All natural circulation-type modular small reactor

A reactor and modular technology, applied in the field of nuclear reactors, can solve problems such as insufficient inherent safety and complex safety system design, and achieve the effects of improving natural circulation capability, improving economy, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

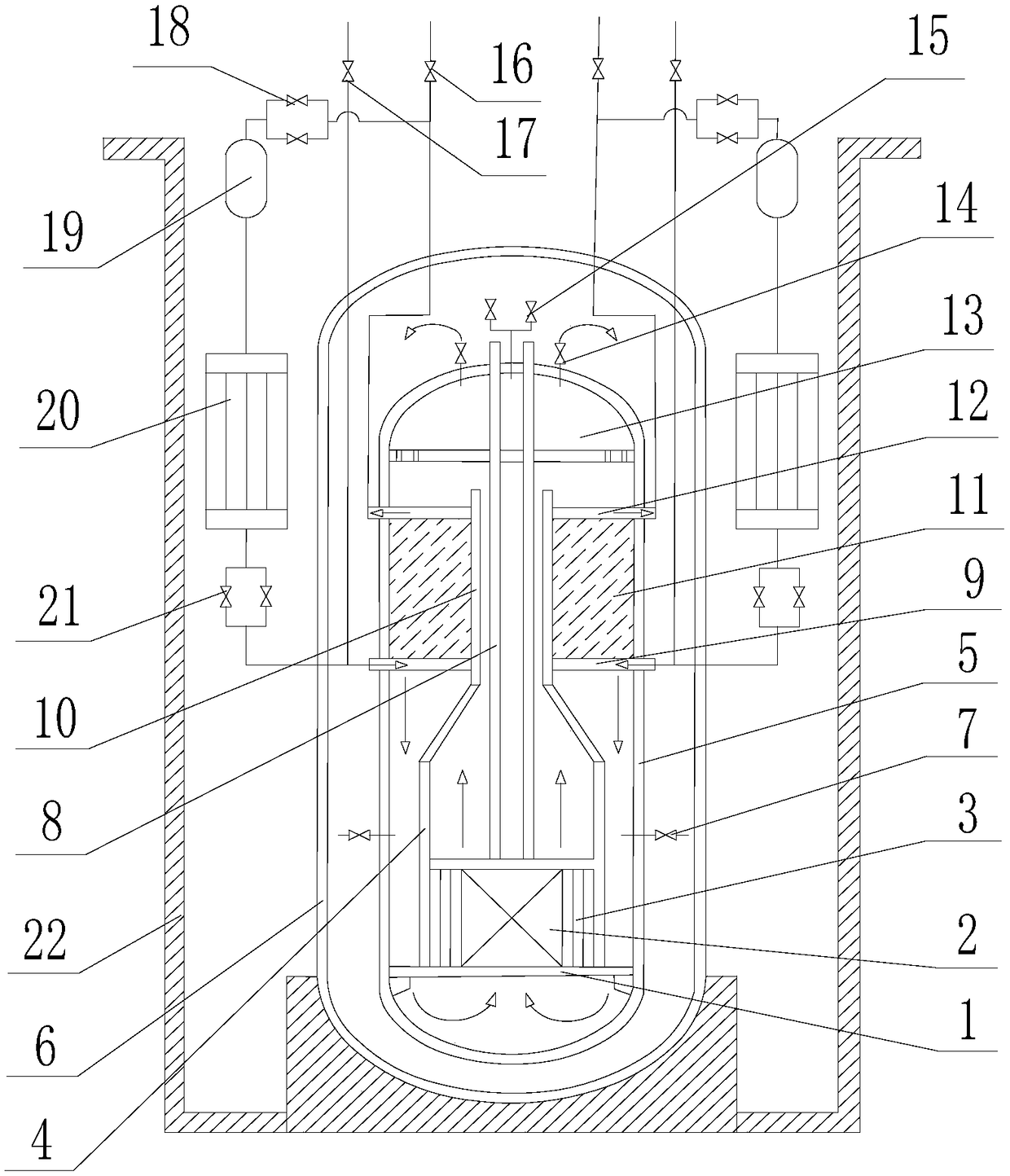

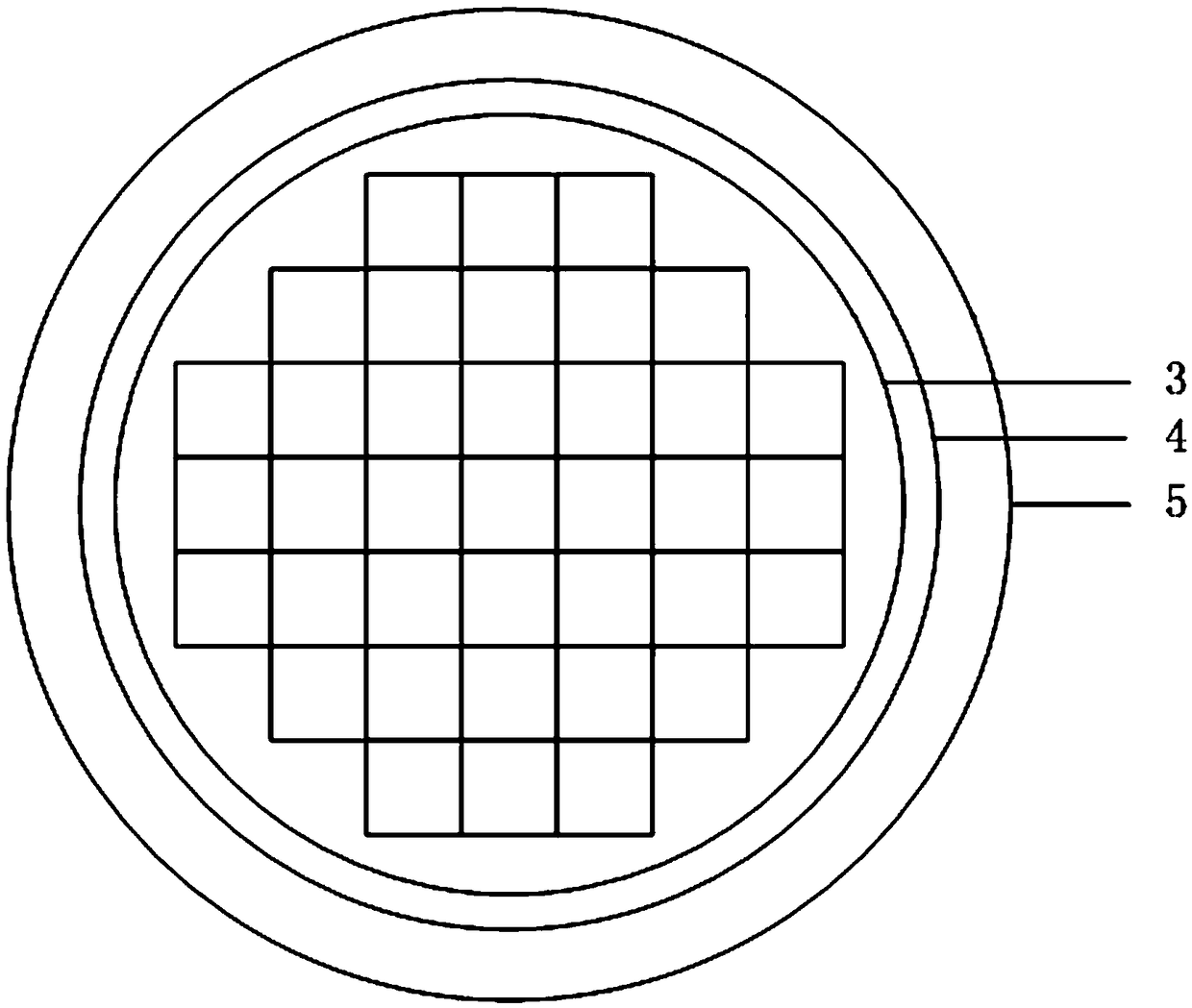

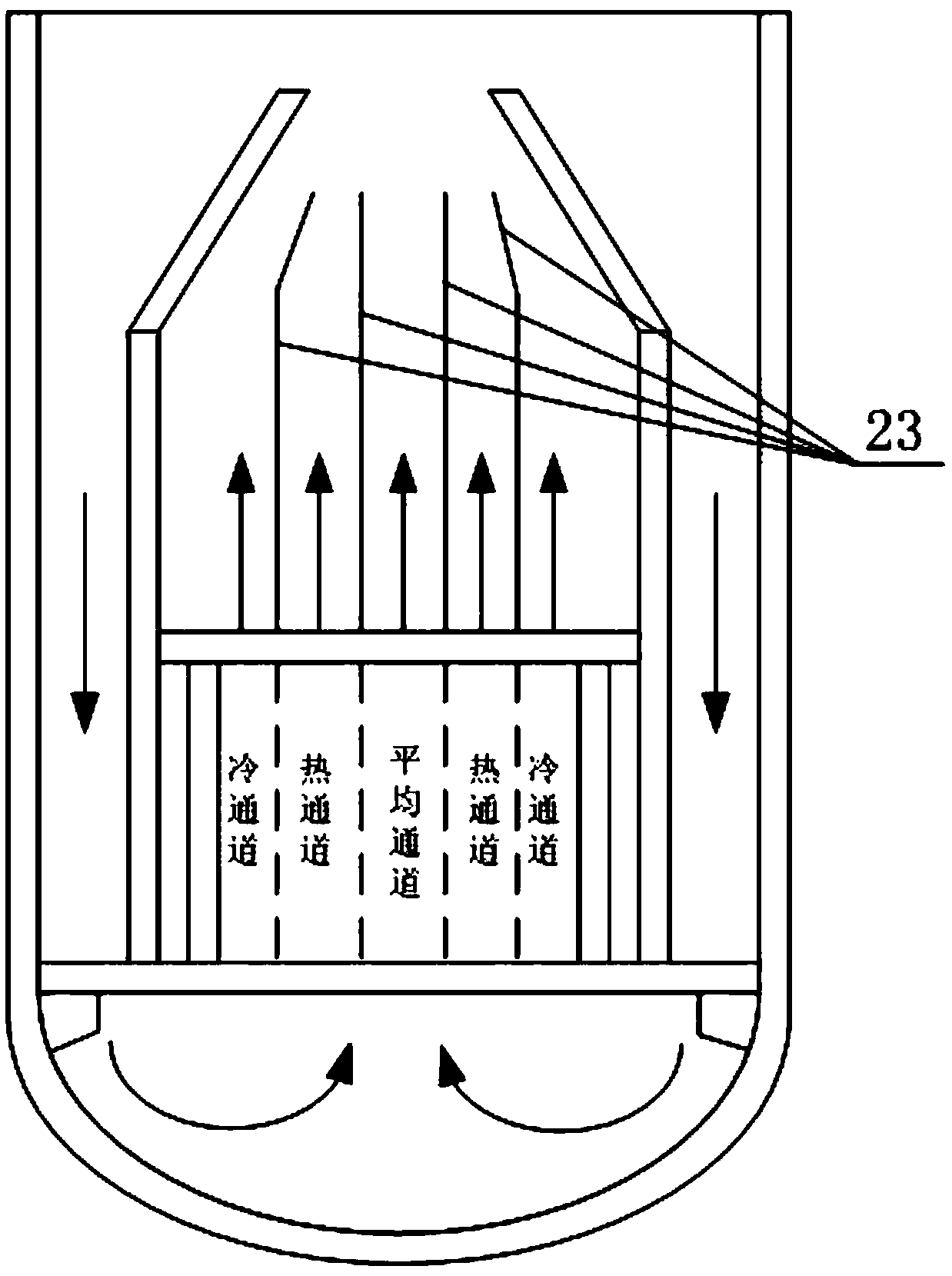

[0043] Such as Figure 1 to Figure 3 As shown, a modular small reactor with full natural circulation includes a reactor body, a containment vessel 6, a pool 22 and a passive safety system. The reactor body includes a pressure vessel 5, which is sequentially arranged with The core 2, the once-through steam generator 11 and the pressurizer 13, one end of the control rod driving mechanism 8 cooperating with the core 2 is arranged on the top cover of the pressure vessel 5, and the pressure vessel 5 is arranged in the containment vessel 6, so The interior of the containment vessel 6 maintains a relatively large vacuum degree. The containment vessel 6 is a steel shell, and the lower part of the containment vessel 6 is fixed on the concrete foundation at the bottom of the pool 22. The containment vessel 6 is completely submerged in the pool 22. The non- The active safety system includes the passive residual heat removal system and the passive containment heat removal system.

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com