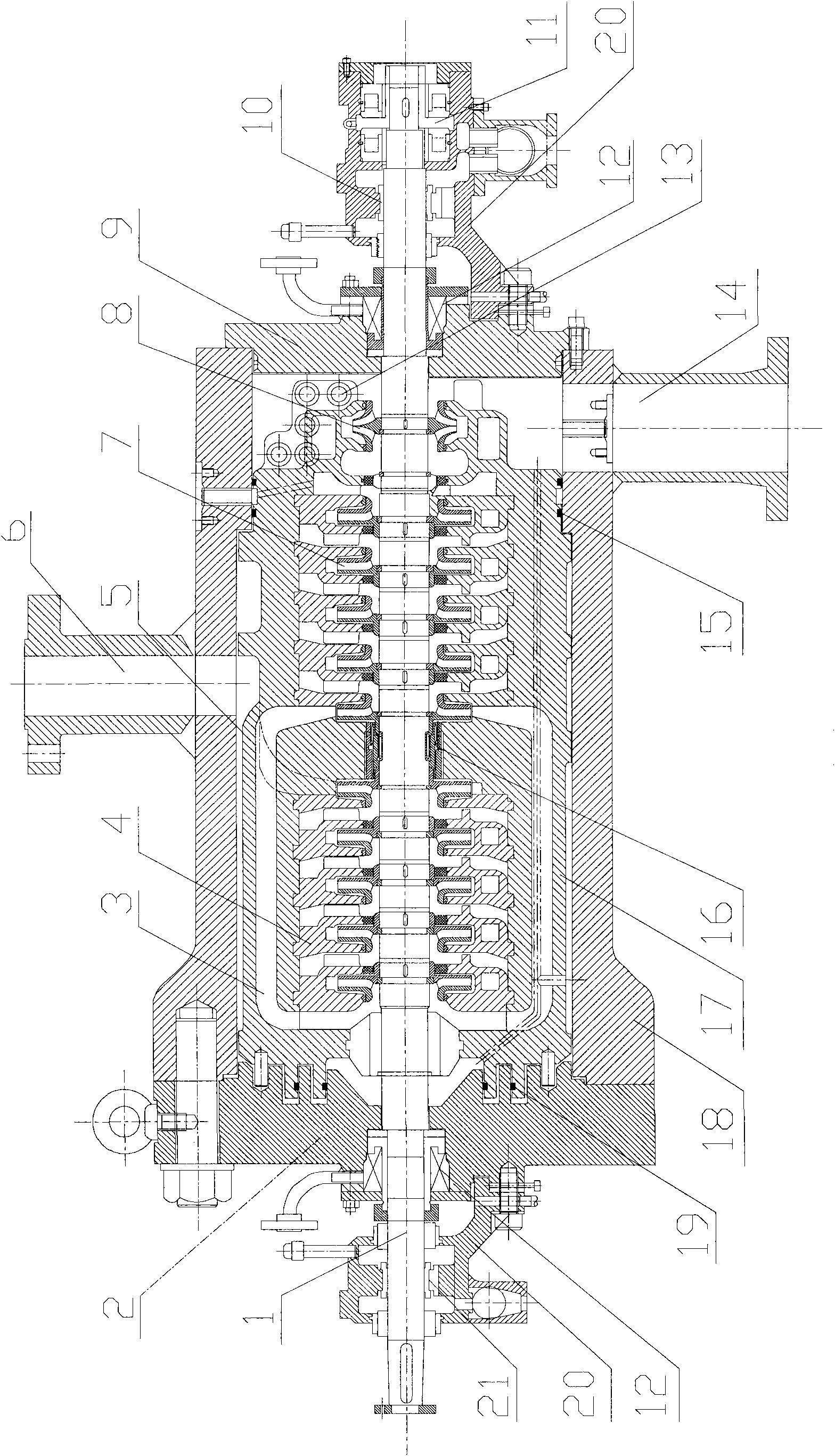

Internal shell split centrifugal charging pump

The invention relates to an internal shell split centrifugal charging pump. When a reactor runs normally, the pump runs under a charging working condition to provide boric acid-containing charging water for a loop and provide shaft seal water for mechanical seal for a main pump; and when coolant loss accidents such as breakage and the like occur in the main loop of the reactor, the charging pump runs under a high-pressure safety injection working condition and injects water to the reactor to prevent the accident from further expanding and ensure the safety of the reactor. The internal shell split centrifugal charging pump mainly comprises an external cylinder body, an internal shell, a water inlet pipeline, a water outlet pipeline, a bracket part, a left-side end cover, a right-side end cover, an intermediate bearing, a shaft, an impeller, a first double suction impeller, a guide vane, a middle flow channel, a final water outlet flow channel, an axle bumper, a left-end double seal ring structure, a right-end seal structure and the like. The internal shell split centrifugal charging pump is reasonable in design and high in thermal shock resistance and completely meets the requirements of a nuclear power station chemical and volume control system in hydraulic design and strength design.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com